Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

400results about How to "Solve loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

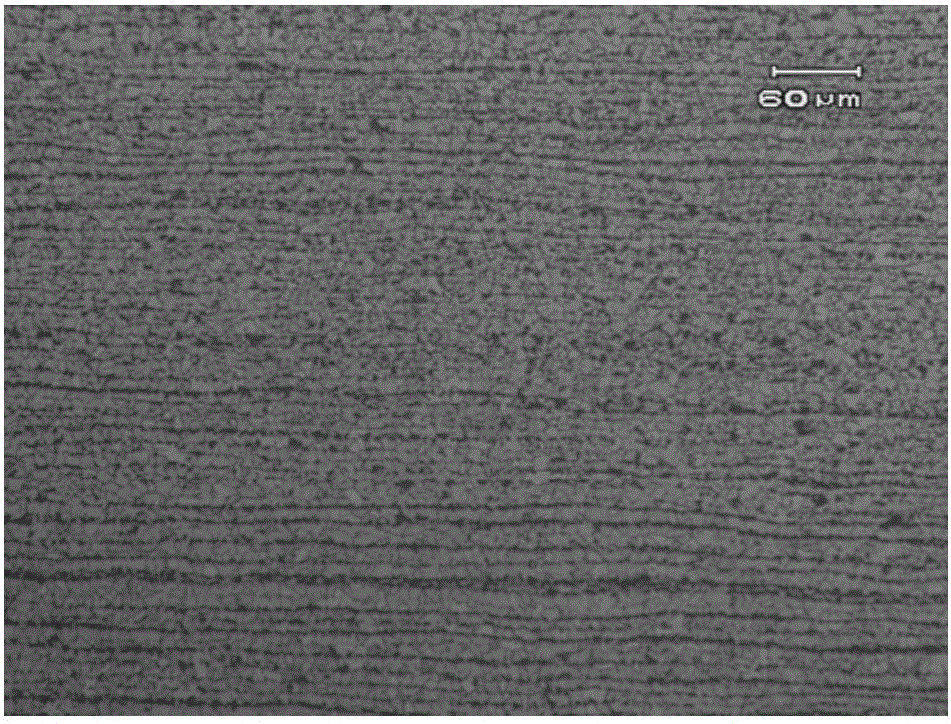

Koala velvet and production method thereof

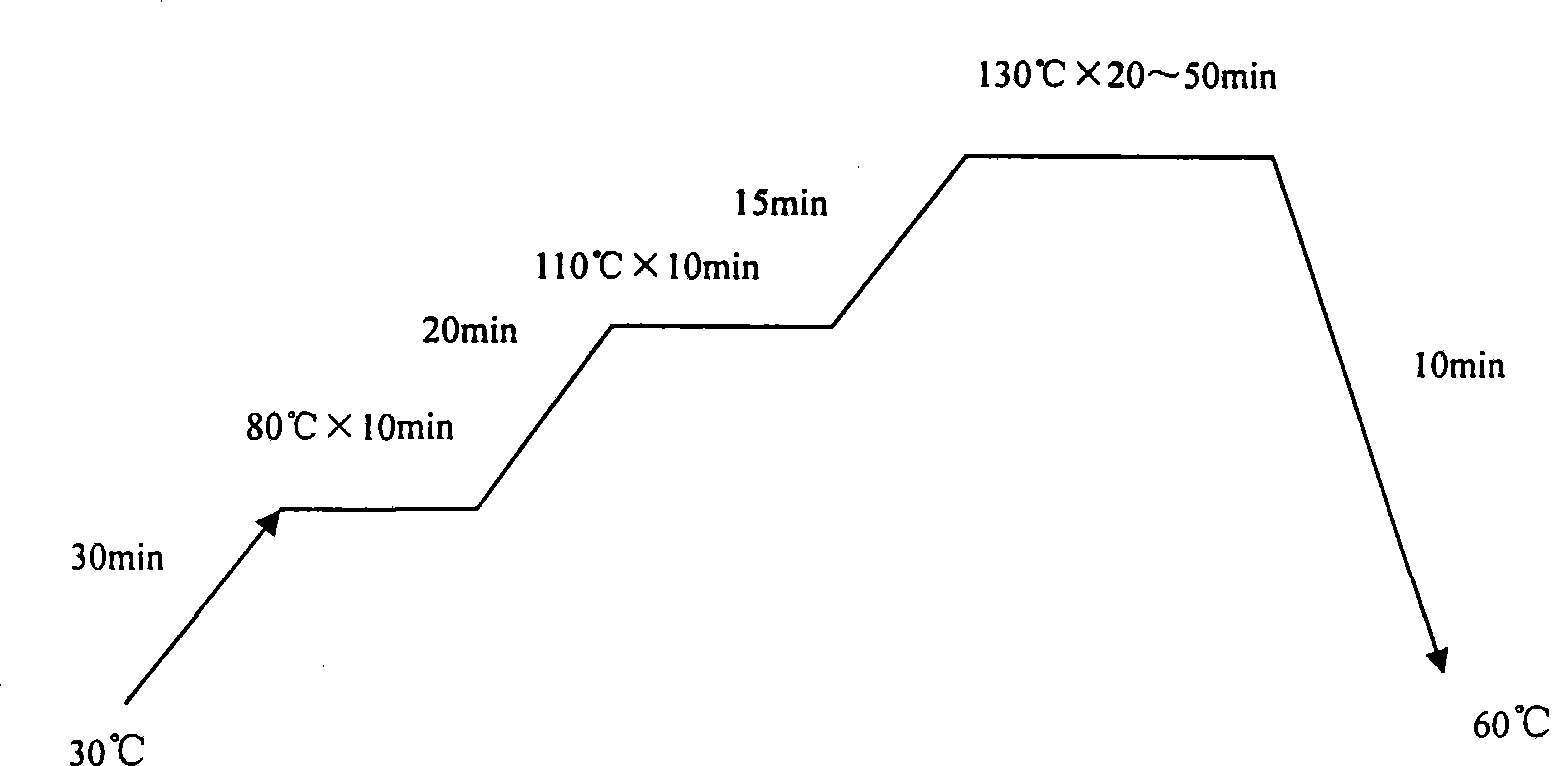

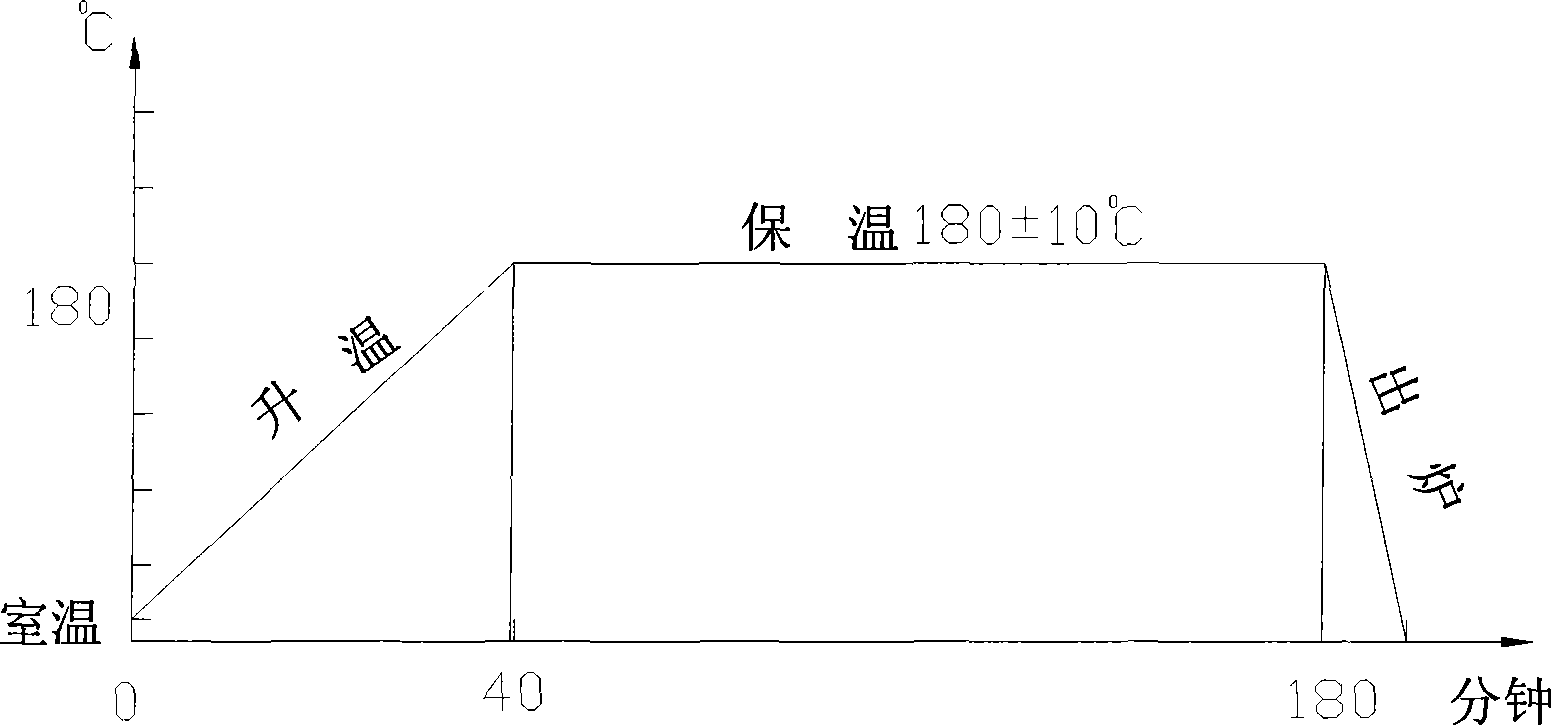

InactiveCN101440552ASolve looseSolve the feelWarp knittingHeating/cooling textile fabricsFiberMaterials preparation

The invention discloses koala flock and a method for manufacturing the same. The koala flock is manufactured by taking 56 to 83dtex Shaoguang flat cross section fibers or semi-Shaoguang flat cross section fibers as koala flock face fibers, and 56 to 76dtex terylene FDY as bottom fibers, whereinthe 56 to 83dtex Shaoguang flat cross section fiber or semi-Shaoguang flat cross section fiber is 30 to 85 portions, and the 56 to 76dtex terylene FDY is 15 to 50 portions. The method comprises production processes of material preparation, weaving, thermal shaping, dyeing, treatment after dyeing, dewatering, colored cloth shaping, front face gigging, finished cloth shaping, combing, scalding, clipping and the like, and the flat fibers are used to replace the conventional circular fiber, so that the simulated koala flock with unique style is produced. The height of the koala flock is between 0.5 and 7mm, and the koala flock touches soft and smooth, and can be widely used in the production of flock toys, indoor flock slippers, blankets, knitting flock and the like, and can fully meet market demands.

Owner:ZHANGJIAGANG JINGDONG KNITTING PLUSH

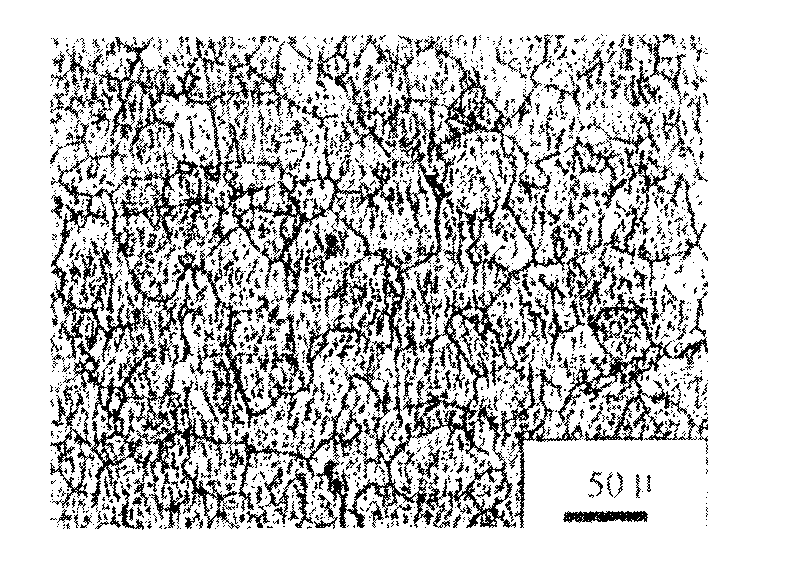

Method for forging superhigh-temperature soft core of steel ingot

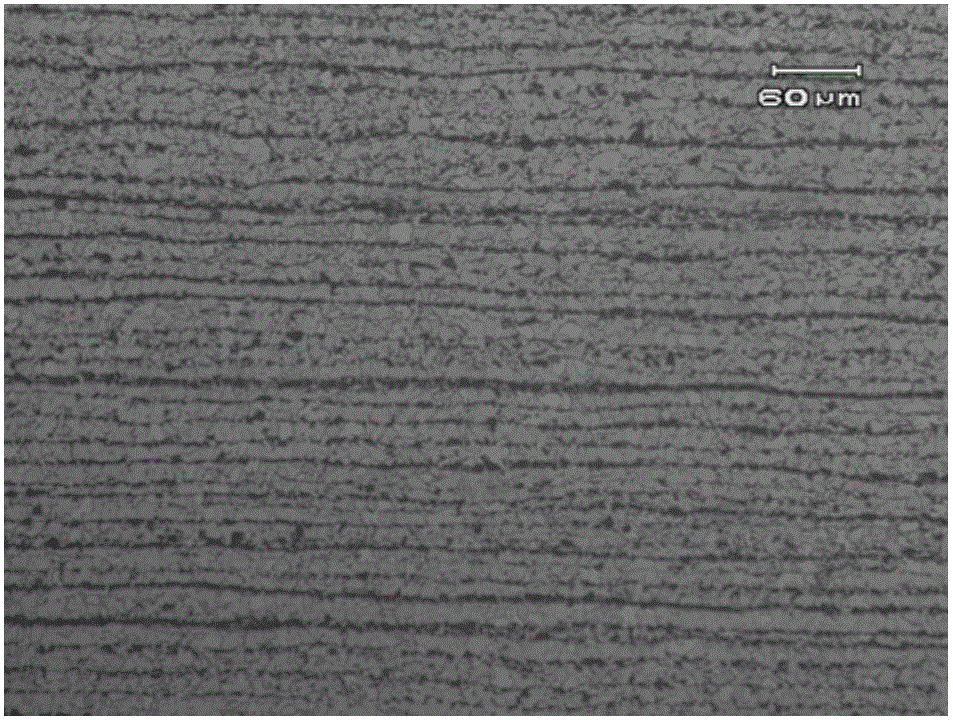

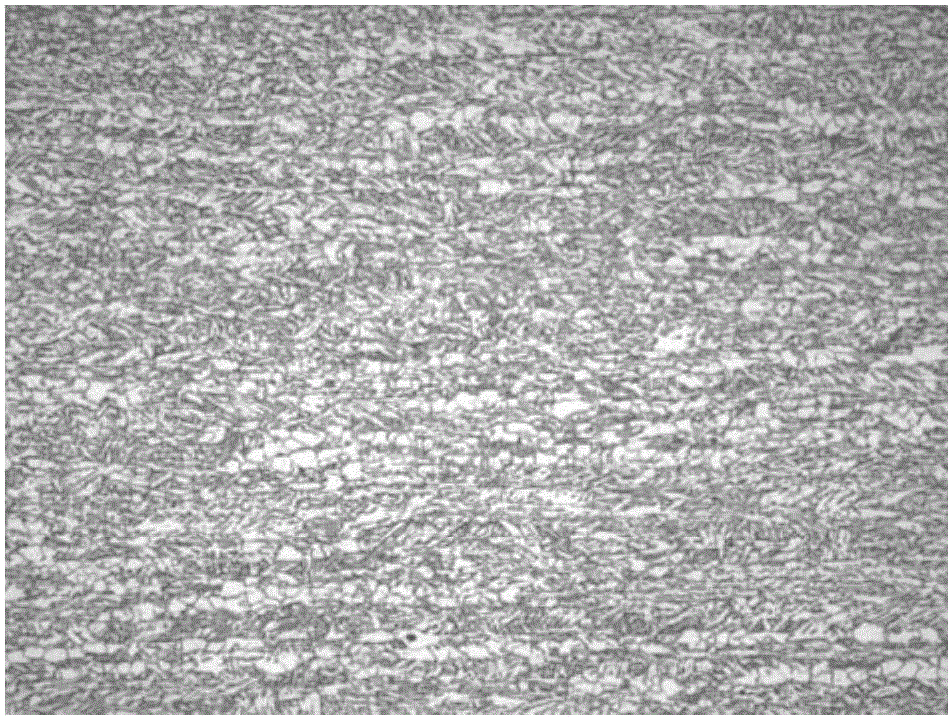

The invention relates to the field of steel forging, in particular to a method for forging a superhigh-temperature soft core of a die cast steel ingot. The method comprises the steps that first, the poured steel ingot with a liquid core is subjected to superhigh-temperature die stripping; second, the poured steel ingot with the liquid core is placed in a thermos van for temperature equilibrium and then is conveyed to a forging press, the steel ingot with the liquid core is subjected to high-temperature pressure maintaining forging, solidified tail end branch crystals are fully broken, a large quantity of equiaxed crystal structures are formed, shrinkage cavities and porosity are eliminated, and dendritic segregation is lightened; and at last, general forging is conducted, and crystalline grains and structures are fully refined. The method breaks through the conventional method that the die cast steel ingot is forged after being completely solidified; a semi-solid structure with excellent liquidity on the core part of the steel ingot and the huge temperature difference between the surface and the core part are created through superhigh-temperature die stripping of the steel ingot with the liquid core; combined with a subsequent heavy pressure and pressure maintaining method, forced feeding and pressure solidification can be achieved; the problems of shrinkage cavities, porosity, segregation and the like of the center of the steel ingot are solved, and the metallurgical quality is improved; the riser weight is lowered, the heating number of forging is decreased, and the service life of a die is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Micro-alloying compound cored wire for high-strength steel

The invention relates to a micro-alloying compound cored wire for high-strength steel, comprising a carbon steel sheath and a powdery core, wherein the core is prepared from the following chemical components by weight percent: 23 to 28 wt% of Ca, 51 to 55 wt% of Si, 0.65 to 1.5 wt% of Mg, 1.3 to 2.5 wt% of Ba, 0.6 to 1.0 wt% of Re, 0.6 to 1.2 wt% of B, 1.6 to 3.5 wt% of Zr, 1.3 to 2.8 wt% of Ti, 0.6 to 1.2 wt% of Nb, and balance of ferrum and inevitable impurities. The invention reduces the content of C in high-strength steel through reasonably designing the chemical components and simultaneously and greatly enhances the grain sizes in continuous casting billets so that the grains are refined. The mechanical properties of the steel can be obviously improved, and the transverse impact properties of the steel are obviously enhanced to approximate to longitudinal impact value. Besides, the invention well solves the problems of center segregation and center porosity of the continuous casting billets, nonuniform impurity distribution, and the like.

Owner:HUBEI KMK WELDING MATERIALS

Fresh bone powder-contained tabletting candy and manufacturing method thereof

InactiveCN105076626ACompletely retain nutrientsDoes not involve high temperatureConfectionerySweetmeatsAntioxidantMagnesium stearate

The invention discloses a fresh bone powder-contained tableting candy and a manufacturing method thereof, and aims at providing the fresh bone tankage-contained dextrose candy which is rich in nutrition and unique in taste. The technical point is that the tableting candy comprises the following components in parts by weight: 1 to 50 parts of bone tankage, 1 to 40 parts of sweetening agent, 1 to 30 parts of milk powder, 1 to 20 parts of resistant dextrin, 1 to 20 parts of maltodextrin, 1 to 20 parts of vegetable fat powder, 0.01 to 10 parts of antioxidant, 0.01 to 24.4 parts of phytosterol and 0.01 to 2 parts of magnesium stearate. The fresh bone powder-contained dextrose candy and the manufacturing method thereof belong to the technical field of food manufacturing.

Owner:广东骨全能生物食品科技有限公司

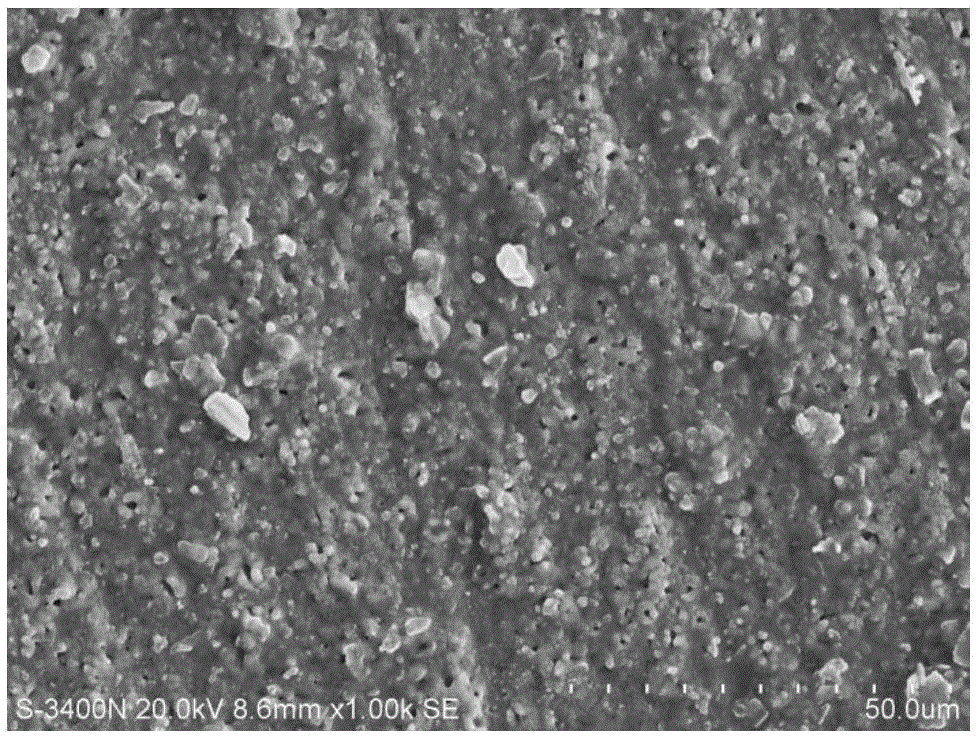

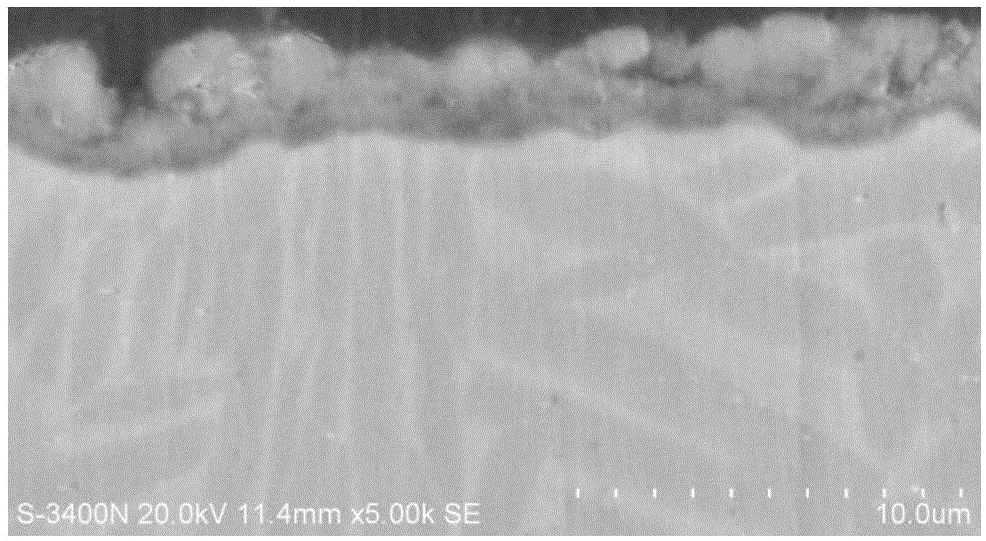

Method for preparing nano SiO2 containing coating on surface of cast aluminium alloy through micro-arc oxidation

InactiveCN105154951ASimple processEasy to operateAnodisationEthylenediaminePlasma electrolytic oxidation

The invention discloses a method for preparing nano SiO2 containing coating on the surface of cast aluminium alloy through micro-arc oxidation. The method comprises the following steps: after pretreatment, a test sample is subjected to the micro-arc oxidation treatment in SiO2 nano-particle containing electrolyte, 1-10 g / L nano SiO2 particles are added, the pH is 10-13, and then water scrubbing is adopted to remove residual electrolyte on the surface of the test sample, wherein the electrolyte is composed of one or more of the followings: 5-16 g / L sodium silicate, 6-14 g / L sodium metaaluminate, 1-5 g / L sodium hydroxide, 1-5 g / L EDTA, 1-5 g / L sodium tungstate, 1-4 g / L sodium fluoride, 1-5 g / L sodium carbonate, and 1-2 g / L sodium pyrophosphate. With adoption of the method, the composition and structure of the cast aluminium alloy micro-arc oxidation coating can be changed, microcracks of a micro-arc oxidation film can be reduced, and the density, abrasive resistance and corrosion resistance of the coating can be improved; in addition, the treatment working procedures are few, the treatment process and aftertreatment are environment-friendly, and the problems that the cast aluminium alloy micro-arc oxidation coating is likely to become loose and have hard spots and is poor in film surface smoothness and is nonuniform in color and luster are solved.

