Crane girder

A technology of cranes and main beams, which is applied in the field of cranes, can solve the problems of carts gnawing on rails, sliding carts, and trolleys climbing slopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

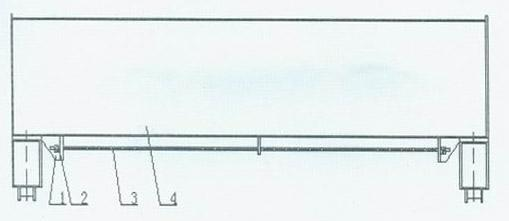

[0005] The embodiment is described in detail in conjunction with the above drawings. The two ends of the lower part of the main girder 4 are fixed with supporting supports 1 , and the tie rods 3 penetrate the middle of the supporting supports at both ends of the main girder and are fixed with tension nuts 2 . The best implementation is: the main girder is made of rectangular tubes, the rectangular tubes are cut into required lengths according to the span length of the main girders, the rectangular tubes pass through the arching machine once into a parabolic shape, and the upper camber is in the range of (0.9-1.4 ) between S / 1000, the supporting base welded at both ends of the main beam is connected with high-strength hinged bolts, the tie rod penetrates into the middle of the supporting base, and the torque is gradually increased in sequence with a special torque wrench, and the tie rod can also be replaced by a cable , adjust the initial stress of each prestressed tie rod to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com