Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Solve large-scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

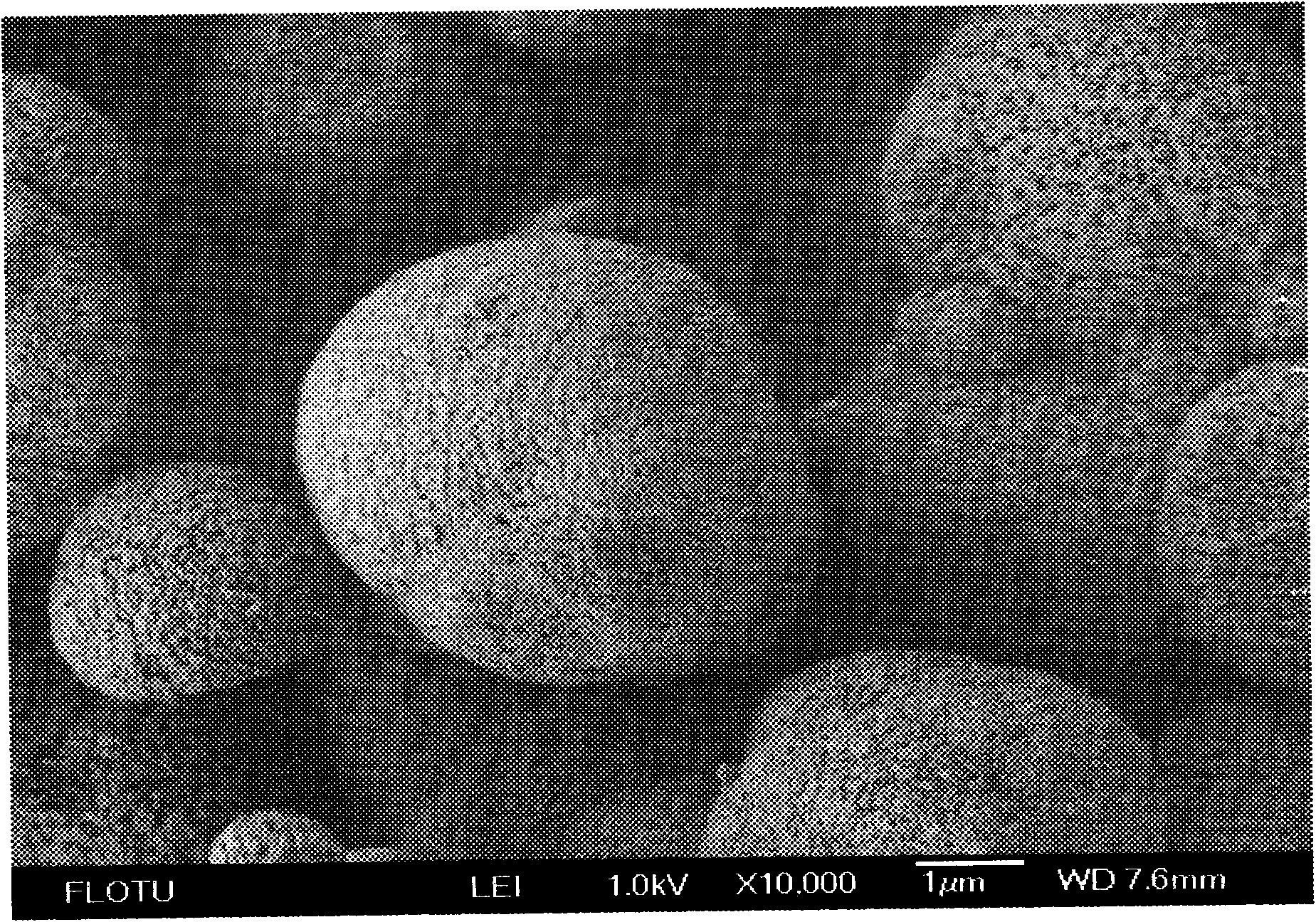

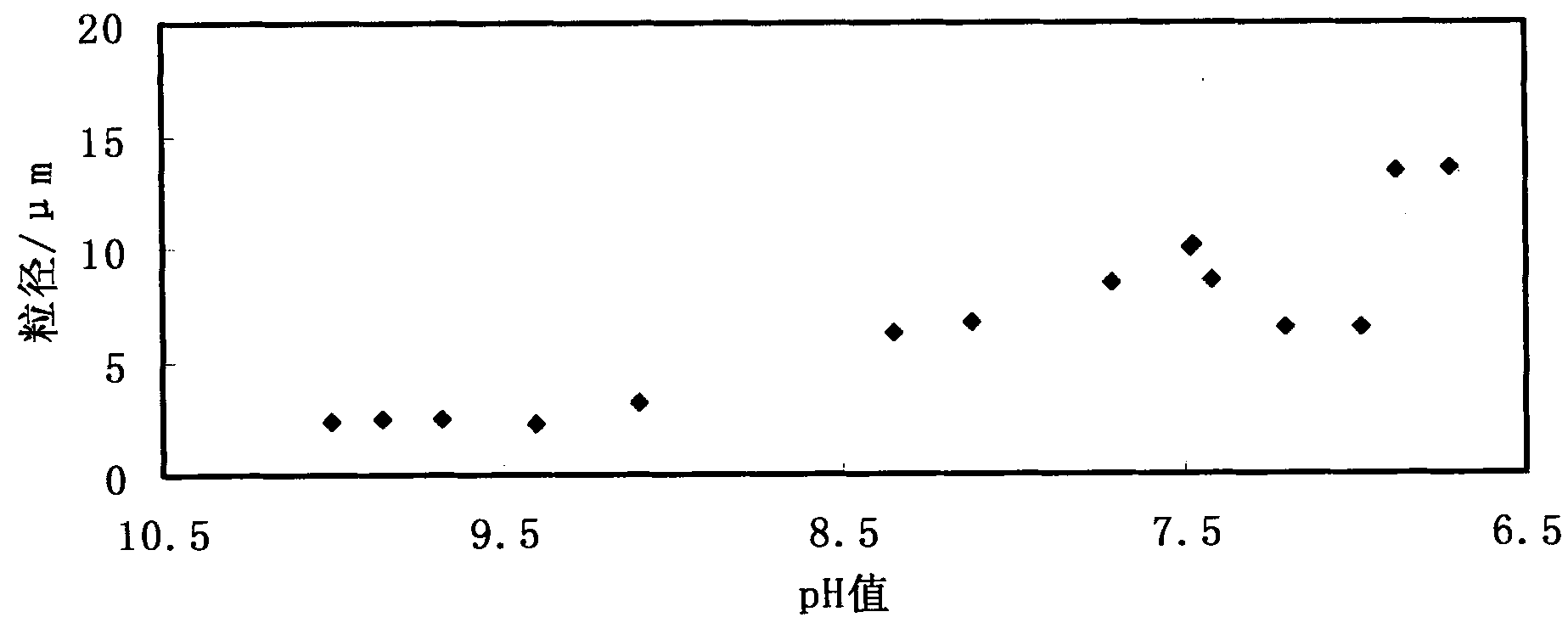

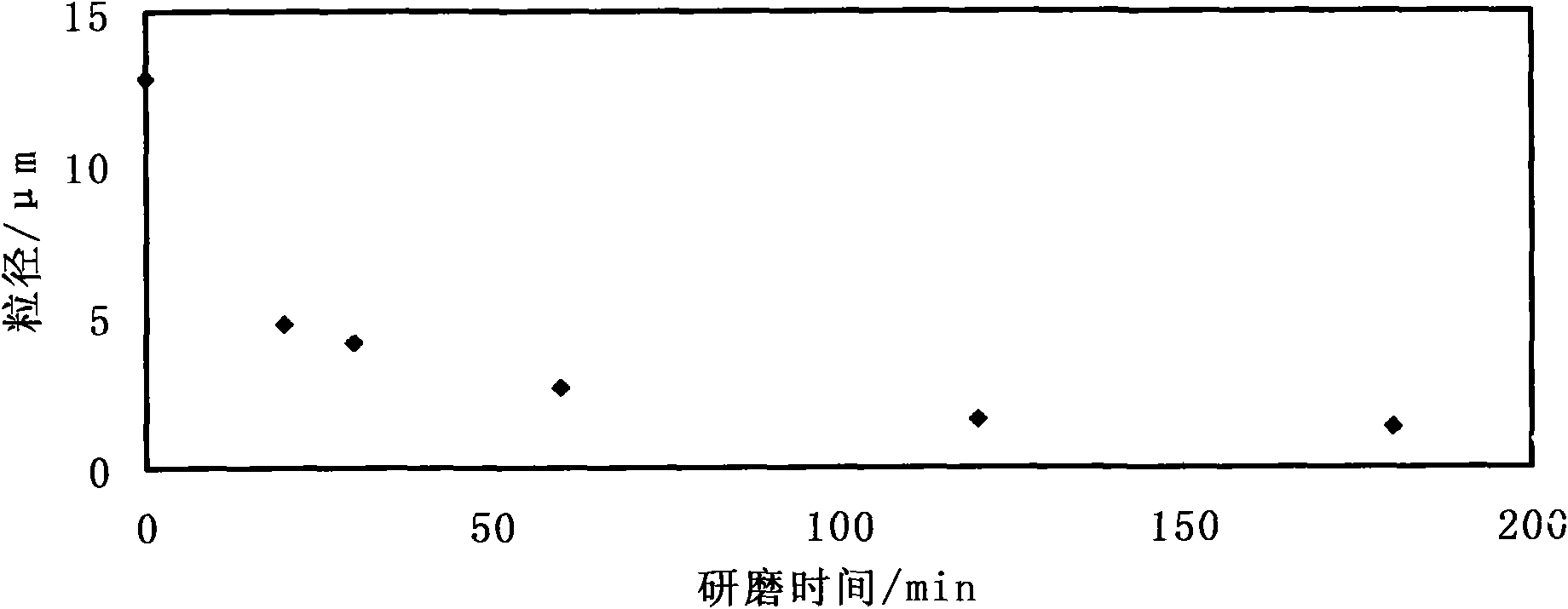

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

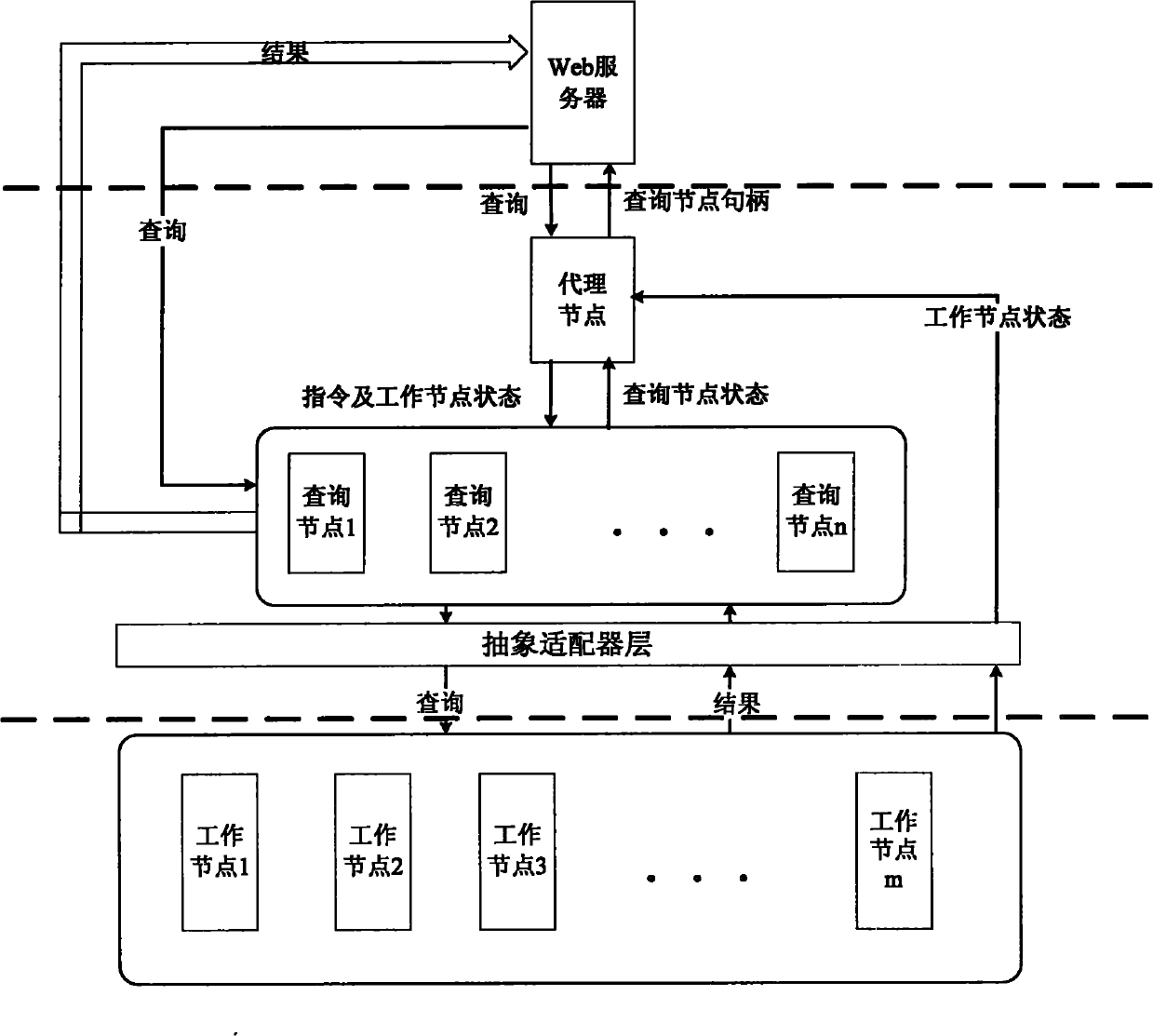

Hierarchical structure, distributed search engine system and implementation method thereof

InactiveCN101950300ASolve large-scaleImprove performanceSpecial data processing applicationsWeb serviceInformation retrieval

The invention discloses a hierarchical structure applied to a distributed search engine. The hierarchical structure comprises a physical layer, an abstract layer, an application layer and a presentation layer. The invention also discloses a distributed search engine system, which comprises a Web server, an agent node, a query agent pool, an abstract adapter and a plurality of working nodes, wherein the query agent pool consists of a plurality of query nodes. The invention also discloses an implement method for the distributed search engine system, which comprises the following steps of: S1, registration of a query node; S2, registration of working nodes; S3, state update of the nodes; and S4, distribution and retrieval of a query request. The hierarchical structure has the advantages of good performance, high reliability, diversification, specialization, strong applicability and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

