Gelcasting method for high strength fused quartz ceramic

A technology of gel injection molding and fused silica, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of difficult machining, large size molding, low mechanical strength of green bodies, etc., and achieve high density, high strength and excellent performance , good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

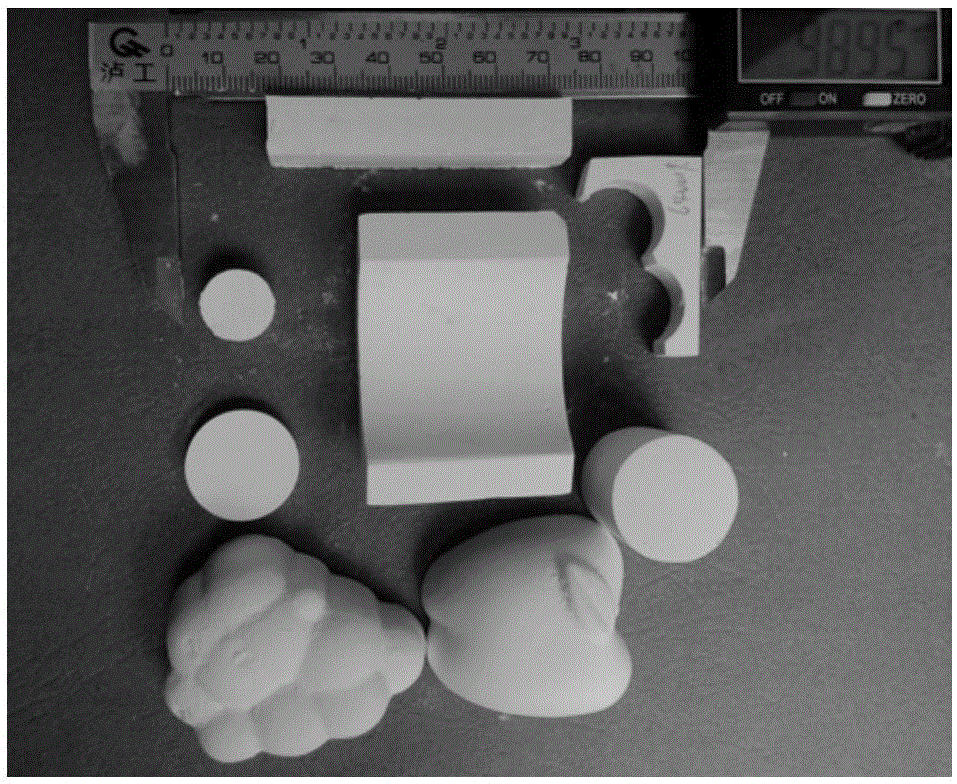

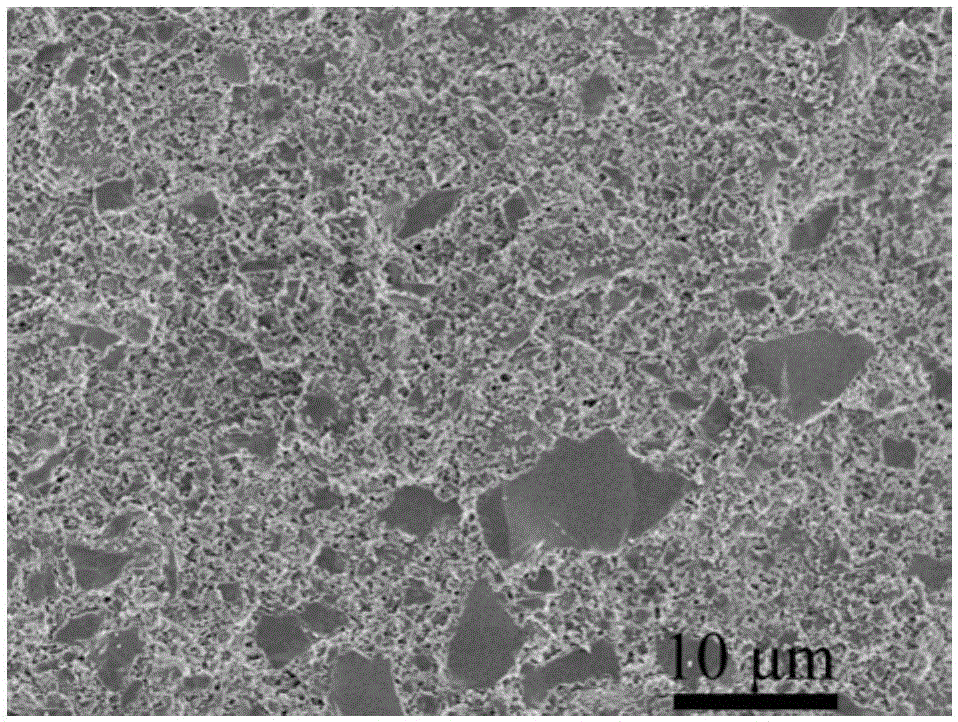

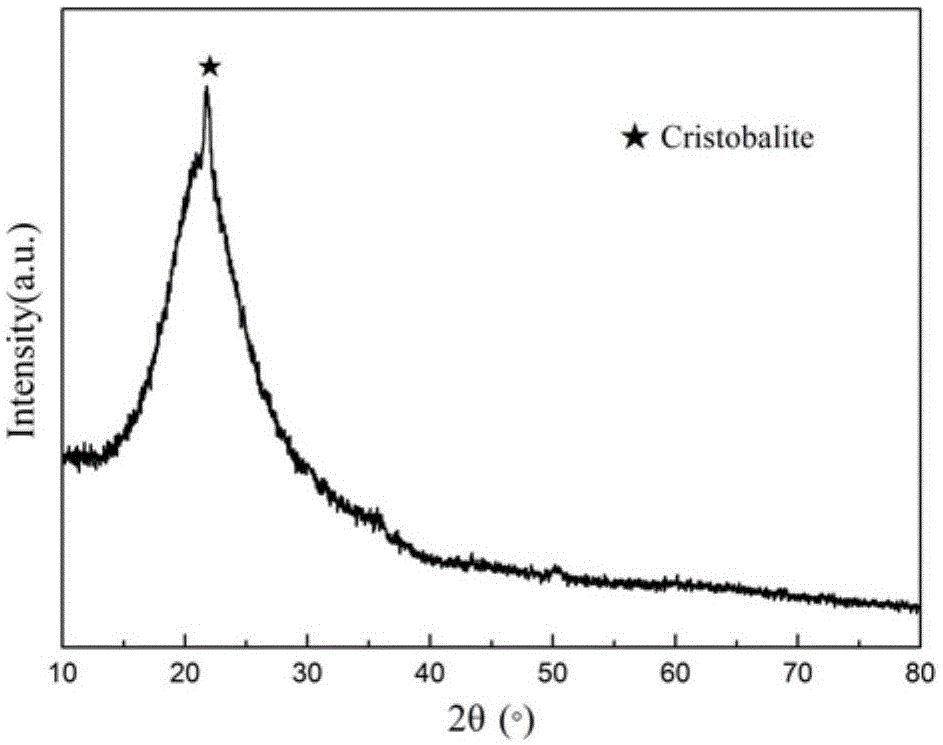

Embodiment 1

[0024] With 61.89g fused silica powder (purity: 99.90%, d 50 : 2.53μm), 21.00g of deionized water, 0.12g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer and 124.00g of grinding balls are added to the grinding tank, and are placed on a planetary ball mill at a speed of 200r / min Ball mill for 7 hours; then add 1.91g of glutinous rice flour and continue ball milling for 15 minutes; degas the milled slurry for 6 minutes in a vacuum environment of -0.15MPa, then inject it into a stainless steel mold and seal it; then put the stainless steel mold in a water bath and heat it at 80°C Constant temperature for 40 minutes to solidify the slurry; after demoulding the green body, first place it in a humid heat oven (30°C, 80% humidity) to dry for 18 hours, and then place it in an ordinary blast oven for 9 hours at 80°C; Sintering at 1250°C for 4 hours to obtain fused silica ceramics. The three-point bending strength of the fused silica green body obtained by this schem...

Embodiment 2

