Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Save welding material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

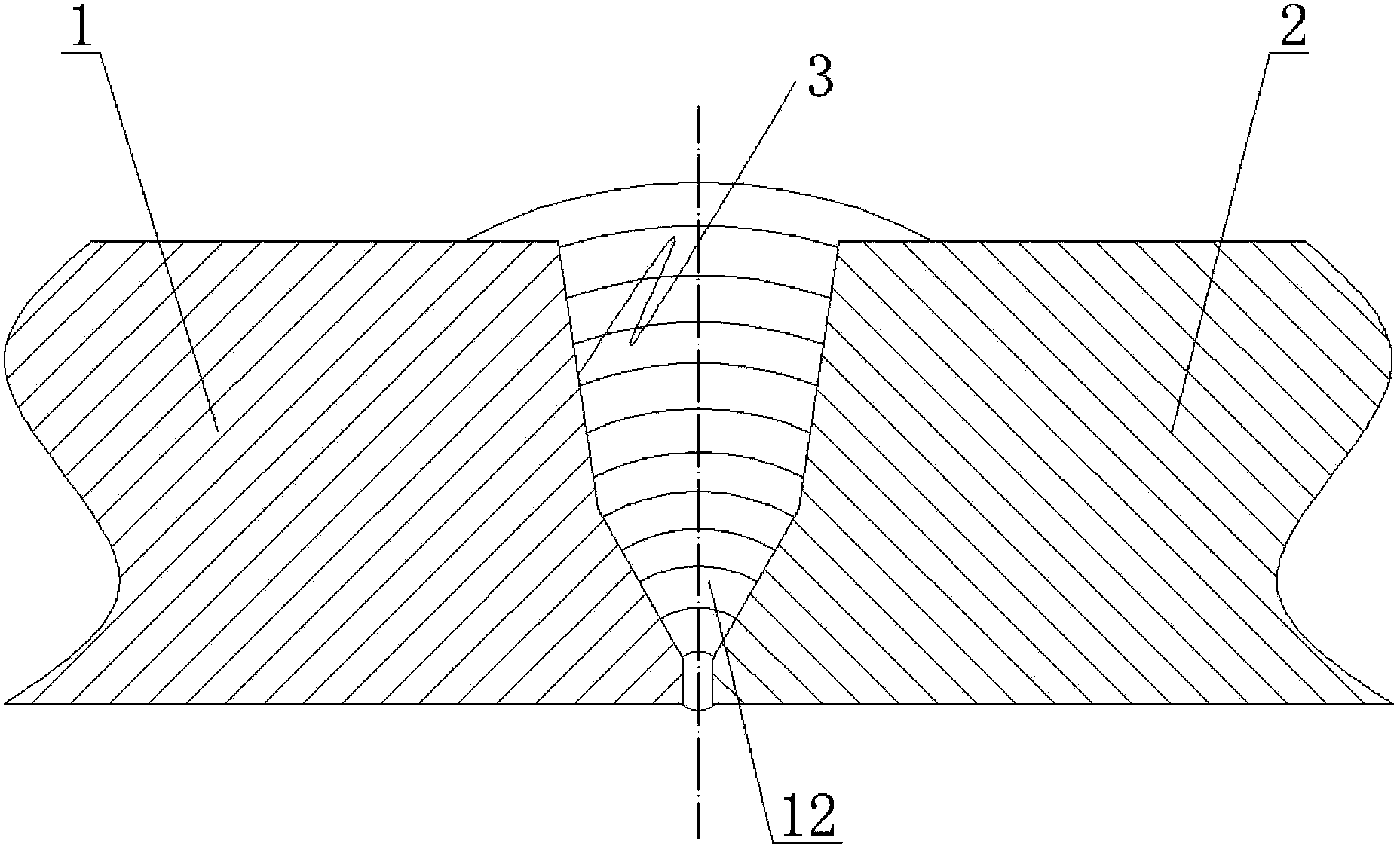

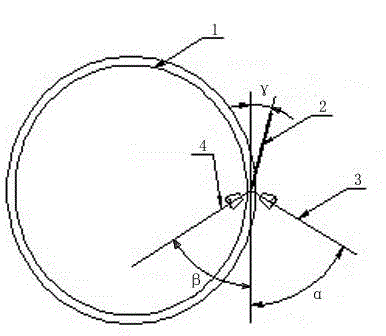

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

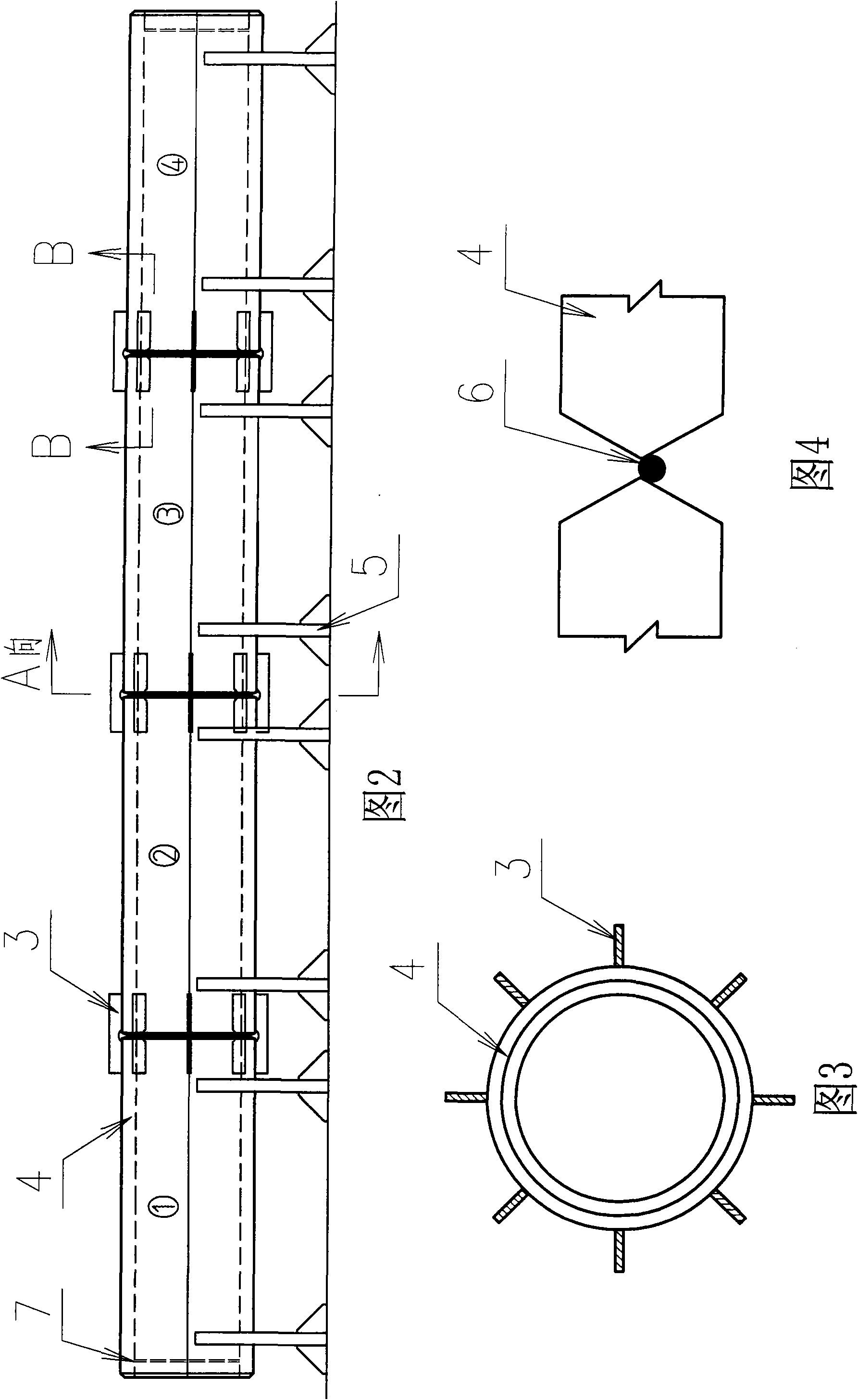

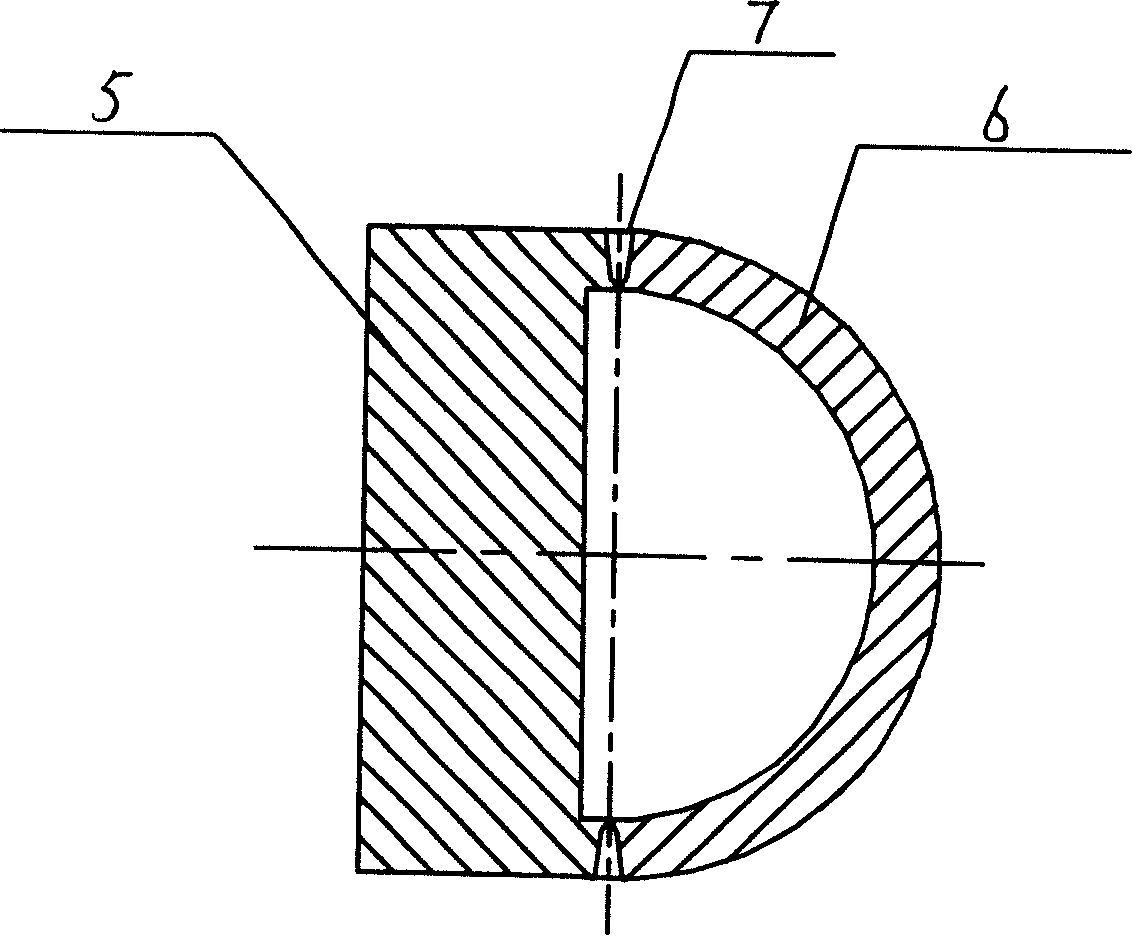

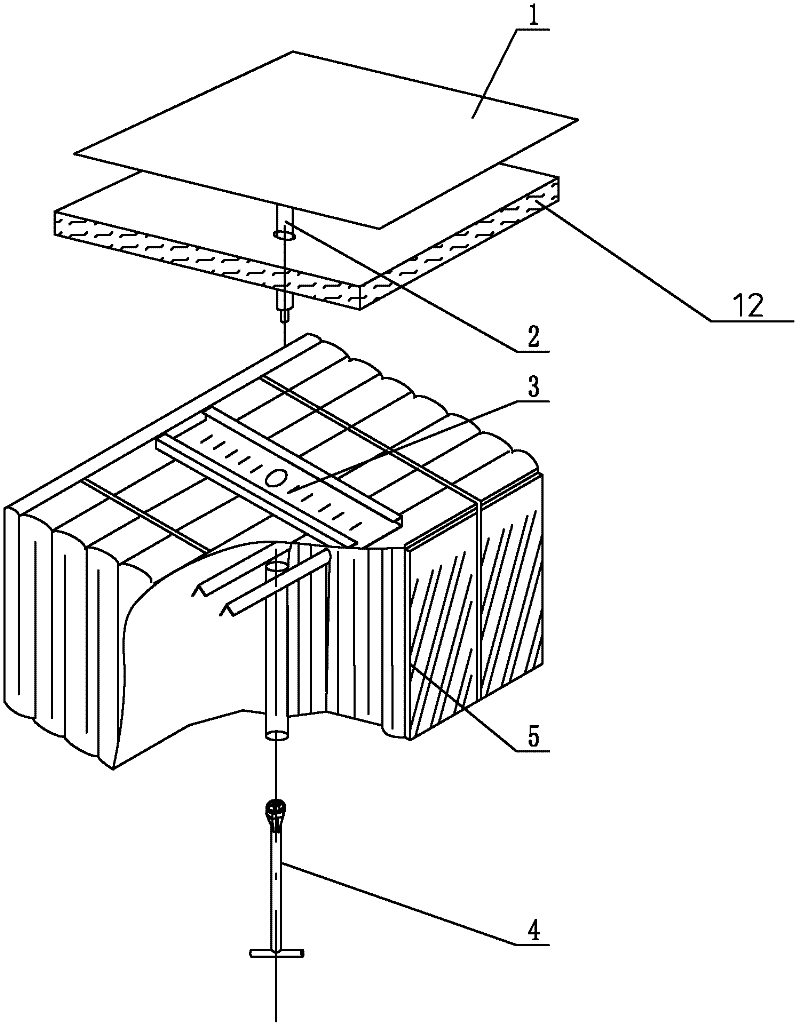

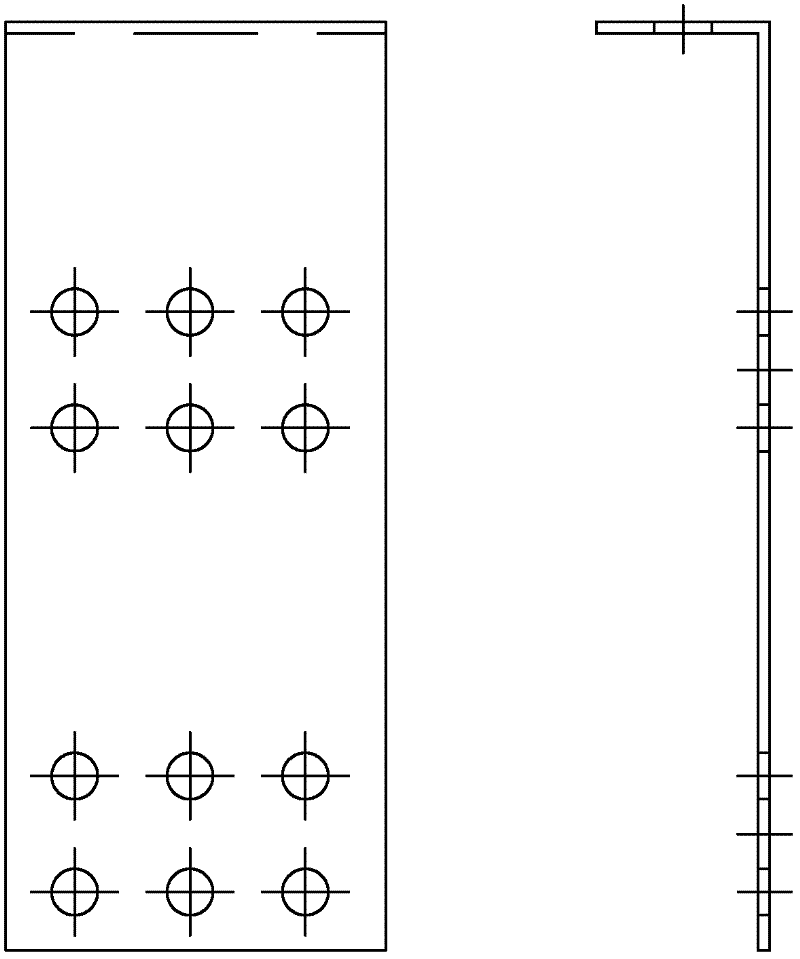

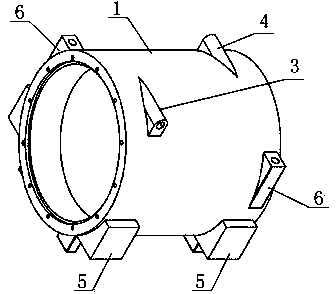

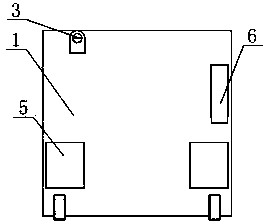

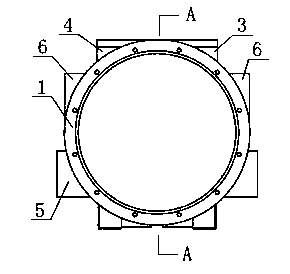

Manufacturing method for ultra-long and ultra-thick circular plate

ActiveCN101579700AImprove mechanical propertiesReduce stressWelding/cutting auxillary devicesArc welding apparatusChemical industryButt welding

A manufacturing method for ultra-long and ultra-thick circular plate is suitable for the steel circular plate which has a length more than 10 meters and has a thickness more than 100 millimeters. The method comprises the following steps: forging a plurality of segments of ultra-thick cylinders; carrying out mechanical processing to make the inner diameter, the wall thickness and the surface roughness accord with the requirements; and processing bevels at two ends. The invention is characterized in that the plurality of segments after procession are placed on a rolling jig bed 5; an interface part is fixed with a fixing plate; then the butt welding is performed after the bevels are added with ceramic gaskets 6; the long cylinder is prepared; the cutting is performed; and the ultra-long ultra-thick circular plate with the required dimension is manufactured. The invention has the advantageous of capability of manufacturing the ultra-long and ultra-thick circular plate with the length of more than 10 meters and the thickness of more than 100 millimeters, having high mechanical property of the manufactured plate, and having simple and convenient manufacturing method, easy operation and reduced manufacturing cost. The manufacturing method for ultra-long and ultra-thick circular plate can be widely used in the watercraft manufacturing industry and other mechanical chemical industry.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

