Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce welding man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

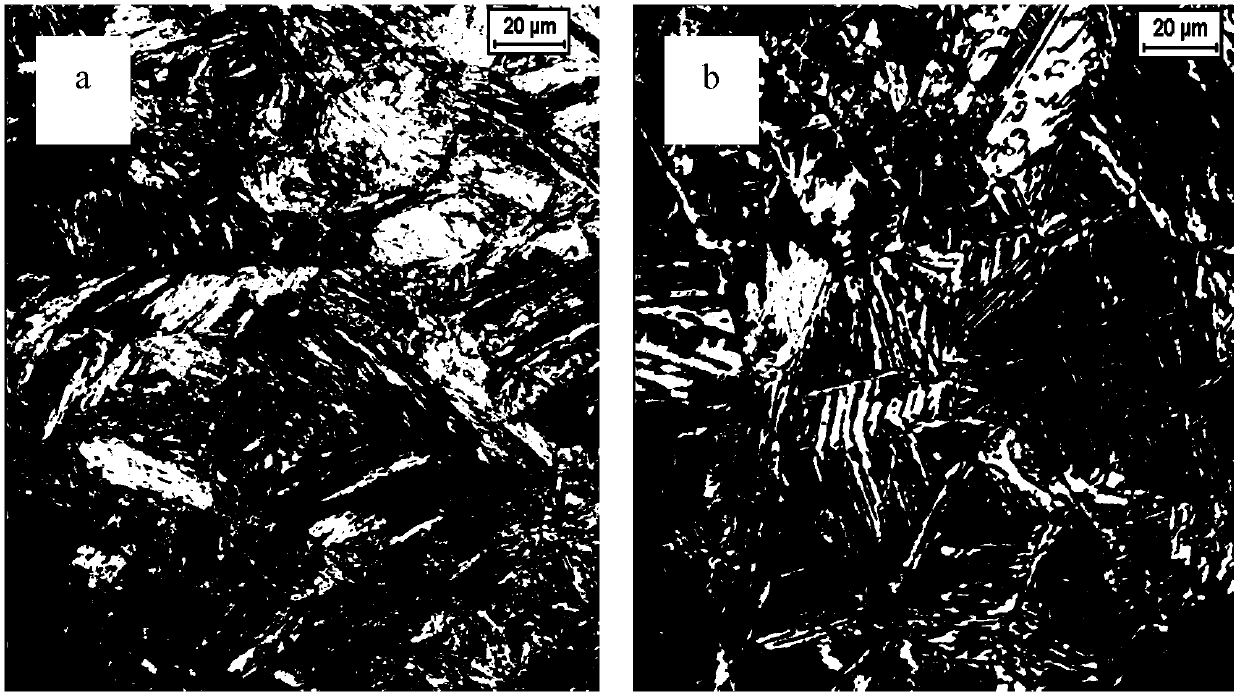

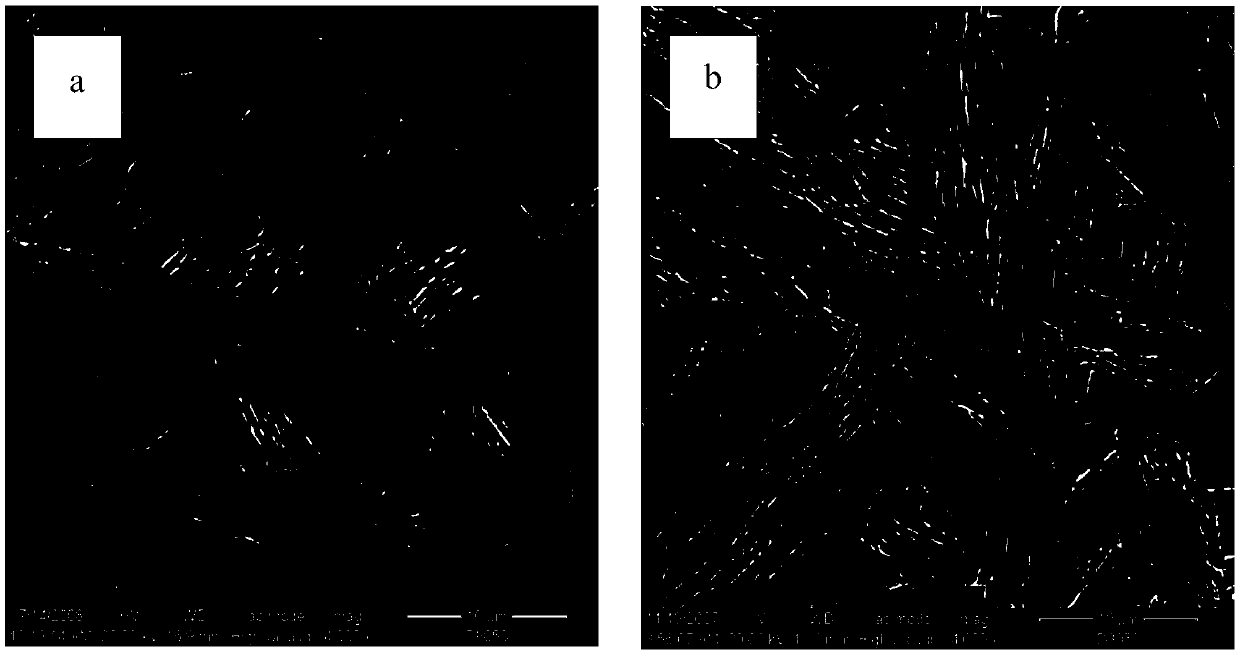

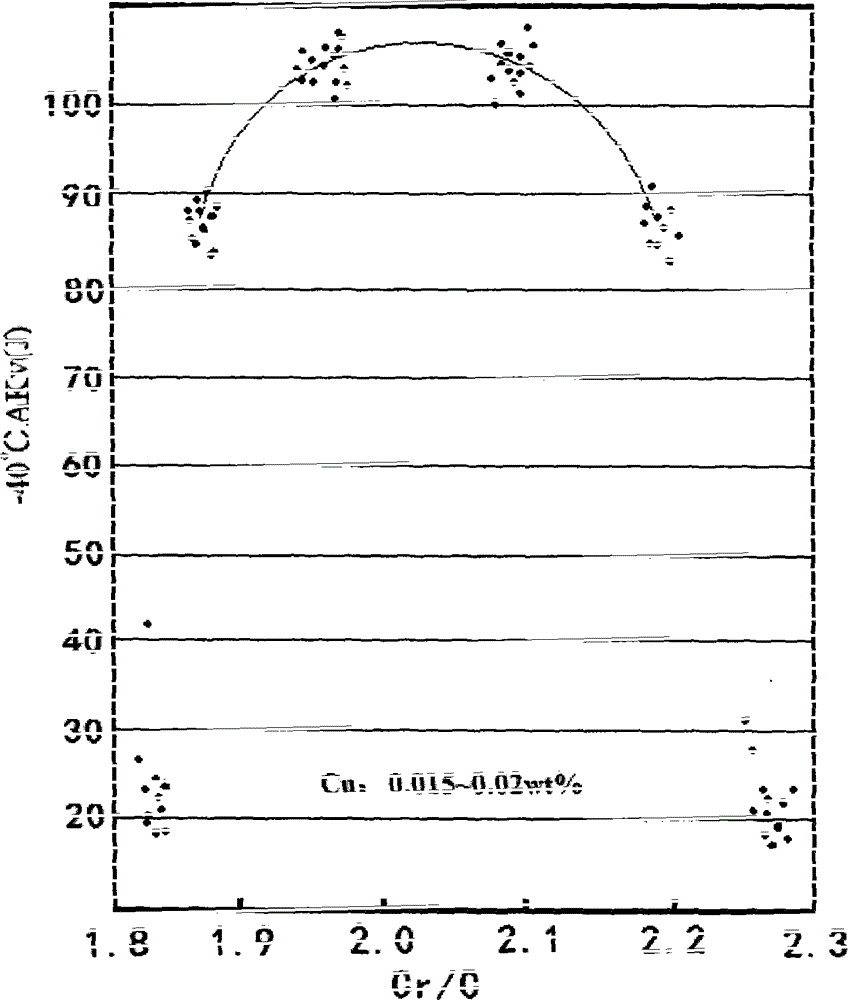

Strategic petroleum reserve tank steel plate based on oxide metallurgy and manufacturing method thereof

ActiveCN108677096AInhibit growthImprove low temperature impact toughnessHeat-affected zoneSheet steel

The invention discloses a strategic petroleum reserve tank steel plate based on oxide metallurgy and a manufacturing method of the strategic petroleum reserve tank steel plate. The yield strength of the steel plate is large than or equal to 490 MPa, the tensile strength is 610-730 MPa, and the yield ratio is smaller than or equal to 0.90. The manufacturing method comprises the steps that a continuous casting billet is manufactured, heated for heat preservation, roughly rolled, finely rolled, directly quenched and cooled at the speed being larger than or equal to 50 DEG C / s, heated, tempered and subjected to air cooling. The steel plate is also applicable to manufacturing of large strategic petroleum reserve tanks with the volume being 100000 m<3>, 150000 m<3> or more; when the steel plateis subjected to large heat input welding when heat input is large than 200 KJ / cm, after welding, the welding heat affected zone -20 DEG C impact energy is not lower than 80 J; a two-face two-pass X-type welding way which sets limitations for 25-60 mm steel plates in existing petroleum reserve tank construction is expected to be changed into single-face single-pass V-type welding, welding labor hours can be reduced by one half almost, the petroleum reserve tank construction speed is remarkably improved, the strategic petroleum reserve tank building cost is greatly reduced, and the application and popularization prospect is quite good.

