Vacuum foamed low-temperature foam glass material and its preparation method and application

A foam glass and vacuum foaming technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of high closed porosity of foam glass, poor stability of binary system, poor water resistance and other problems, and achieve Improve stability and mechanical properties, reduce hydroxyl content, and increase expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The experiment was carried out with liquid sodium silicate water glass, boric acid and calcium-based bentonite with a modulus of 2.4 and a solid content of 48.95%. The chemical composition and content of the calcium-based bentonite used are shown in Table 1-1; the parameters of the sodium silicate used are shown in Table 1-2.

[0047] Table 1-1 Chemical composition and content of calcium-based bentonite

[0048] chemical composition SiO 2

al 2 o 3

Fe 2 o 3

FeO TiO CaO MgO MnO K 2 o

Na 2 o

Content (wt%) 65.04 16.08 1.12 0.20 0.27 5.01 2.13 0.29 1.00 0.27

[0049] Table 1-2 Parameters of sodium water glass

[0050]

[0051] Table 1-3 Experimental formula

[0052]

[0053] The raw materials were sheared at high speed for 30 minutes, dispersed and mixed evenly, and a mixed sol was obtained without gelling. Put the mixed sol into an oven at 110°C for about 24 hours to obtain an intermediate mat...

Embodiment 2

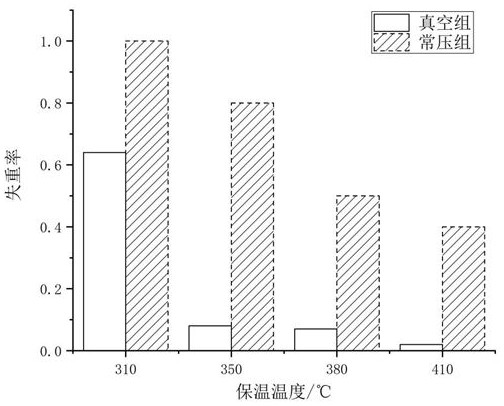

[0081] Figure 4 It is a comparison chart of the measurement data of the samples obtained by incubating at different temperatures with the formula raw materials in Example 1 under the environment of full vacuum but different relative vacuum degrees.

[0082] according to Figure 4 It can be seen that changing the relative vacuum degree of the vacuum environment has a significant impact on the durability of the material. Under the same conditions of other heat treatment, the greater the negative pressure, the lower the residual hydroxyl content of the prepared material. For example, for the three samples obtained at 350°C, the weight loss rate of the sample prepared by negative pressure 0.1MPa is close to 0, and the negative pressure 0.01MPa The weight loss rate of the prepared samples is close to 1.

Embodiment 3

[0084] The open porosity of the material is an important index to characterize the pore structure of the material, and the present invention mainly regulates the pore structure by changing the introduction stage of the vacuum environment.

[0085] Using the formulation raw materials in Example 1, the raw materials were sheared at high speed for 30 minutes, dispersed and mixed evenly, and a mixed sol was obtained without gelling. Put the mixed sol into an oven at 110°C for about 24 hours to obtain an intermediate material with a certain moisture content.

[0086] (1) After the intermediate pellets are moved into the tube furnace, the negative pressure in the furnace is 0.1Mpa and the temperature rises. When it reaches 100°C, 200°C, 300°C, and 350°C, quickly open the valve to let the air enter the tube furnace, wait for 15 seconds, and then quickly evacuate After the negative pressure in the tube reaches 0.1Mpa, continue to heat up to 350°C and immediately cool down with the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com