Owner:GUANGXI UNIV +1

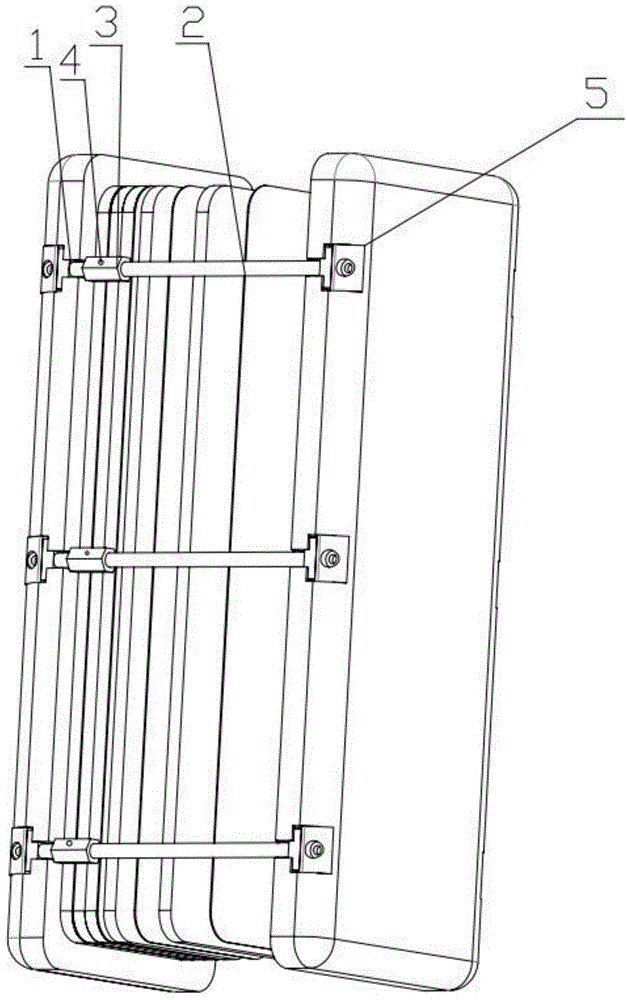

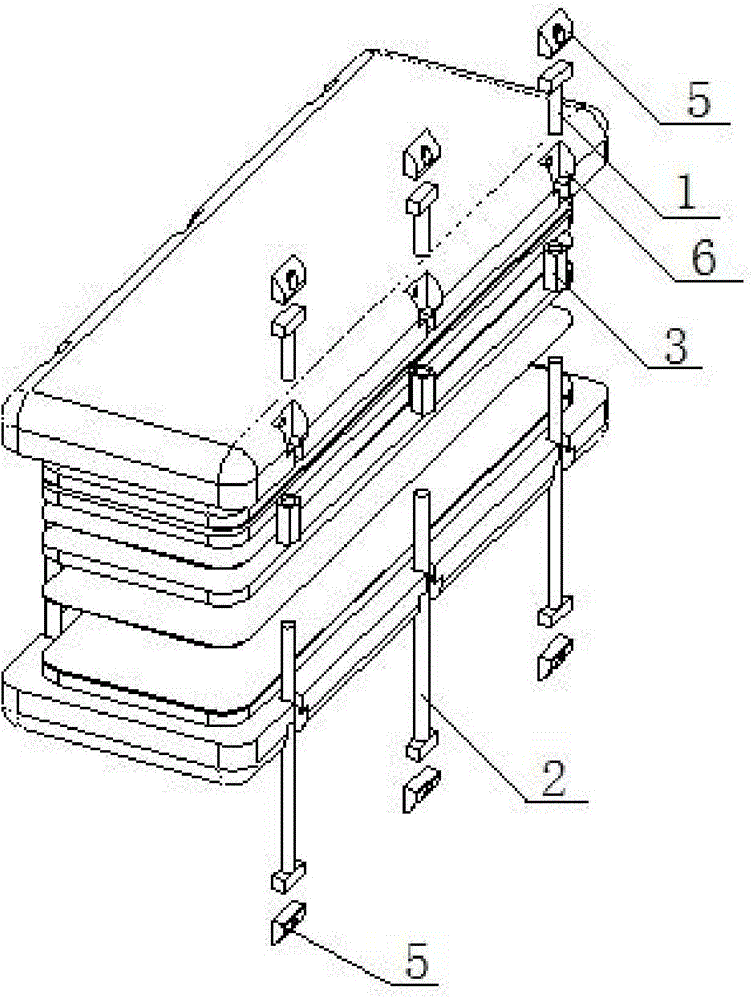

Fuel cell stack fixed structure convenient for adjustment

ActiveCN104538663ASolve looseGuaranteed uptimeFuel cells groupingFuel cell detailsStructural engineeringMechanical engineering

The invention discloses a fuel cell stack fixed structure convenient for adjustment. The structure includes end plates arranged at two ends in the stacking direction of the fuel cell stack. The end plates at two ends are in fixed connection through several sets of T-shaped threaded rods 1, T-shaped threaded rods 2, connecting nuts, stop screws and limiting blocks. One ends of the T-shaped threaded rods 1 are fixed on the end plate at one end through the limiting blocks, the other ends of the T-shaped threaded rods 1 are connected to one ends of the T-shaped threaded rods 2 through the connecting nuts, the other ends of the T-shaped threaded rods 2 are fixed on the end plate at the other end through the limiting blocks, and the connecting nuts are fastened through the stop screws. By disposing adjustable connection structures at side edges of the end plates, the distance between the end plates can be controlled precisely to realize fastening of the fuel cell stack formed by different amounts of cells, the adjustment process is simple, and loosening, fastening force decline and other problems can be avoided. By adjusting the connecting nuts, the fastening force can be restored, and normal operation of the fuel cell stack can be ensured.

Owner:江苏氢电新能源有限公司

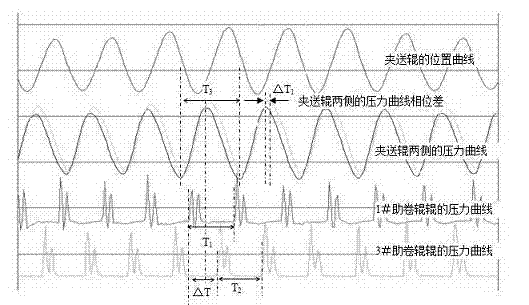

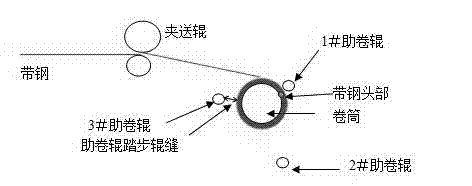

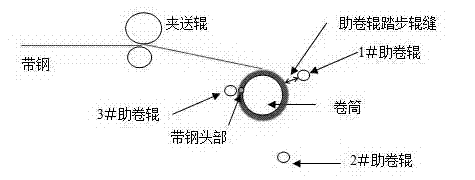

High-strength, low-temperature, and thick-gauge hot-rolled plate strip coil shape control method

The present invention relates to a high-strength, low-temperature and thick-gauge hot-rolled plate strip coil shape control method, which is characterized in that the control method comprises that: 1) before a strip steel reaches a coiler, a clamping and conveying roller and auxiliary coiling rollers are in roller gap control manners; 2) after the clamping and conveying roller bites the strip steel, the roller gap control manner of the clamping and conveying roller is switched into a pressure control manner; 3) during coiling of the previous several circles of the strip steel by a coiling cylinder, the auxiliary coiling rollers 1#, 2# and 3# are in the pressure control manners or roller gap control manners; 4) after coiling of the previous several circles of the strip steel by the coiling cylinder, the number of the circles is set as the X0 and is manually set, the auxiliary coiling roller 2# is completely opened so as to make a coil unloading trolley lift and be ready for unloading, and the auxiliary coiling rollers 1# and 3# enter a stepping control manner and the roller gap control and pressure control alternate control manner, wherein the phenomenon that the auxiliary roller always presses on the strip steel so as to cause the strip steel surface scratch can be avoided; and 5) the clamping and conveying roller both-side pressure control PID adjuster control parameters P value and I value are adjusted.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

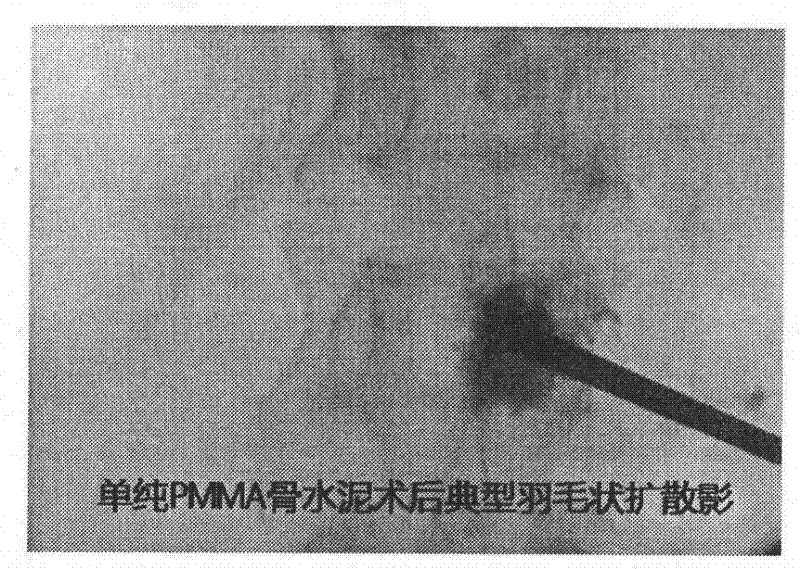

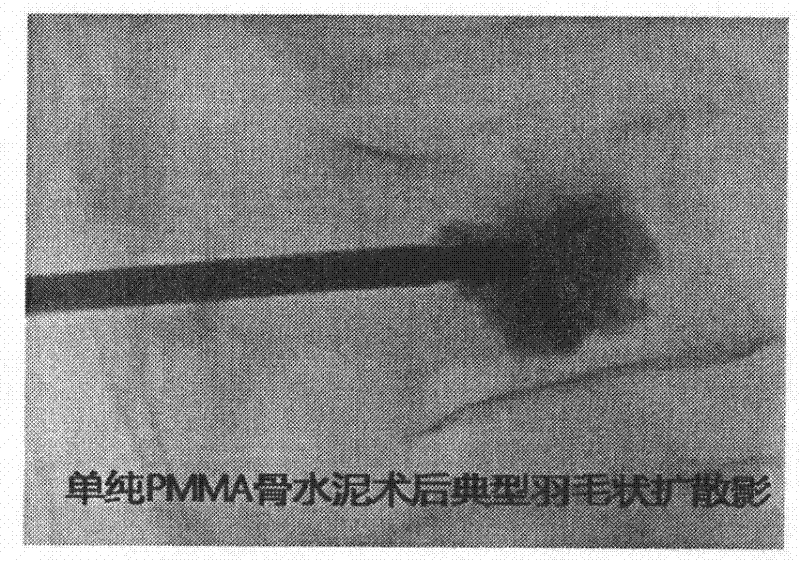

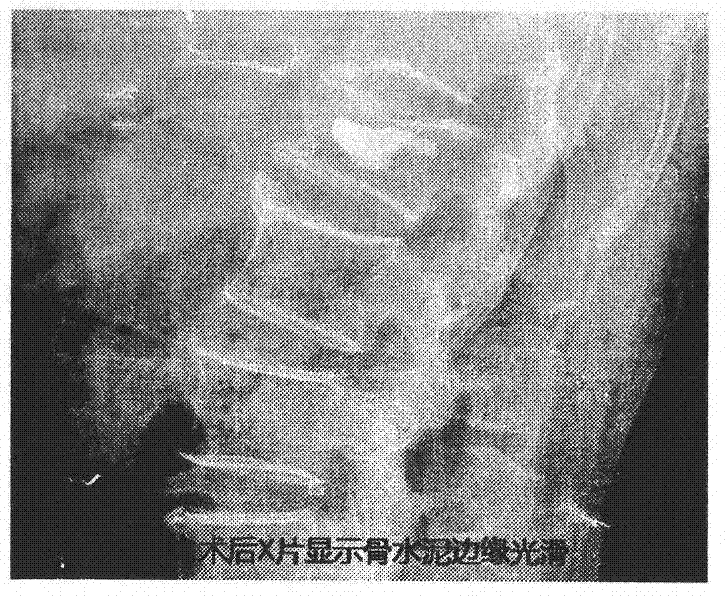

Novel mixed bone cement

InactiveCN102688522AReduce in quantitySolve looseImpression capsDentistry preparationsBone cementCancellous bone

The invention provides novel mixed bone cement. The novel mixed bone cement provided by the invention provides a strong support for the bone at the initial stage, and gradually the rigidity of PMMA bone cement is decreased with the ingrowth of cancellous bone at the later stage, so that the implant has elastic modulus similar tothe cancellous bone, and has both mechanical and biological fixation, thus long-term complications of PMMA bone cement can be reduced. The characteristics of high viscosity and low liquidity of the mixed bone cement are very important in percutaneousvertebroplasty and percutaneous kyphoplasty (PVP and PKP), and the occurrence of bone cement leakage can be reduced.

Owner:SHANGHAI RUIPING BIOTECH TECH

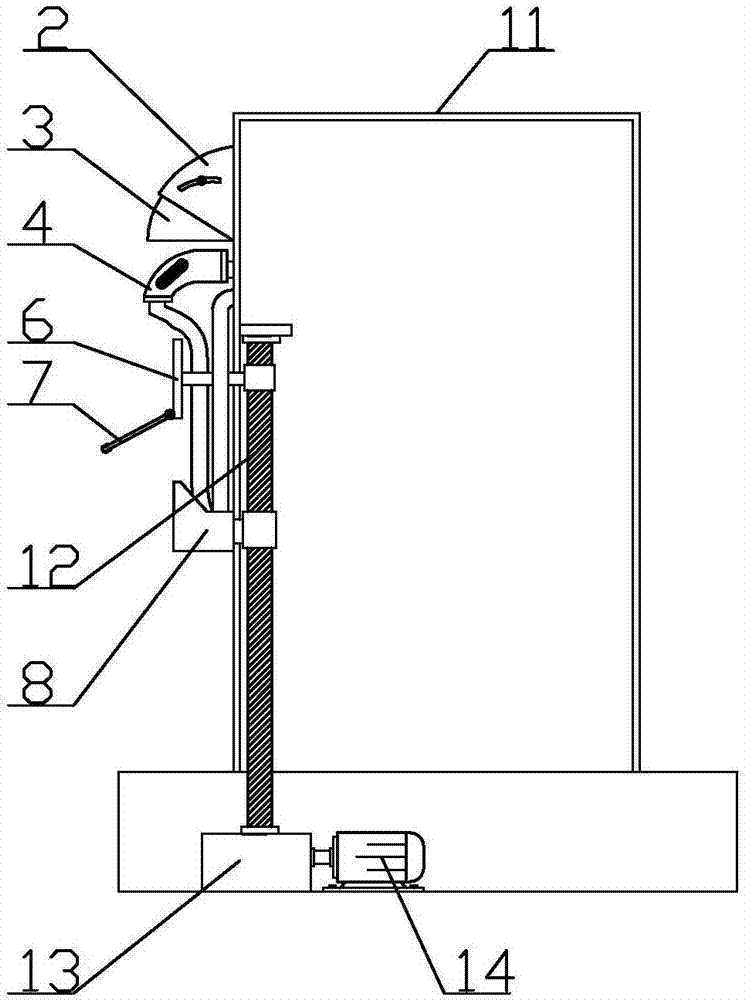

Centrifugal pump used for producing heparin sodium and chemical equipment

InactiveCN108843625ATo achieve the effect of not looseningSolve loosePump componentsPumpsCompound (substance)Engineering

The invention discloses a centrifugal pump used for producing heparin sodium and chemical equipment. The centrifugal pump comprises a base and a pump body, the pump body is located over the base, theupper surface of the base is provided with a square groove, a groove and a guide groove which are sequentially arranged from left to right, the groove communicates with the guide groove, an installingblock is movably connected to the interior of the square groove, the upper surface of the installing block is fixedly connected with the lower surface of the pump body through a connecting block, theleft side and the right side of the installing block are provided with an insertion slot and an insertion hole, a sliding groove is formed in the position, corresponding to the insertion slot, of theleft side of the inner wall of the square groove, the interior of the sliding groove is movably connected with an insertion block and a reset spring, and a movable rod is fixedly connected to the left side of the insertion block. The centrifugal pump is provided with the insertion block, the reset spring, a bolt, a tension spring and a clamping block, and the problems that when most chemical centrifugal pumps are installed, fixed bolts are used for installing the centrifugal pumps, and looseness of the centrifugal pumps is easily caused are solved.