Owner:NORTHEASTERN UNIV +1

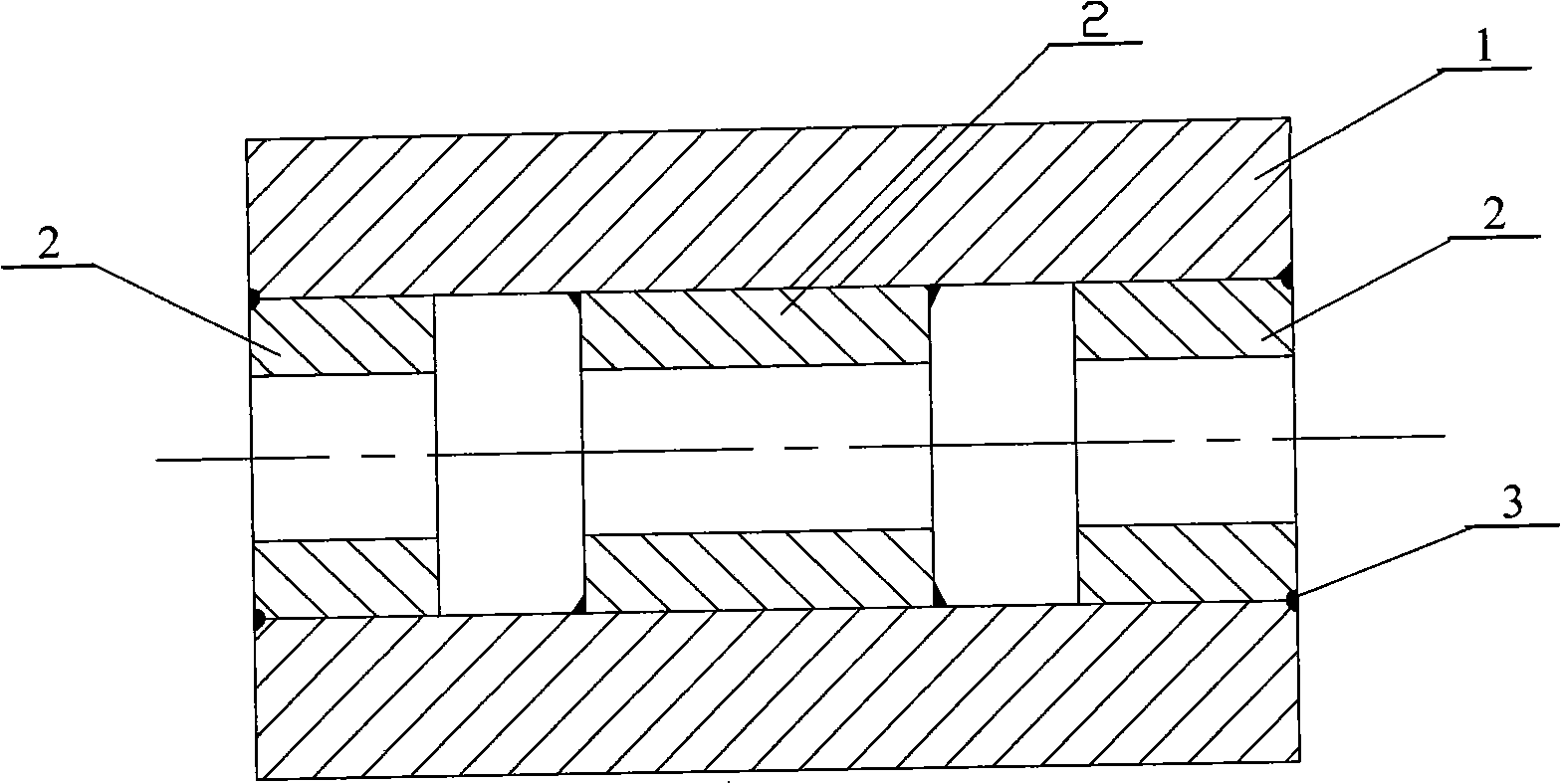

Pipe-shell type heat converter pipe plate and hemispherical closing head single-side welding narrow gap welding technology

InactiveCN101164729AReduce widthReduce the angleArc welding apparatusHeat exchange apparatusShell and tube heat exchangerSpray coating

The present invention relates to a shell-and-tube heat exchanger and hemispherical head one-side weld narrow gap welding process. It is characterized by that its backing weld adopts pen-type manual argon shielded are welding process, its welding material adopts mushroom-type consumable backing ring; the transion weld adopts electrode electric arc welding process, adopts spray coating spatter-proof material; and its main weld adopts narrow gap submerged-arc automatic welding process.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Cast iron welding technique using cold welding and bead welding

InactiveCN102000922AReduce welding man-hoursSave welding materialWelding apparatusPower flowThermal insulation

The invention disclose a cast iron welding process using cold welding and bead welding, comprising the following welding process steps of: (1) clearing parts to be welded: removing oil stains, iron rust and other flaws; (2) preparing a welding rod: using an E5015 basic welding rod of which the diameter is 3.2mm, drying the welding rod at a temperature from 360 DEG C to 380 DEG C for 1 to 2 hours, putting the dried welding rod in a thermal insulation bucket, and preserving heat for later use; (3) welding: selecting a direct current welding machine, and adopting a direct current straight polarity method, namely that the welding rod is connected with a negative electrode, a component to be welded is connected with a positive electrode, and the current is kept in a range from 95A to 105A. In the invention, a casting is welded by adopting the casting welding process using a cold welding method. The welding process using cold welding and bead welding solves the problems that the work environments of a casting welding process using a hot welding method are poor, and the site heating conditions can not meet the requirements on the welding process using a hot welding method in most conditions. Welding time is shortened, and welding materials are saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