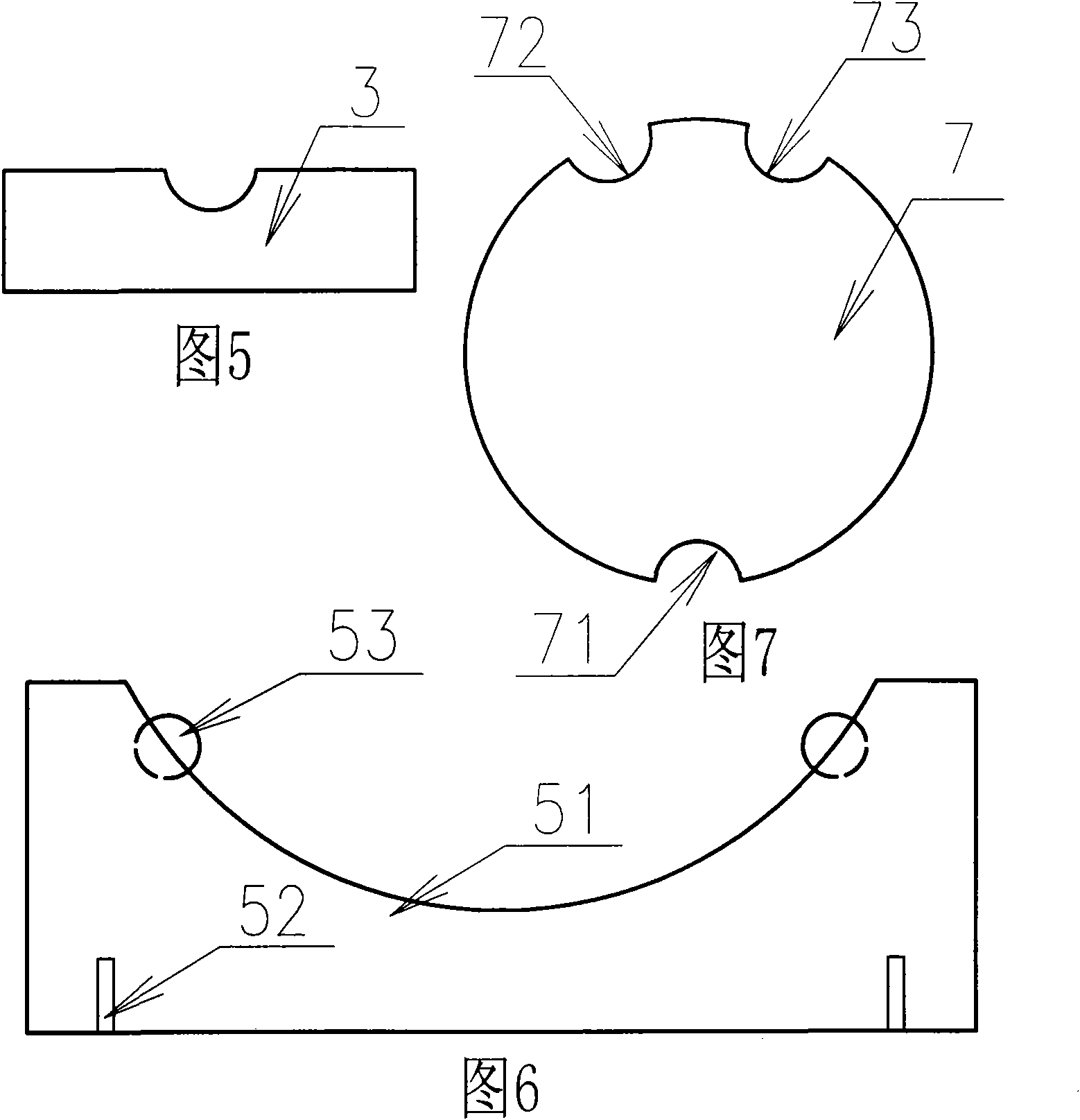

Processing method of press forming soldering high rolling composite blank

InactiveCN1686653AReduce welding workloadReduce edge lossWelding/cutting media/materialsAuxillary arrangementsManufacturing technologyDetackifier

A technology for making the combined blank includes providing the basic metal plate and additional metal plate, cleaning their surfaces, putting two additional metal plates between two basic ones, putting solder between the basic and additional metal plates, putting the high-temp detackifier between two additional metal plates, welding sealing plates on their periphery while pressing, drilling holes, vacuumizing, heating, hot pressing and cooling.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