Owner:NANJING JINGYUN CHEM

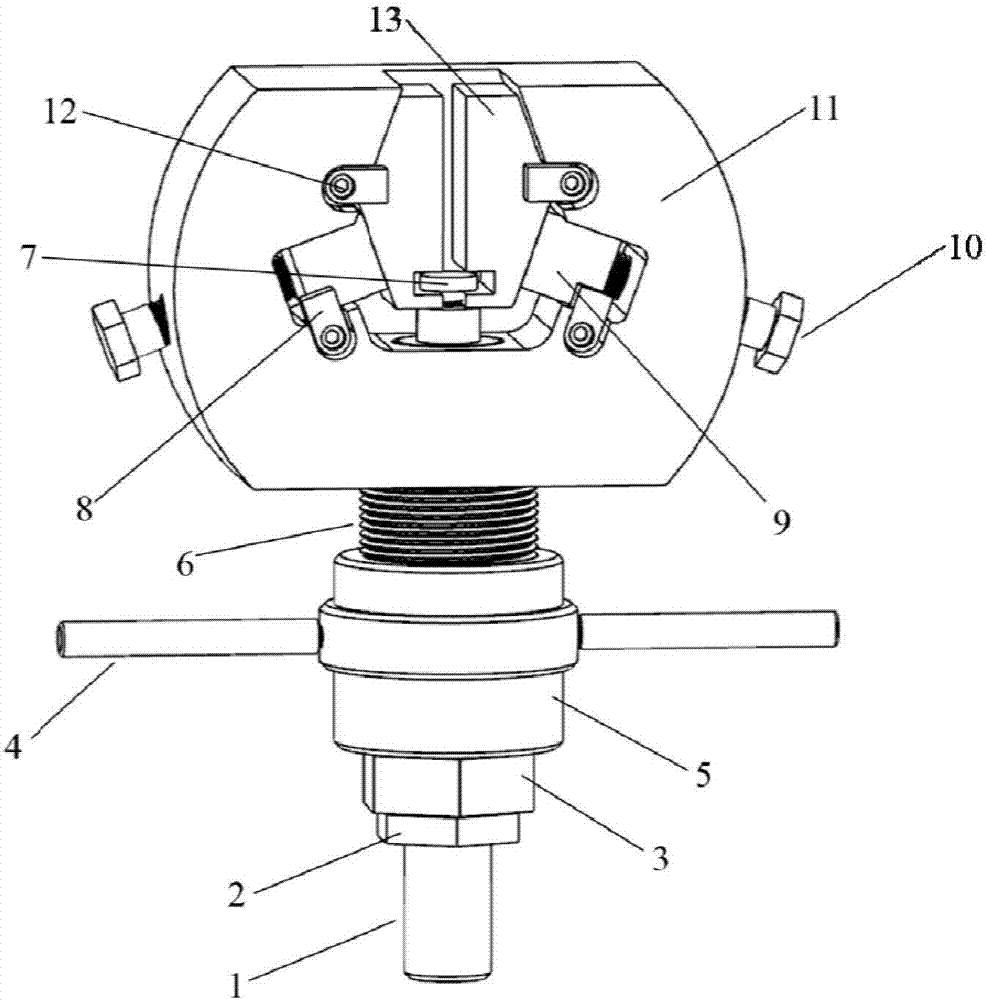

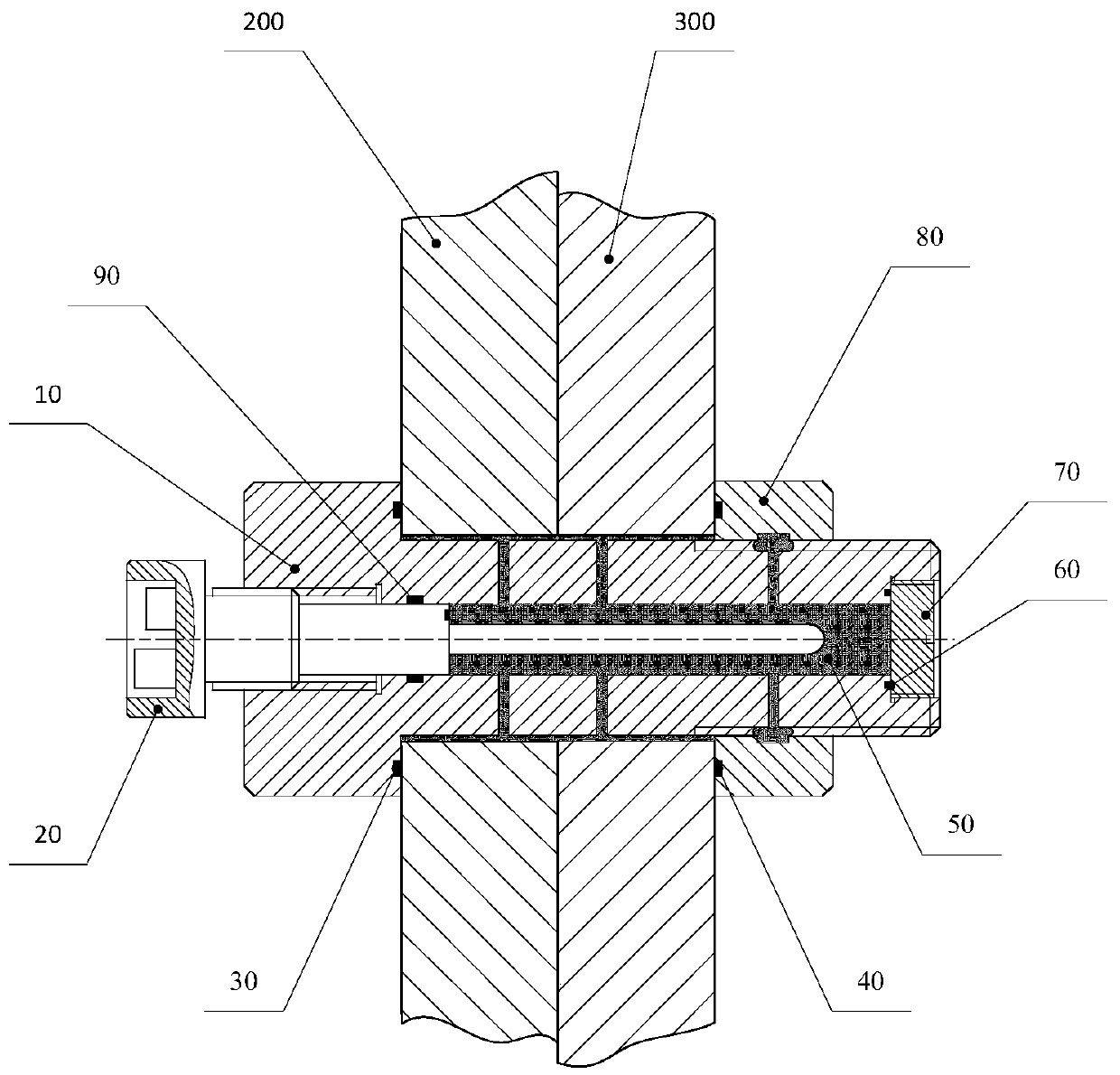

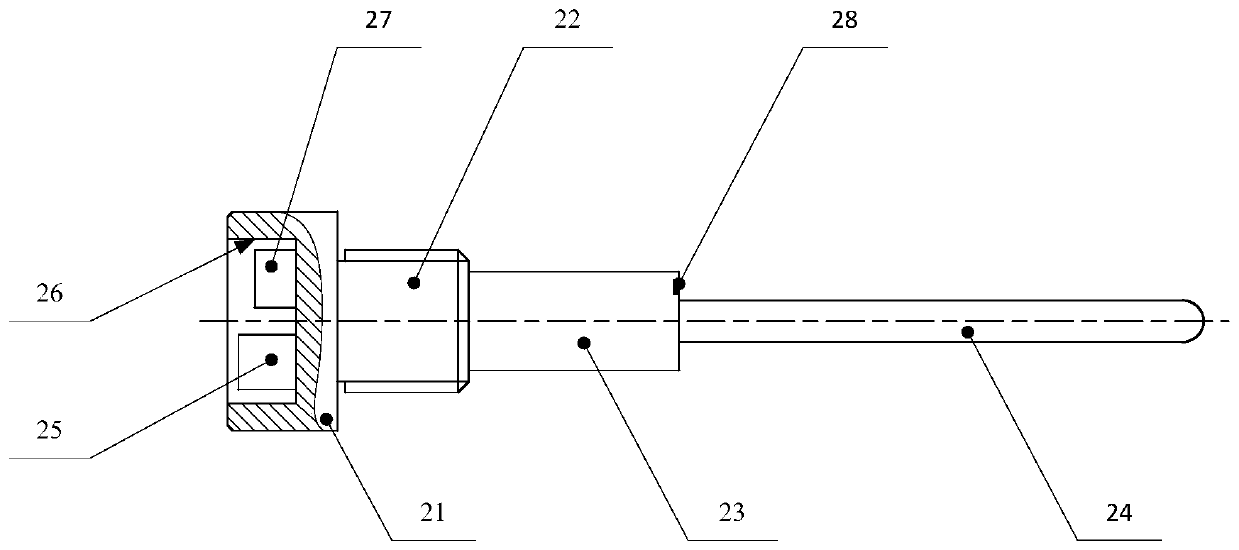

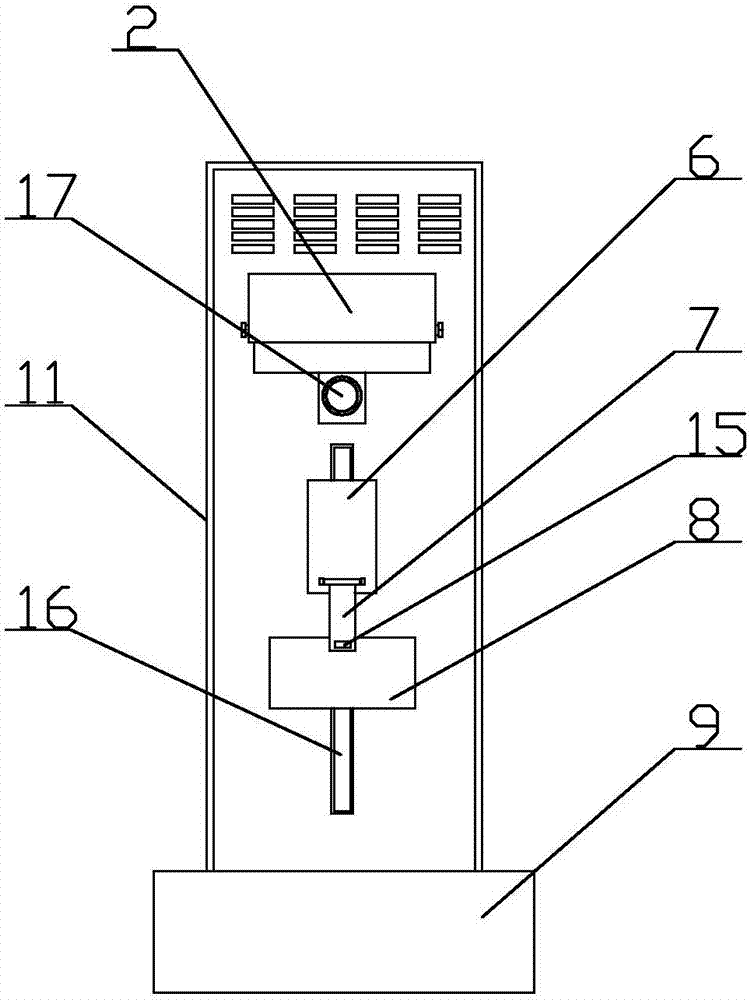

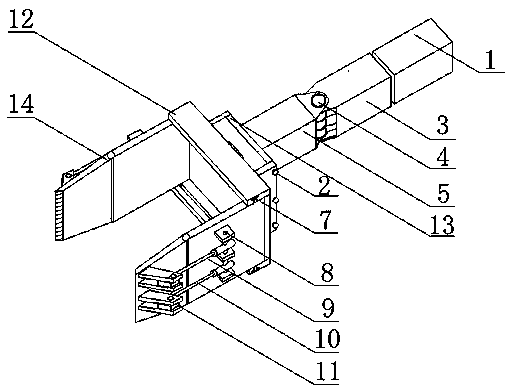

Flat specimen high-temperature tension-compression fatigue test clamp and method

ActiveCN106885729AAchieve clampingStable clampingMaterial strength using repeated/pulsating forcesTension compressionBody contact

The invention discloses a flat specimen high-temperature tension-compression fatigue test clamp and method. The clamp and method implement clamping on the flat specimen in a high-temperature test, so that the flat specimen can be subjected to the tension-compression test under high-temperature conditions. A fatigue machine hydraulic clamping head clamps an optical rod end of a central shaft and is connected with a connecting rod through a sleeve, and the central shaft is provided with a fixing nut which is used for restricting the downward displacement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is connected with a wedge clamp body through threads; the central shaft penetrates through a through hole in the middle of the connecting rod, and the shaft end is connected with a guide table; the guide table is positioned in a groove between two wedge clamping bodies, and used for guiding the wedge clamping blocks to move up and down; the specimen is clamped by the wedge clamping blocks in the wedge clamp body, the bottoms of the wedge clamping blocks are abutted by the top end of the guide table, and both ends contact the wedge surface inside the wedge clamp body so as to restrict the upward displacement of the clamping blocks; and the top ends of locking threads extending from threaded holes on both sides of the wedge clamp body contact the square clamping blocks, so that the square clamping blocks abut against both sides of the clamp blocks, thereby restricting the downward displacement of the wedge clamping blocks.

Owner:BEIHANG UNIV

Processing method of sand core in engine aluminum alloy cylinder metal mould low-pressure casting

ActiveCN101497109AReduce moisture contentLack of angerFoundry mouldsFoundry coresPressure castingMetal mold

The invention relates to a casting technique, in particular to a method for processing a metal mold low-pressure casting medium sand core for an aluminum alloy cylinder of an engine, wherein a method for coating a coating layer, removing water content and drilling vent holes is adopted to process the sand core so as to achieve the aim of preventing phenomena of sand inclusion, air holes, looseness, cracks, and the like.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

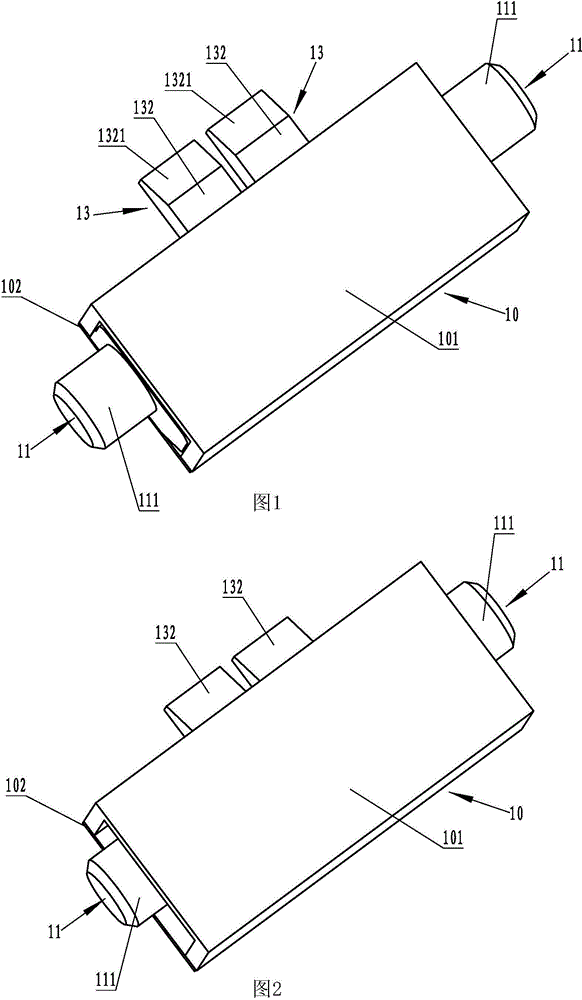

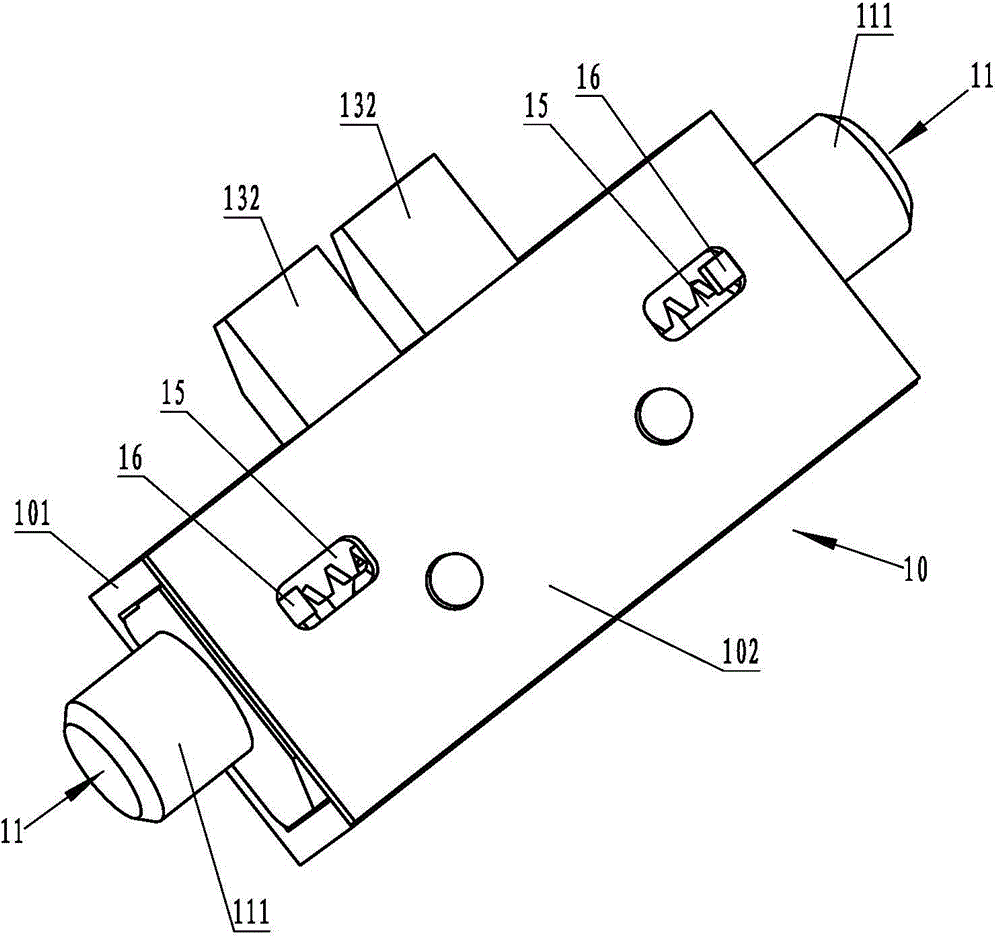

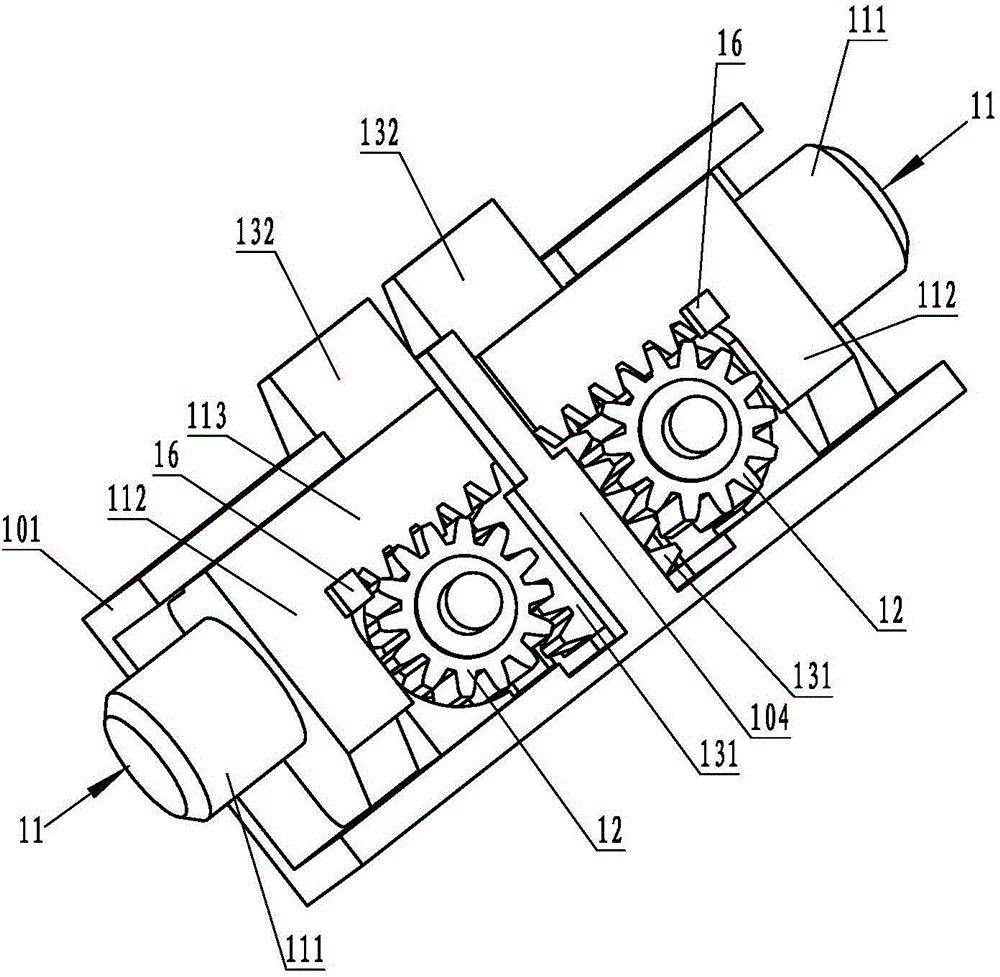

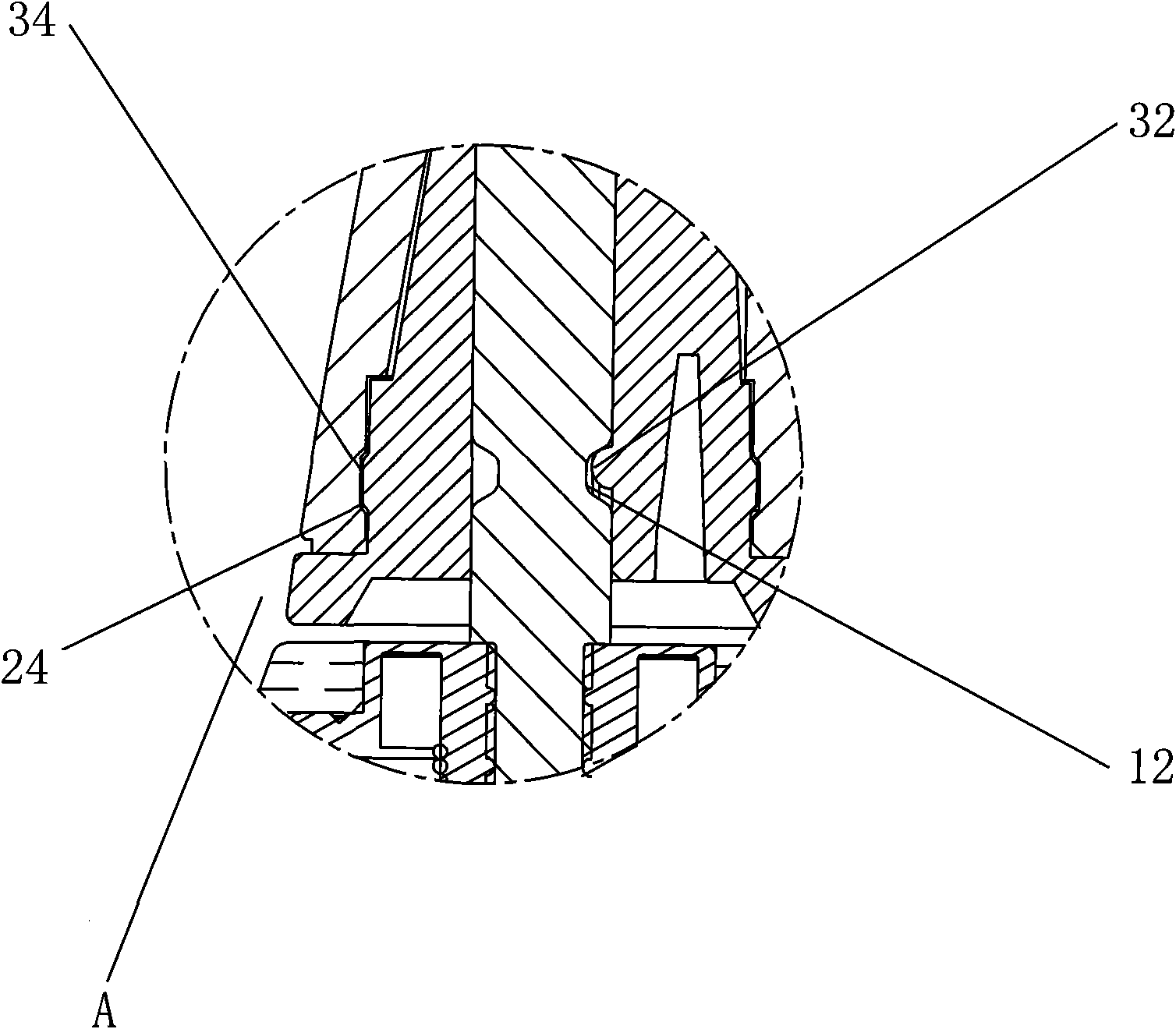

Double-buckle device and wearing product structure

ActiveCN104534235APlay a locking roleUnlocking does not causeStands/trestlesKey pressingClosed cavity

The invention belongs to the technical field of buckles and particularly relates to a double-buckle device and a wearing product structure. The double-buckle device comprises a shell, wherein a first buckle structure and a second buckle structure are arranged in a non-closed cavity defined by the shell, and the first buckle structure and the second buckle structure each comprise a gear rotationally connected with the shell, a key, a buckle and an elastic reset piece arranged in the pressing direction of the key and used for resetting the key. A limiting device used for limiting the stroke of each key is arranged between each key and the shell. Each key comprises a pressing part stretching out of the outer side of the shell, a sliding part which is fixedly connected with the pressing part and can slide along the shell, and a key transmission part which is fixedly connected with the sliding part and used for being meshed with the corresponding gear. Each buckle comprises a buckle transmission part and a buckling part, wherein the buckle transmission part is arranged on the side portion of the corresponding gear and used for being meshed with the corresponding gear, and the buckling part is fixedly connected with the buckle transmission part, stretches out of the shell and is used for buckling and fixing. The problem that the buckle structure is loosened due to error triggering in the prior art is solved.

