Method for preparing ultralow elasticity modulus high-wearing feature shell microstructural membrane on surface of titanium

A technology with elastic modulus and high wear resistance, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of poor medical performance and achieve the effect of simple process and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a shell-type microstructure film with ultra-low elastic modulus and high abrasion resistance on the surface of titanium metal, comprising the following steps:

[0030] First, using titanium metal as the base material and pure magnesium as the target material, a layer of inductive pure magnesium interlayer film is evenly deposited on the surface of the cleaned titanium metal base material by using magnetron sputtering technology in a direct current manner;

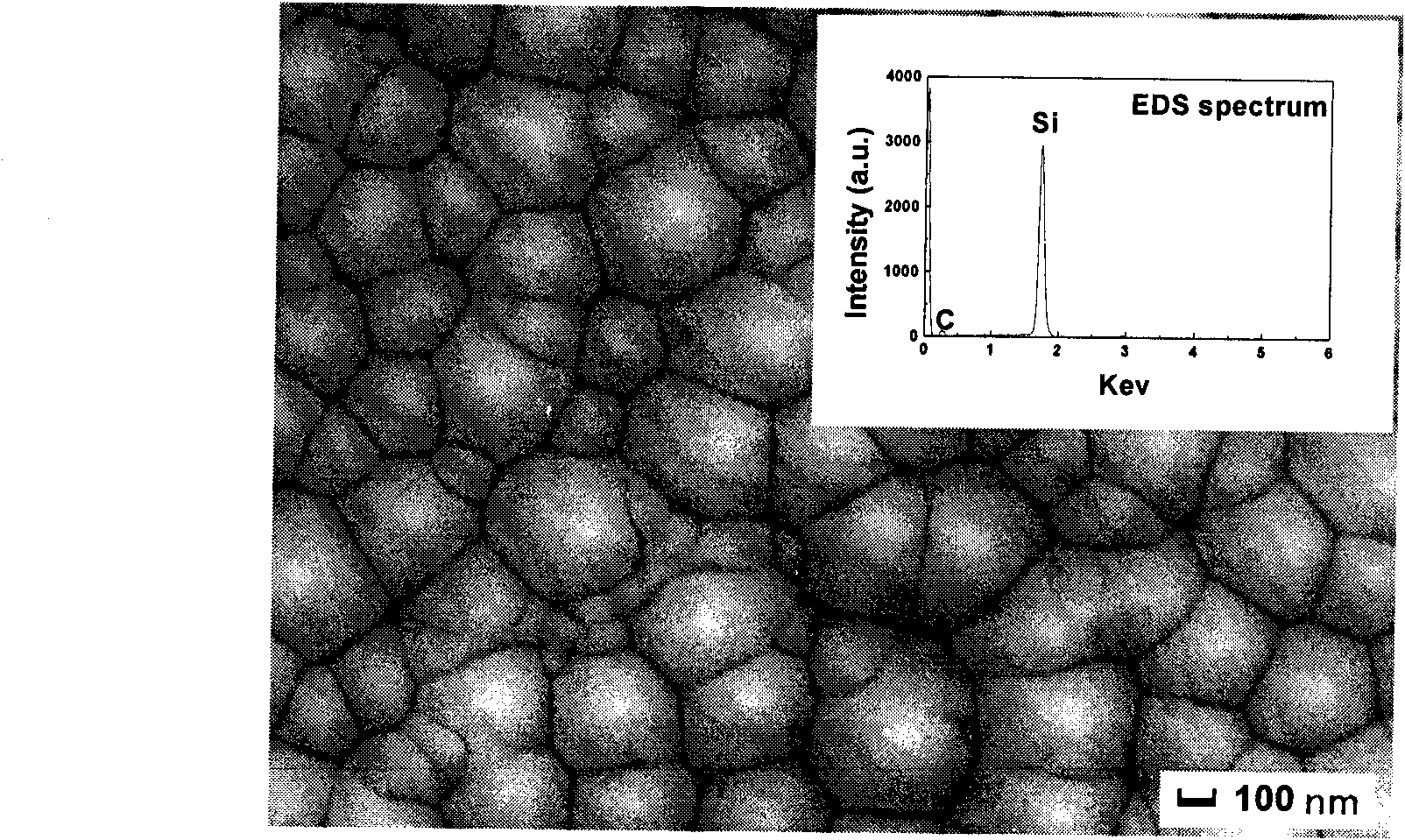

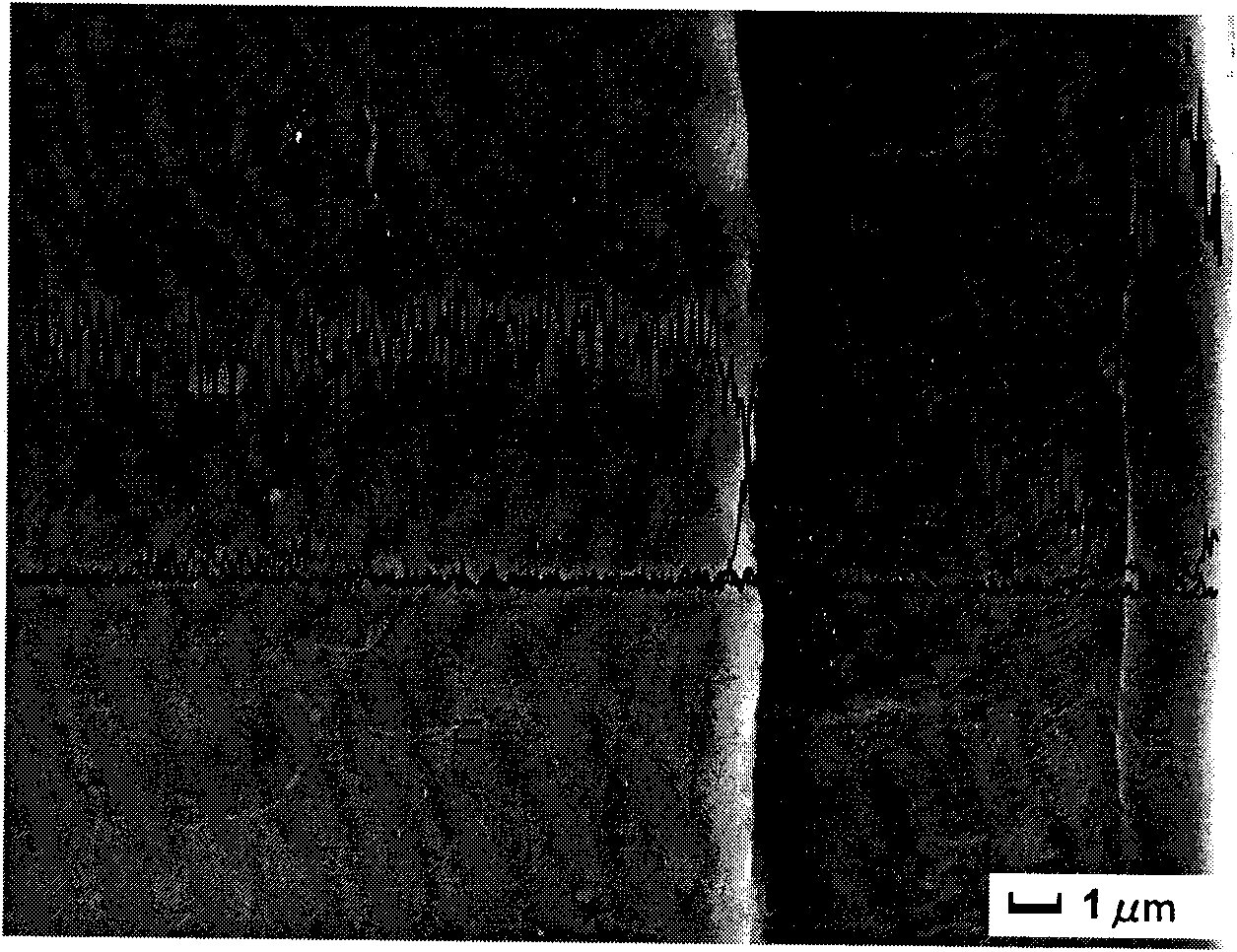

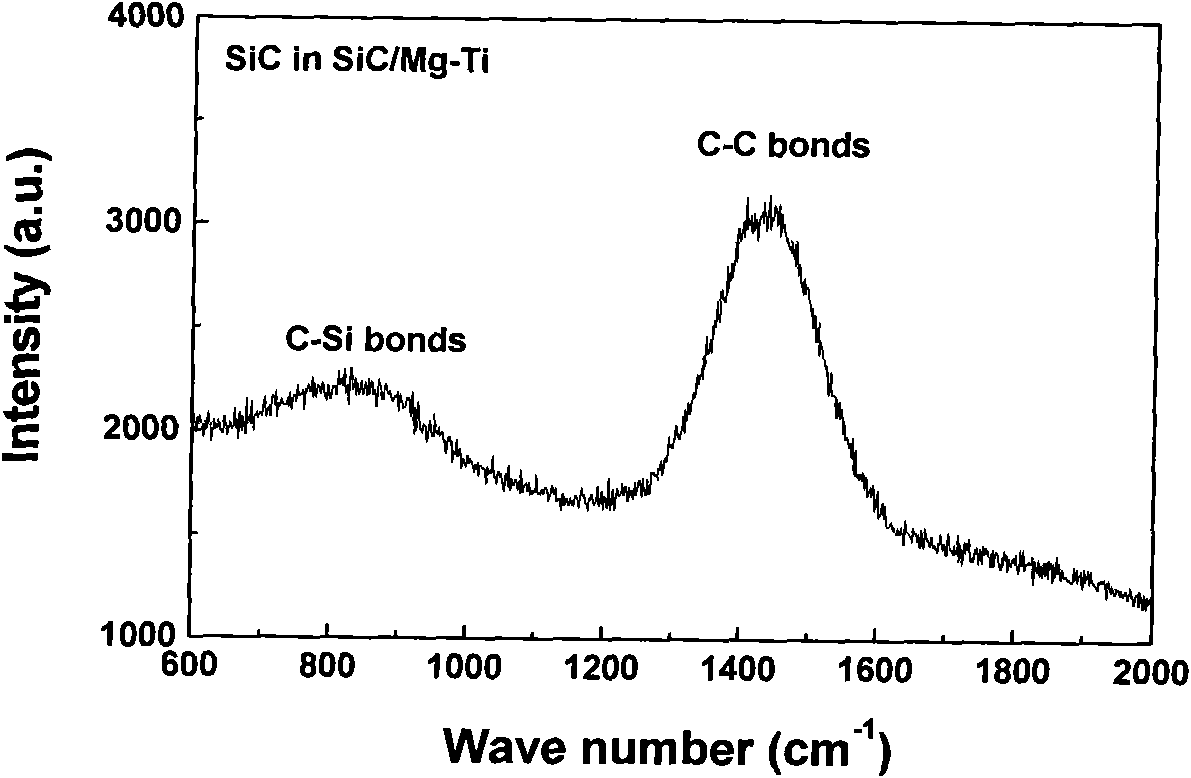

[0031] Secondly, immediately after the deposition of the interlayer film, the magnetron sputtering technology is used to deposit the silicon carbide film on the interlayer film by radio frequency, and the silicon carbide film is combined with multiple shell-shaped structures of submicron scale by relying on the diffusion of magnesium. body, so that the elastic modulus of the final surface film is between 7 and 30 GPa.

[0032] The cleaning of the base material and pure magnesium refers to remov...

Embodiment 2

[0036] Such as Figure 1-8 shown.

[0037] The base material is titanium, there is a magnesium interlayer film, and the surface film is a silicon carbide film. Follow the steps described in Example 1. The background pressure when preparing magnesium film and silicon carbide film is 2.5×10 -5Pa and substrate temperature are all at room temperature, and the target-substrate distance is 70 mm. The technology used when depositing the magnesium film is the direct current (DC) magnetron sputtering technology, the target material is pure magnesium, the pressure of the working gas (argon) is 1.1Pa, the flow rate of the argon gas is 56sccm, the sputtering power is 100W, and the sputtering The time is 60 minutes. The technology used to prepare the silicon carbide film is radio frequency (RF) magnetron sputtering technology, the target material is silicon carbide, the pressure of the working gas (argon) is 2.0Pa, the flow rate of argon gas is 52sccm, and the sputtering power is 200W....

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com