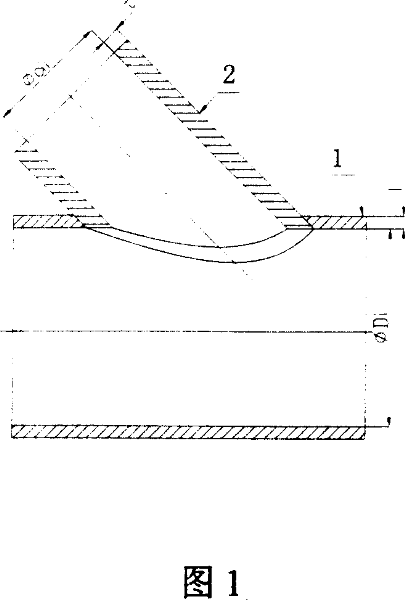

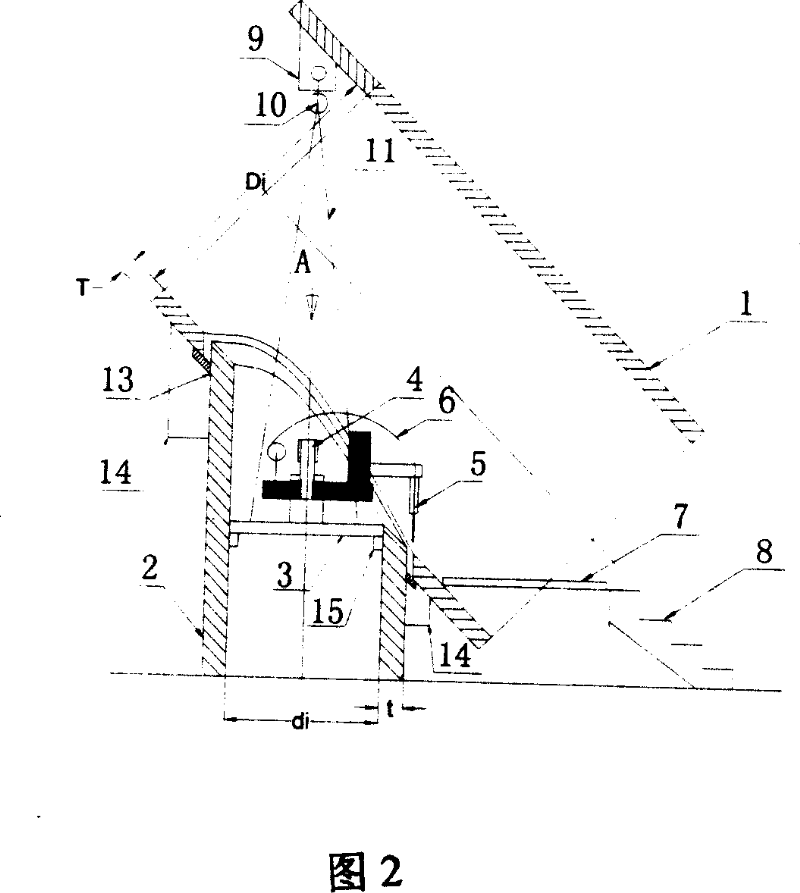

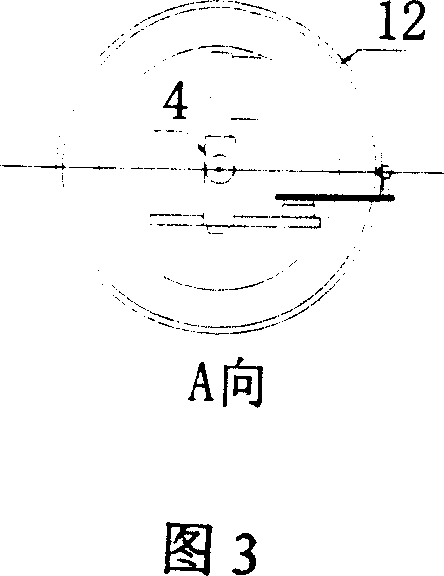

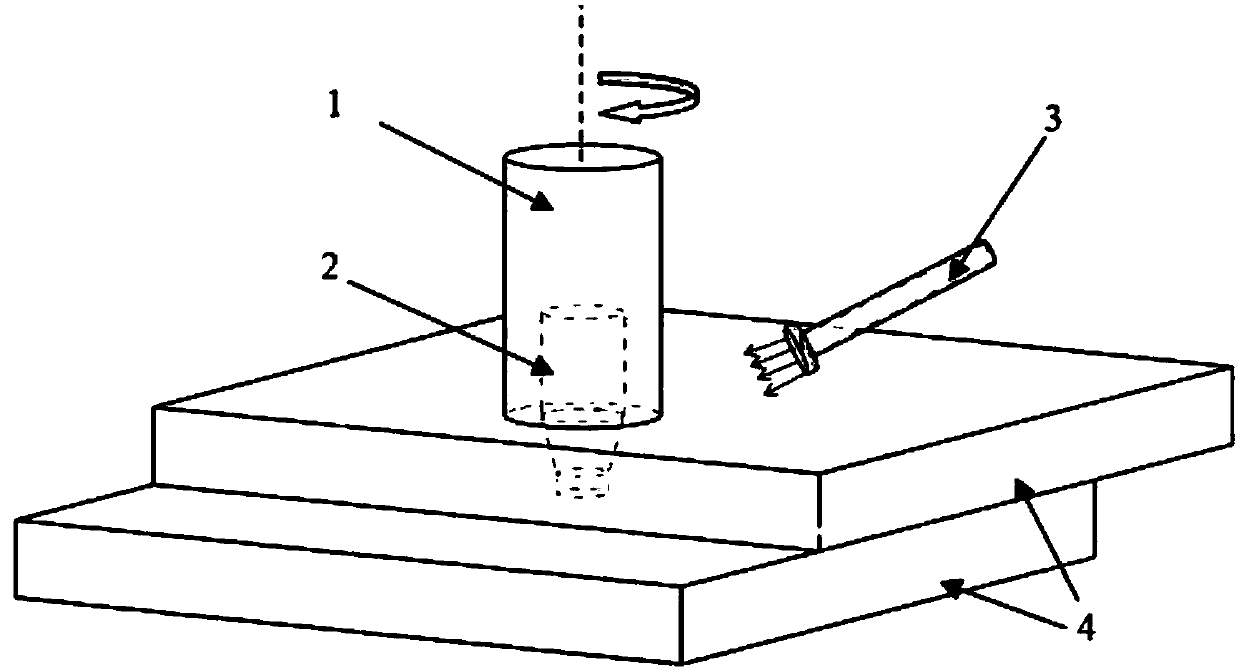

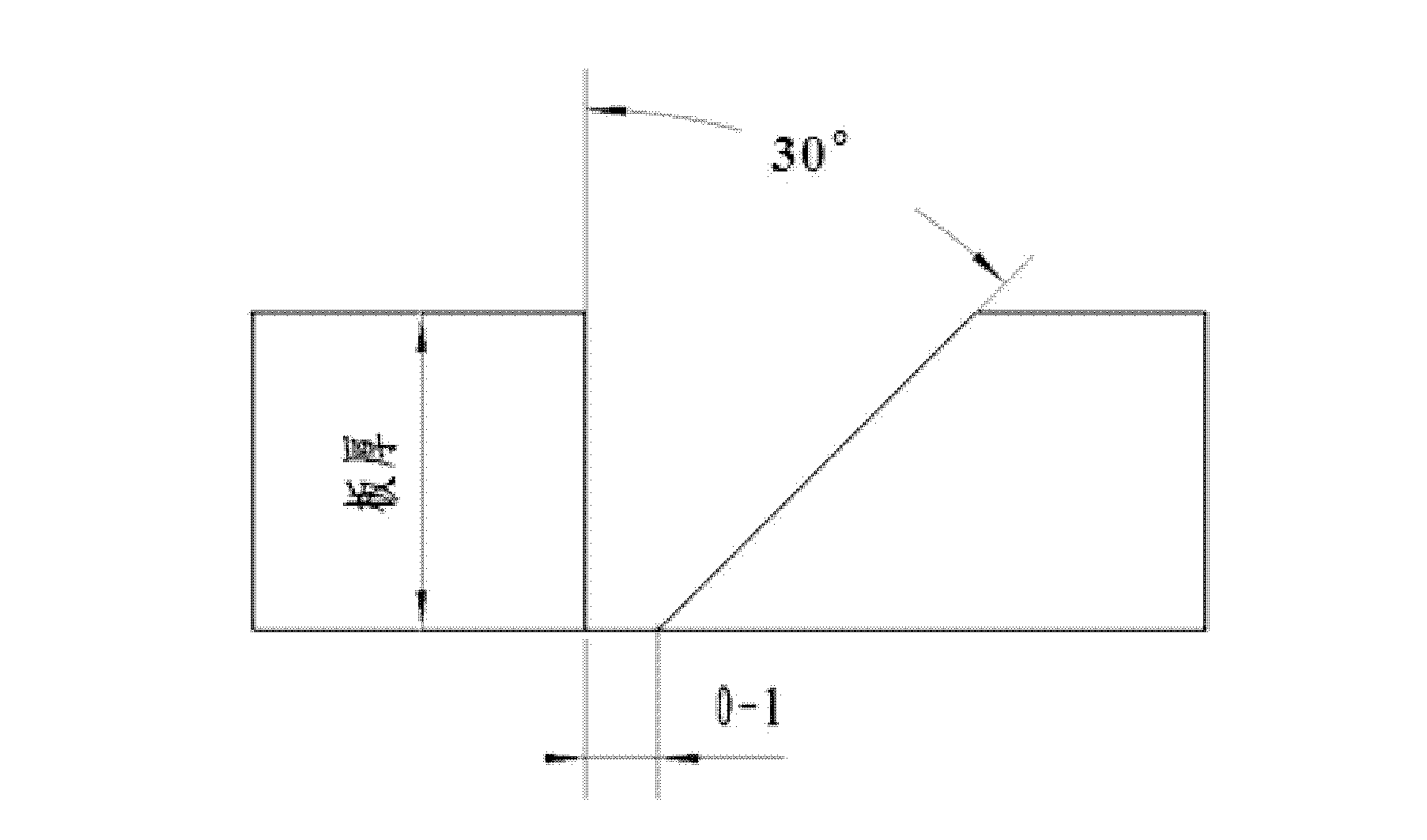

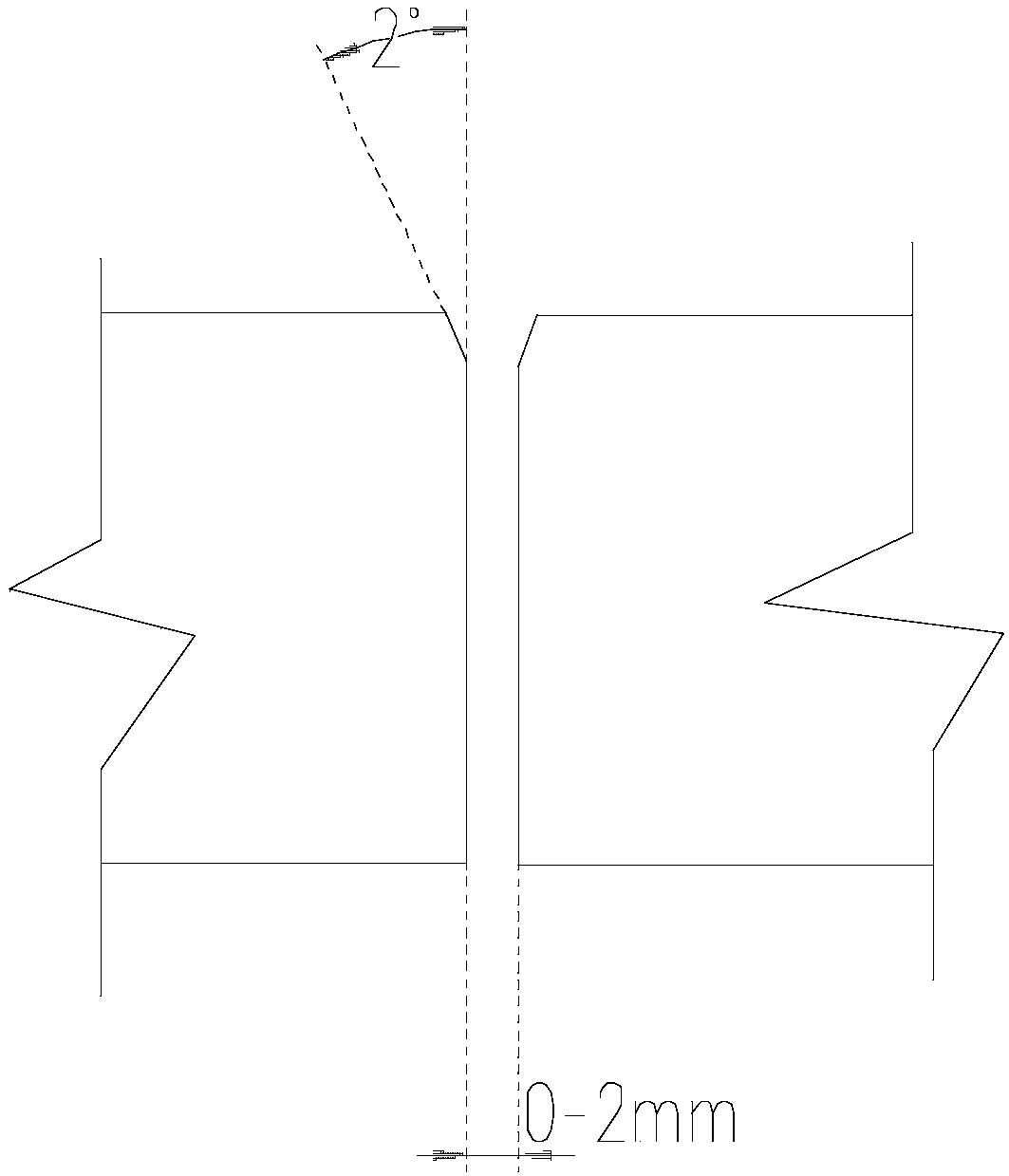

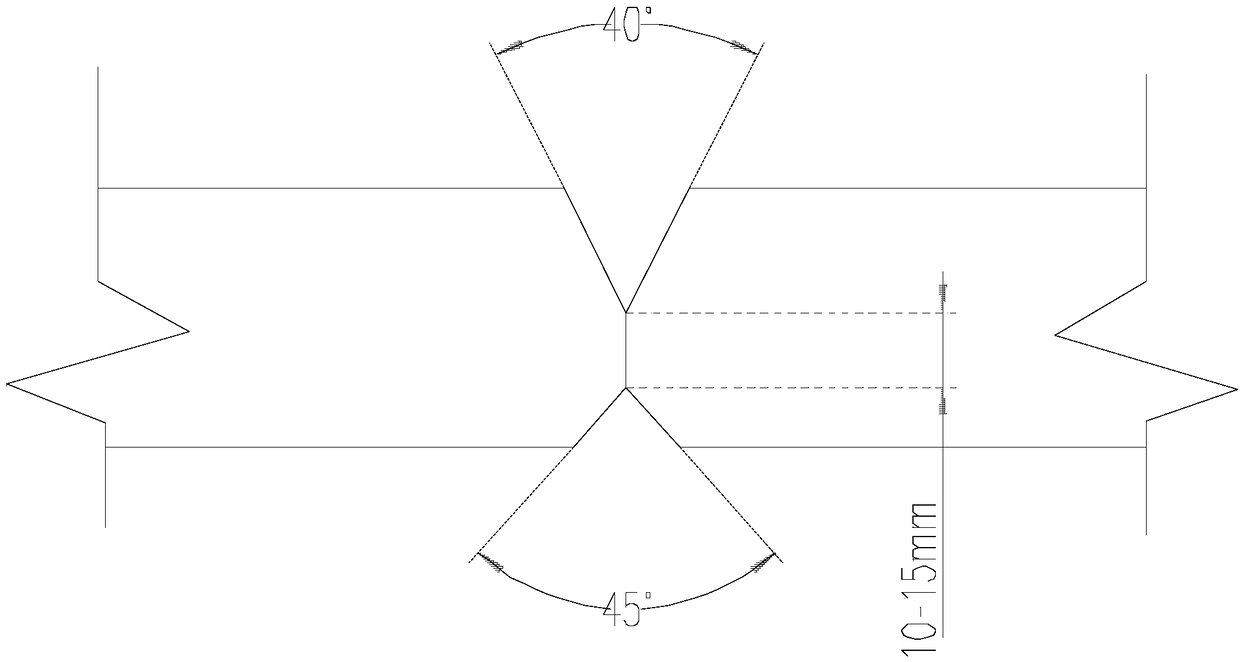

Method of welding the plug in type connection nozzle and the un-orthogonal crossed connection nozzle of the cylinder

ActiveCN101041200AImprove welding efficiencySave welding materialArc welding apparatusWorkpiece edge portionsSubmerged arc weldingEngineering

The invention relates to a welding method for insertion nozzle and cylinder non-rectangular intersection connector, characterized in that saddle automatic submerged arc welding machine or deep and narrow groove welding torch is used; the groove shape is I-type, namely the angle of groove at two sides is O; the nozzle is set vertically and the cylinder is oblique; auxiliary tooling is used; the welding method from the lower part to middle part to upper part is adopted to achieve purposes of automatic submerged arc welding and control deformation. The merit of invention is that the influence of human factor to welding quality is decreased; the welding efficiency is improved greatly and the machining period is shortened; welding material can be saved notably; welding quality can be guaranteed in effect; and the machining cost is decreased greatly.

Owner:SHANGHAI BOILER WORKS

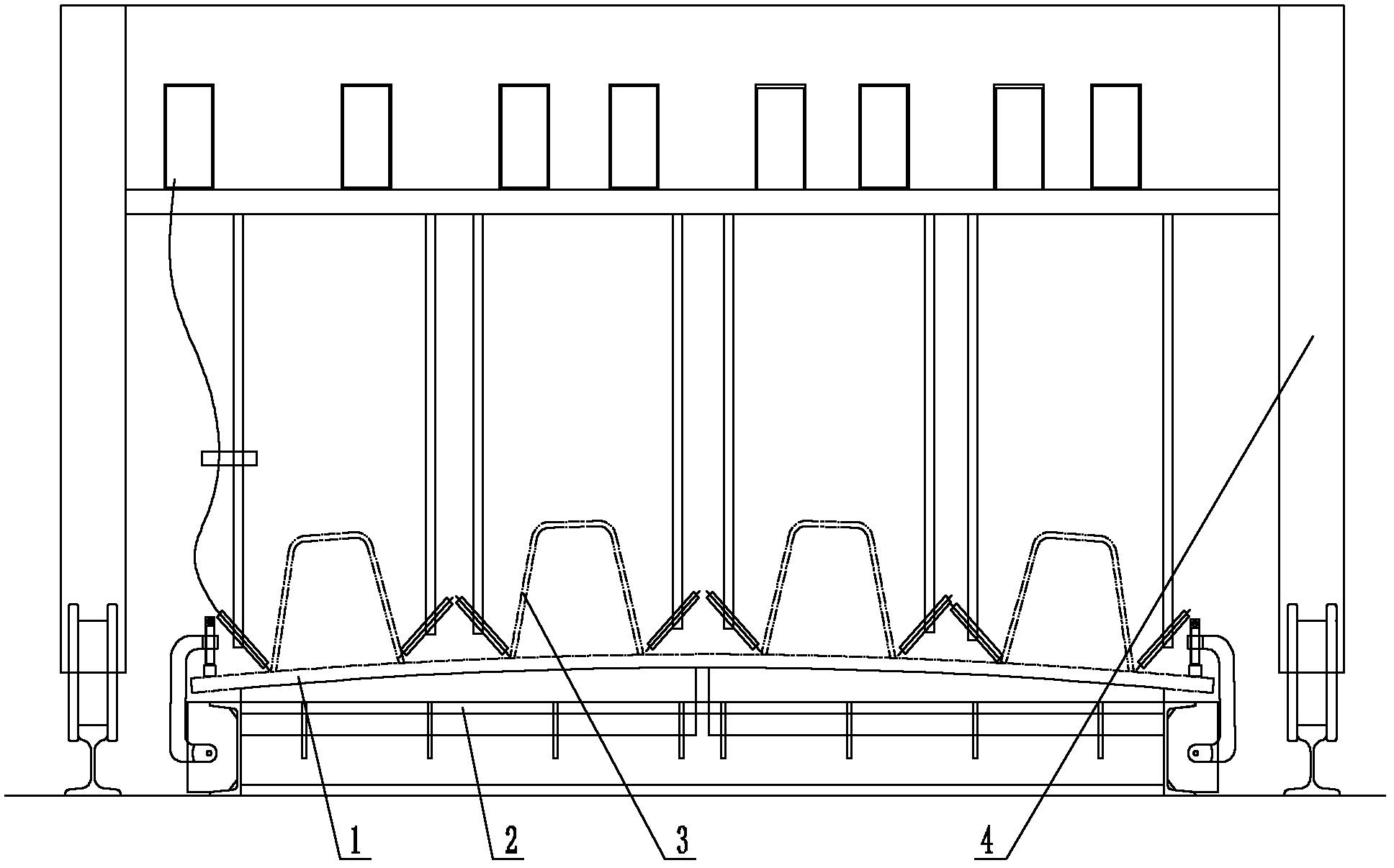

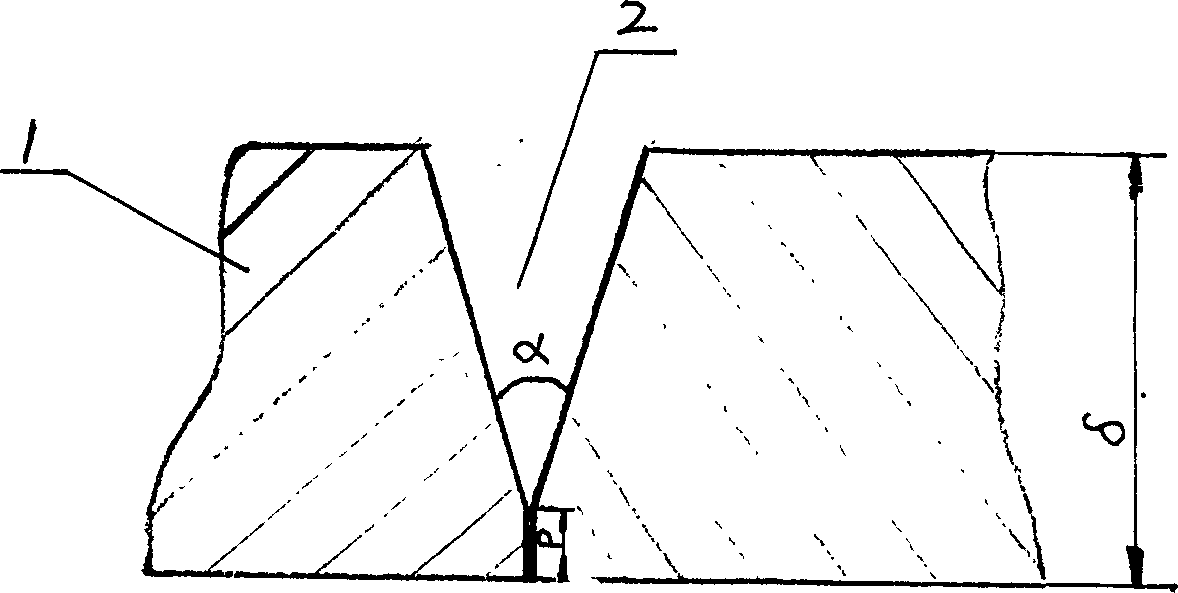

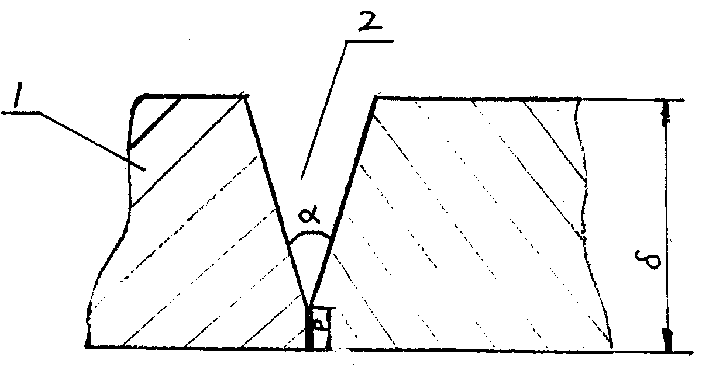

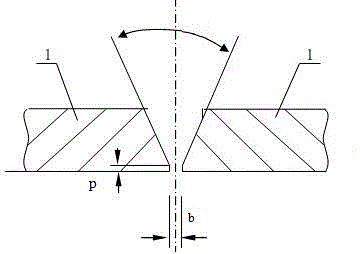

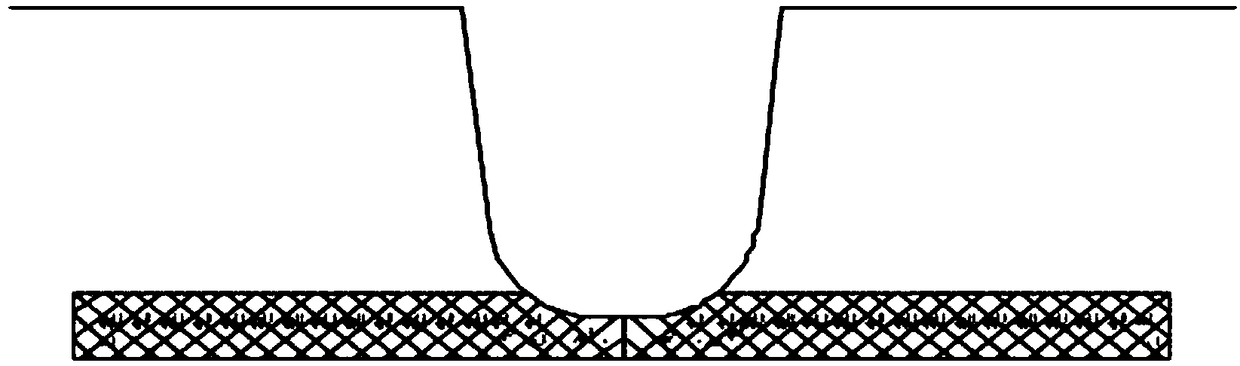

Welding method for U-shaped ribs of orthotropic plate of bridge girder

ActiveCN102601498ASolve the problem of penetrationSolve slag inclusionArc welding apparatusWorkpiece edge portionsStructural engineeringEngineering

A welding method for U-shaped ribs of an orthotropic deck plate of a bridge girder comprises the following steps that: 1) bevels are formed at the outer sides of the U-shaped ribs, each truncated edge P is 1-3mm, and the angle alpha of each bevel is 45-55 degrees; 2) the U-shaped ribs are longitudinally arranged on the deck plate and are positioned on the deck plate; 3) the deck plate is fixed on a reversible deformation jig frame, and the reversible deformation angle is 0.3-0.45 degrees; and 4) the U-shaped ribs are wholly welded on the deck plate through a solid welding wire argon-riched shielded welding process. According to the welding method, the defects in the prior art can be overcome, and the welding method has the advantages that the safety and the reliability are good, the efficiency is high, the cost is low, etc.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Pipe-shell type heat converter pipe plate and hemispherical closing head single-side welding narrow gap welding technology

InactiveCN101164729AReduce widthReduce the angleArc welding apparatusHeat exchange apparatusShell and tube heat exchangerSpray coating

The present invention relates to a shell-and-tube heat exchanger and hemispherical head one-side weld narrow gap welding process. It is characterized by that its backing weld adopts pen-type manual argon shielded are welding process, its welding material adopts mushroom-type consumable backing ring; the transion weld adopts electrode electric arc welding process, adopts spray coating spatter-proof material; and its main weld adopts narrow gap submerged-arc automatic welding process.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Technique for welding car axle housing made by punching medium heavy steel plates

InactiveCN1431080AImprove welding strengthEliminate generationWelding apparatusMelting tankSheet steel

A technology for welding the punched bridge shell of car includes punching on (12-20)-mm steel plate to form bridge shell, making, Y-shape bevels by 6-20 deg. of angle, fixing by dot welding, and gasprotected welding with consumable electrode. Its advantages are high welding strength and quality, and no splash.

Owner:重汽(济南)车桥有限公司

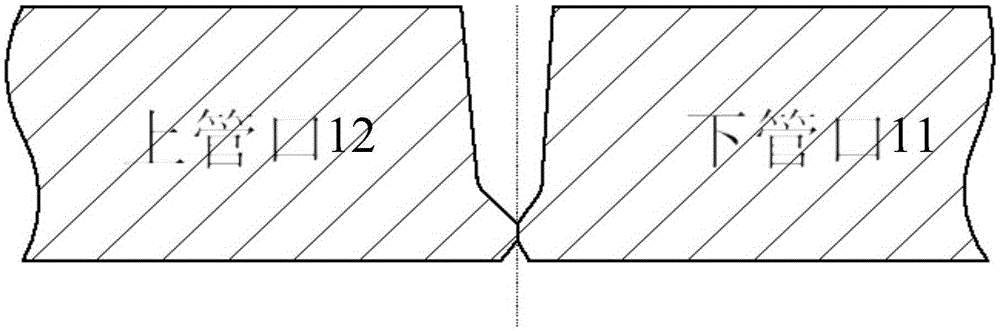

Pipeline welding process for sloping field

InactiveCN105252114ASolve the problem of automatic weldingImprove construction efficiencyArc welding apparatusThermodynamicsProcess engineering

The invention discloses a pipeline welding process for a sloping field. Groove preparation is conducted on pipe openings of two pipelines, asymmetric double-V-shaped combined grooves are formed, and then locating, pairing, preheating, root welding, hot welding, filling welding, cosmetic welding are carried out in sequence, operation is easy, stability is high, labor cost is reduced, and meanwhile reliable weld quality can be guaranteed. Furthermore, the double-V-shaped combined grooves are adopted in the process, the size of the grooves is small, required filling welding material is less, and welding cost can be lowered as well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