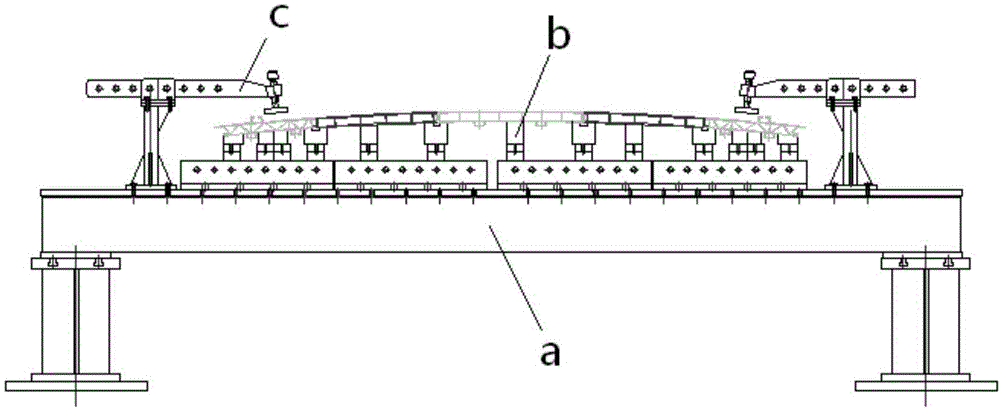

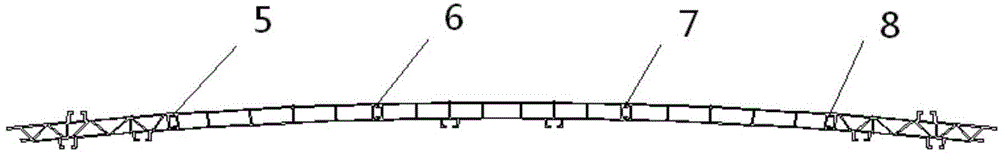

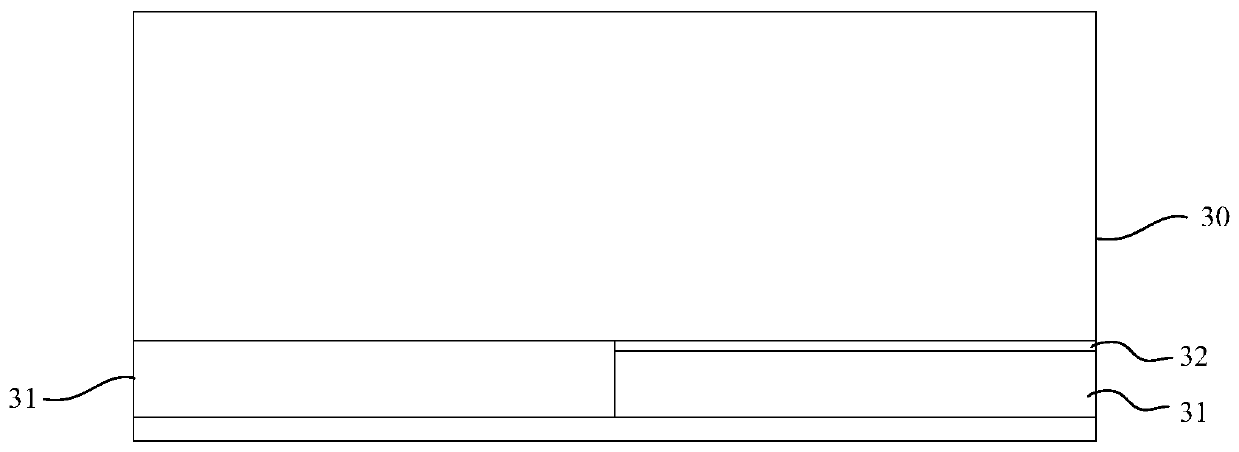

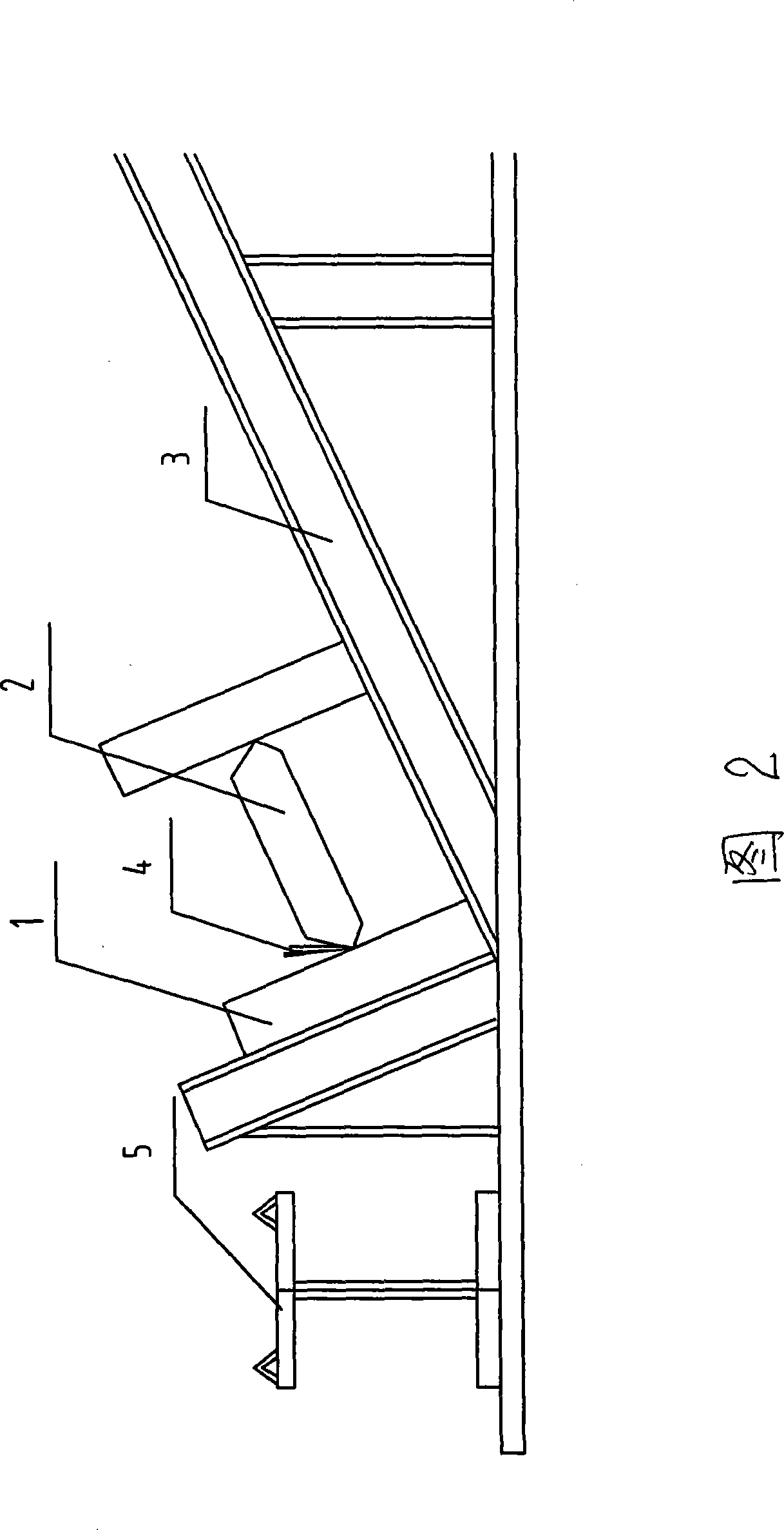

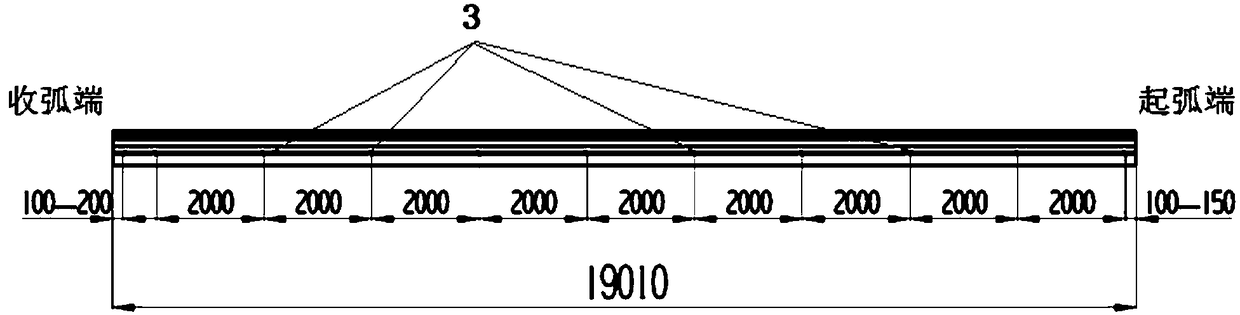

Welding technology of aluminum alloy ceiling used for subway compartment

The invention discloses a welding technology of an aluminum alloy ceiling used for a subway compartment. The ceiling is formed by welding five subway roof plates and two subway roof edge beams, and the subway roof plates are hollow profiles, wherein the length of each subway roof plate ranges from 16 m to 20 m, the width of each subway roof plate ranges from 0.3 mm to 0.6 mm, and the wall thickness of each subway roof plate ranges from 2 mm to 3 mm. In the welding process, all the subway roof plates are firstly welded, and then the subway roof edge beams and a subway roof plate assembly are welded; the subway roof plates are welded through double-wire double-machine linkage welding, firstly, forward installation welding is performed, and then reverse installation welding is performed; the subway roof edge beams and the subway roof plate assembly are welded through single-wire double-machine linkage welding, wherein forward installation welding and reverse installation welding are also performed in sequence. The material of welded components, the steps and the technology are improved, the using requirements for the quality and size of product weld joints are completely met, the qualified rate of the product is substantially increased, and meanwhile welding working hours are reduced.

Owner:辽宁忠旺铝合金精深加工有限公司

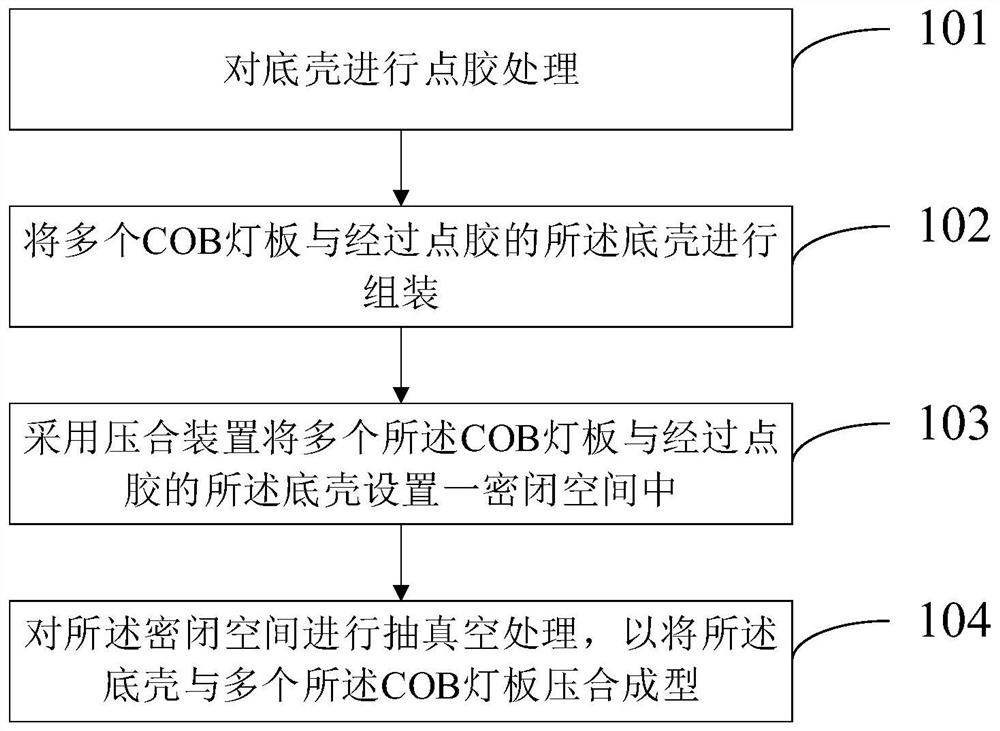

COB module and manufacturing method thereof

The application discloses a COB module and a manufacturing method thereof. The manufacturing method comprises the following steps: carrying out dispensing treatment on a bottom shell; assembling a plurality of COB lamp panels and the bottom shell subjected to adhesive dispensing; arranging the multiple COB lamp panels and the bottom shell subjected to dispensing in closed space through a pressingdevice; and carrying out vacuumizing treatment on the closed space and thus pressing the bottom shell and the multiple COB lamp panels into one. According to the application, the COB lamp panel and the bottom shell are connected in an adhesive mode and thus the flatness of the light-emitting face of the COB lamp panel and the flatness between the COB modules can be guaranteed, so that the COB modules are prevented from generating inclination angles, accordingly, bright and dark lines are prevented from being generated, the display uniformity is improved; besides, a screw fixing mode is omitted, copper columns do not need to be welded to the COB lamp panel, the welding time is shortened, and the manufacturing efficiency is improved.

Owner:深德彩智能科技(东莞)有限公司

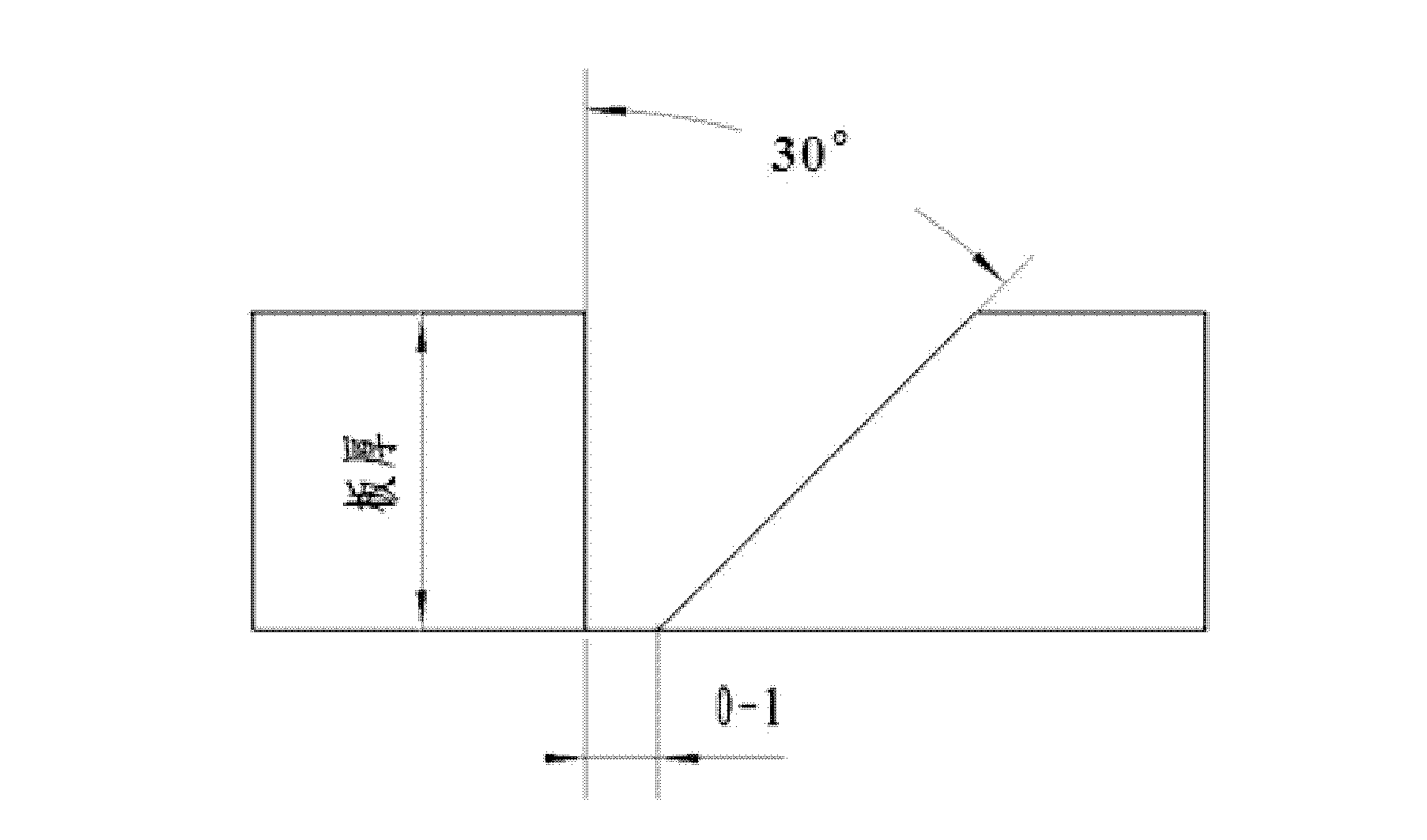

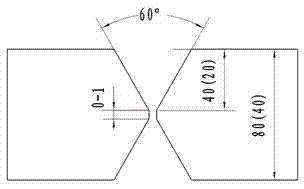

Single edge groove submerged arc welding technique of plate with moderate thickness

InactiveCN102632327AGuaranteed pass rateReduce welding man-hoursArc welding apparatusPower flowSurface layer

The invention discloses a single edge groove submerged arc welding technique of a plate with moderate thickness. The technique utilizes a DC (direct current) opposition method, and comprises the following technical steps: first to third layers on the facade: a phi 3.2 welding wire is utilized, the current is 380-400A, a rod is stretched by 2.8-3.0cm, the voltage is 24-25V, and the speed is 55-57cm / min; the other layers on the facade of the welding rail: a phi 4 welding wire is utilized, the rod is stretched by 3.0-3.5cm, the current is 560-600A, the voltage is 28-30V and the speed is 45-50 cm / min, or a phi 4 welding wire is utilized, the rod is stretched by 3.8-4.0cm, the current is 650-680A, the voltage is 33-34V, and the welding speed is 38-40 cm / min; and the back surface layer: a phi 4 welding wire is utilized, the rod is stretched by 3.8-4.2cm, the current is 680-700A, the voltage is 34-35V, and the speed is 34-36 cm / min. According to the invention, the submerged arc welding is directly used for bottoming, and no back chipping is performed on the back surface of the weld, thereby solving the complex welding method of the traditional technique, guaranteeing the percent of pass of the weld flaw detection, reducing the welding time and saving the welding material.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