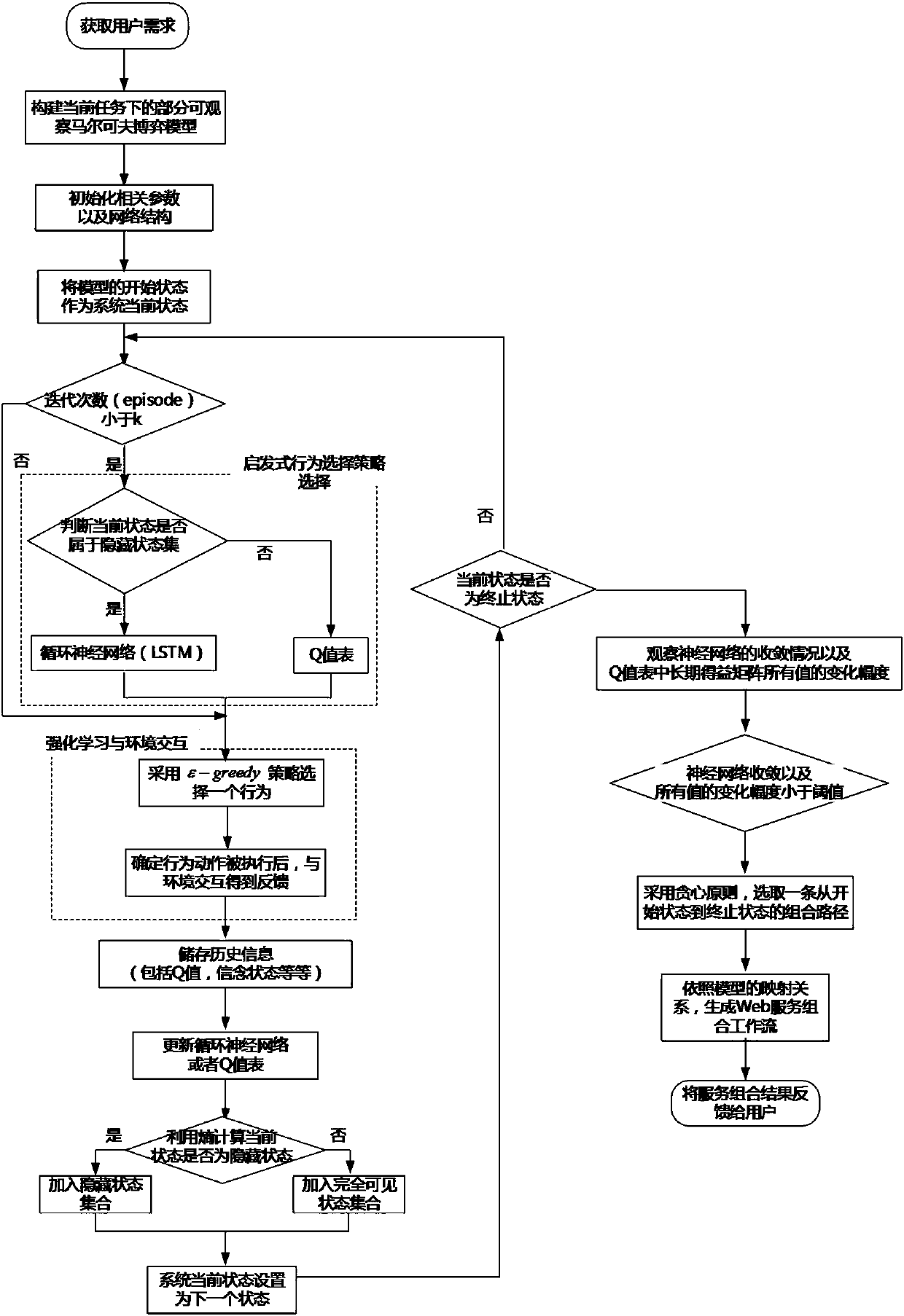

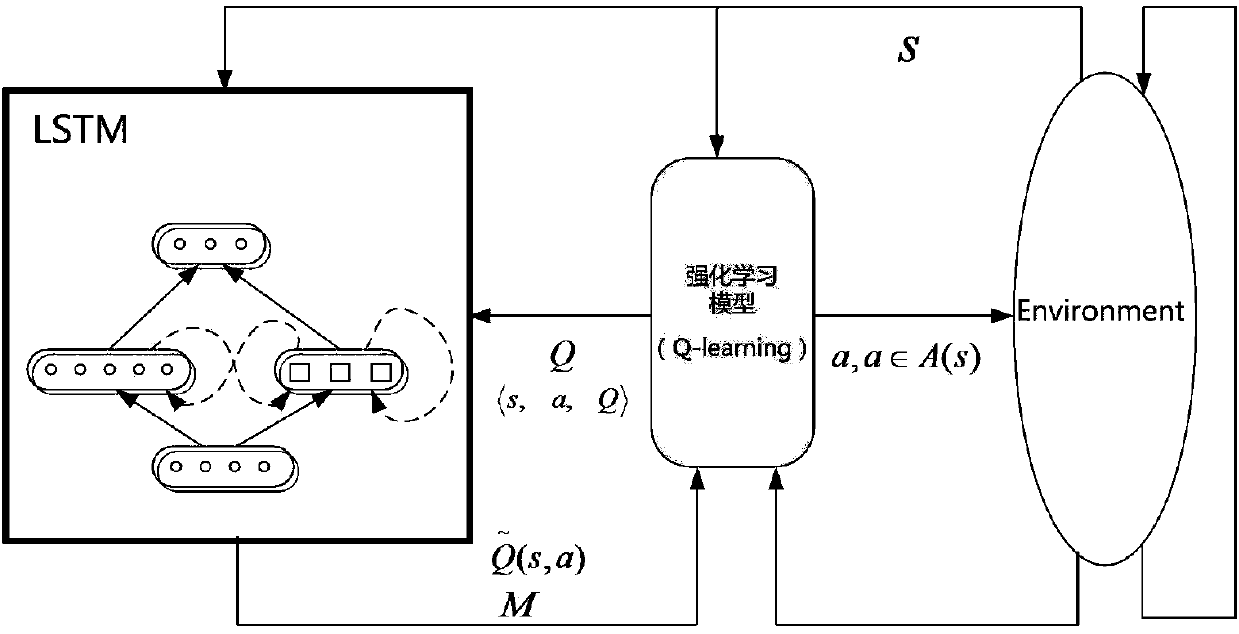

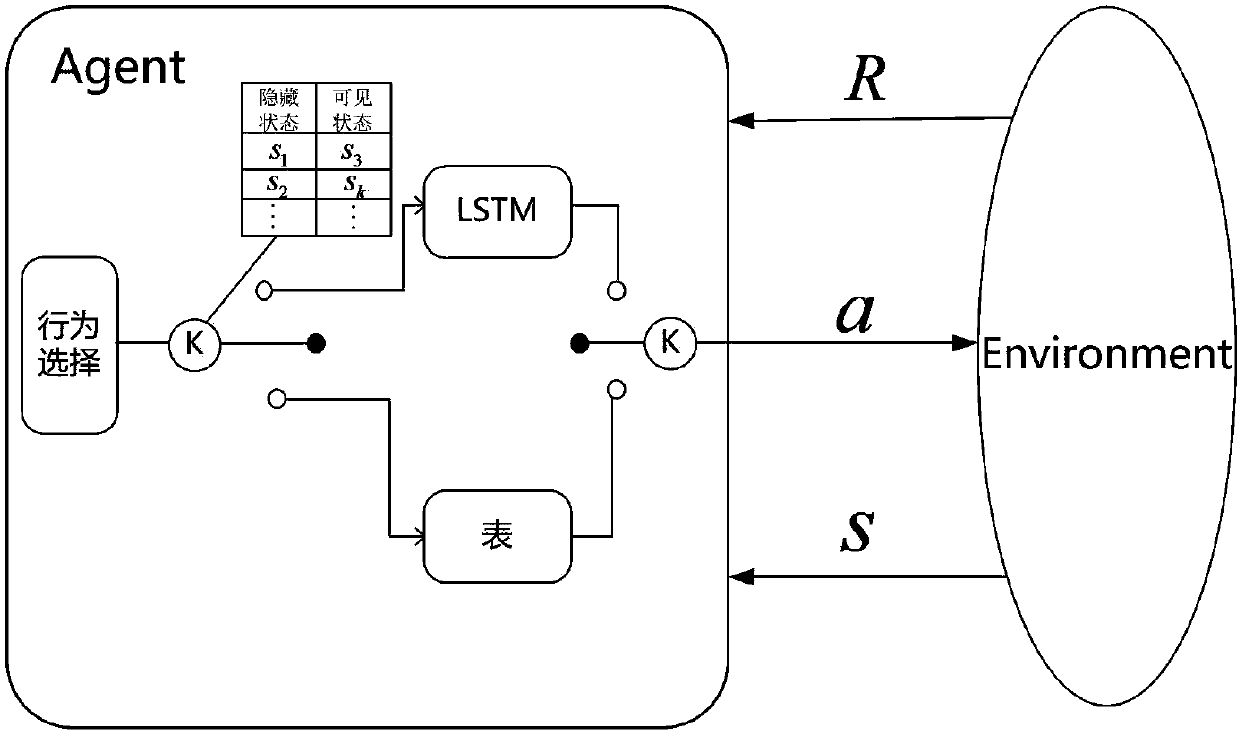

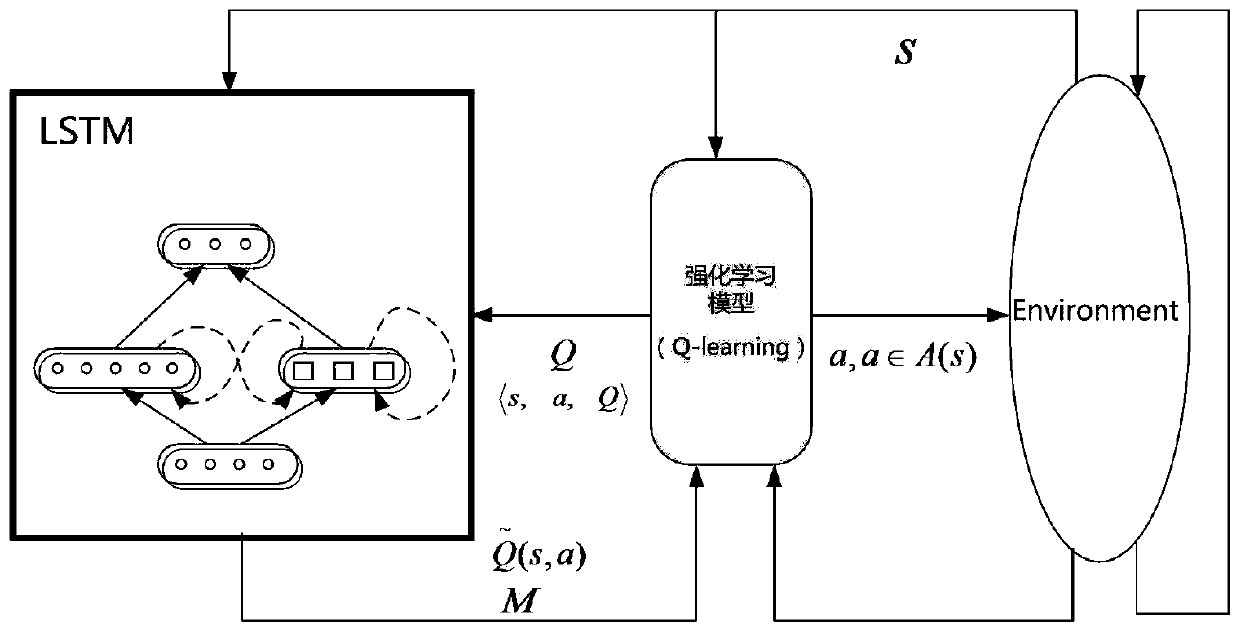

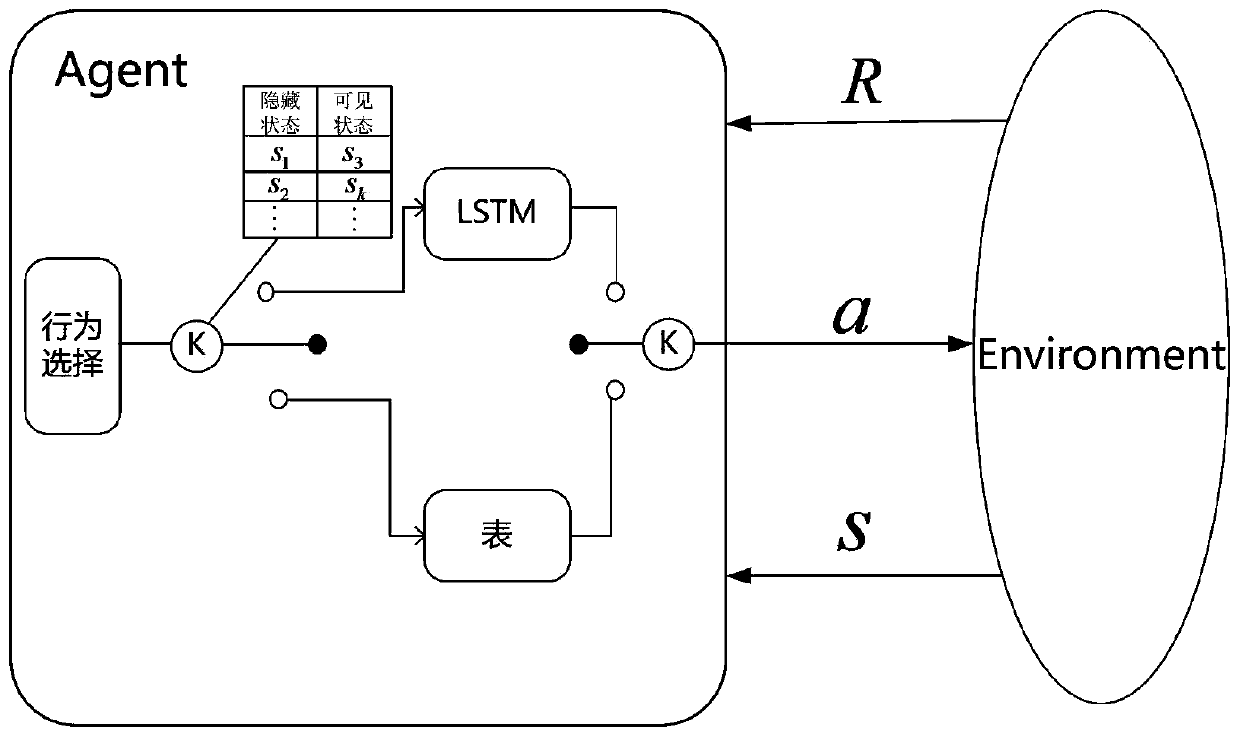

Web service combination method based on depth reinforcement learning

ActiveCN107241213ASolving Partial ObservabilityAccurately combine resultsData switching networksNeural learning methodsService compositionCurse of dimensionality

The invention discloses a web service combination method based on depth reinforcement learning for overcoming the problems of long time consumption, poor flexibility and non-ideal combination effect of the traditional service combination method in large-scale service scenes. The depth reinforcement learning technology and the heuristic thought are applied to the service combination problem. In addition, by considering the partial observability of the real environment, the service combination process is converted into a partially-observable Markov decision process POMDP, the solution problem of the POMDP is solved by using a recurrent neural network, and the method still expresses high efficiency encountering the challenge of curse of dimensionality. By adoption of the method provided by the invention, the solution speed can be effectively improved, the dynamic service combination environment is automatically adapted on the basis of ensuring the quality of the service combination scheme, and the adaptability and the flexibility of the service combination efficiency is effectively improved in a large-scale dynamic service combination scene.

Owner:SOUTHEAST UNIV

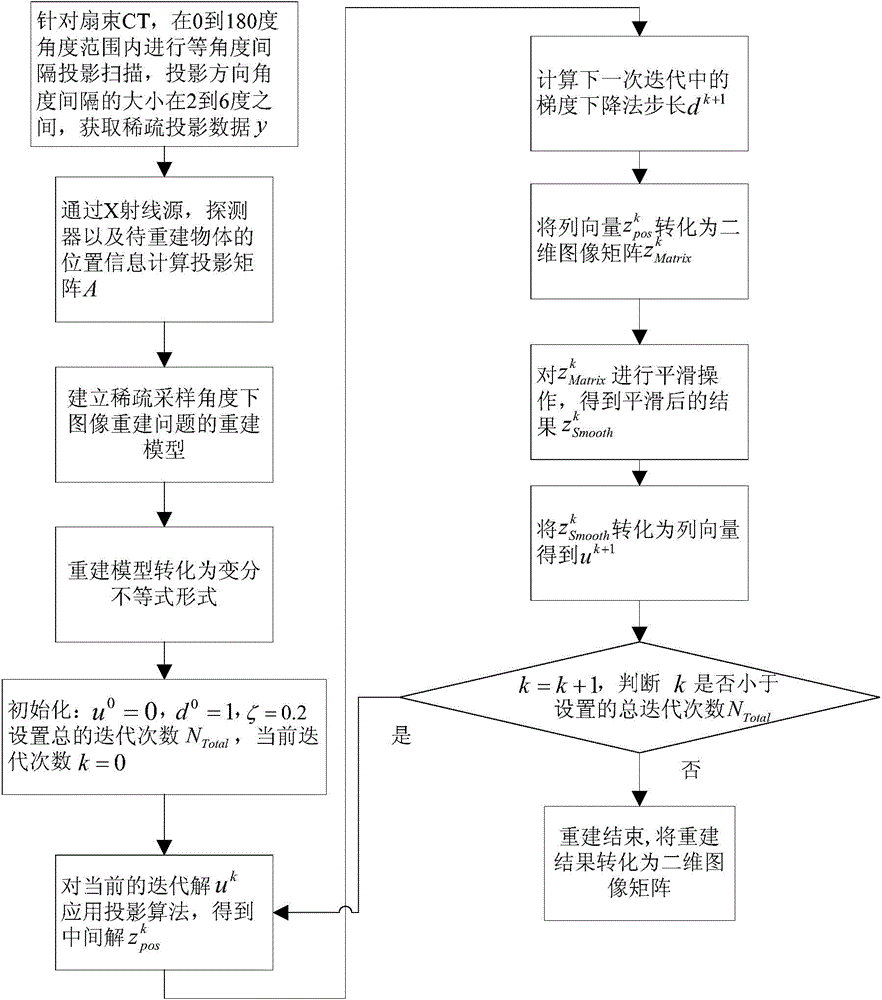

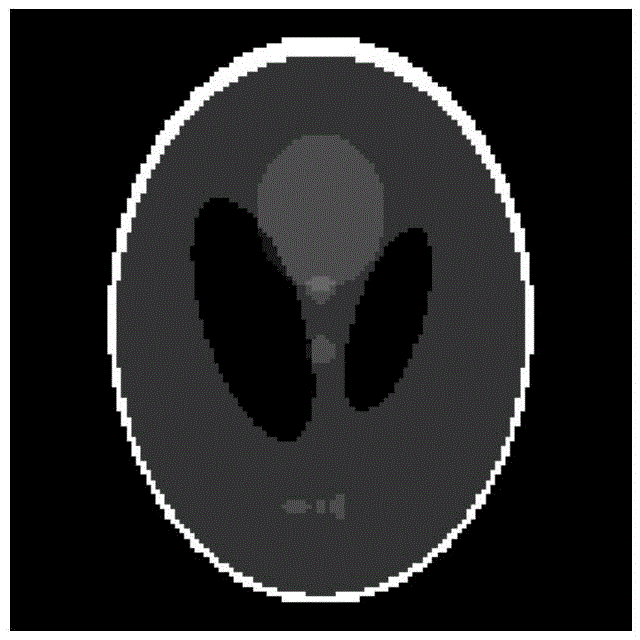

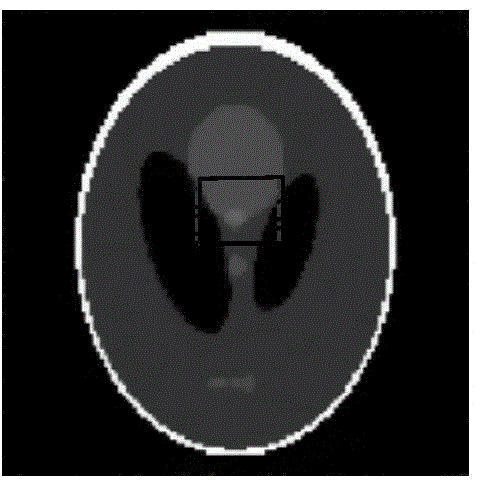

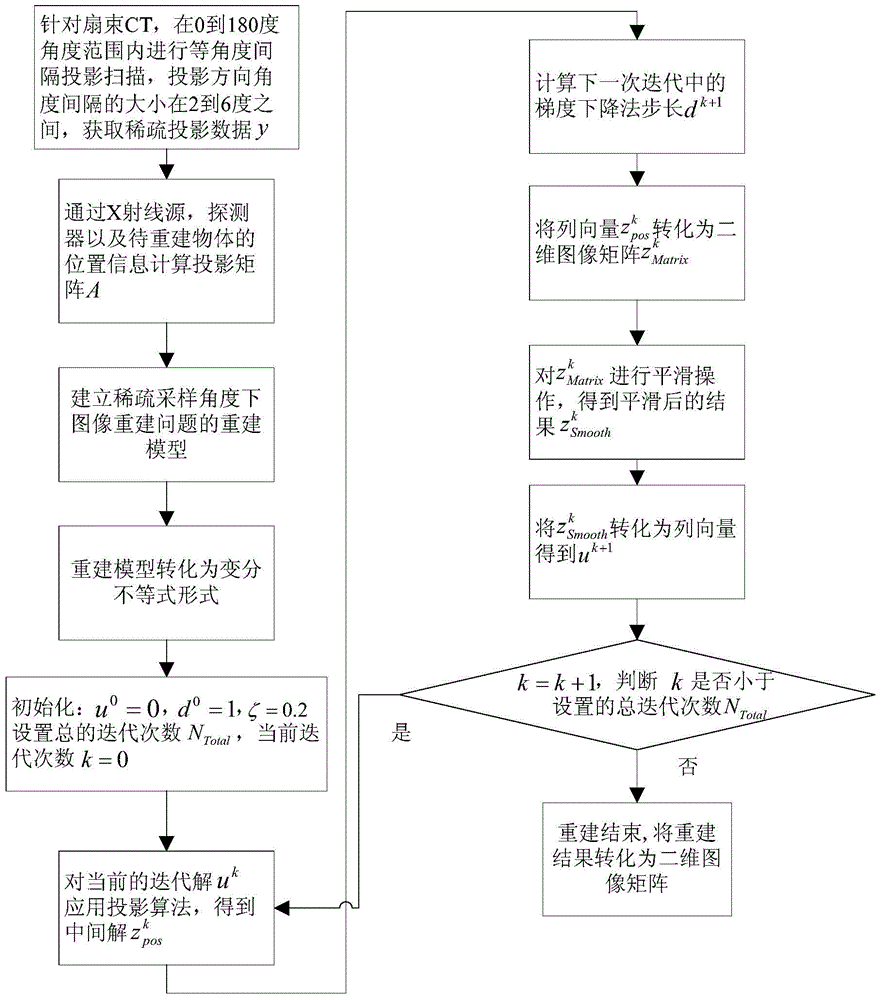

CT (Computed Tomography) image reconstruction method based on variational inequality at sparse sampling angle

ActiveCN104103086AGuaranteed piecewise smoothnessSmall amount of calculation2D-image generationComputerised tomographsHat matrixComputed tomography

The invention discloses a CT (Computed Tomography) image reconstruction method based on a variational inequality at a sparse sampling angle. The CT image reconstruction method comprises the following steps: (1) carrying out equal-angle interval projection scanning within an angle range of 0-180 degrees by aiming at a fan-beam CT to obtain spare projection data y, wherein an angle interval in a projection direction is between 2 and 6 degrees; (2) calculating a projection matrix A through an X-ray source, a detector and the position information of an object to be reconstructed; (3) according to the projection data y obtained in the step (1) and the projection matrix A obtained in the step (2), simultaneously introducing the sparsity and the non-negativity of an image gradient to serve as priori knowledge to obtain a reconstruction model of an image reconstruction problem at the sparse sampling angle; (4) converting the reconstruction model in the step (3) into a variational inequality form; and (5) solving the variational inequality in the step (4) to obtain a reconstructed image. On the premise that image reconstruction quality is guaranteed, reconstruction convergence speed can be quickened, and single-iteration time is shortened.

Owner:SOUTH CHINA UNIV OF TECH

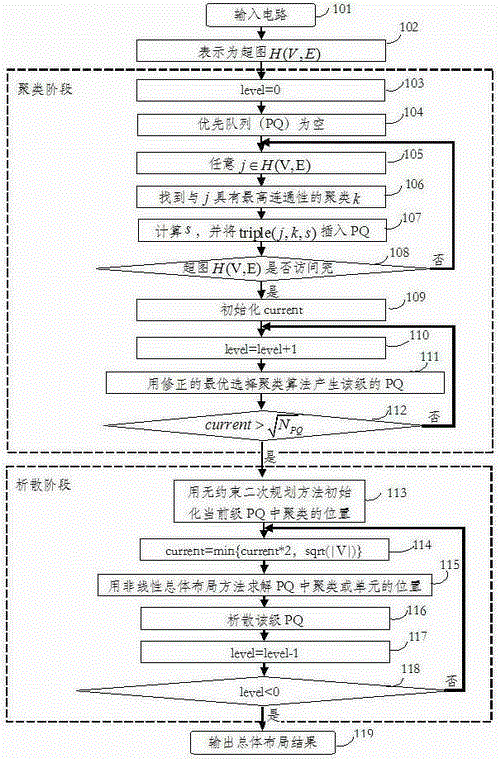

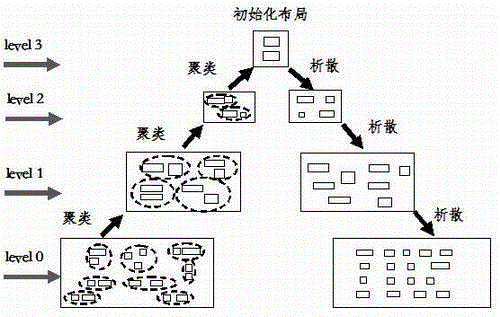

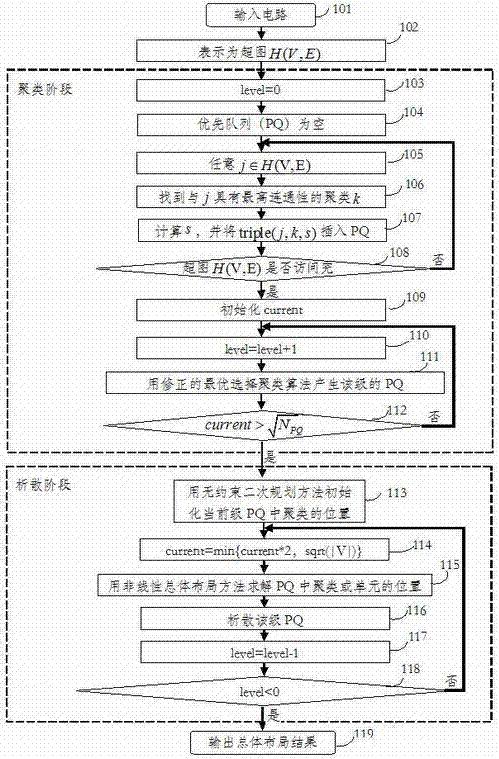

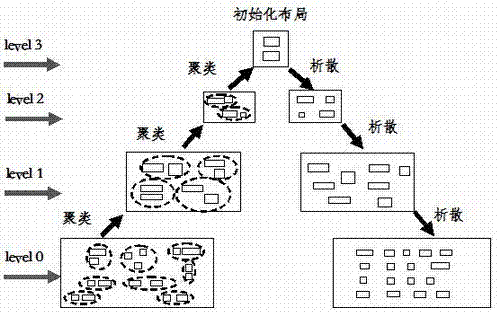

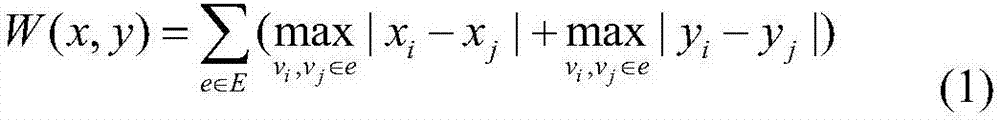

Very large scale integration (VLSI) standard unit overall arranging method based on L1 form model

InactiveCN103605820AImprove performanceEfficient and practical layout resultsSpecial data processing applicationsVery large scale integrated circuitsCluster algorithm

The invention relates to a very large scale integration (VLSI) standard unit overall arranging method based on an L1 form model and belongs to the technical field of VLSI physical design automation. The method includes indicating a circuit as a super graph, modeling a VLSI standard unit overall arranging problem which adopts semi-cycle long-line calculation with the density constrained to be non-smooth into an L1 form minimum problem, adopting an optimum selection clustering algorithm applicable to modification of an L1 form model in a clustering stage to conduct clustering on a unit and conducting declustering on clusters in a declustering stage by adopting a nonlinear planning overall arranging method. The VLSI standard unit overall arranging method is reasonable in arrangement, high in efficiency, practical and good in arranging effect.

