Locking bolt/nut

A technology for preventing loosening of bolts and nuts, applied in the directions of bolts, nuts, screws, etc., can solve problems such as bolt loosening, and achieve the effects of enhanced locking force, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

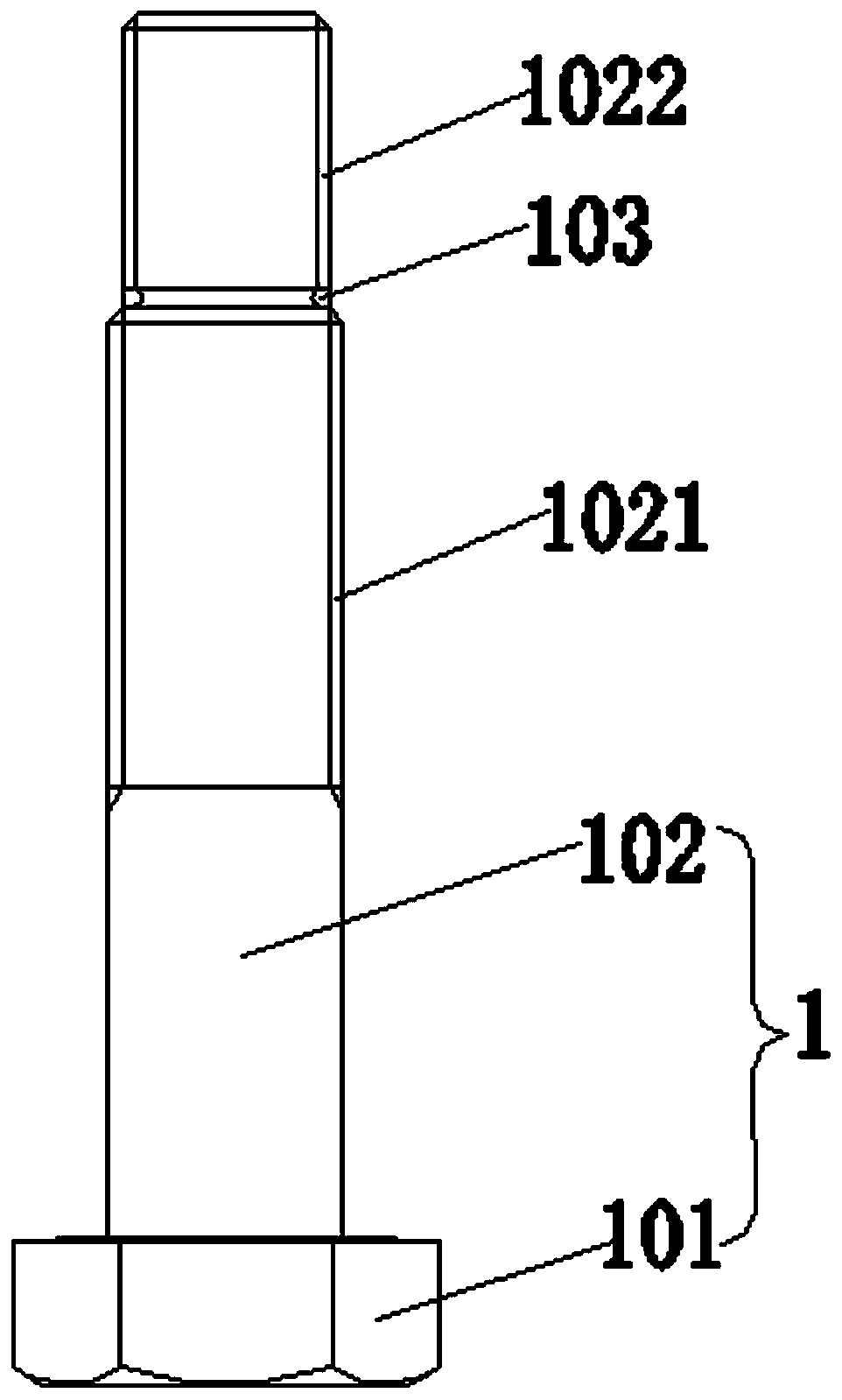

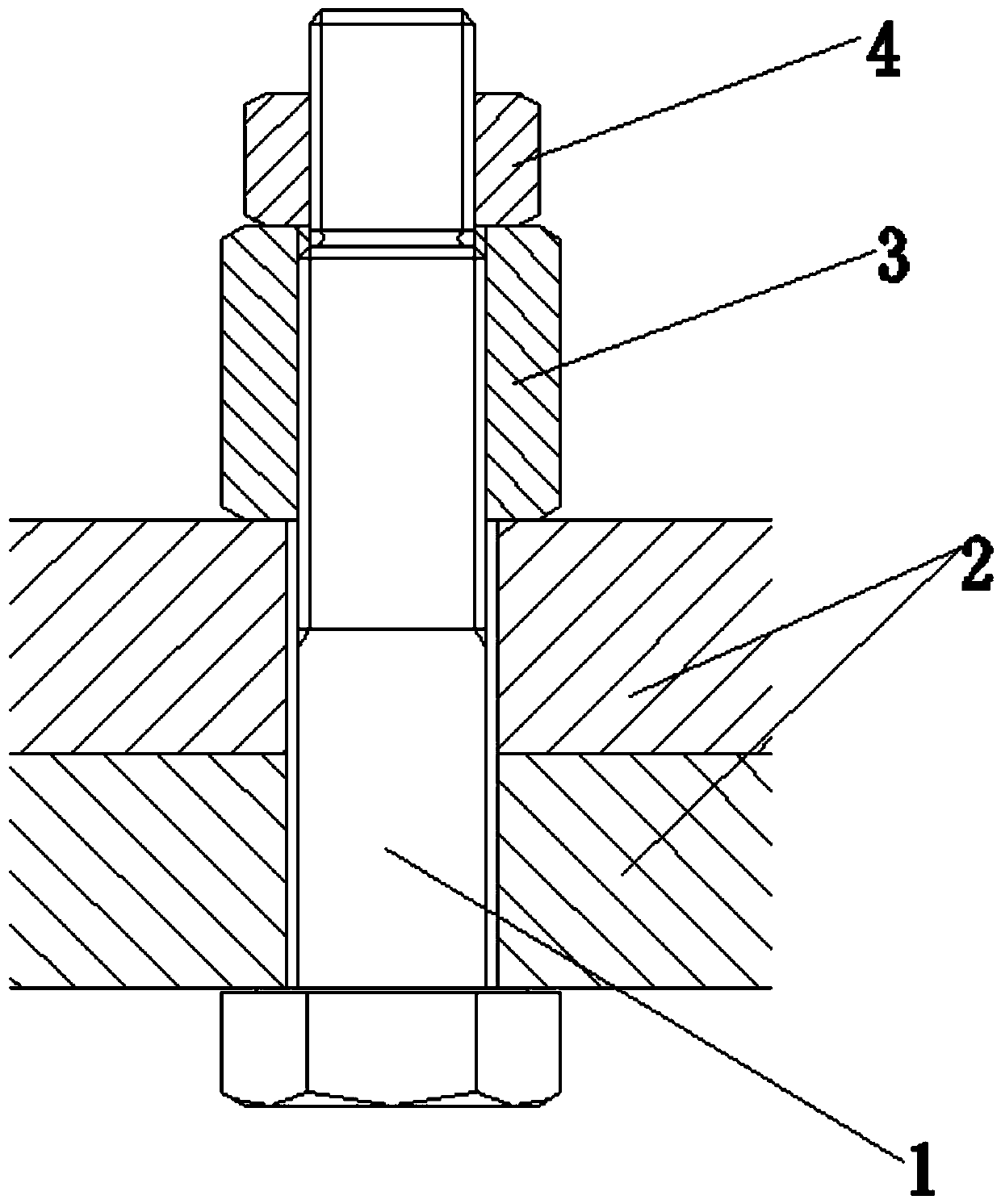

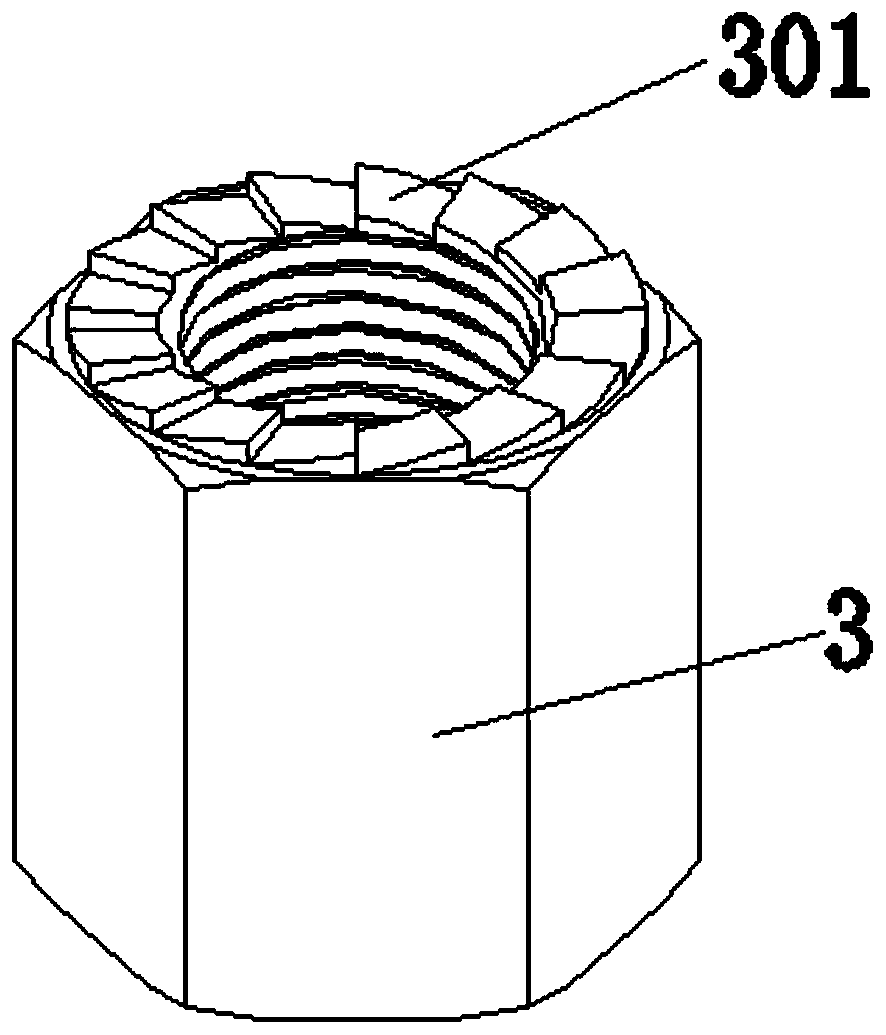

[0044] like Figure 1~2 As shown, the present embodiment provides an anti-loosening bolt and nut, including a bolt 1, a first nut 3 and a second nut 4, the bolt 1 includes a fixed end 101 and a screw rod 102, and the screw rod 102 is provided with a first thread 1021 and a second screw thread 102. Thread 1022, the first thread 1021 and the second thread 1022 have opposite screw rotation directions; the screw rod 102 penetrates into the connected part 2, and is screwed into the first nut 3 and the second nut 4 in turn to make the connected part 2 close to the The fixed end 101; the first nut 3 has an inner thread that matches the first thread 1021, and the first nut 3 is connected with the first thread 1021 on the screw rod 102; the second nut 