Owner:QINGDAO GOERTEK

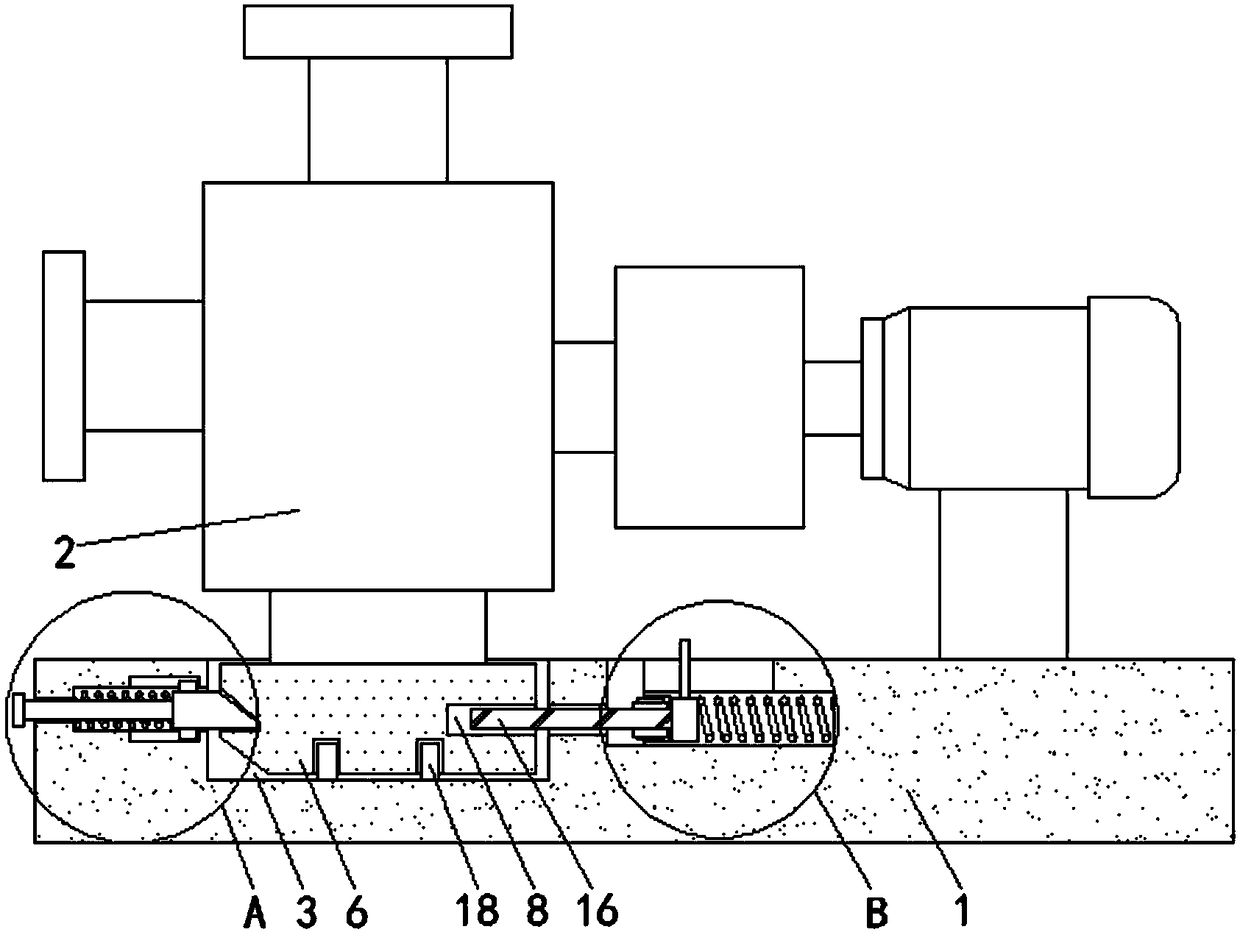

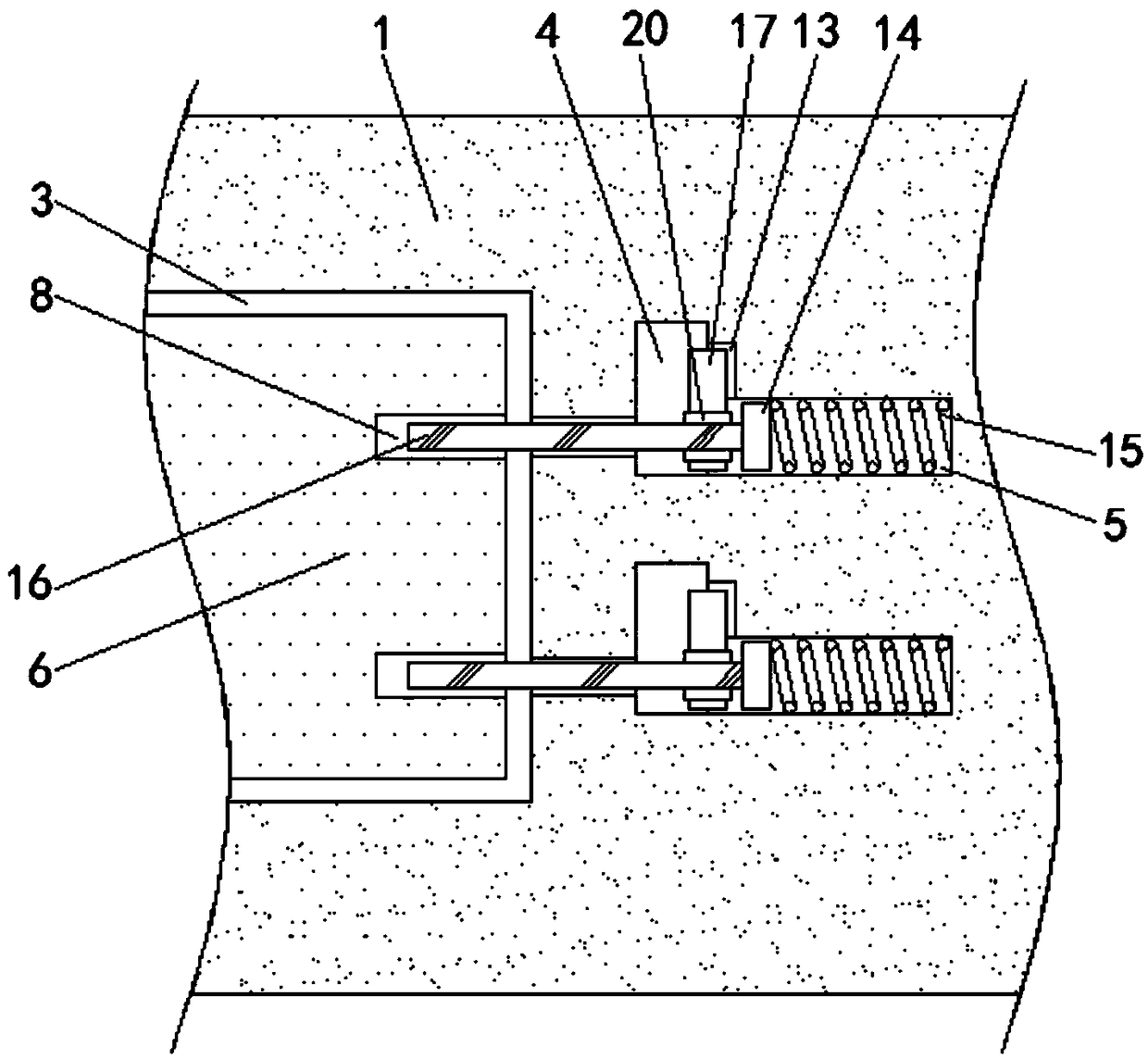

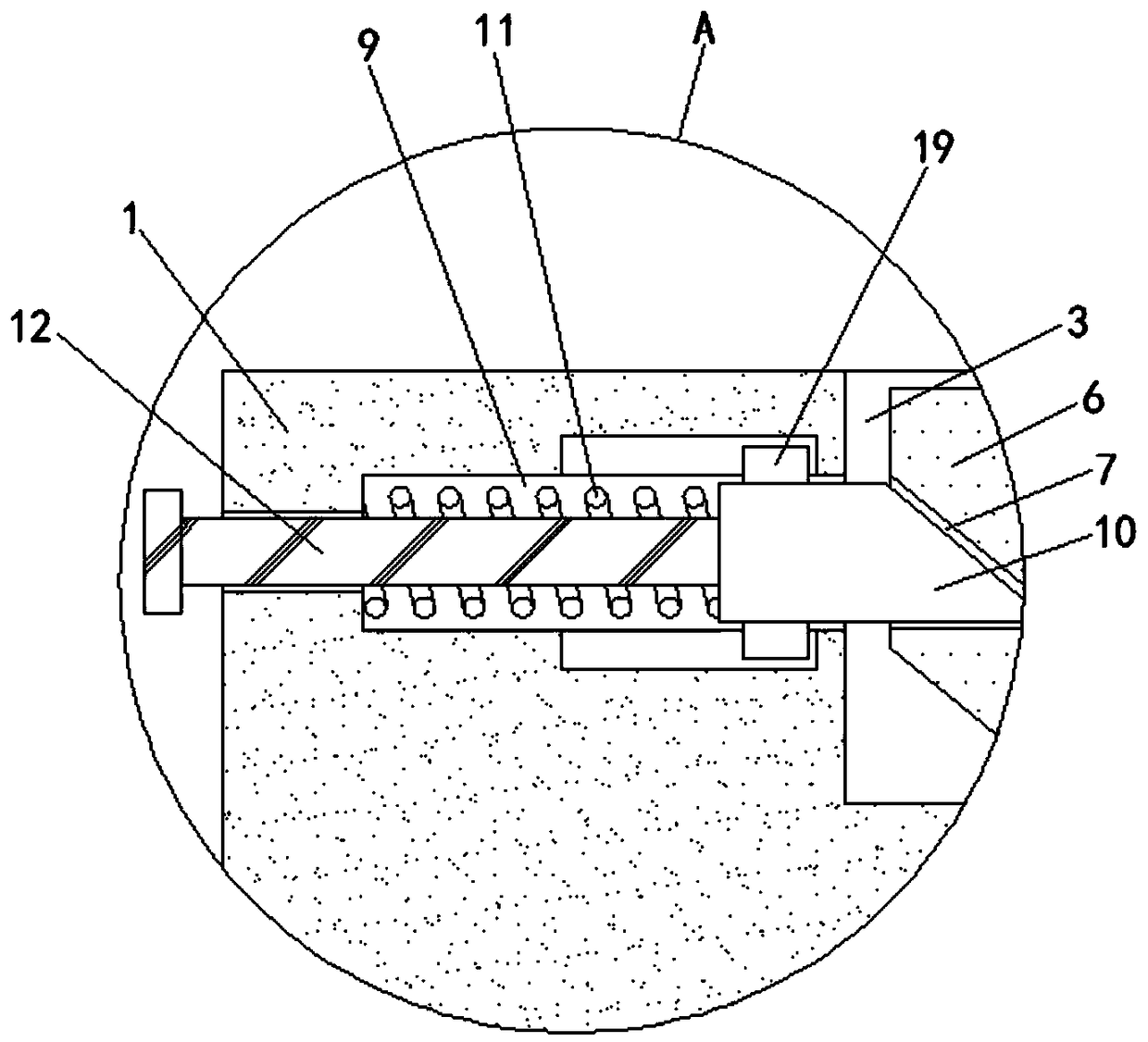

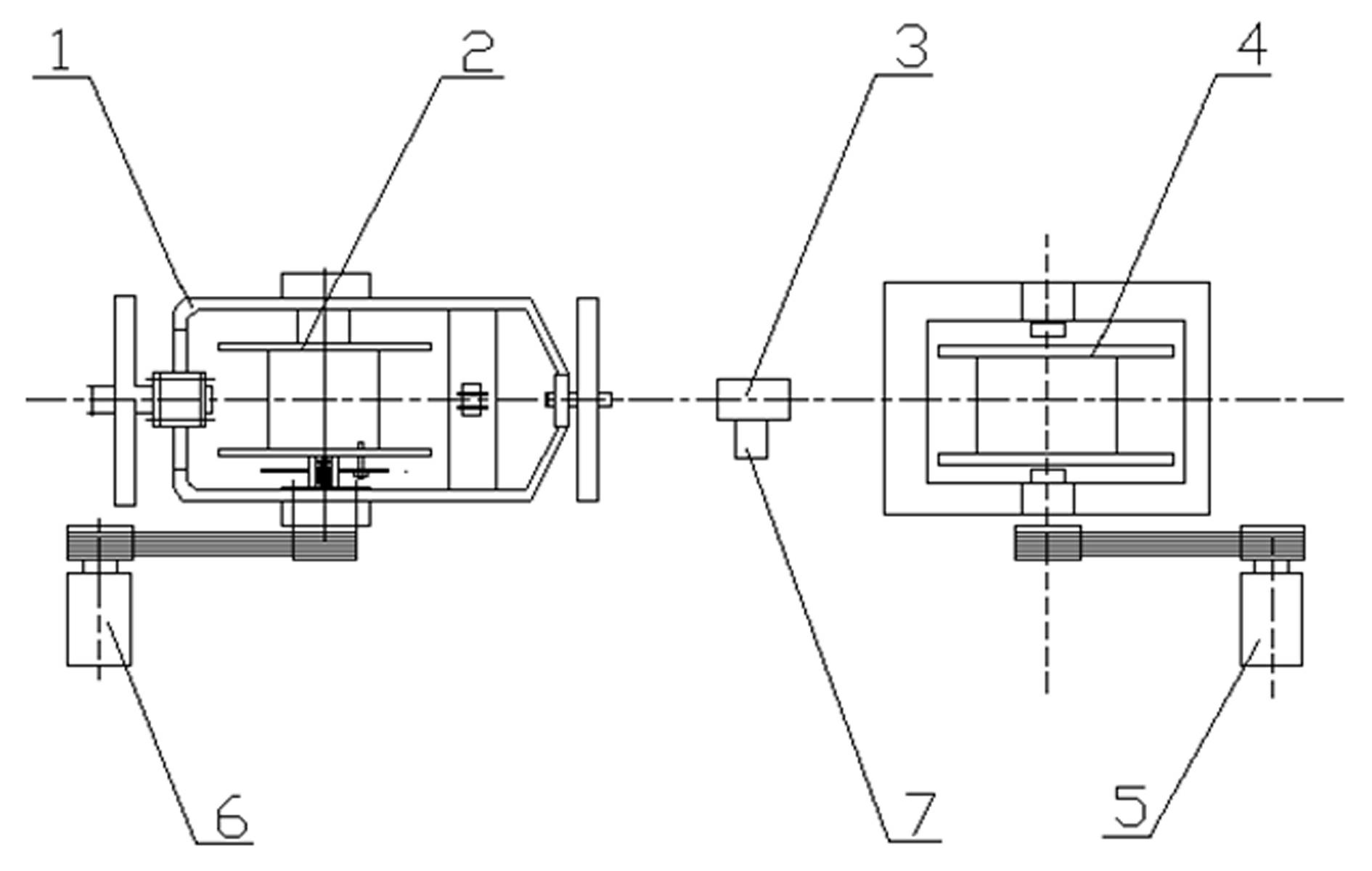

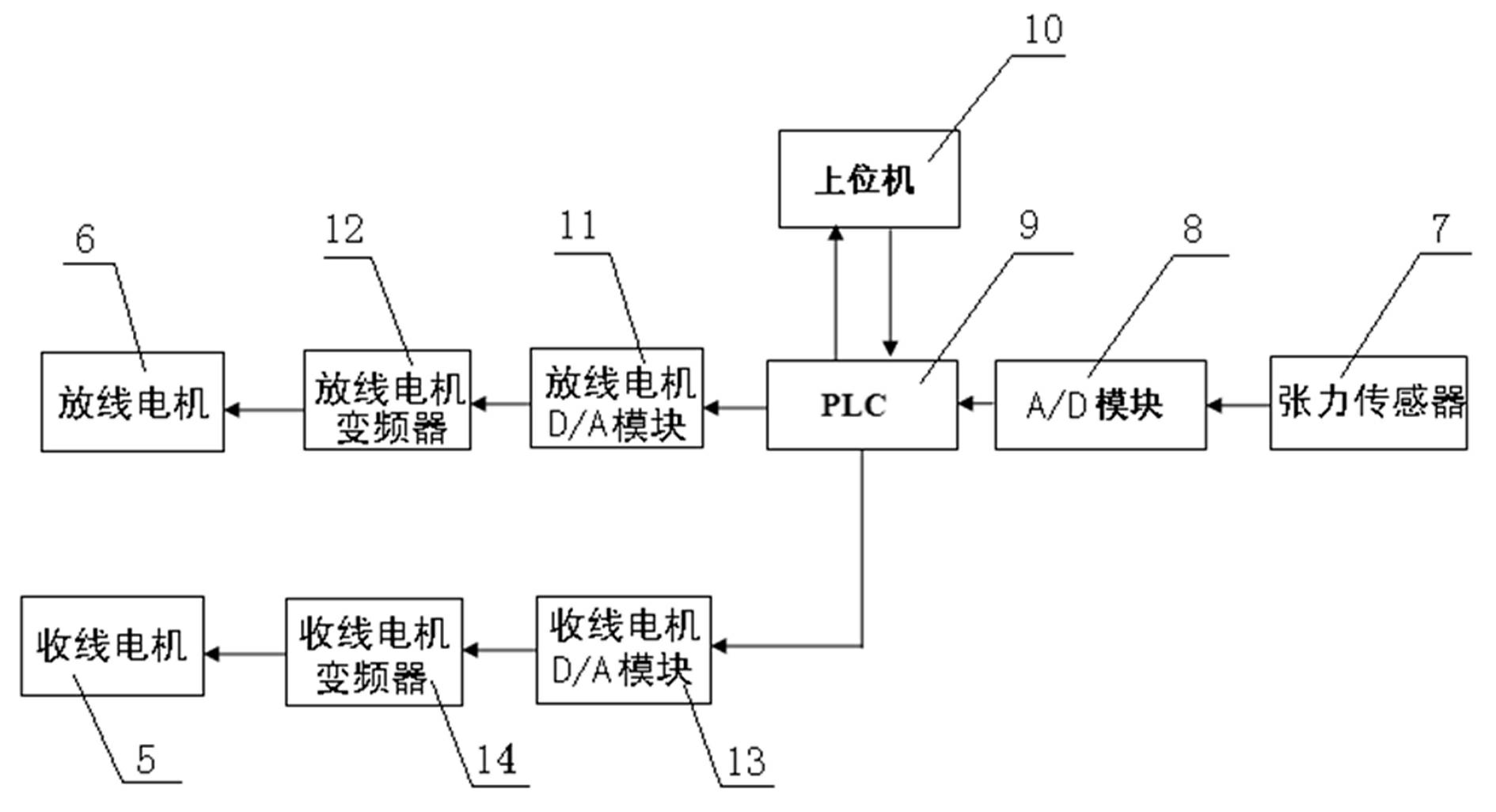

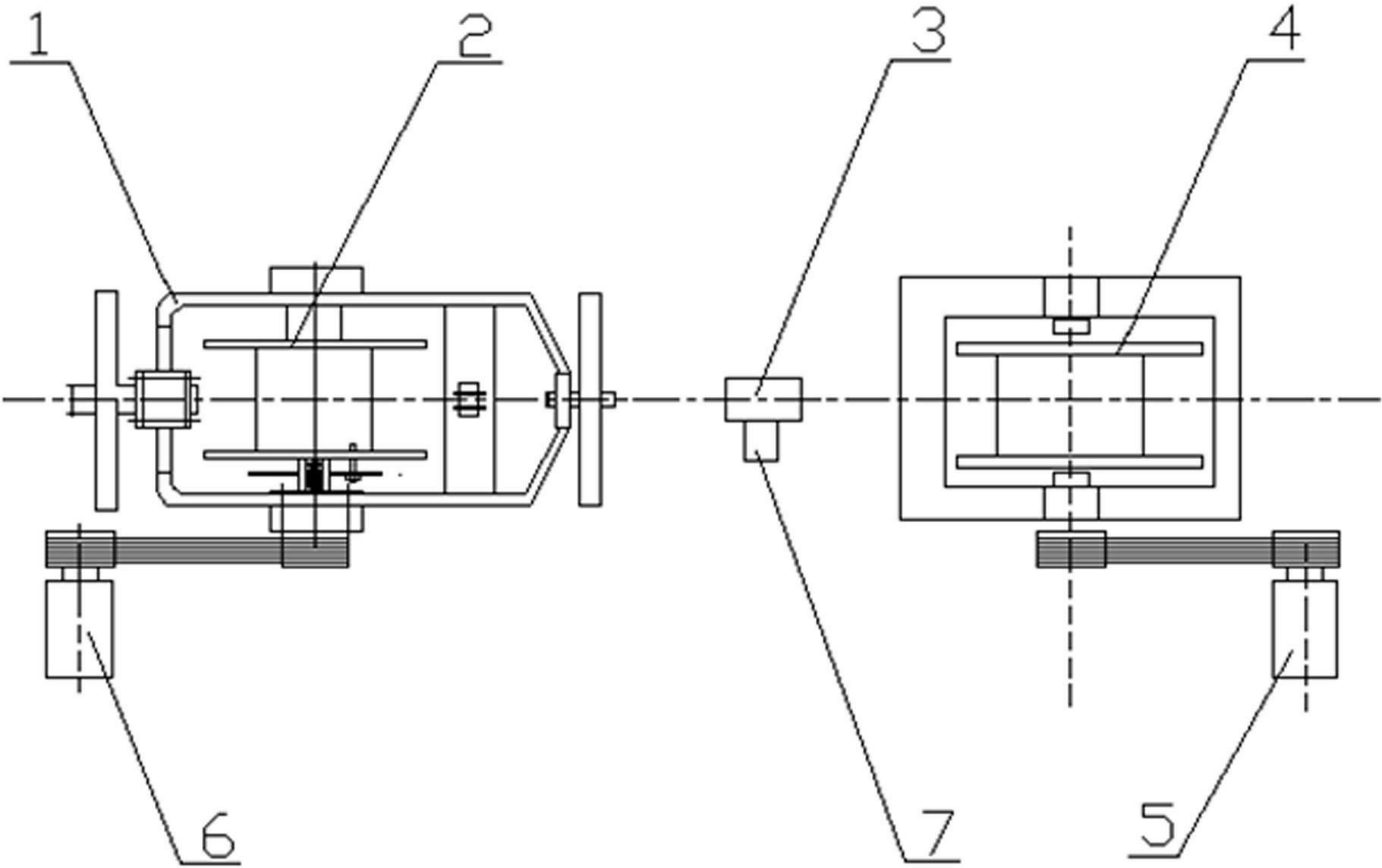

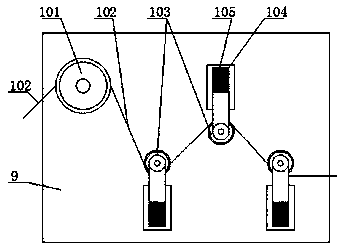

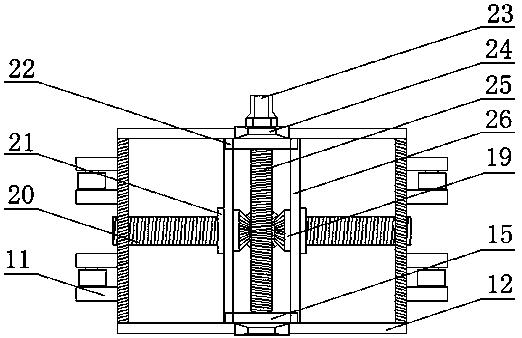

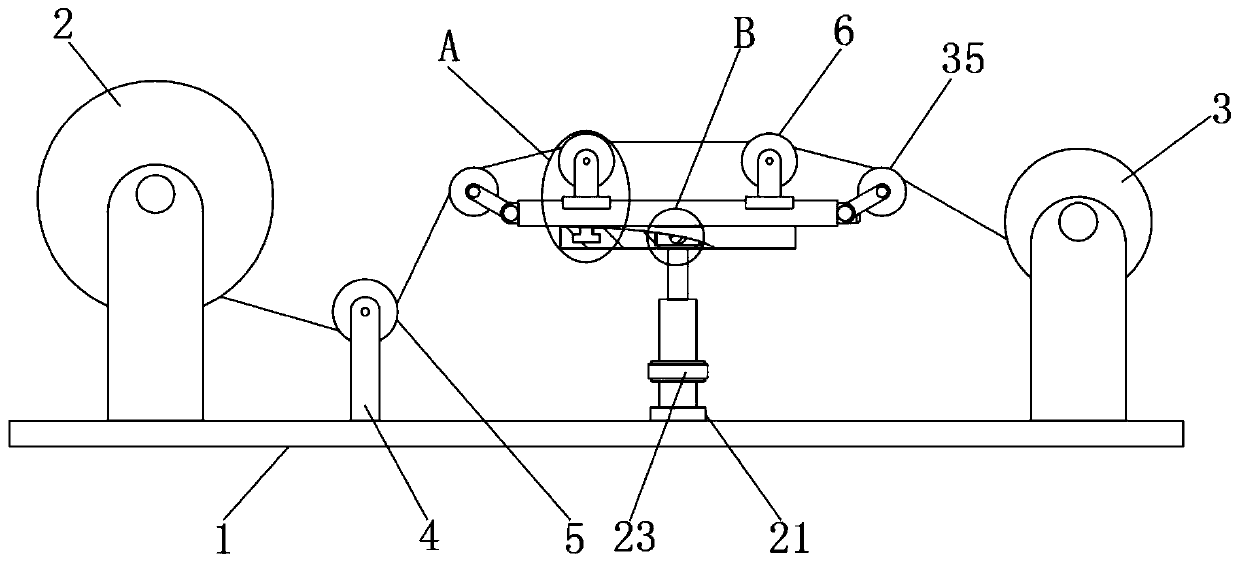

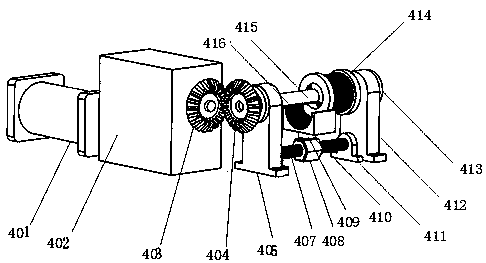

System for automatically controlling tension of stranded cables of superconducting conductor

InactiveCN102664078ASolve the problem that the precise control of the tension value cannot be satisfiedEasily brokenCable/conductor manufactureControl systemEngineering

The invention discloses a system for automatically controlling the tension of stranded cables of a superconducting cable conductor. The system comprises a stranded wire frame, wherein a pay-off disk is arranged in the stranded wire frame through a rotating shaft; wire guiding wheels are arranged behind the stranded wire frame; a take-up disk is arranged behind the wire guiding wheels; and the take-up disk is connected with a take-up motor. The system also comprises a pay-off motor connected with the pay-off disk; a tension sensor is connected with the wire guiding wheels; signals of the tension sensor are switched in a control circuit in a control cabinet; and a frequency converter of the take-up motor and a frequency converter of the pay-off motor are respectively connected with the control circuit. By adoption of the system, the tension can be accurately controlled, so that wires can be paid off stably, the problem that a tension value cannot be accurately controlled during stranding of superconductive wires is solved, and the problems that the superconductive wires are loosen and nonuniform, are easily snapped and the like during stranding are solved.

