Mixed firing process of gem particles and purple sand raw materials

A raw material, purple sand technology, applied in the production of ceramic materials, clay products, applications, etc., can solve the problems of no translucency of the porcelain body, slow firing efficiency, difficult operation, etc., to improve the overall ornamental and artistic effect. , The effect of improving the working efficiency of the kiln and improving the surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

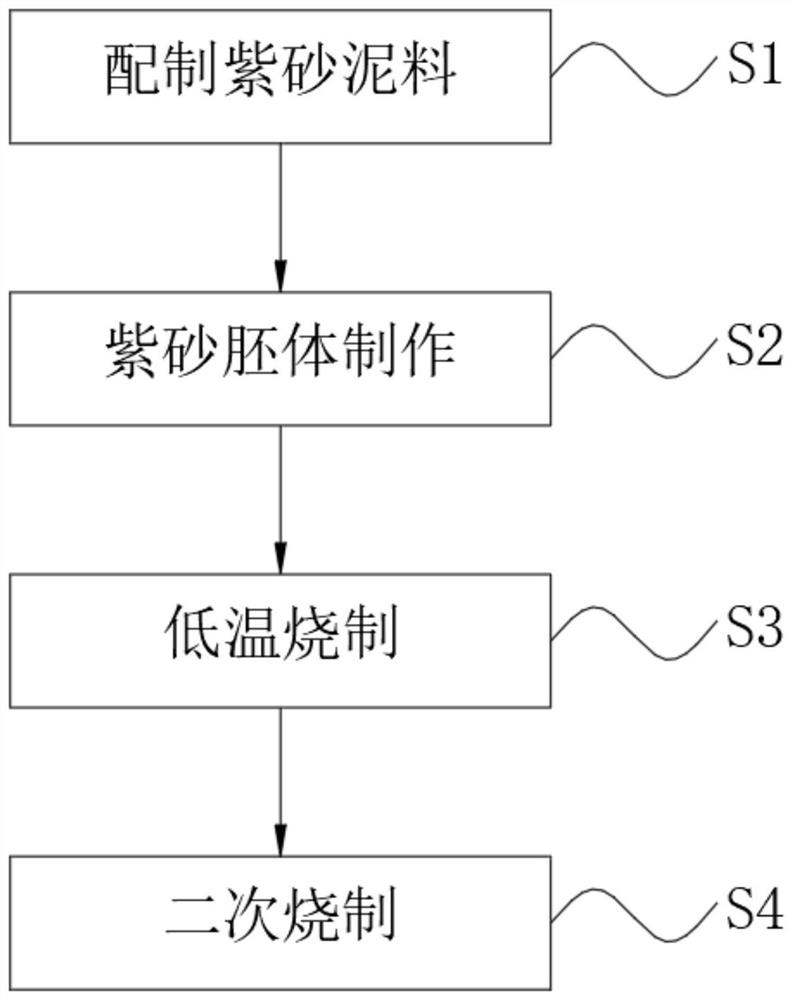

[0017] Such as figure 1 Shown, a kind of ruby particle and purple sand raw material mix firing process, comprise the following steps;

[0018] Step S1: Prepare purple sand mud, select suitable purple sand mineral materials as raw materials for firing purple sand pottery, stack the purple sand mineral materials, and carry out natural aging. After a period of natural aging, the purple sand mineral materials are ground by a grinding device, so that The purple sand ore powder is obtained, and the purple sand ore powder is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com