Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Suitable for industrial production promotion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as main material and preparation method thereof

The invention relates to a reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as a main material and a preparation method thereof. The technical scheme is as follows: grinding ferrotitanium slag globules until the granularity is less than or equal to 100 mu m, putting the ferrotitanium slag powder into a muffle furnace, and incinerating at a temperature of 700-750 DEG C for 3-5 hours; adding 1-3mol / L hydrochloric acid solution into the incinerated ferrotitanium slag powder, wherein the mass ratio of the incinerated ferrotitanium slag powder to the hydrochloric acid solution is 1:(2-3); stirring, washing with water and performing suction filtration, thereby obtaining precursor ferrotitanium slag powder; then adding water which accounts for 10-15wt% of the precursor ferrotitanium slag powder into the precursor ferrotitanium slag powder, performing wet grinding until the granularity is less than or equal to 60 mu m, performing vacuum mud extrusion molding, and ageing the mixture for 36-48 hours; and putting the mixture into a resistance furnace, heating to 1500-1550 DEG C, performing heat preservation for 1-3 hours, and crushing, thereby obtaining the reproducible high-aluminum fireproof raw material utilizing the ferrotitanium slag as the main material. The preparation method has the characteristics of simple process, low production cost and no special requirements on equipment; and the prepared reproducible high-aluminum fireproof raw material is high in fire resistance and favorable in sintering performance.

Owner:WUHAN UNIV OF SCI & TECH +1

Method for treating 2-mercaptobenzothiazole production waste

ActiveCN102603668AChemically stableSolve the pollution problemAmino compound purification/separationSulfur compoundsEnvironmental resistanceDistillation

The invention discloses a method for treating 2-mercaptobenzothiazole production waste. The method comprises the steps of: heating the 2-mercaptobenzothiazole production waste to 90-95 DEG C, carrying out solid-liquid separation to obtain solid matter and liquid A, returning the solid matter to an accelerator M workshop, refining and purifying the solid matter to obtain a product accelerator M, distilling and separating the liquid A to obtain a fraction B and a fraction C, cooling residues in a distillation kettle to obtain asphalt-shaped matter D, absorbing hydrogen sulfide gas generated in the distillation separation process by using a sodium hydroxide solution to obtain a sodium hydrosulfide solution, concentrating the sodium hydrosulfide solution to obtain sodium hydrosulfide solids, rectifying and separating the fraction C to obtain aniline and benzothiazole. The method disclosed by the invention is capable of realizing the resourceful treatment of the 2-mercaptobenzothiazole production waste and has the advantages of various by-products, good product quality, simpleness in process flow, easiness in operation, mildness in reaction condition, low production cost and is environment-friendly.

Owner:HEBI HENGLI RUBBER PLASTIC CO LTD

Mullite raw material adopting alumina-chrome slag as main ingredient and preparation method thereof

The invention relates to a mullite raw material adopting alumina-chrome slag as a main ingredient and a preparation method thereof. According to the technical scheme, the method comprises the steps that the alumina-chrome slag is placed into a muffle furnace, and calcination is performed under the temperature of 700-750 DEG C for 3-5 h to obtain calcined alumina-chrome slag; the calcined alumina-chrome slag, silica powder and aluminite powder are mixed on the basis that the mass ratio of the calcined alumina-chrome slag to the silica powder to the aluminite powder is 100:(16.0-16.5):(2.0-4.5) for 15-20 min, and a mixed material is obtained; the mixed material is placed into an electromagnetic induction furnace, the temperature is increased to 1,800-1,840 DEG C and kept constant for 2-3 h; then, an upper scum layer is separated out, furnace cooling is performed to the room temperature, and crushing is performed to obtain the synthesis mullite raw material adopting the alumina-chrome slag as the main ingredient. The alumina-chrome slag contains main chemical components: 80-85 wt% of Al2O3, 10-15 wt% of Cr2O3 and not larger than 1 wt% of Fe2O3. The technology is simple, the production cost is low, and no special requirement for equipment is needed; the prepared mullite raw material adopting the alumina-chrome slag as the main ingredient is high in refractoriness, good in sintering performance and high in mullite conversion rate.

Owner:锦州集信高温材料有限公司

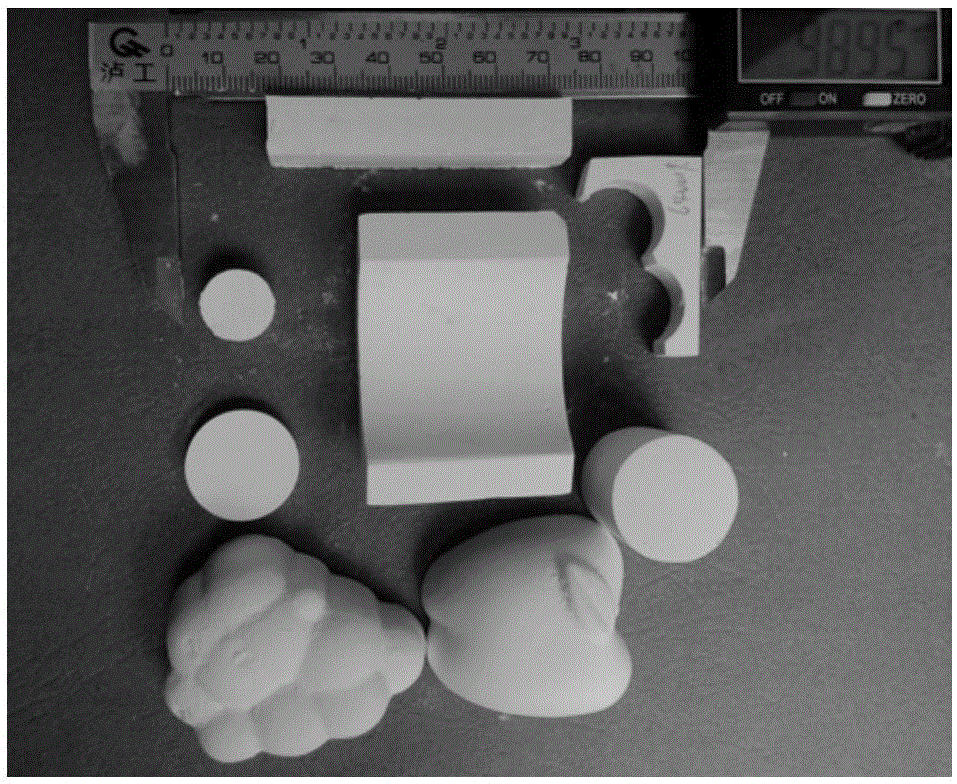

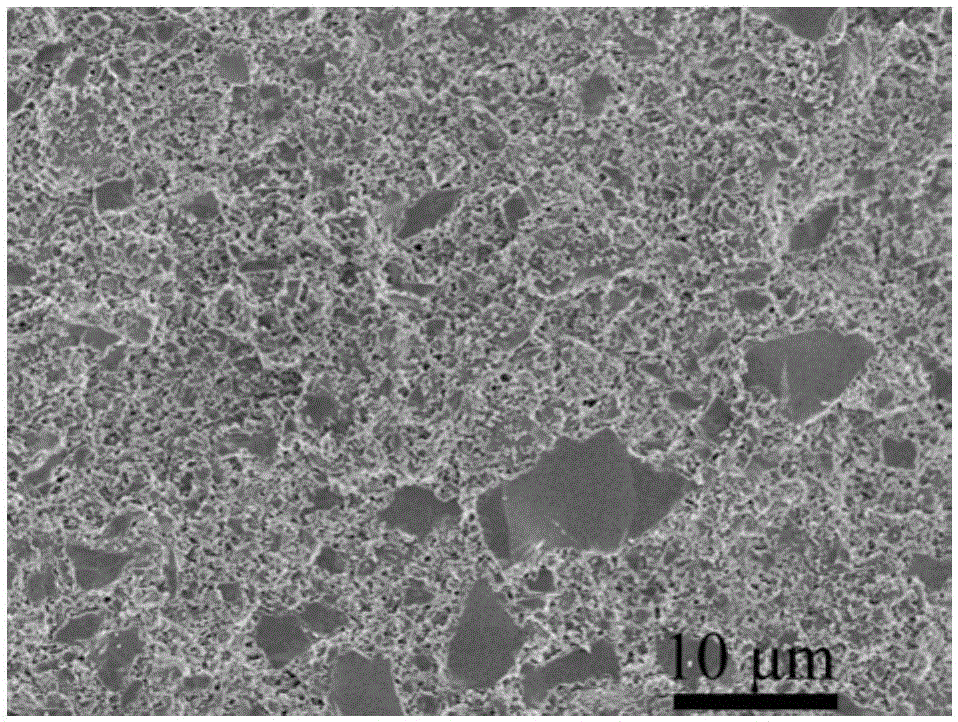

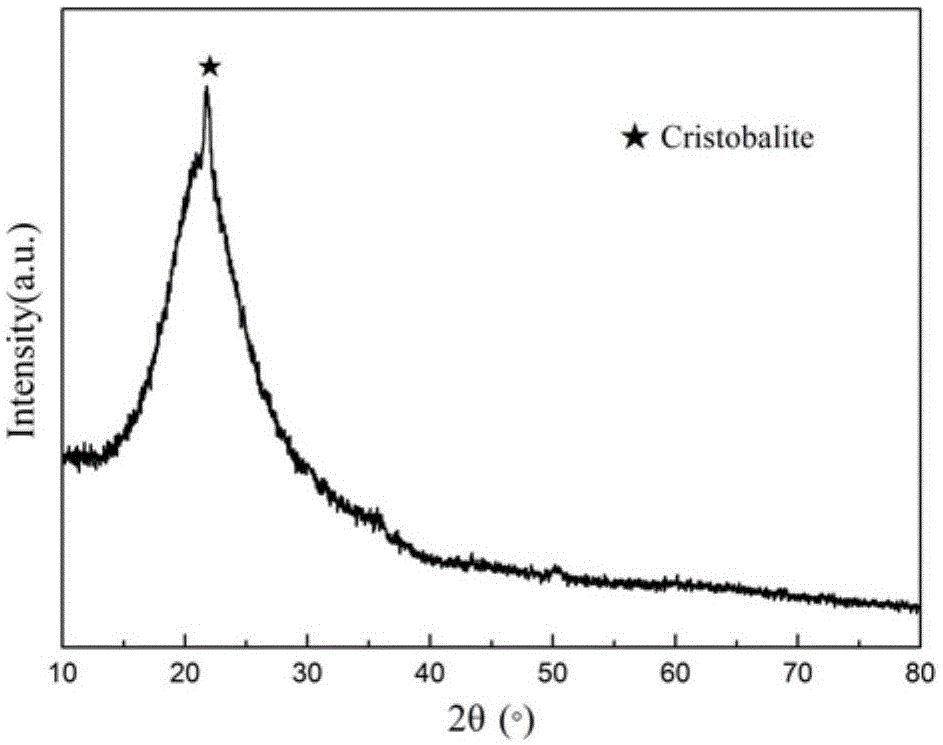

Gelcasting method for high strength fused quartz ceramic

The invention relates to a gelcasting method for a high strength fused quartz ceramic. The method is characterized in that by taking a non-toxic substance food grade glutinous rice flour as a gel, the high strength fused quartz ceramic is prepared through size grinding, vacuum defoaming, injection molding, blank curing, blank drying and ceramic sintering. According to the fused quartz prepared by using the non-toxic gel, a crosslinking agent, an initiator and a catalyst are not needed to be added. The prepared fused quartz blank is good in uniformity and high in strength and can meet the machining requirements, and the method is suitable for preparing large-sized abnormal fused quartz ceramic parts. The three-point bending strength of the fused quartz blank can reach the highest 11.4MPa. The three-point bending strength of the fused quartz ceramic sintered at 1220-1280 DEG C can reach the highest 65.9MPa. Less cristobalite phase in the ceramic is separated out, and the performance is excellent. The method provided by the invention is environmental-friendly, simple in process and low in cost, and the prepared fused quartz blank and ceramic are excellent performance and are suitable for industrial production and popularization.