Owner:BAIYIN NONFERROUS GROUP

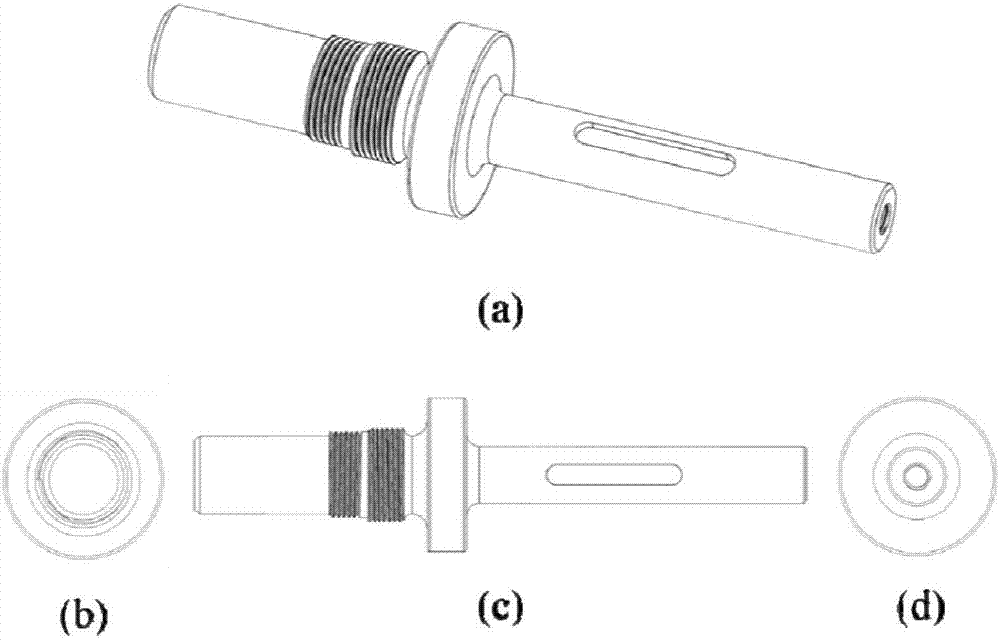

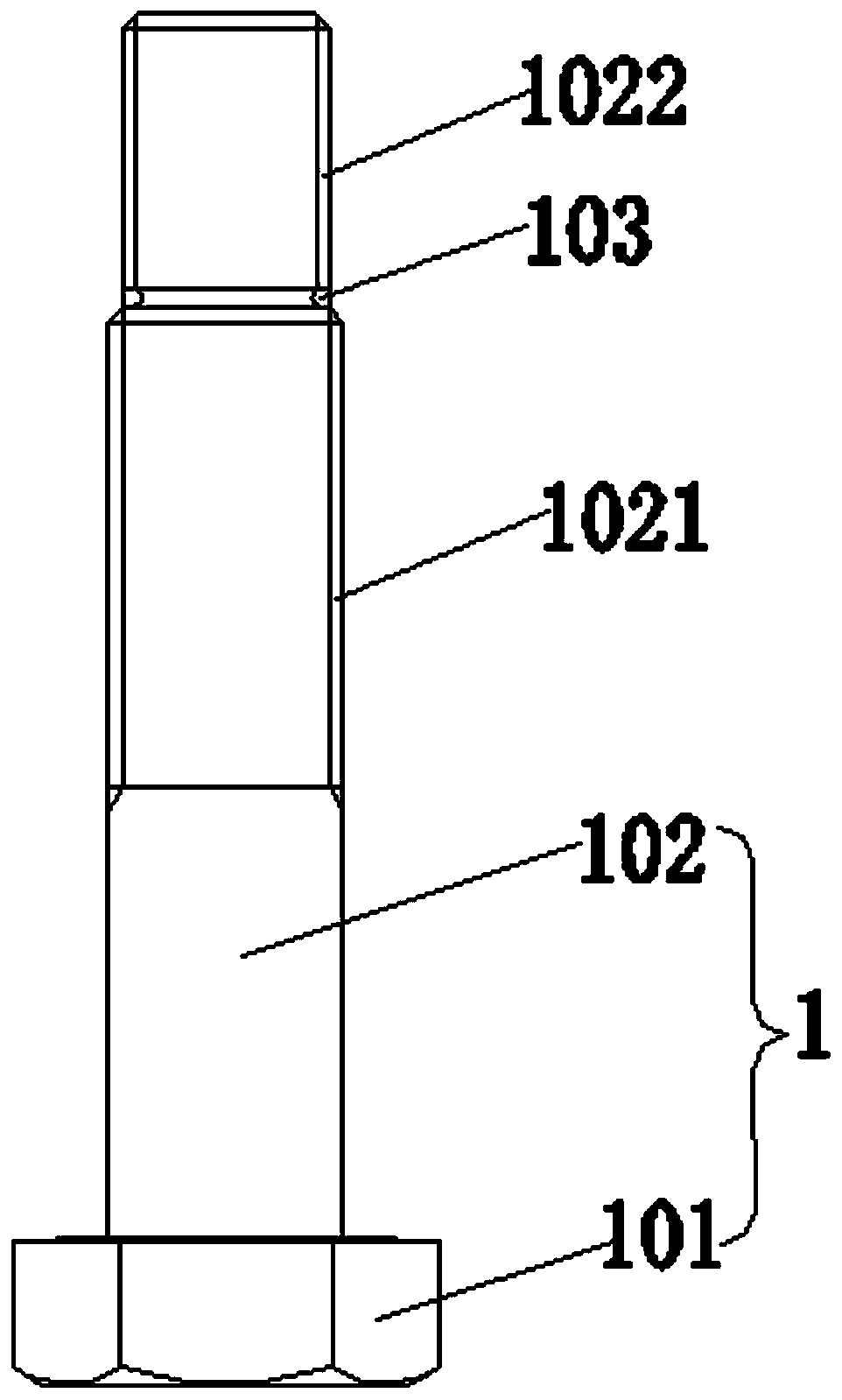

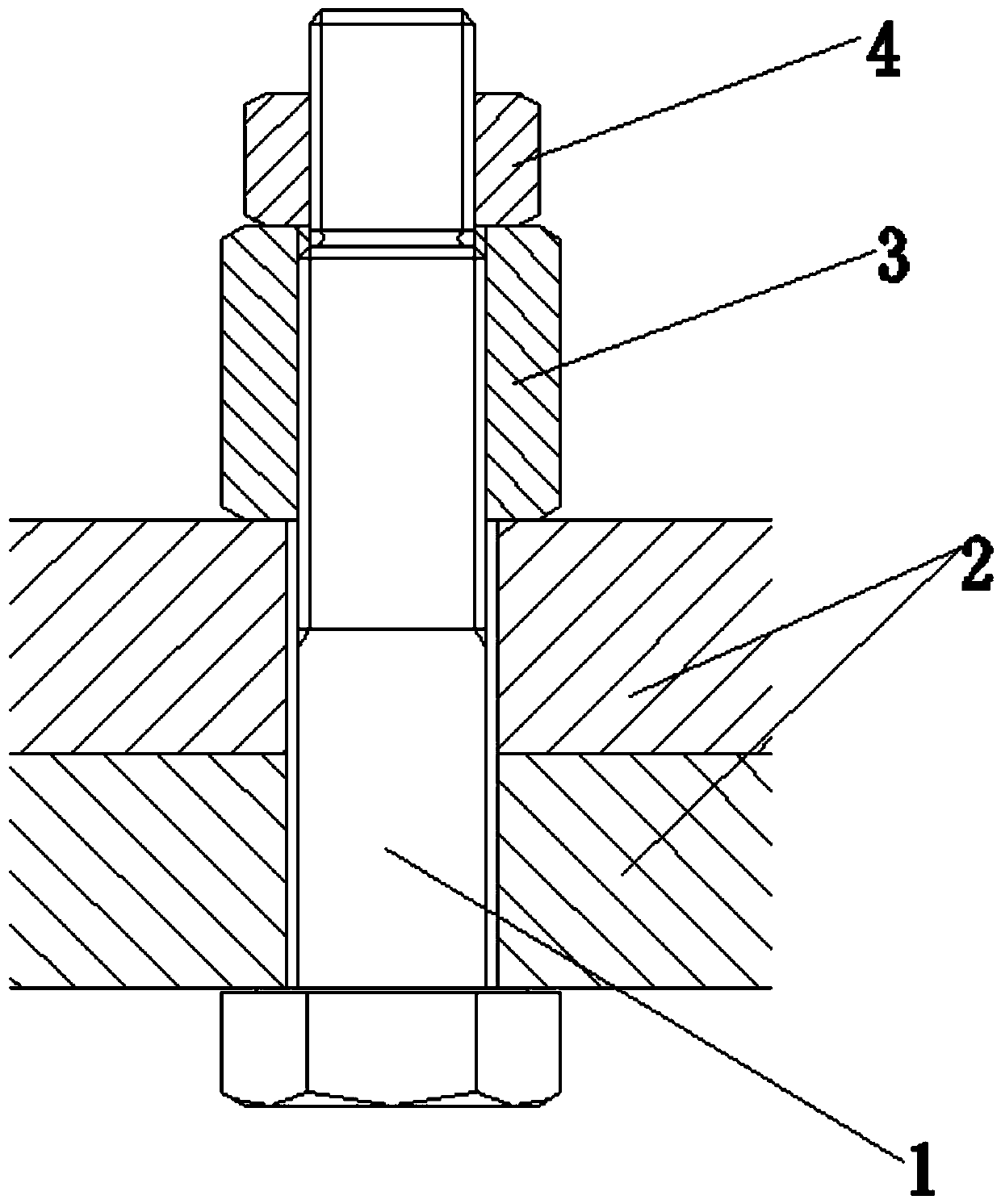

Anti-loosening fastening device and using method thereof

The invention discloses an anti-loosening fastening device and a using method thereof. The anti-loosening fastening device comprises a fastening bolt and a fastening nut; the fastening bolt is provided with an inner hole; one end of the inner hole is provided with a heating pressuring bolt, and the heating pressurizing bolt is in threaded connection with the fastening bolt; the other end of the inner hole is provided with a plug, and the plug is in threaded connection with the fastening bolt; low-melting-point alloy is filled in the inner hole of the fastening bolt in a sealing mode; and the inner hole is provided with a plurality of through holes in the radial direction, and the through holes communicate with the gaps between the fastening bolt and a part well as between the fastening bolt and the fastening nut. According to the using method, the fastening bolt, the fastening nut and the part are fixedly connected together through the low-melting-point alloy, and the nut is effectively prevented from loosening and disengaging and being stolen; after the solid low-melting-point alloy between the matched surfaces of the part, the fastening bolt and the fastening nut is heated to melt and released, the fastening device can be quickly disassembled.

Owner:西安飞宇航空仿真技术股份有限公司

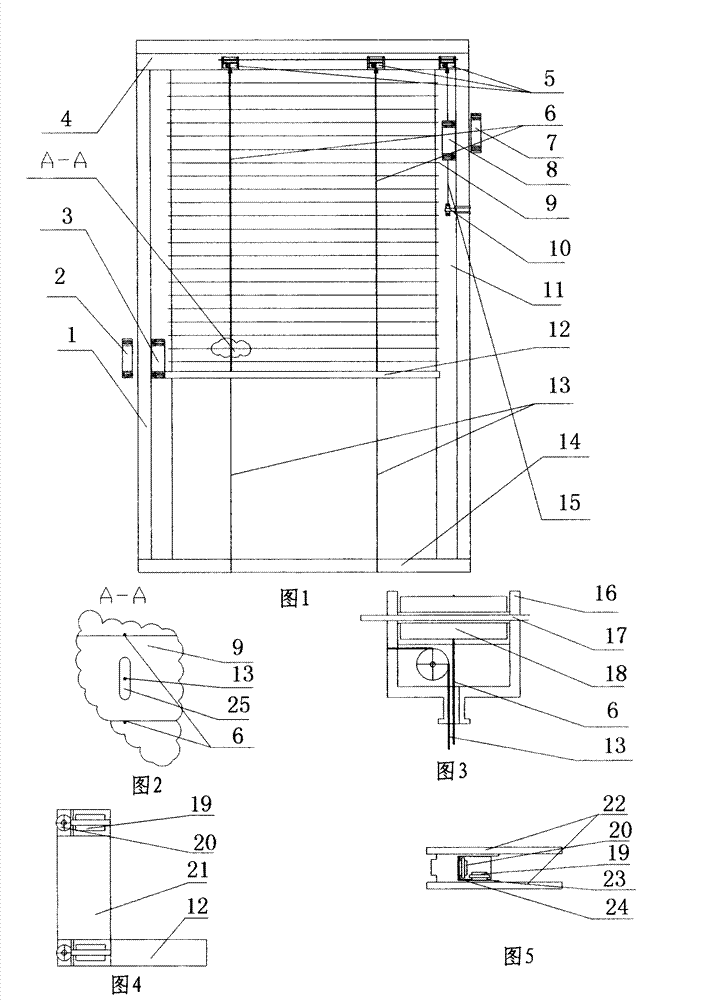

Ropeless type built-in shutter hollow glass

InactiveCN102900346ASolve looseSolve the problem of breakingDoor/window protective devicesMagnetEngineering

The invention discloses a piece of ropeless type built-in shutter hollow glass which comprises a frame, a piece of glass, a turnover control magnet, an elevation control magnet, shutter blades, an elevating mechanism, an elevating rod, a position screw and a turnover mechanism, wherein the positioning screw is used for positioning through holes in the shutter piece; the elevating rod is installed on the positioning screw; the elevation of the shutter blades is driven by the elevating rod; the elevation of the elevating rod is driven by the elevation control magnet, so that the elevation of a shutter is driven; a positioning pulley is additionally arranged on the elevating mechanism and a positioning iron bar is arranged on the operation track of the positioning pulley; and an elevating iron bar is arranged on the operation track of the elevating pulley so as to maintain that the elevating rod is always at a position parallel to the positions of the shutter blades. The positioning screw and the elevating rod take the place of an elevating rope, so that the problem that the elevating rope is loosened or snapped when the shutter is elevated is thoroughly solved, and further, the popularization and the use of the built-in shutter hollow glass are facilitated.

Owner:俞焱文

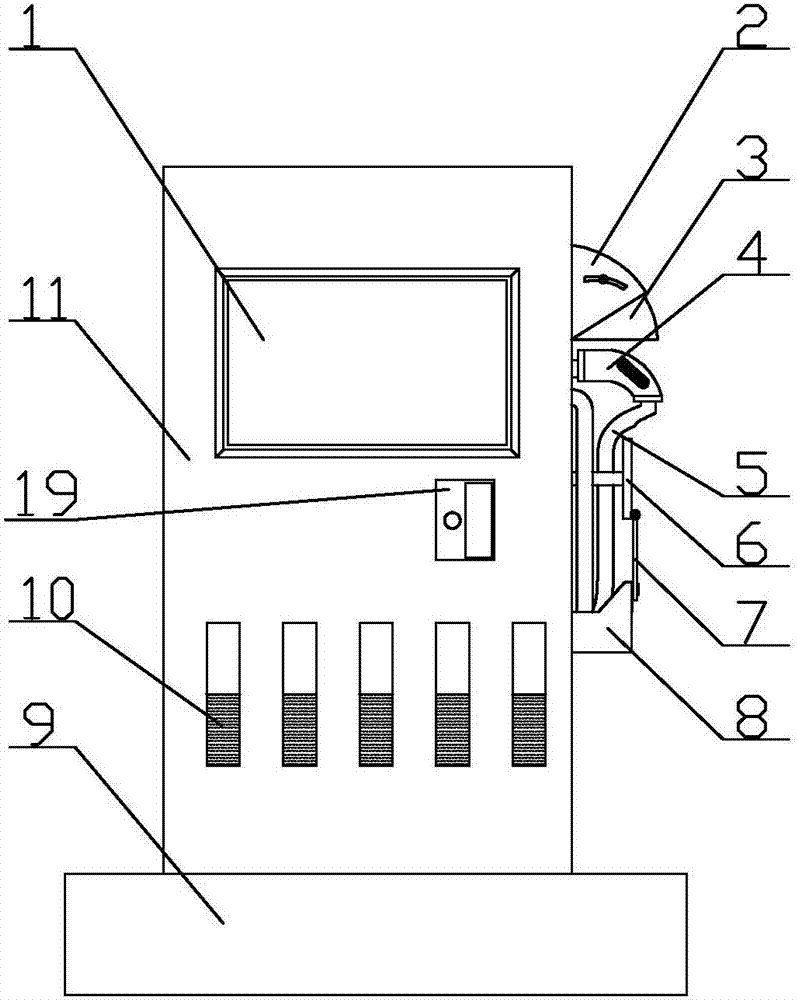

Charging pile for electric automobile

InactiveCN107176060AFix damageEasy accessCharging stationsLighting elementsElectric machineDrive motor

The invention discloses a charging pile for an electric automobile. The charging pile for the electric automobile comprises a charging gun and a charging pile housing, wherein a display screen is arranged on the upper end of the front surface of the charging pipe housing, and a reflective stripe is arranged at a lower side, close to the display screen, of the front surface of the charging pile housing; a charging pile base is arranged at the bottom of the charging pile housing, and a fixed protective cover is arranged at the upper end on one side of the charging pile housing; a movable protective cover is arranged on the inner side of the fixed protective cover; a charging gun fixing groove is formed in the lower side, close to the fixed protective cover, of one side of the charging pile housing; and the charging gun is mounted in the charging gun fixing groove. By designing a roller lead screw connected to a cable winding rack and a driving motor in the charging pile housing, a user drives a cable to be close to the fixed protective cover after use, so that the cable is protected by the protective cover to the maximum extent, and the problem that the cable is damaged as the cable is directly dragged on the ground is solved.

Owner:HANGZHOU LEE POOL TECH CO LTD

Locking bolt/nut

The invention provides a locking bolt / nut. The locking bolt / nut comprises a bolt, a first nut and a second nut; the bolt comprises a fixed end and a screw rod; the screw rod is provided with a first thread and a second thread, and the rotating directions of the two threads are opposite; the screw rod is inserted in a connected piece, and is screwed in the first nut and the second nut in sequence to tightly bond the connected piece on the fixed end; the first nut is provided with an internal thread matched with the first thread; the second nut is provided with an internal thread matched with the second thread; and the nominal diameter of the first thread is larger than the nominal diameter of the second thread. The locking bolt / nut is simple in structure and convenient to operate; the step-shaped screw rod is provided with two nuts, with opposite rotating directions, for cooperation; inclined teeth are arranged at the connected ends of the two nuts; and the inclined teeth are engaged with each other, so that the bolt / nut is provided with a permanent self-locking structure, guarantees permanent, stable and firm bolt connection, and solves the problem of bolt looseness caused by alternate strain due to external disturbance factors of alternating load or equipment vibration.