Owner:FUZHOU UNIV

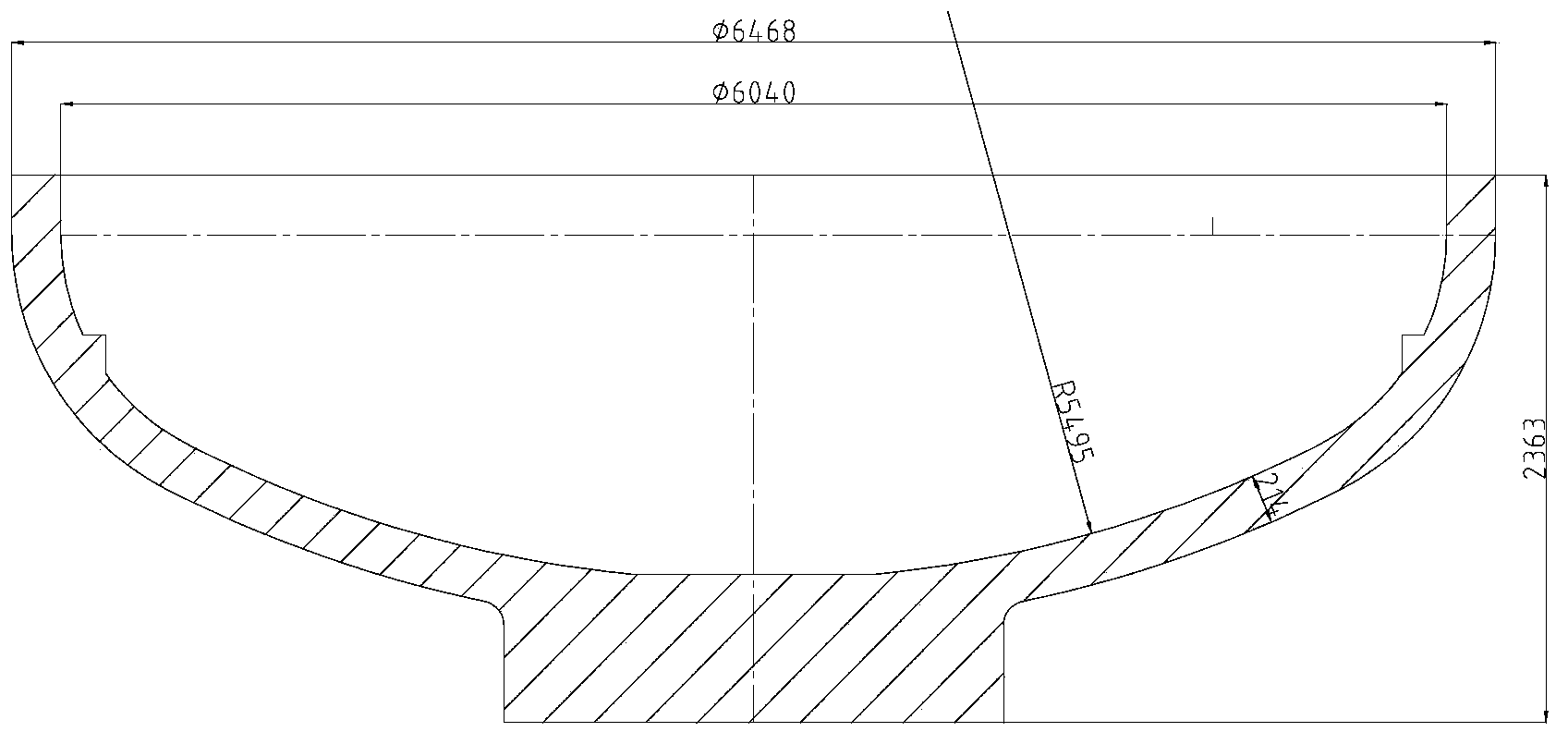

Forging method for elliptical seal head of CAP1400 steam generator

ActiveCN103567339ASolving Manufacturing ChallengesBloomMetal-working apparatusEngineeringMechanical engineering

The invention discloses a forging method for an elliptical seal head of a CAP1400 steam generator. The forging method comprises the steps of 1) manufacturing a blank; 2) heating; 3) assembling a die; 4) preforming; 5) stamping. By adopting the forging method, when the elliptical seal head with ultra-large size cannot be directly forged, firstly a circular plate blank with smaller diameter is preformed through a forging method of rotary drawing to increase the arc length of a workpiece and form an enough large circular-arc-shaped blank, and then the blank is stamped as a whole body to meet the requirement on the final size of the ultra-large size elliptical seal head. Therefore, the forging method for the elliptical seal head of the CAP1400 steam generator can effectively solve the problem that the large-sized and integrated forged piece of the elliptical seal head of the CAP1400 steam generator is difficult to manufacture.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

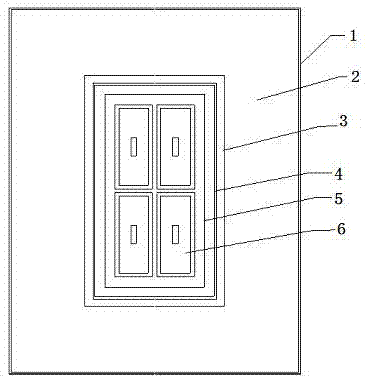

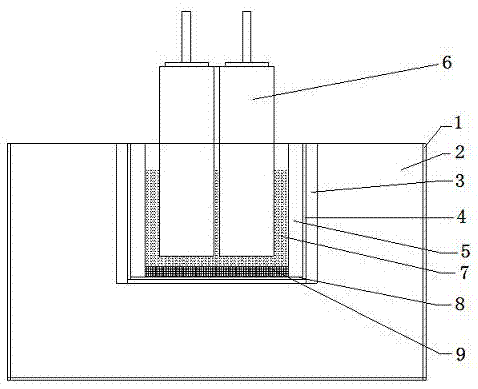

Rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using liquid cathode

InactiveCN105441987AImprove current efficiencyExtended service lifeCellsElectrodesRadiative heat lossRare-earth element

The invention discloses a rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using a liquid cathode. The rare earth fused-salt electrolysis cell mainly comprises an electrolysis cell body, an anode and the liquid cathode; the anode and the cathode are provided with horizontal planes parallel to and facing each other; the anode is vertically inserted in the electrolysis cell body; the liquid cathode is a liquid metal electrolyzed at the bottom; a tungsten plate is inlaid in the internal bottom of the electrolysis cell body; a molybdenum plate or a niobium plate can be taken as a cathode bottom plate or a rare earth metal catcher for an electrolytic product separated out on the cathode. The rare earth fused-salt electrolysis cell for producing rare earth metals and alloys by using the liquid cathode has the advantages of high current efficiency, low radiant heat losses, high anode utilization rate, long electrolysis cell service life and low investment of the electrolysis cell body; the single plant capacity can reach above 100 KA, the energy consumption per unit product is greatly reduced, and produced products are stable in quality, low in production cost and relatively closed.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

High-altitude tower embedded type vertical type wind power generation system

InactiveCN102840108ASolve the problem that it cannot be used for high-altitude signal transmission relay towersSolve large-scaleWind motor controlSingle network parallel feeding arrangementsTransmission towerAir volume

The invention discloses a high-altitude tower embedded type vertical type wind power generation system which comprises a high-altitude tower, a global position system (GPS) time service generator excitation grid-connection control system and a vertical type wind power generation system. The vertical type wind power generation system is arranged on the high-altitude tower, a GPS timing excitation grid-connection control mode is used, a GPS time service timer controls an excitation grid-connection control system which controls a wind-collect system and a vertical type generator excitation control system respectively, and a patulous angle of a wind-collect plate is controlled so that supply air rate of a wind power generator, generator speed and amplitude frequency and phase of voltage waveform output by the generator are adjusted. The high-altitude tower embedded type vertical type wind power generation system is small in size, easy to mount and repair, stable in operation performance, high in anti-storm ability, good in power-generation quality and performance, suitable for a high-altitude signal-radiation tower, a high voltage transmission tower and other high-altitude frames which can be used as frames for a vertical wind power generator and fit for power-generation and application in various climates and geographical conditions.

Owner:李树广

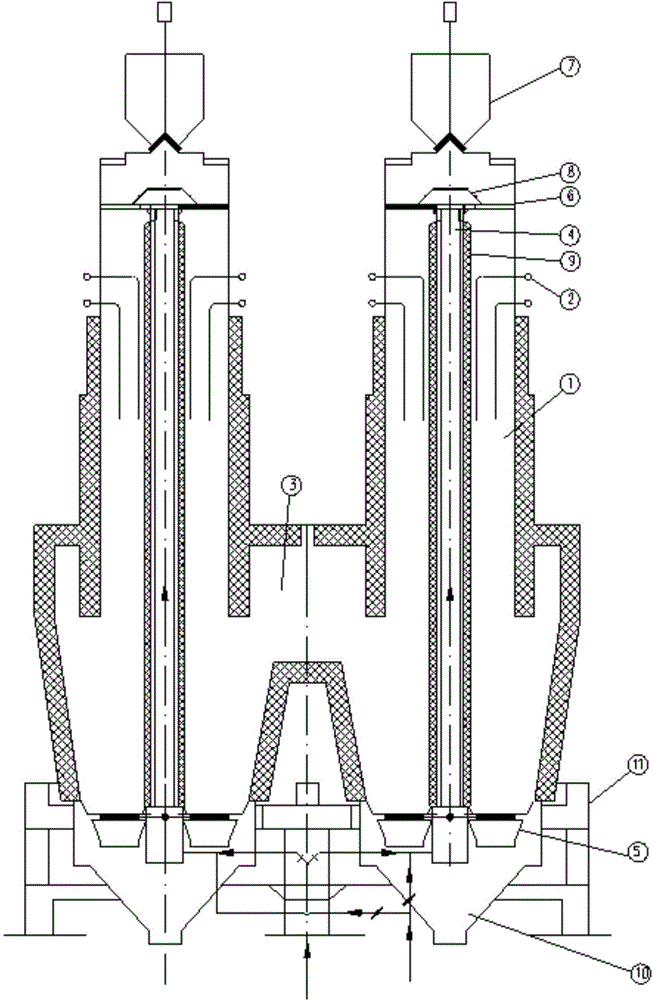

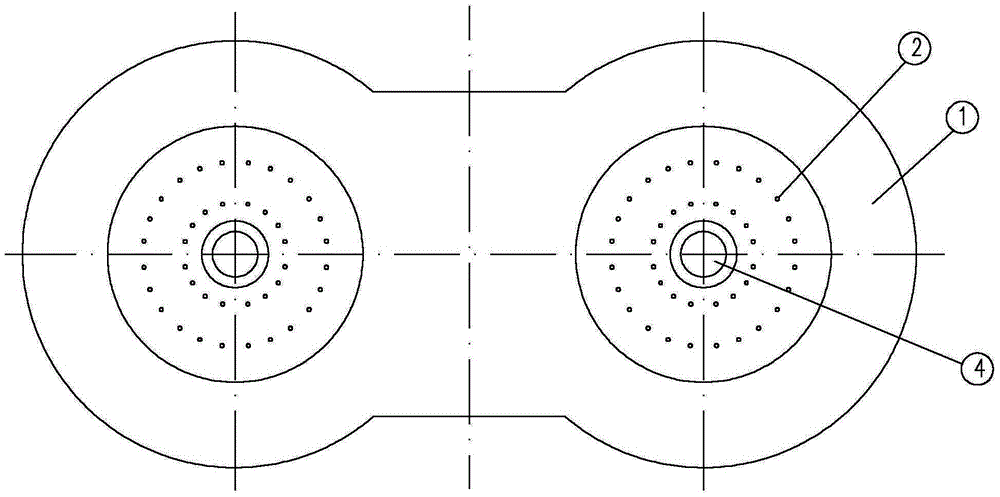

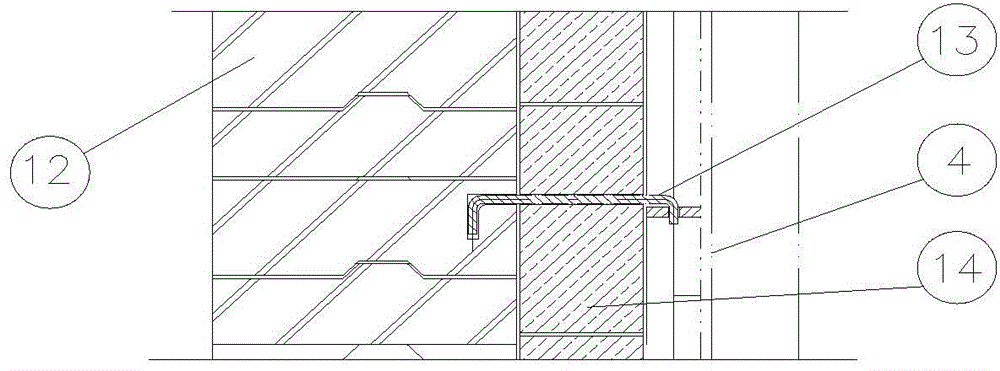

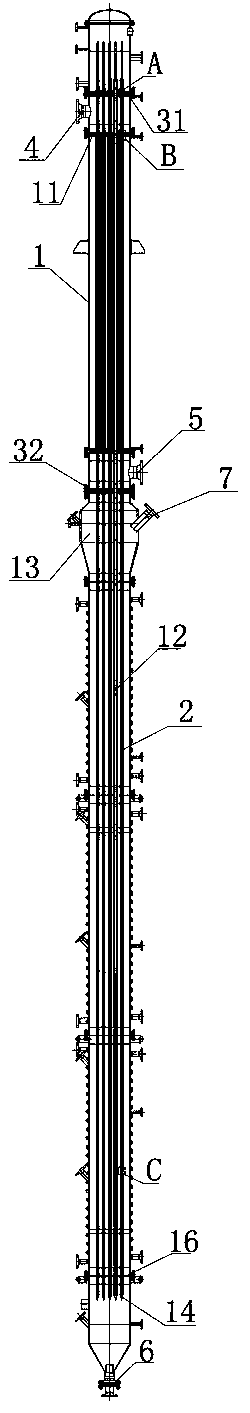

Sleeve type double-hearth shaft kiln

The invention relates to the field of roasting kilns and in particular relates to a sleeve type double-hearth shaft kiln. The sleeve type double-hearth shaft kiln is characterized in that inner sleeves are respectively arranged at the centers of two kiln hearths; the upper ends of the inner sleeves are hinged to the upper sides of the kiln hearths; the end sockets of axial positioning clamps are hinged to kiln hearth shells; the inner sleeves are of steel structure bodies from bottom to top; protection covers made of fireproof materials are built outside the inner sleeves; air channels are formed in the inner sleeves; the specification and the size of the shaft kiln are only related to a regional area of an annular section; basically, heights of a preheating region, a roasting region and the like of the kiln body are not changed along with the change of the specification of the kiln. Compared with the prior art, the sleeve type double-hearth shaft kiln disclosed by the invention has the beneficial effects that the resistance loss of the kiln body is low, the phenomenon that heat cannot be distributed uniformly in a roasting process is improved, the quality of a product is high, electric energy can be saved, and the problem in large sizes of lime and dolomite double-hearth shaft kilns is solved; the sleeve type double-hearth shaft kiln is suitable for new construction, reconstruction and extension and the technical design of the conventional kiln with the daily yield being more than 600 tons and even the daily yield being more than thousands of tons.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

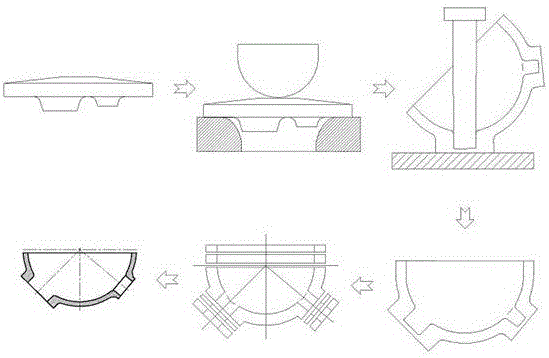

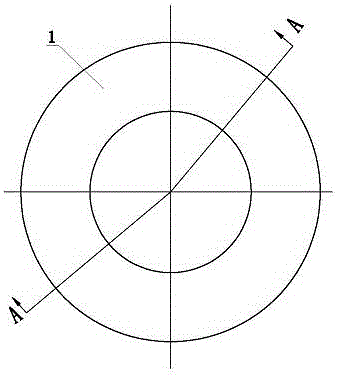

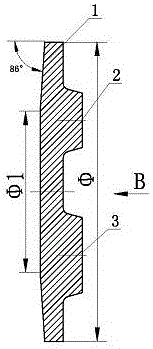

Integral seal punch molding method of nuclear power pressure container

The invention discloses an integral seal punch molding method of a nuclear power pressure container. The punch molding method comprises the following steps: roughening of a plate blank: the heated seal plate blank is machined; heating of the plate blank: the roughened seal plate blank is sent in a heating furnace for heating; molding of a seal: the seal plate blank is shifted to an annular mold with a center hole for punching to mold a semi-spherical seal blank; punching of the seal: a seal punching part with two man holes and two pipe holes is punched; heat treatment of the punched part: the punched part is discharged from a furnace for air cooling when being cooled to 180 DEG C along with the furnace after autoclaving; machining of the punched part: the heated seal punched part is machined as a seal rough finished product; performance heat treatment: the quenching treatment is performed firstly; and then, the thermal refining is performed; and the finished product is machined to a qualified seal finished product. The method realizes integral molding of a steam generator seal, and is uniform and compact in metal structure and complete in streamline.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