Owner:NANJING TECH UNIV

Preparation method of Dapagliflozin intermediate used for treating II-type diabetes

InactiveCN107200683AHigh yieldGood reserve supportOrganic compound preparationCarbonyl compound preparation by condensationTert-butyldimethylsilyl chloride2-Chlorobenzoic acid

The invention discloses a preparation method of a Dapagliflozin intermediate used for treating II-type diabetes. The preparation method comprises the following steps: 1) performing a reaction on 5-bromine-2-chlorobenzoic acid and oxalyl chloride in anhydrous dichloromethane under the catalysis of DMF (dimethyl formamide), so as to obtain 5-bromine-2-chloro-benzoyl chloride; 2) under the condition that tert-Butyldimethylsilyl chloride exists, performing a reaction on 5-bromine-2-chloro-benzoyl chloride obtained in step 1) and phenetole under the catalysis of ferric trichloride, so as to obtain 5-bromine-2-chloro-4'-ethyoxyl benzophenone. According to the preparation method provided by the invention, no ortho-by-product is generated, and the yield of a target product is high, so that the good support of storage of raw materials is provided for Dapagliflozin. Additionally, the preparation method is mild in conditions and short in reaction time, therefore, the preparation method is suitable for industrial production and promotion.

Owner:QINGDAO CHENDA BIOLOGICAL SCI & TECH

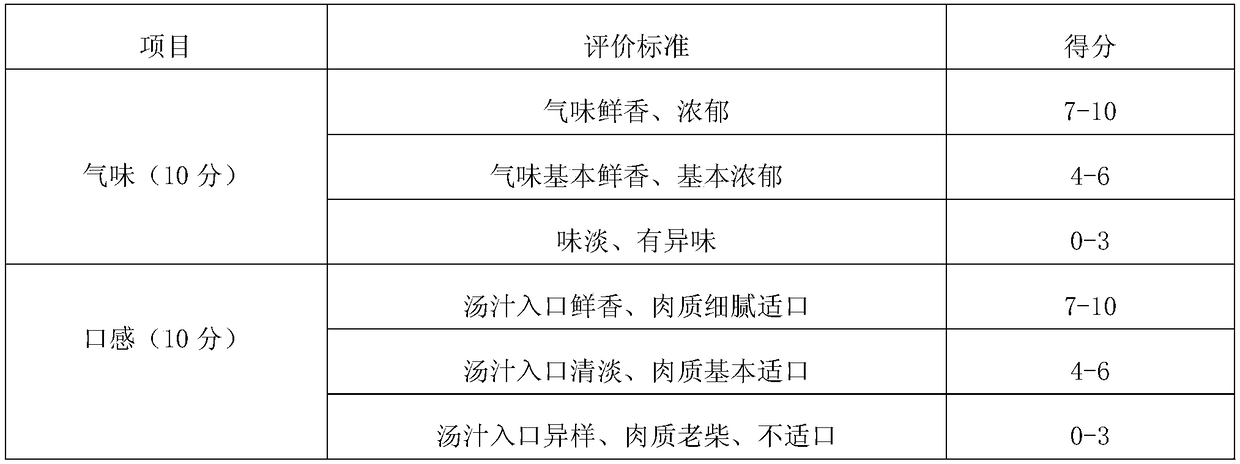

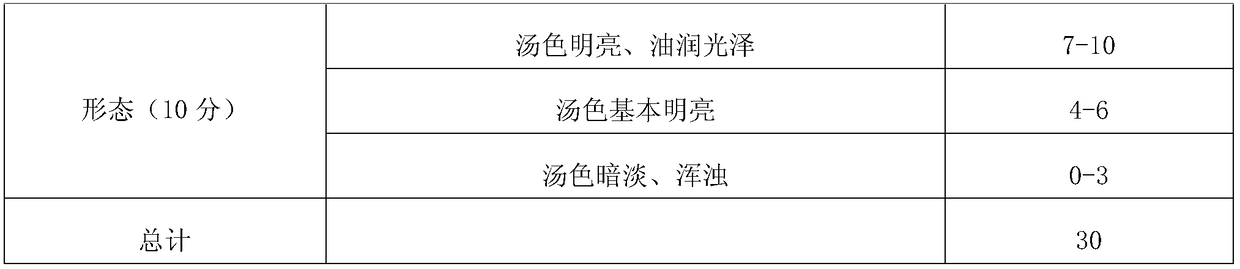

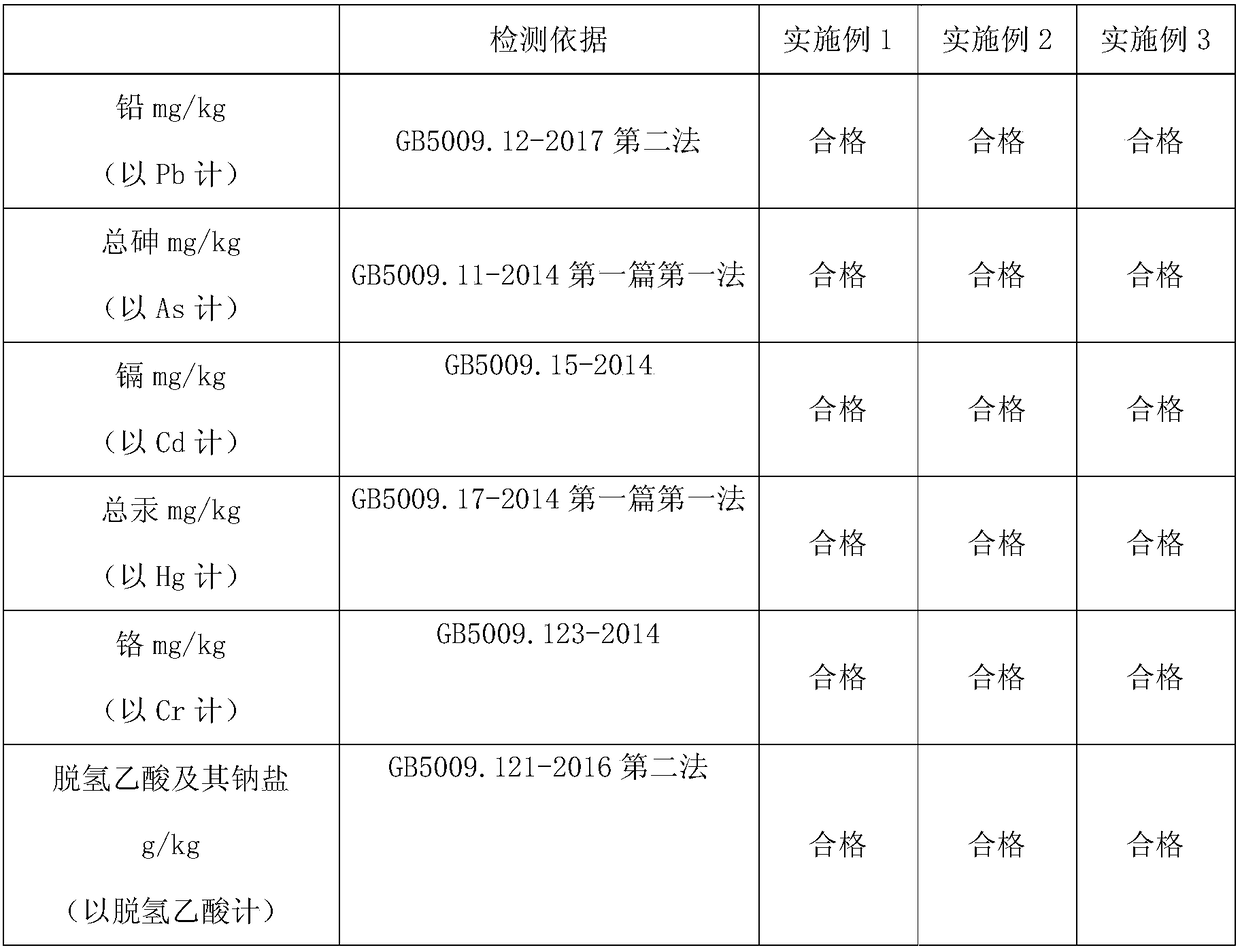

Seafood free-range chicken soup and production technology thereof

InactiveCN109170754ALow fat contentGreat tasteFood ingredient functionsAdditive ingredientRemoving hair

The invention provides seafood free-range chicken soup and a production technology thereof, and belongs to the field of processing of free-range chickens. The production technology comprises the following steps of unfreezing frozen free-range chickens, removing hair, performing peeling, performing degreasing and the like, then performing thorough cleaning, performing cutting into blocks, performing blanching treatment, adding auxiliary materials and ingredients to the blanched chicken blocks, performing boiling with an intense fire, then boiling with a small fire, performing boiling in a covered pot over a slow fire, and then performing filtering, so as to obtain boiled auxiliary materials, solid chicken meat and cooking liquid; and mixing the boiled auxiliary materials with the solid chicken meat and the cooking liquid, performing filling in proportion, and performing sterilization, so that the finished products of the seafood free-range chicken soup are obtained. The production technology of the seafood free-range chicken soup is simple, and the seafood free-range chicken soup is rich in nutrition, fresh, delicious and rich in taste, convenient to eat and suitable for various crowds to eat.

Owner:广西万寿谷投资集团股份有限公司

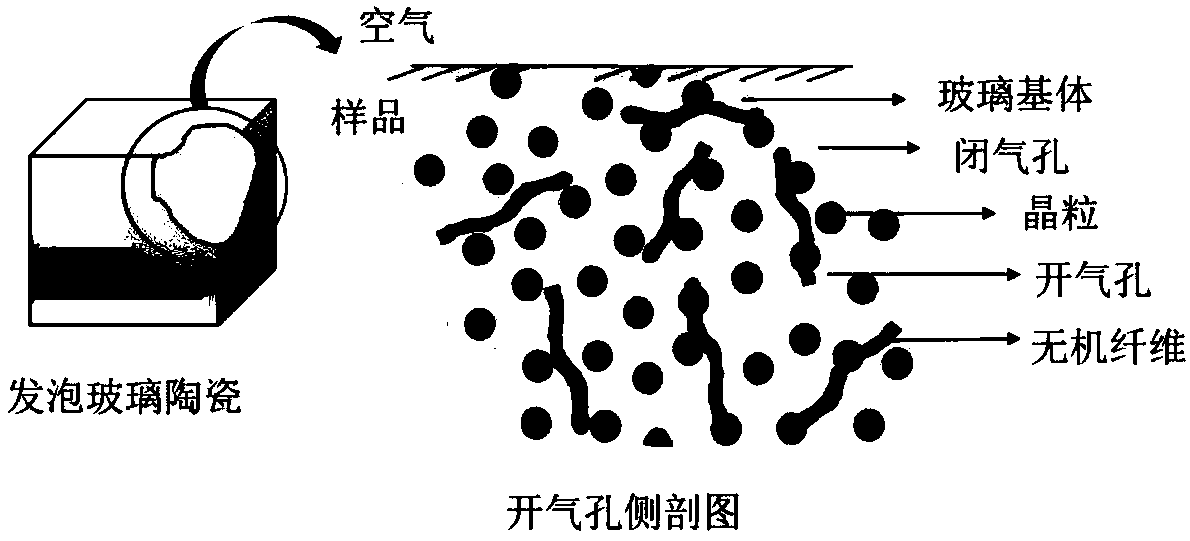

Foam glass ceramic composite building thermal insulation material and preparation method thereof

The invention relates to a foam glass ceramic composite building thermal insulation material and a preparation method thereof. The material comprises a hydrated glass substrate, a crystal phase mineral and inorganic fibers. The preparation technology includes hydrated glass substrate preparation by a wet chemical method, crystal phase mineral and inorganic fiber blending, low-temperature foaming and dehydroxylation heat treatment. The material is excellent in physical and chemical property and fireproof performance, has moderate open pore rate and breathing humidity controlling behaviors and meets grade-A non-combustible standards. Raw materials are wide in variety and low in cost, the preparation process is green and environmentally friendly, and the material is applicable to thermal insulation of building walls.