[0026] With 69.00g fused silica powder (purity: 99.93%, d 50 : 3.74μm), 18.00g of deionized water, 0.07g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer and 138.00g of grinding balls were added to the grinding tank, and the speed was 220r / min on the planetary ball mill Ball mill for 5 hours; then add 1.41g of glutinous rice flour and continue ball milling for 10 minutes; degas the ball milled slurry for 10 minutes in a vacuum environment of -0.10MPa, then inject it into a stainless steel mold and seal it; then put the stainless steel mold in a water bath and heat it at 75°C Constant temperature for 1 hour to solidify the slurry; after demolding the green body, first place it in a humid heat oven (40°C, 100% humidity) to dry for 12 hours, and then place it in an ordinary blast oven for 12 hours at 70°C; Sintering at 1225°C for 4 hours to obtain fused silica ceramics. The three-point bending strength of the fused silica body obtained by using this scheme rea...

Embodiment 3

[0028] With 63.69g fused silica powder (purity: 99.93%, d 50 : 3.74 μm), 20g deionized water, 0.16g naphthalenesulfonic acid formaldehyde condensate and 128.00g grinding balls were added into the grinding tank, and ball milled on a planetary ball mill for 4h at a speed of 230r / min; then, 2.31g glutinous rice flour was added to continue ball milling 20min; the ball-milled slurry was defoamed for 15min in a vacuum environment of -0.10MPa, then poured into a stainless steel mold and sealed; then the stainless steel mold was placed in a water bath, and the slurry was solidified at a constant temperature of 70°C for 1.5h; the green body After demoulding, first place it in a humid heat oven (25°C, 60% humidity) to dry for 24 hours, then place it in a common blast oven at 90°C for 6 hours; the dried green body is sintered at 1225°C for 6 hours to obtain fused silica ceramics . The three-point bending strength of the fused silica body obtained by adopting this scheme reaches 11.2MPa....

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com