Method for preparing filtering material from copper tailings and application

A filter material, copper tailings technology, applied in the application, filtration separation, separation method, etc., can solve the problems of chronic soil and groundwater pollution, secondary pollution, waste earth and stone, etc., achieve uniform and stable filter aperture, reduce pollution, high potency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

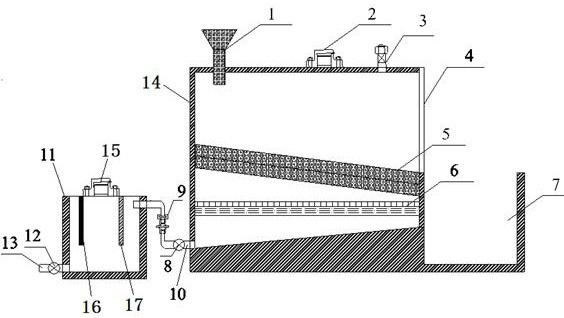

Image

Examples

Embodiment 1

[0035] Embodiment 1: The method for preparing filter material by using copper tailings and treating sludge with a moisture content of 99% are as follows:

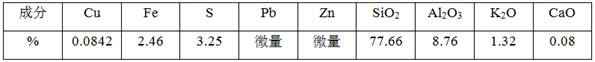

[0036] The chemical composition of copper tailings is shown in the table:

[0037]

[0038] (1) Copper tailings pretreatment: Wash the tailings repeatedly with deionized water until the pH rises to 7; dry the tailings at 105°C, crush and sieve until the particle size is less than 0.1mm, and set aside;

[0039] (2) Raw meal preparation: Mix and stir the pretreated tailings, water, modifier, and binder to make a raw meal with a moisture content of 20%;

[0040] (3) Raw material injection molding: Pour the stirred raw material into the installed plate-shaped steel formwork, and die-cast it with a pressure of 2MPa;

[0041] (4) Roast raw materials to prepare new energy-saving and environment-friendly filter materials.

[0042] The specific content is: wash the copper tailings repeatedly with deionized water, so that the pH r...

Embodiment 2

[0047] Embodiment 2: The method of using copper tailings to prepare filter materials and the treatment of tailings with a pulp concentration of 10-15%

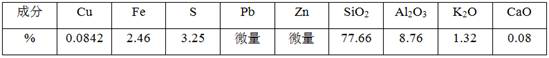

[0048] The chemical composition of copper tailings is shown in the table:

[0049]

[0050] Wash the copper tailings repeatedly with deionized water until the pH rises to 8, and remove the water-soluble substances and suspended solids in the tailings gravel; dry the tailings at 110°C to ensure that water is removed while removing Other substances that are easy to evaporate and remain on the surface of the tailings, avoid affecting the combination of synthetic materials at high temperatures; crush and screen the tailings, and use high-strength mechanical action to break its crystal lattice; then pretreated tailings Powder, water, sodium sulfate and carbon powder (the amount of sodium sulfate and carbon powder added is 3% of the mass of the tailings powder), clay (the amount added is 15% of the mass of the tailings), etc. are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com