Owner:宁波荣山新型材料有限公司

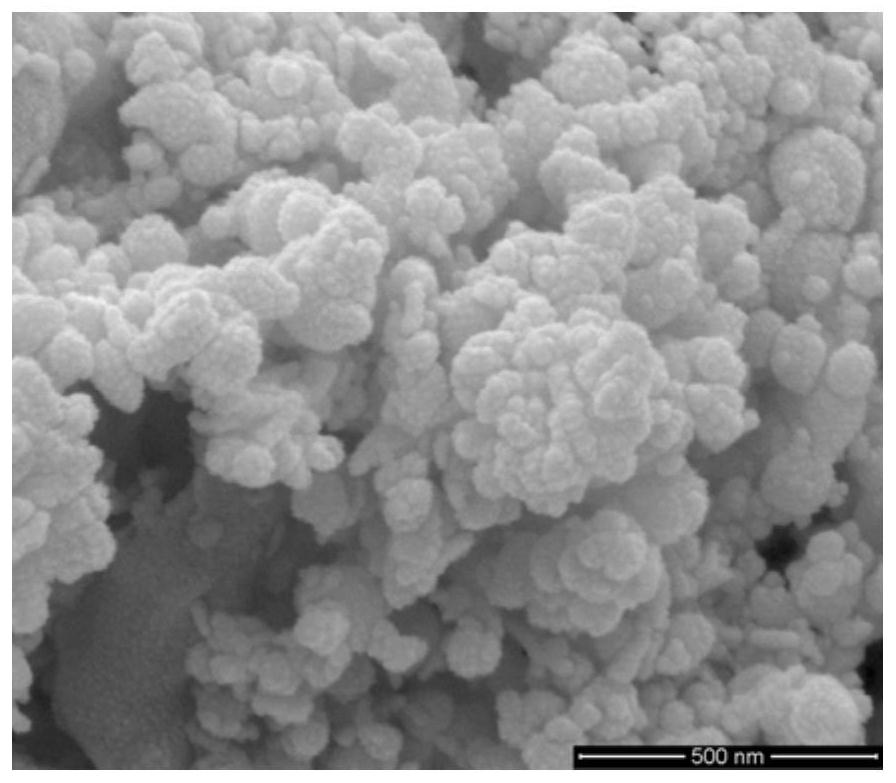

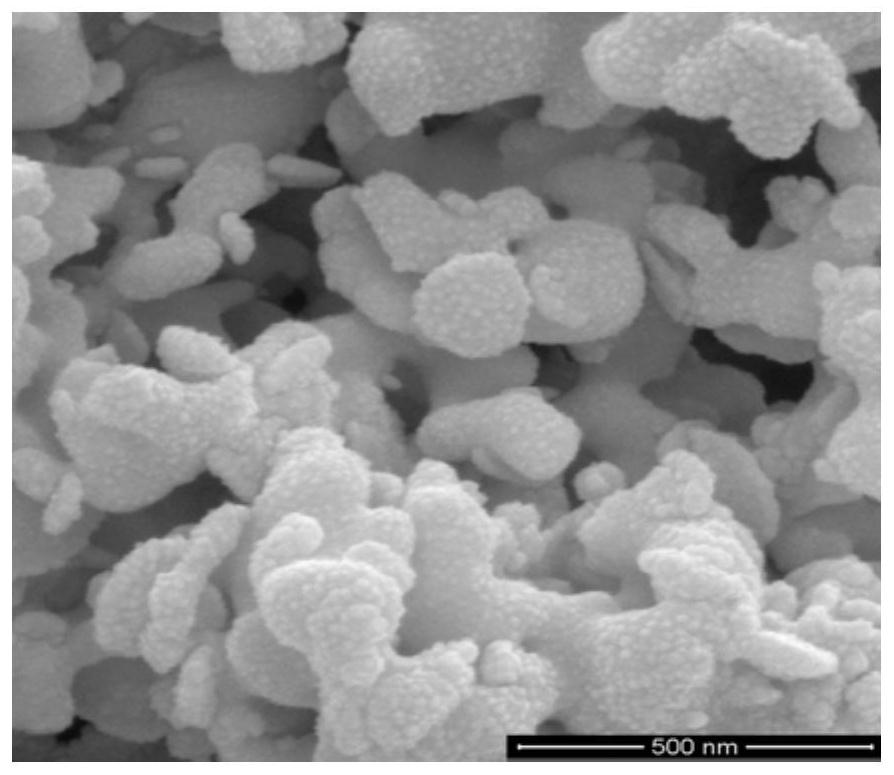

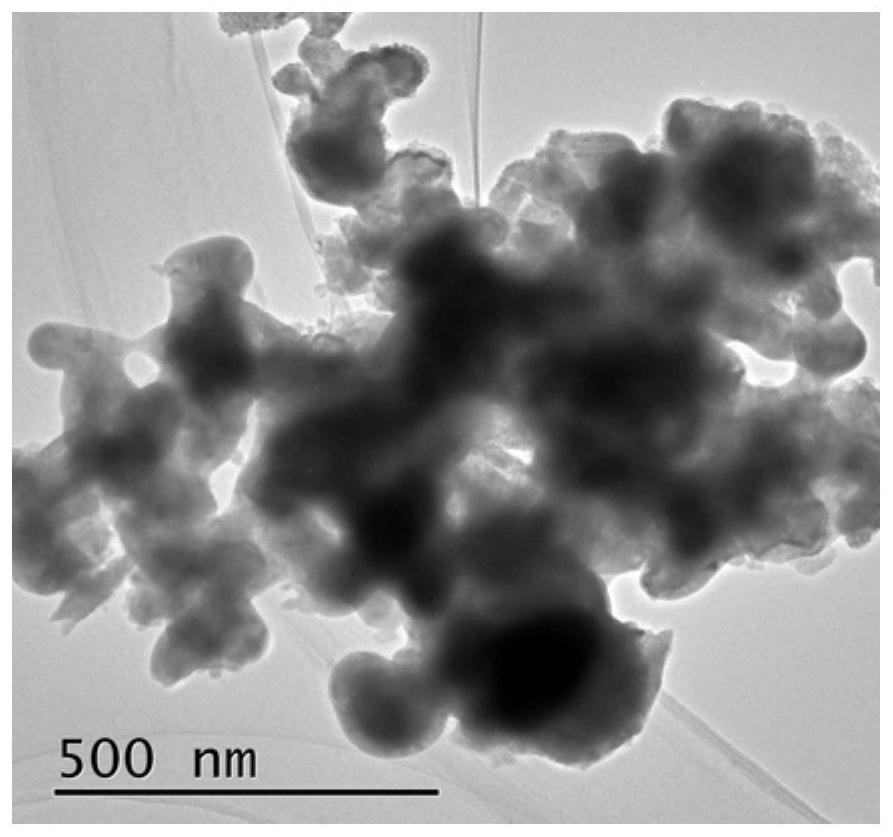

Preparation method of sulfur-doped bismuth trioxide, negative electrode material and supercapacitor

ActiveCN112875751AExcellent capacitance performance and cycle stabilitySave raw materialsMaterial nanotechnologyHybrid capacitor electrodesMuffle furnaceHydration reaction

The invention provides a preparation method of sulfur-doped bismuth trioxide, a negative electrode material and a supercapacitor. The method comprises the following steps: (1) weighing a predetermined amount of bismuth nitrate pentahydrate, adding the bismuth nitrate pentahydrate into a predetermined volume of an alcohol solvent, and then stirring at room temperature for 30 minutes; (2) transferring the solution obtained in the step (1) into a high-pressure reaction kettle, and then carrying out heat preservation and centrifugal treatment to obtain a white precipitate; (3) washing the white precipitate obtained in the step (2), thoroughly drying, and fully grinding into fine powder; (4) calcining the powder obtained in the step (3) in a muffle furnace to obtain yellow bismuth trioxide powder; and (5) further annealing the bismuth trioxide powder obtained in the step (4) in the presence of sulfur powder to prepare the sulfur-doped bismuth trioxide. The preparation method has the advantages of cheap and easily available raw materials, low equipment cost, simple operation process and short time consumption, and is suitable for popularization of industrial production.

Owner:INNER MONGOLIA UNIV OF TECH

Method for treating 2-mercaptobenzothiazole production waste

ActiveCN102603668BSolve the pollution problemAvoid pollutionAmino compound purification/separationSulfur compoundsDistillationSodium hydrosulfide

The invention discloses a method for treating 2-mercaptobenzothiazole production waste. The method comprises the steps of: heating the 2-mercaptobenzothiazole production waste to 90-95 DEG C, carrying out solid-liquid separation to obtain solid matter and liquid A, returning the solid matter to an accelerator M workshop, refining and purifying the solid matter to obtain a product accelerator M, distilling and separating the liquid A to obtain a fraction B and a fraction C, cooling residues in a distillation kettle to obtain asphalt-shaped matter D, absorbing hydrogen sulfide gas generated in the distillation separation process by using a sodium hydroxide solution to obtain a sodium hydrosulfide solution, concentrating the sodium hydrosulfide solution to obtain sodium hydrosulfide solids, rectifying and separating the fraction C to obtain aniline and benzothiazole. The method disclosed by the invention is capable of realizing the resourceful treatment of the 2-mercaptobenzothiazole production waste and has the advantages of various by-products, good product quality, simpleness in process flow, easiness in operation, mildness in reaction condition, low production cost and is environment-friendly.

Owner:HEBI HENGLI RUBBER PLASTIC CO LTD

Method for preparing tryptophan, fermentation medium used for the same, and special nutrient element for tryptophan fermentation

PendingCN109182407AIncreased acid production and conversionImprove the level of fermentation technologyFermentationNutrientTryptophan

The invention provides a method for preparing tryptophan, a fermentation medium used for the same, and a nutrient special for tryptophan fermentation. The method for preparing tryptophan includes thesteps: obtaining a mixture by mixing the defatted silkworm pupa protein, yeast powder and peptone, adding 5 to 20% of purified water into the mixture to prepare a feed liquid, stirring uniformly, heating the mixture to 80 to 100 DEG C, then cooling to 40-60 DEG C, adding 1-10% protease of the mixture to carry out enzymatic hydrolysis for 2-15h, heating the enzymatic hydrolysate to 90-120 DEG C tokill the enzyme, filtering the enzyme hydrolysate to obtain filtrate, concentrating and drying the filtrate to obtain tryptophan fermentation special nutrient element, wherein the tryptophan fermentation special nutrient element is obtained. As the special nutrient element for tryptophan fermentation is use in tryptophan fermentation, the acid production and conversion rate of tryptophan can be greatly improved, and the technical level of tryptophan fermentation can be improve.

Owner:江苏澳创生物科技有限公司

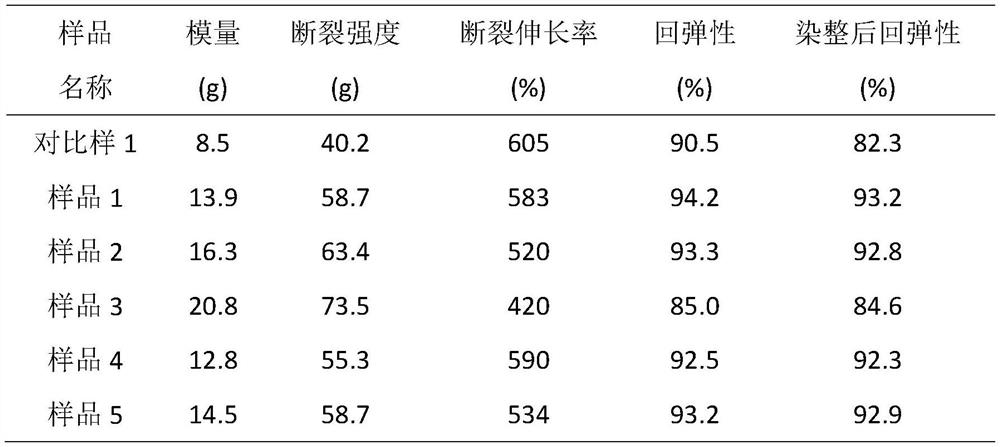

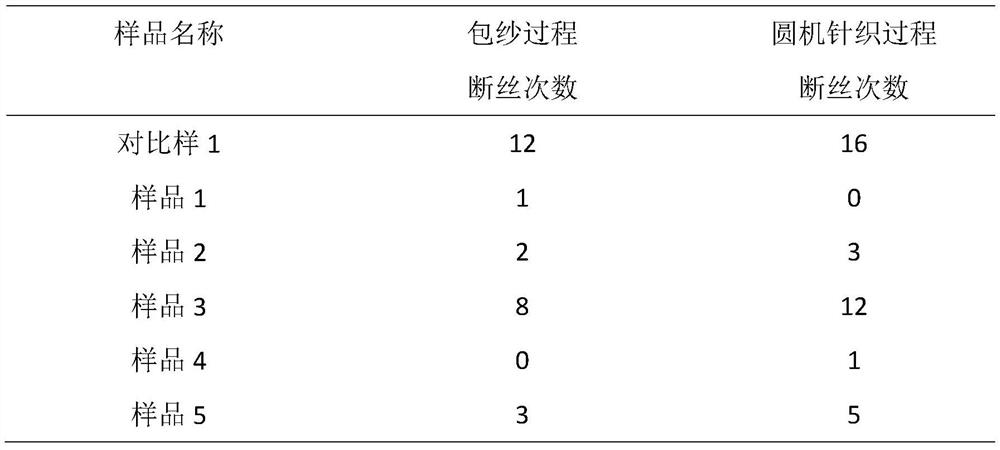

A kind of preparation method with high modulus high elastic polyurethane fiber

ActiveCN109355730BHigh modulusEasy to reboundMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer dissolutionYarn