4 has an inner thread that matches the second thread 1022 thread, the second nut 4 is coupled with the second thread 1022 on the screw rod 102; the nominal diameter of the first thread 1021 is larger than the nominal diameter of the secon...

Embodiment 2

[0050] This embodiment provides an anti-loosening bolt and nut, including a bolt 1, a first nut 3 and a second nut 4, the bolt 1 includes a fixed end 101 and a screw rod 102, and the screw rod 102 is provided with a first thread 1021 and a second thread 1022, The screw rotation direction of the first thread 1021 and the second thread 1022 are set in opposite directions; the screw rod 102 penetrates into the connected part 2, and is screwed into the first nut 3 and the second nut 4 in turn to make the connected part 2 close to the fixed end 101 ; The first nut 3 has an internal thread that cooperates with the first thread 1021, and the first nut 3 is connected with the first thread 1021 on the screw rod 102; the second nut 4 has an internal thread that cooperates with the second thread 1022, and the second The nut 4 is coupled with the second thread 1022 on the screw rod 102 ; the nominal diameter of the first thread 1021 is larger than the nominal diameter of the second thread ...

Embodiment 3

[0060] This embodiment provides an anti-loosening bolt and nut, including a bolt 1, a first nut 3 and a second nut 4, the bolt 1 includes a fixed end 101 and a screw rod 102, and the screw rod 102 is provided with a first thread 1021 and a second thread 1022, The screw rotation direction of the first thread 1021 and the second thread 1022 are set in opposite directions; the screw rod 102 penetrates into the connected part 2, and is screwed into the first nut 3 and the second nut 4 in turn to make the connected part 2 close to the fixed end 101 ; The first nut 3 has an internal thread that cooperates with the first thread 1021, and the first nut 3 is connected with the first thread 1021 on the screw rod 102; the second nut 4 has an internal thread that cooperates with the second thread 1022, and the second The nut 4 is coupled with the second thread 1022 on the screw rod 102 ; the nominal diameter of the first thread 1021 is larger than the nominal diameter of the second thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com