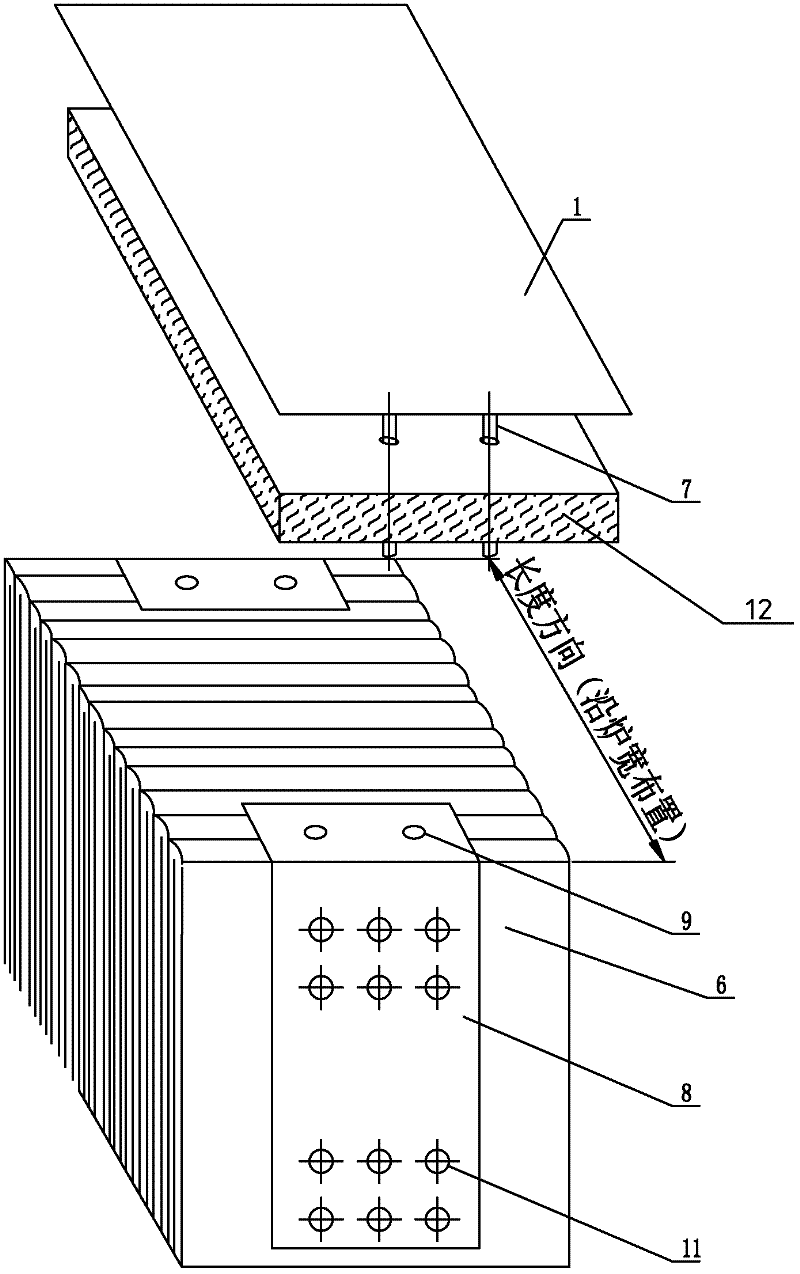

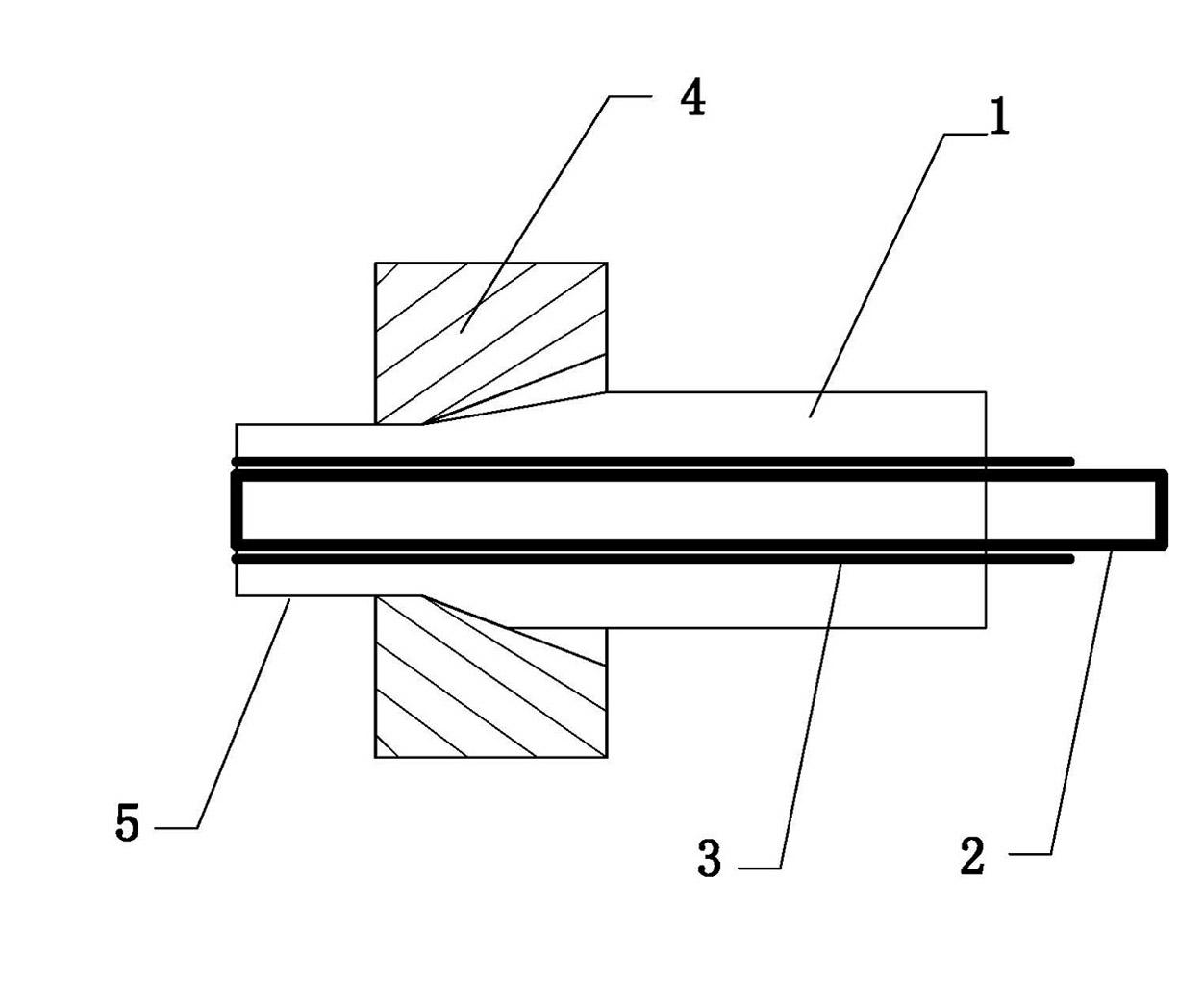

Efficient submerged-arc welding gasket

InactiveCN103008832AProtection Mechanical PropertiesQuality assuranceArc welding apparatusGlass fiberIron powder

The invention provides an efficient submerged-arc welding gasket which comprises a plurality of ceramic welding gaskets connected end to end. The bottom of the welding gasket is packaged in a strip strengthening casing, and a glass fiber tape with the size being matched with that of the welding gasket is arranged on the upper surface of the welding gasket. The invention further provides a manufacture method and an application method of the efficient submerged-arc welding gasket. As the submerged-arc welding gasket is connected and mounted into the strengthening casing, the submerged-arc welding gasket has certain extrusion resistance capability, when small plate edge difference exists in a welding connector, the gasket can not be damaged during the process of applying external force to correct the plate edge difference. During the process of one side welding, welding slag formed by burning the gasket through a welding arc can be molten into the slag of a same slag system with the welding slag of welding wires, iron powder and welding fluid, and back weld can be guaranteed to achieve required mechanical property and chemical elements. The efficient submerged-arc welding gasket accelerates the welding speed, saves welding material and guarantees the weld quality.

Owner:象山焊接衬垫厂

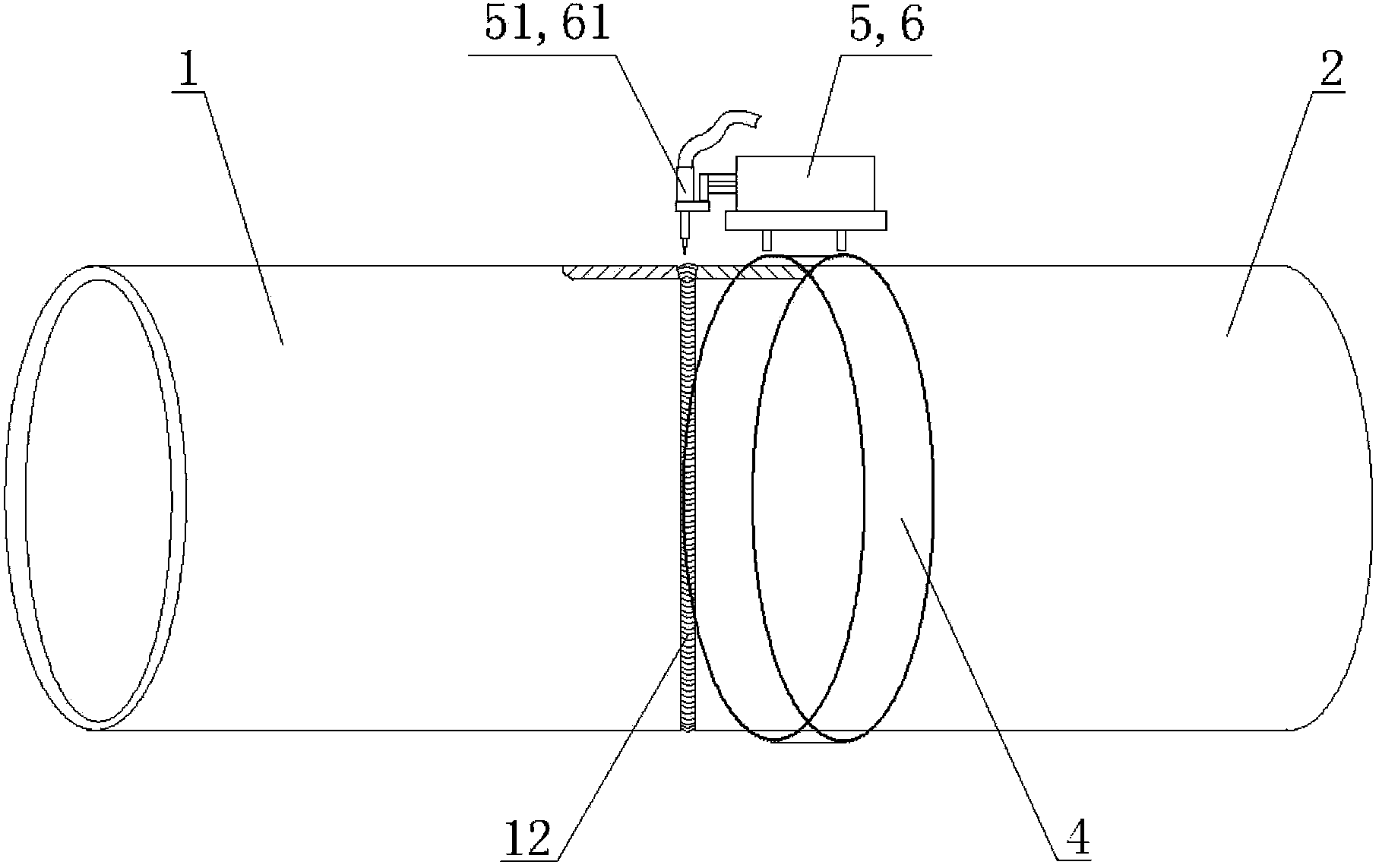

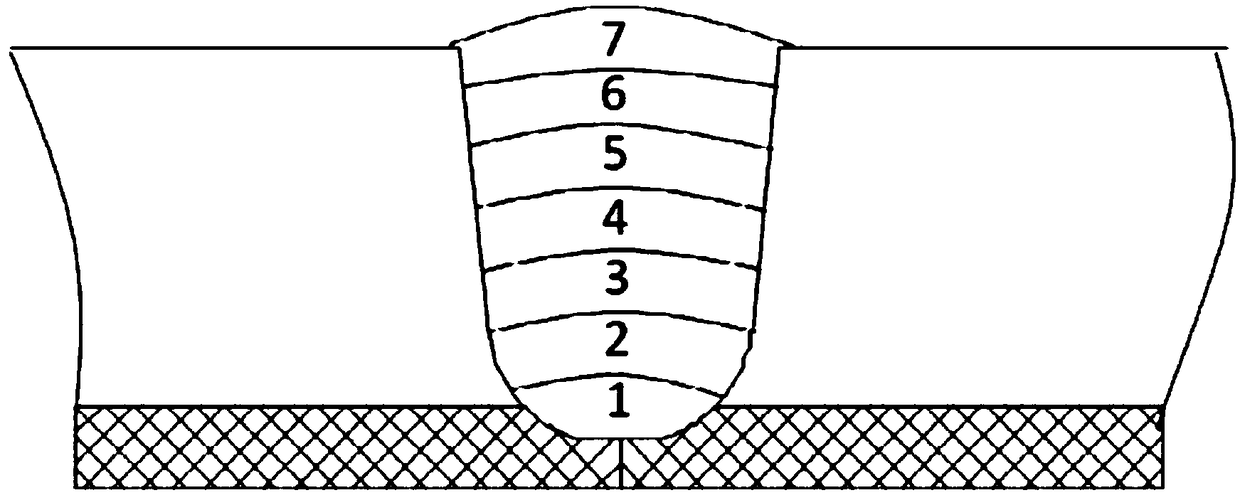

Double-side double-arc welding process for root layer of pipeline

ActiveCN102744499AAvoid it happening againImprove liquidityArc welding apparatusEngineeringWeld seam

The invention discloses a double-side double-arc welding process for a root layer of a pipeline, and the process comprises preparation before welding and backing welding. By utilizing the backing welding process of the double-side double-arc welding for the root layer of a pipeline disclosed by the invention, the inside and outside welding seams of the pipeline can be formed once, and the both surfaces of a molten pool for the pipeline are always in the protection of argon, so that the generation of air vents is avoided, the formation for the inside and outside welding seams of the pipeline is good, the dimensional requirements are relatively decreased due to assembly, the welding difficulty of welders is decreased, welding deformations are reduced, welding speed is increased, welding efficiency is increased, welding defects are reduced, energy and welding materials are saved, and welding cost is reduced. Simultaneously, by virtue of the design for the process parameters of a welding gun for the inside and outside of the pipeline, and under the action of the blowing force of double arcs, the flowability of metals in the molten pool is improved, the heat energy of the double arcs is adequately exerted, the penetration capacity is improved, and the welding characteristics of stainless steel are adapted, thus improving the quality of welding joints, and guaranteeing the welding quality.

Owner:CHINA NAT CHEM ENG NO 7 CONSTR

Argon arc welding process for narrow gap hot wire

InactiveCN102233474ASave welding materialReduce processArc welding apparatusWorkpiece edge portionsArc weldingButt joint

The invention provides an argon arc welding process for a narrow gap hot wire. The process comprises pre-welding preparation processes which comprise a groove formation process, a groove butt joint assembly process, a welding material selection process and a welding parameter setting process, a bottoming welding process, a filling welding process and a surface covering welding process. In the improvement of the process, a groove is a narrow gap U-shaped groove; a hot wire process is used for the bottoming welding process, the filling welding process and the surface covering welding process; the argon arc welding process meets the requirements of full-automatic all-position welding and has a reasonable design; by the process, welding processes can be reduced, welding materials can be saved, cost and labor intensity of workers can be reduced, and welding quality and efficiency can be effectively improved; and the process is particularly suitable for the pre-manufacturing welding of a pipeline which cannot be rotated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