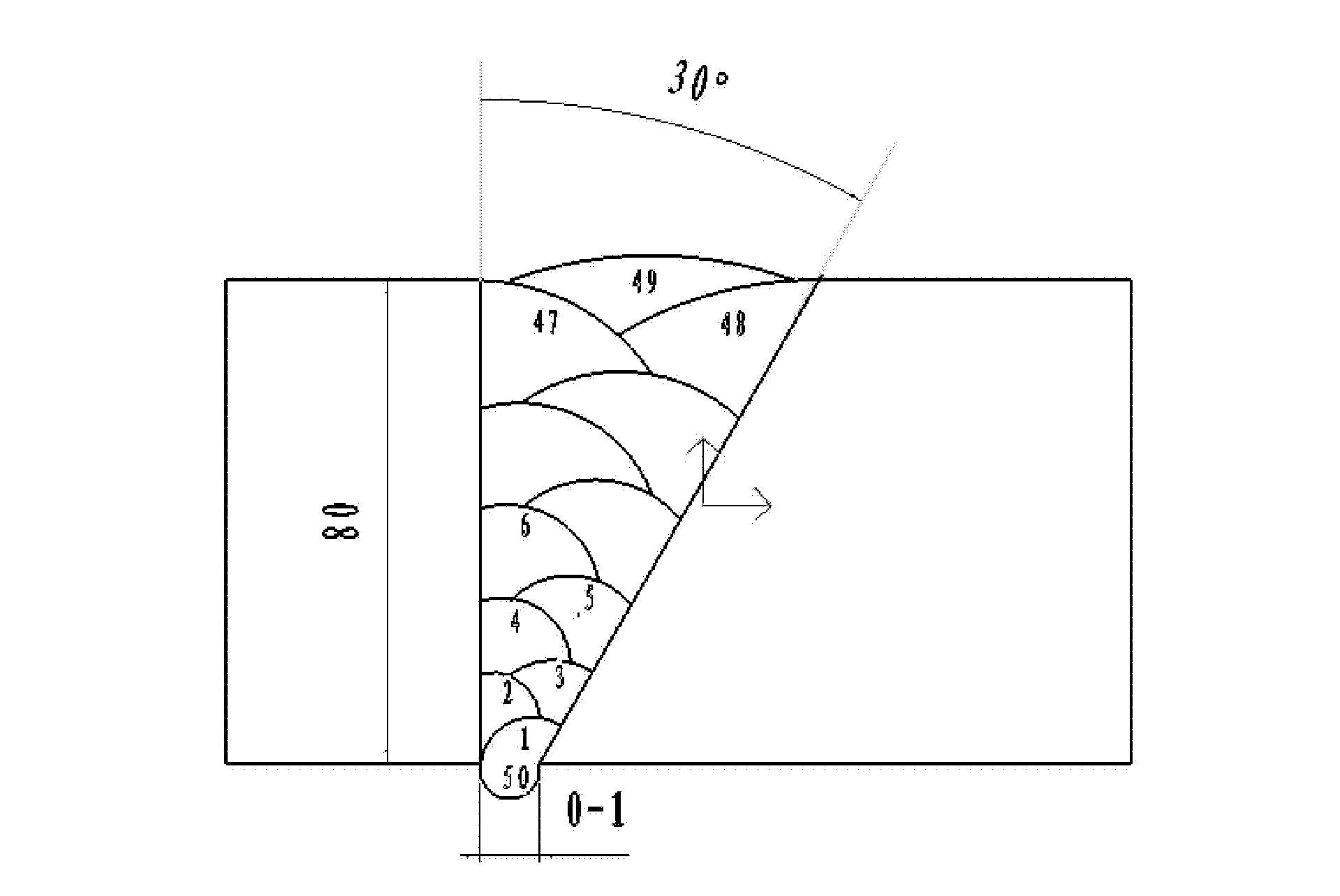

Welding technology of submerged-arc welding of X-shaped groove of medium plate

ActiveCN102000901BGuaranteed pass rateReduce welding man-hoursArc welding apparatusEngineeringWeld seam

The invention discloses a welding technology of submerged-arc welding of an X-shaped groove of a medium plate, which adopts the following technological steps: (1) when the front surface is welded: the welding current is 450 to 480A; the welding voltage is 25 to 26V; the welding speed is 54 to 58cm / min; and the rod extends by 30 to 35cm; (2) and when the back surface is welded: the welding currentis 600 to 640A; the welding voltage is 30 to 32V; the welding speed is 44 to 47cm / min; and the rod extends by 35 to 40cm. The welding technology has the advantages that the submerged-arc welding is directly adopted for priming; the back chipping is not required on the back surface of a welding seam; the appropriate welding current and voltage is selected and the welding speed is reasonably matched; the problem on the complicated welding method in the prior art is solved; the qualification rate of the welding seam flaw detection is simultaneously guaranteed; the working time of the welding is reduced; and the welding material is saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

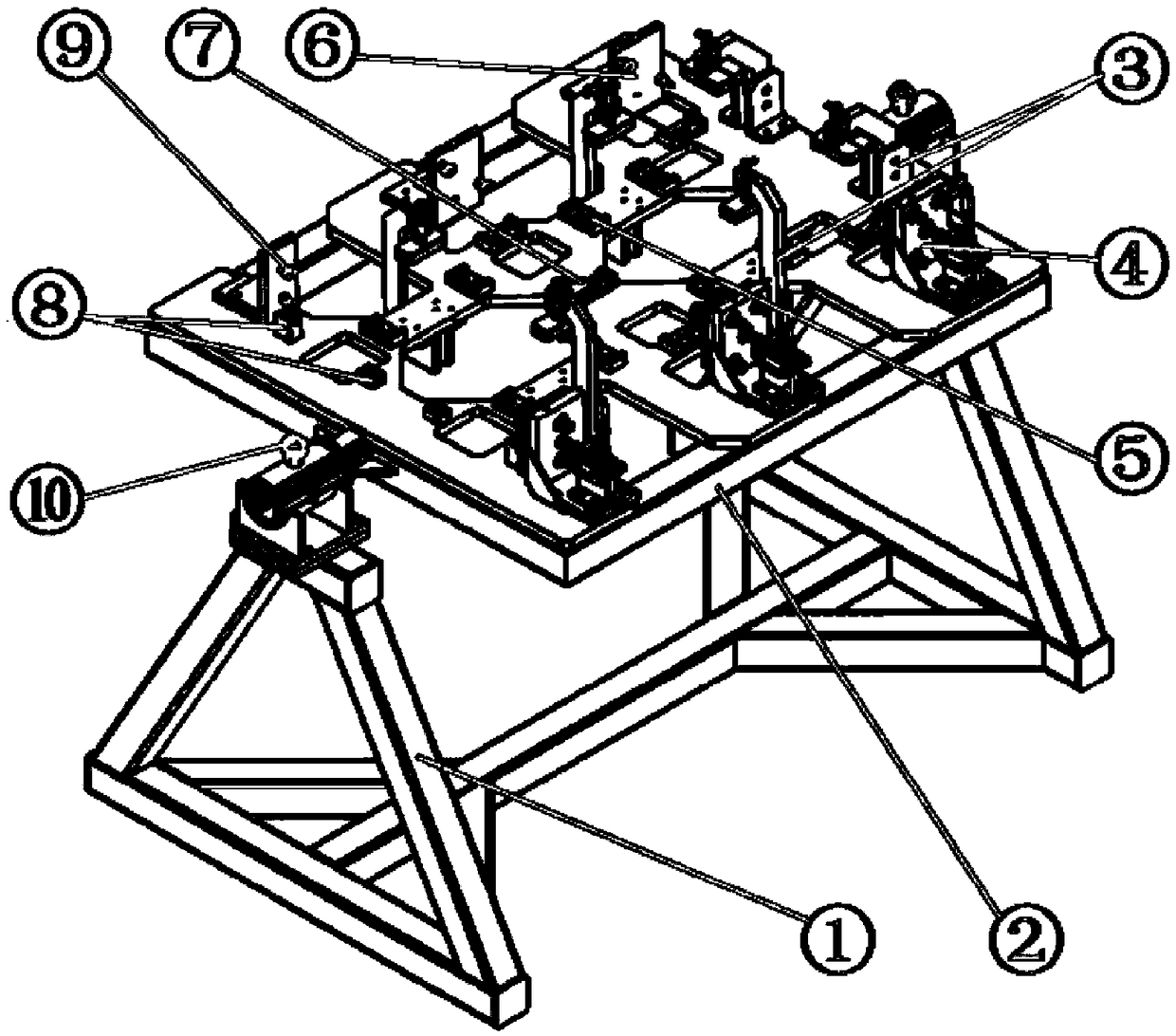

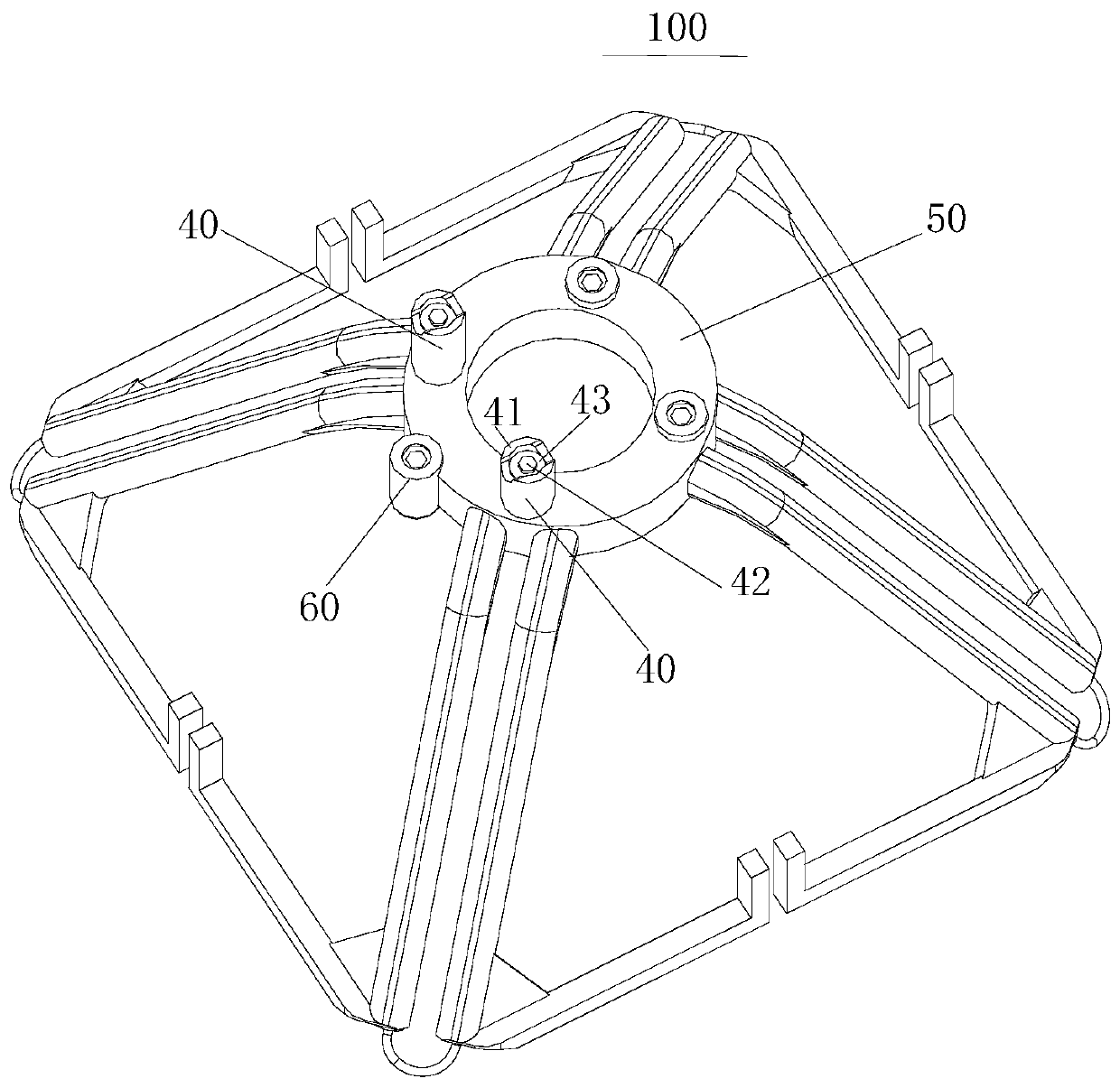

Semitrailer grillage-shaped beam welding tooling and welding process thereof

PendingCN109366032AEliminate the effects ofEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesShaped beamMobile end

