Integral seal punch molding method of nuclear power pressure container

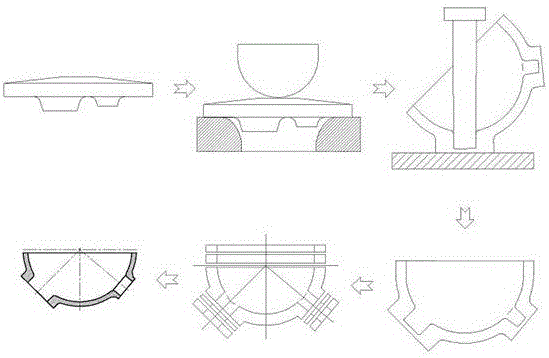

A stamping forming and pressure vessel technology, which is applied in the field of stamping forming of the integrated head of the pressure vessel used in nuclear power, can solve the problems of poor quality stability in the stress area, rising manufacturing costs, complicated welding process, etc., and achieve stable comprehensive mechanical properties and eliminate Internal stress, improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

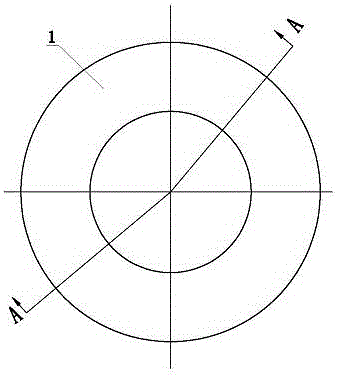

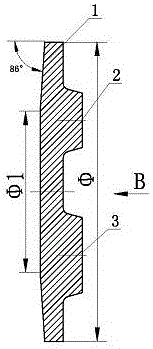

[0030] In this process step, firstly select such as figure 2 , image 3 and Figure 4 As shown in the head slab, the material of the head slab is 508-3 steel.

[0031] Rough processing of slab: Carry out preliminary machining on the head slab to facilitate the rough forming of the next head. First, the outer periphery of the slab is turned to remove the burr and concave-convex surface of the slab to form a circular plate-shaped slab; milling is used The four conical surfaces and the end faces of the four circular platforms on the reverse side of the head slab are machined by other machining methods; the front of the slab is turned by turning and other machining methods to form a circular table with a large cone angle on the front of the slab. The conical angle of the conical table is controlled at 170°-175°, and the conical angle of the conical table is the angle between the two busbars on the same plane. The ratio of the upper and lower diameter φ1 of the large cone angle...

Embodiment 2

[0040] Still choose to have in this embodiment figure 2 , image 3 and Figure 4 For the head slab of the structural shape shown, the material of the head slab is still 508-3 steel, but the outer dimension and weight of the head slab in this embodiment are larger than the head slab in Embodiment 1.

[0041] Rough machining of the slab: firstly, the outer periphery of the slab is turned to remove the burr and concave-convex surface of the slab, thereby forming a circular plate-shaped slab; using milling and other machining methods to machine the four conical surfaces and Its end face; the front of the slab is turned by turning and other machining methods to form a circular table surface with a large cone angle on the front of the slab. The cone angle of the circular table is controlled at 170°-175°. The slab body of the head slab The ratio of the upper and bottom diameter φ1 of the upper large cone angle circular table to the outer diameter φ of the slab main body is: φ1 / φ=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com