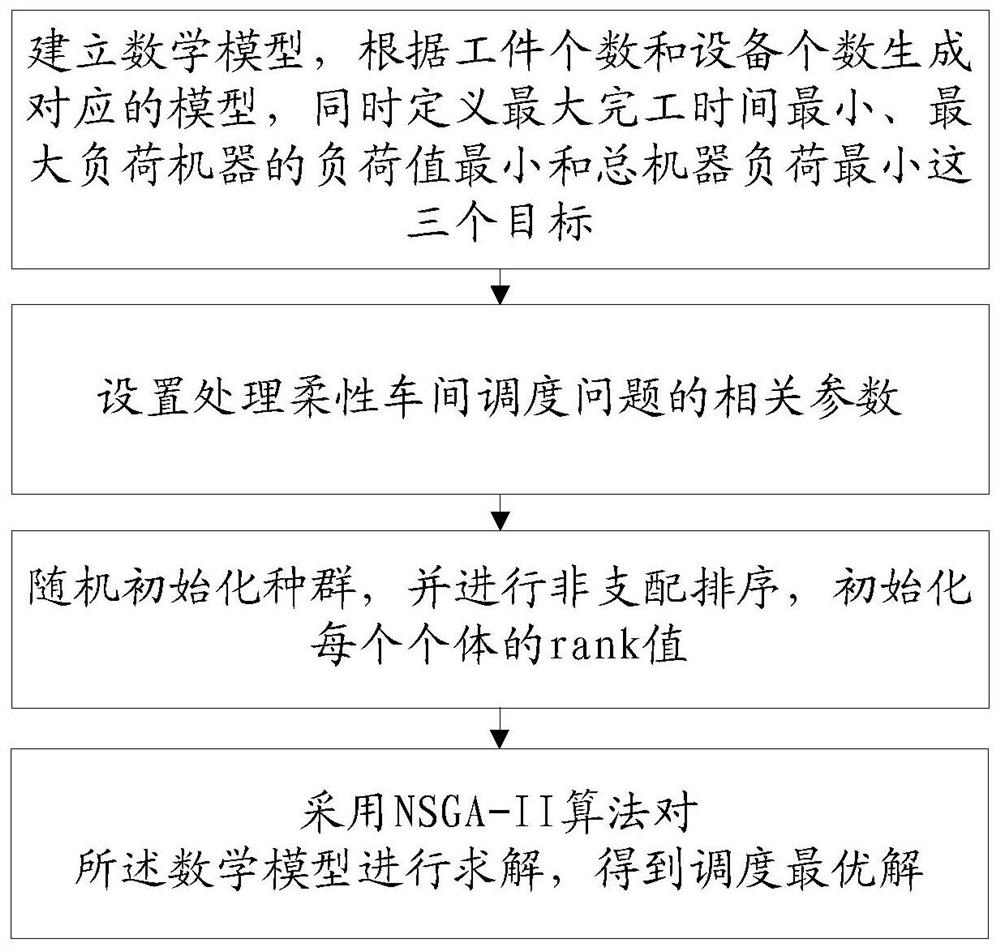

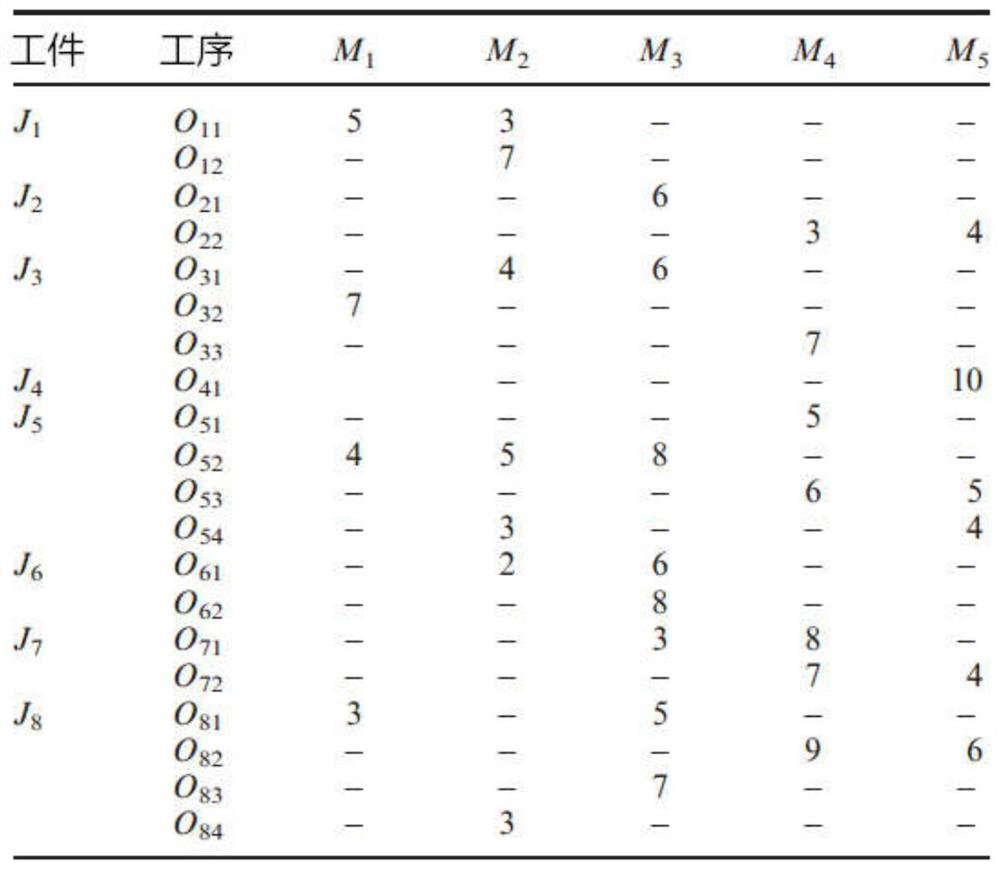

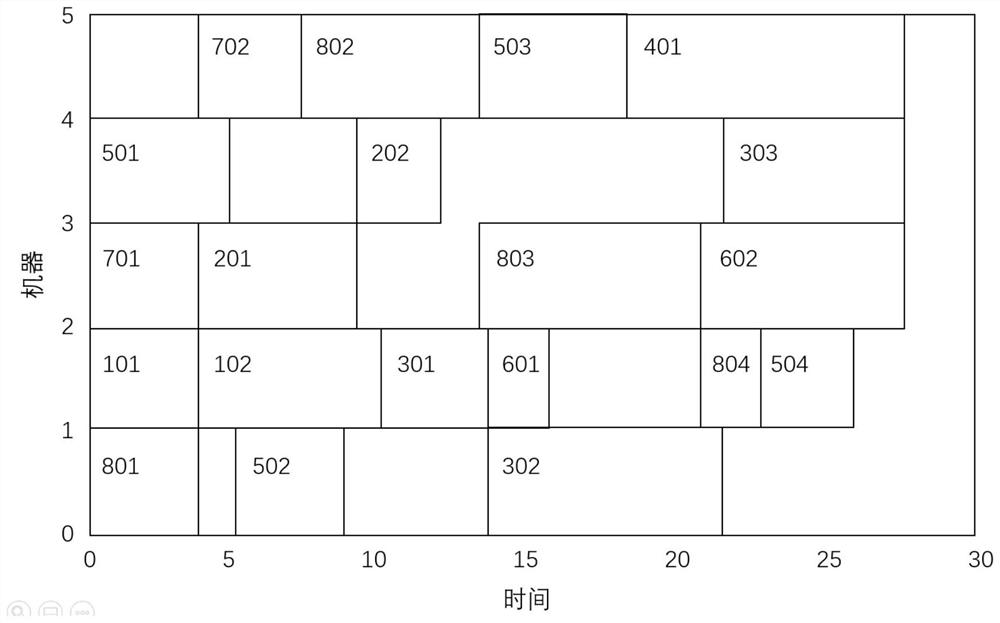

Multi-target flexible job shop scheduling method

PendingCN112699544AImprove work efficiencySolve scheduling problemsArtificial lifeDesign optimisation/simulationMultiple targetReal-time computing

The invention provides a multi-target flexible job shop scheduling method, which comprises the following steps of: S10, establishing a mathematical model, generating a corresponding model according to the number of workpieces and the number of equipment, and defining three targets of minimum maximum completion time, minimum load value of a maximum load machine and minimum total machine load at the same time; S20, setting related parameters for processing the flexible workshop scheduling problem; S30, randomly initializing a population, carrying out non-dominated sorting, and initializing a rank value of each individual; and S40, solving the mathematical model by adopting an NSGA-II algorithm to obtain a scheduling optimal solution. The multi-target mathematical model is set, the corresponding parameters are set, the NSGA-II algorithm is adopted to solve the optimal solution of the mathematical model, and production scheduling can be completed through simple and convenient operation while the actual production requirements of enterprises are met.

Owner:QUANZHOU INST OF EQUIP MFG

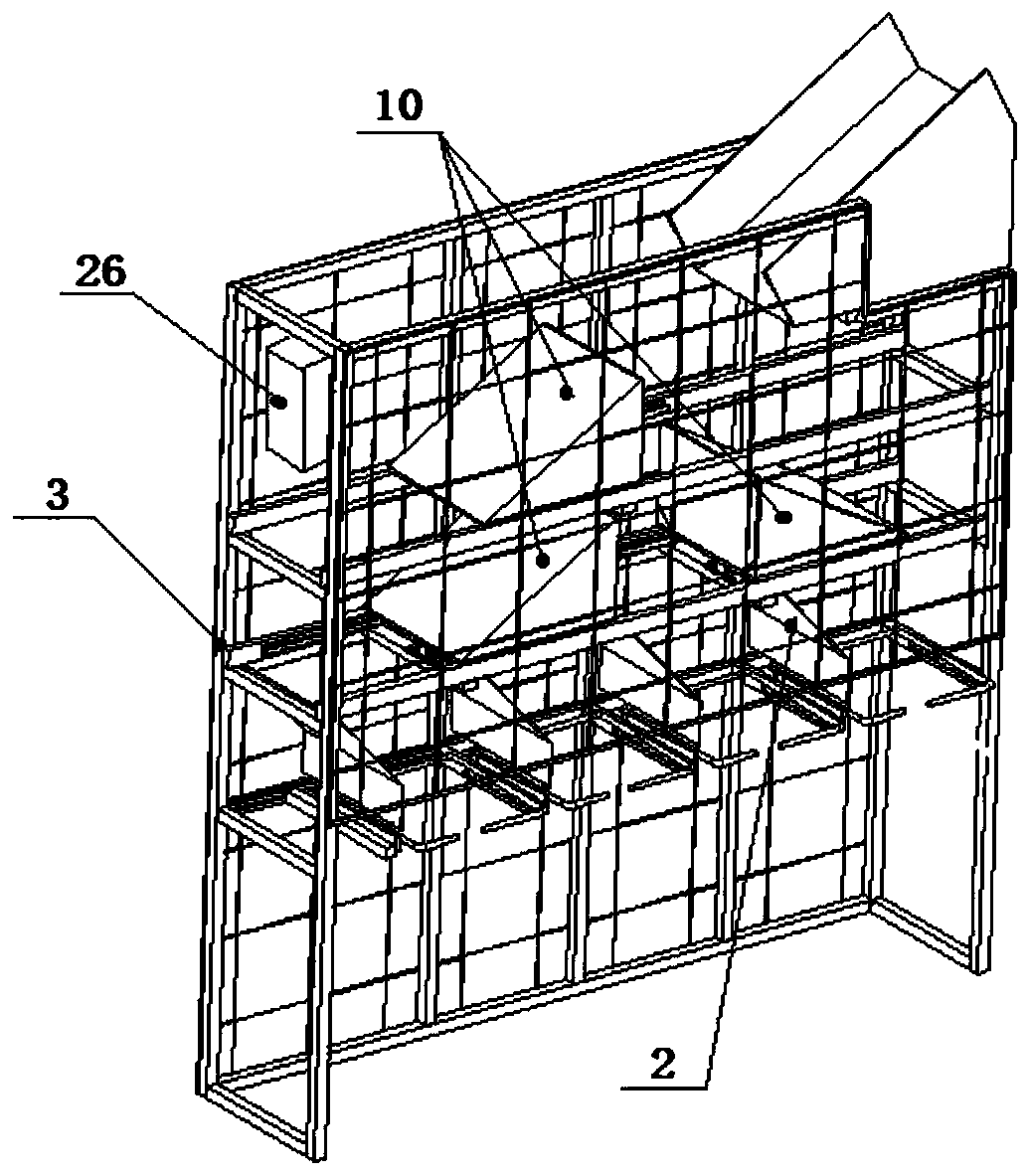

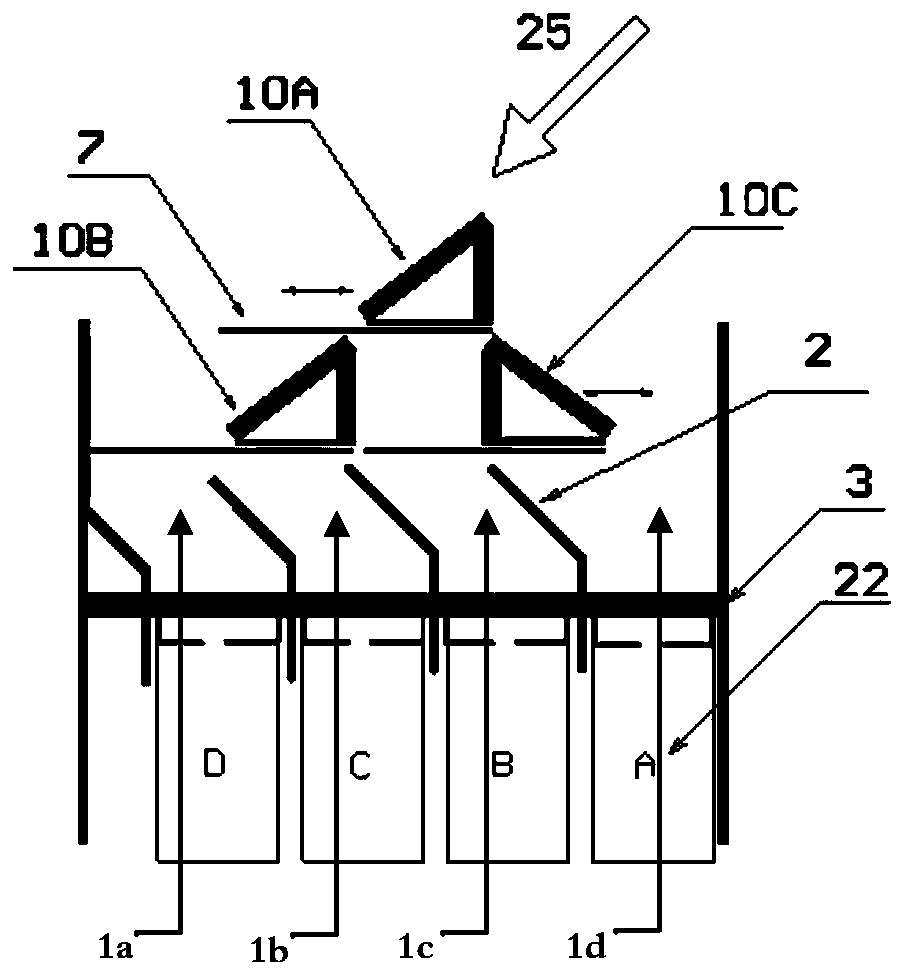

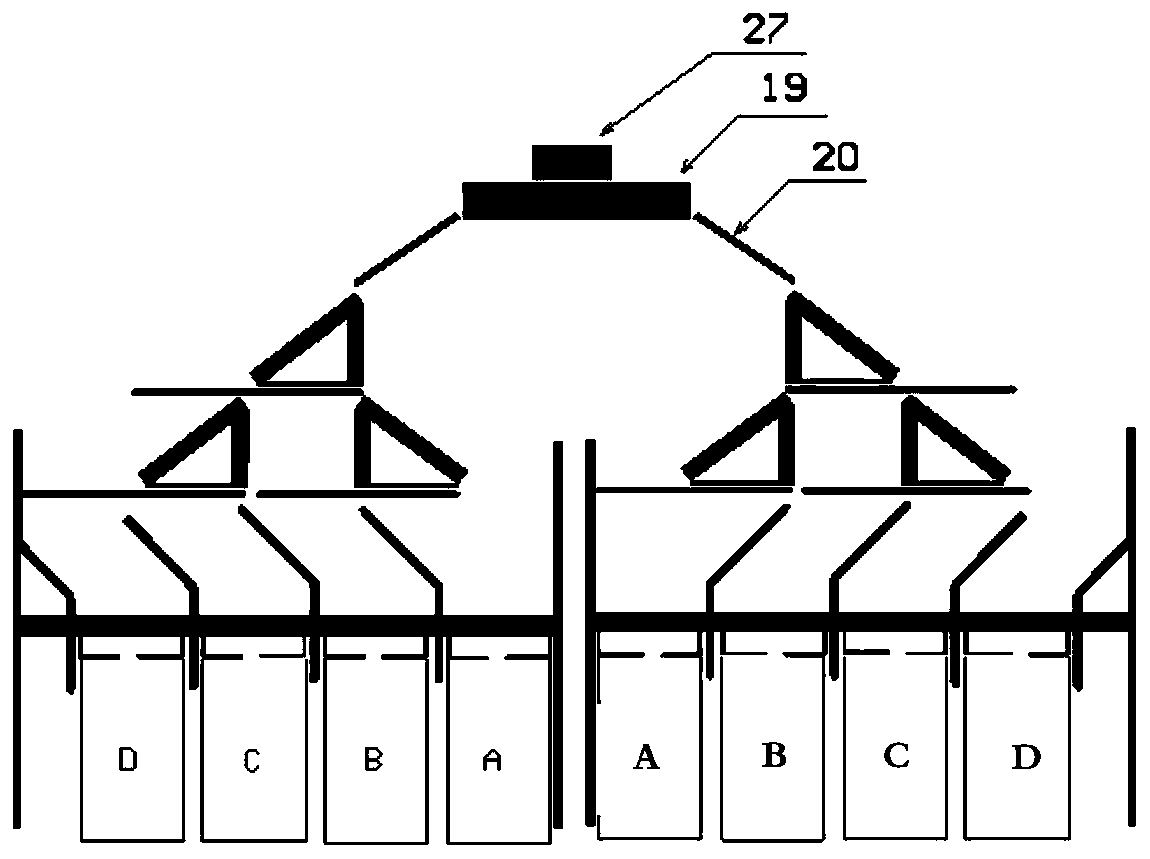

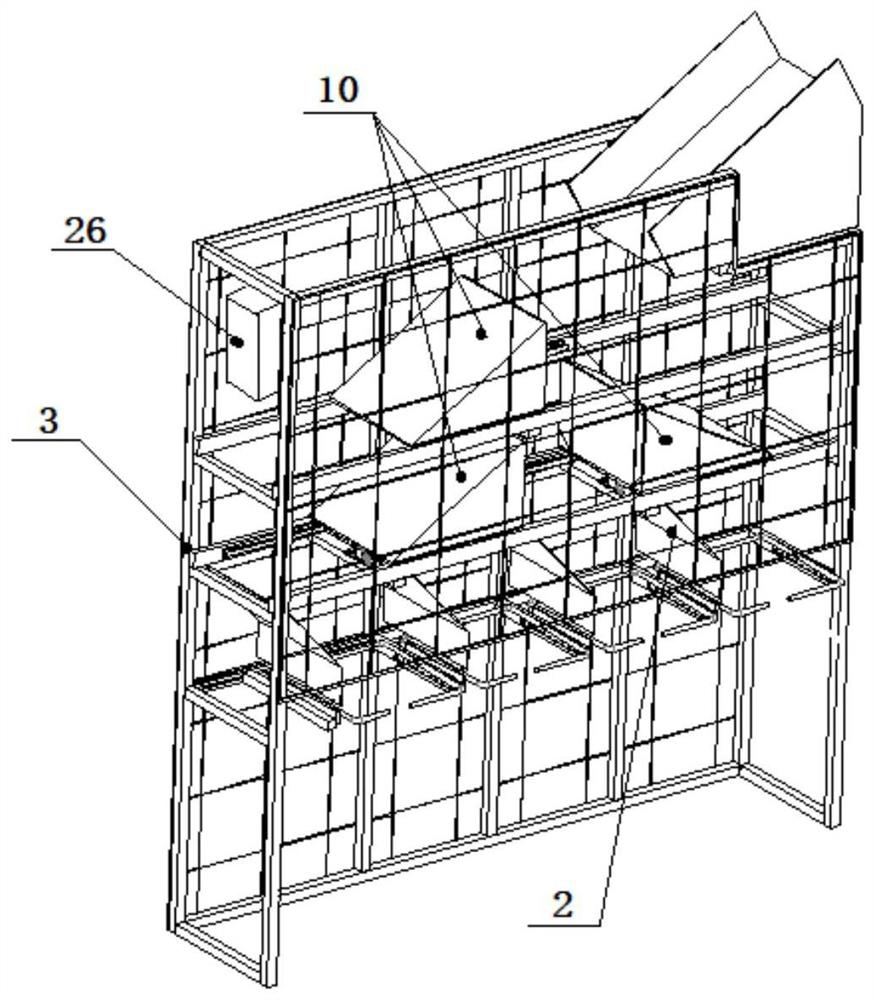

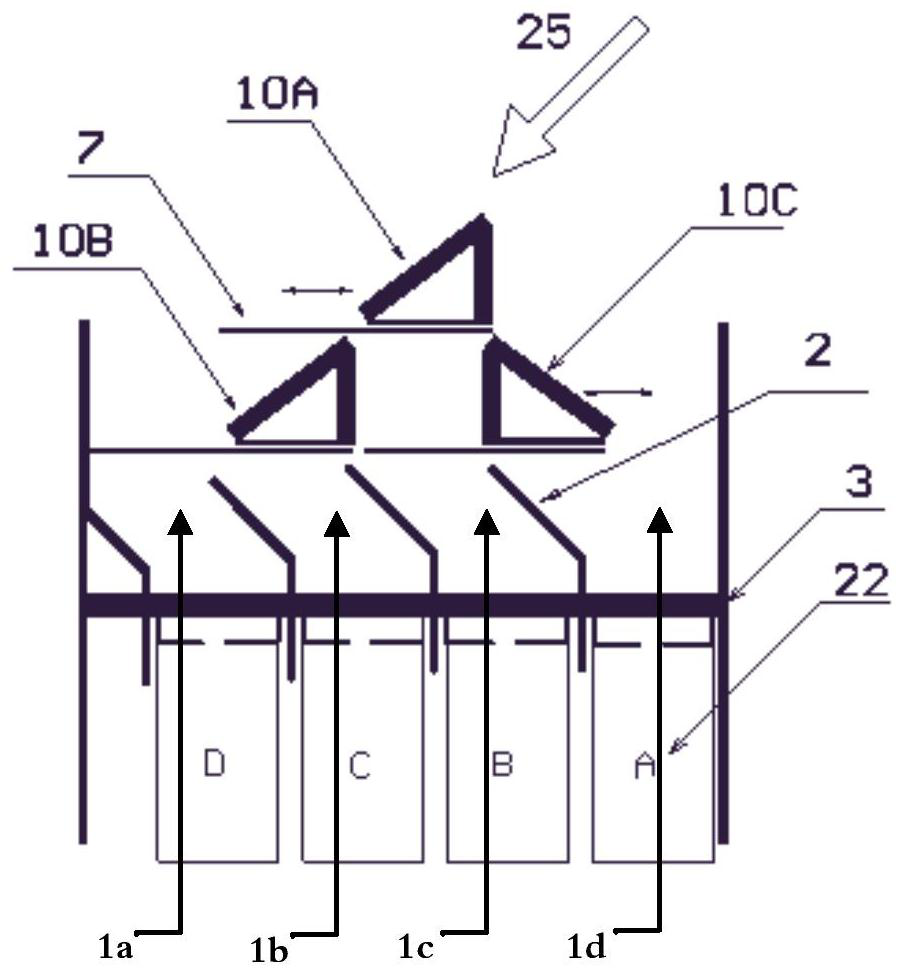

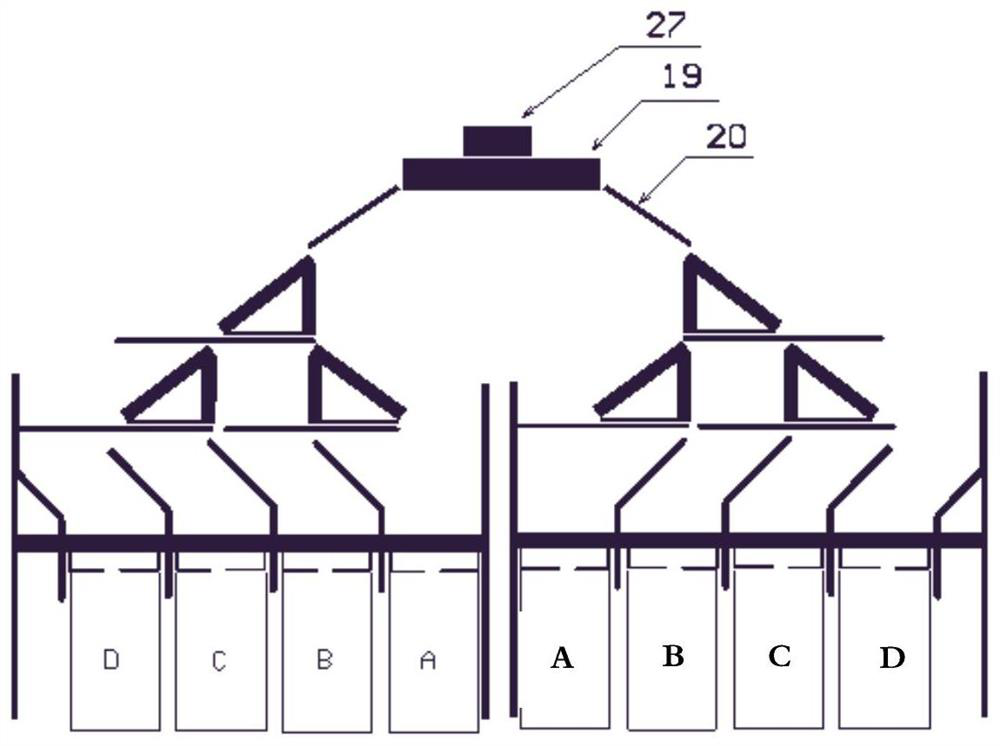

Three-dimensional structural package sorting device

ActiveCN109719040AImprove efficiencyImprove accuracySortingElectrical and Electronics engineeringEngineering

The invention discloses a three-dimensional structural package sorting device. The device comprises a support main body, a movable guide part and a power mechanism, wherein at least two package collecting openings are formed in the support main body, the package collecting openings are connected with package collecting bags of different address information respectively so as to load sorted packages of the corresponding address information, the movable guide part is movably connected to the support main body, and is connected with the power mechanism, the power mechanism is controlled by a controller, and the power mechanism drives the movable guide part to move above the package collecting openings, so that the sorted packages can be guided into any one of the package collecting openings.According to the three-dimensional structural package sorting device, the technical problems that an existing automatic sorting machine is large in size and large in occupied area are solved, so thatthe technical effects of reducing the cost, improving the sorting efficiency and realizing the three-dimensional structure of the equipment are achieved.