Owner:DAYE SPECIAL STEEL CO LTD

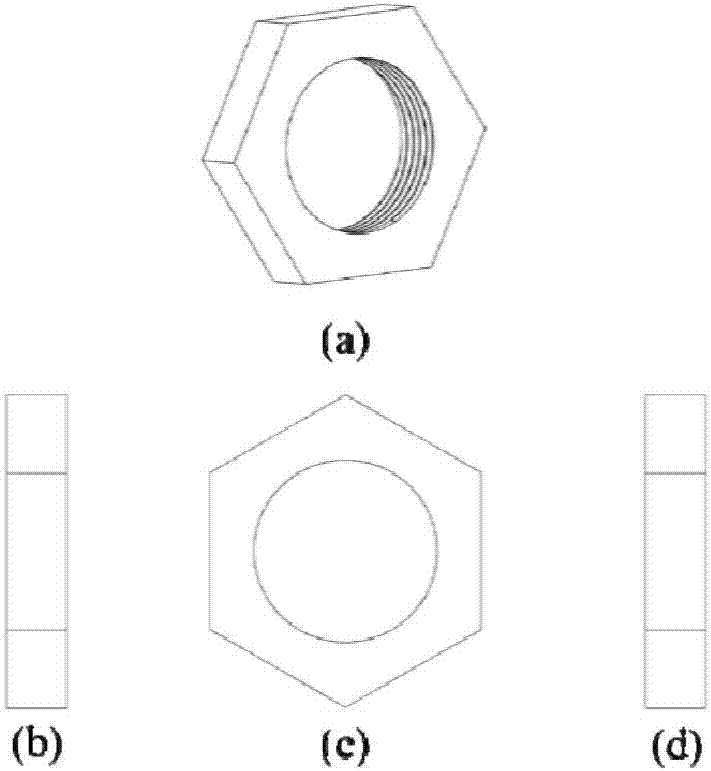

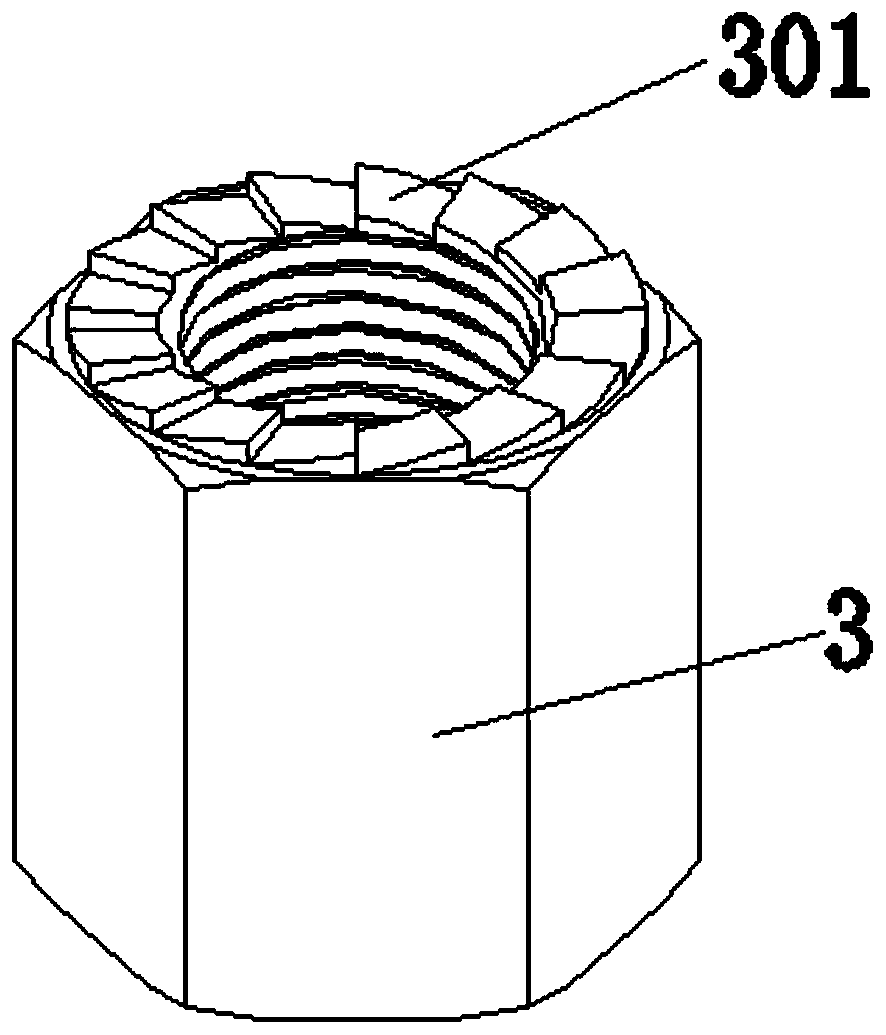

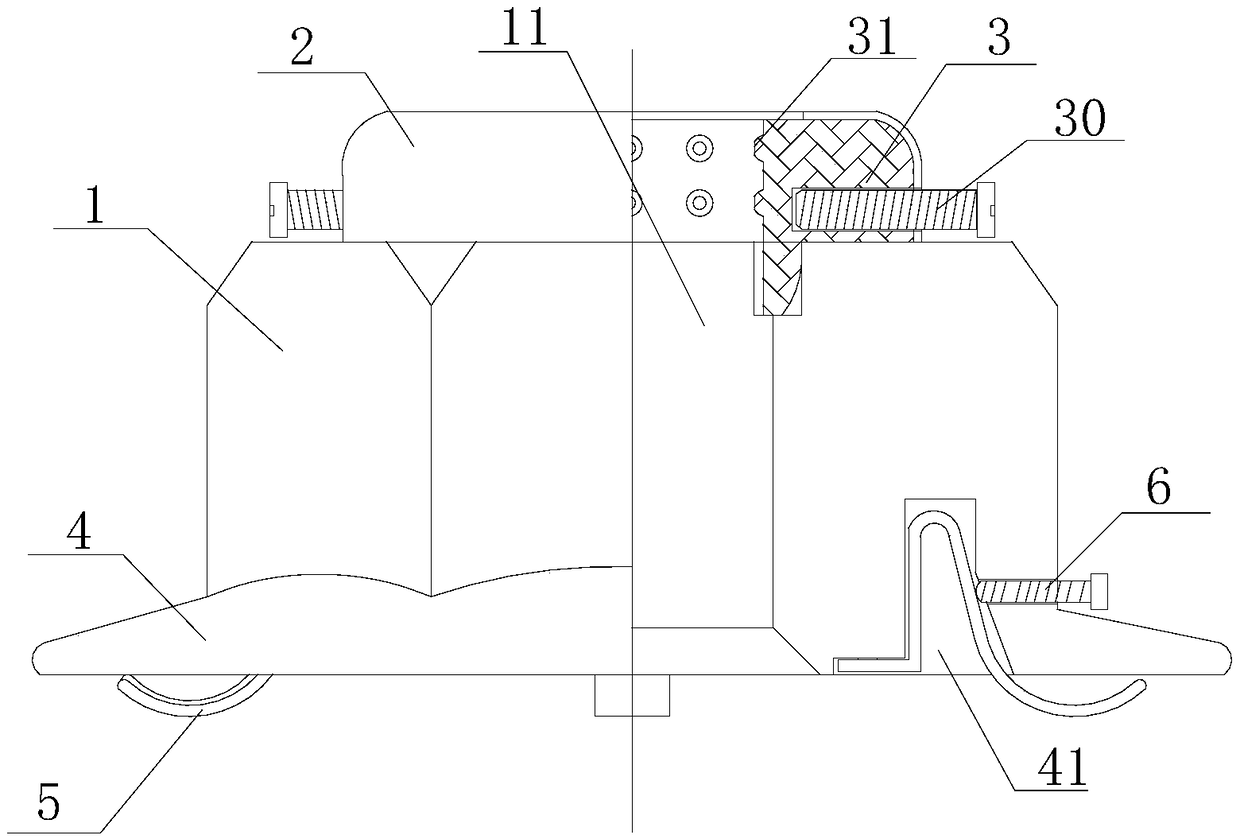

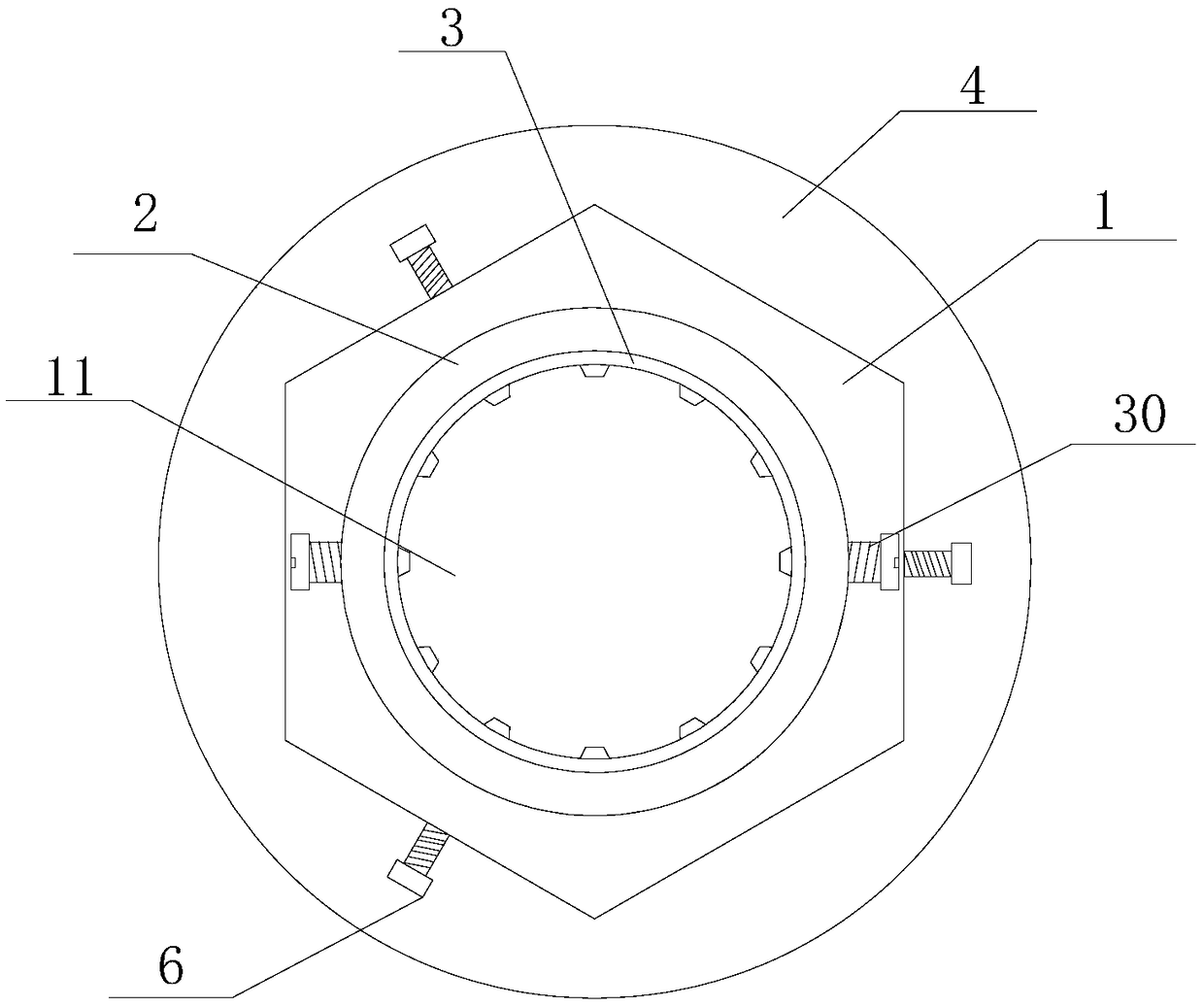

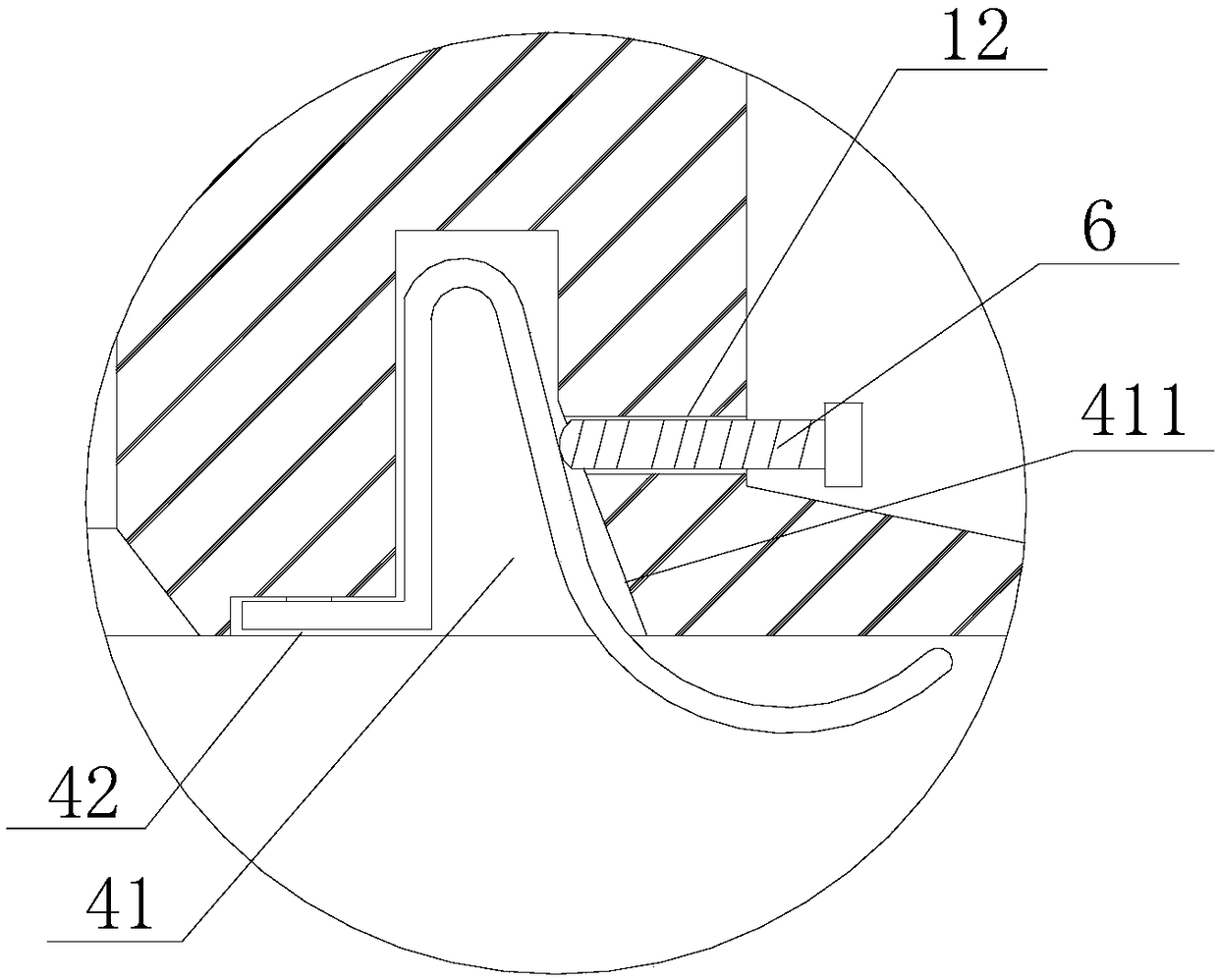

Locking nut

The invention discloses a locking nut, comprising a hexagon nut body, an annular boss, a nylon ring, a flange gasket, anti-loosening elastic pieces and adjusting screws, wherein the upper end surfaceof the hexagon nut body is provided with the annular boss, the annular boss is provided with a mounting ring groove, the nylon ring is embedded in the mounting ring groove, the center line of the hexagon nut body is provided with a central threaded hole, the lower end face of the hexagon nut body is connected with the flange gasket, the lower end face of the flange gasket is provided with a plurality of containing grooves, the anti-loosening elastic pieces are arranged in the containing grooves, and the adjusting screws are installed on the side wall of the hexagon nut body. The adjusting screws cooperate with the anti-loosening elastic pieces, the multiple adjustable anti-loosening elastic pieces are arranged under the flange gasket, so that the locking reliability is ensured, and the locking nut is especially suitable for the uneven fastening situation of the fastening end face, and the resilience force to the bolt is generated by extruding deformation of the threads of the bolt to the nylon ring, so that the problems of loosening and slipping off under the condition of vibration can be effectively solved.

Owner:HAIYAN HUASHENG AUTO PARTS

Closed isolation composition applied to treatment of gangue hill and implementation method thereof

The invention provides a closed isolation composition applied to the treatment of a gangue hill and an implementation method thereof, and belongs to the technical field of environmental treatment andmine ecological restoration. The closed isolation composition comprises inorganic substances, a polymer, fiber, an additive and water, the weight ratio of the inorganic substances is 20-75%, the weight ratio of the polymer is 0.2-5%, the weight ratio of the fiber is 0.05-5%, the weight ratio of the additive is 0.05-2%, and the weight ratio of the water is 20-75%; the above materials are mixed according to a certain ratio to prepare a mixed slurry, the slurry is sprayed on the surface of the gangue hill for sealing of the gangue hill and isolation from a vegetation area to completely eliminatethe hazard of the gangue hill, and the disturbance influence of vegetation on the gangue hill is eliminated. The closed isolation layer has the advantages of airtightness, seepage resistance, heat insulation, firmness and durability, the used materials are all environmentally friendly, the construction is simple, the efficiency is high, and the cost is low.

Owner:山西智德生态环保股份有限公司

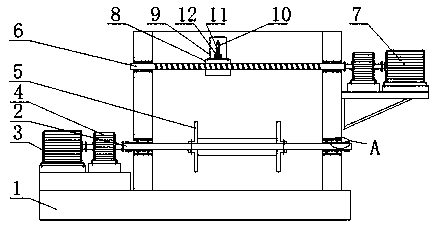

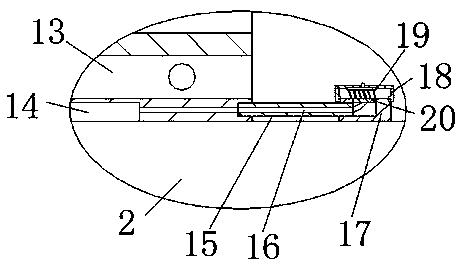

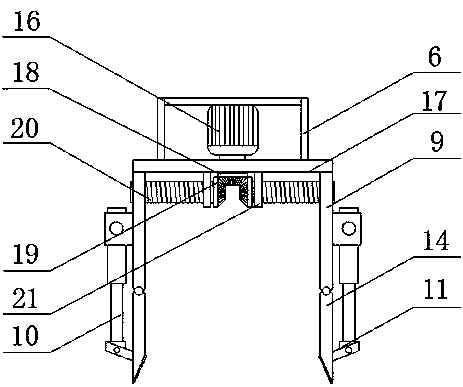

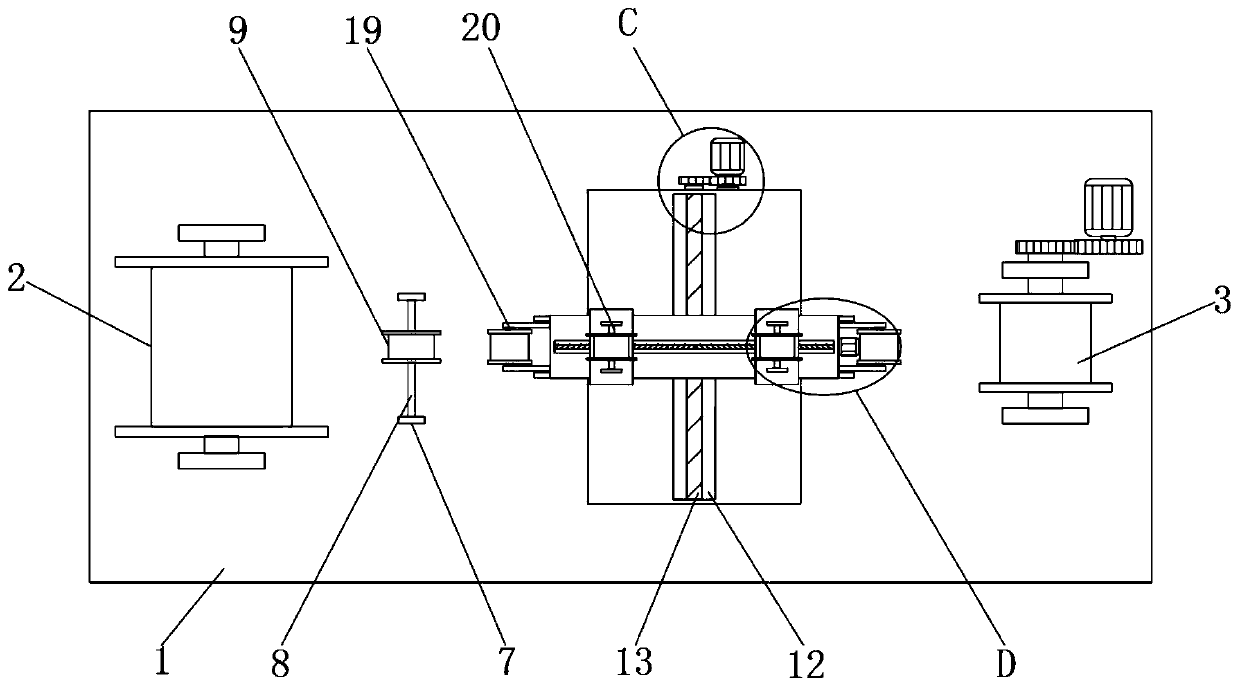

A winding device for an electromagnetic wire

PendingCN109148147AImprove the uniformity of forceImprove uniformityInductances/transformers/magnets manufactureBobbinDrive motor

The invention belongs to the technical field of electromagnetic wire production, and discloses a winding device for electromagnetic wires, in order to solve the problem that the tightness degree of the electromagnetic wires in the winding process of the prior electromagnetic wires is inconsistent. The invention comprises a base, the base is provided with a rotating shaft and a driving motor for driving the rotating shaft to rotate, A bobbin for winding the electromagnetic wire is sleeved on the rotating shaft, characterized by, a lead screw is fixedly mounted on the base above the bobbin, Thebase is provided with a first servo motor for driving the lead screw to rotate, the lead screw sleeve is provided with a lead screw nut capable of moving on the lead screw, the lead screw nut is fixedly connected with a mounting plate, the mounting plate is provided with a wire inlet head for entering the electromagnetic wire, bearings are installed on both sides of the base, and the two ends of the rotating shaft are sleeved on the bearings.

Owner:湖州市练市三峰线缆厂

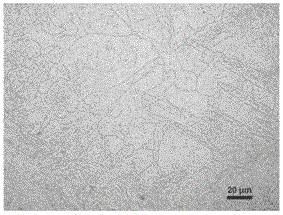

Low-alloy steel high in strength and toughness performance and preparing method of low-alloy steel

The invention discloses low-alloy steel high in strength and toughness performance and a preparing method of the low-alloy steel. The preparing method is a reasonable matching method for improving the strength and toughness performance in the manner that the aspects of component improvement, short-procedure design in which casting blank reheating is omitted, casting blank core part quality improvement, structure micronization control and rolling schedule optimization are taken into comprehensive consideration, the technical skill potential of modern material machining is fully reflected, and the actions of grain refinement, controlled rolling, rapid cooling and other technology means on steel strengthening and toughening are brought into play. It is ensured that brittle phase crack initiation of products of moderate-thickness plates is reduced and a new structure form is obtained so as to prevent crack expanding, and the breakthrough of the short-procedure technology of direct hot rolling of the ultrahigh strength and toughness steel casting blank is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

