Ropeless type built-in shutter hollow glass

A louver hollow glass, cordless technology, applied in the direction of door/window protection devices, windows/doors, building components, etc., can solve the problems of loosing and breaking of louvers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

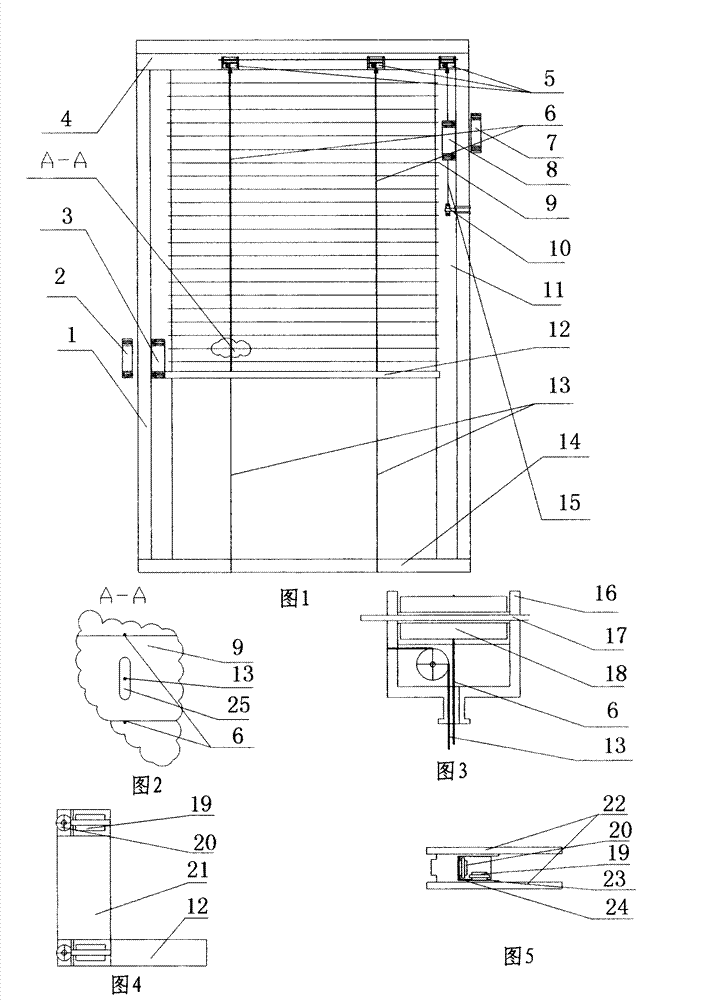

[0015] In the figure, the frame is composed of left frame 1, upper frame 4, right frame 11 and lower frame 14. Glass 22 is installed on the front and back of the frame. The lifting system consists of lifting control magnet 2, lifting mechanism 3, lifting rod 12, lifting The iron sheet 24 and the positioning iron sheet 23 are composed, the lifting mechanism 3 is composed of the lifting pulley 19, the positioning pulley 20 and the magnet 21, the louver system is composed of the louver blade 9, the positioning wire 13 and the ladder rope 6, and the louver blade 9 is provided with a louver blade Hole 25, overturning system is made up of overturning control magnet 7, overturning magnet 8, support 5, overturning rope 15 and following overturning wheel 10, and support 5 is made up of bearing 16, overturning shaft 17 and upper overturning wheel 18, and lifting control magnet 2 and Flip control magnet 7 is installed outside the glass for easy operation.

[0016] The working principle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com