Owner:珠海星植流电机有限公司

Distributed search engine system and implementation method thereof

InactiveCN101950300BSolve large-scaleImprove performanceSpecial data processing applicationsWeb servicePhysical layer

The invention discloses a hierarchical structure applied to a distributed search engine. The hierarchical structure comprises a physical layer, an abstract layer, an application layer and a presentation layer. The invention also discloses a distributed search engine system, which comprises a Web server, an agent node, a query agent pool, an abstract adapter and a plurality of working nodes, wherein the query agent pool consists of a plurality of query nodes. The invention also discloses an implement method for the distributed search engine system, which comprises the following steps of: S1, registration of a query node; S2, registration of working nodes; S3, state update of the nodes; and S4, distribution and retrieval of a query request. The hierarchical structure has the advantages of good performance, high reliability, diversification, specialization, strong applicability and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

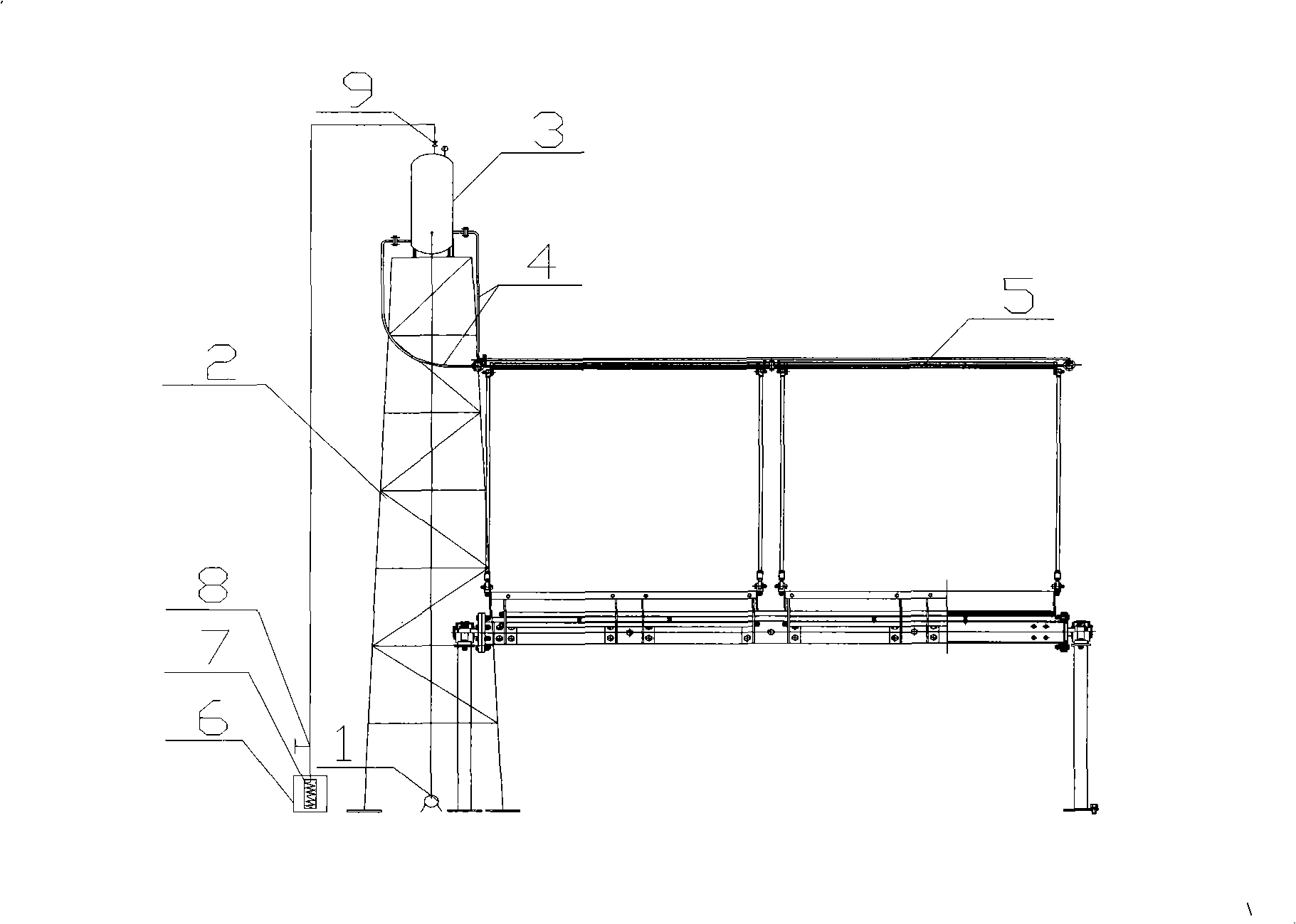

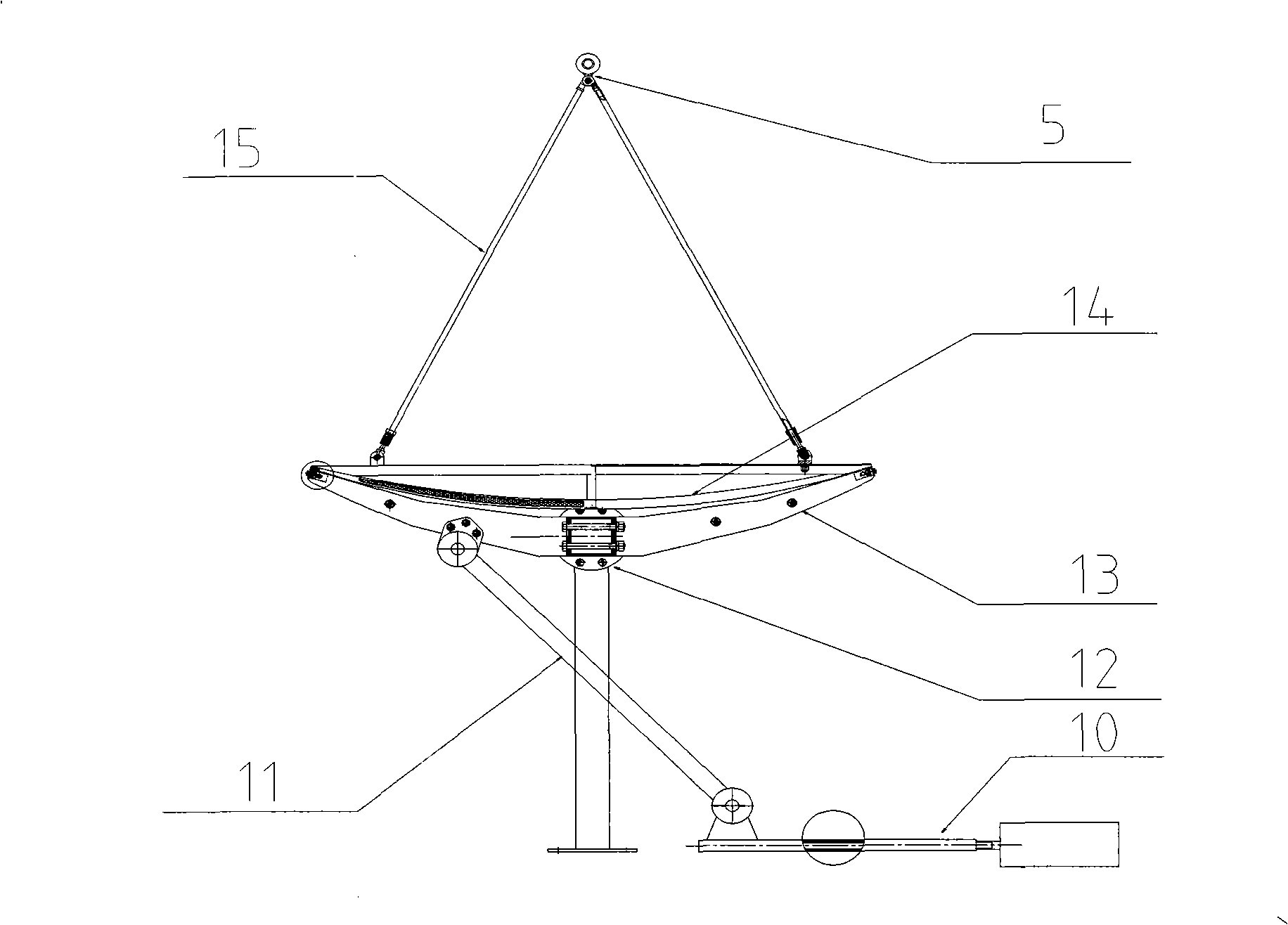

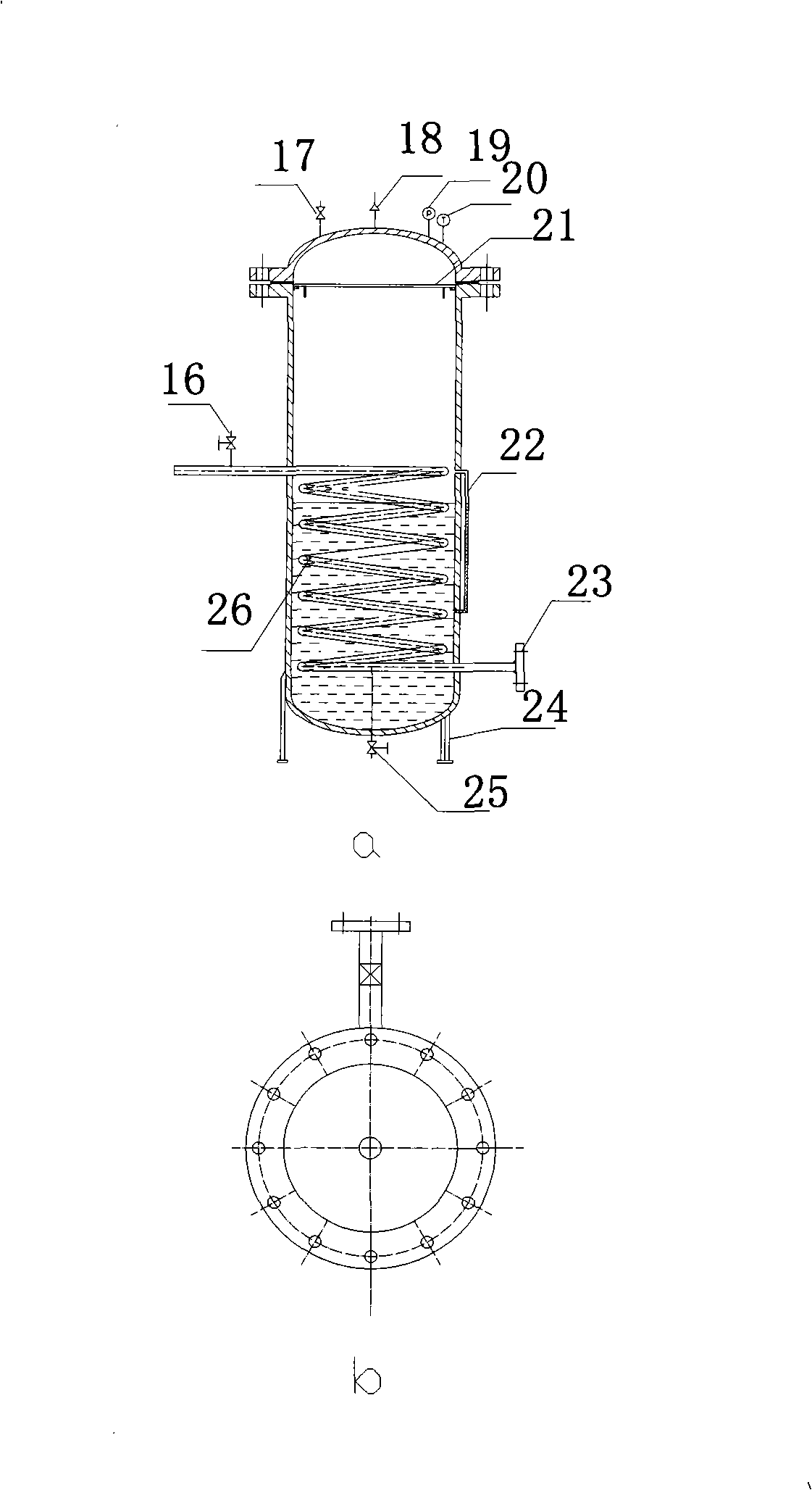

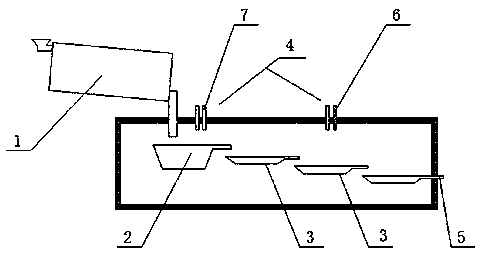

Gas-liquid two-phase separation type gravity assisted heat pipe solar boiler

InactiveCN101403493AReduce maintenanceEasy to removeSolar heating energySteam generation heating methodsVapor liquidHeat transmission

The invention discloses a vapor-liquid phase separation type gravity heat pipe solar boiler, which comprises a water pump, a first bracket, a drum, a metal flexible pipe, a heat pipe type solar evaporator, a bucket, a condenser, a controlling valve, a one way valve and a solar optical collector; the upper end of the first bracket is provided with the drum which is connected with the heat pipe type solar evaporator by the metal flexible pipe so as to form the vapor-liquid phase separation type gravity heat pipe, the drum is connected with the condenser by the one way valve through the controlling valve, the water pump is connected with the drum, and the position corresponding to the heat pipe type solar evaporator is provided with the solar optical collector which is driven by a hydraulic device for tracking the sun. The solar boiler adopts the solar optical collector for focusing the sunlight to the evaporation section of a loop type heat pipe so as to generate heat and adopts the characteristic of high-efficiency heat transmission of the loop type gravity heat pipe for transmitting the heat into the boiler so as to carry out heat exchange with the water in the boiler and generate medium and high temperature saturated vapor; and the boiler has high system efficiency, is not easy for scale formation, is simple and can operate with high efficiency for a long time.

Owner:ZHEJIANG UNIV

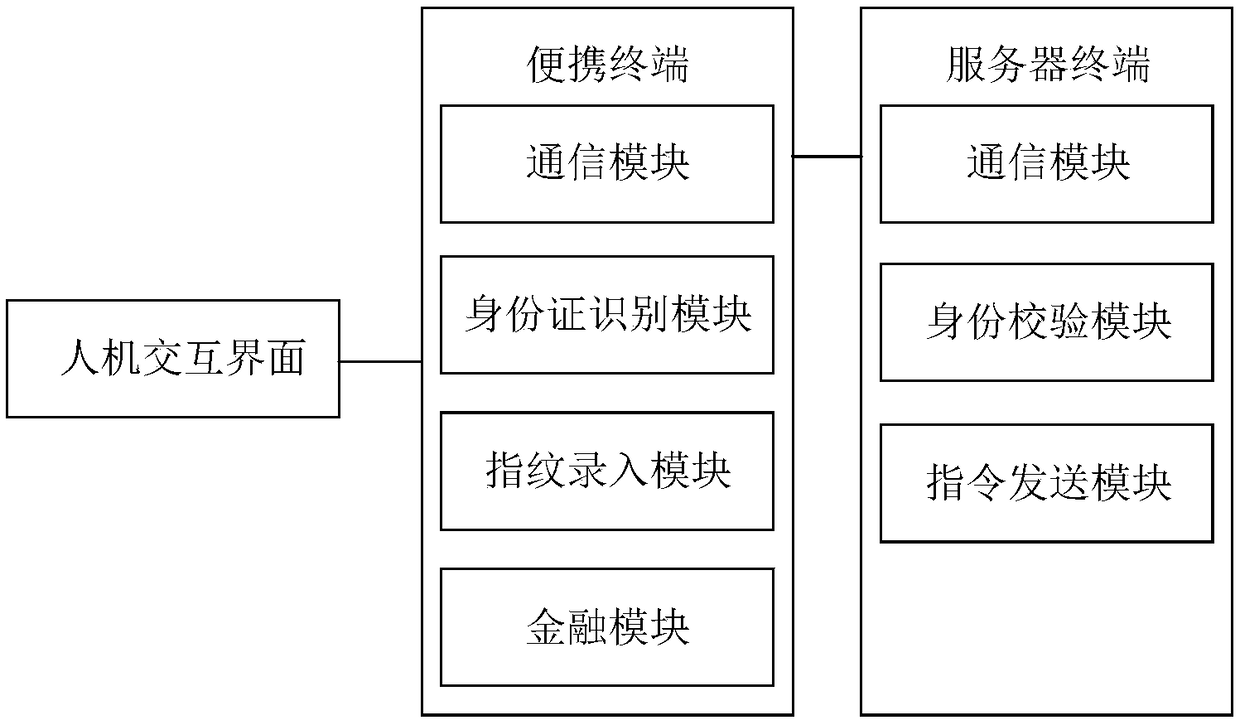

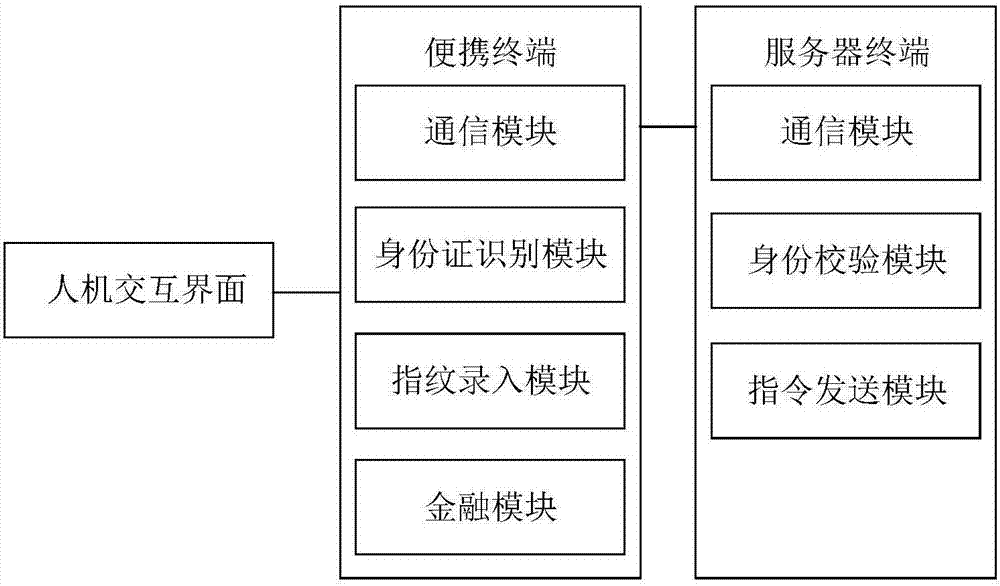

Portable financial server

InactiveCN108922075ASolve large-scaleImprove service qualityComplete banking machinesElectricityQuality of service

The invention relates to a portable financial server. The server includes a portable terminal and a server terminal; the portable terminal includes a human-machine interaction interface and a communication module, an identity card identification module, a fingerprint entry module and a financial module which are electrically communicated with the human-machine interaction interface; the server terminal includes a communication module, an identity verification module and an instruction sending module; the portable terminal and the server terminal complete a communication connection through thecommunication module. Through the above manner, the server solves the problem of large-scale traditional financial terminals so that financial related staff can improve own service quality, complete the on-site service of specific customers, and enhance the image of the industry.

