Weaving treatment method for avoiding reduction of mechanical properties of high-strength fiber fabric

A high-strength fiber and processing method technology, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, fabrics, etc. Passability, damage reduction, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A weaving treatment method for avoiding the reduction of the mechanical properties of high-strength fiber fabrics, the steps comprising:

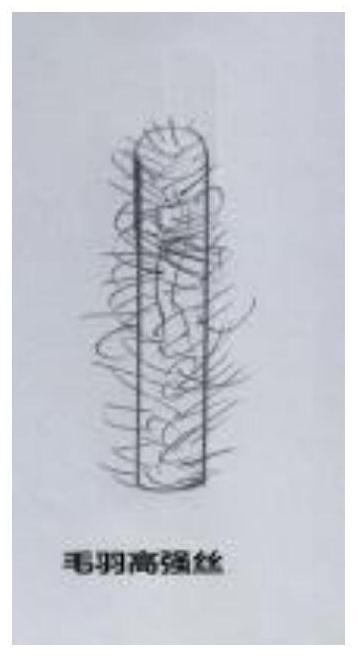

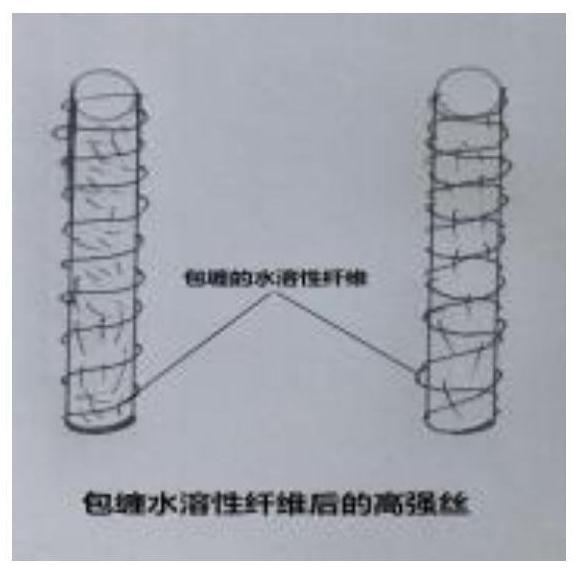

[0029] First, double yarn; the high-strength fiber with hairiness (which can be any one of aramid, PBO, carbon fiber, ultra-high molecular weight polyethylene, and PIPD) is machine-wrapped on the coating machine, made of high-strength fiber The core wire is wrapped with water-soluble fibers (either pectin-based fibers, gum-based fibers, polyvinyl acetal fibers, or hydroxymethylcellulose fibers) to ensure water solubility. The super-position twist of the fiber is 300-900 twists, so as to produce the composite fiber;

[0030] Second, warping: hang the bobbin wound with the composite fiber on the front bobbin creel, and carry out drawing warp and section warping;

[0031] Third, winding and paralleling; the composite fiber after warping is wound onto the warp beam according to the requirements of the head portion;

[0032] Fourth, wea...

Embodiment 2

[0037] The equipment used in this embodiment is:

[0038] Coating machine 1 (Continental MP-168 fully automatic);

[0039] 1 warping machine (Huafang HF928H high-speed intelligent slitting);

[0040] Parallel machine 1 (KARL MAYER AMR type);

[0041] 1 rapier loom (Smit FAST2.0);

[0042] 1 washing and setting machine (Germany Gaulle);

[0043] The method comprises the steps of:

[0044] The first, double yarn; will have the high-strength fiber with hairiness (in the present embodiment, high-strength fiber selects the ultra-high molecular weight polyethylene of 400D for use), adopt machine-wrapping process on the coating machine, do core with high-strength fiber, wrap around ( The composite fiber is produced by single wrapping or front and back wrapping) water-soluble fiber (in this embodiment, polyvinyl alcohol fiber is selected as the water-soluble fiber), and the super-position twist of the water-soluble fiber is 300 twists to 900 twists.

[0045] Second, warping: hang...

Embodiment 3

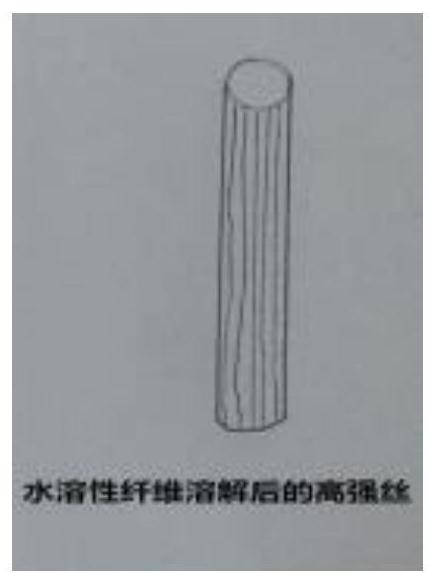

[0051] The pure high-strength fiber fabric prepared based on the above-mentioned weaving treatment method for avoiding the reduction of the mechanical properties of the high-strength fiber fabric has superior fabric properties, and the detection results according to the physical test are as follows:

[0052]

[0053] Using the same material and the same machine to prepare the fabric according to the conventional method, according to the physical test results are as follows:

[0054]

[0055] By comparison, it is found that the breaking strength of the fabric prepared by the conventional method is 6900N; while the pure high-strength fiber fabric prepared by the method of the present invention has a breaking strength of 8900N, and the performance is improved by 29%.

[0056] In summary, this method effectively reduces the wear of high-strength fibers on loom components caused by single-filament breakage; effectively improves the passage of fibers during the weaving process;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com