The invention is a preparation method of polyurethane fiber with high modulus and high elasticity. In this method, firstly, acrylonitrile polymer is dissolved in an organic solvent to form a uniform and stable solution; then it is mixed and matured with a polyurethane solution to obtain a spinning stock solution; the spinning stock solution is evaporated in a high-temperature tunnel to remove the organic solvent to form a primary fiber , and then through false twisting, drafting, oiling, winding, and finally get spandex finished product. The spandex prepared by the present invention has the characteristics of high modulus, good resilience, and high elasticity retention rate; the spandex has smooth unwinding and low end-breakage rate during the use of high-speed empty bag and circular knitting, and can effectively improve the yarn quality. And the production efficiency of fabrics; the woven fabric samples are flat and uniform, with excellent elasticity, and can still maintain the original performance after processing such as setting and dyeing.

Owner:ZHEJIANG HUAFENG SPANDEX

A kind of benzomelamine modified amino resin and preparation method thereof

Owner:ZHEJIANG XINHUA NEW MATERIAL TECH CO LTD

Recycling method of carbide slag

InactiveCN101817651BSolve intractableReduce pollutionCement productionFerric hydroxideClinker (cement)

The invention discloses a recycling method of carbide slag, which comprises the following steps of: (1) reacting the carbide slag with the solution of sodium carbonate and filtering the reaction solution to obtain filtrate B and filter residue A, wherein the filtrate B is the solution of sodium hydroxide; (2) adding the filtrate A into hydrochloric acid, heating the mixture till the mixture boilsto perform a reaction, filtering the reaction solution to obtain a filter residue C and a filtrate D, wherein the filter residue C is used as clinker for cement production; and (3) adding hydrogen peroxide into the filtrate D to perform a reaction for 10 and 20 minutes, adjusting pH value of the reaction solution to 8.5 and 9.0 by using saturated lime water, filtering the reaction solution, drying the filter residue to obtain ferric hydroxide, concentrating the filtrate to precipitate a calcium chloride dehydrate solid, processing the obtained concentrated residual liquid by using the solution of sodium carbonate, filtering the mixed solution to obtain a solid mixture of magnesium carbonate and calcium carbonate, reacting the mixture react with the solution of sulphuric acid and filteringthe reaction solution to obtain calcium sulphate solids and the solution of magnesium sulfate. The resource processing method for the carbide slag has the advantages of various byproducts, high product quality, simple process flow, small equipment investment, easy operation, mild reaction conditions, low production cost, environmental friendliness and wide application prospect.

Owner:开封新巨源环保科技开发有限公司

Reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as main material and preparation method thereof

The invention relates to a reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as a main material and a preparation method thereof. The technical scheme is as follows: grinding ferrotitanium slag globules until the granularity is less than or equal to 100 mu m, putting the ferrotitanium slag powder into a muffle furnace, and incinerating at a temperature of 700-750 DEG C for 3-5 hours; adding 1-3mol / L hydrochloric acid solution into the incinerated ferrotitanium slag powder, wherein the mass ratio of the incinerated ferrotitanium slag powder to the hydrochloric acid solution is 1:(2-3); stirring, washing with water and performing suction filtration, thereby obtaining precursor ferrotitanium slag powder; then adding water which accounts for 10-15wt% of the precursor ferrotitanium slag powder into the precursor ferrotitanium slag powder, performing wet grinding until the granularity is less than or equal to 60 mu m, performing vacuum mud extrusion molding, and ageing the mixture for 36-48 hours; and putting the mixture into a resistance furnace, heating to 1500-1550 DEG C, performing heat preservation for 1-3 hours, and crushing, thereby obtaining the reproducible high-aluminum fireproof raw material utilizing the ferrotitanium slag as the main material. The preparation method has the characteristics of simple process, low production cost and no special requirements on equipment; and the prepared reproducible high-aluminum fireproof raw material is high in fire resistance and favorable in sintering performance.

Owner:WUHAN UNIV OF SCI & TECH +1

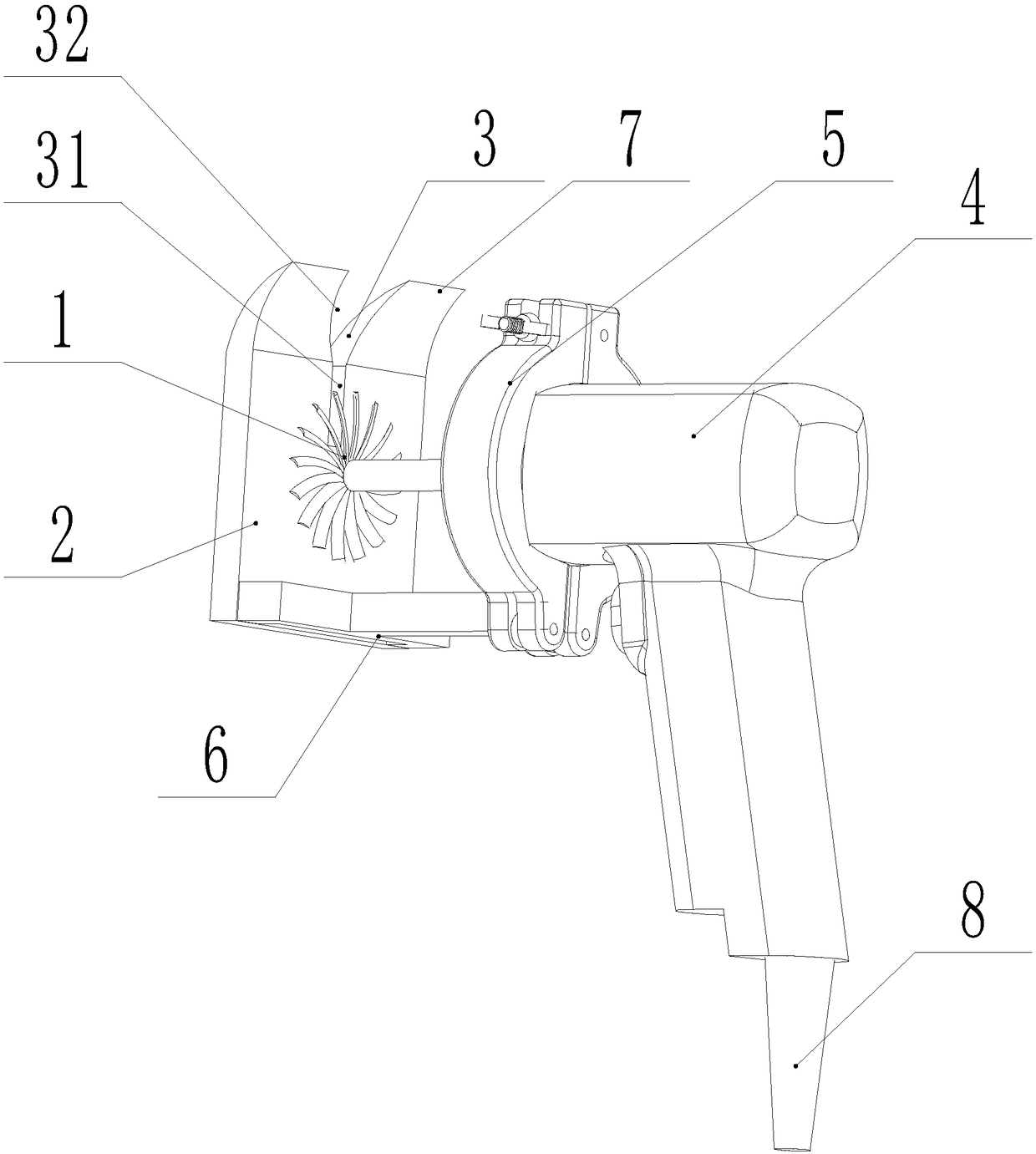

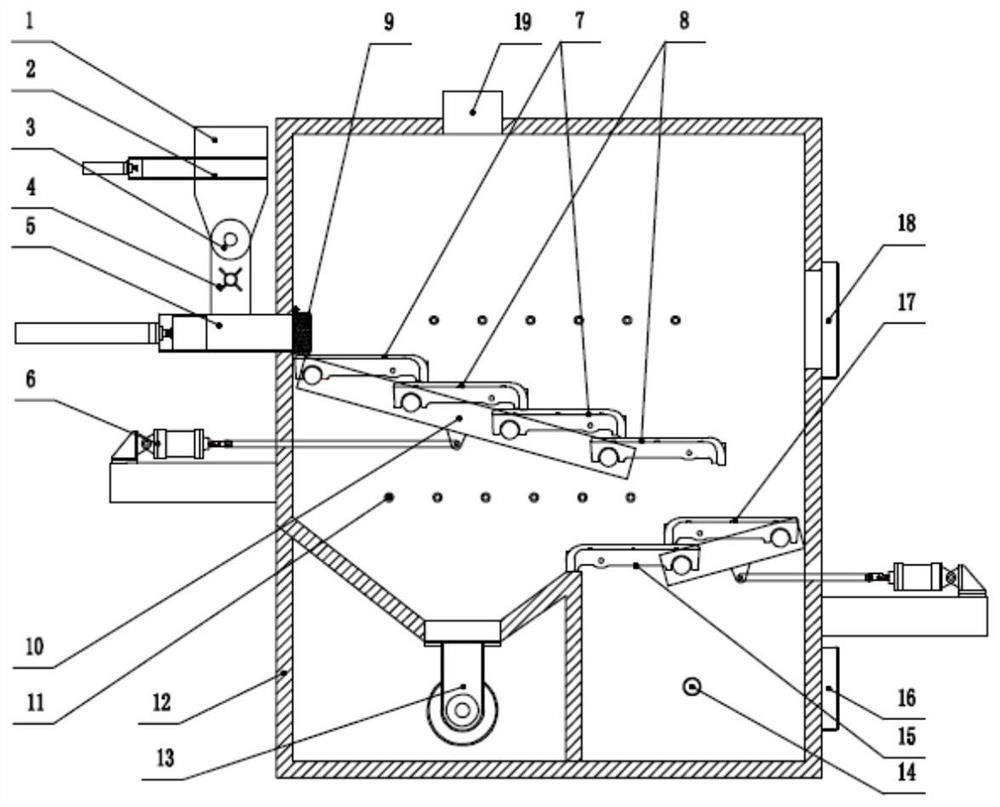

Pneumatic sponge burr trimming machine

The invention provides a pneumatic sponge burr trimming machine. The pneumatic sponge burr trimming machine comprises rotary blades and a thin piece; the thin piece is arranged in a gap at the bottomsof the rotary blades; an accommodating cavity for accommodating sponge burrs is formed in the thin piece. The invention provides the pneumatic sponge burr trimming machine which is high in automationdegree, high in sponge burr shearing efficiency, and long in service life.

