Slip warming fiber fabric and processing technique thereof

A thermal fiber and processing technology, applied in textiles and papermaking, knitting, warp knitting and other directions, can solve the problems of poor hand feel and poor thermal insulation, and achieve the effect of good hygroscopicity, bright color and no hair loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

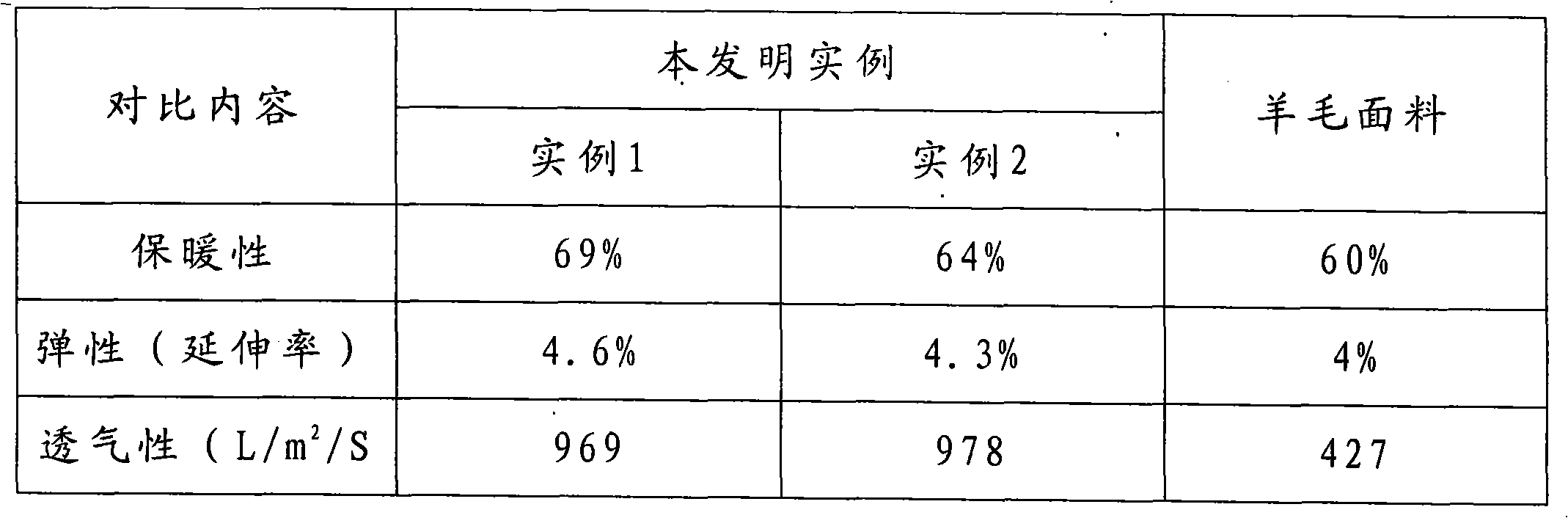

Examples

Embodiment 1

[0028] (1) Material selection: use 200D / 240F composite yarn compounded with 50% DTY flat yarn and 50% FD Y flat yarn as the top yarn, 68D polyester FDY as the bottom yarn; the top yarn accounts for 65%, and the bottom yarn accounts for 35%;

[0029] (2) Weaving: A double needle bed Lahr warp knitting machine is used, using a latch needle type, the weaving speed is up to 600 courses / minute, and the inch row speed is 20 courses / minute. The woven gray fabric has a plush height of 20mm, a gram weight of about 250 grams per square meter, and is flat and without horizontal stripes.

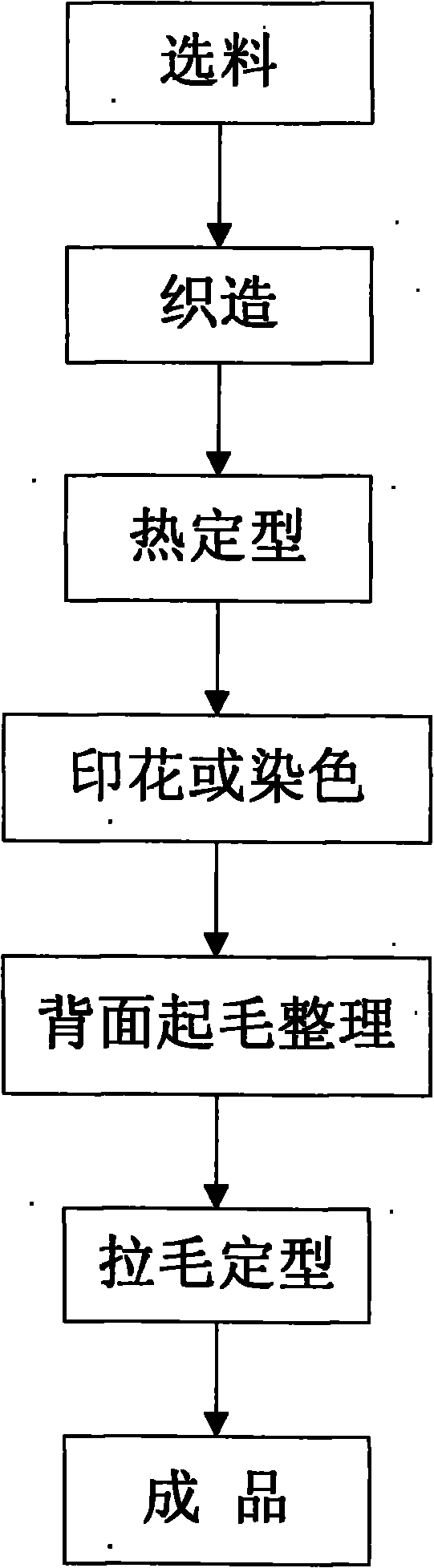

[0030] (3) Subsequent processing of the gray cloth: heat setting, printing or dyeing, back raising finishing, napping and setting;

Embodiment 2

[0032] (1) Material selection: use 150D / 96F composite yarn compounded with 10% DTY flat yarn and 90% FDY flat yarn as the top yarn, 100D polyester FDY as the bottom yarn; the top yarn accounts for 75%, and the bottom yarn accounts for 25%;

[0033] (2) Weaving: A double needle bed Lahr warp knitting machine is used, using a latch needle type, the weaving speed is up to 600 courses / minute, and the inch row speed is 20 courses / minute. The woven gray fabric has a plush height of 8mm, a gram weight of about 220 grams per square meter, and is flat and without horizontal stripes.

[0034] (3) Subsequent processing of the gray cloth: heat setting, printing or dyeing, back raising finishing, napping and setting;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com