The invention belongs to the technical field of aluminum alloy welding and relates to a semitrailer grillage-shaped beam welding tooling and a welding process for the semitrailer grillage-shaped beamwelding tooling. The semitrailer grillage-shaped beam welding tooling comprises a base and a main body frame rotatably installed on the base, wherein the left side and the right side of the main bodyframe are provided with three fixed end position-limiting blocks and moving end position-limiting blocks correspondingly, the outer sides of the fixed end position-limiting blocks and the moving end position-limiting blocks are fixedly provided with corresponding two sets of traction pin plate longitudinal beam compressing devices and a set of front end locking horizontal beam compressing devicescorrespondingly, the part, between the front end locking horizontal beam compressing devices, of the main body frame is evenly and fixedly provided with a plurality of front end locking horizontal beam connection angle part position-limiting grooves, and the part, between the traction pin plate longitudinal beam compressing devices, of the main body frame is evenly and fixedly provided with a plurality of traction pin plate position-limiting grooves used for clamping traction pin plate workpieces. By means of the welding tooling, the welding position is conveniently and efficiently adjusted toeliminate influence of the narrow and small space on welding operations, and by means of the position-limiting blocks and the compressing devices, the group matching accuracy is guaranteed to controlwelding deformation in the welding process.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

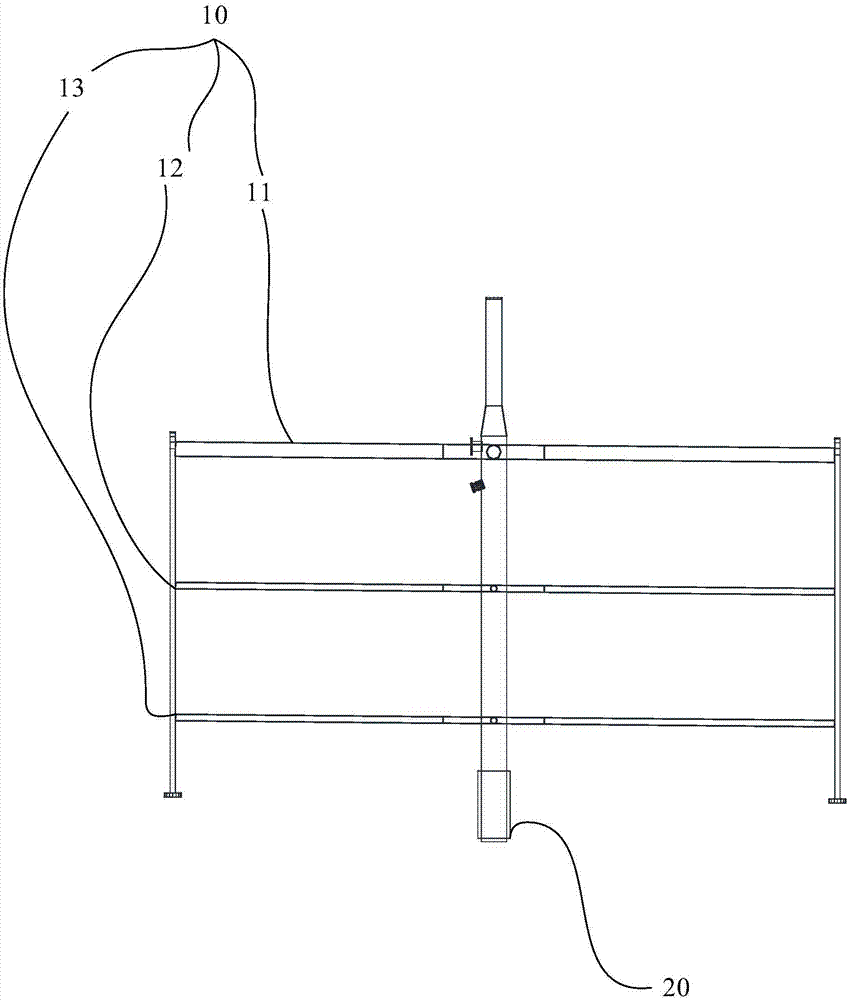

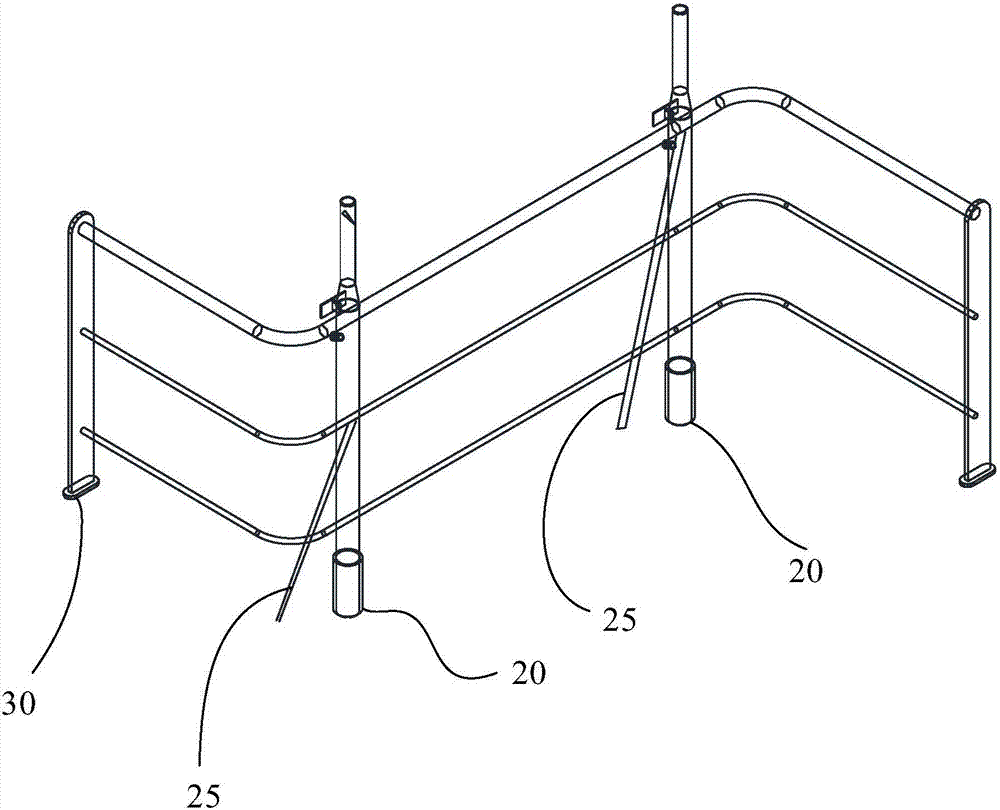

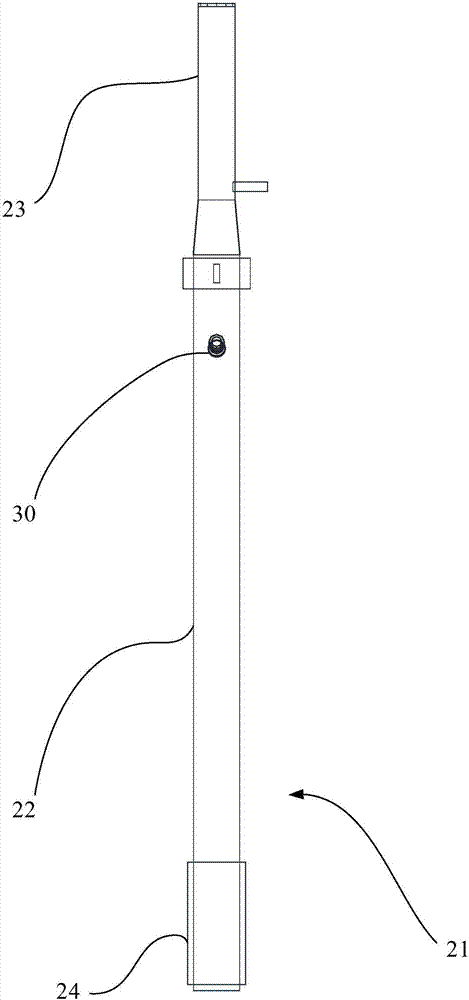

Ship railing and antenna base integrated ship

ActiveCN105752272ATotal weight lightReduce solder jointsAntenna supports/mountingsVessel partsMarine engineeringBuilding construction

The invention discloses a ship railing and antenna base integrated ship.The ship comprises ship railings and an antenna base.Each ship railing comprises a high rod, a middle rod and a low rod in the transverse direction, wherein the high rod, the middle rod and the low rod are arranged sequentially in parallel at intervals.The antenna base comprises a hollow antenna pillar used for penetration of a cable.The ship is characterized in that at least two sets of the ship railings are symmetrically arranged on the two sides of the antenna pillar respectively and fixedly connected with the antenna pillar; the bottom of the antenna pillar is fixedly connected to a deck of the ship.By the adoption of the ship railing and antenna base integrated ship, a hull is low in total weight, few welding spots exist, the construction period is short, the strength is high, vibration is small, and the antenna base is attractive.

