Porous structure material and its preparation method and application

A porous structure and material technology, applied in the field of industrial waste recycling, can solve the problems of bubbling, cracking, sound insulation and thermal insulation performance, small bulk density, etc., and achieve the effects of reducing energy consumption, good anti-freezing performance, and short firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In one embodiment, the preparation method of the porous structure material at least includes the following steps:

[0044] Weigh cement, alkali slag, ceramic sludge, fiber, aluminum powder and water according to the above-mentioned formula components;

[0045] dry-blending the cement, alkali slag, ceramic sludge, and fibers to obtain a first material;

[0046] wet-mixing the water and the first material to obtain a second material;

[0047] Mixing the aluminum powder and the second material to obtain a third material;

[0048] The third material is fired, and the temperature is raised to 150°C-220°C during firing, kept for 15min-30min, then continued to be heated to 850°C-950°C, kept for 25min-50min, and then cooled to room temperature to obtain the described Porous structure material.

[0049] The above-mentioned preparation method will be further described in detail below.

[0050]Preferably, the average particle size of the cement is 30 μm to 60 μm, and the stren...

Embodiment 1

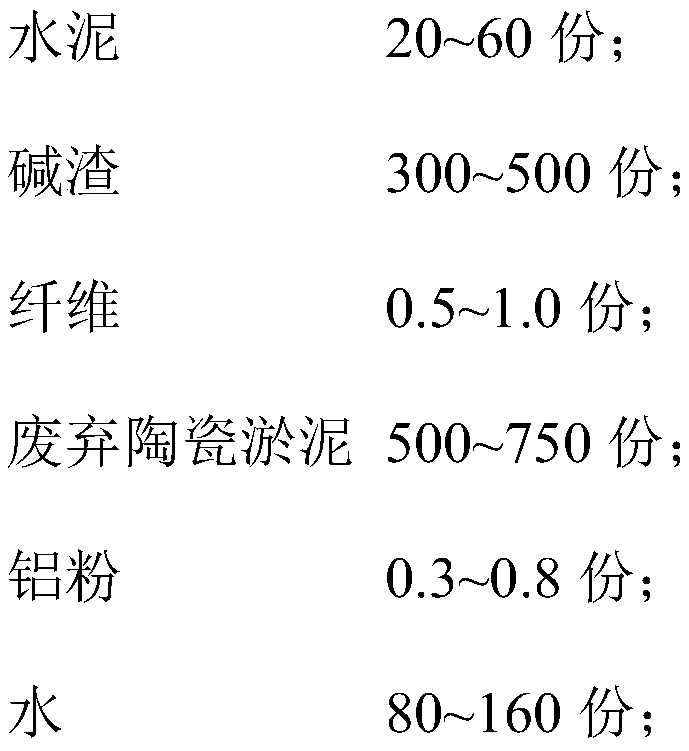

[0062] A porous structure material, comprising the following raw material components in parts by weight:

[0063]

[0064] Among them, the average particle size of cement is 30 μm to 60 μm, and the strength grade is not less than 42.5;

[0065] The average particle size of alkali slag is 45μm~80μm;

[0066] The average length of the fiber is 3mm to 5mm;

[0067] The average particle size of the ceramic sludge is 1 μm to 100 μm.

[0068] The above-mentioned porous structure material needs to be prepared from raw materials by the following preparation method:

[0069] Step S01. Weigh the above-mentioned cement, alkali slag, ceramic sludge, and fiber, add to a mixer and stir for 1 to 3 minutes to obtain a uniform first material;

[0070] Step S02, adding the above-mentioned amount of water and the first material together into a mixer and stirring for 2-5 minutes until uniform, to obtain a second material;

[0071] Step S03, adding the above-mentioned amount of aluminum pow...

Embodiment 2

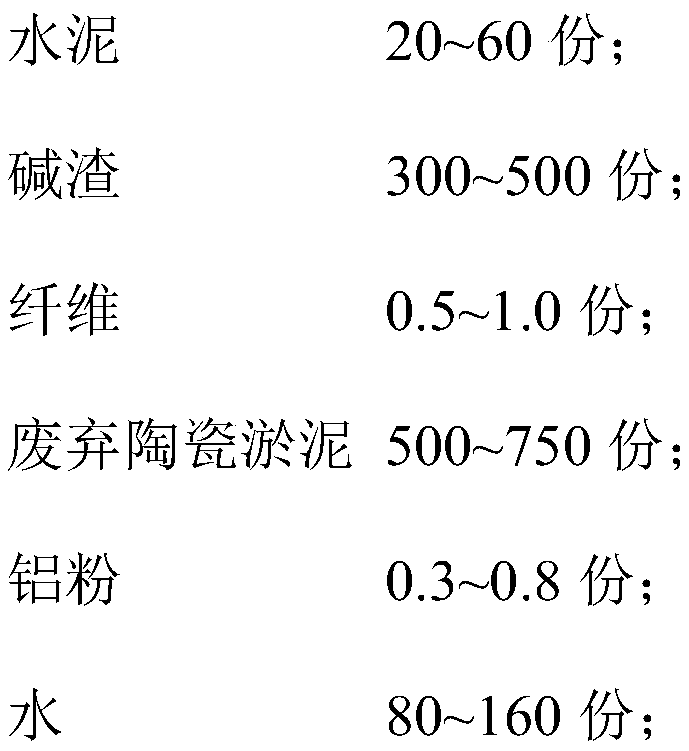

[0075] A porous structure material, comprising the following raw material components in parts by weight:

[0076]

[0077] Among them, the average particle size of cement is 30 μm to 60 μm, and the strength grade is not less than 42.5;

[0078] The average particle size of alkali slag is 45μm~80μm;

[0079] The average length of the fiber is 3mm to 5mm;

[0080] The average particle size of the ceramic sludge is 1 μm to 100 μm.

[0081] The above-mentioned porous structure material needs to be prepared from raw materials by the following preparation method:

[0082] Step S01, weighing the cement, alkali slag, ceramic sludge, and fiber as above, adding to a mixer and stirring for 3 min to obtain a uniform first material;

[0083] Step S02, adding the above-mentioned amount of water and the first material together into a mixer and stirring for 5 minutes until uniform, to obtain a second material;

[0084] Step S03, adding the above-mentioned amount of aluminum powder into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com