Ceramic firing method and ceramic intelligent firing control device thereof

A control device and control method technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of non-constant heating rate, complex physical and chemical changes, etc., and achieve strong practicability and promotion of use value, firing The process is simple and the effect of improving the quality and efficiency of firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

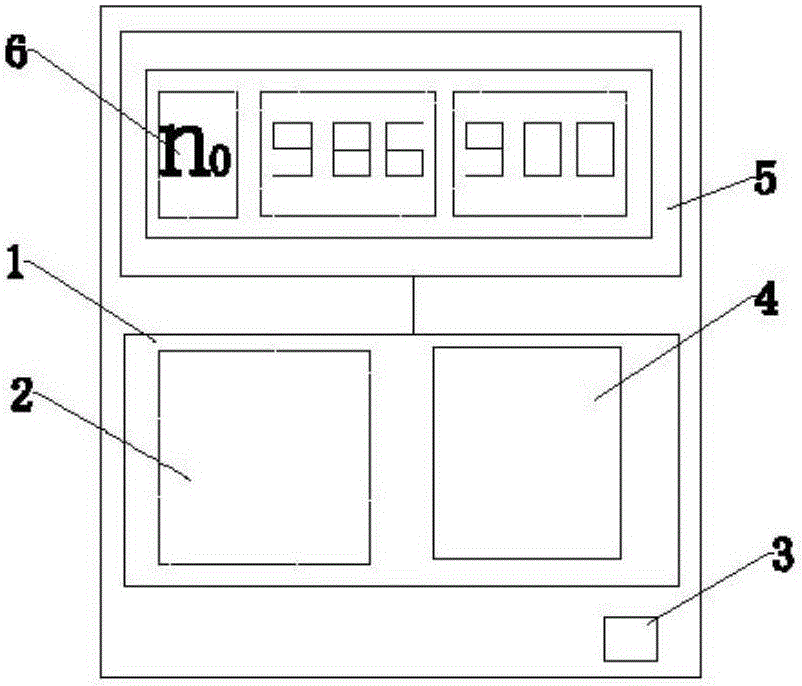

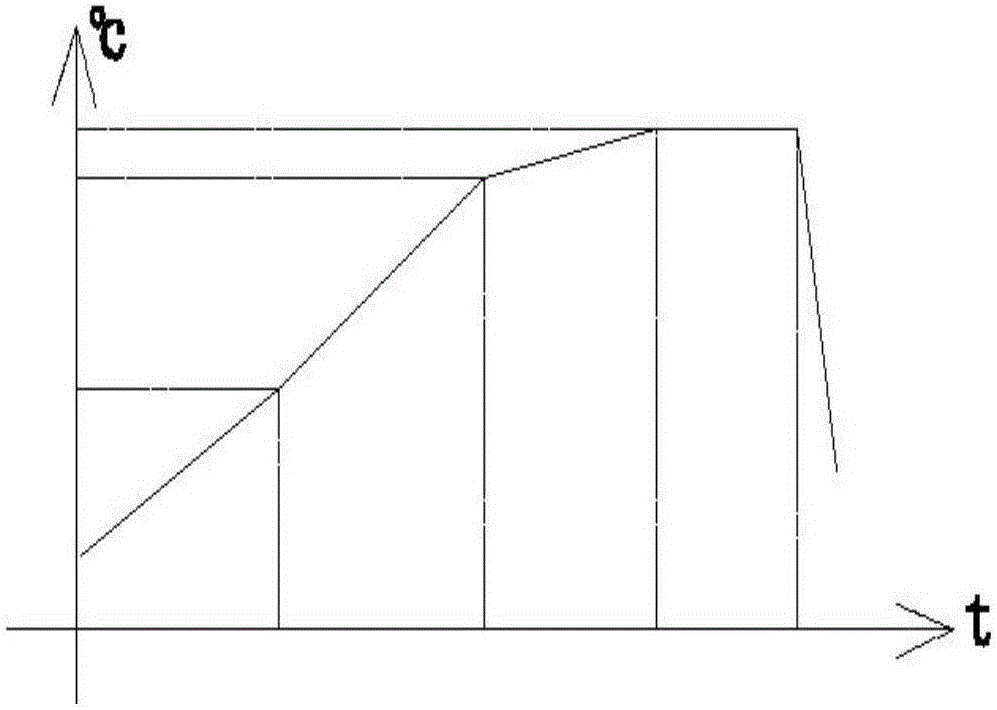

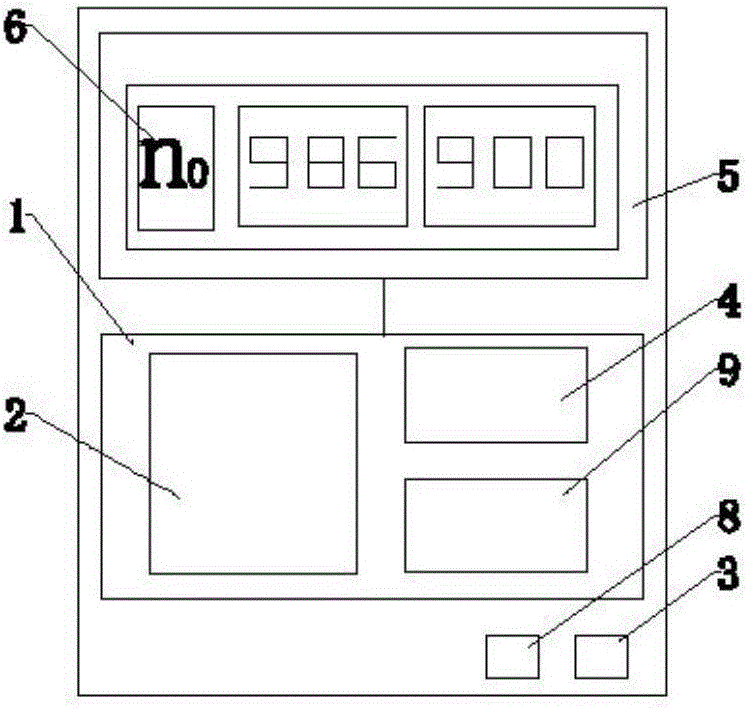

[0014] Such as figure 2 The shown ceramic firing method of the present invention includes the use of a ceramic intelligent firing control device with only one execution key, and the firing process corresponding to different types, types and / or different firing quality requirements of the same ceramic product ( That is, the corresponding firing process method, firing process curve or firing process program) are respectively written (stored and solidified) in the firing process module of the system firing master control unit of the ceramic intelligent firing control device. Only one execution key is used to switch and select the types of firing processes in the firing process module of the ceramic intelligent firing control device through the corresponding codes displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com