Preparation method of sulfur-doped bismuth trioxide, negative electrode material and supercapacitor

A negative electrode material, sulfur-doped technology, applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems that hinder the development of new high-energy-density energy storage devices, and achieve excellent capacitance performance and cycle stability, short time consumption, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 0.458g of bismuth nitrate pentahydrate into 21mL of solvent (the volumes of ethanol and ethylene glycol are 14mL and 7mL, respectively), and stir at room temperature for 30min;

[0033] (2) The obtained solution was transferred to a 100 mL reaction kettle, and kept at 160° C. in an electric blast drying oven for 8 hours.

[0034] (3) cooling and centrifuging to obtain a white precipitate, washing the precipitate with deionized water and absolute ethanol three times alternately, drying in vacuum at 80°C for 12 hours, and fully grinding the precipitate into a fine powder;

[0035] (4) Put the above powder in a muffle furnace for calcination at 300°C for 1 hour, and thus obtain yellow Bi 2 o 3 Powder, marked as Bi-0S.

Embodiment 2

[0037] (1) Add 0.458g of bismuth nitrate pentahydrate into 21mL of solvent (the volumes of ethanol and ethylene glycol are 14mL and 7mL, respectively), and stir at room temperature for 30min;

[0038] (2) The obtained solution was transferred to a 100 mL reaction kettle, and kept at 160° C. in an electric blast drying oven for 8 hours.

[0039] (3) cooling and centrifuging to obtain a white precipitate, washing the precipitate with deionized water and absolute ethanol three times alternately, drying in vacuum at 80°C for 12 hours, and fully grinding the precipitate into a fine powder;

[0040] (4) Put the above powder in a muffle furnace for calcination at 300°C for 1 hour, and thus obtain yellow Bi 2 o 3 powder.

[0041] (5) will Bi 2 o 3 The powder was further annealed at 400 °C for 30 min in the presence of 0.025 g of sulfur powder to form S-doped Bi 2 o 3 , labeled Bi-25S.

Embodiment 3

[0043] (1) Add 0.458g of bismuth nitrate pentahydrate into 21mL of solvent (the volumes of ethanol and ethylene glycol are 14mL and 7mL, respectively), and stir at room temperature for 30min;

[0044] (2) The obtained solution was transferred to a 100 mL reaction kettle, and kept at 160° C. in an electric blast drying oven for 8 hours.

[0045] (3) cooling and centrifuging to obtain a white precipitate, washing the precipitate with deionized water and absolute ethanol three times alternately, drying in vacuum at 80°C for 12 hours, and fully grinding the precipitate into a fine powder;

[0046] (4) Put the above powder in a muffle furnace for calcination at 300°C for 1 hour, and thus obtain yellow Bi 2 o 3 powder.

[0047] (5) will Bi 2 o 3 The powder was further annealed at 400 °C for 30 min in the presence of 0.050 g sulfur powder to form sulfur-doped Bi 2 o 3 , labeled Bi-50S.