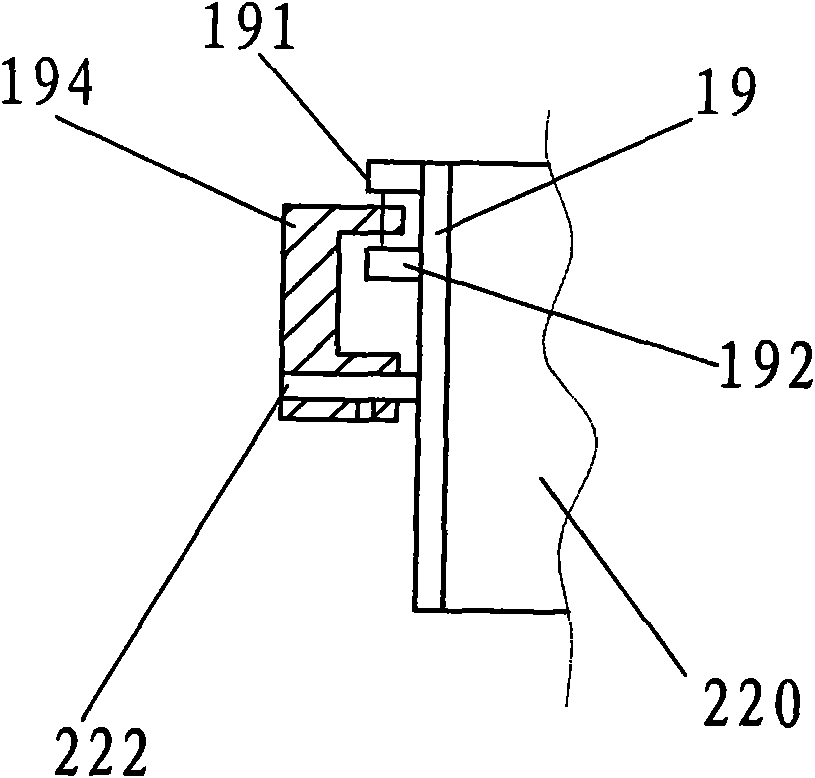

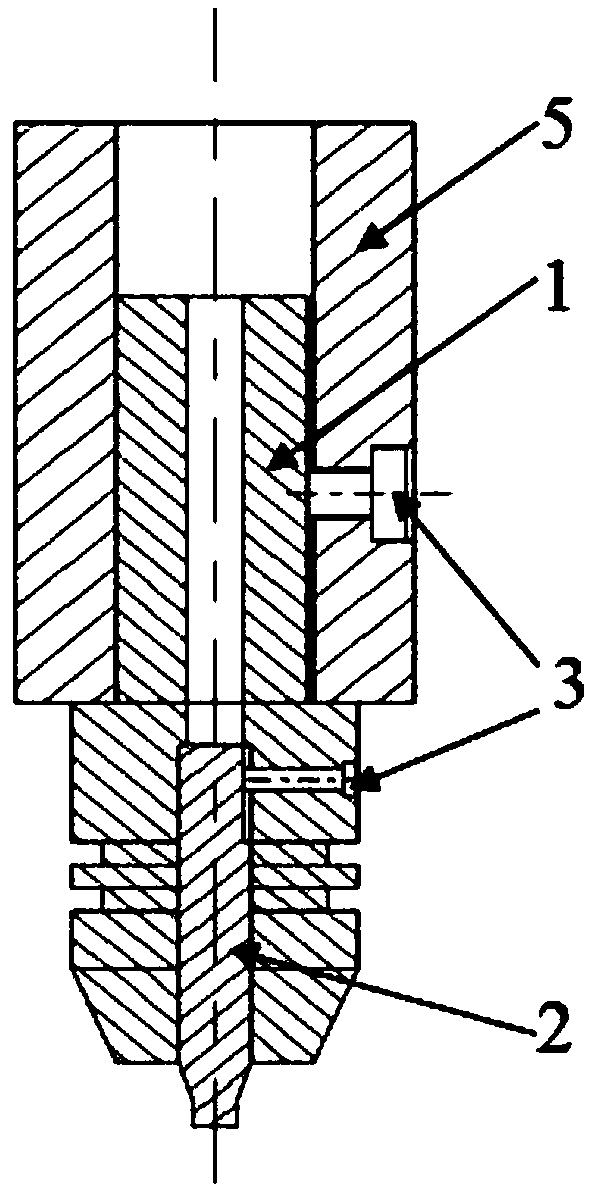

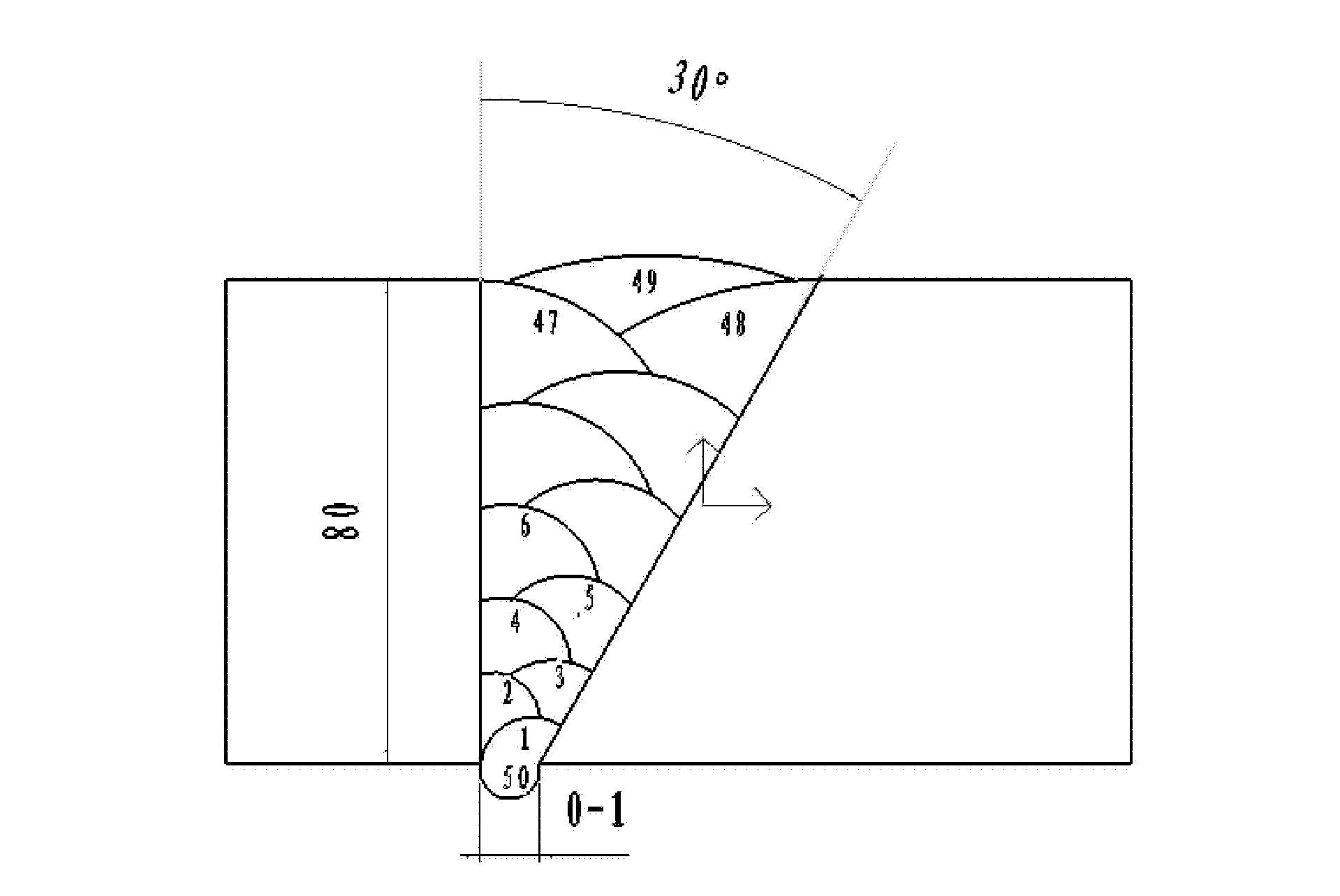

Adaptive welding method for pipe-plate circumference welding and subsection parameter setting and arc welding equipment

ActiveCN102069273ASave welding materialImprove welding efficiencyArc welding apparatusThick plateWelding power supply

The invention discloses an adaptive welding method for pipe-plate circumference welding and subsection parameter setting, which comprises the following steps of: dividing the circumferential seam of a welded workpiece pipe-plate into n arc sections, and presetting the welding parameter of each arc section; storing n groups of preset welding parameters in a memory; placing a welding gun at a welding start position; switching on a welding power supply, taking out the welding parameters from the memory under the control of a central processing unit to control welding current and voltage suppliedto the arc section by the welding power supply and control arc striking and arcing of the welding gun, and rotating the welding gun to complete the angular displacement of a given value; and after the welding gun completes welding of the arc section, taking the welding parameter of the next arc section to continuously implement welding till completing welding of all n arc sections. The adaptive welding method can save welding materials, improve the welding efficiency, improve the seam forming efficiency and improve the welding qualification rate and the like, is greatly convenient for most users, and is particularly suitable for welding thick-wall pipes and thick plates.

Owner:SHENZHEN RILAND IND

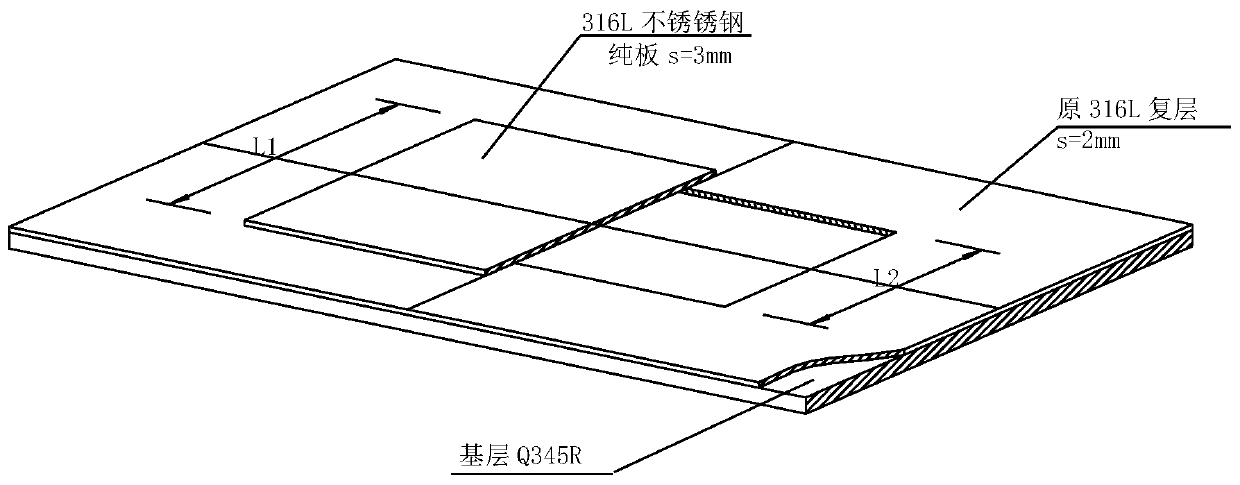

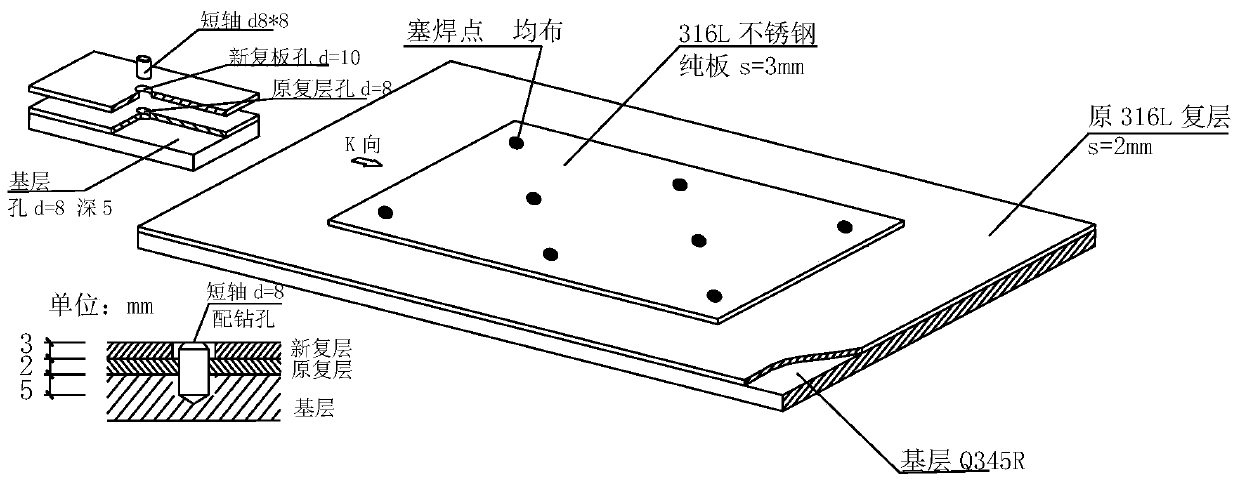

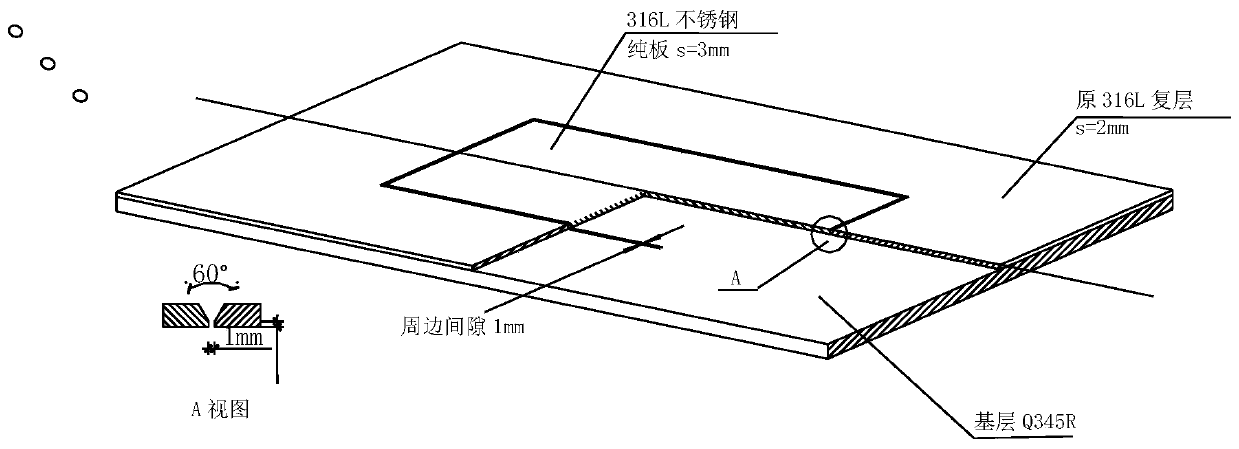

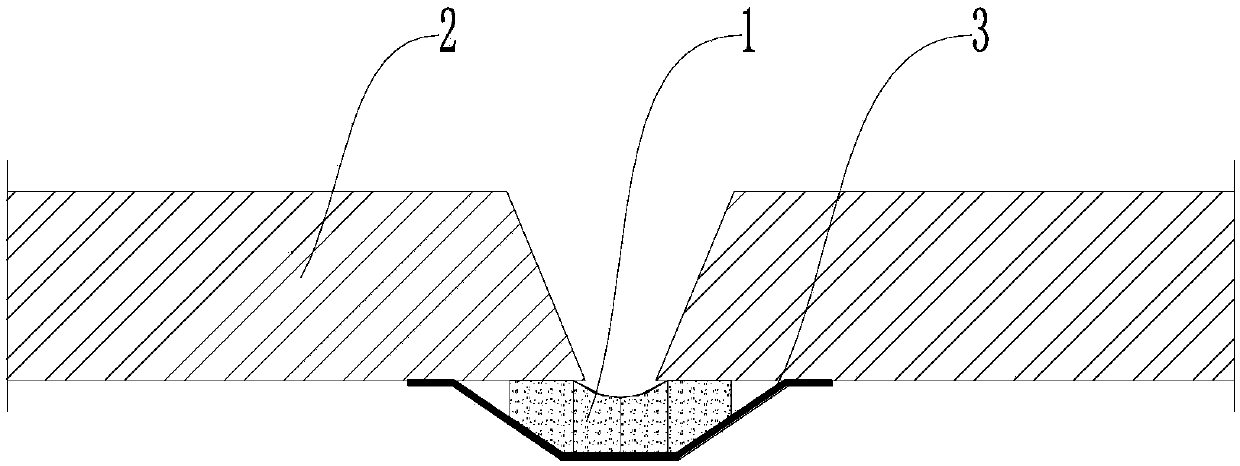

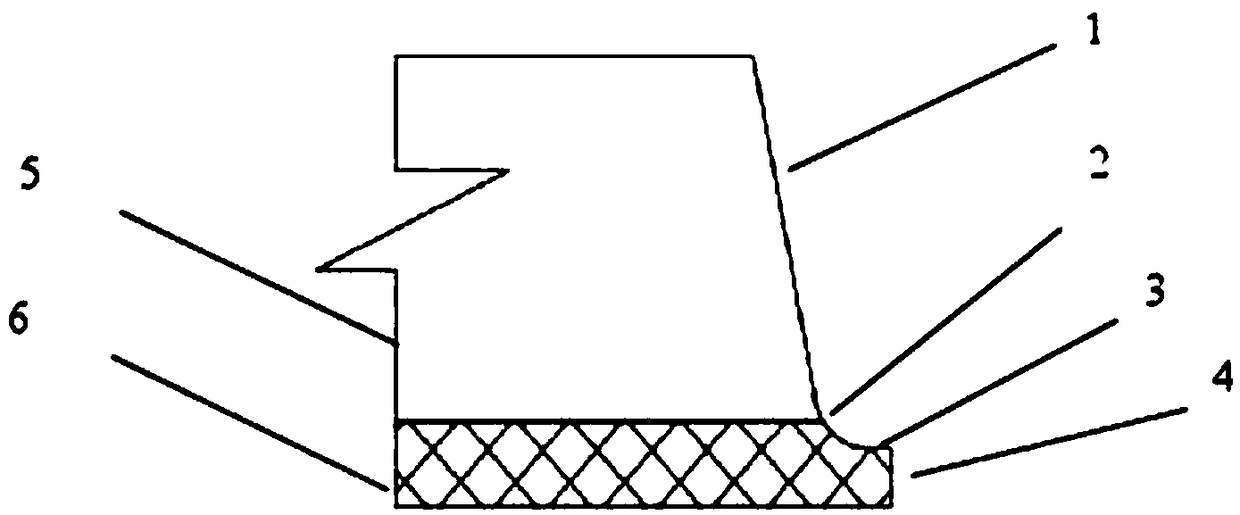

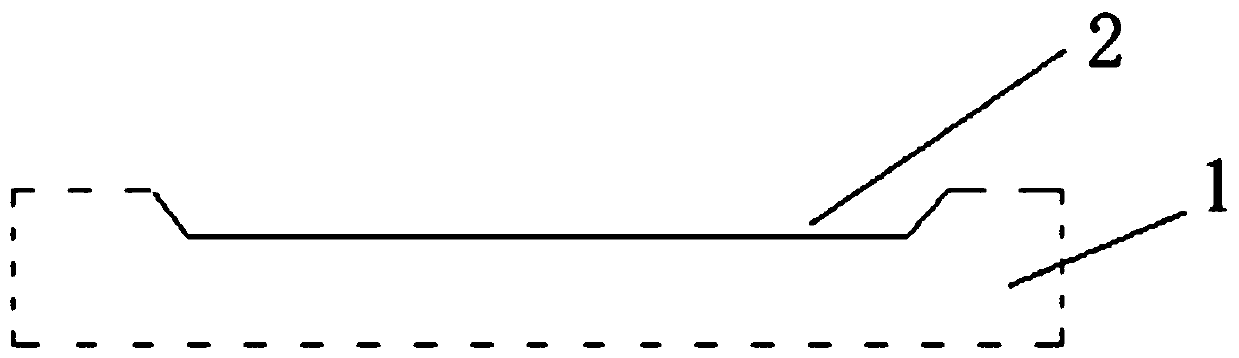

Repairing processing method of corrosion parts of original tank composite layer

InactiveCN109702427ALess welding rodReduced corrosion resistanceArc welding apparatusStress concentrationMetal

The invention provides a repairing processing method of corrosion parts of an original tank composite layer, belongs to the technical field of metal tank processing, and discloses two types of repairing processing methods of different corrosion areas and different corrosion degrees of the original composite layer of a tank and other equipment. The repairing processing method comprises the steps ofa ''flitch plate type'' repairing method and a ''plug welding type'' repairing method; the ''flitch plate type'' repairing method is a repairing mode performing by adopting a ''flitch plate '' technology principle and comprises a ''patch type'' flitch plate repairing method and an ''embedded type'' flitch plate repairing method, and the repairing technology is mainly applied to the conditions ofnot too large corrosion parts and not too obvious corrosion of the original composite layer of the tank and other equipment; the ''plug welding type'' repairing method is a repairing mode performing by adopting a ''plug welding'' technology principle, is mainly applied to the conditions of larger corrosion areas, more serious corrosion of the original composite layer of the tank and other equipment, due to larger areas in a repairing position, the ''plug welding type'' repairing ensures surfacing, avoids the generation of stress concentration, and the performance is good after repairing. The repairing technology is scientific and reasonable, and is convenient and fast.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Construction method for ceramic backing for butt weld of steel box bridge

The invention discloses a construction method for a ceramic backing for a butt weld of a steel box bridge. The construction method aims to improve the welding efficiency and is environmentally friendly. The construction method comprises the following steps of 1) processing a welding groove; 2) carrying out welding assembling; 3) pasting the ceramic backing; 4) carrying out welding, specifically, starting from the groove in a run-on plate, striking the arc into a weld seam and carrying out arc quenching on a run-off plate, wherein the process from arc striking to arc quenching should be continuous, in the downward welding butt joint process, the welding speed is 13-25cm / min, in the vertical-position welding butt joint process, the welding speed is 9-23cm / min, and in the horizontal-positionwelding butt joint process, the welding speed is 20-26cm / min. According to the construction method, the process of back gouging is omitted, pollution such as smoke and noise caused by carbon arc gouging and grinding wheel grinding can be avoided, in addition, the labor intensity of workers can be greatly reduced, the working efficiency can be improved, welding materials can be saved, and the production cost can be lowered; the quality grade and the mechanical property of the weld seam can meet the requirements of the design and the specification, in addition, the forming of the back weld seamis good, spatter can be avoided, and the welding quality is easy to control; and compared with a traditional welding technology, the construction has the advantage of being more environmentally friendly.

