Manufacturing method of antenna device

A technology of antenna device and manufacturing method, applied in the directions of antenna support/mounting device, antenna coupling, radiation element structure form, etc., can solve the problems such as bad influence of antenna device 935 characteristics, large-scale, antenna device 935 exceeding, etc., and achieve solution Adverse effects, the effect of solving large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described below with reference to the drawings.

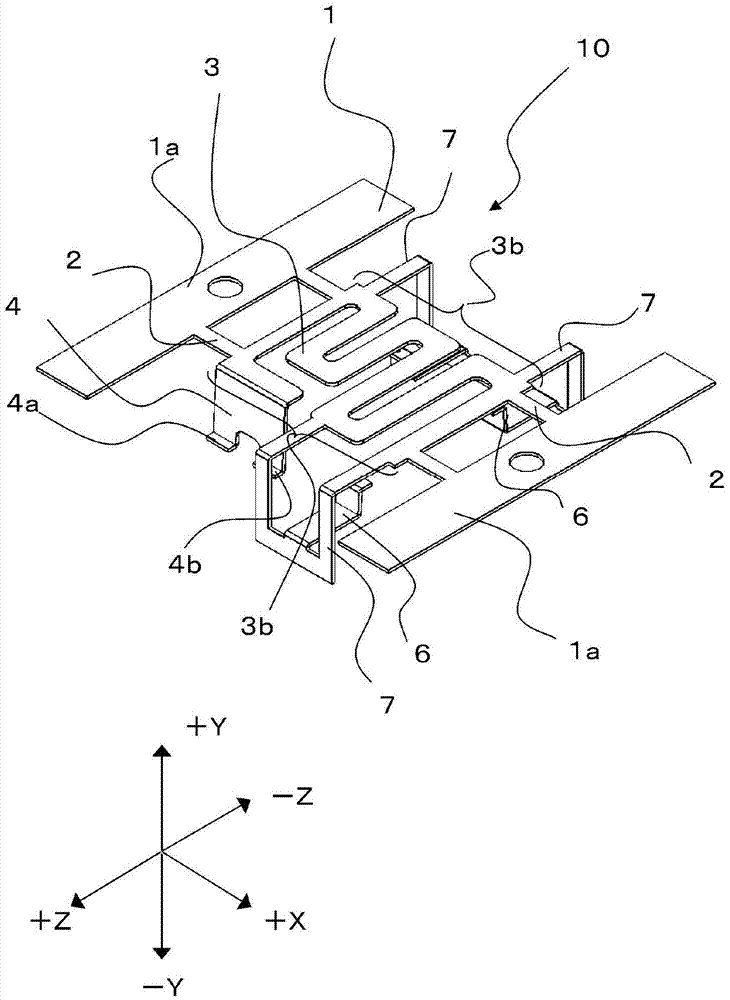

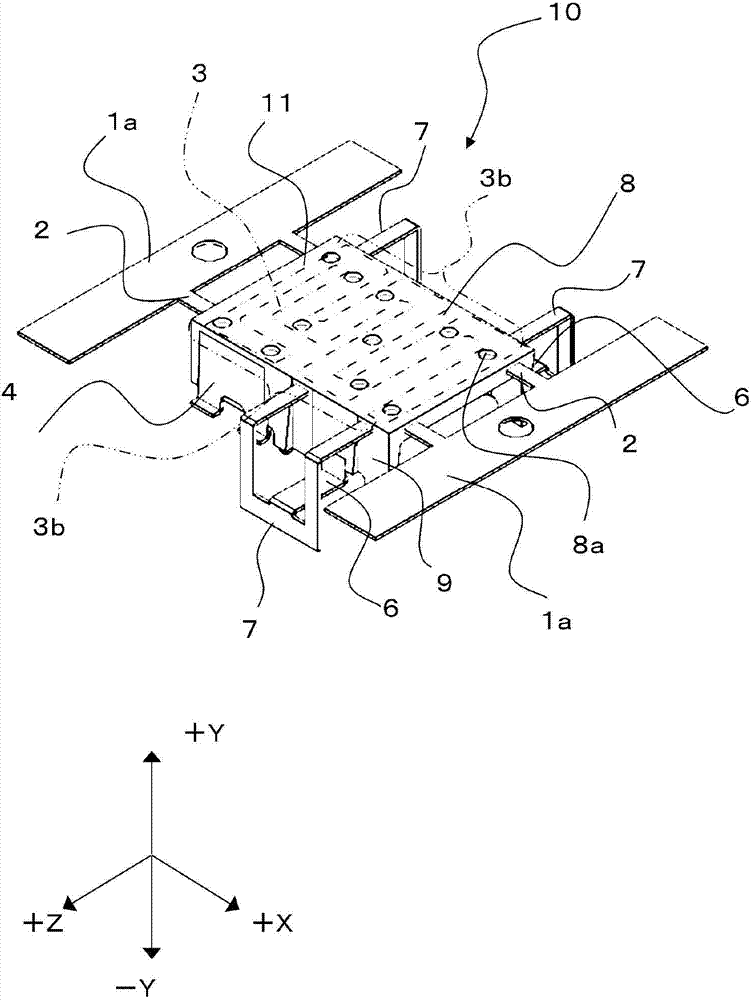

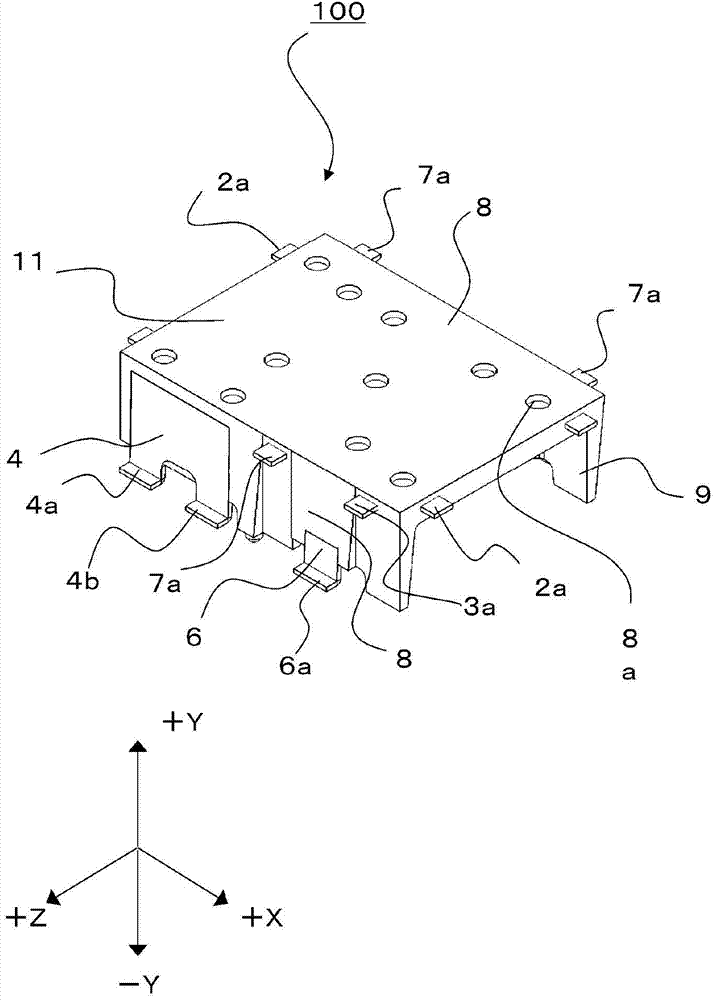

[0054] The present invention is an antenna device manufacturing method for manufacturing an antenna device based on an antenna component made of metal, figure 1 It is a perspective view after bending the antenna component involved in the antenna device manufacturing method of the present invention. figure 2 for right figure 1 The perspective view of the antenna part after resin inlay molding, image 3 for right figure 2 A perspective view of the antenna assembly after cutting and removing the link stack.

[0055] In the antenna device manufacturing method related to the embodiment of the present invention, after punching the metal plate 1 according to the shape of the antenna, as figure 1 As shown, the stamped metal sheet 1 is bent, whereby the antenna component 10 is formed. In addition, the detail of a bending process is mentioned later.

[0056] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com