Pneumatic sponge burr trimming machine

A technology of trimming machine and sponge, which is applied in the field of machinery, can solve the problems of high production cost, low production efficiency, and low labor efficiency, and achieve the effects of long service life, simple structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

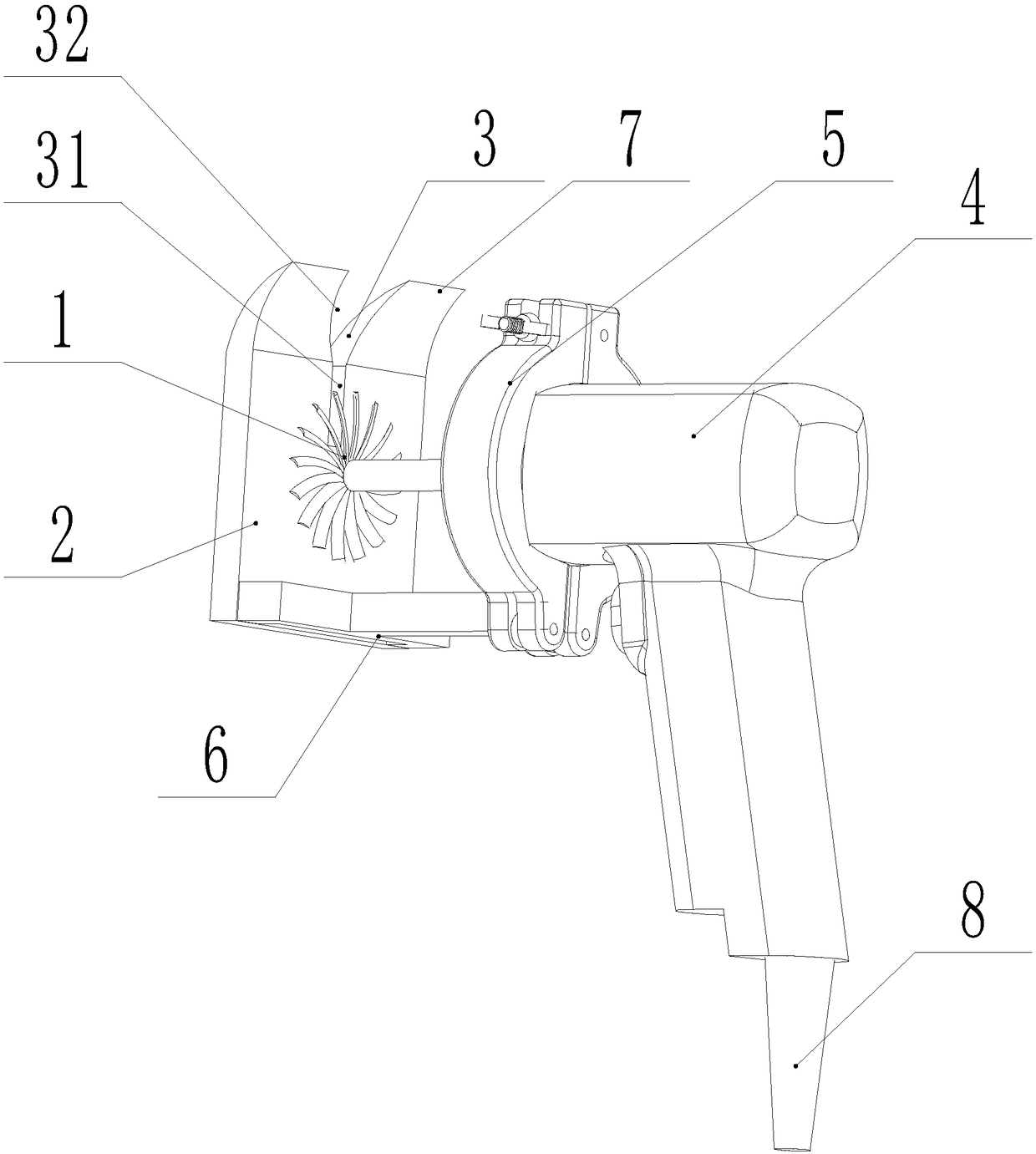

[0025] see figure 1 , the present invention provides a pneumatic sponge trimming machine, including a rotary blade 1 and a sheet 2, the bottom gap of the rotary blade 1 is provided with a sheet 2, and the sheet 2 is provided with an accommodation chamber 3 for accommodating the sponge burrs.

[0026] As a further improvement of the present invention, the sheet 2 is made of metal.

[0027] As a further improvement of the present invention, a driving device 4 for driving the rotary blade 1 to rotate is also included.

[0028] As a further improvement of the present invention, the driving device 4 is an engraving machine or a hand-held motor.

[0029] As a further improvement of the present invention, the air inlet nozzle 8 of the engraving machine is connected to the air compressor through a pipeline, the rotating blade 1 is sleeved on the cutter shaft, and the knife shaft is clamped in the chuck of the engraving machine. The pneumatic sponge burr trimming machine of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com