Owner:SHANGHAI WAIGAOQIAO SHIPBUILDING & OFFSHORE ENG

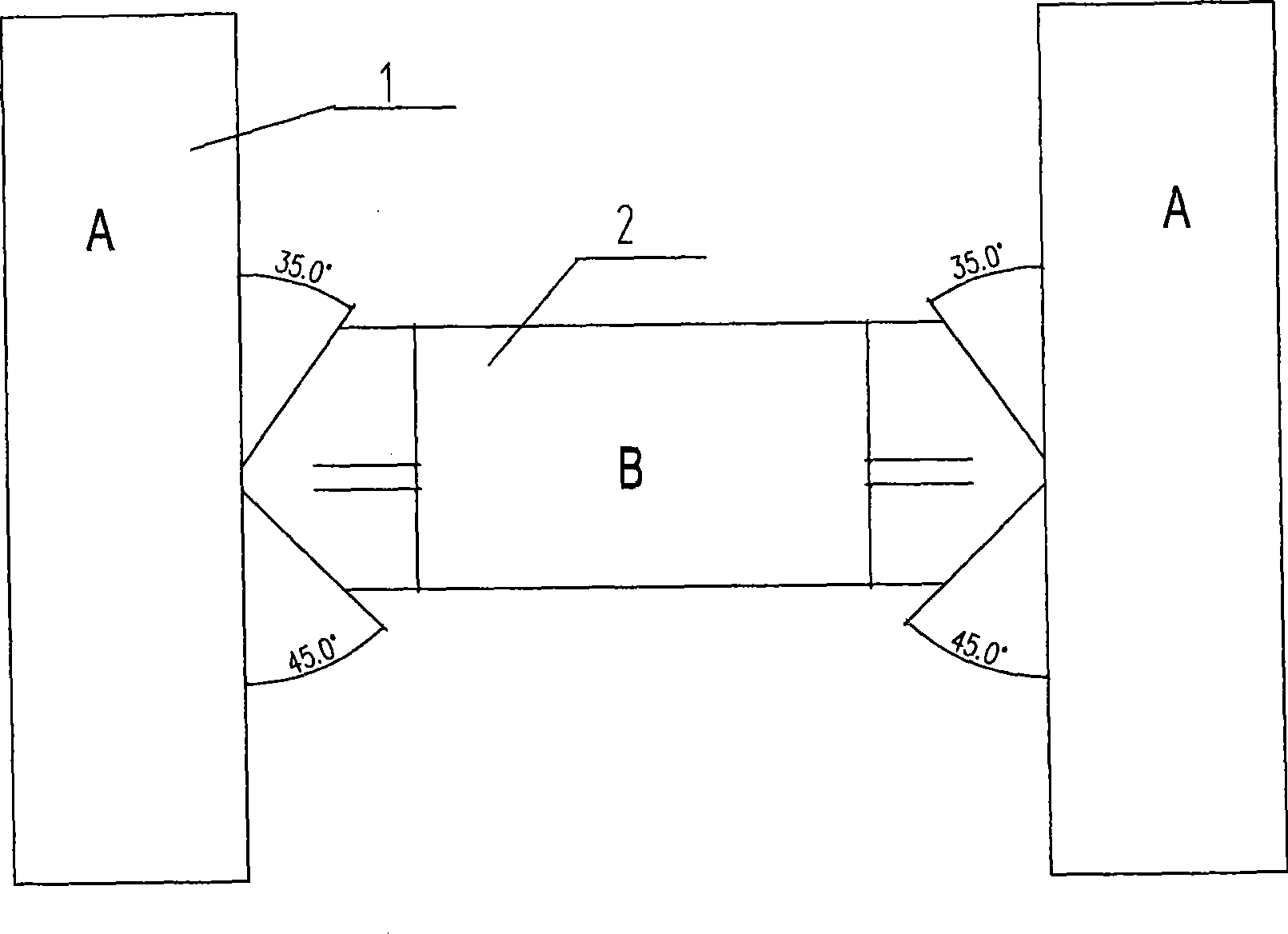

Welding process of union melt welding small divided edge

InactiveCN101412145AFast welding speedGuaranteed Progress RequirementsArc welding apparatusEconomic benefitsEngineering

The invention relates to a welding process, in particular to an automatic submerged arc welding small groove welding process. The welding process comprises the following steps: a groove is cut on a welding piece, the angle of one side of the groove is 35 degrees, and the angle of other side of the groove is 45 degrees; the H pair group of the welding piece is performed, and the welding piece is fixed by the spot adhibiting method, and the spot adhibiting fixing welding seam is arranged on the 45-degree side of the groove; the welding piece is welded, the 35-degree side of the groove is firstly welded, when one-third of the 35-degree side of the groove is welded, the root part of the 45-degree side of the groove is cleaned, after the cleaning, the welding continues, through the repeatedly staggered welding, the weld pass is completely filled. Compared with the prior art, the welding process has the advantages of reducing the welding time, improving the welding speed of the workpiece, ensuring the scheduling requirements on a project, reducing the filler level of weld metal, saving one-third of welding materials, directly improving actual economic benefits and reducing the welding deformation; moreover, because the angle of the groove is reduced, the welding process also has the advantages of reducing the pre-heating width of the welding seam, lowering the defect of the welding seam and lowering the repair cost.

Owner:MCC JINGTANG CONSTR

Welding technology of shell covers and cylinder body of aluminum alloy tank

InactiveCN107695557AEliminate Welding DefectsReduce the number of weldsArc welding apparatusWorkpiece edge portionsWelding defectAluminium alloy

The invention relates to a welding technology of shell covers and a cylinder body of an aluminum alloy tank. The welding positions of the shell covers and the cylinder body are polished before welding; gaps are left between the shell covers and the cylinder body in advance, and then TIG is used for welding and fixing on the outer side; finally, the shell covers and the cylinder body adopt the two-side arc-alignment TIG for welding. The welding technology eliminates the situation that when a manual TIG welding method is used for welding the circular seams between the front shell cover and the cylinder body and between the back shell cover and the cylinder body, chain-shaped air hole welding defects exist at the longitudinal center positions of welding seams, the qualified welding seams canbe obtained, and the safety of a tank assembly is ensured.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

Manufacturing process for weldless total-prefabricated rollers

InactiveCN107755985AEasy to processReduce welding man-hoursMechanical working/deformationManufacturing cost reductionInterference fit

The invention provides a manufacturing process for weldless total-prefabricated rollers, and relates to the technical field of processing and manufacturing of rollers. The manufacturing process for weldless total-prefabricated rollers is technically characterized in that a position where a shaft head is connected with a roller does not have weld, and requirements of stress of the roller and / or airtightness and processing precision of the roller are met and ensured by bonding strength generated by reliable interference fit between the shaft head and the roller completely. After the shaft headand the roller are assembled, welding, stress-relieving heat treatment, heat treatment such as medium-frequency hardening, processing such as finish turning of the shaft head and dynamic balance emendation of the roller are not required, a technological process can be greatly shortened, processing procedures can be greatly reduced, processing time can be greatly shortened, processing difficulty can be greatly relieved, manufacturing costs can be greatly reduced, and perfect dynamic balance grade and manufacturing precision are realized. Therefore, a series of configuration and matching of machine tool equipment, change and innovation of technical requirements, change and innovation of fixtures, workshop planning and layout and change and innovation of a technology of the manufacturing process for rollers can be further initiated.

Owner:抚顺东旭精工制辊科技有限公司

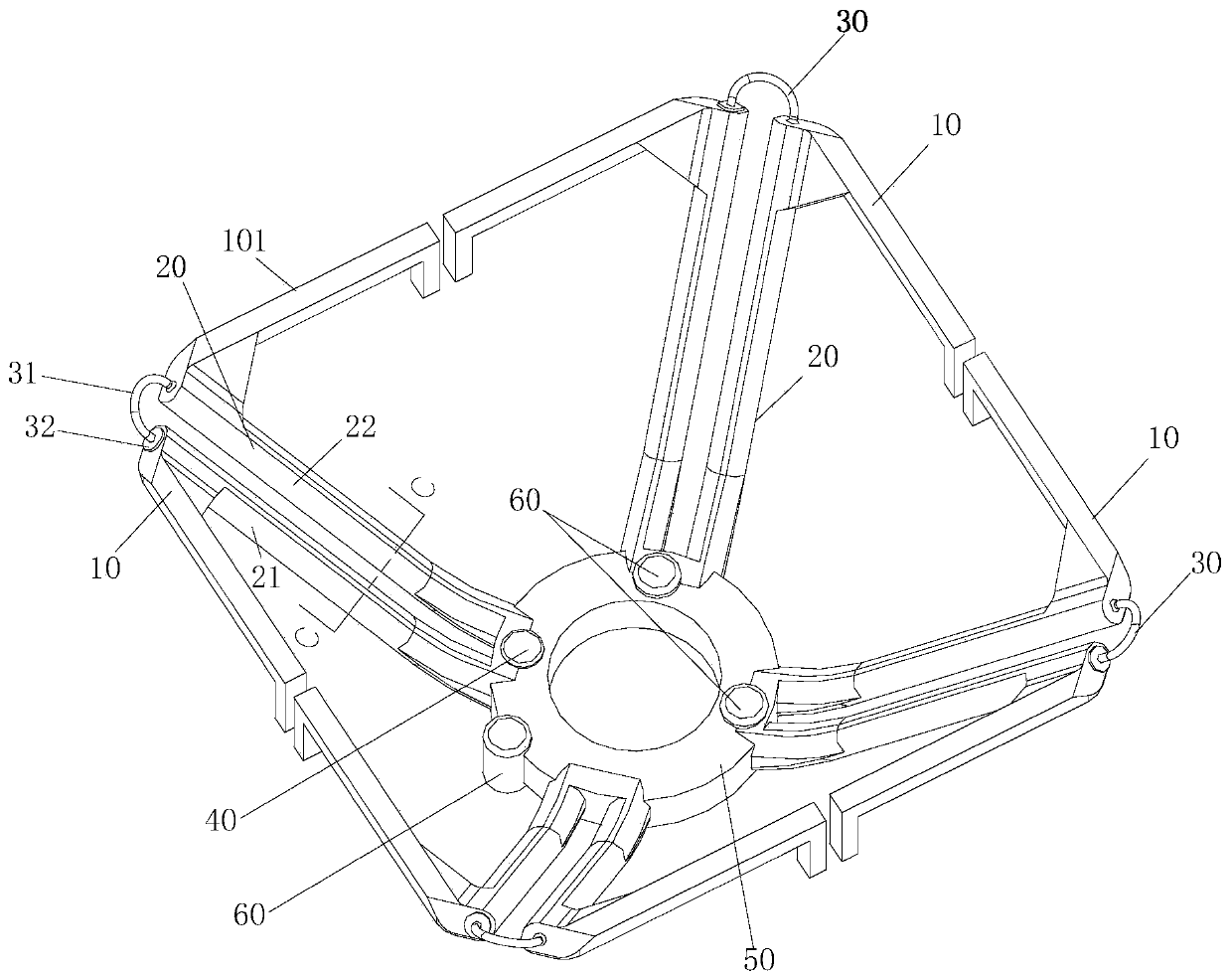

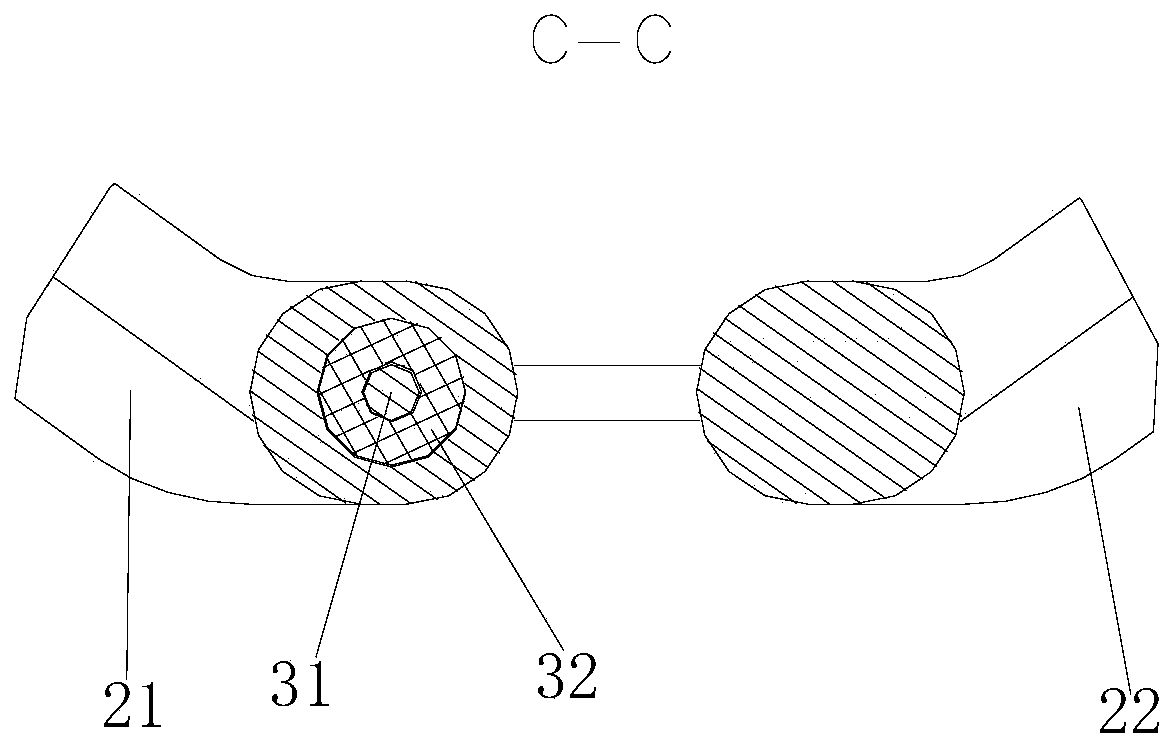

Base station antenna and radiation unit thereof

ActiveCN111180860AReduce welding man-hoursReduce electrical performance instability factorsSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorCoaxial cable

