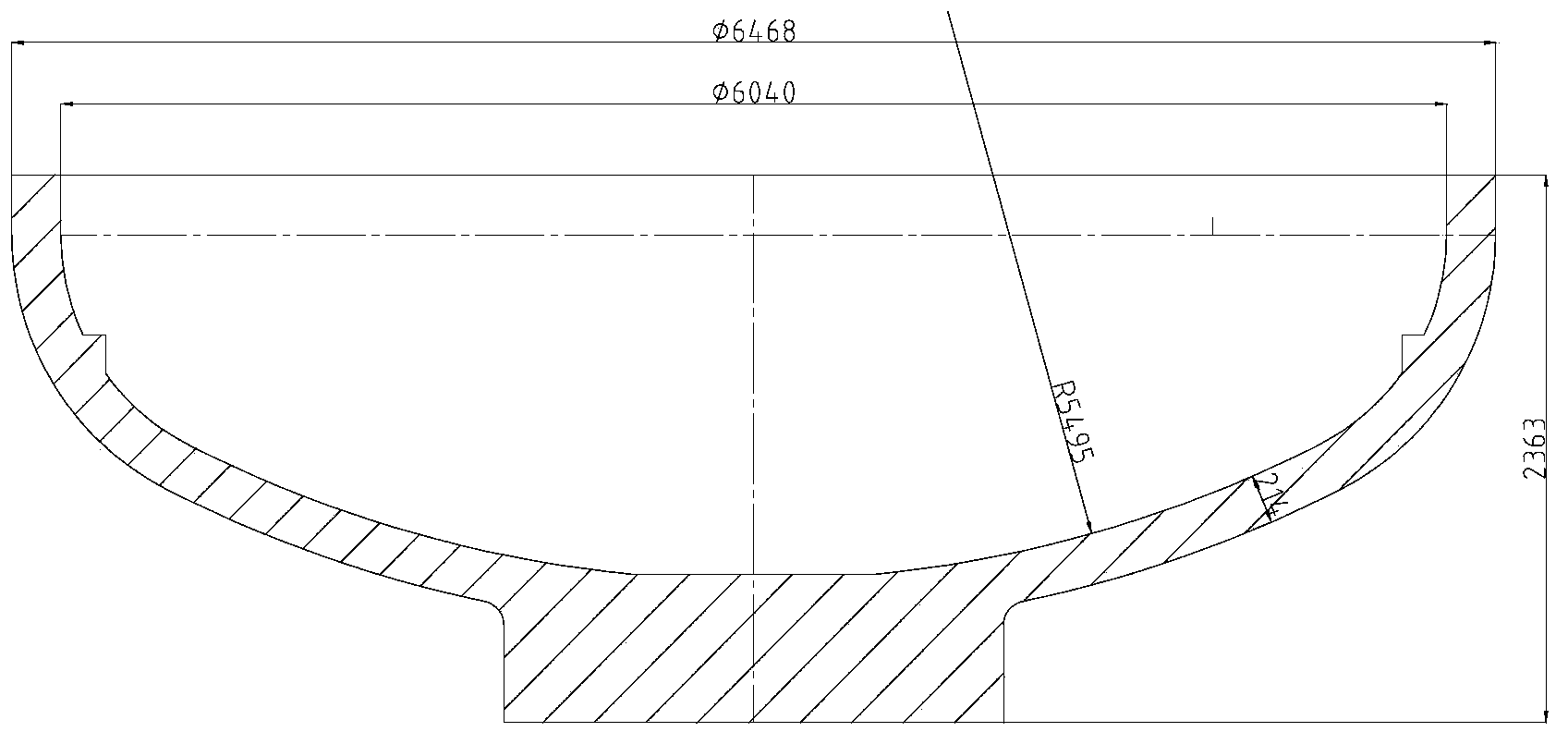

Forging method for elliptical seal head of CAP1400 steam generator

An elliptical head and steam generator technology, which is applied to metal processing equipment and other directions, can solve the problems of small head slabs, inability to directly stamp and forge oval heads, etc., and achieve the effect of solving manufacturing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method for forging and forming the elliptical head of the CAP1400 steam generator of the present invention is used for the forging and forming of the super-sized elliptical head with an inner diameter not less than 5000mm, comprising the following steps:

[0035] The first step is blank making; forming a circular slab with a diameter of 7200±100mm and a thickness of 330±10mm (maximum thickness), such as figure 2 As shown; the top surface of the circular slab is a plane, and the thickness of the central part of the circular slab is greater than the thickness of the peripheral part;

[0036] The second step is heating; put the round slab into the heating furnace for heating, so that the temperature of the round slab is controlled at 900-1150°C; when heating, place a pad iron under the round slab to make the round slab The two sides of the body are evenly heated and kept warm so that the surface is at the same temperature as the heart;

[0037] The third step is to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com