Owner:刘兵

Synthetic mullite raw material with aluminum chromium slag as main material and preparation method thereof

The invention relates to a mullite raw material adopting alumina-chrome slag as a main ingredient and a preparation method thereof. According to the technical scheme, the method comprises the steps that the alumina-chrome slag is placed into a muffle furnace, and calcination is performed under the temperature of 700-750 DEG C for 3-5 h to obtain calcined alumina-chrome slag; the calcined alumina-chrome slag, silica powder and aluminite powder are mixed on the basis that the mass ratio of the calcined alumina-chrome slag to the silica powder to the aluminite powder is 100:(16.0-16.5):(2.0-4.5) for 15-20 min, and a mixed material is obtained; the mixed material is placed into an electromagnetic induction furnace, the temperature is increased to 1,800-1,840 DEG C and kept constant for 2-3 h; then, an upper scum layer is separated out, furnace cooling is performed to the room temperature, and crushing is performed to obtain the synthesis mullite raw material adopting the alumina-chrome slag as the main ingredient. The alumina-chrome slag contains main chemical components: 80-85 wt% of Al2O3, 10-15 wt% of Cr2O3 and not larger than 1 wt% of Fe2O3. The technology is simple, the production cost is low, and no special requirement for equipment is needed; the prepared mullite raw material adopting the alumina-chrome slag as the main ingredient is high in refractoriness, good in sintering performance and high in mullite conversion rate.

Owner:锦州集信高温材料有限公司

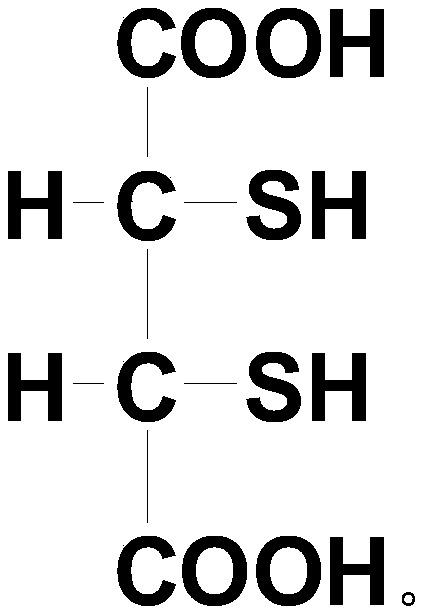

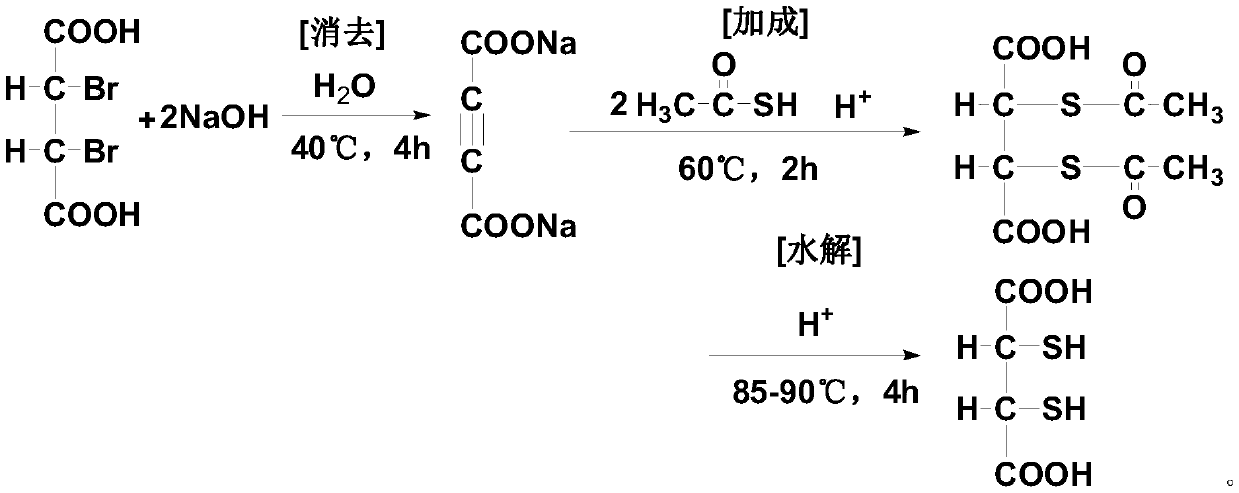

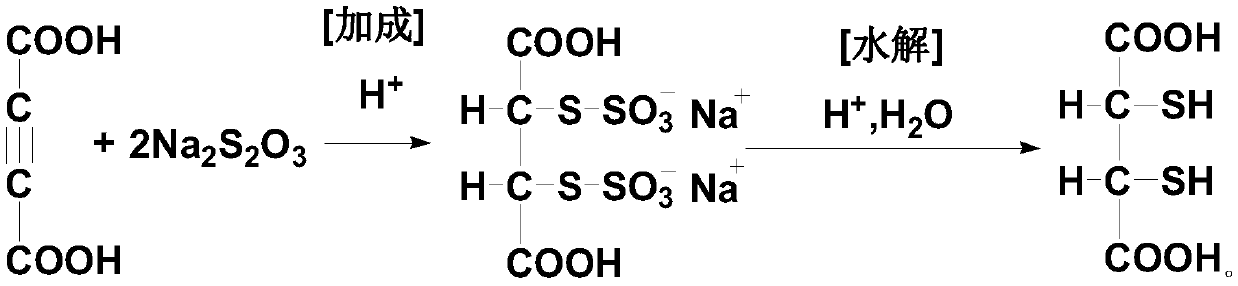

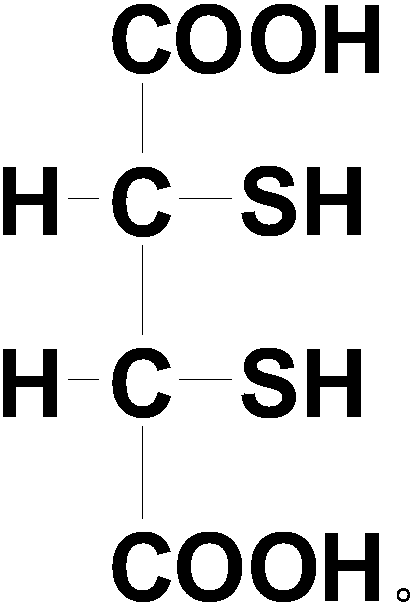

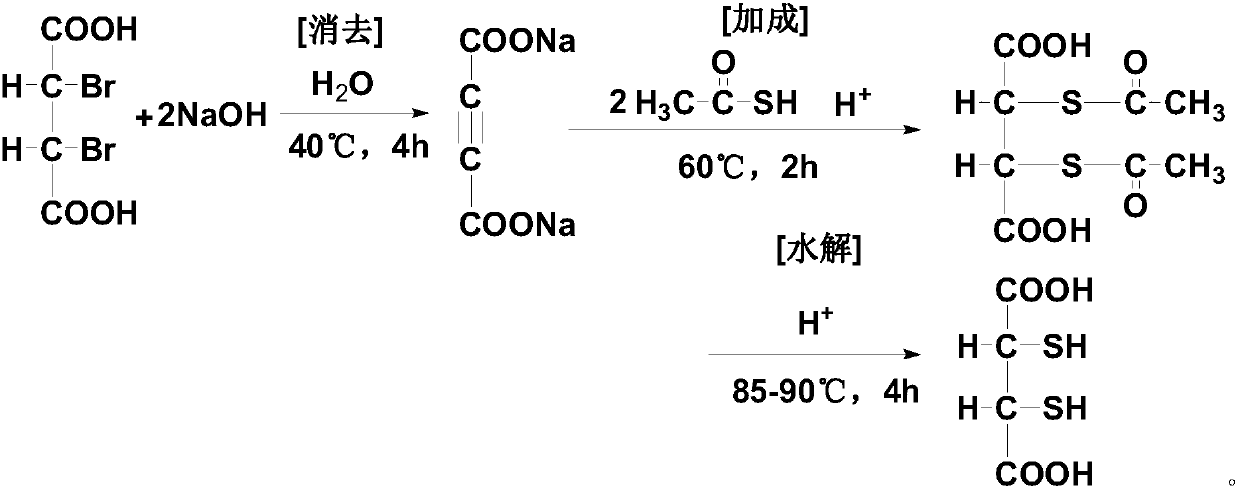

A kind of dimercaptosuccinic acid and its salt and preparation method

ActiveCN107628974BSimple processShort preparation cycleThiol preparationOrganic synthesisLiquid state

The invention relates to the technical field of organic synthesis, in particular to dimercaptosuccinic acid and salt thereof and a preparation method. The preparation method comprises the following steps: carrying out reaction on ethyl xanthate and 2,3-dibromosuccinic acid, so that 2,3-diethyl xanthate-1,4 succinic acid is obtained; hydrolyzing the 2,3-diethyl xanthate-1,4 succinic acid, so that 2,3-dimercaptosuccinate solution is obtained; and acidifying the obtained 2,3-dimercaptosuccinate solution, so that 2,3-dimercaptosuccinic acid is obtained. The preparation method provided by the invention has the advantages that technology is simple, liquid-state thioacetic acid with strong odor and unstable quality does not need to be used, unsafe addition reaction does not need to be carried out, preparation period is short, yield is high, cost is low, and the dimercaptosuccinic acid can be applicable to industrial production and popularization and can be further prepared into a dimercaptosuccinate product. The dimercaptosuccinic acid product and the dimercaptosuccinate product are high in purity and low in cost.

Owner:HEFEI LIFEON PHARMA

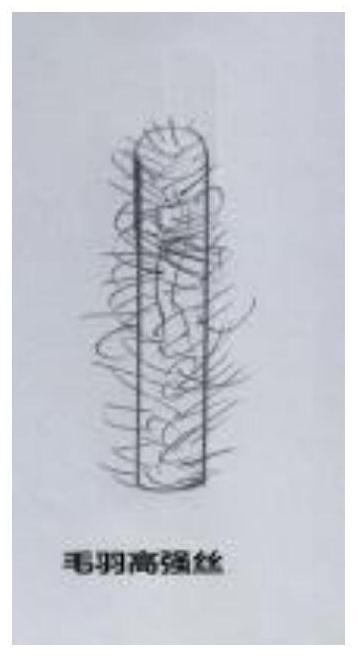

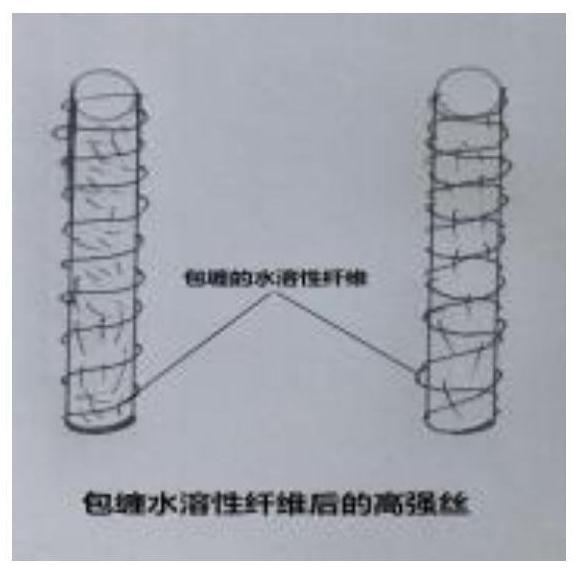

Weaving treatment method for avoiding reduction of mechanical properties of high-strength fiber fabric

InactiveCN112501753AReduce wearImprove passabilityHeating/cooling textile fabricsWoven fabricsSoluble fiberIndustrial engineering

The invention discloses a weaving treatment method for avoiding reduction of mechanical properties of a high-strength fiber fabric. The weaving treatment method comprises the following steps that by high-strength fibers are used as a core and wrapped with water-soluble fibers by using a compound yarn machine wrapping process to obtain high-strength composite fibers, and the high-strength compositefibers are woven into a high-strength fabric containing the water-soluble fibers on a rapier loom by using a plain weaving process; and then water treatment is conducted to completely dissolve the water-soluble fibers, and drying and winding are conducted to obtain the pure high-strength fiber fabric. According to the method, abrasion of the high-strength fibers to loom assemblies due to monofilament breakage is effectively reduced, and the trafficability of the fibers in the weaving process is effectively improved; the damage of the acid-base concentration of traditional water treatment to the mechanical properties of the high-strength fabric is effectively reduced, and the overall mechanical properties of the high-strength fiber fabric are effectively improved; and the product defects such as the hairiness rate of the cloth cover are greatly reduced, and the weaving production benefits are also improved.