Owner:CHINA 19TH METALLURGICAL CORP

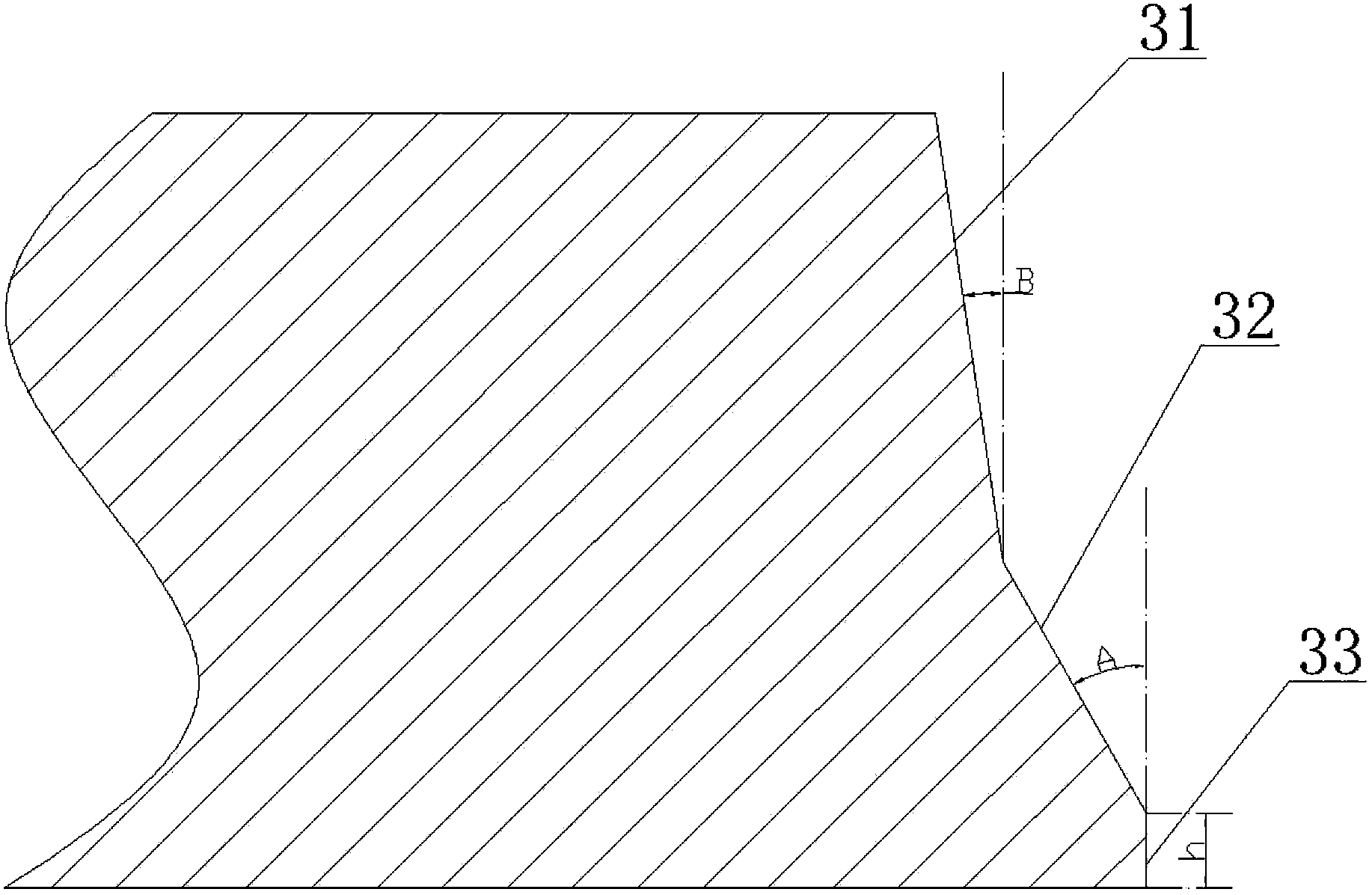

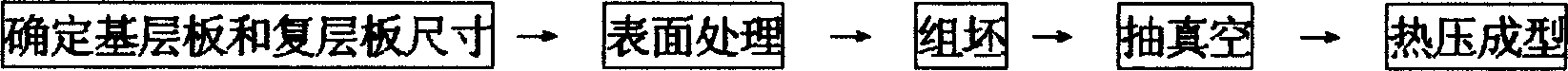

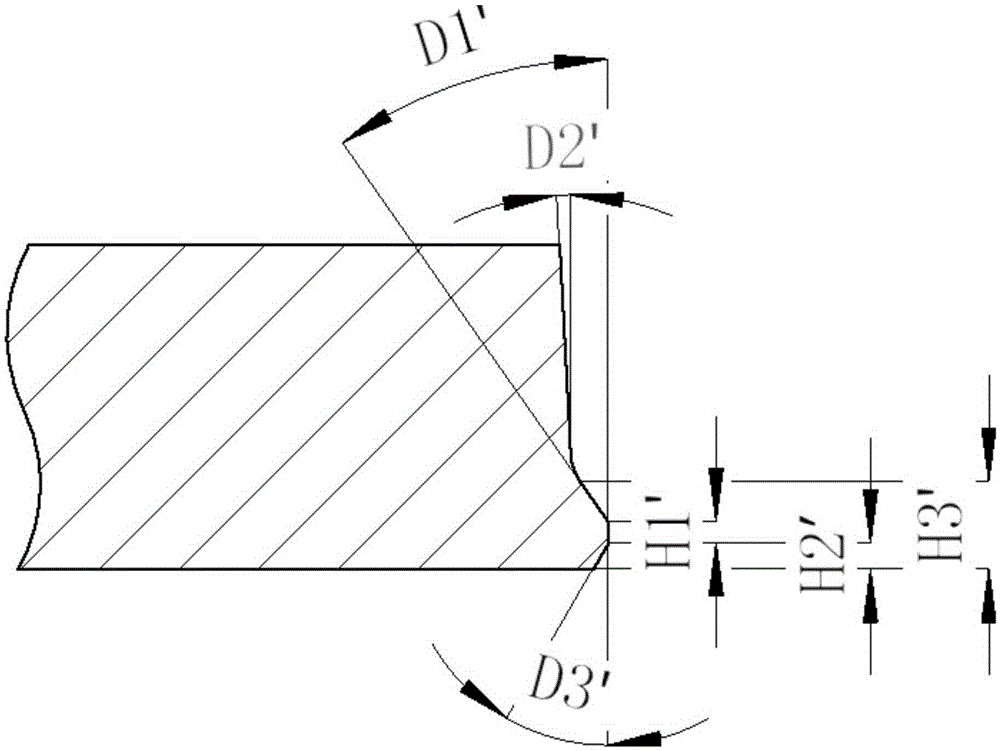

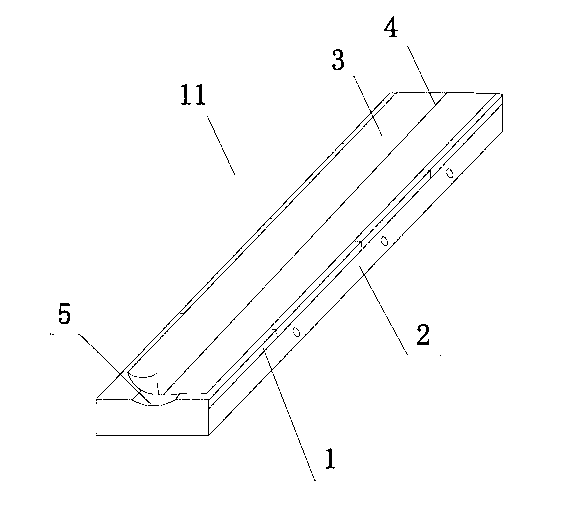

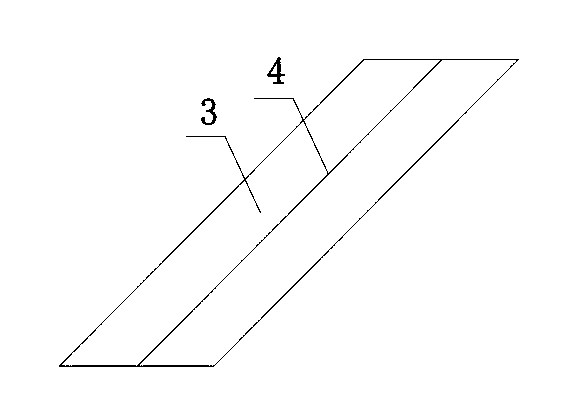

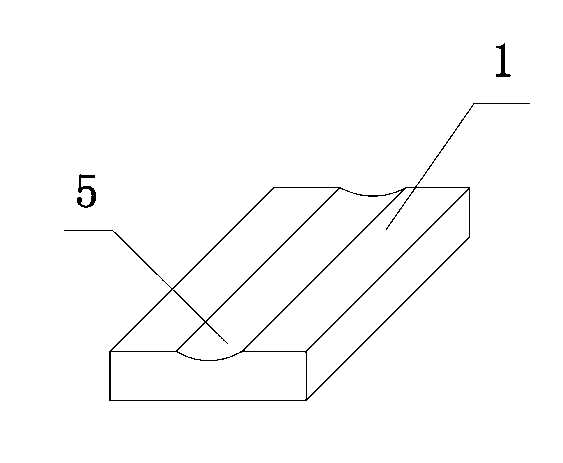

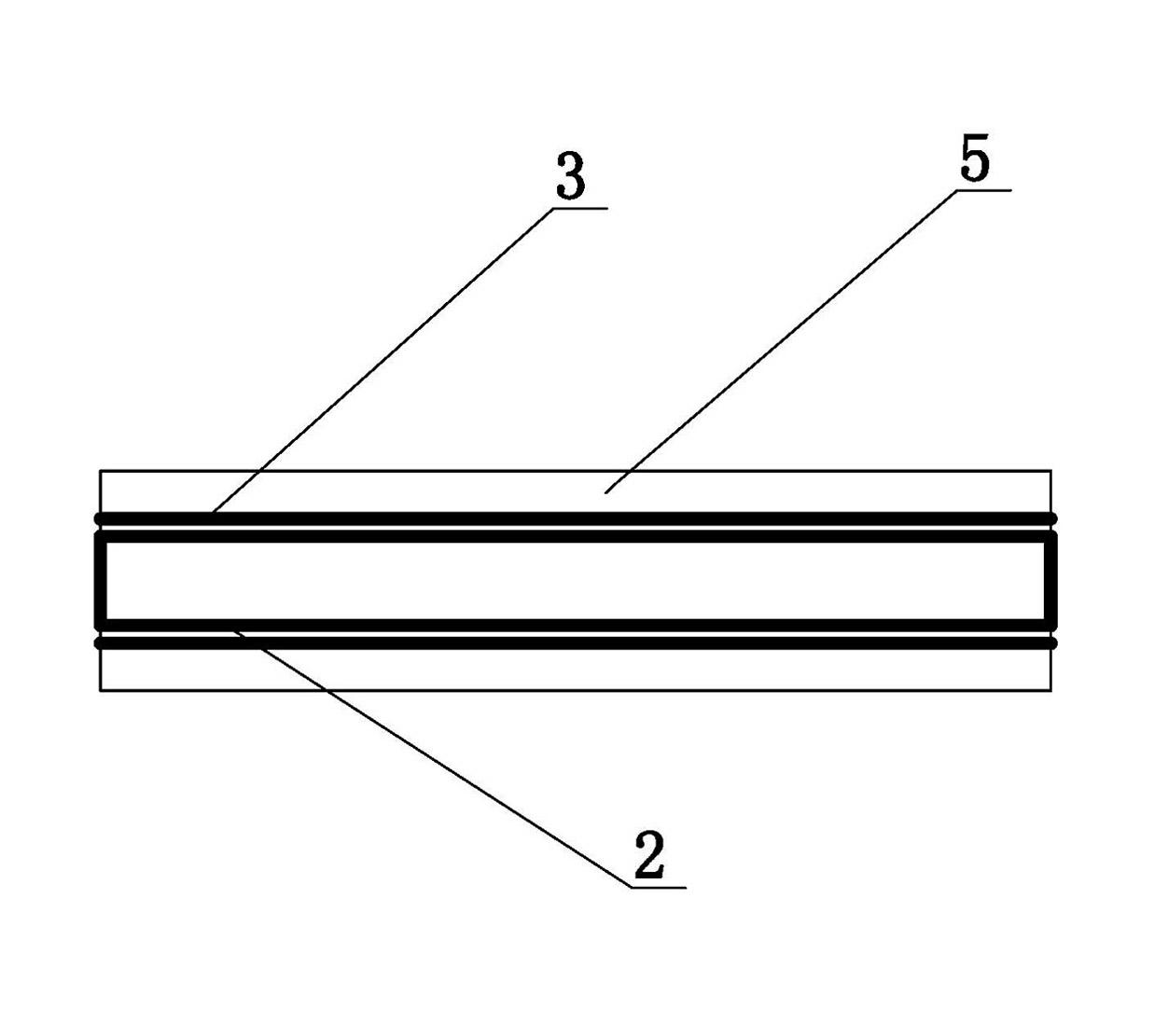

Welding groove process of mechanical bimetallic composite marine pipe

InactiveCN102615392AReduce areaReduce difficultyArc welding apparatusWorkpiece edge portionsCorrosion resistant alloyButt welding

The invention discloses a welding groove process of a mechanical bimetallic composite marine pipe. Groove manufacturing steps are as follows: (1), preparation: 1, preprocessing a pipe end so that the mechanical composite marine pipe forms a local metallurgical composite marine pipe in a pipe end area; and 2, processing a reference surface, and clearing a groove and two sides of the outer wall of the groove so as to obtain a level end surface till metallic luster appears; (2), manufacturing of the groove: 1, manufacturing a single-sided groove by one time, wherein a groove angle is 8 degrees plus or minus 1 degree, a blunt edge is 1.8mm plus or minus 0.2mm, a transitional arc for connecting the groove and the blunt edge is a combined groove with the radian R of 3mm, a butting gap between grooves is 0mm, and a corrosion-resistant alloy material layer at the root of the groove is provided with a platform with the width of 1mm; and 2, checking and verifying that a welded part and the edge thereof are free of defects; and (3) performing butt welding on the grooves. By the welding groove process of the mechanical bimetallic composite marine pipe, the area of the welding groove is reduced, the welding material is saved, the labor intensity of working staff and the difficulty of butting construction are reduced, the welding time is shortened, the marine construction cost is reduced, and a technical support is provided for later construction of the mechanical bimetallic composite marine pipe.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Upright full-automatic argon arc welding process for bimetal composite pipes

InactiveCN108581138AReduce labor intensityImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthIndustrial engineering

The invention discloses an upright full-automatic argon arc welding process for bimetal composite pipes. The process comprises the following steps: (1) the preparation is performed before welding; (2)the bottoming welding is performed; and the upright welding is performed in bottoming from the position of 6 o'clock to the position of 12 o'clock; (3) the welding process is divided into a hot welding bead and filling; the upright welding is performed in the hot welding bead and the filling from the position of 6 o'clock to the position of 12 o'clock, wherein the peripheral angles of pipe bodiesare divided into four sections; the filling is divided into multiple layers according to different wall thicknesses; and each layer is once welded; (4) a cover surface is adopted in the welding process, and is uprightly welded from the position of 12 o'clock to the position of 6 o'clock; and (5) nondestructive detection is performed after welding. The process solves the full-automatic all-position welding demand problem, reduces welding procedures, saves welding materials, greatly reduces the production cost and the labor intensity of workers, and improves the welding quality and efficiency of bimetal composite seabed pipelines.

Owner:OFFSHORE OIL ENG CO LTD

Fixing device and method for refractory material in strip steel heat treatment furnace

InactiveCN102312077AWon't fall offHigh strengthFurnace typesHeat treatment furnacesFiberThermal insulation

The invention provides a fixing device and method for a refractory material in a strip steel heat treatment furnace. The fixing device comprises a furnace shell steel plate, a thermal insulation layer and fireproof ceramic fiber folding blocks, and the furnace shell steel plate, the thermal insulation layer and the fireproof ceramic fiber folding blocks are connected in order. The fixing method comprises the following steps: marking a line to specify welding positions of bolts; welding bolts on the furnace shell steel plate and allowing the bolts to pass through the thermal insulation layer; sleeving an L-shape steel plate onto the bolts through location holes in the L-shape steel plate and fixing nuts on the bolts; destroying screw threads below the nuts by spot welding after the nuts are positioned; allowing penetration ribs to pass through suspension apertures in the L-shape steel plate; sequentially sleeving the fireproof ceramic fiber folding blocks on the penetration ribs and installing the fireproof ceramic fiber folding blocks in place; repeating the previous step so as to install all the rest fireproof ceramic fiber folding blocks until the furnace is filled with the fireproof ceramic fiber folding blocks. According to the invention, the rest fireproof ceramic fiber folding blocks are fixed on a furnace wall or a furnace roof; meanwhile, problems resulting from utilization of fireproof ceramic fiber modules are avoided successfully.