Owner:成都蓝锦科技有限公司

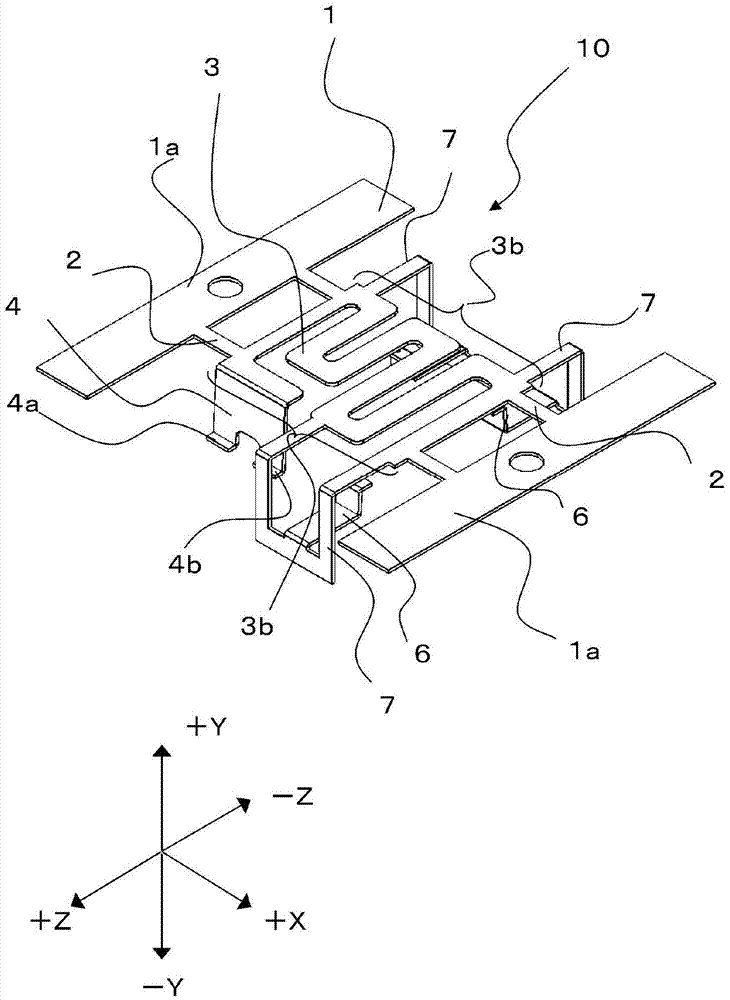

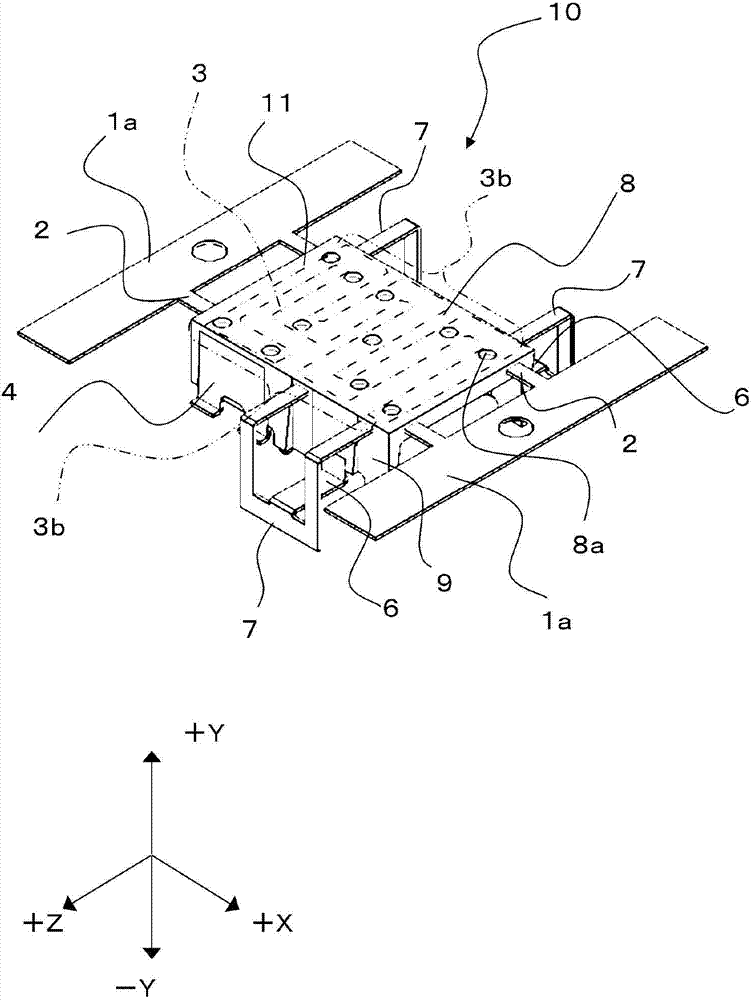

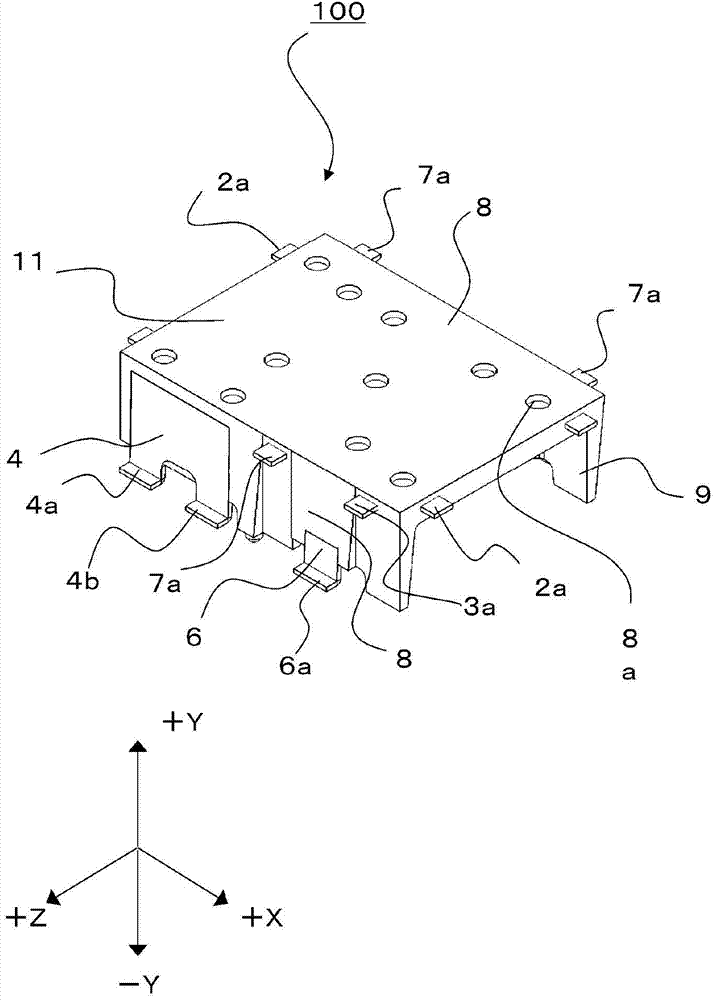

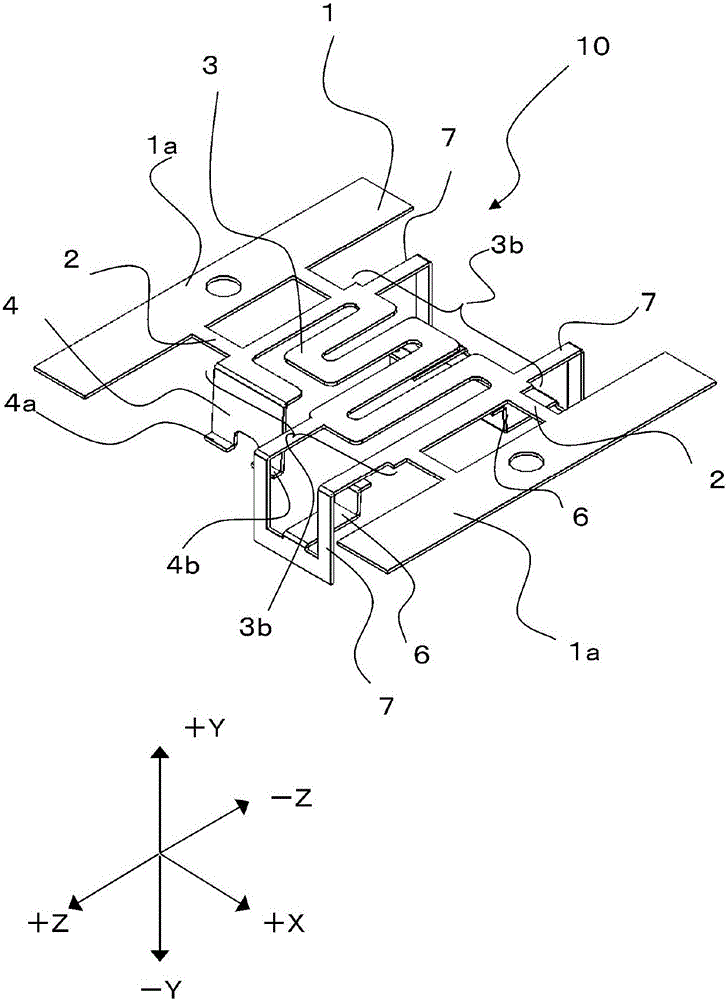

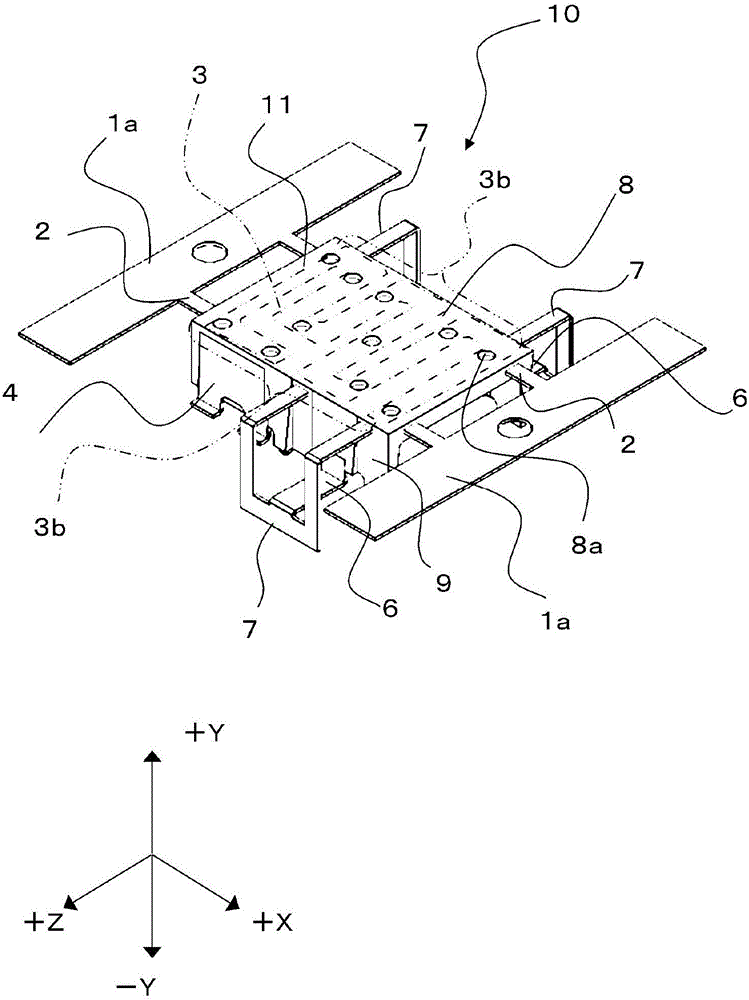

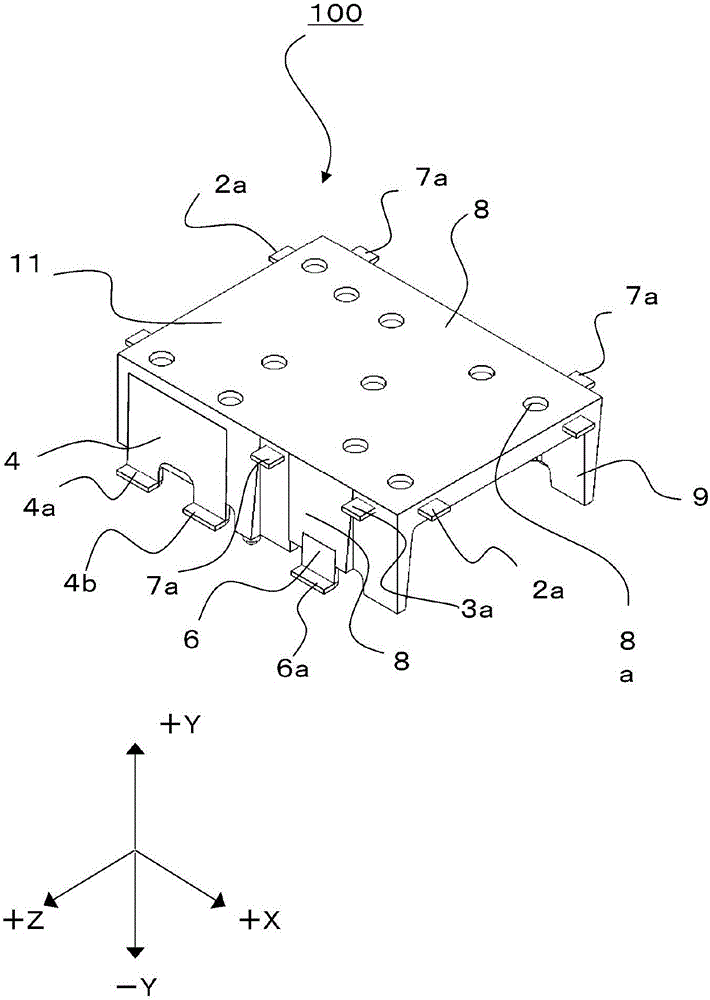

Manufacturing method of antenna device

InactiveCN103700940AAddresses issues where traits have unwanted effectsSolve large-scaleAntenna supports/mountingsRadiating elements structural formsMechanical engineeringLinkage concept

The present invention provides a manufacturing method of an enchasing moulding antenna device which can not change large and the character of which can not suffer ill effects brought by mounting terminals. The manufacturing method of the antenna device includes: an antenna component (10) bended by the bending process is conducted an enchasing moulding process and a severing process to cut the first linkage stack (2) and the second linkage (7), bending the second linkage (7) outside the end face (3b) of a radiant element of the antenna device at the bending process and bending the mounting terminals (6) in order to make the front end (6c) of the mounting terminals (6) to be installed inside of the end face (3b) of the radiant element of the antenna device, a resin (8) turning into a leg (9) to support the main body of the antenna device (100) and the resin (8) provided with the mounting terminals (6).

Owner:ALPS ALPINE CO LTD

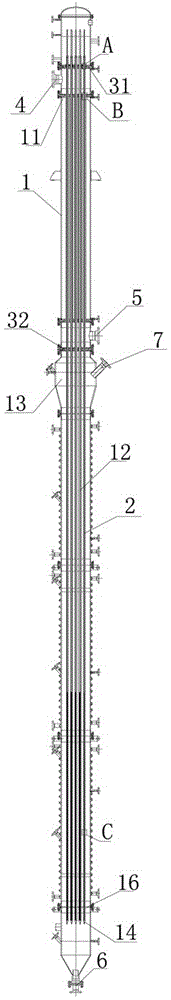

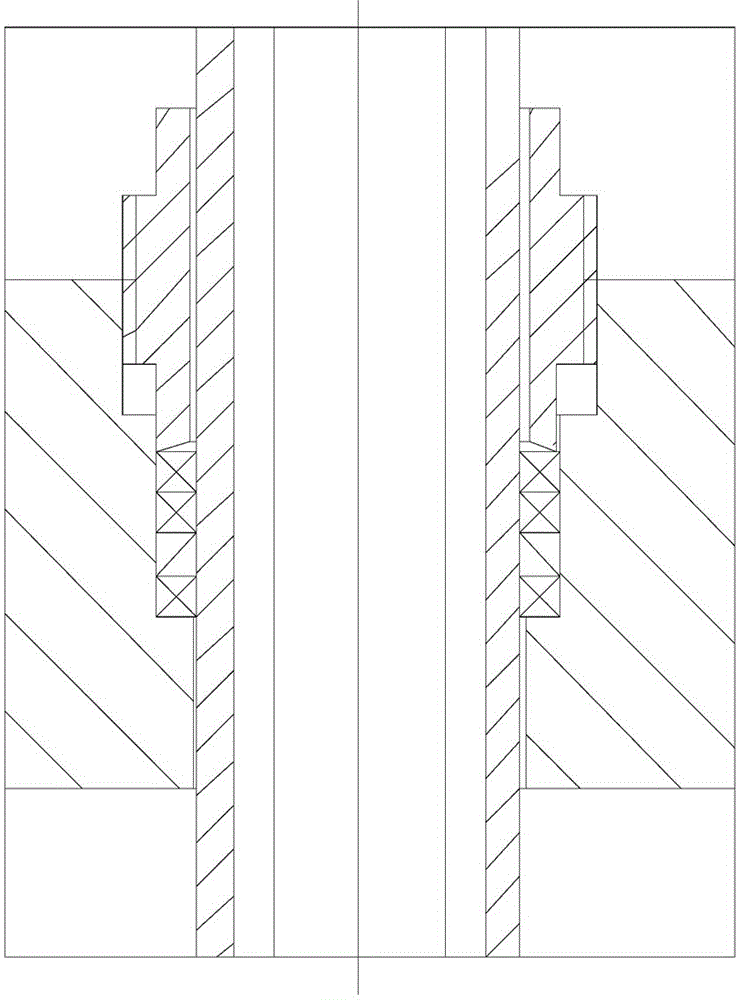

Novel industrial fluidized bed reactor adopting inorganic thermal superconducting technology

ActiveCN105664806ARemove heatPrevent removalChemical/physical processesInorganic ChemicalThermal insulation

The invention discloses a novel industrial fluidized bed reactor adopting the inorganic thermal superconducting technology.The novel industrial fluidized bed reactor comprises a barrel body and one or more inorganic thermal superconducting pipes arranged in the barrel body; the barrel body is separated into a thermal insulation area, a heat exchange area and a reaction area from top to bottom through an upper partition plate and a lower partition plate; each inorganic thermal superconducting pipe is internally provided with a casing pipe, a cavity between each casing pipe and the corresponding inorganic thermal superconducting pipe is filled with an inorganic thermal superconducting working medium, each internally-arranged casing pipe comprises an internally-arranged electrical heating pipe on the lower portion and a lead-out wire protective pipe on the upper portion, and the two ends of each inorganic thermal superconducting pipe extend into the thermal insulation area and the reaction area respectively.By means of the novel industrial fluidized bed reactor, the structural form of an existing industrial fluidized bed is changed completely, and the novel industrial fluidized bed reactor had the advantages that a cold medium (or a heat medium) is isolated from the reaction area, heating and heat obtaining are integrated, the structure is simple, maintenance is convenient to conduct, heat transfer efficiency is high, temperature uniformity inside a bed is good, operation safety is high, and the applicable temperature range is wide.

Owner:南通科恩化工技术有限公司 +1

A Web Service Composition Method Based on Deep Reinforcement Learning

ActiveCN107241213BImprove quality requirementsImprove accuracyData switching networksNeural learning methodsService compositionHeuristic

The invention discloses a web service combination method based on deep reinforcement learning. Aiming at the problems of long time consumption, poor flexibility and unsatisfactory combination results of the traditional service combination method in the face of large-scale service scenarios, the deep reinforcement learning technology and heuristic Ideas applied to the problem of service composition. In addition, considering the characteristics of partial observability of the real environment, the present invention transforms the service composition process into a partially observable Markov decision process (Partially-Observable Markov Decision Process, POMDP), and utilizes a recurrent neural network to solve the problem of POMDP , so that the method can still show high efficiency in the face of the "curse of dimensionality" challenge. The method of the present invention can effectively improve the solution speed, and independently adapt to the dynamic service composition environment on the basis of ensuring the quality of the service composition scheme, effectively improving the efficiency and self-adaptability of the service composition in the large-scale dynamic service composition scene and flexibility.

Owner:SOUTHEAST UNIV

How to make an antenna device

InactiveCN103700940BAddresses issues where traits have unwanted effectsSolve large-scaleAntenna supports/mountingsRadiating elements structural formsEngineeringMechanical engineering

The present invention provides a manufacturing method of an enchasing moulding antenna device which can not change large and the character of which can not suffer ill effects brought by mounting terminals. The manufacturing method of the antenna device includes: an antenna component (10) bended by the bending process is conducted an enchasing moulding process and a severing process to cut the first linkage stack (2) and the second linkage (7), bending the second linkage (7) outside the end face (3b) of a radiant element of the antenna device at the bending process and bending the mounting terminals (6) in order to make the front end (6c) of the mounting terminals (6) to be installed inside of the end face (3b) of the radiant element of the antenna device, a resin (8) turning into a leg (9) to support the main body of the antenna device (100) and the resin (8) provided with the mounting terminals (6).

