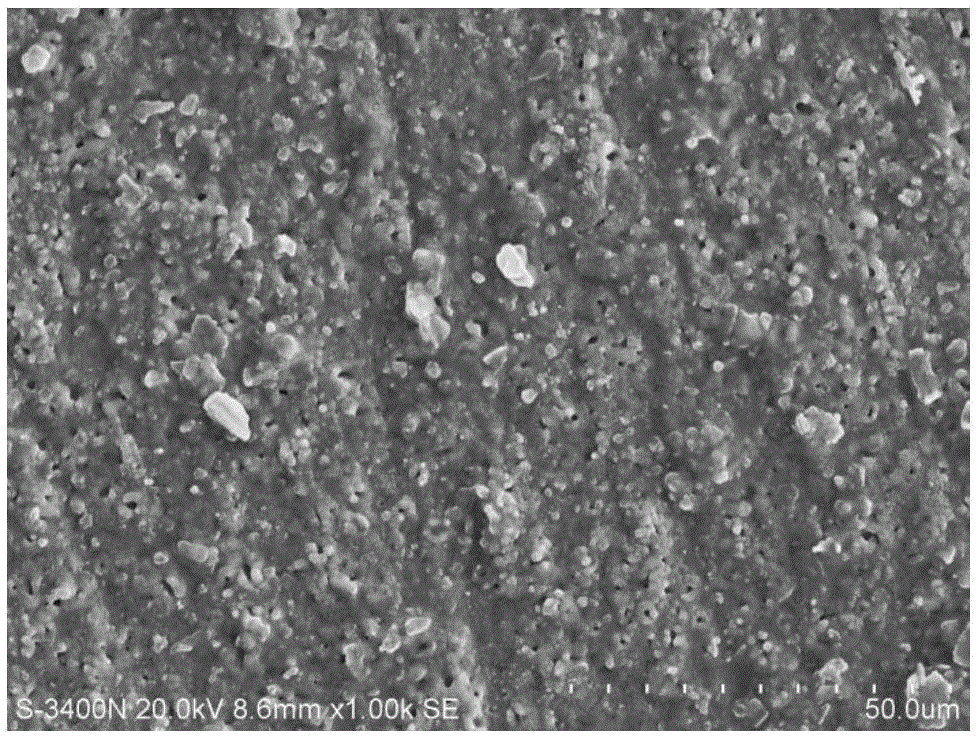

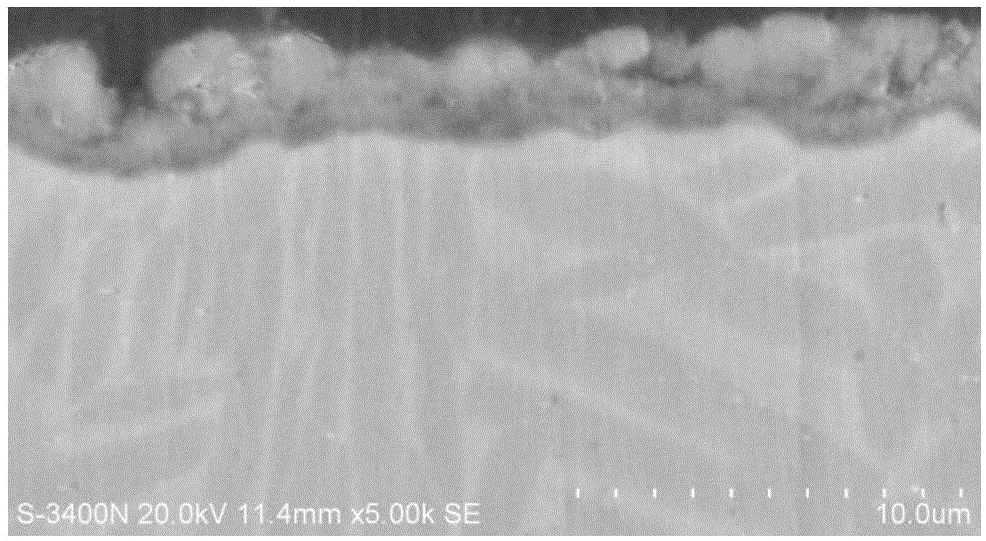

Method for preparing nano SiO2 containing coating on surface of cast aluminium alloy through micro-arc oxidation

A casting aluminum alloy, micro-arc oxidation technology, applied in the direction of coating, anodic oxidation, electrolytic coating, etc., can solve the problems of easy looseness of aluminum alloy micro-arc oxidation coating, poor film surface finish, uneven color, etc., to achieve the applicable Wide range, good coating density and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of nano-SiO by micro-arc oxidation on the surface of cast aluminum alloy 2 A coating method comprising the steps of:

[0025] 1. Pretreatment: Sand the cast aluminum alloy sample step by step with sandpaper until the surface is smooth without obvious scratches, then ultrasonically clean it in acetone for 10 minutes, and air dry at room temperature;

[0026] 2. SiO 2 Nanoparticle treatment: SiO with particle size less than 100nm 2 Nanoparticles were soaked in a solution of non-ionic surfactant OP-21 with a concentration of 1g / L for 8 minutes, and dispersed ultrasonically, with an ultrasonic frequency of 40kHz and a treatment time of 10min;

[0027] 3. Prepare the coating: take the cast aluminum alloy sample as the anode and the stainless steel plate as the cathode, immerse the anode in the electrolyte, then apply a pulse voltage between the cathode and the anode, and perform micro-arc oxidation in constant voltage mode. The stirring speed is 60r / min, the p...

Embodiment 2

[0033] 1. Pretreatment: Sand the cast aluminum alloy sample step by step with sandpaper until the surface is smooth without obvious scratches, then ultrasonically clean it in alcohol for 25 minutes, and air dry at room temperature;

[0034] 2. SiO 2 Nanoparticle treatment: SiO with particle size less than 100nm 2 Nanoparticles were soaked in a solution of non-ionic surfactant OP-21 with a concentration of 5g / L for 15 minutes, and dispersed ultrasonically, with an ultrasonic frequency of 60kHz and a treatment time of 25 minutes;

[0035] 3. Prepare the coating: take the cast aluminum alloy sample as the anode and the stainless steel plate as the cathode, immerse the anode in the electrolyte, then apply a pulse voltage between the cathode and the anode, and perform micro-arc oxidation in constant voltage mode. The stirring speed is 90r / min, the processing temperature does not exceed 60°C, and the processing time is 60min.

[0036] The electrical characteristic parameters are: ...

Embodiment 3

[0041] 1. Pretreatment: Sand the cast aluminum alloy sample step by step with sandpaper until the surface is smooth without obvious scratches, then ultrasonically clean it in acetone for 30 minutes, and air dry at room temperature;

[0042] 2. SiO 2 Nanoparticle treatment: SiO with particle size less than 100nm 2 Nanoparticles were soaked in a solution of non-ionic surfactant OP-21 with a concentration of 10g / L for 20 minutes, and dispersed by ultrasonic, with an ultrasonic frequency of 50kHz and a treatment time of 15 minutes;

[0043] 3. Prepare the coating: take the cast aluminum alloy sample as the anode and the stainless steel plate as the cathode, immerse the anode in the electrolyte, then apply a pulse voltage between the cathode and the anode, and perform micro-arc oxidation under constant current mode. The stirring speed is 220r / min, the treatment temperature does not exceed 40°C, and the treatment time is 40min.

[0044] The electrical characteristic parameters are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com