The invention provides a base station antenna and a radiation unit thereof. The radiation unit comprises a dipole, a balun supporting the dipole, and a feeding pack for feeding the dipole. The balun comprises a pair of balun arms which are oppositely arranged, at least one balun arm being arranged in a hollow mode; the feed part comprises a feed conductor and an insulating medium, wherein the feedconductor is arranged in the hollow balun arm in a penetrating mode and connected with one radiation arm supported by the other balun arm; and the insulating medium is filled between the feed conductor and the inner wall of the balun arm and enables the feed conductor to be fastened in the balun arm. A feed part composed of a feed conductor and an insulating medium is arranged in an inner cavityof a hollow balun arm; and the feeding part and the balun arm form a structure similar to a coaxial cable, so that coaxial cable feeding is not needed, welding is not needed, welding time is saved, unstable factors of electrical performance caused by welding are reduced, and meanwhile, cost can be reduced due to the fact that the coaxial cable is not used.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

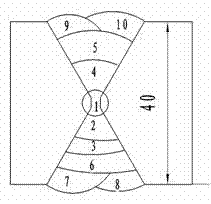

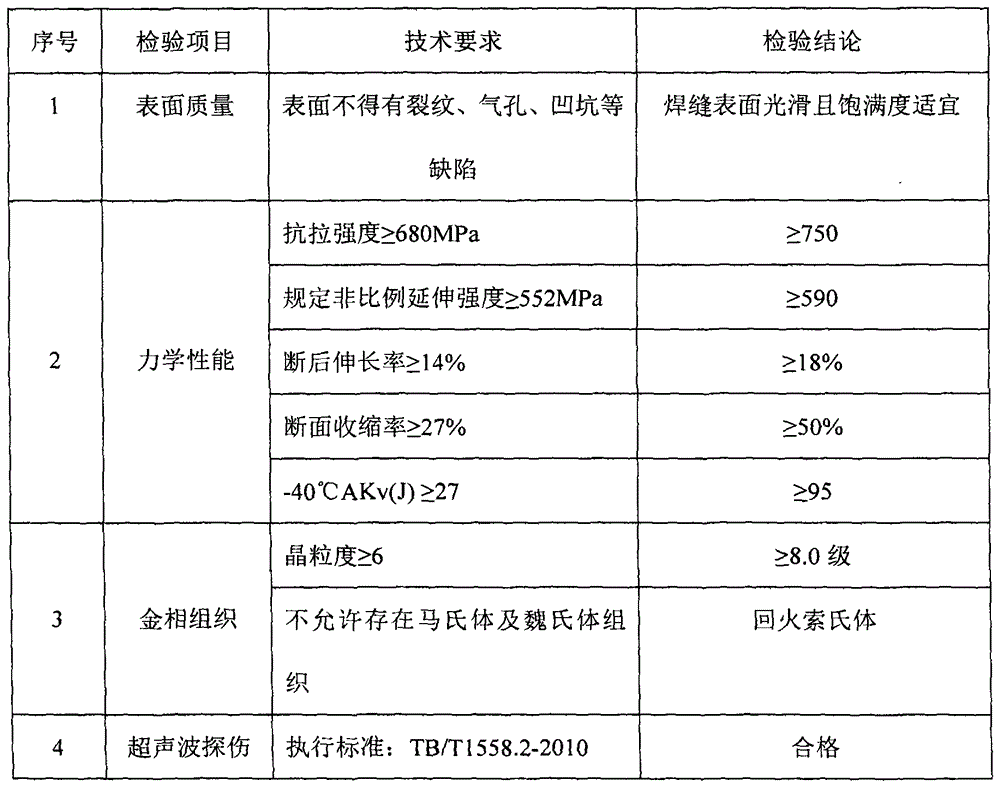

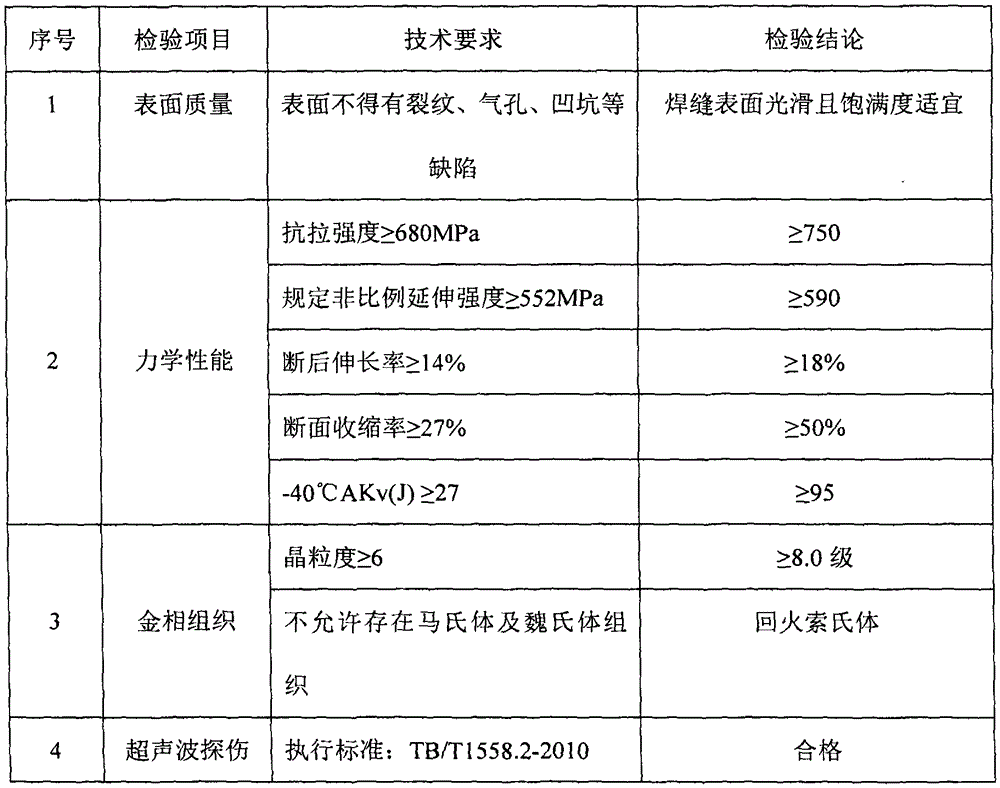

Method of using robot for automatic welding of forged coupler yokes

ActiveCN104148832AReduce labor intensityReduce welding man-hoursWelding/cutting auxillary devicesArc welding apparatusWater circulationAtmosphere

The invention relates to a method of using a robot for automatic welding of forged coupler yokes. The welding method includes the steps: (1) forming a shape of an X-shaped weld groove, arranging a water cooling pad at the lower end of the X-shaped weld groove after a weld part is fixed, flushing the water cooling pad with the center of the groove, fixing the water cooling pad to the groove, and then starting a cooling water circulation device arranged in the water cooling pad; (2) in a protective atmosphere, instructing a welding robot to perform four-gate welding at the upper end of the weld groove; (3) taking off the water cooling pad, and instructing the welding robot to perform four-gate welding at the lower end of the weld groove in the protective atmosphere. The method of using the robot for automatic welding of the forged coupler yokes has the advantages that labor intensity is remarkably relieved, welding labor hours are reduced, back gouging is not needed, weld testing acceptability is guaranteed, and welding materials are saved.