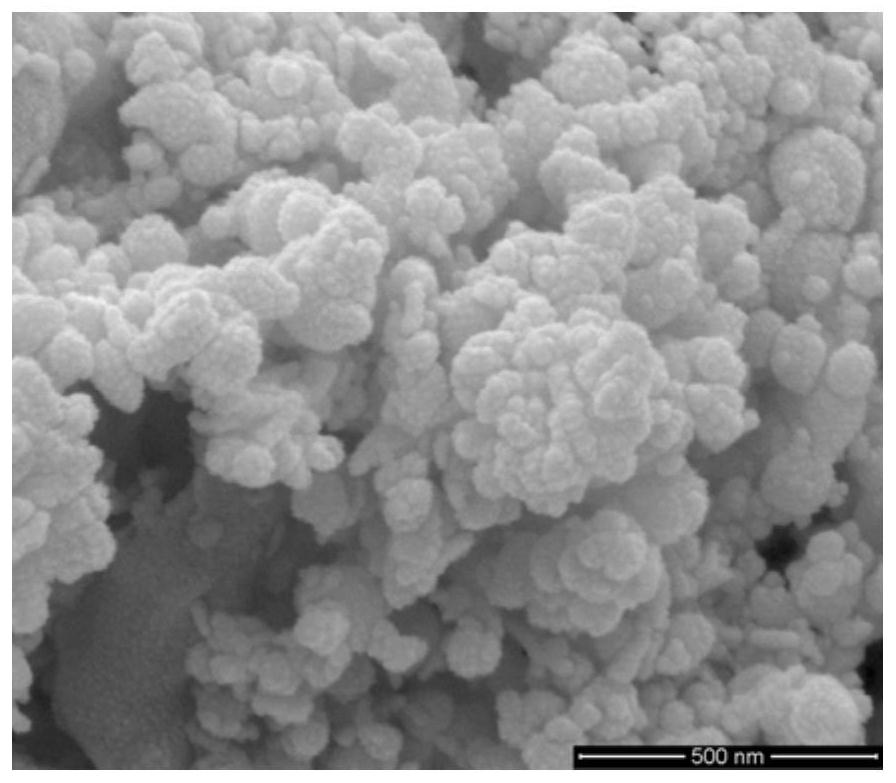

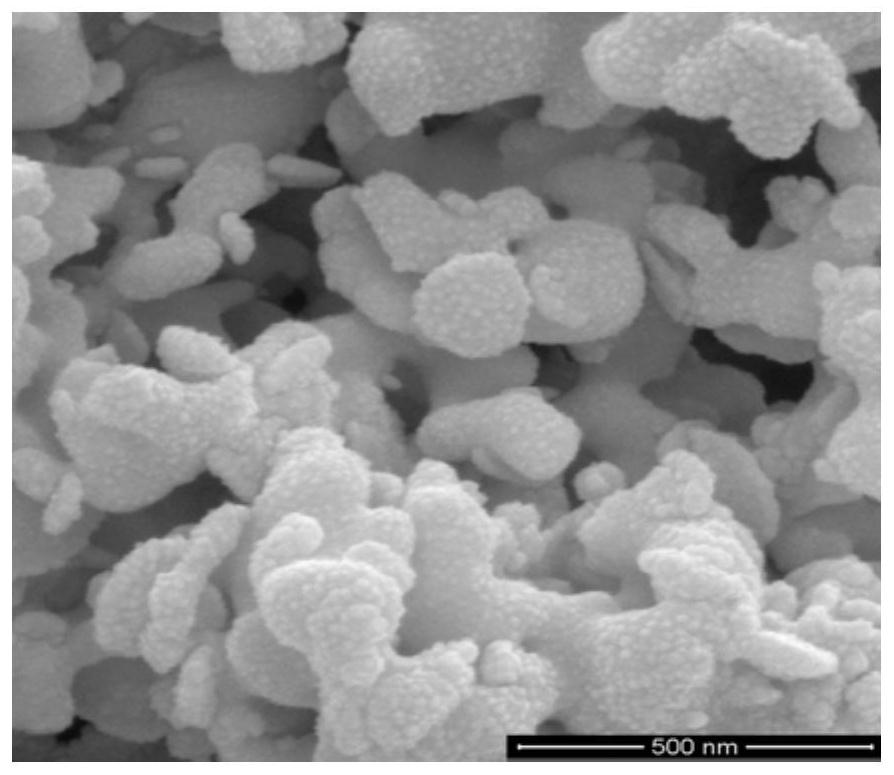

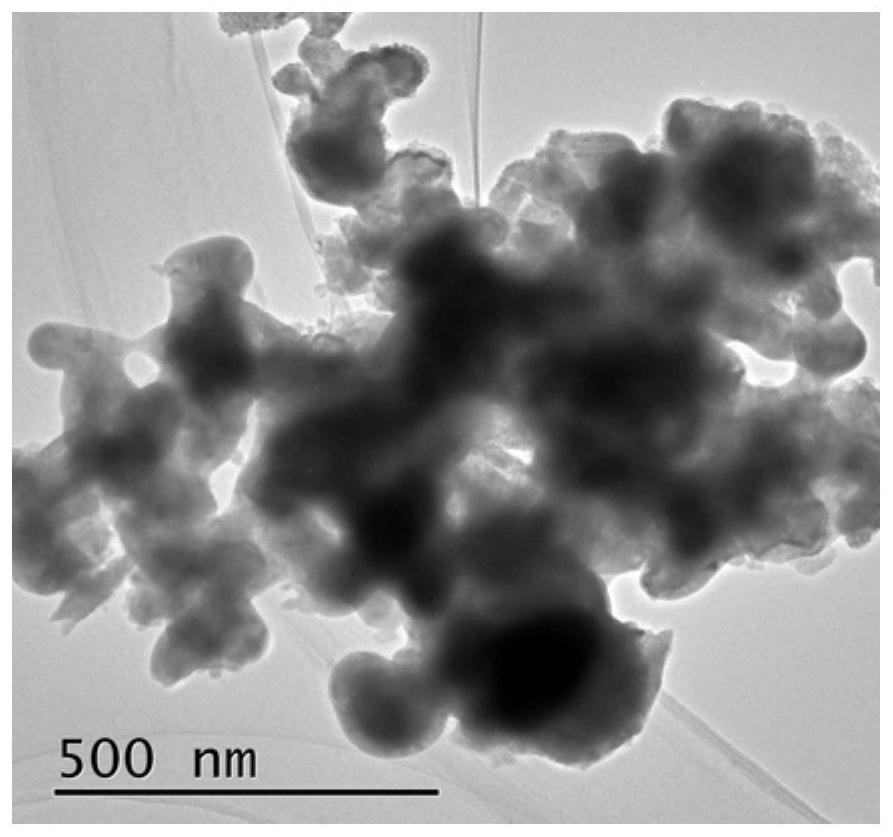

[0048]The scanning electron microscope (SEM) images and transmission electron microscope (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com