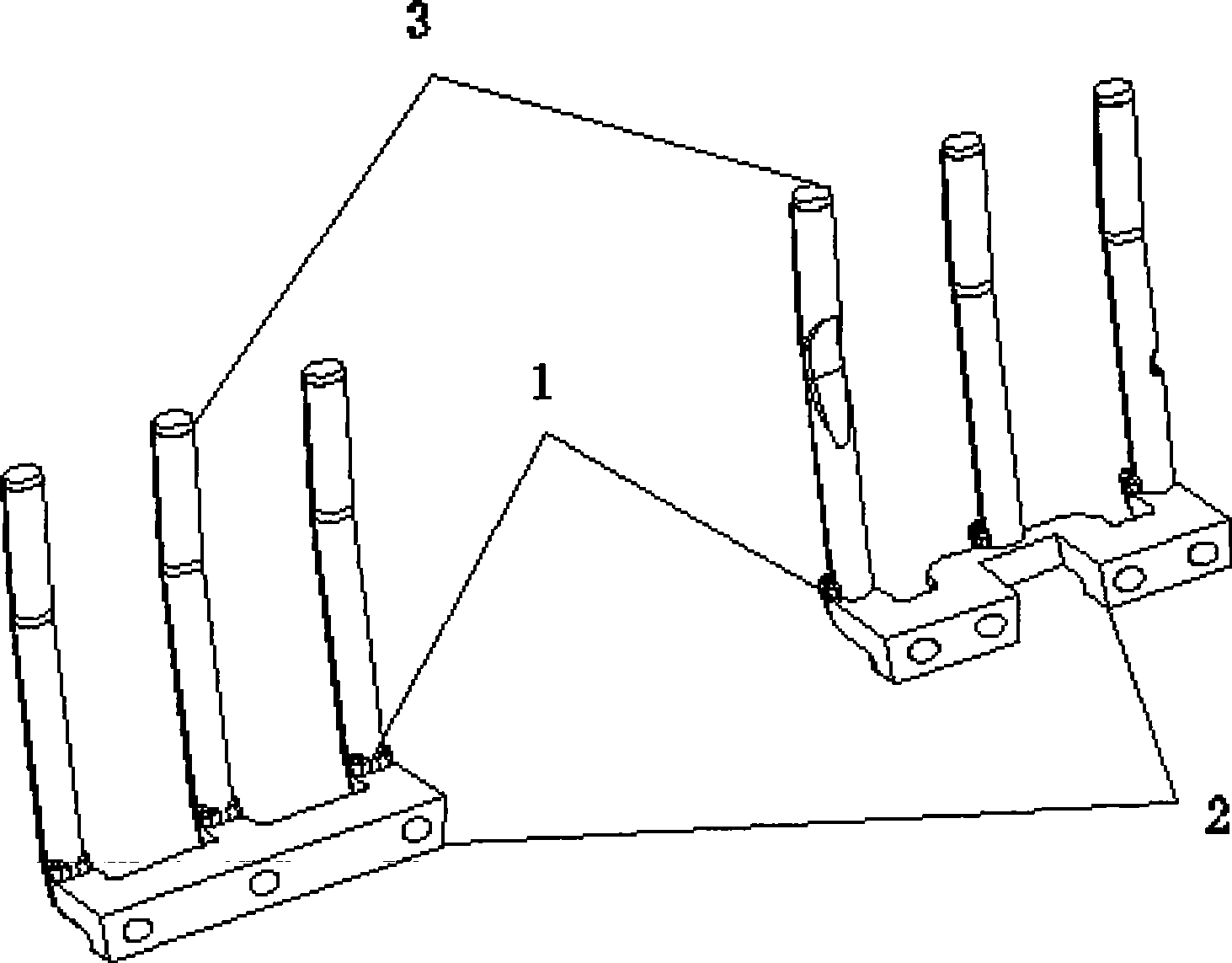

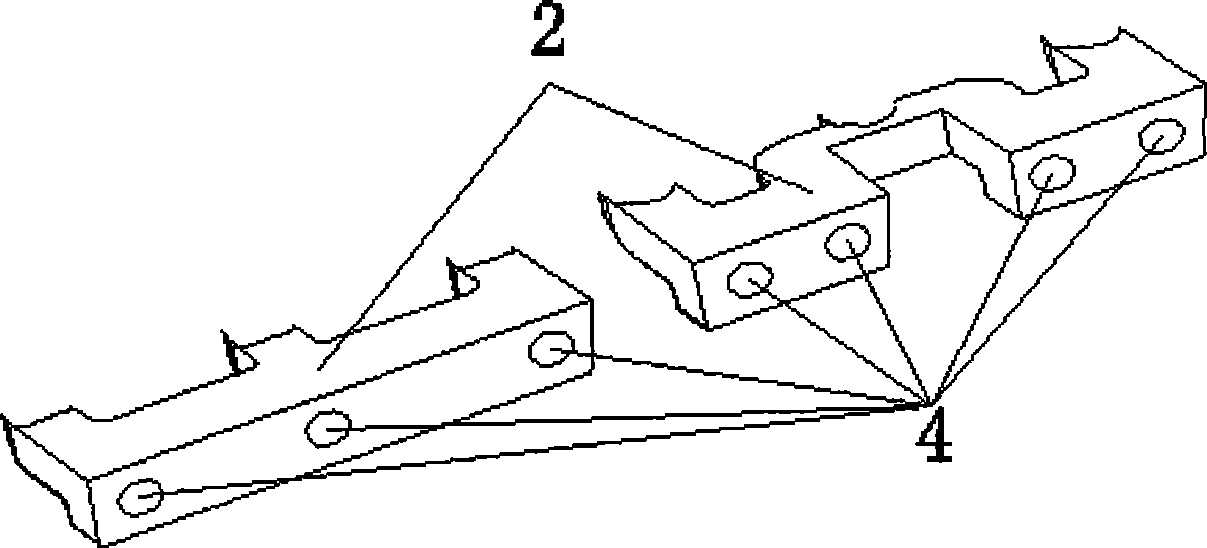

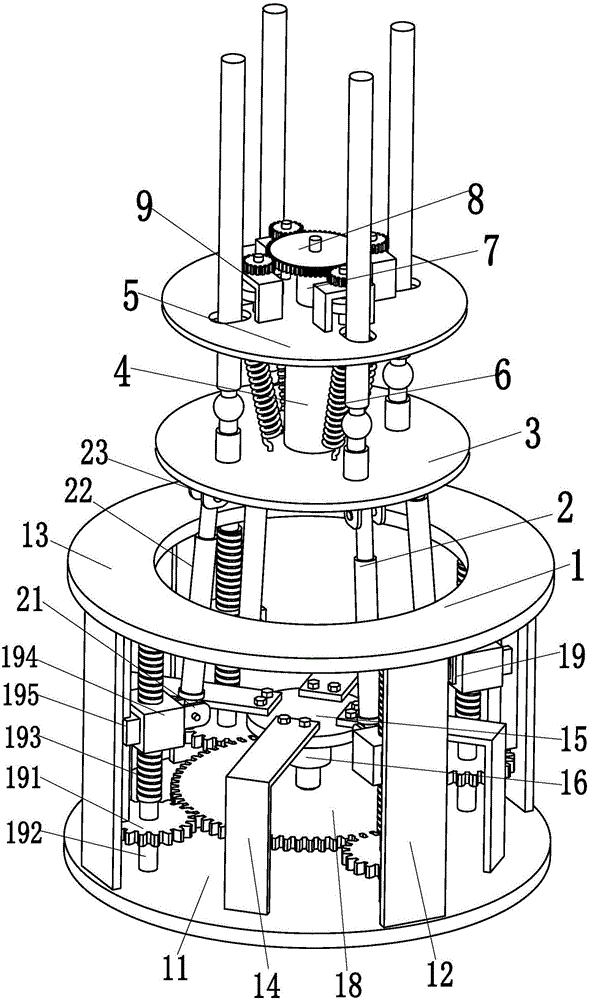

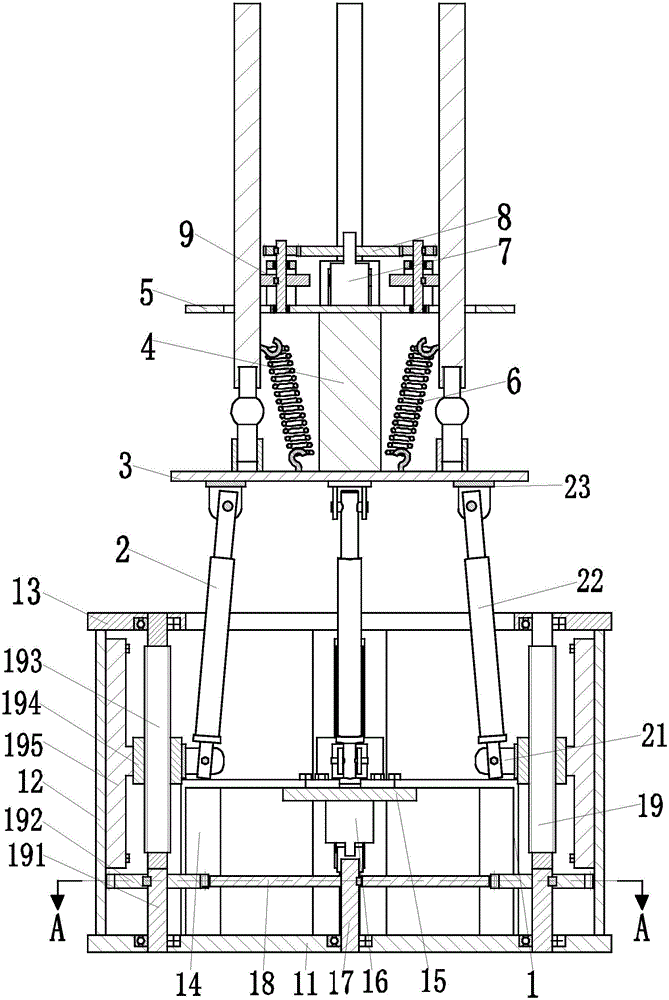

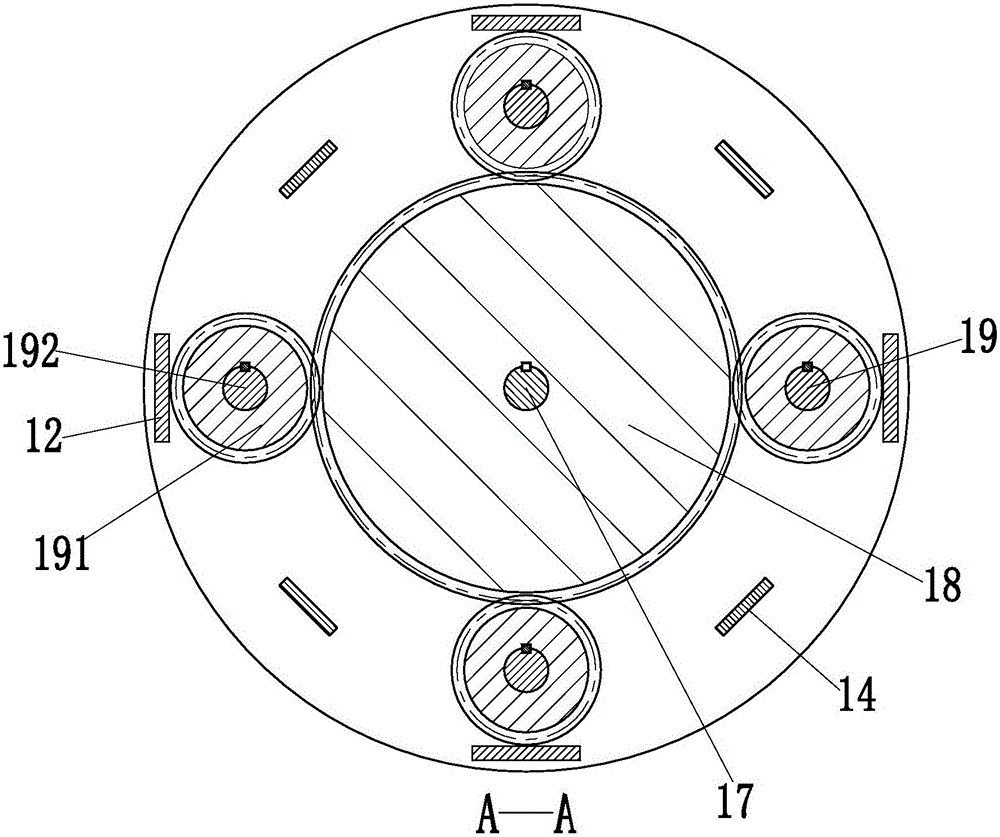

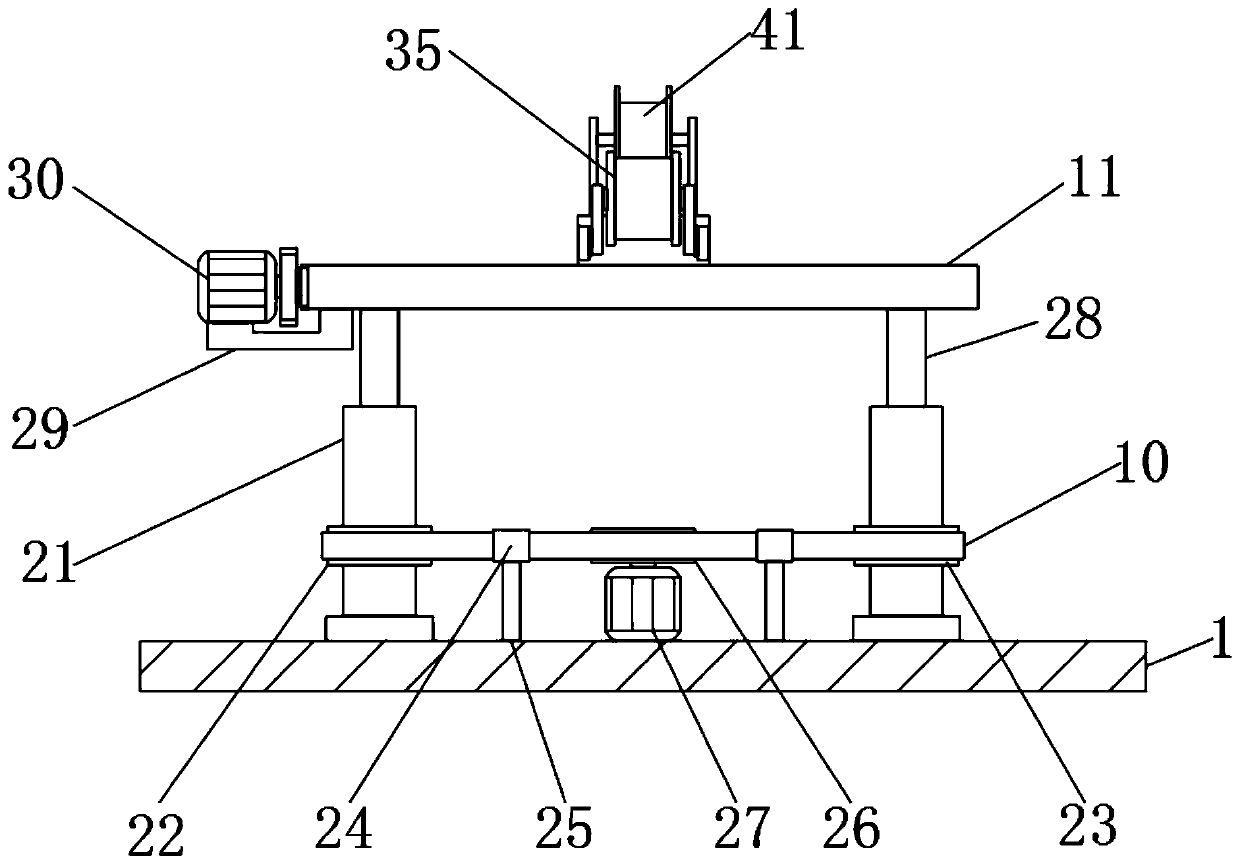

Building concrete pouring vibration robot

ActiveCN106012840ANo manual operationHigh degree of automationBridge erection/assemblyBuilding material handlingCircular discElectric machinery

The invention relates to a building concrete pouring vibration robot which comprises a fixing rack. Locating columns are arranged at the middle portion of the upper end face of an operation table. A limiting disc is welded to the upper ends of the locating columns. The locating columns achieve the effect of supporting the limiting disc. Four kidney-shaped limiting holes are evenly formed in the limiting disc in the axis direction. Four vibration branch chains are evenly installed on the operation table in the axis direction. The four vibration branch chains can conduct the high-frequency vibration movement on poured concrete at the same time, the concrete compacting speed is high, and the work efficiency is high. The middle portion of the upper end face of the limiting disc is provided with a transmission motor through a motor seat. A driving gear is fixedly installed at the output end of the transmission motor and engaged with four transmission branch chains. By the adoption of the robot, the function of compacting the poured concrete through multiple vibration bars at the same time can be achieved, the robot has the beneficial effects of being high in concrete compacting speed, good in damping performance, high in work efficiency, high in automation degree and the like, and a new way for automatically and quickly compacting the poured concrete is provided.

Owner:福建省东霖建设工程有限公司

Clamping device for industrial robot

InactiveCN108527430AStable clampingReasonable structureGripping headsIndustrial engineeringIndustrial robot

The invention discloses a clamping device for an industrial robot. The clamping device for the industrial robot comprises a back arm, a connecting arm is rotatably connected to one end of the back arm, a first bolt is arranged on the side wall of one end of the connecting arm in a penetrating mode, a front arm is arranged on the first bolt in a penetrating mode, the side wall of one end of the connecting arm and the side wall of one end of the front arm are each provided with a second through hole and a third through hole, the first bolt sequentially penetrates through the second through holesand the third through holes and extends to one side of the front arm, a nut is arranged at the tail end of the first bolt, a supporting plate is fixed to the side wall of one end of the front arm, and connecting blocks are fixed to the side walls of the two ends of the supporting plate correspondingly. According to the clamping device for the industrial robot, the structure is reasonable, transverse and longitudinal adjusting and clamping are achieved, and the problem that loosening and falling occur when clamping is conducted is solved; and through cooperation of air cylinders and connectingplates, stable clamping on short and small articles can be achieved, the clamping efficiency is improved, the cost is reduced, the practicability is high, and the clamping device is suitable for being popularized.

Owner:CHANGSHU GAOTONG INTELLECT EQUIP CO LTD

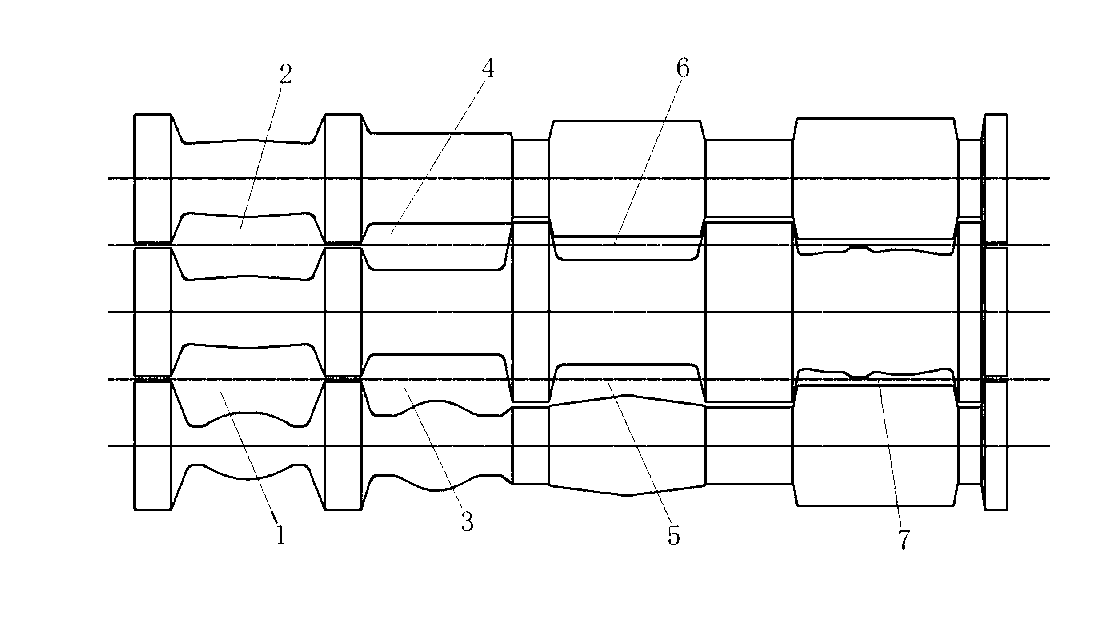

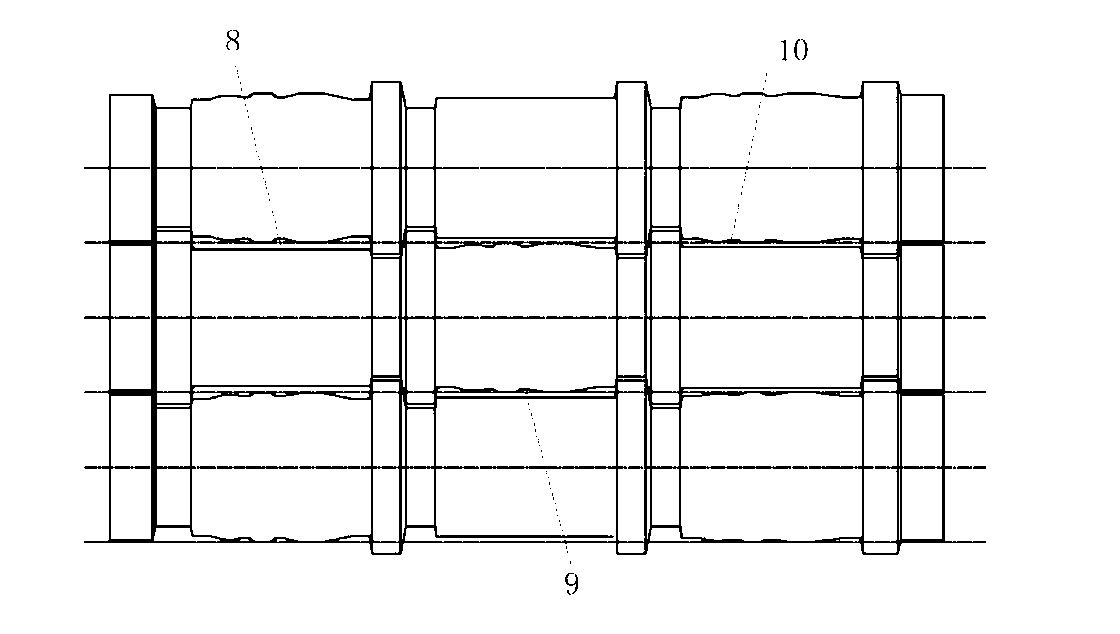

Die and method for rolling tubeless rim plate

InactiveCN103240372ASolve looseSolve the problem of internal defects such as shrinkage cavitiesMetal rollingMetallurgyStructural engineering

The invention discloses a die and a method for rolling a tubeless rim plate. The die comprises a plurality of rolls and is characterized in that the plurality of rolls are provided with hole patterns in different shapes respectively. During rolling of the tubeless rim plate, high-temperature billets are sequentially fed into rolls with hole pattern structures in different shapes to finish rolling of the tubeless rim plate. According to the die and the method, the plurality of rolls are provided with the hole patterns in different shapes, a multi-rolling mode is adopted, the problems that shapes of finished plate edges are out of control, and internal defects, such as looseness and shrinkage in metal of plate edges during rolling by existing rolls are solved, the bearing capacity of wheels and the metal utilization rate are improved, edges of wheels cannot deform easily, rolling processes are reduced, and the rolling efficiency is improved.

Owner:李昕远

Brush head device for electronic toothbrush

The invention discloses a brush head device for an electronic toothbrush. The device comprises a rotating shaft and a toothbrush head, wherein a brush head plug is arranged between the rotating shaftand the toothbrush head, and is provided with an inner cavity which corresponds to the shape of the upper end of the rotating shaft; the upper end of the inner cavity wall is provided with a flat partof the inner cavity; the upper end of the rotating shaft corresponding to the flat part of the inner cavity is provided with a flat part of the rotating shaft; the lower end of the inner cavity wallis provided with a first hook flange protruding inwards; the circumference surface of the rotating shaft corresponding to the first hook flange is provided with a first hook groove recessing inwards;and the first hook flange and the first hook groove are closely buckled. The wearable brush head plug arranged between the metal rotating shaft and the brush head of the hard plastic toothbrush solvesthe problem that an electric toothbrush has large abrasion all the time for a long time to cause the joint of the toothbrush head and the upper end of the rotating shaft to get loose, and improves the service life and the quality of the electronic toothbrush.