Owner:苏州福洹纺织科技有限公司

Method for recovering candesartan cilexetil intermediate mother liquor

ActiveCN113444009AReduce manufacturing costAvoid interferenceIsocyanic acid derivatives preparationOrganic compound preparationMedicinal chemistryPharmacology

The invention provides a recovery method of candesartan cilexetil intermediate mother liquor. The candesartan cilexetil intermediate mother liquor obtained in real production comprises candesartan tert-butyl ester, candesartan tert-butyl ester decomposition impurities and candesartan tert-butyl ester diester impurities; and the mother liquor is not treated in conventional production procedures and is directly treated as waste liquor, so resources are wasted and cost is increased. The method for recovering the mother liquor provided by the invention can recover candesartan cilexetil in the mother liquor, convert decomposed impurities and diester impurities into candesartan cilexetil for recovery, and recover more than 90% of substances in the mother liquor, so the production cost of candesartan cilexetil is greatly reduced. According to the recovery method, interference of diester impurities can be avoided when the decomposed impurities are recycled, and generation of byproduct diester impurities is avoided as much as possible when the diester impurities are recycled; and operation is easy and convenient, and raw materials are low in price, so the method is suitable for industrial production and popularization.

Owner:珠海润都制药股份有限公司

A pyrolysis treatment process for organic solid waste

ActiveCN107760338BAvoid secondary pollutionAvoid it happening againSludge treatment by de-watering/drying/thickeningWater contaminantsSocial benefitsPtru catalyst

The invention provides a pyrolysis treatment process for organic solid waste, which includes the following steps: (1) pretreatment: drying and pulverizing the organic solid waste; (2) pyrolysis: discarding the pretreated organic solid waste After the pyrolysis treatment, solid products and gas products are obtained; (3) cracking and reforming: the gas products after pyrolysis enter the reforming furnace, and are cracked and reformed under the action of the catalyst; (4) post-treatment : the gas produced after cracking and reforming is cooled and purified, the present invention eliminates the organic pollution factors in the organic solid waste, the solid product can be handed over to the building material production unit for use as a raw material or auxiliary agent, and the gas product can be used as a fuel to reduce and avoid It eliminates the pollution of waste to the environment in industrial production activities, and has remarkable environmental benefits, social benefits and economic benefits.

Owner:JIANGMEN LVRUN ENVIRONMENTAL SCI TECH CO LTD

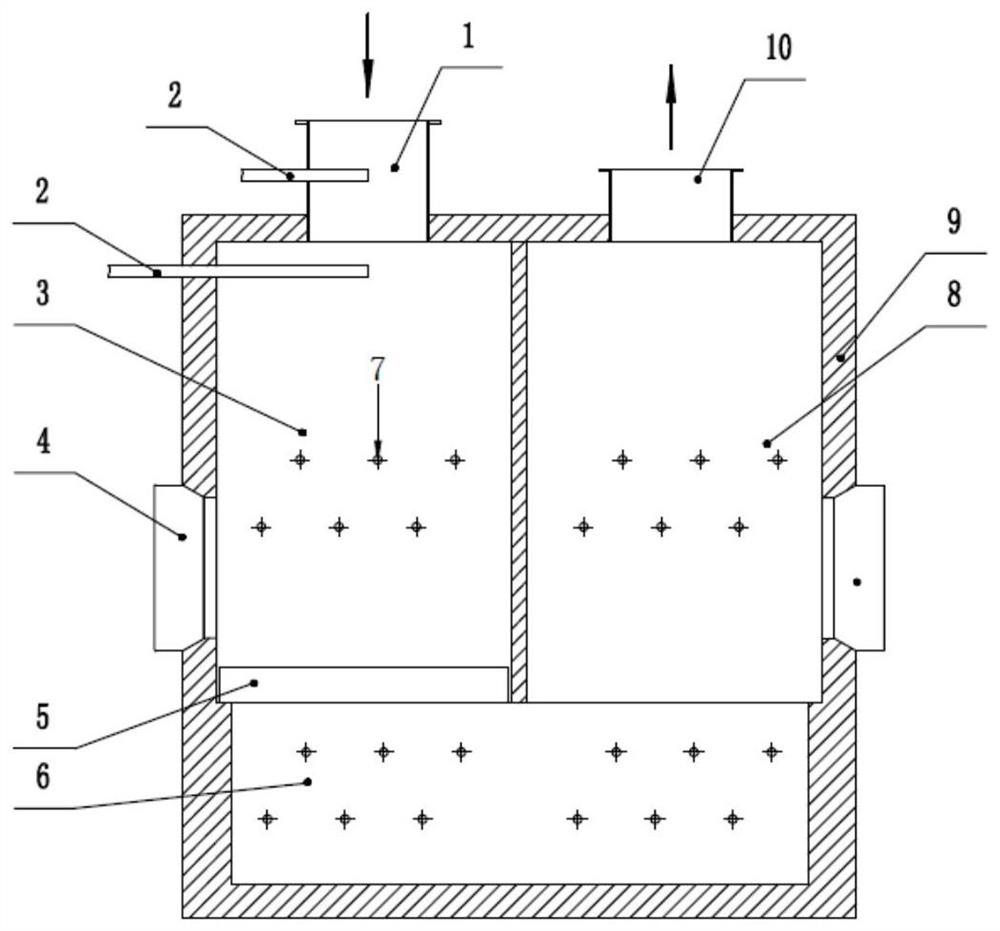

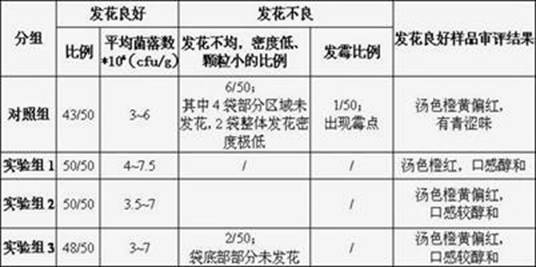

Eurotium cristatum-growing loose tea processing technology

PendingCN112237222ASimple processLow environmental requirementsPre-extraction tea treatmentProcess engineeringFood science

The invention relates to an eurotium cristatum-growing loose tea processing technology. The processing technology comprises the following processing steps of mixing and steaming tea, compressing and preserving heat, dispersing, packaging, sterilizing, eurotium cristatum growing, alcoholizing and drying. The process is low in processing cost and easy for industrial production and popularization, and the produced loose tea is uniform in eurotium cristatum growing, high in eurotium cristatum density, full in particles, stable in finished product quality, mellow in taste and obvious in fragrance.

Owner:XIANYANG JINGWEI EIGHT TEA CO LTD

Dimercaptosuccinic acid and salt thereof and preparation method

ActiveCN107628974ASimple processShort preparation cycleThiol preparationOrganic synthesisLiquid state

The invention relates to the technical field of organic synthesis, in particular to dimercaptosuccinic acid and salt thereof and a preparation method. The preparation method comprises the following steps: carrying out reaction on ethyl xanthate and 2,3-dibromosuccinic acid, so that 2,3-diethyl xanthate-1,4 succinic acid is obtained; hydrolyzing the 2,3-diethyl xanthate-1,4 succinic acid, so that 2,3-dimercaptosuccinate solution is obtained; and acidifying the obtained 2,3-dimercaptosuccinate solution, so that 2,3-dimercaptosuccinic acid is obtained. The preparation method provided by the invention has the advantages that technology is simple, liquid-state thioacetic acid with strong odor and unstable quality does not need to be used, unsafe addition reaction does not need to be carried out, preparation period is short, yield is high, cost is low, and the dimercaptosuccinic acid can be applicable to industrial production and popularization and can be further prepared into a dimercaptosuccinate product. The dimercaptosuccinic acid product and the dimercaptosuccinate product are high in purity and low in cost.

Owner:HEFEI LIFEON PHARMA

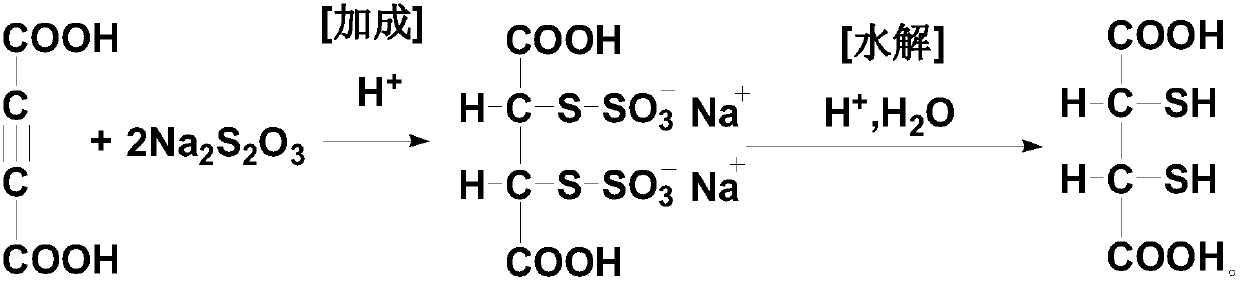

Sludge direct drying and incineration integrated system and working method thereof

PendingCN113292213ARealize self-heating dryingTake advantage ofSludge treatment by de-watering/drying/thickeningIncinerator apparatusCombustionSludge

The invention discloses a sludge direct drying and incineration integrated system and a working method thereof. The sludge direct drying and incineration integrated system comprises a sludge pool, a biogas digester and a sludge drying device, a wet sludge outlet of the sludge pool is connected with the biogas digester, a biogas outlet of the biogas digester is connected with a combustion device, and a high-temperature smoke outlet of the combustion device is connected with the sludge drying device; the sludge drying device is also connected with a wet sludge outlet of the sludge tank and a sludge outlet of the methane tank, and a dried sludge outlet of the sludge drying device is connected with a dried sludge inlet of the combustion device. Self-heat-supply drying is achieved, additional heat supply fuel is not needed, self-heat-supply drying circulation is achieved while sludge is treated, a large number of resources are saved, the cost is greatly reduced, and the system is suitable for industrial production and popularization.