Owner:ALPS ALPINE CO LTD

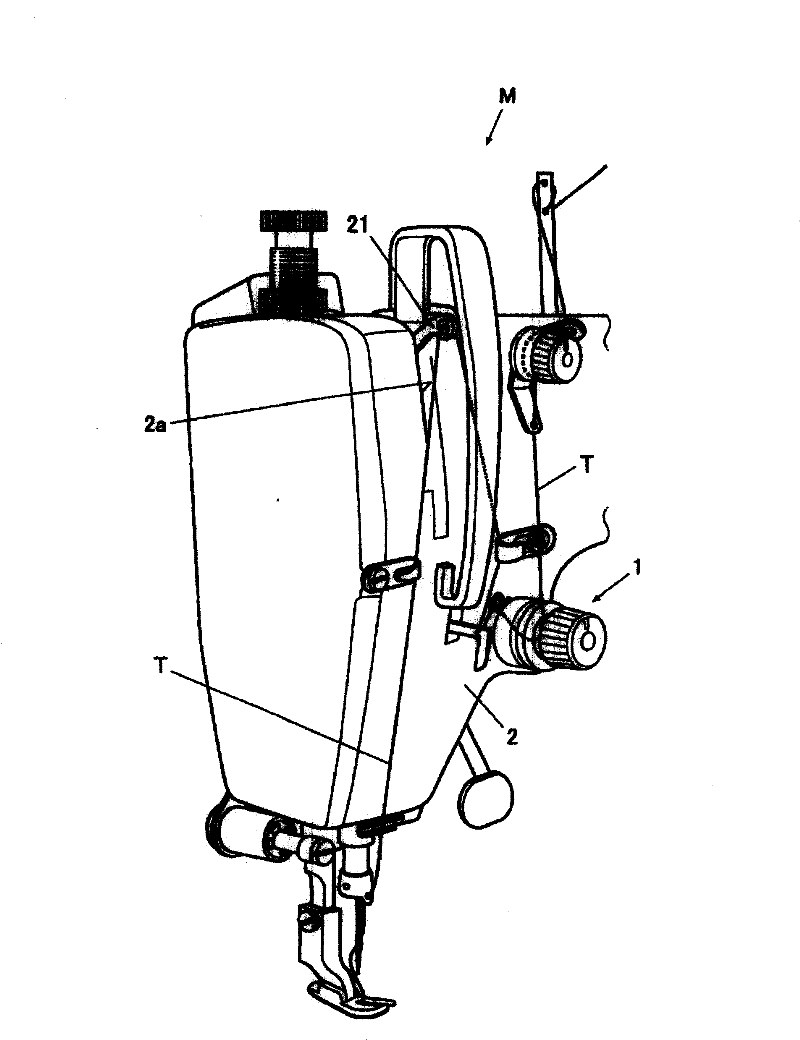

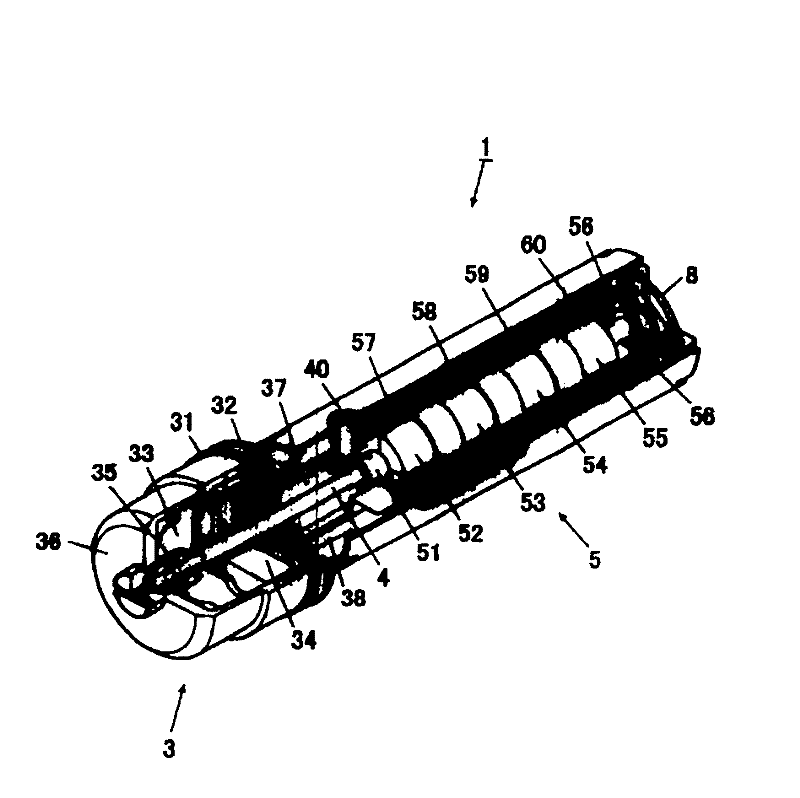

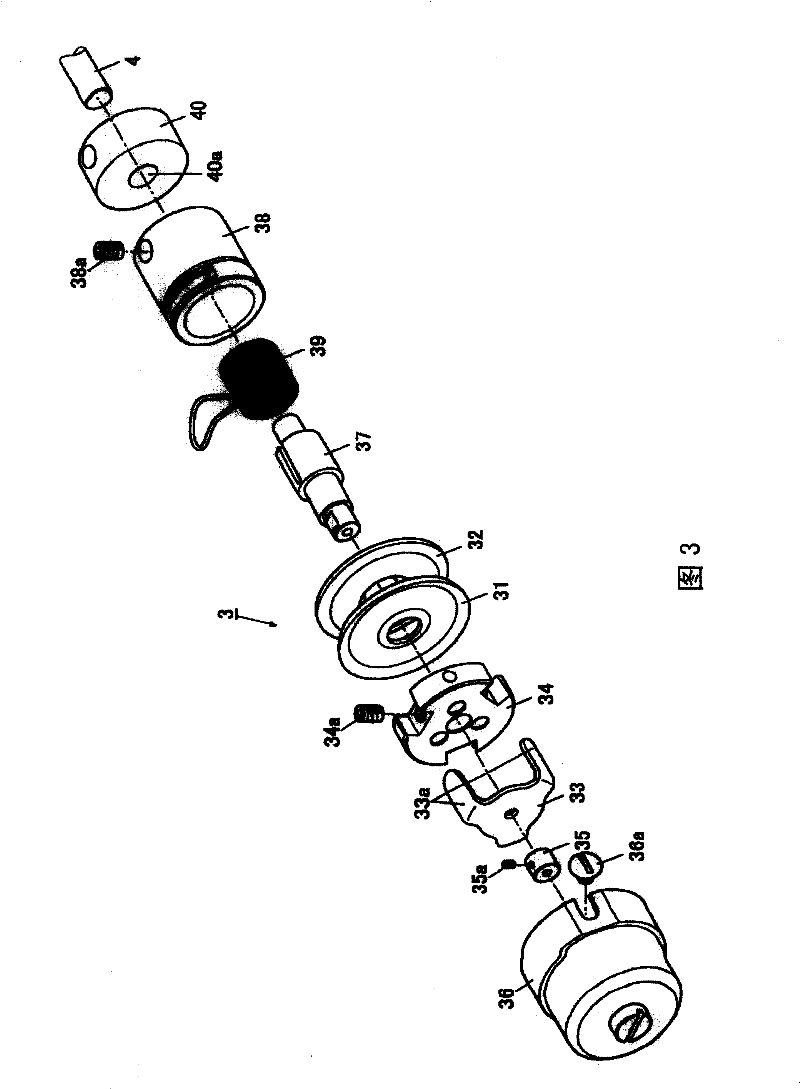

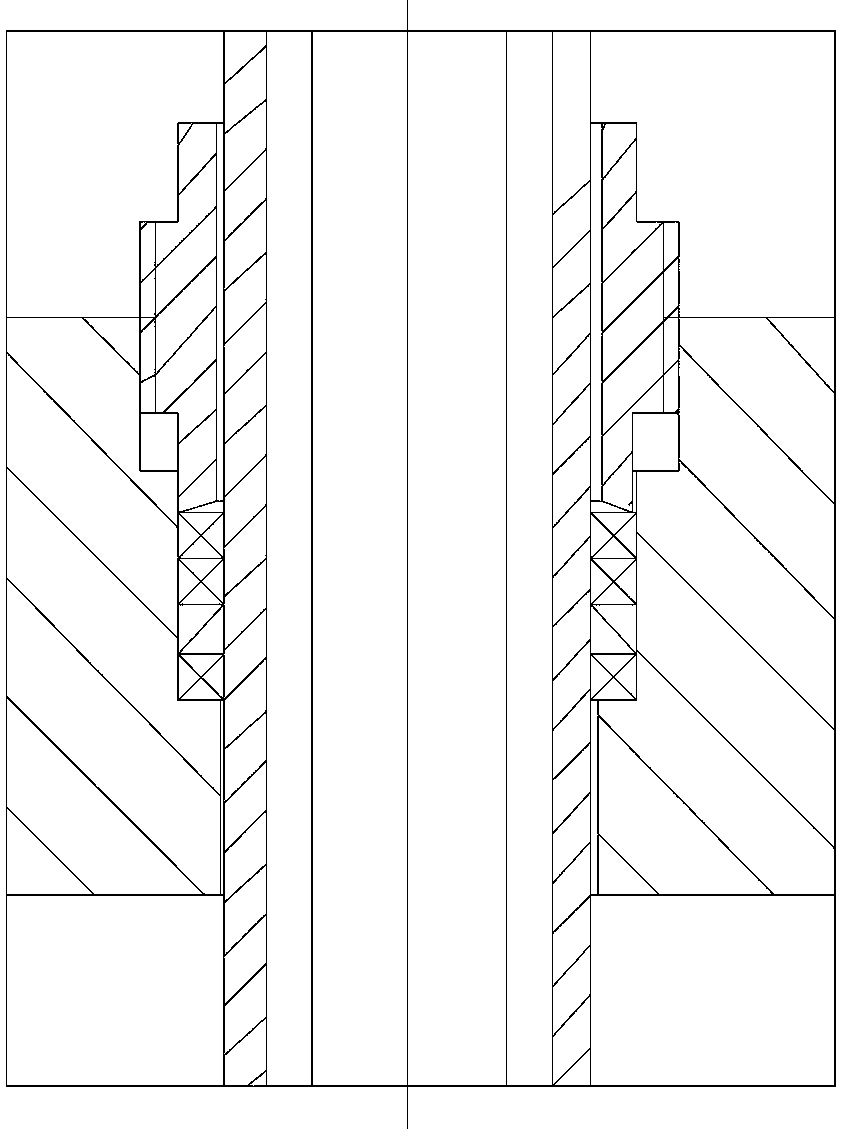

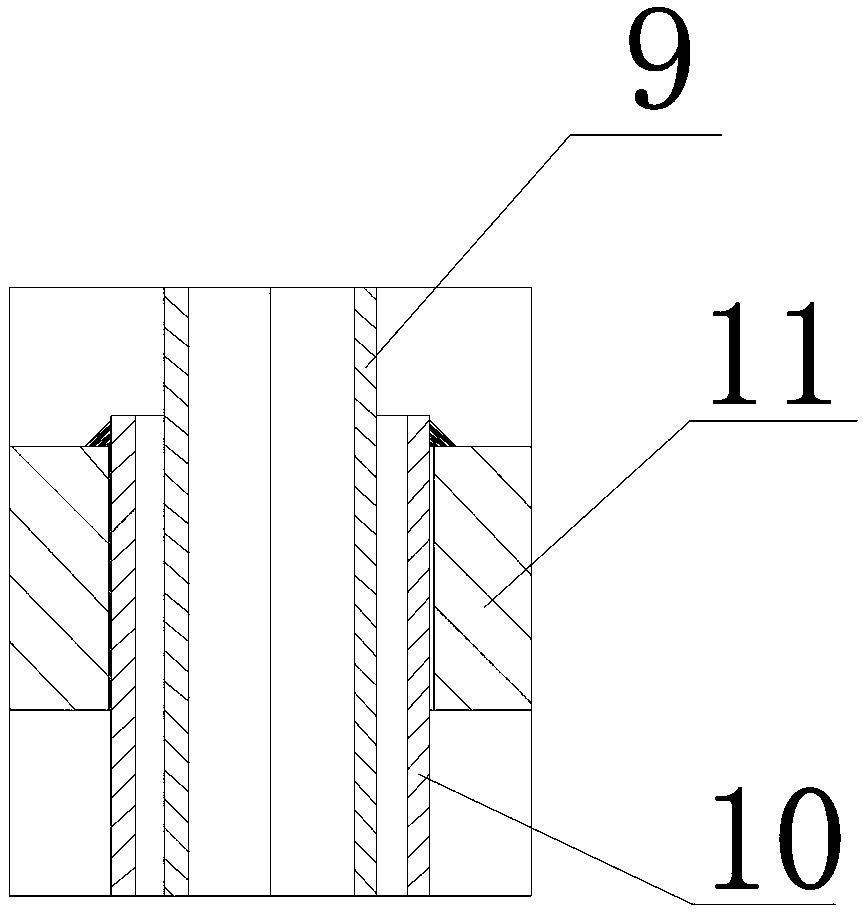

Wire-clamping device for sewing machine

A thread tightening device for sewing machine can reduce the friction when driving a drive, and can further improve the reproduce property, response property and durability. The thread tightening device (1) for sewing machine (M) has a pair of tightening disks (31, 32) which holds a thread; a drive mechanism (4, 33) for driving one tightening disk (31) contact to another tightening disk (32) and separate from it; a drive source (5) for driving the drive mechanism (4, 33), the drive source (5) has a movable member (6) which has a movable member shaft (51) moving along the axial direction and permanent magnets (52-55) disposed on the movable member shaft (51); a fixed member (7) which has windings (57-60) wrapped around the permanent magnets (52-55) with a pre-determined distance; and bearings (40, 8) which supports the two end parts of the movable member shaft (51), wherein the bearings at the end parts of the drive source (5) side for supporting the movable member shaft (51) are a plate spring bearings made of plate spring.

Owner:JUKI CORP

A Global Layout Method for VLSI Standard Cells Based on L1 Norm Model

InactiveCN103605820BImprove performanceEfficient and practical layout resultsSpecial data processing applicationsVery large scale integrated circuitsCluster algorithm

The present invention relates to a global layout method of VLSI standard cells based on the L1 norm model, which belongs to the field of VLSI physical design automation technology. The method first expresses the circuit as a hypergraph, and uses half-circumference length and line length The global placement problem of VLSI standard cells computed and density constrained to be non-smooth is modeled as an L1-norm minimization problem, and then the cells are clustered in the clustering stage using a modified optimal choice clustering algorithm adapted to the L1-norm model , and then in the disintegration stage, the clusters are dissociated using the nonlinear programming global placement method. The method has reasonable layout, high efficiency and practicality, and good layout effect.

Owner:FUZHOU UNIV

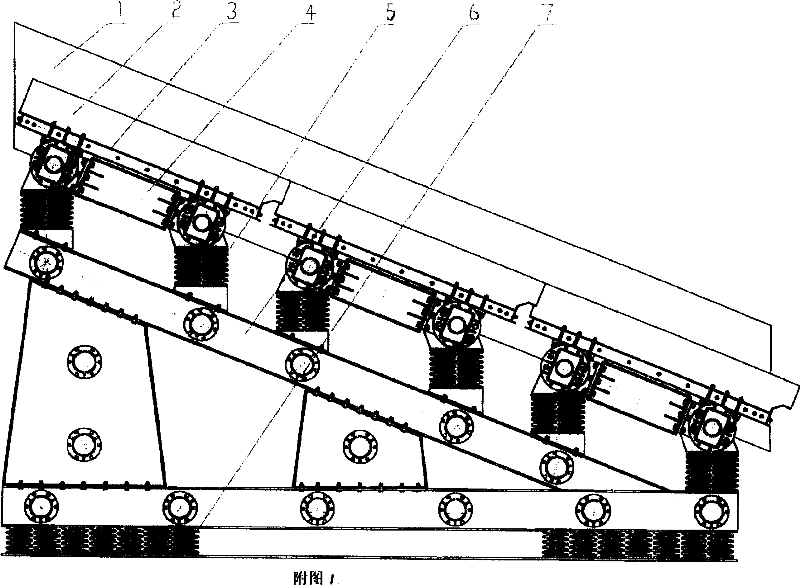

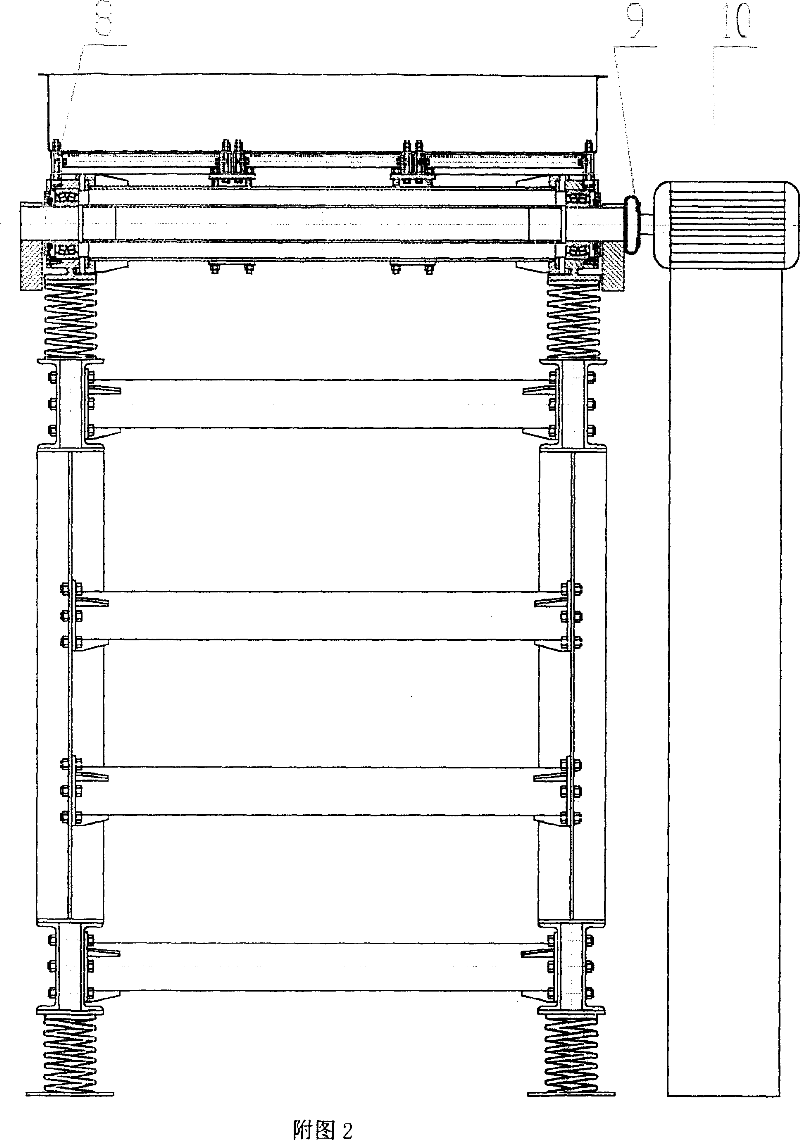

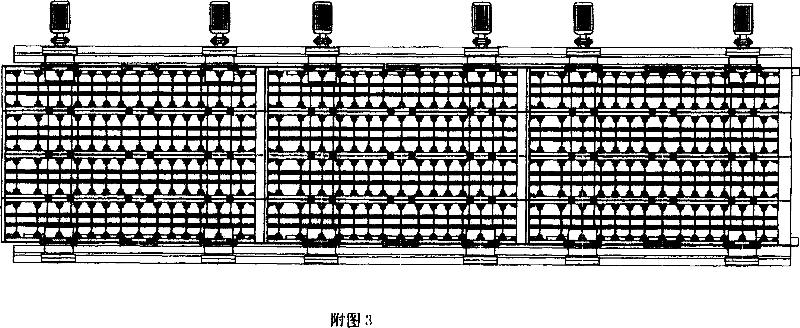

Bohou sieve

The present invention provides one sieving apparatus completing effective sieving based on the granularity of sieved material. The present invention has vibrating sieve plate, no-vibration sieve box, great vibration amplitude, great vibration strength and elastic sieve surface for meeting the requirement of vibration machine and suiting the needs of sieving humid small-granularity sticky material. The present invention has excellent sieving effect and great processing capacity. The present invention has altered mechanical structure of sieve, adopts the moving mode of several independent circular surfaces in vibration and no-vibration frame, lowers the vibration participating mass of the sieve and realizes large-scale sieving apparatus. In addition, secondary damping can lower the dynamic load of sieve.

Owner:吴玲 +2

A three-dimensional structure package sorting device

A package sorting device with a three-dimensional structure, including a bracket main body, a movable guide part, and a power mechanism; wherein, at least two bag collection ports are provided in the bracket body, and the bag collection ports are respectively connected with bag collection bags with different address information to accommodate Pack the sorting parcels corresponding to the address information; the movable guide part is movably connected to the main body of the bracket, and the movable guide part is connected to the power mechanism; the power mechanism is controlled by the controller, and the power mechanism drives the movable guide Pick up the package and guide it into any one of the bag collection ports. The three-dimensional structured parcel sorting device provided by the present invention solves the technical problems of the existing automatic sorting machines of large size and large floor area, and achieves the technical effects of reducing costs, improving sorting efficiency and realizing the three-dimensional structure of the equipment.

