Modified calcium oxide expansion agent with controllable expansion process and preparation method thereof

A calcium oxide and expansion agent technology, applied in the field of building materials, can solve the problems of consumption, inability to form effective expansion, reduction, etc., achieve obvious technical and economic advantages, reduce expansion energy loss, and simple mixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

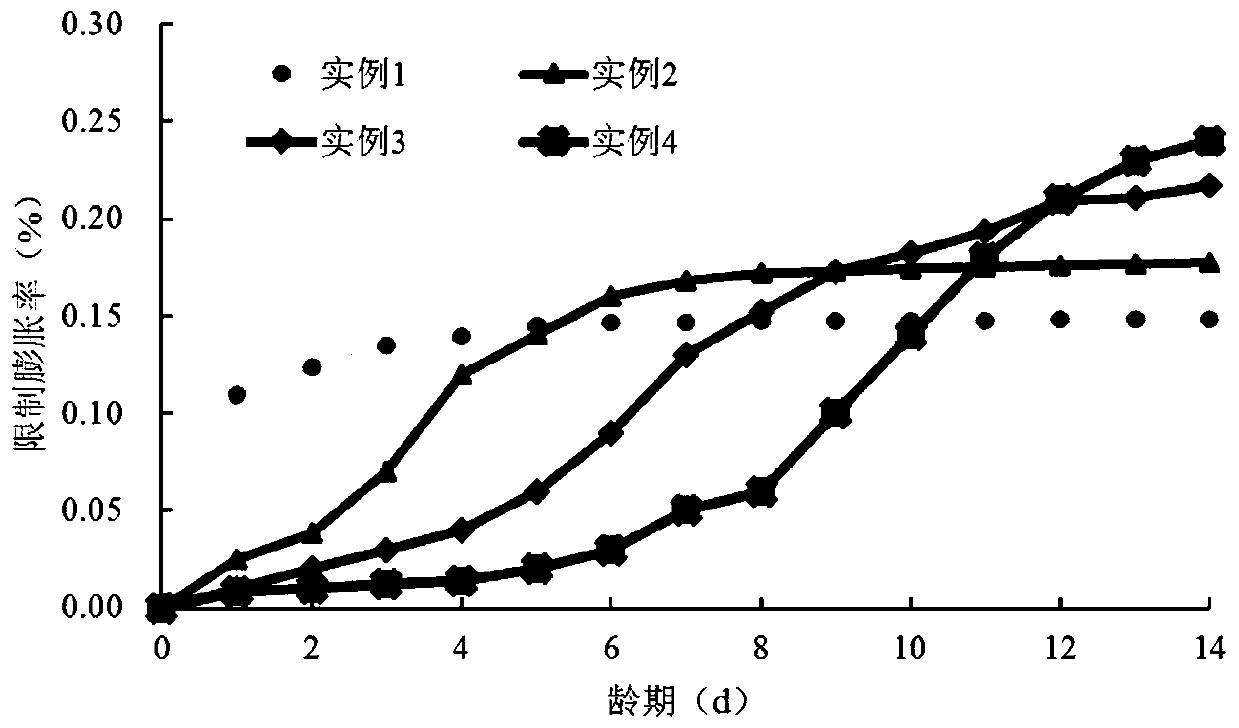

Embodiment 1

[0052] Limestone with a mass ratio of 90:10 is mixed with mineral fillers and ground together by a ball mill until the specific surface area is 250m 2 / kg of raw meal powder, where the mineral fillers are gypsum, alumina and aluminum sulfate (mass ratio is 80:10:10). The ground raw meal was calcined at 1280°C for 150min, then the sample was taken out and immediately quenched in the air, and ground to a specific surface area of 300m 2 / kg to obtain calcium oxide clinker. As the benchmark group of unmodified calcium oxide clinker, the number is 1.

Embodiment 2

[0054] Dissolve rosin resin acid and absolute ethanol at a mass ratio of 1:50, and stir until uniform. Control the mixing mass ratio of calcium oxide clinker and rosin resin acid to be 990:8, mix the calcium oxide clinker prepared in Example 1 with the rosin resin acid dissolved in ethanol until uniform (stir for about 5min), then Dry at ℃ for about 3 hours, remove the absolute ethanol, and grind the obtained solid until the specific surface area is 300m 2 / kg. The number is 2 as the comparison group of single rosin resin acid coating modification.

Embodiment 3

[0056] The calcium oxide clinker prepared in Example 1 is directly mixed with boric acid (powder) in a mass ratio of 990:2. As a comparison group representing the modification of the compound coagulation adjustment component, the number is 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com