Owner:XI AN JIAOTONG UNIV

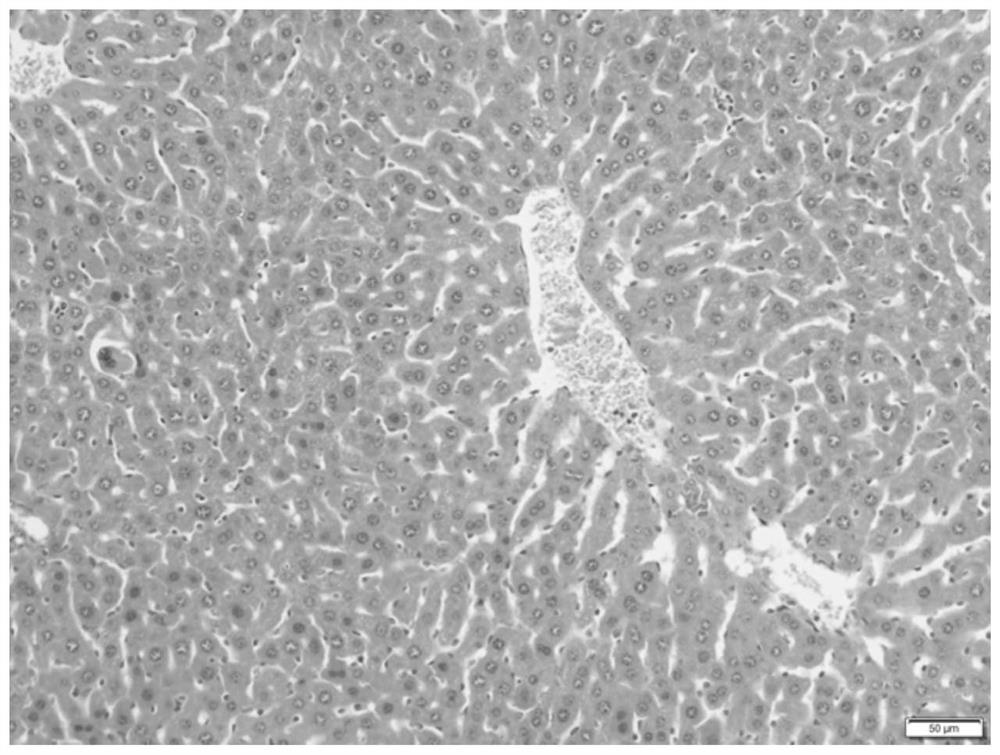

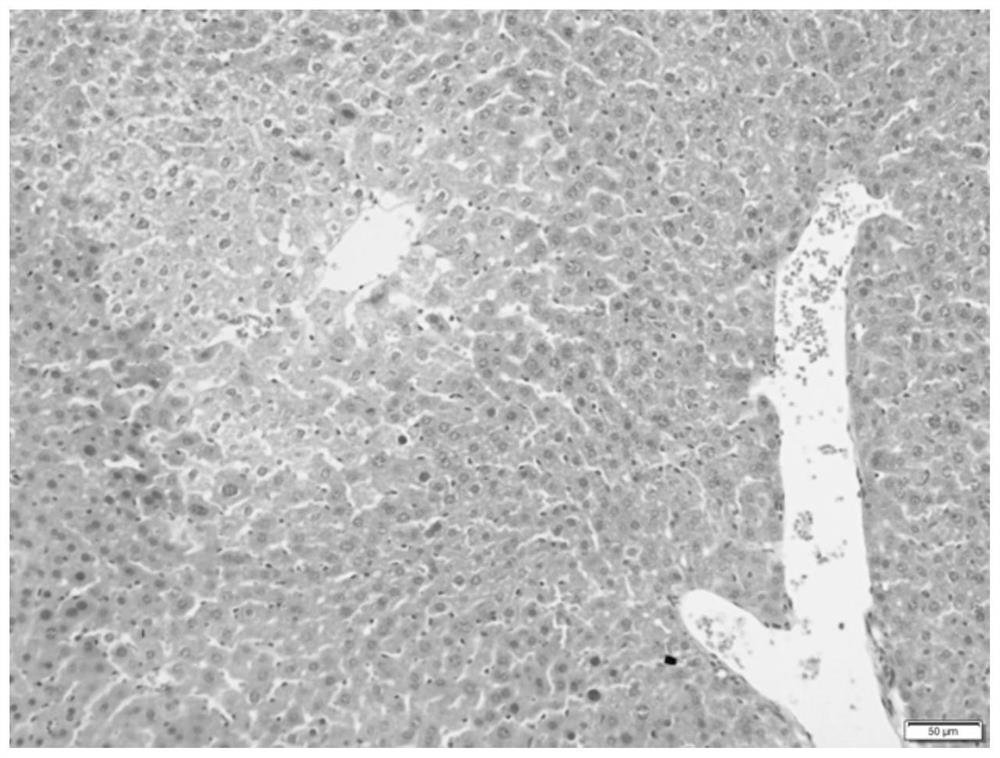

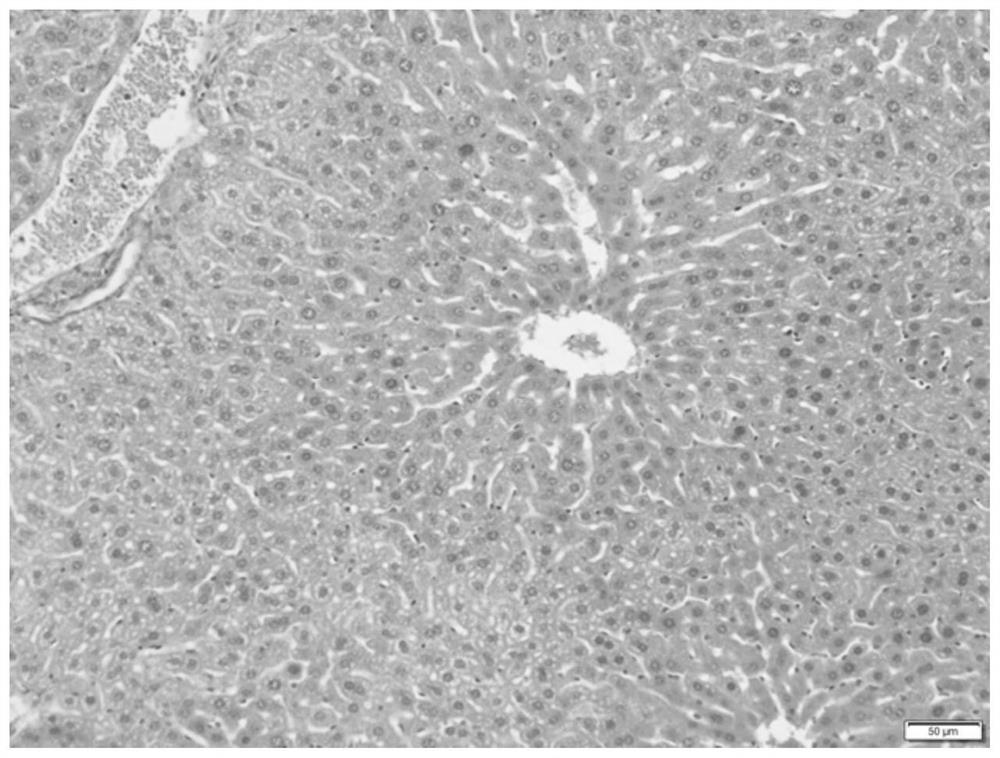

Yunzhi schisandra extract and its preparation method and application

ActiveCN109793825BDamage causedGood treatment effectDigestive systemPlant ingredientsBiotechnologyWestern medicine

The invention provides a Yunzhi Schisandra extract, a preparation method and application thereof, and relates to the field of traditional Chinese medicines. The raw material of the Yunzhi Schisandra extract is composed of Yunzhi and Schisandra, and the mass ratio of Yunzhi and Schisandra It is (400-800): (80-160), the invention can solve the technical problems that traditional single-component traditional Chinese medicine liver protection products have poor curative effect and that long-term use of western medicine will cause new side effects such as liver damage. The invention provides Yunzhi schisandra extract is obtained by extracting Yunzhi and schisandra, not only has significant prevention and treatment of alcoholic liver damage and chemical (carbon tetrachloride) liver damage, but also has less side effects when taken for a long time, and at the same time The preparation method is simple, easy to operate, low in cost, suitable for industrial production and popularization, and has broad application prospects.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

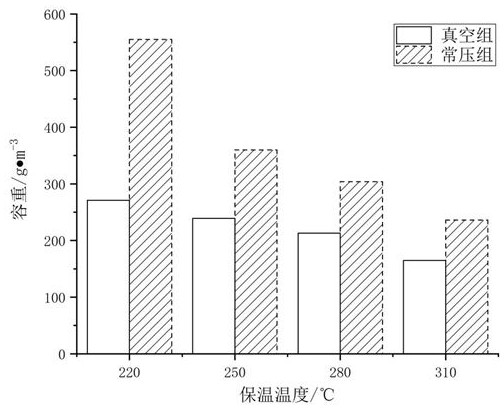

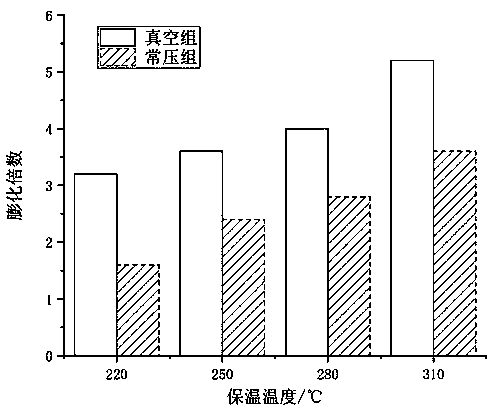

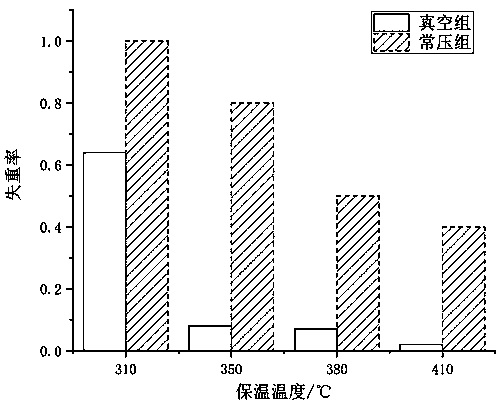

Vacuum foamed low-temperature foam glass material and its preparation method and application

ActiveCN111362582BLower firing temperatureImprove stabilityGlass shaping apparatusFoam glassAlkali metal

The invention discloses a vacuum foaming low-temperature foam glass material as well as a preparation method and application thereof. The material is prepared by taking an alkali metal silicate aqueous solution and a glass matrix modifier as raw materials through a wet chemical method under a vacuum low-temperature condition, wherein the chemical formula of the alkali metal silicate aqueous solution is R2O.mSiO2.H2O; the modulus m ranges from 2.4 to 2.8, and R is one or more of Li, Na and K; the glass matrix modifier is a boron-containing raw material and an aluminum-containing raw material, the boron-containing raw material is boric acid; and the aluminum-containing raw material is one or more of bentonite and montmorillonite. The material can be applied to multiple fields, including thefields of wall insulation and photo-catalysis. The energy consumption is saved, the cost is reduced, and the material stability is improved. The foam glass material has controllable open-close porosity, and is suitable for industrial application; and the preparation method is carried out under wet chemical conditions in the whole process, produces less dust and is ecological and environmentally friendly.

Owner:ZHEJIANG UNIV

Method for obtaining somatic cells by performing enzymolysis on purple laver by using conch digestive glands

InactiveCN105670984AExtended operating cycleEasy to operateCell dissociation methodsCultivating equipmentsSomatic cellCellulase

The invention discloses a method for obtaining somatic cells by performing enzymolysis on purple laver by using conch digestive glands. The method comprises the following steps: homogenizing fresh conch digestive glands, carrying out salting-out, and carrying out enzymolysis on purple laver tissues by directly using the salting-out product as the enzyme solution, thereby obtaining the somatic cells. The treatment method can simplify the operation and shorten the enzymolysis time, has favorable enzymolysis effect, does not need to add cellulase or other enzymes in the enzymolysis process, can effectively lower the cost, has favorable economic benefits, and is suitable for industrialized production and popularization.

Owner:福建省平潭县水产良种实验有限公司

Vacuum foaming low-temperature foam glass material as well as preparation method and application thereof

ActiveCN111362582ALower firing temperatureImprove stabilityGlass shaping apparatusFoam glassAlkali metal

The invention discloses a vacuum foaming low-temperature foam glass material as well as a preparation method and application thereof. The material is prepared by taking an alkali metal silicate aqueous solution and a glass matrix modifier as raw materials through a wet chemical method under a vacuum low-temperature condition, wherein the chemical formula of the alkali metal silicate aqueous solution is R2O.mSiO2.H2O; the modulus m ranges from 2.4 to 2.8, and R is one or more of Li, Na and K; the glass matrix modifier is a boron-containing raw material and an aluminum-containing raw material, the boron-containing raw material is boric acid; and the aluminum-containing raw material is one or more of bentonite and montmorillonite. The material can be applied to multiple fields, including thefields of wall insulation and photo-catalysis. The energy consumption is saved, the cost is reduced, and the material stability is improved. The foam glass material has controllable open-close porosity, and is suitable for industrial application; and the preparation method is carried out under wet chemical conditions in the whole process, produces less dust and is ecological and environmentally friendly.