Owner:珠海星植流电机有限公司

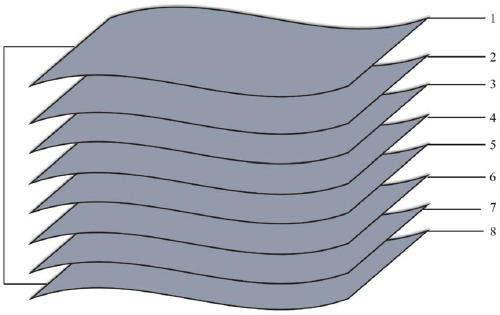

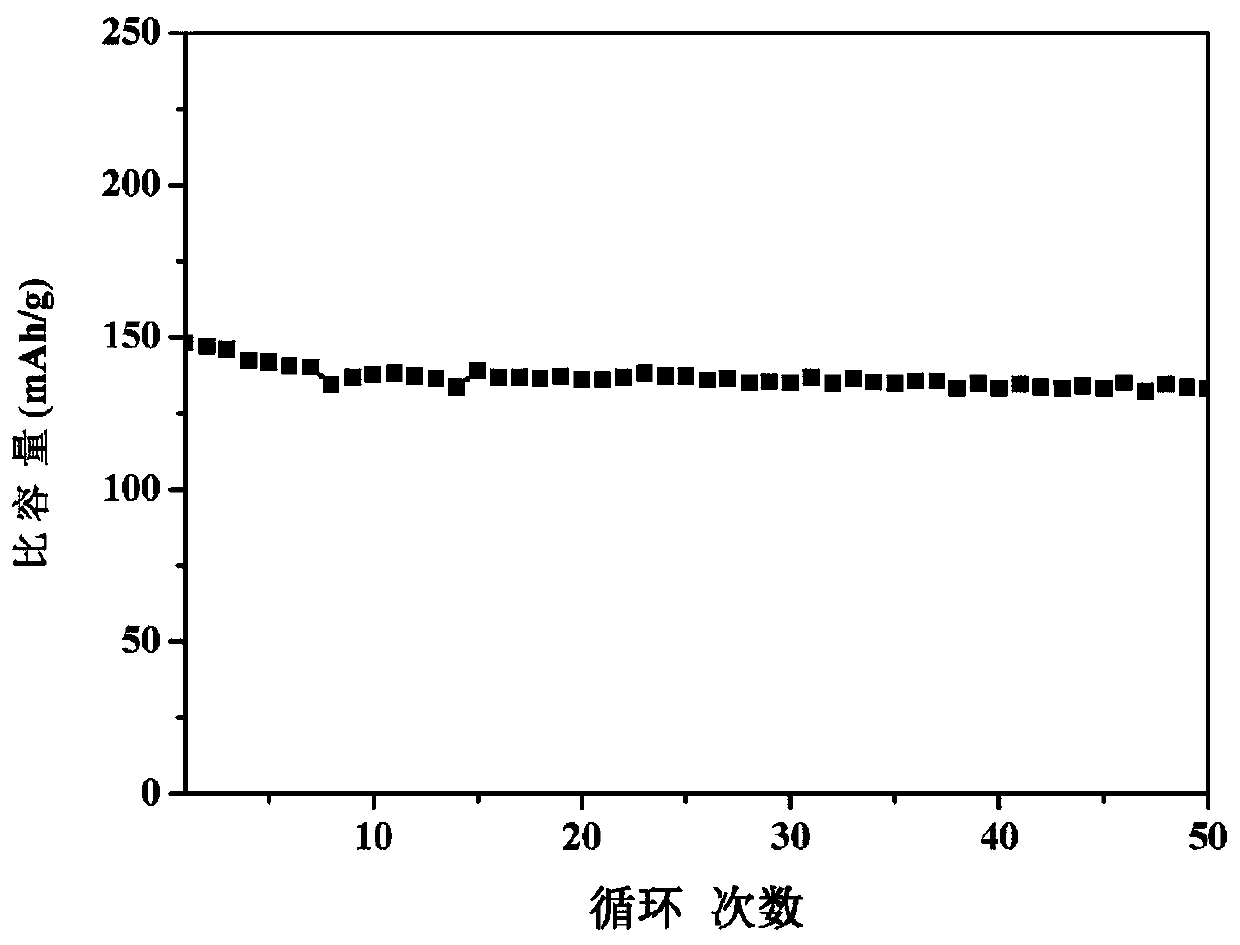

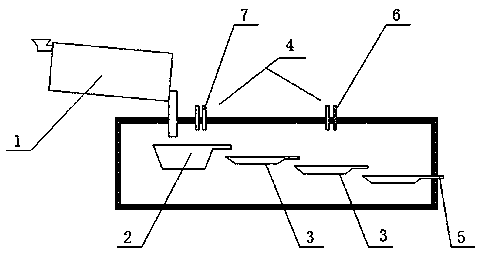

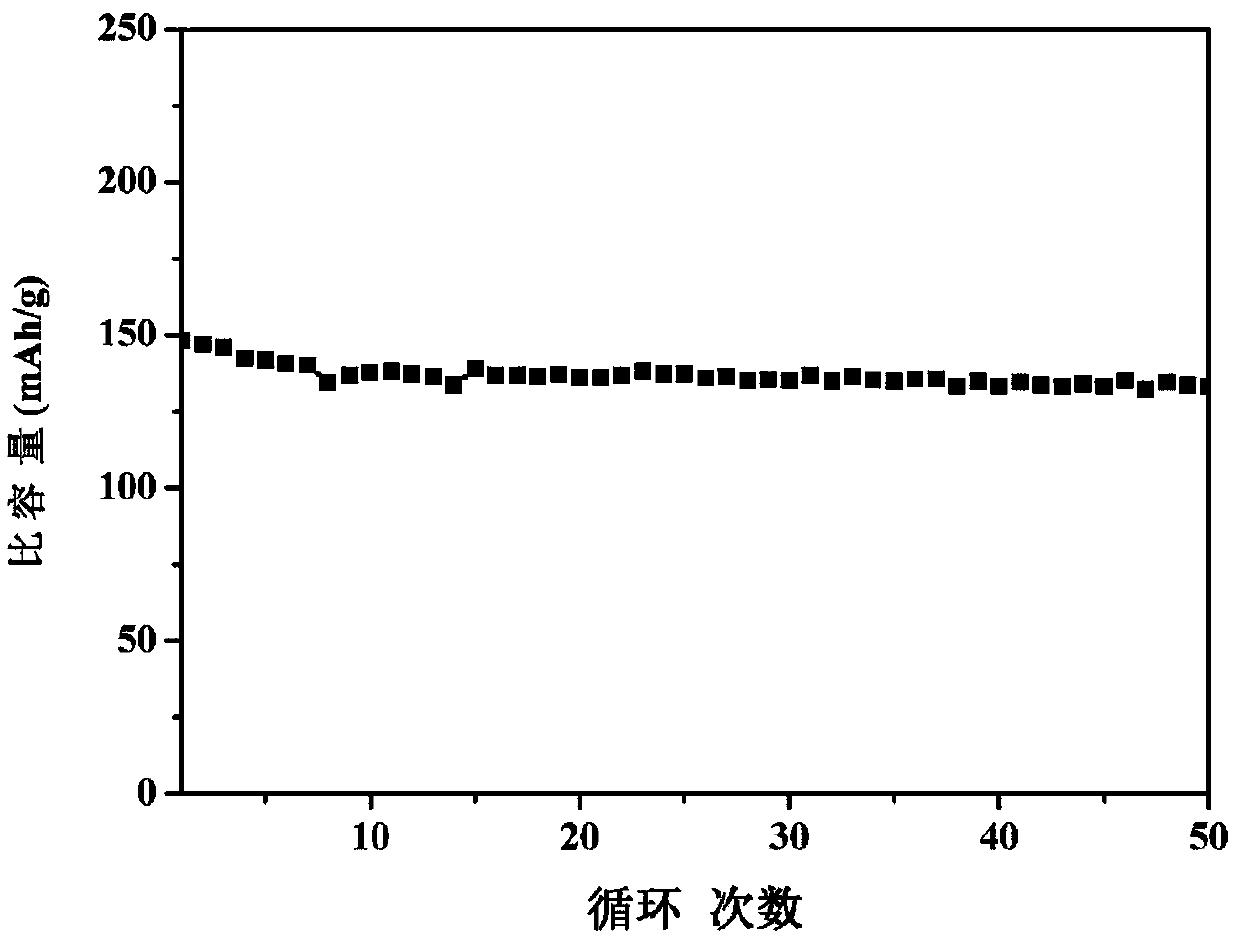

A photoelectric integrated thin film power supply system and its preparation and application

ActiveCN110071323BImprove energy efficiencyImprove portabilityPhotovoltaicsSecondary cellsElectrical batteryEngineering

The invention discloses a photoelectric integrated power supply and a preparation method thereof. A magnetron sputtering method is adopted to prepare a photoelectric integrated thin film power supplysystem. The power supply comprises a thin film substrate, a lithium-ion thin film battery arranged on one surface of the thin film substrate in a composite mode and a solar battery arranged on the other surface of the thin film substrate in a composite mode; and a cathode material layer and a light absorption layer are made of a silicon-based material or at least one of sulfide, oxide and selenium-based matter of at least one of copper, zinc, titanium, iron and tin. Through the design method, the defects of large scale, low efficiency and the like, caused by the situation that traditionally anexternal circuit is used to connect a solar battery and a lithium-ion battery, are overcome, and the energy efficiency and portability of the power supply system can be greatly improved. Meanwhile, by use of an electrode material, integrated application of the material is realized; and through the application mode, in the heat treatment process of a thin film made of the same substance, high crystallinity of the substance under the same temperature can be guaranteed, electrochemical properties of the material are improved, and battery conversion efficiency is improved.

Owner:CENT SOUTH UNIV

A method for removing organic matter in inorganic salts

ActiveCN107128951BAvoid cakingAvoid cloggingCalcium/strontium/barium chloridesChemical industryInorganic saltsSoil organic matter

The invention discloses a method for removing organic matters in inorganic salt. The method comprises the following steps: 1) cracking solid-state salt containing organic matter impurities under temperature less than a salt melting point and adding the cracked solid-state salt into a salt melting furnace; 2) heating to melt the solid-state salt into liquid-state salt; enabling the solid-state salt to flow through a plurality of containers arranged in high-temperature hot gas, so as to enable the high-temperature hot gas to be in direct contact with a liquid surface of the liquid-state salt in the containers; heating the liquid-state salt through the liquid surface of the liquid-state salt and container walls and cracking or oxidizing to remove the organic matters in the liquid-state salt; discharging the organic matters from a discharging hole. By adopting the method disclosed by the invention, the problems that the solid-state salt is caked and equipment is blocked are effectively solved; heat for melting the solid-state salt is also reduced and industrialized production is easy to realize; the permeation of the liquid-state salt is avoided; the method has the advantages of simple process, high heat transferring efficiency, capability of completely cracking the organic matters, reliability in operation, low cost, less waste gas amount, safety, simple structure and the like.

Owner:南京诚朴环保科技有限公司

Photoelectric integrated thin film power supply system and preparation and application thereof

ActiveCN110071323AImprove energy efficiencyImprove portabilityPhotovoltaicsSecondary cellsCrystallinitySolar battery

The invention discloses a photoelectric integrated power supply and a preparation method thereof. A magnetron sputtering method is adopted to prepare a photoelectric integrated thin film power supplysystem. The power supply comprises a thin film substrate, a lithium-ion thin film battery arranged on one surface of the thin film substrate in a composite mode and a solar battery arranged on the other surface of the thin film substrate in a composite mode; and a cathode material layer and a light absorption layer are made of a silicon-based material or at least one of sulfide, oxide and selenium-based matter of at least one of copper, zinc, titanium, iron and tin. Through the design method, the defects of large scale, low efficiency and the like, caused by the situation that traditionally anexternal circuit is used to connect a solar battery and a lithium-ion battery, are overcome, and the energy efficiency and portability of the power supply system can be greatly improved. Meanwhile, by use of an electrode material, integrated application of the material is realized; and through the application mode, in the heat treatment process of a thin film made of the same substance, high crystallinity of the substance under the same temperature can be guaranteed, electrochemical properties of the material are improved, and battery conversion efficiency is improved.

Owner:CENT SOUTH UNIV

Portable finance service terminal

InactiveCN107358760ASolve large-scaleImprove service qualityComplete banking machinesDigital data authenticationElectricityComputer terminal

The invention relates to a portable financial service terminal, including a portable terminal and a server terminal; the portable terminal includes a human-computer interaction interface and a communication module, an ID card identification module, a fingerprint input module and a financial module electrically connected with it; the The server terminal includes a communication module, an identity verification module and an instruction sending module; the communication connection between the portable terminal and the server terminal is completed through the communication module. Through the above method, the present invention solves the problem of large-scale traditional financial terminals, so that financial related staff can improve their own service quality, complete door-to-door service for specific customers, and improve the industry image.

Owner:CHENGDU USINGWIN ELECTRONICS TECH CO LTD

A New Industrial Fluidized Bed Reactor with Inorganic Thermal Superconducting Technology

ActiveCN105664806BRemove heatPrevent removalChemical/physical processesThermal insulationFluidized bed

The invention discloses a novel industrial fluidized bed reactor adopting the inorganic thermal superconducting technology.The novel industrial fluidized bed reactor comprises a barrel body and one or more inorganic thermal superconducting pipes arranged in the barrel body; the barrel body is separated into a thermal insulation area, a heat exchange area and a reaction area from top to bottom through an upper partition plate and a lower partition plate; each inorganic thermal superconducting pipe is internally provided with a casing pipe, a cavity between each casing pipe and the corresponding inorganic thermal superconducting pipe is filled with an inorganic thermal superconducting working medium, each internally-arranged casing pipe comprises an internally-arranged electrical heating pipe on the lower portion and a lead-out wire protective pipe on the upper portion, and the two ends of each inorganic thermal superconducting pipe extend into the thermal insulation area and the reaction area respectively.By means of the novel industrial fluidized bed reactor, the structural form of an existing industrial fluidized bed is changed completely, and the novel industrial fluidized bed reactor had the advantages that a cold medium (or a heat medium) is isolated from the reaction area, heating and heat obtaining are integrated, the structure is simple, maintenance is convenient to conduct, heat transfer efficiency is high, temperature uniformity inside a bed is good, operation safety is high, and the applicable temperature range is wide.

Owner:南通科恩化工技术有限公司 +1

A CT Image Reconstruction Method Based on Variational Inequality under Sparse Sampling Angles

ActiveCN104103086BGuaranteed piecewise smoothnessSmall amount of calculation2D-image generationComputerised tomographsHat matrixComputed tomography

The invention discloses a CT (Computed Tomography) image reconstruction method based on a variational inequality at a sparse sampling angle. The CT image reconstruction method comprises the following steps: (1) carrying out equal-angle interval projection scanning within an angle range of 0-180 degrees by aiming at a fan-beam CT to obtain spare projection data y, wherein an angle interval in a projection direction is between 2 and 6 degrees; (2) calculating a projection matrix A through an X-ray source, a detector and the position information of an object to be reconstructed; (3) according to the projection data y obtained in the step (1) and the projection matrix A obtained in the step (2), simultaneously introducing the sparsity and the non-negativity of an image gradient to serve as priori knowledge to obtain a reconstruction model of an image reconstruction problem at the sparse sampling angle; (4) converting the reconstruction model in the step (3) into a variational inequality form; and (5) solving the variational inequality in the step (4) to obtain a reconstructed image. On the premise that image reconstruction quality is guaranteed, reconstruction convergence speed can be quickened, and single-iteration time is shortened.

Owner:SOUTH CHINA UNIV OF TECH

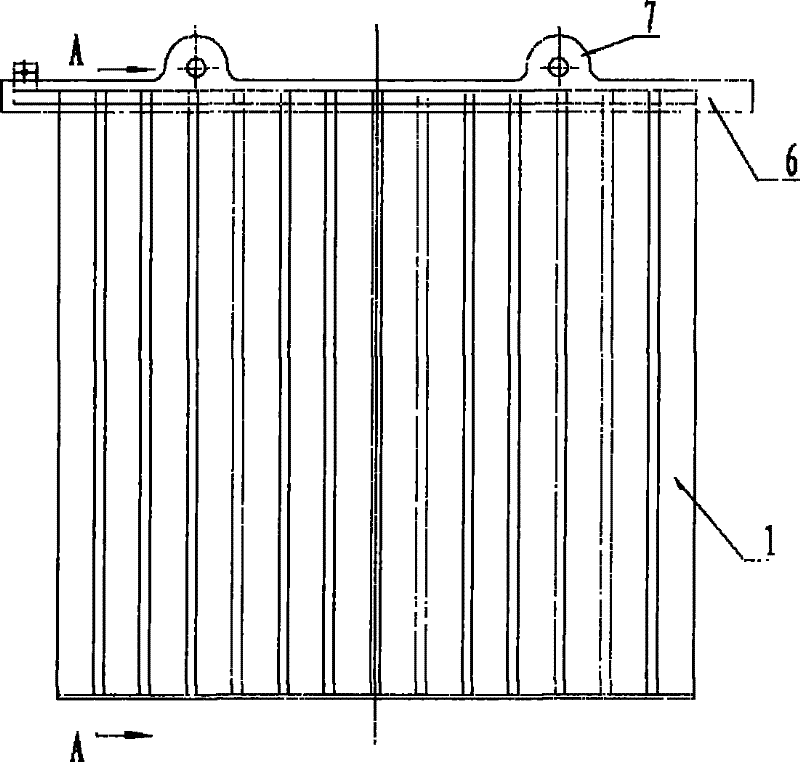

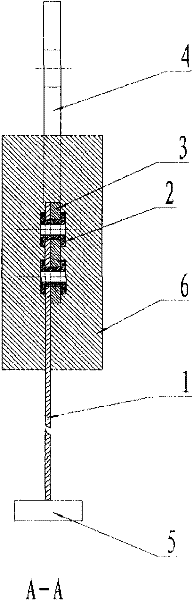

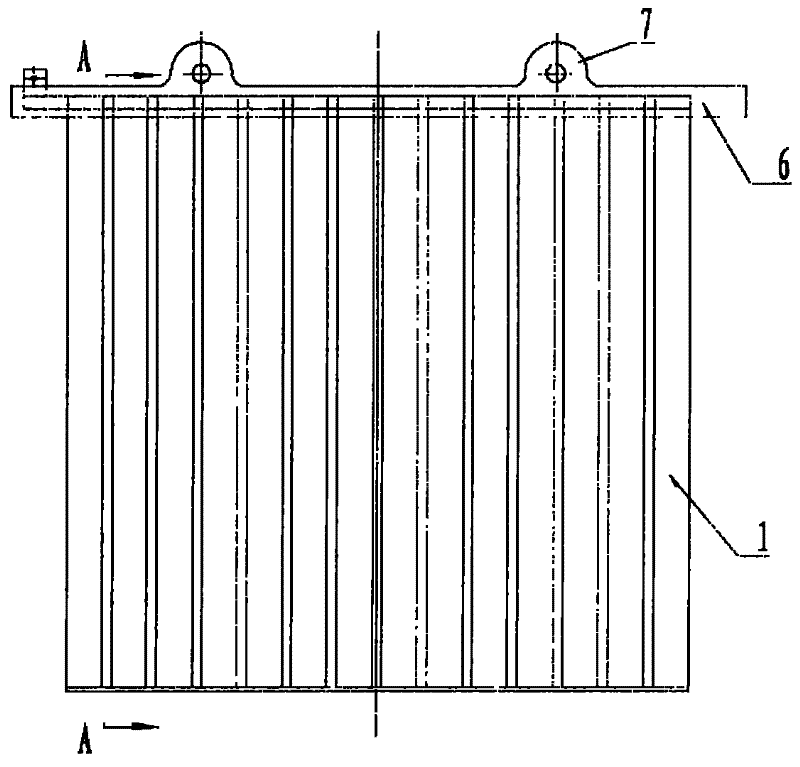

Method for preparing positive plate for electrolyzing manganese dioxide

ActiveCN101705499BStrong passivation resistanceReduce manufacturing costElectrode shape/formsMetal coatingHeating time

The invention discloses a method for preparing positive plates for electrolyzing manganese dioxide, which belongs to the technical field of preparation of positive plates for electrolysis. The preparation method comprises the steps of coating a layer of metal powder on the surface of a titanium plate; conducting high-temperature vacuum pulling-sintering to the titanium plate coated with metal powder to form a compound positive strip with metal coating on the surface and titanium in the center; and conducting welding assembly and aluminum-casting assembly to a plurality of compound positive strips to obtain the positive plates, wherein the high-temperature vacuum pulling-sintering is carried out at the temperature of 1000 to 1400 DEG C; and the pulling speed is controlled to ensure that the effective heating time of each part of work pieces is between 5 and 120 minutes. The positive plate prepared by the method for electrolyzing manganese dioxide has high anti-passivation property, andbath voltage of the positive plate is lower than that of the pure titanium positive plate by more than 0.5 to 1 volt; after being discharged from a trough by electrolysis, the positive plates can be directly put in the trough to continue the electrolysis of the next cycle, without depassivation processes such as sand-blasting or anti-electrolysis and the like; therefore, the production efficiencyis high and the manufacturing cost is low; and the positive plates are ideal positive plates for electrolyzing manganese dioxide.

Owner:有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com