Owner:WISDRI WUHAN WIS IND FURNACE

Cast iron welding technique using cold welding and bead welding

InactiveCN102000922AReduce welding man-hoursSave welding materialWelding apparatusPower flowThermal insulation

The invention disclose a cast iron welding process using cold welding and bead welding, comprising the following welding process steps of: (1) clearing parts to be welded: removing oil stains, iron rust and other flaws; (2) preparing a welding rod: using an E5015 basic welding rod of which the diameter is 3.2mm, drying the welding rod at a temperature from 360 DEG C to 380 DEG C for 1 to 2 hours, putting the dried welding rod in a thermal insulation bucket, and preserving heat for later use; (3) welding: selecting a direct current welding machine, and adopting a direct current straight polarity method, namely that the welding rod is connected with a negative electrode, a component to be welded is connected with a positive electrode, and the current is kept in a range from 95A to 105A. In the invention, a casting is welded by adopting the casting welding process using a cold welding method. The welding process using cold welding and bead welding solves the problems that the work environments of a casting welding process using a hot welding method are poor, and the site heating conditions can not meet the requirements on the welding process using a hot welding method in most conditions. Welding time is shortened, and welding materials are saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

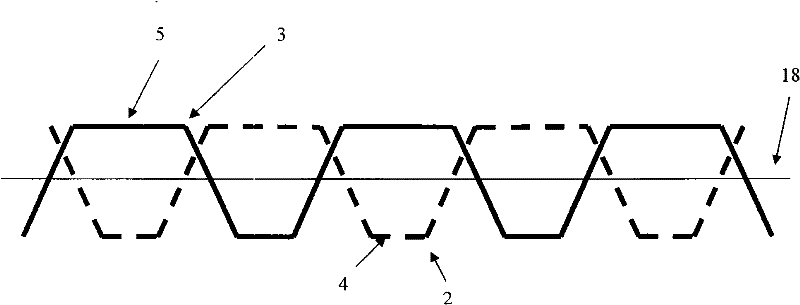

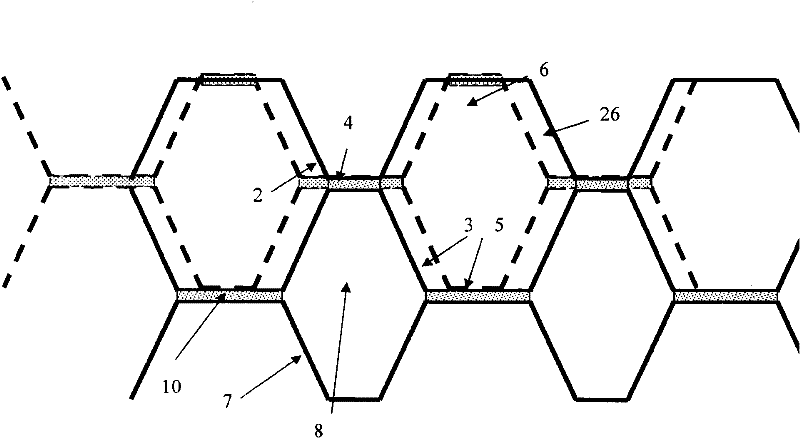

Heat exchanger

ActiveCN102564176ALow fluid resistanceHigh mechanical strengthHeat exhanger finsLaminated elementsPlate heat exchangerEngineering

The invention relates to a plate heat exchanger (9), comprising a plurality of heat exchanger plates (1, 13), comprising at least one section showing indentations (2, 3, 14, 15), intended to be placed against corresponding indentations (2, 3, 14, 15) of a heat exchanger plate (1, 13) of a corresponding design. At least a first type of indentations (2, 14) and at least a second type of indentations (3, 15) is provided, wherein said first type of indentations (2, 14) and said second type of indentations (3, 15) are of a different design.

Owner:DANFOSS AS

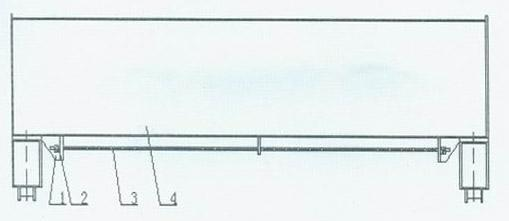

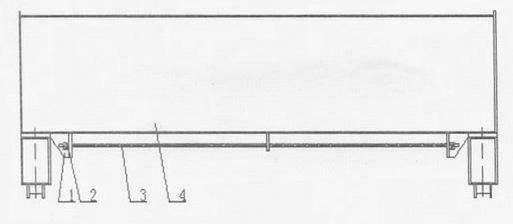

Crane girder

InactiveCN102674151AReduce initial investmentSmall wheel pressureLoad-engaging girdersSheet steelEngineering

The invention discloses a crane girder. The crane girder comprises a girder, wherein supporting pedestals are fixed at two ends of the lower part of the girder made of a rectangular pipe; a pull rod passes through the middle part of the supporting pedestals at the two ends of the girder and is fixed by a tensioning nut; the rectangular pipe is subjected to one-step parabolic formation by an arch raising machine; the supporting pedestals fixed at the two ends of the girder made of the rectangular pipe are connected through a high-strength hinged bolt; the pull rod can also adopt a guy cable; and a thin steel plate cover with the same width as that of the girder is arranged at the lower part of the girder. The crane girder has the following effects that: welding deformation is reduced; almost no welding stress exists; the problem that the camber of the conventional girder is gradually reduced because the welding stress releases is solved; the self weight of the crane is 15 to 20 percent lighter than that of the conventional crane, so the problem about the initial investment of users is solved; and the wheel pressure is low, so the service life of a workshop is prolonged, the building cost of the workshop is reduced, welding materials such as welding rod flux and the like are greatly saved, industrial pollution is reduced and the manual manufacturing cost is reduced.

Owner:河南中州起重集团有限公司

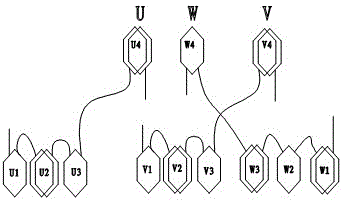

Effective alternating-current motor stator winding preparation method

InactiveCN104617721AGood winding processEasy windingManufacturing dynamo-electric machinesEngineeringAlternating current

The invention discloses an effective alternating-current motor stator winding preparation method. The effective alternating-current motor stator winding preparation method includes wire wrapping, wiring and wire inserting. The wire wrapping technique includes that each phase U, V or W has six coils U1, U2, U3, U4, V1, V2, V3, V4, W1, W2, W3 and W4, wherein 6 coils of each phase wrap continuously, the wrapping directions of the wrapped coils are consistent, and there is no joint between the six coils of each phase; each of the W1, W3, V2, V4, U2 and U4 comprises two large coils, the span of the large coil is 1 to 9 tanks, the W2, W4, V1, V3, U1 and U3 are small coils, and the span is 1 to 8 tanks. The wiring is performed after the wire wrapping technique and before the wire inserting technique, and the wiring enables the wrapping directions of the large coils of each phase to be opposite to the winding direction of the small coil. The effective alternating-current motor stator winding preparation method is good in coil winding technique, enables the cost to be saved and enables the motor winding reliability to be improved.

Owner:江苏利得尔电机有限公司

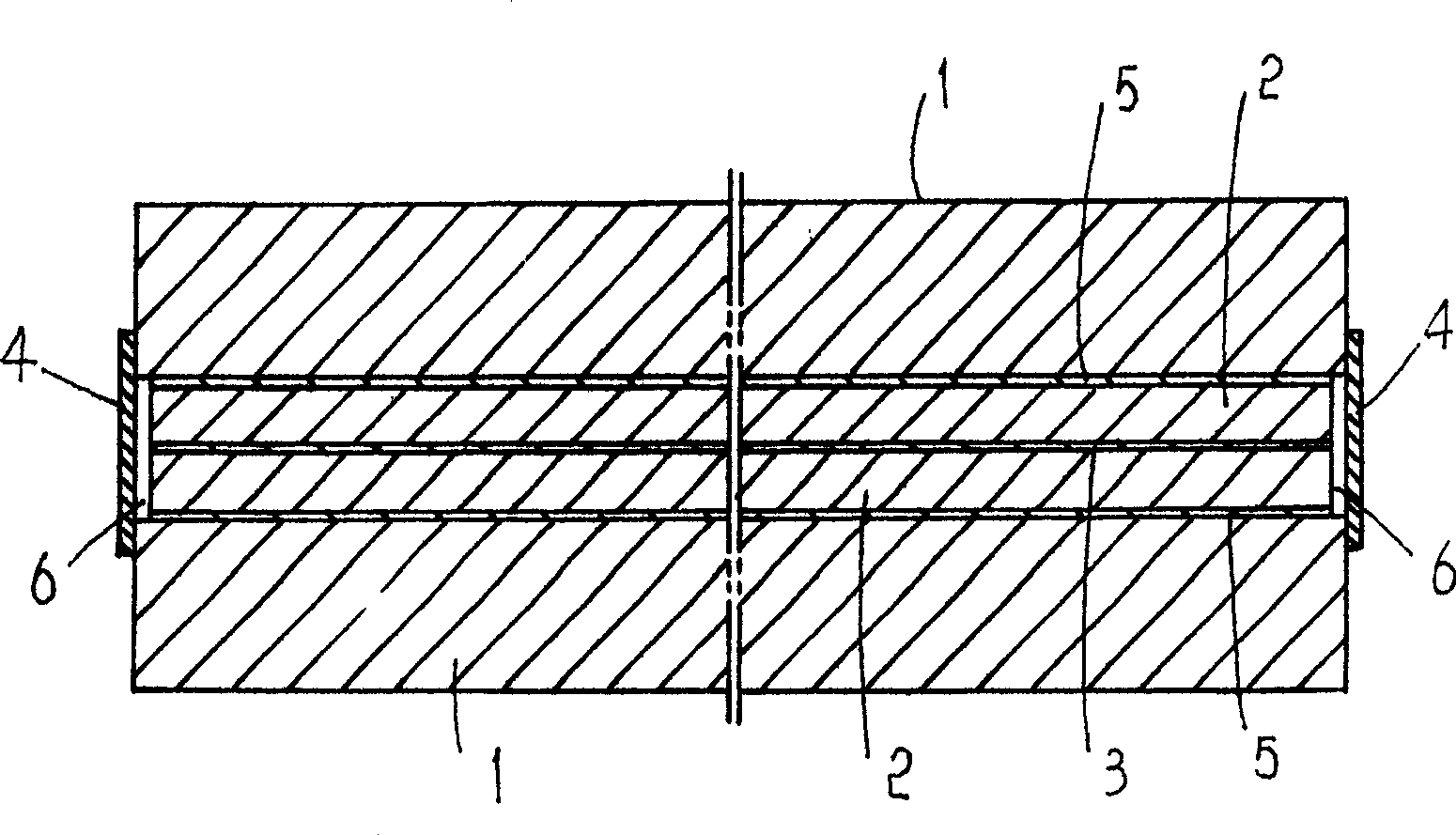

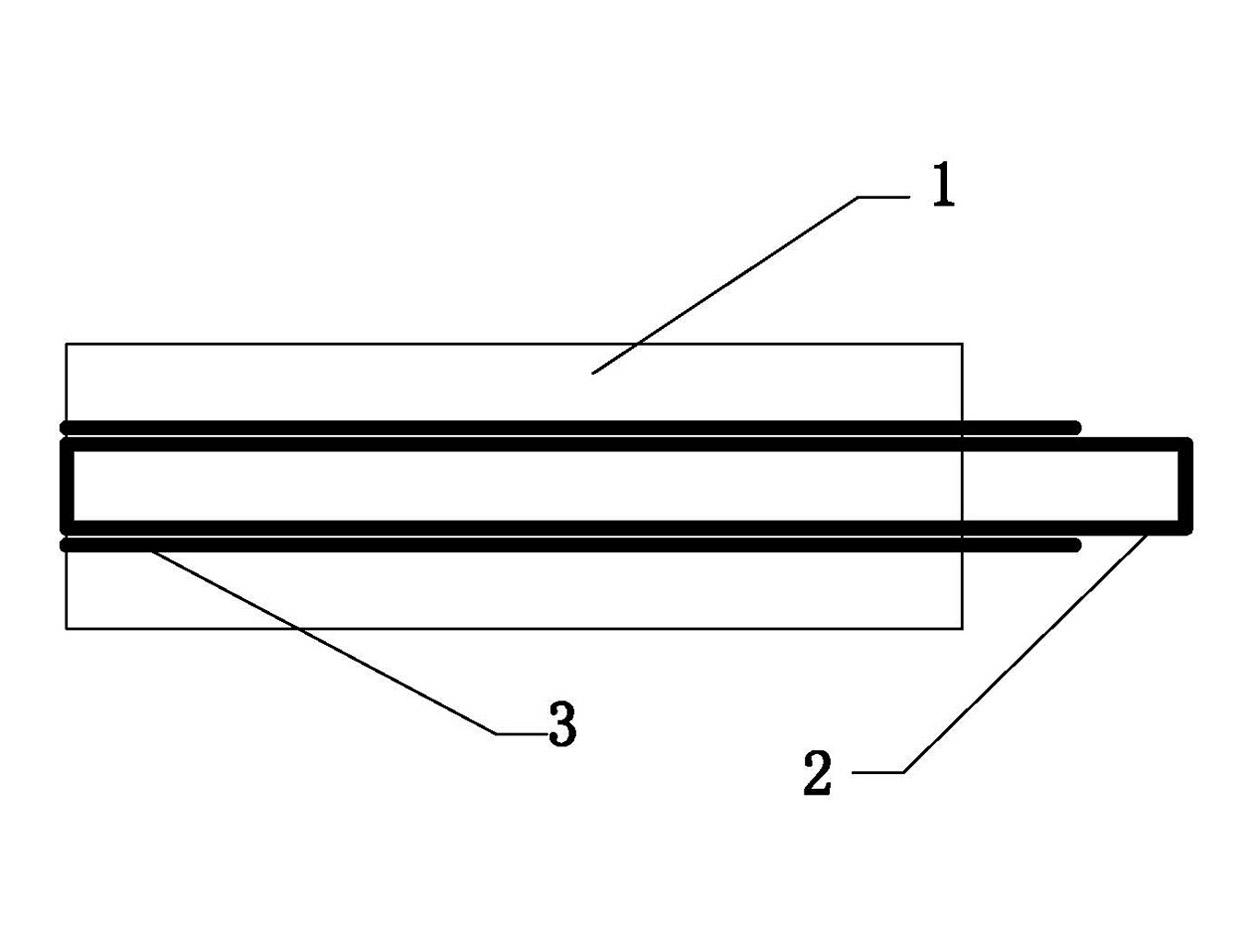

Tubular target bonding method

InactiveCN102513401AUniform thicknessImprove welding qualitySoldering apparatusImage qualityMaterials science

The invention relates to a tubular target bonding method for bonding a tubular target and a metal lining tube. The method makes the whole tubular target with large length be bonded with the metal lining tube in high quality; and the high quality bonding is concretely embodied in cases that the weld thickness is controlled, the weld thickness can be reduced to a common weld thickness of a planar target, even thinner, and the uniformity of the weld thickness can be maintained. The method is beneficial to the welding flux saving and target use performance improvement. The method is suitable for the production of the tubular target with certain plasticity, and the plasticity of the tubular target satisfies requirements of a cold drawing technology.

Owner:JIYUAN YUGUANG NEW MATERIAL TECH

Plug pin type titanium alloy panel friction stir spot welding method

InactiveCN108838509ASimple structureReasonable structureNon-electric welding apparatusShielding gasEngineering

The invention discloses a plug pin type titanium alloy panel friction stir spot welding method which comprises the following steps of (1) processing a preset hole: using an expanding drill for processing a concave conical preset hole in a base metal welding part; (2) welding: loading a conical plug pin into a clamping hole of a stirring head of a welding tool, under the argon shield atmosphere, starting the stirring head to rotate and insert a plug pin into the preset hole, carrying out friction stir welding, and carrying out static-pressure upset forging on a welding area through the stirringhead so as to realize structure densification; and (3) removing the welding tool, clearing, closing the shield gas, unloading the welding tool, removing flanges, and accomplishing welding. Accordingto the plug pin type titanium alloy panel friction stir spot welding method provided by the invention, the welding tool and the plug pin are simple in structure and convenient to process, the consumables are saved, the plug pin is convenient to replace during the welding process, and the continuous spot welding operation in batch can be realized easily; and a post-welding fill area material structure is dense, the mechanical property is excellent, the deformation is less, and the pollution is free.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Single edge groove submerged arc welding technique of plate with moderate thickness

InactiveCN102632327AGuaranteed pass rateReduce welding man-hoursArc welding apparatusPower flowSurface layer

The invention discloses a single edge groove submerged arc welding technique of a plate with moderate thickness. The technique utilizes a DC (direct current) opposition method, and comprises the following technical steps: first to third layers on the facade: a phi 3.2 welding wire is utilized, the current is 380-400A, a rod is stretched by 2.8-3.0cm, the voltage is 24-25V, and the speed is 55-57cm / min; the other layers on the facade of the welding rail: a phi 4 welding wire is utilized, the rod is stretched by 3.0-3.5cm, the current is 560-600A, the voltage is 28-30V and the speed is 45-50 cm / min, or a phi 4 welding wire is utilized, the rod is stretched by 3.8-4.0cm, the current is 650-680A, the voltage is 33-34V, and the welding speed is 38-40 cm / min; and the back surface layer: a phi 4 welding wire is utilized, the rod is stretched by 3.8-4.2cm, the current is 680-700A, the voltage is 34-35V, and the speed is 34-36 cm / min. According to the invention, the submerged arc welding is directly used for bottoming, and no back chipping is performed on the back surface of the weld, thereby solving the complex welding method of the traditional technique, guaranteeing the percent of pass of the weld flaw detection, reducing the welding time and saving the welding material.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