Owner:ZHEJIANG UNIV

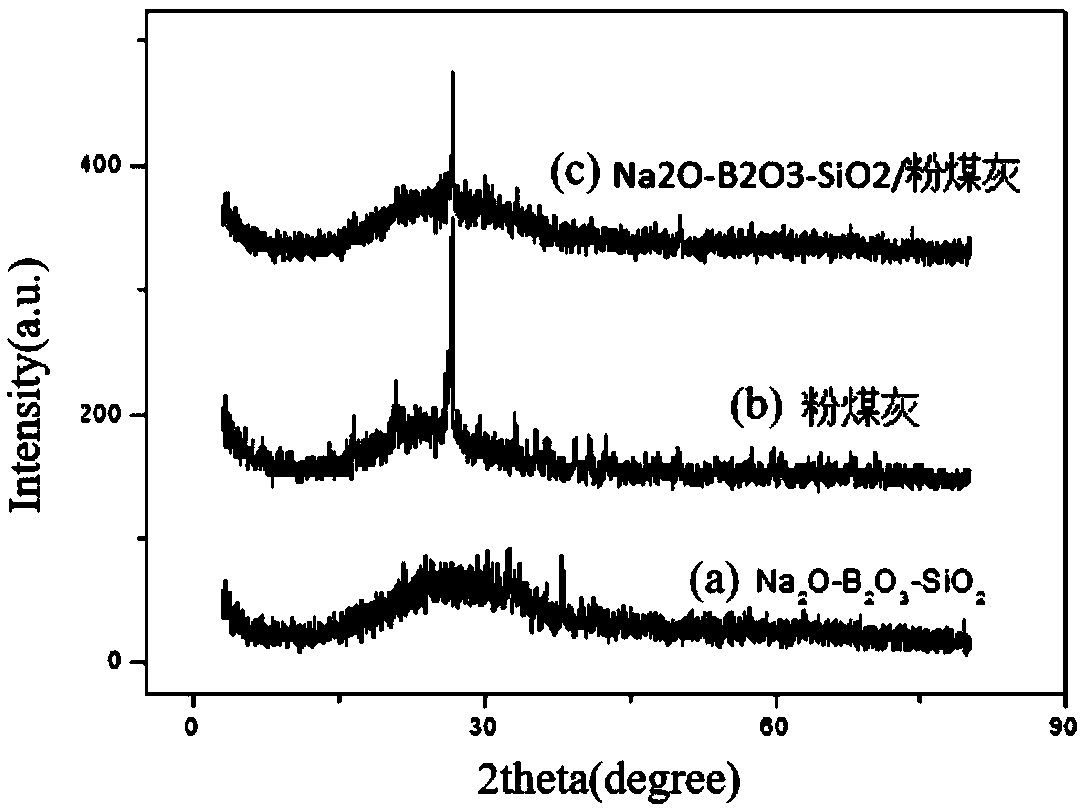

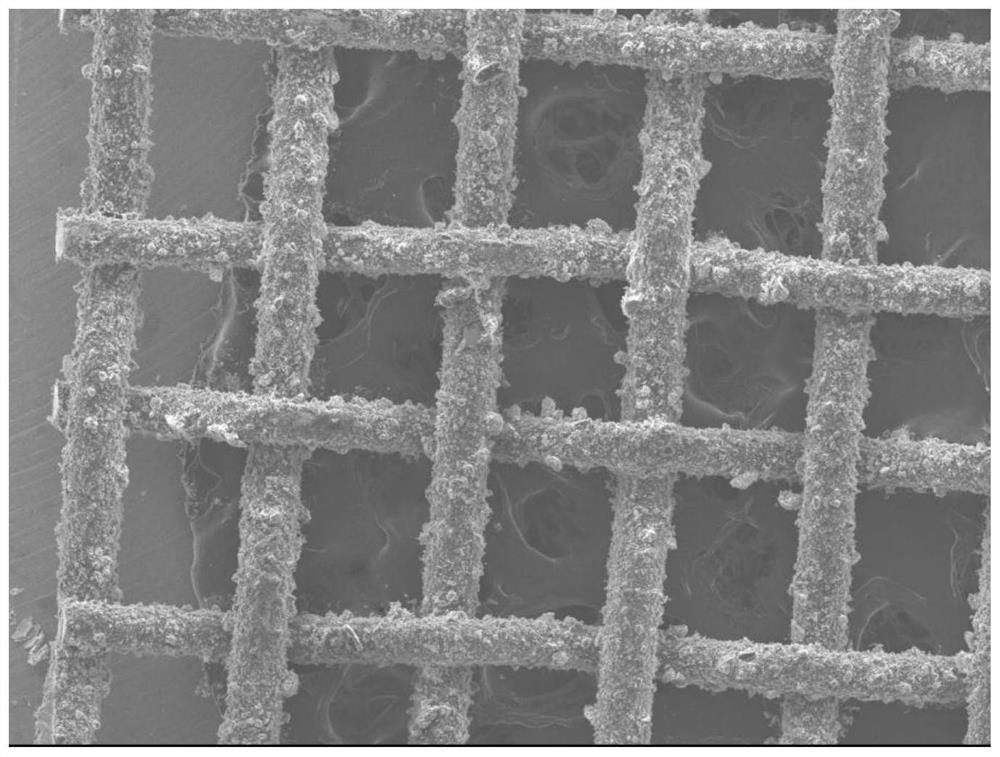

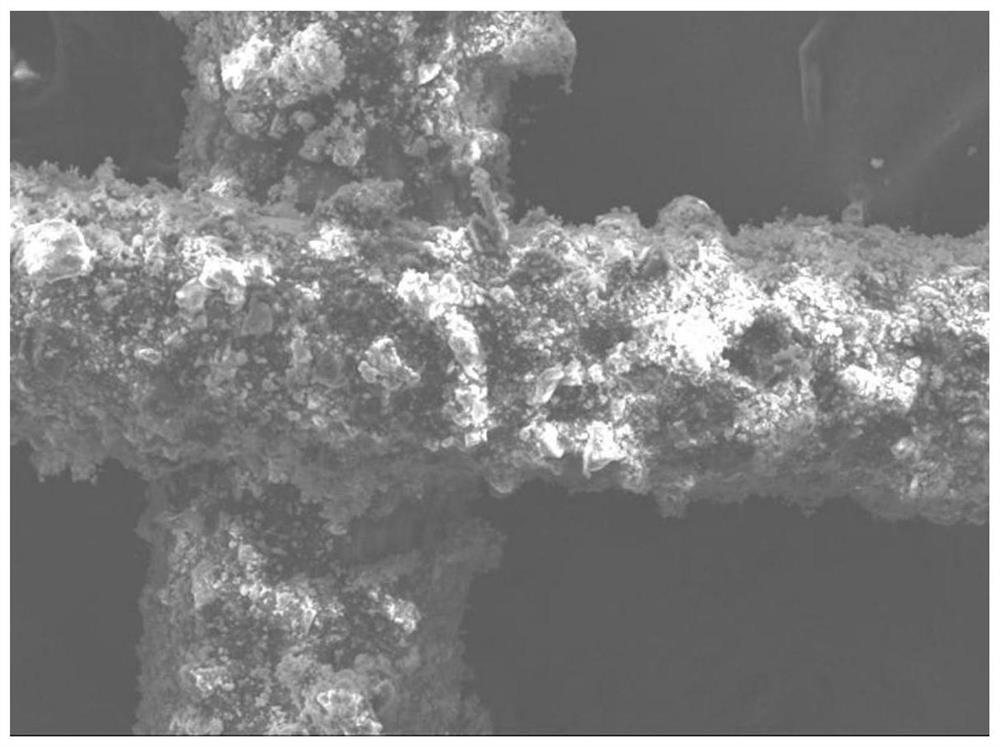

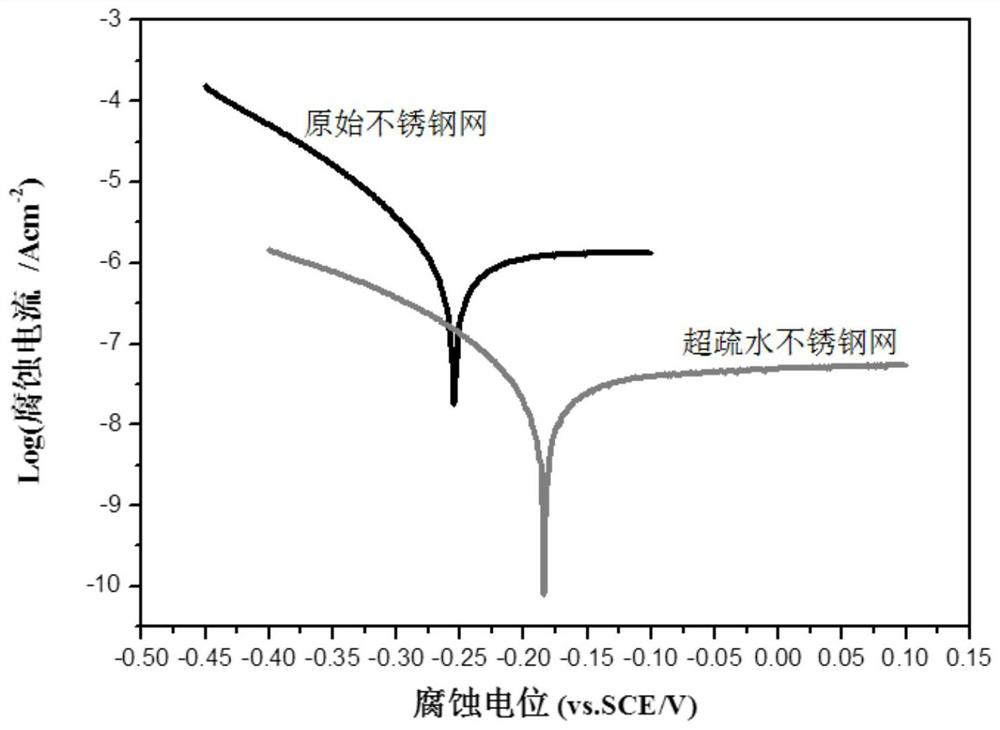

A kind of preparation method and application of corrosion-resistant super-hydrophobic stainless steel mesh

ActiveCN110152354BSimple preparation processReduce manufacturing costNon-miscible liquid separationSuperhydrophobeSS - Stainless steel

The invention discloses a preparation method and application of a corrosion-resistant super-hydrophobic stainless steel mesh. The oil-water separation mesh uses stainless steel mesh as a base material, and adopts a resin bonding method to firmly bond modified fly ash to the base On the material skeleton, corrosion-resistant super-hydrophobic stainless steel mesh is obtained after curing. The corrosion-resistant stainless steel mesh of the present invention still maintains high superhydrophobic durability after 100 wear tests. The corrosion-resistant stainless steel mesh of the present invention can be applied in the fields of separation of oil / water mixture and treatment of oily wastewater, and continuous oil-water separation can be realized by building a device, the treatment capacity of oil-water mixture is large, the operation is simple, and the separation effect is good. The corrosion-resistant oil-water separation stainless steel mesh of the present invention has a simple preparation process, the whole production cycle is as low as 5 hours, and the preparation raw materials are cheap and easy to obtain, and the environment is friendly, which is convenient for industrial large-scale batch production, and has high economic benefits and practical value.

Owner:YANAN UNIV

Recycling method of high concentration phosphate and compound fertilizer residues

InactiveCN106745147AHigh recovery rateSuitable for industrial production promotionCalcium/strontium/barium carbonatesFertilizerChemistry

The invention relates to a recycling method of a high concentration phosphate and compound fertilizer residue. The method comprises the following steps: by taking a high concentration phosphate and compound fertilizer waste residue as a raw material, putting the waste residue wet powder in a reactor; adding water to dilute; slowly injecting dilute nitric acid; continuously stirring the mixture till no air bubbles emit; performing press filtering; injecting ammonia water into the filtrate; continuously stirring the mixture; filtering; injecting carbon dioxide gas into the filtrate; continuously stirring the mixture; filtering the same; and drying the filter residue with a drier to obtain a finished product light calcium carbonate.

Owner:毛竹青

Forming method of polytetrafluoroethylene impregnated sheet with high filling amount

PendingCN114161741AEasy to operateReduce impregnation costsFlat articlesPolymer chemistryPTFE - Polytetrafluoroethylene

The invention relates to a forming method of a polytetrafluoroethylene impregnated sheet with high filler quantity, which comprises the following steps: firstly impregnating a glass fabric with polytetrafluoroethylene slurry with high filler quantity in an impregnating manner to obtain a pre-impregnated sheet with the thickness of 200-250 microns, and then passing the impregnated sheet through a double-roller calender with heatable rollers to obtain the polytetrafluoroethylene impregnated sheet with high filler quantity. And the impregnated sheet with the thickness of 150-170 microns is obtained. By using the method, the polytetrafluoroethylene impregnated sheet with high filling amount can be obtained, and the thickness uniformity of the impregnated sheet is excellent; and through calendaring treatment of the impregnated sheet, bubbles on the surface of the impregnated sheet can be removed to a certain extent, and the method is suitable for industrial production and popularization.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com