Owner:黄拔梓

Automatic winding device

Owner:宁波铂汉科技有限公司

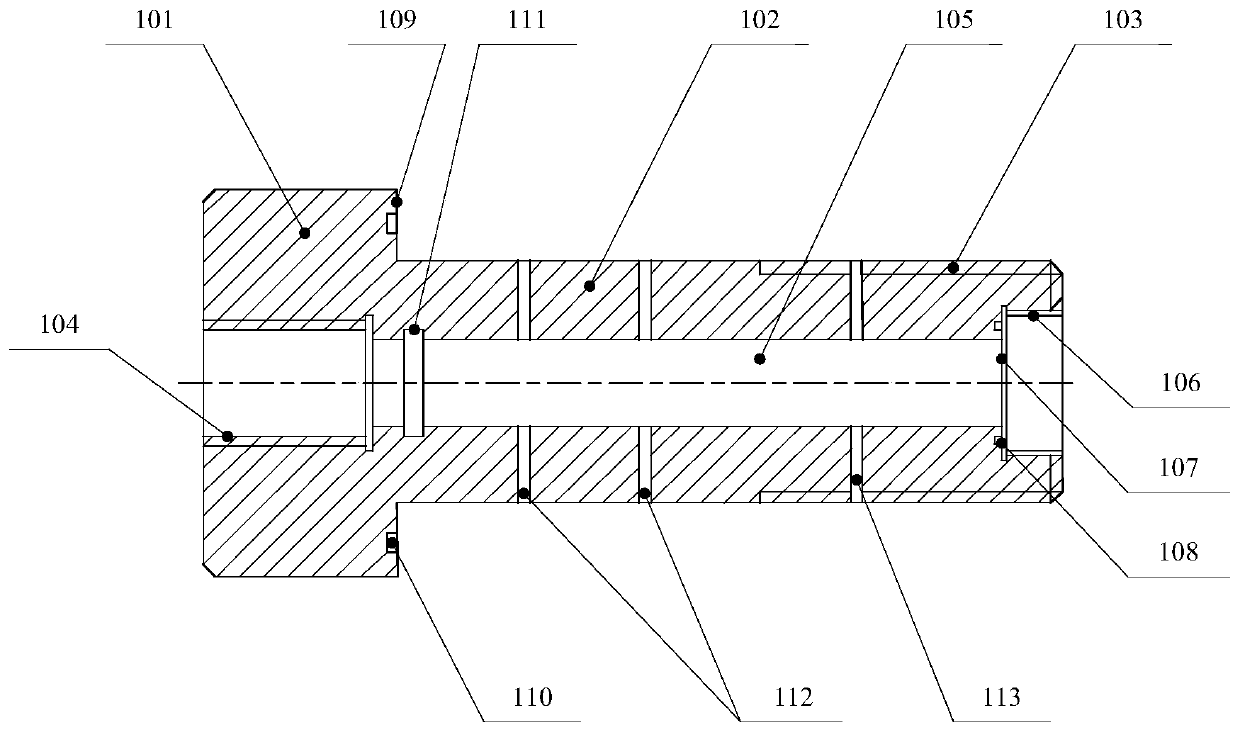

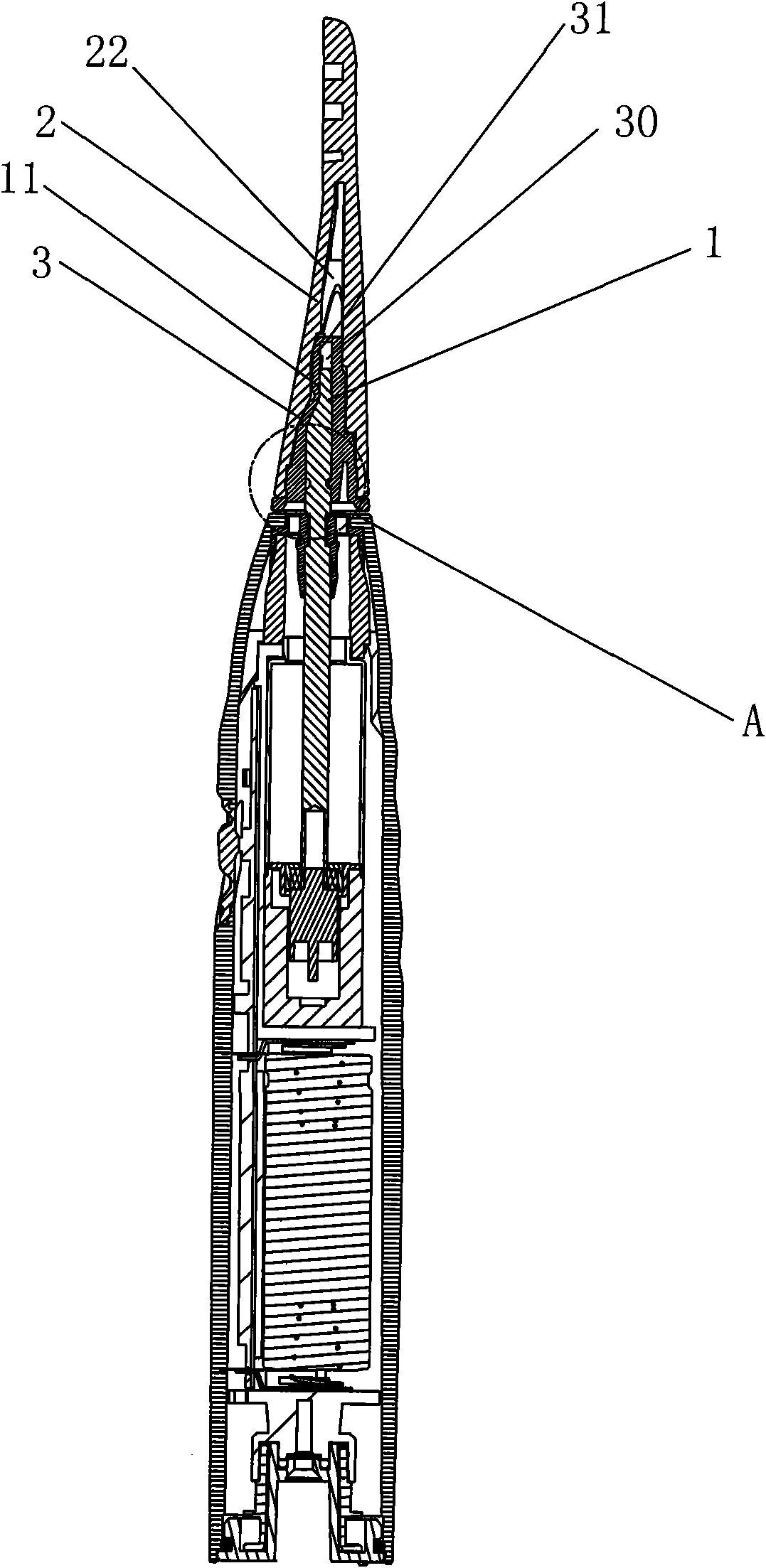

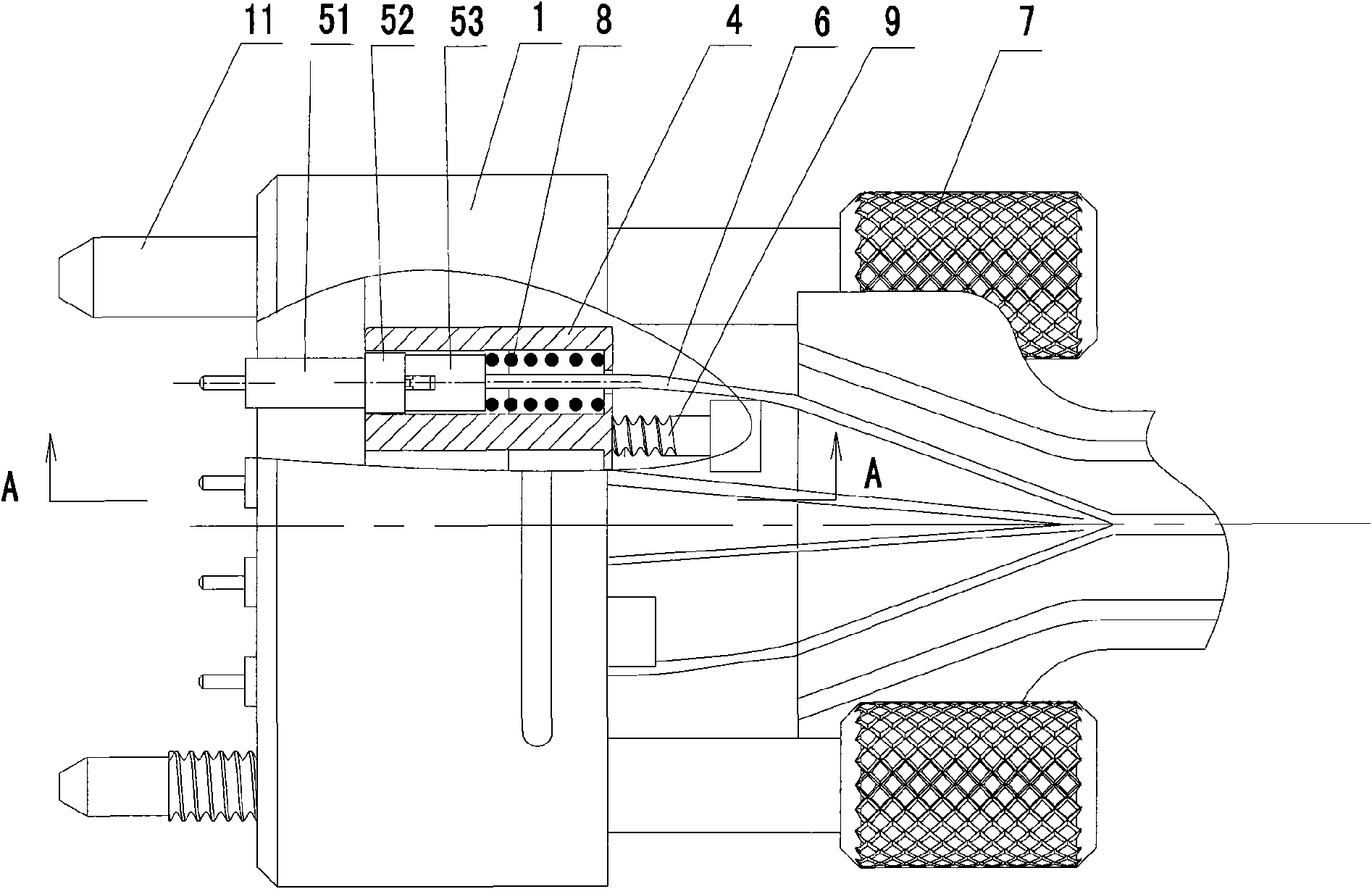

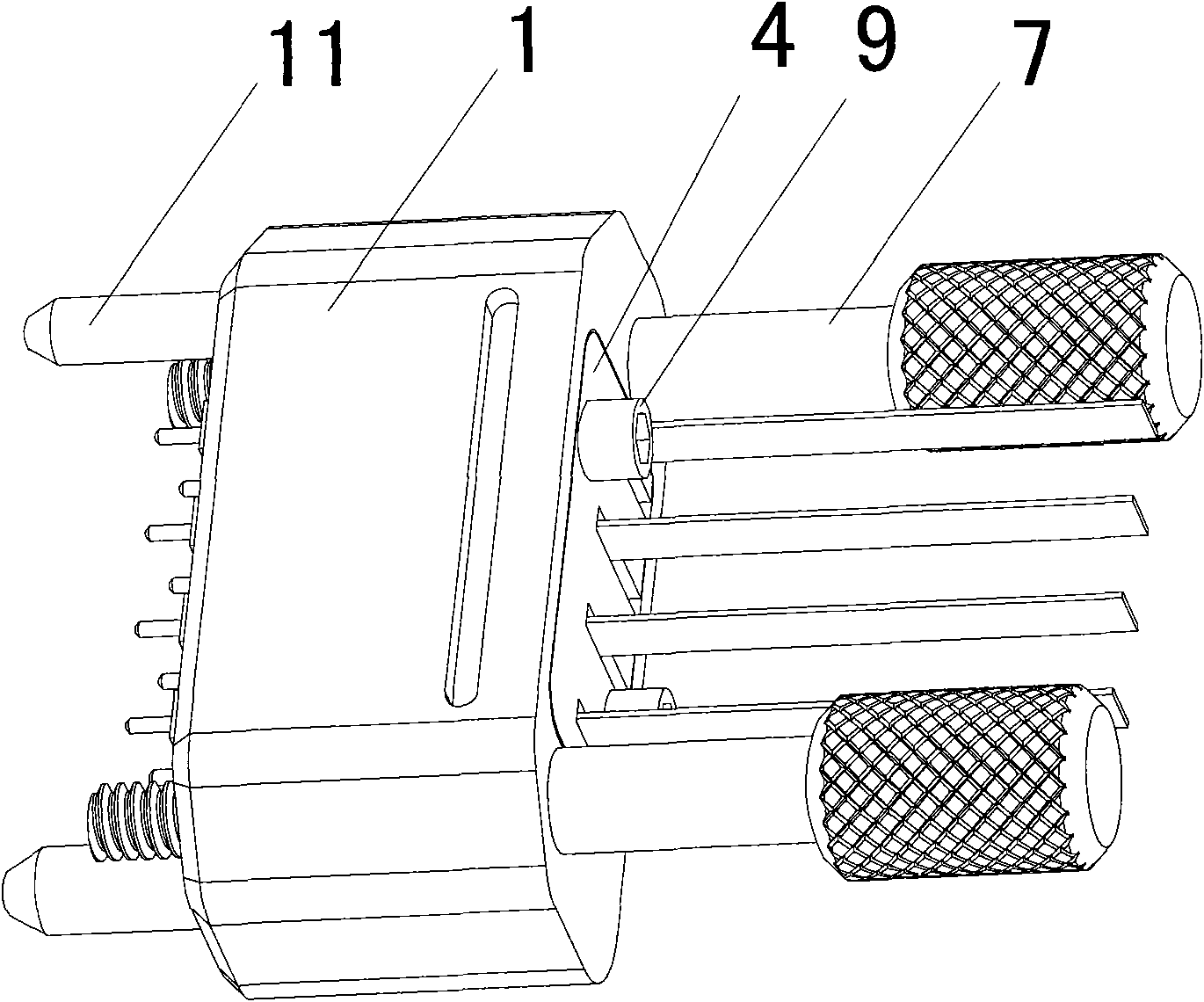

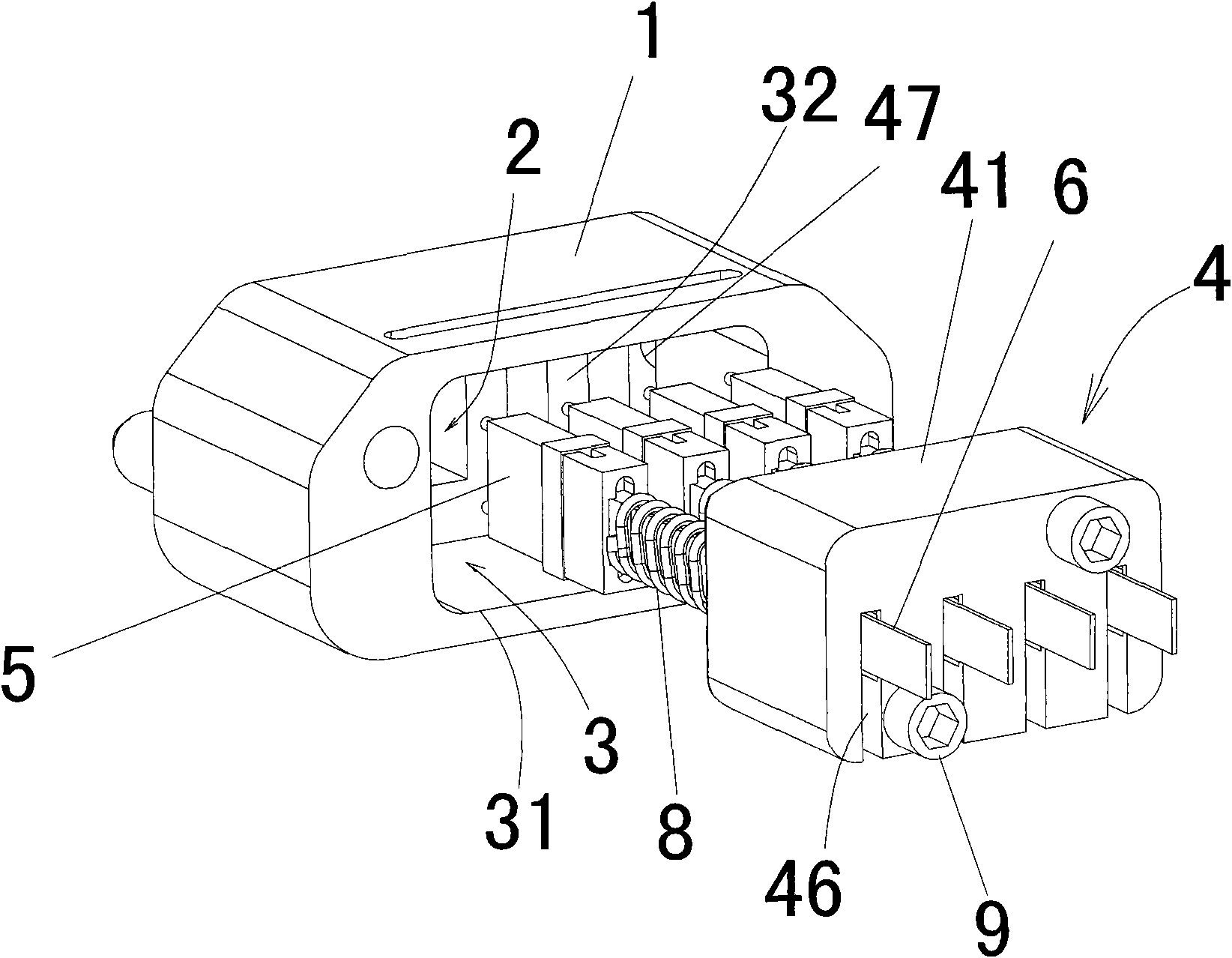

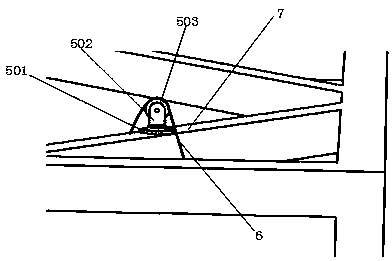

Optical fiber connector integrated with a plurality of rectangular multi-core optical fiber contact pins and integrated connector

InactiveCN101587213AStructural solutionSolve the problem of weak integrityCoupling light guidesEngineeringContact mode

The present invention provides an optical fiber connector integrated with a plurality of rectangular multi-core optical contact pins and an integrated connector. The connector comprises a connector casing which is provided with contact pin installation channels that extend from the incoming end of the optical fiber to the insertion end and a plurality of parallelly equipped rectangular multi-core optical fiber contact pins. Each contact pin installation channel is provided with a spring stopping structure and a spring which is provided between the spring stopping structure and the contact pin with a contacting mode. The connector casing is inserted and fixed with a press plate. Each contact pin installation channel comprises a corresponding front part and a corresponding back part which are respectively installed in the casing and the press plate. The press plate is provided with a back end plane which is installed at the back end of the connector casing. Furthermore the back end plane is provided with an optical fiber insertion opening communicated with the back part of the contact pin installation channel. The spring stopping structure is provided in the back part of the contact pin installation channel in the press plate. The optical fiber connector of the invention has the advantages of: compact structure of contact pin fixing structure, strong wholeness and suitability for the fast pulling-inserting occasion.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Transmission mechanism suitable for waist rehabilitation robot and control method

ActiveCN107928988ARealize real-time detectionRealize intelligenceChiropractic devicesMovement coordination devicesEngineeringPneumatic artificial muscles

To overcome the deficiencies of the prior art, the invention provides a transmission mechanism suitable for a waist rehabilitation robot and a control method. The transmission mechanism suitable for the waist rehabilitation robot includes a bracket, a pneumatic artificial muscle, a base plate, a rope winding mechanism, a guide mechanism, a rope, a top beam, a waist movement assembly and a leg movement assembly. According to the control method, the clamping can be performed when shutdown is required, and thus rope disorder caused by inertia during sudden shutdown is avoided. The transmission mechanism has the advantages that a state of a rope on the rope winding mechanism can be monitored, to prevent the rope disorder; a pretightening force is provided automatically for the rope, the trouble of manually providing the pretightening force is avoided, the mechanism intelligence is achieved, and the safety, reliability and economic value are improved.

Owner:HEFEI UNIV OF TECH

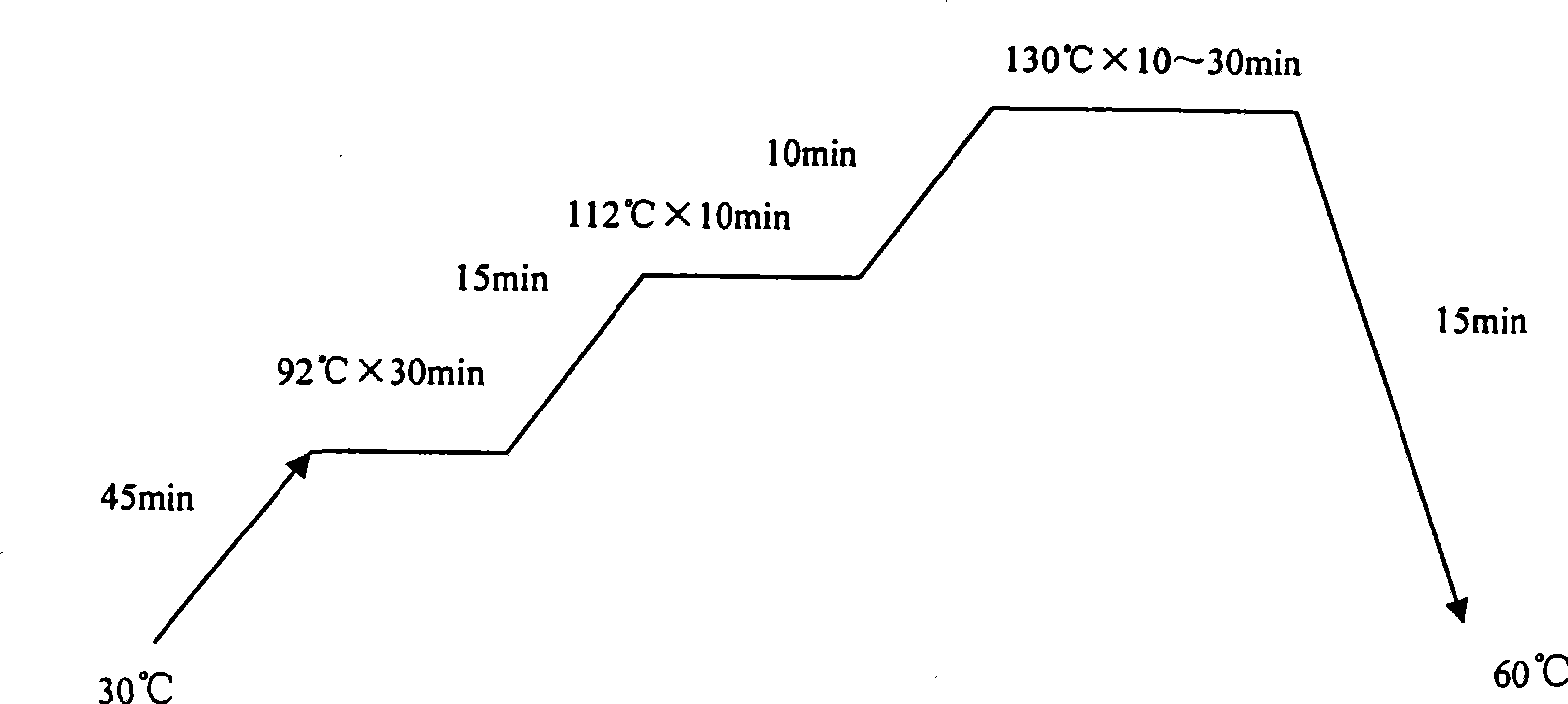

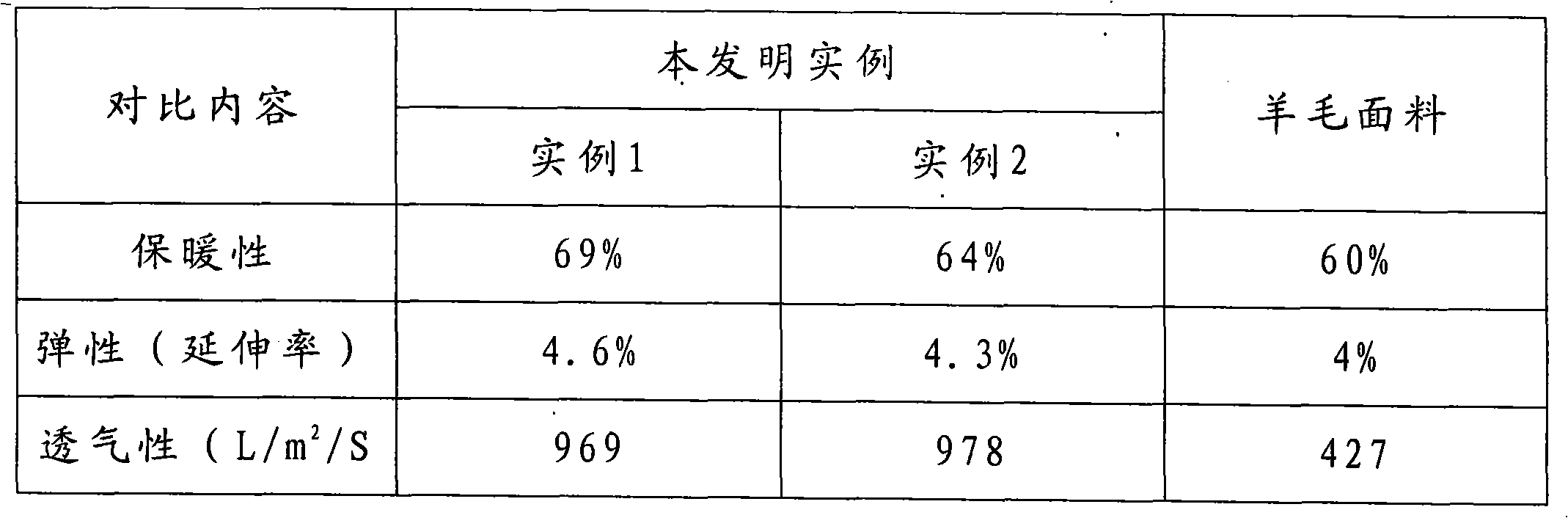

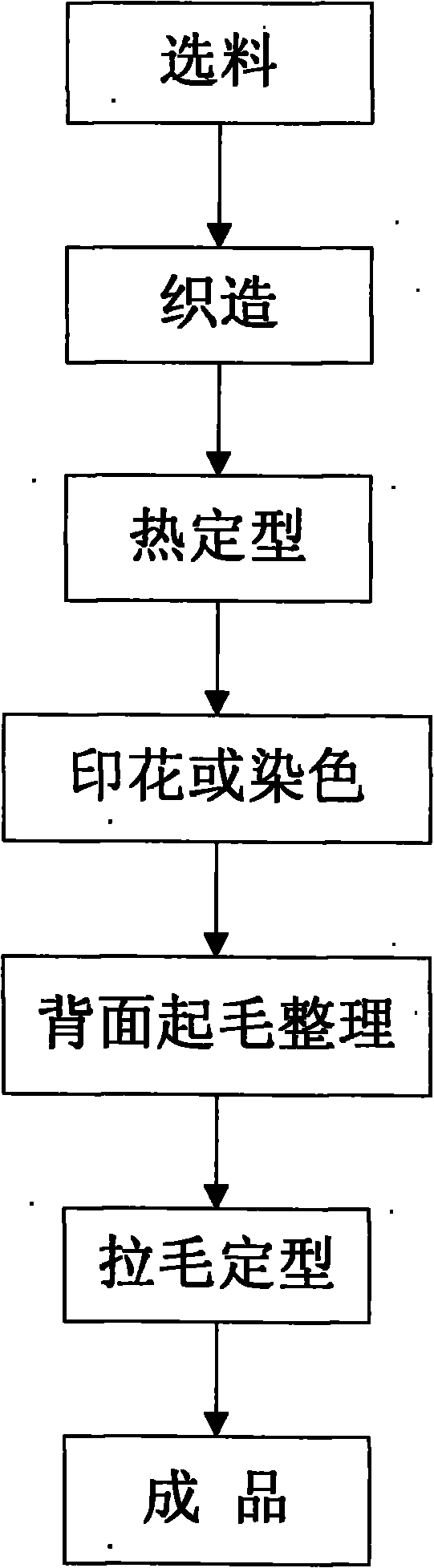

Slip warming fiber fabric and processing technique thereof

InactiveCN101942739AGood anti-hair effectIncrease elasticityWarp knittingPolyesterMoisture absorption

The invention discloses a slip warming fiber fabric, which comprises surface silks and bottom silks, wherein the surface silks are woven on the bottom silks to form lint; the surface silks are composite silks of DTY flat silks and FDY flat silks; and the bottom silks are FDY polyester silks. The invention also discloses a processing technique for the fiber fabric, which comprises the following steps of: material selection, weaving, heat setting, printing or dyeing, back fuzz finishing and napping sizing, wherein in the material selection step, the surface silks are composite silks of DTY flat silks and FDY flat silks; and in the weaving step, the weaving equipment is a tricot machine or a loom. Proper fiber raw materials, brand-new preparation processes and equipment are synthesized; the finished product has stable gram weight, the hair side has strong third dimension, and the hair height achieves the expected effect; and the fabric is exquisite and smooth, soft in handfeel, light, thin and warm-keeping, has good moisture absorption property, no hair loss and bright color, and can directly contact the skin.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

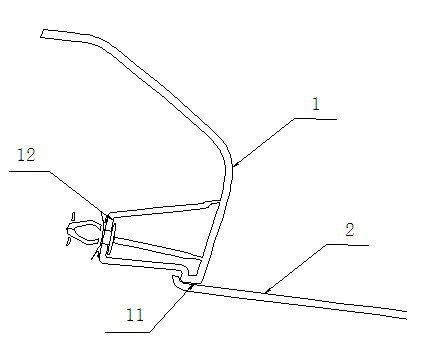

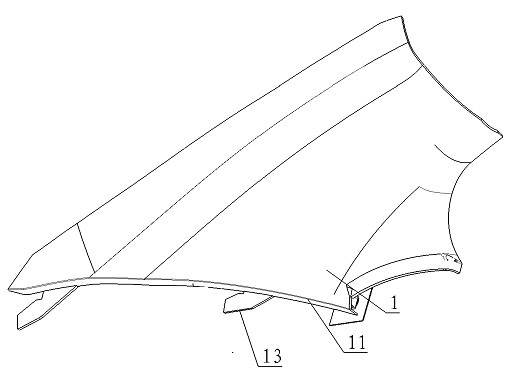

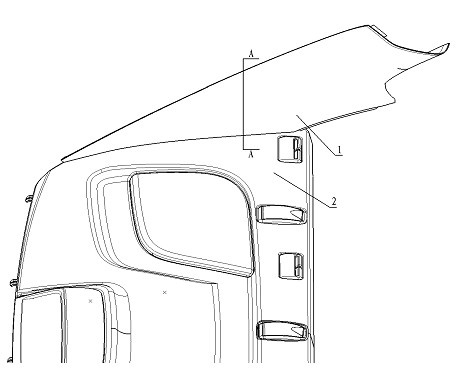

Installation structure of C stand column interior trimming plate of automobile

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com