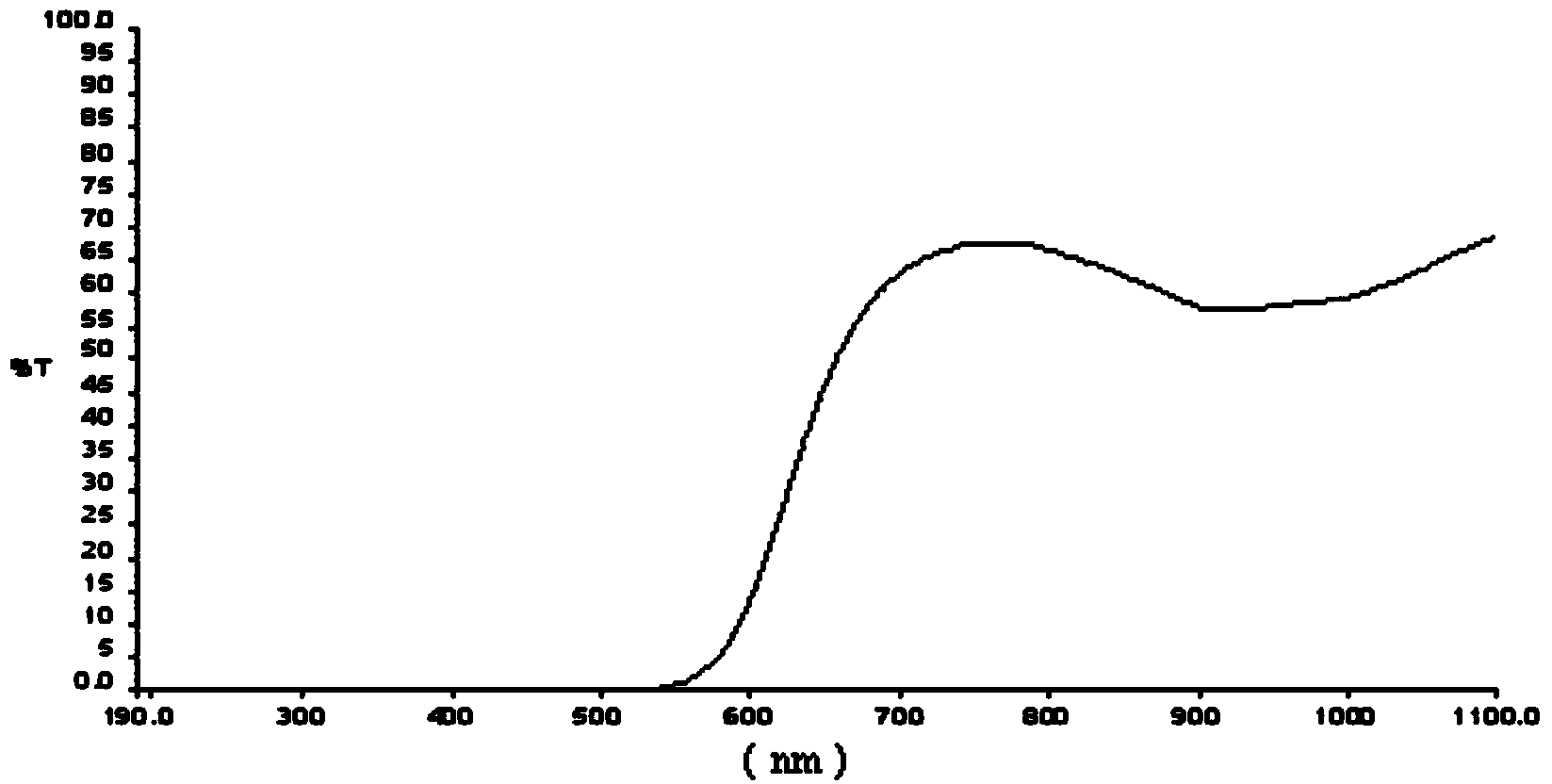

Filter lens for electric welding and method for manufacturing filter lens for electric welding

The invention discloses a filter lens for electric welding and a method for manufacturing the filter lens for electric welding. The lens is made of resin lens materials, iron oxide particles of core-shell structures, titanium oxide particles of core-shell structures, and copper oxide nano particles of core-shell structures, wherein the iron oxide particles, the titanium oxide particles and the copper oxide nano particles are scattered in the resin lens materials, the overall weight of the nano particles is 0.5%-3.5% of the overall weight of the resin lens materials, the weight ratio of the iron oxide particles to the titanium oxide particles and the copper oxide nano particles is 1.8-2.1:1.8-2.1:0.9-1.1, the inner cores of the nano particles are made of iron oxide, titanium oxide and copper oxide, the particle sizes of the nano particles are 10 nm-50 nm, a shell is a surface finishing agent or a surface modification agent, and the thickness of the shell is 3 nm-10 nm. By the adoption of the filter lens, a workpiece can be clearly seen before arcing, harmful hard light can be filtered out after arcing, and eyes are protected.

Owner:江苏新视客光电科技有限公司

Integrated water-cooled motor base for new energy electric vehicle

InactiveCN103368318ASmall water resistanceReduce manufacturing costElectric machinesSupports/enclosures/casingsWater leakageWater channel

The invention discloses an integrated water-cooled motor base for a new energy electric vehicle. The integrated water-cooled motor base comprises a shell (1), wherein a spiral water channel (2) is formed in the shell (1); the spiral water channel (2) and the shell (1) are integrally formed; a water inlet (3) and a water outlet (4) are formed in two ends of the outer surface of the shell (1) respectively; flow channels in the water inlet (3) and the water outlet (4) are tangent to the two ends of the spiral water channel (2) respectively. The integrated water-cooled motor base has the beneficial effects that the spiral water channel and inner and outer shells of the base are simultaneously cast without welding, and a finish machining process is directly carried out after casting is completed, so that the manufacturing cost is reduced, and the problems of water leakage caused by welding and poor appearance of the base in a welding structure caused by existence of welding seams are solved; the spiral water channel is in total contact with the shell, so that the heat transfer efficiency is high; the water resistance is further reduced, the energy of a vehicle-mounted battery can be saved, and the driving range of the electric vehicle is expanded.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

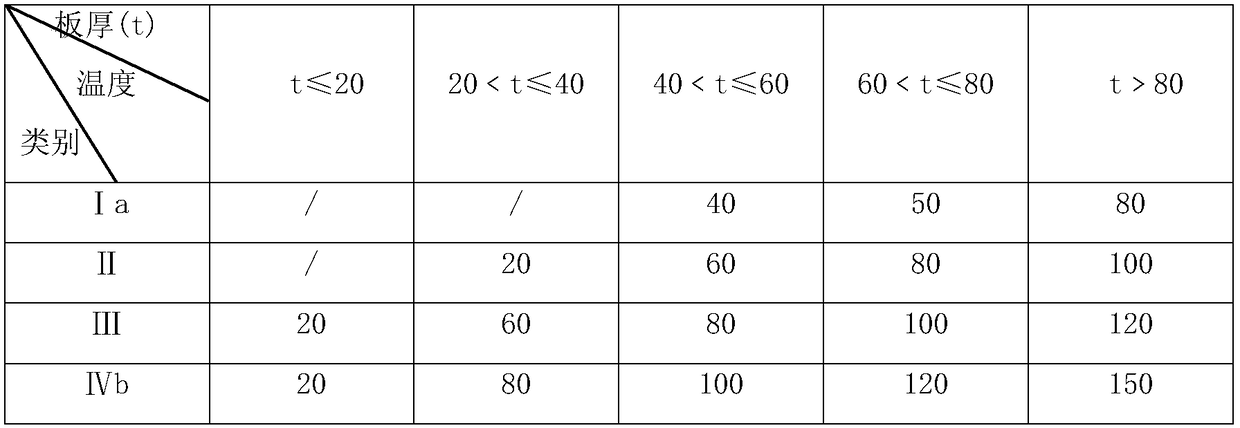

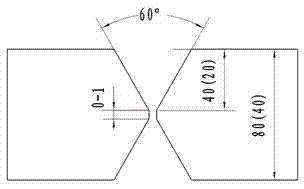

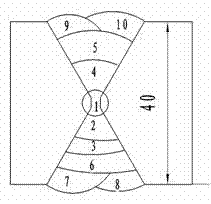

Thick steel plate submerged arc penetration welding back-chipping-free welding method and groove structure thereof

ActiveCN108941860ASave time and moneySave welding materialArc welding apparatusWorkpiece edge portionsSteel platesSubmerged arc welding

The invention discloses a thick steel plate submerged arc penetration welding back-chipping-free welding method and a groove structure thereof. The method includes the steps that (a) the positions ofwelding grooves of two steel plates equal in thickness are determined, and the steel plates displayed to have defects through flaw detection are replaced, wherein t is the thickness of the steel plates; (b) the two steel plates are cut and blanked; (c) butt joint grooves are formed, wherein when t is smaller than or equal to 30 mm, the butt joint grooves are formed to be in I shapes, and when t islarger than 30 mm and smaller than or equal to 100 mm, the butt joint grooves are formed to be X-shaped grooves with reserved truncated edges; (d) the two steel plates and a twin-wire welding machineare assembled in place, and the two steel plates are preheated, wherein direct current is provided for a front wire, and alternating current is provided for a back wire; (e) submerged-arc welding front face welding is carried out; (f) submerged-arc welding back face welding is carried out; and (g) postwelding heat preservation is carried out in a heat preservation groove at the temperature ranging from 300 DEG C to 400 DEG C. The thick steel plate submerged arc penetration welding back-chipping-free welding method and the groove structure are used for solving the problem that in the prior art, the thick steel plates with the thickness smaller than 100 mm are long in time wasted for welding and large in loss, and the aims of shortening the welding time of the thick steel plates with the thickness smaller than 100 mm and improving the welding efficiency are achieved.

Owner:CHINA HUASHI ENTERPRISES

Welding technology of submerged-arc welding of X-shaped groove of medium plate

ActiveCN102000901BGuaranteed pass rateReduce welding man-hoursArc welding apparatusEngineeringWeld seam

The invention discloses a welding technology of submerged-arc welding of an X-shaped groove of a medium plate, which adopts the following technological steps: (1) when the front surface is welded: the welding current is 450 to 480A; the welding voltage is 25 to 26V; the welding speed is 54 to 58cm / min; and the rod extends by 30 to 35cm; (2) and when the back surface is welded: the welding currentis 600 to 640A; the welding voltage is 30 to 32V; the welding speed is 44 to 47cm / min; and the rod extends by 35 to 40cm. The welding technology has the advantages that the submerged-arc welding is directly adopted for priming; the back chipping is not required on the back surface of a welding seam; the appropriate welding current and voltage is selected and the welding speed is reasonably matched; the problem on the complicated welding method in the prior art is solved; the qualification rate of the welding seam flaw detection is simultaneously guaranteed; the working time of the welding is reduced; and the welding material is saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Nickel-based alloy surfacing welding process for alloy tank

ActiveCN110216360ALow dilution rateImprove high temperature and corrosion resistanceArc welding apparatusTemperature resistanceWelding defect

The invention relates to a nickel-based alloy surfacing welding process for an alloy tank. A welding process is carried out by way of cold metal transition welding, and shielded welding is carried outby adopting consumable electrode gas in the welding process. During use, the dilution rate of the surface of the surfacing is reduced greatly, the high-temperature resistance and the corrosion resistance of a material are improved and a welding material is saved by adopting the nickel-based alloy surfacing welding process by way of cold metal transition welding. Meanwhile, a multi-pass surfacingmode with at least two passes is adopted in the welding process to fill the alloy tank, so that the welding defects of incomplete fusion, solder skips and the like during welding can be solved, and the welding quality is guaranteed.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所) +1

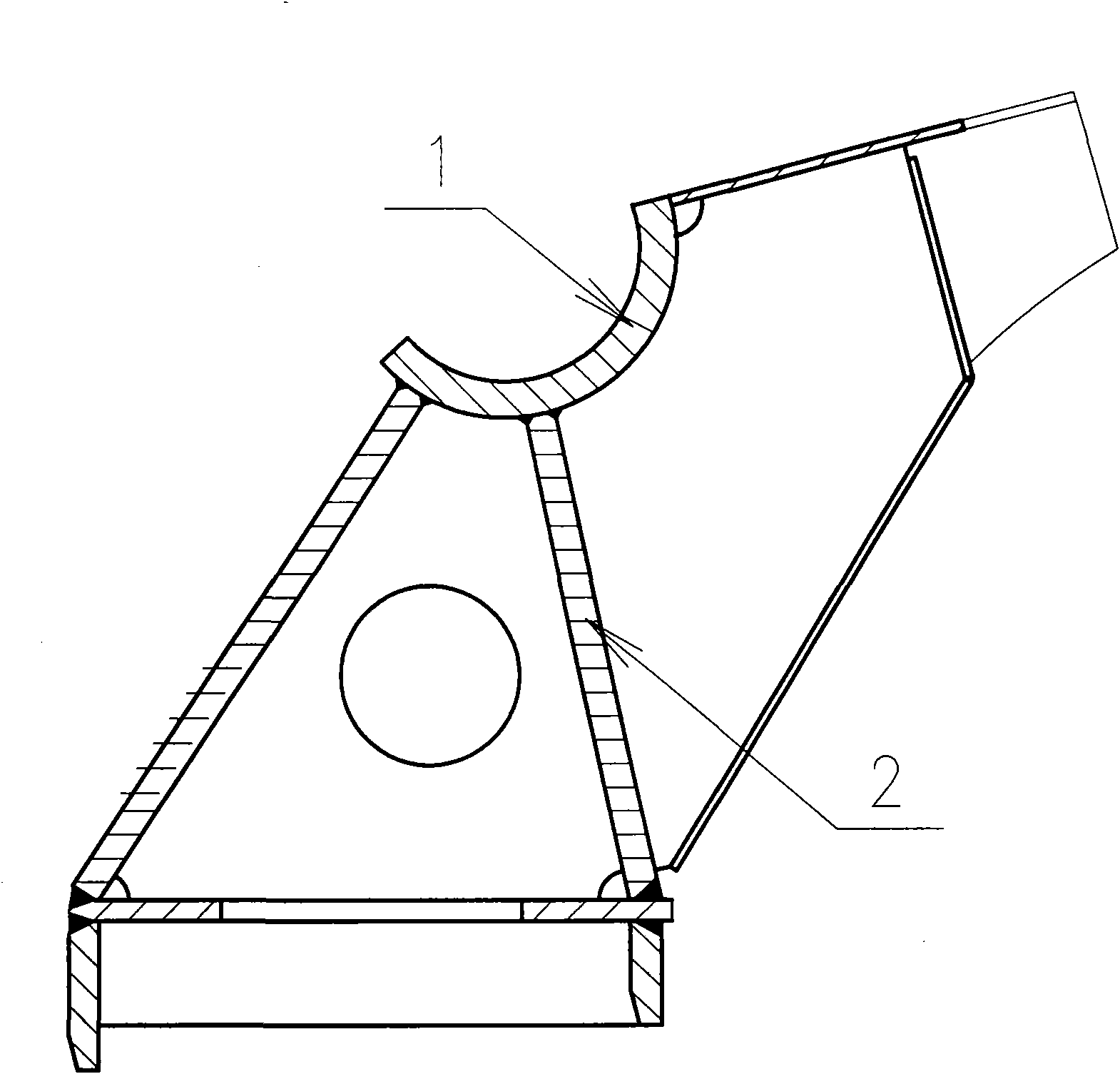

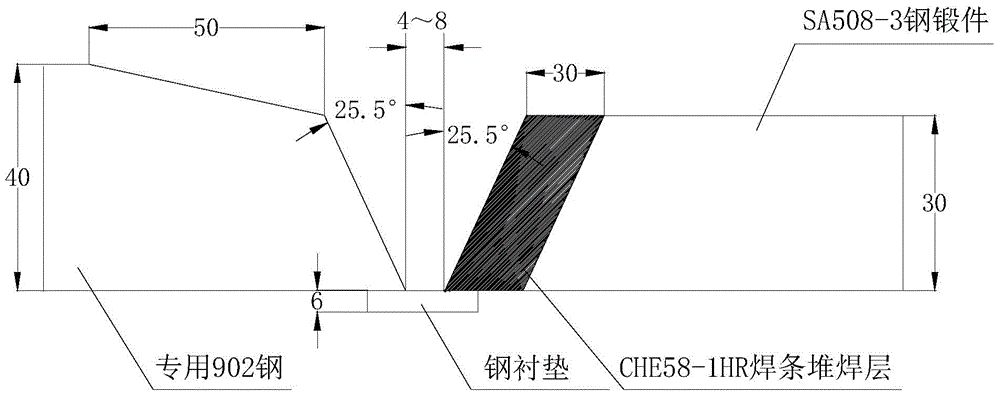

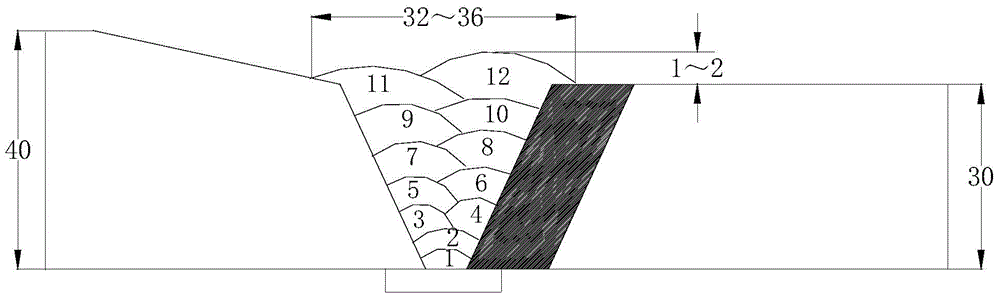

Structural steel and forged steel stud butt joint welding method for hull

ActiveCN105234525AShorten the construction periodEasy to processArc welding apparatusWelding/soldering/cutting articlesButt jointMan-hour

The invention provides a structural steel and forged steel stud butt joint welding method for a hull and belongs to a welding method among high-strength steel materials. The method solves the problems that by means of an existing high-strength structural steel and forged steel stud butt joint welding method, the welding seam strength is low, and the welding workload is large. The method includes the steps of groove forming, unilateral bead welding, preheating and welding. By means of the structural steel and forged steel stud butt joint welding method, machining is easy, welding deformation is reduced effectively, special 902 steel and SA508-3 forged steel stud butt joint welding is achieved smoothly, weldability test and welding process evaluation are achieved, labor efficiency can be improved, welding materials and electric energy are saved, man hours are reduced, production cost is lowered, the building period of ships is reduced, and the blank in structural steel and high-strength forged steel stud butt joint welding for ships in China is filled.

Owner:WUCHANG SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com