Micro electrochemical machining device and machining method for discontinuous microstructures on inner wall of micro heat pipe

A technology of micro electrolysis and machining device, which is applied in electric machining equipment, electrochemical machining equipment, machining electrodes, etc., can solve the problems of tool electrode wear, difficulty in deep processing of micro heat pipe inner wall, low efficiency of EDM method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Using the micro electrolytic machining device of the present invention to electrolytically process micro heat pipes

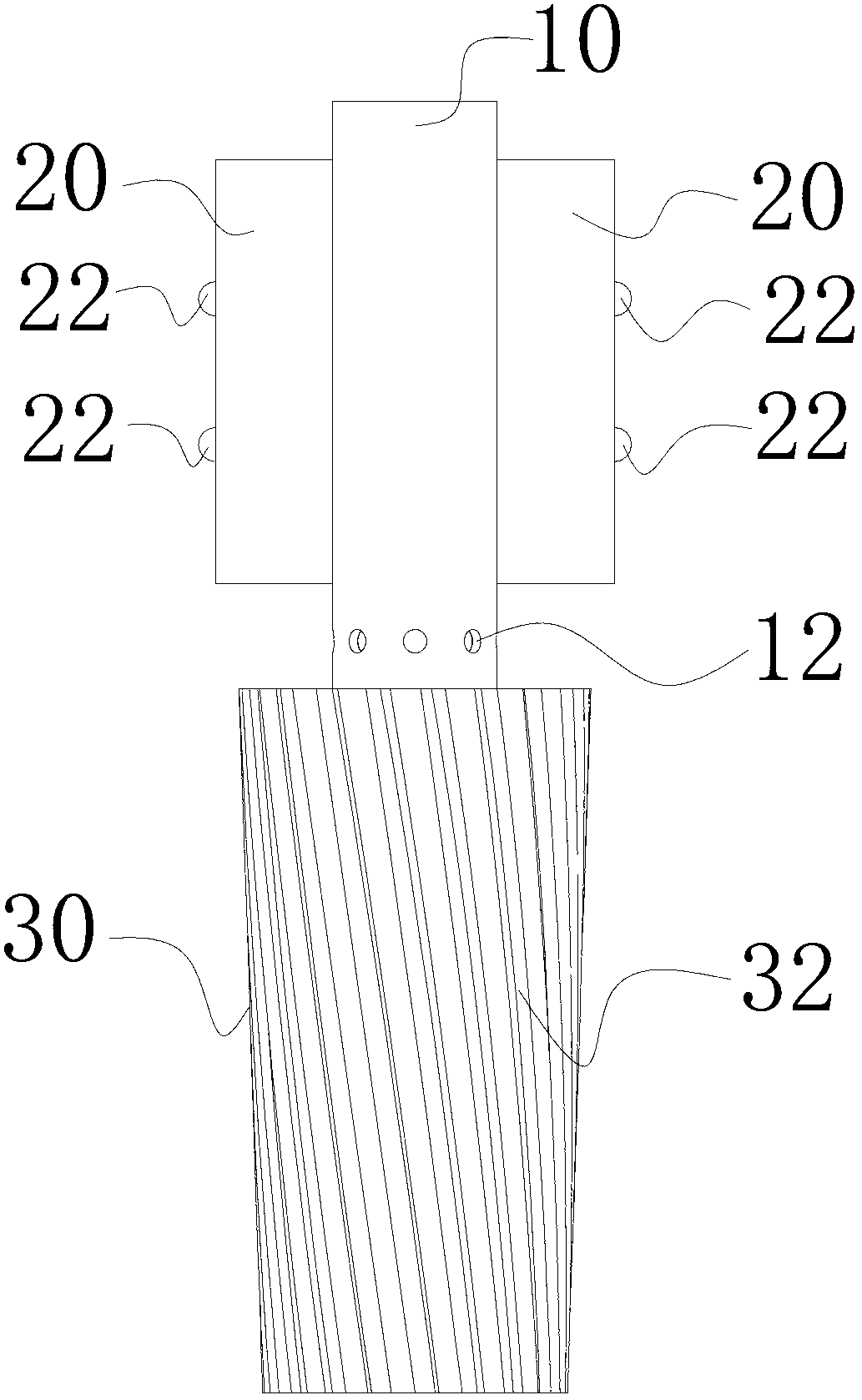

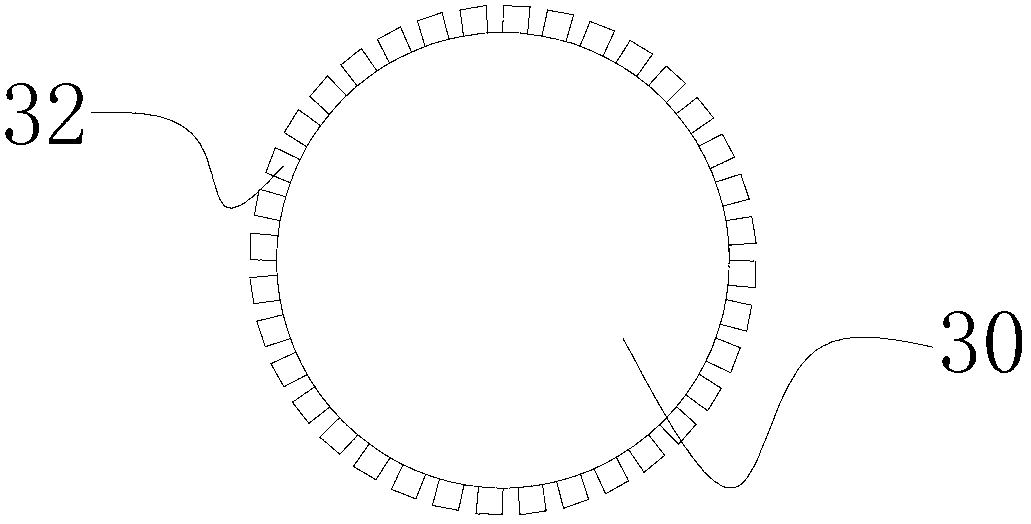

[0038] Using the discontinuous structure micro-electrolytic machining device on the inner wall of the micro-heat pipe according to the present invention to perform electrolytic machining on the micro-heat pipe, as shown in the attached image 3 As shown, in general, the micro heat pipe 40 is clamped on a special fixture (not shown in the figure), the lower end of the conductive liquid guide rod 10 of the electrolytic processing device is connected to the working cone 30, and the upper end is clamped on the micro electrolytic processing device. The main shaft of the machine tool (not shown in the figure) is connected with the electrolyte pool (not shown in the figure), the positive pole of the power supply 50 is connected with the micro heat pipe 40 , and the negative pole is connected with the conductive liquid guide rod 10 . The guide devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com