Owner:南京力源轨道交通装备有限公司

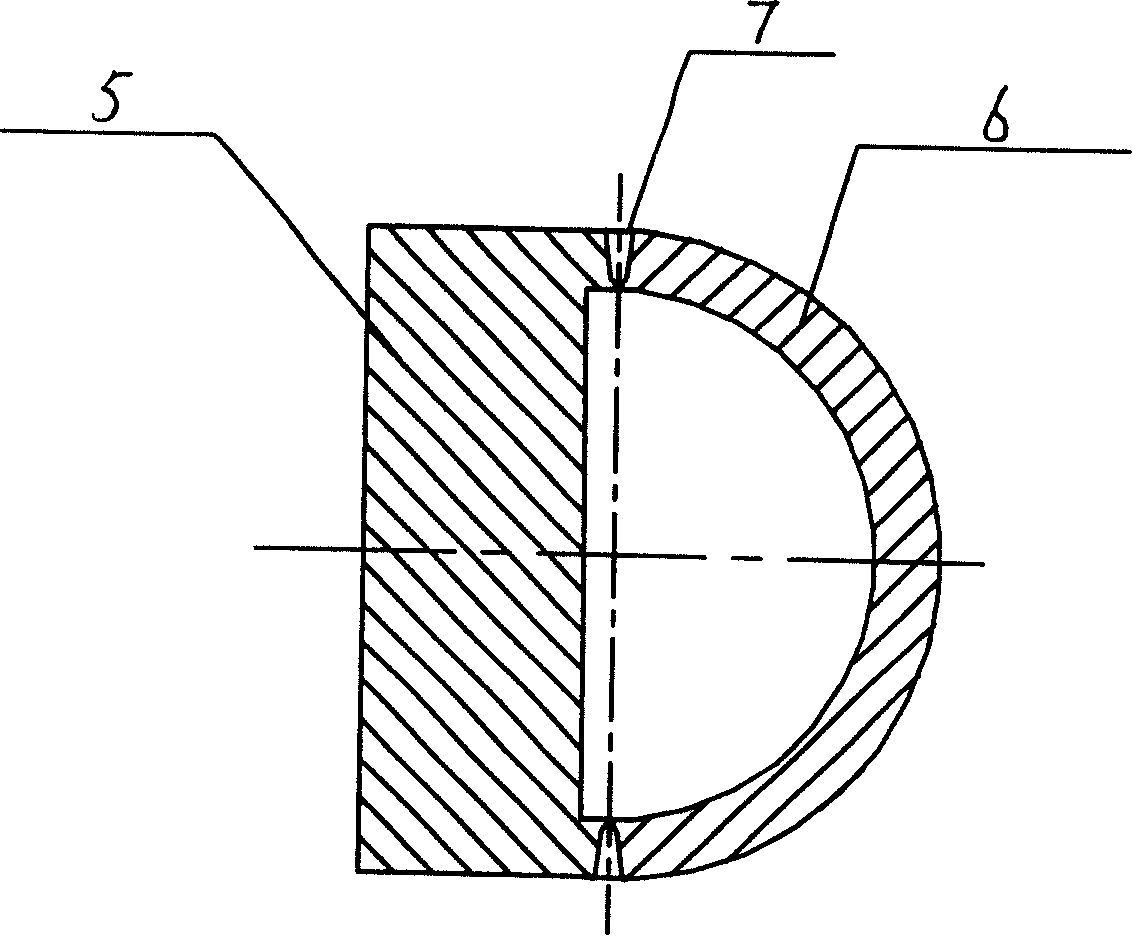

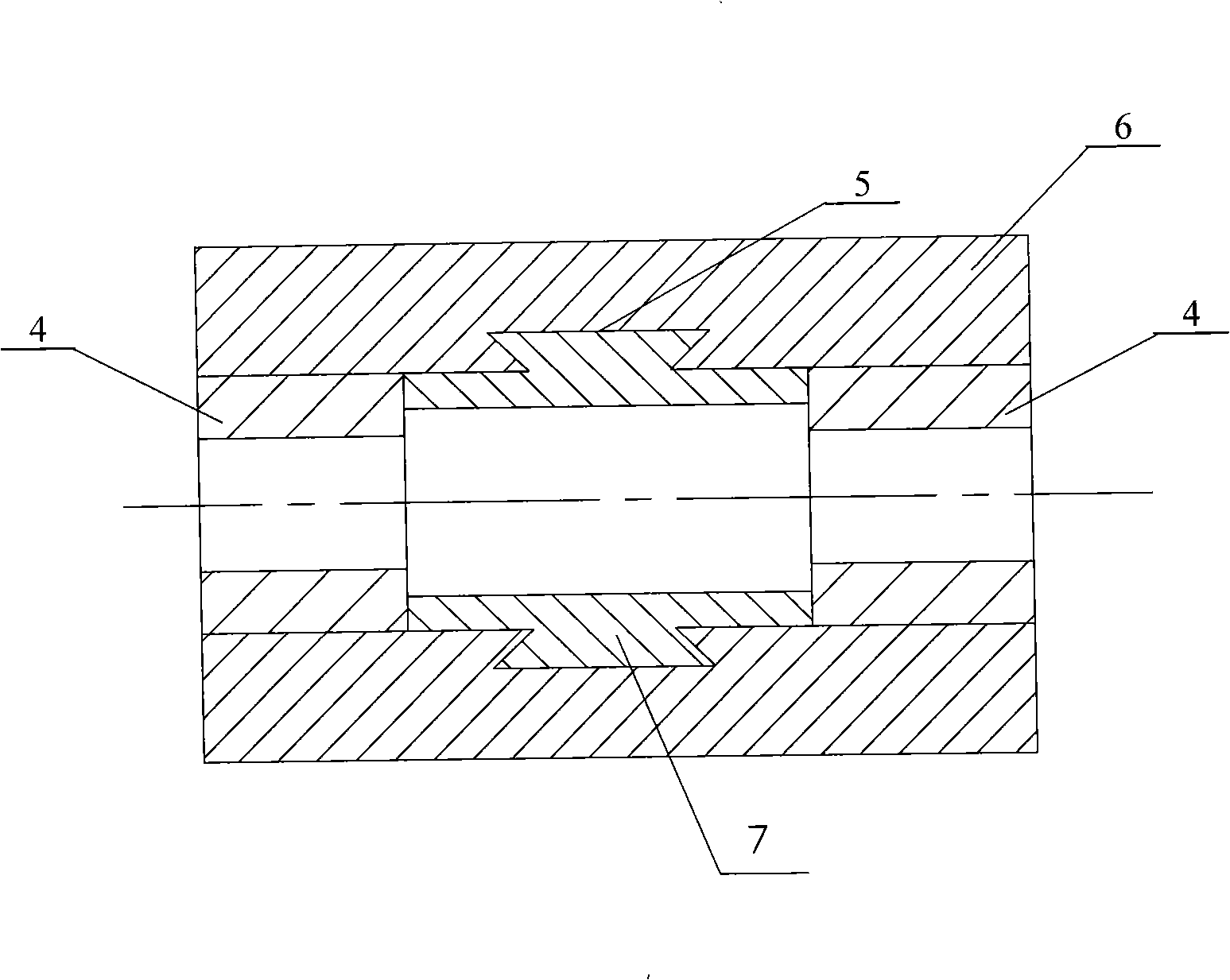

Direct foundry connection method for rare-earth permanent magnet motor rotor magnetism-isolating loop

InactiveCN101355276AOvercome the defect that needs to be fixed by multiple weldingReduce the numberMagnetic circuit rotating partsManufacturing stator/rotor bodiesRare earthPermanent magnet motor

The invention discloses a direct casting connection method for magnetic isolation rings of a rotor of a rare earth permanent-magnet motor and relates to an assembly method for the magnetic isolation rings of the rotor of the rare earth permanent-magnet motor. The method overcomes the defects that the prior technology has time-consuming processing and does not contribute to the mass production. The method is realized through the following steps: firstly, a turning method is used to process two magnetic isolation ring bodies (4); secondly, the two magnetic isolation ring bodies (4) are respectively arranged on both ends of an inner hole of a rotor block (6); and thirdly, molten stainless steel is cast into a space formed between the two magnetic isolation ring bodies (4) and the inner wall of the rotor block (6), thereby solidifying into a stainless steel magnetic shield (7), and the stainless steel magnetic shield (7) is respectively solidified into a whole with the inner end surfaces of the magnetic isolation ring bodies (4) and the inner wall of the rotor block (6). The method can finish the work of shaping the magnetic shield and fixing the magnetic isolation rings in the inner hole of the rotor (6) by casting one time, and overcomes the defect that the magnetic isolation rings in the prior technology need to be welded and fixed for a few times.

Owner:林增禄 +1

Column welding method of q420b steel building steel structure for heavy and large

ActiveCN104741744BImprove impact toughnessReduce the occurrence of cold cracksArc welding apparatusEngineeringSlow cooling

The invention discloses a vertical column welding method for a heavy and large Q420B steel building steel structure. The method comprises the steps of manufacturing a web welding part and a wing flange plate welding part; forming a grooving opening in a weld joint; dehumidifying the web welding part and the wing flange plate welding part; performing full penetration welding to abut and weld the web welding part to obtain a web; performing full penetration welding to abut and weld the wing flange plate welding part to obtain a wing edge plate; performing local penetration welding for a T joint for combining the web and the wing edge plate; performing temperature maintenance and slow cooling treatment for the weld joint. According to the method, the automatic submerged arc welding multi-layer multi-weld process is utilized, so that the automation degree of welding is high; extremely less cold cracks occur in the weld joint structure, and thus the welding quality is high; the labor intensity in welding process is reduced, little welding is performed, so that the welding hours can be greatly reduced; the demand of construction of the heavy and large building steel structure can be comprehensively met by the welding process.

Owner:CHINA 19TH METALLURGICAL CORP

Calculator circuit structure for realizing solar cell power supply automatic switching

ActiveCN105354168ASave the diodeSave its welding man-hoursDigital computer detailsElectric digital data processingElectrical batteryPower switching

The invention relates to a calculator circuit structure for realizing solar cell power supply automatic switching. The calculator circuit structure comprises: a voltage comparator, wherein a first input end of the voltage comparator is connected with a solar cell of a calculator, and a second input end is connected with a dry cell of the calculator; a power switch, used for selecting the solar cell or the dry cell to supply power to the calculator according to a comparison result output by the voltage comparator; and a voltage stabilizer, connected between the power supply output end of the power switch and the power input end of a load of the calculator. With the adoption of the calculator circuit structure for realizing solar cell power supply automatic switching, three functional modules of the voltage comparator, the power switch and the voltage stabilizer are combined together, so that the functions of voltage comparison, voltage source selection and voltage stabilization during dual-power input can be achieved; and a relatively stable working voltage can be provided for a circuit through the voltage stabilizer, so that the circuit can be better ensured to work stably. Therefore, the calculator circuit structure has a wider application range.

Owner:CRM ICBG (WUXI) CO LTD

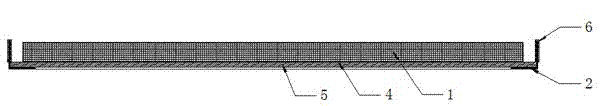

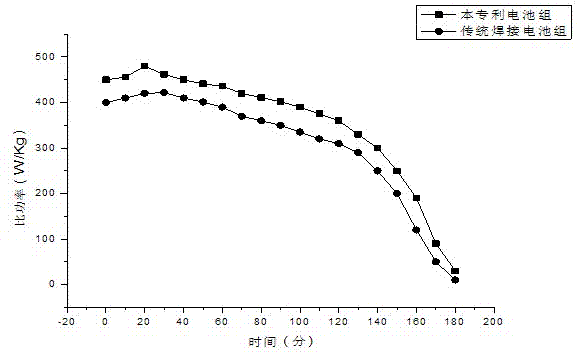

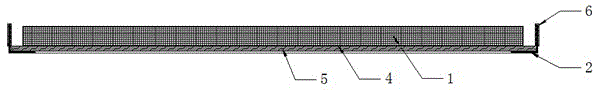

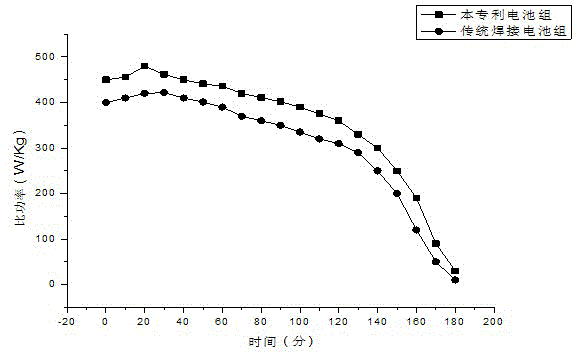

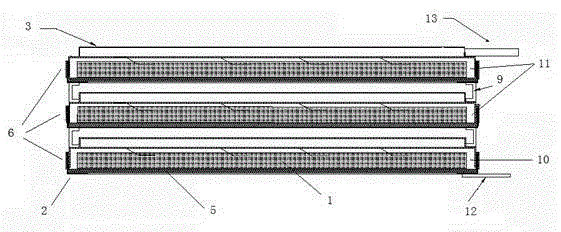

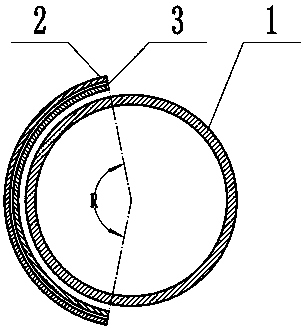

Zinc-air battery pack capable of being assembled conveniently

ActiveCN103208667AFast replacementAvoid efficiency lossFuel and primary cellsCell component detailsEngineeringZinc–air battery

The invention discloses a zinc-air battery pack capable of being assembled conveniently. Compared with the prior art, the zinc-air battery pack overcomes the defects that the battery replacement speed is low and the battery replacement is inconvenient. The zinc-air battery pack disclosed by the invention comprises an A-type battery (10), a B-type battery (11) and a current collector (3), wherein the A-type battery (10) is formed by putting an air pole (5) on the upper part of a battery jar (2) flatwise and spreading calamine cream (1) on the air pole through a diaphragm (4); the lower part of the current collector (3) is provided with a copper claw (8); the B-type battery (11) is formed by connecting the lower part of the A-type battery (10) with the current collector (3) by using a double-pole connector (9); the B-type battery (11) is installed on the calamine cream (1) of the A-type battery (10) through the copper claw (8); and the current collector (3) is installed on the calamine cream (1) of the B-type battery through the copper claw (8). According to the invention, the replacement speed of a zinc-air battery is increased, and the problem of reduction of battery efficiency caused when the welding is poor is solved.

Owner:AGA TECH CO LTD

Ships with integrated ship railings and antenna bases

ActiveCN105752272BTotal weight lightReduce solder jointsAntenna supports/mountingsVessel partsMarine engineeringBuilding construction

Owner:SHANGHAI WAIGAOQIAO SHIPBUILDING & OFFSHORE ENG

Welding method of flange plate and web plate of q390d steel crane girder in heavy work system

ActiveCN104759767BImprove impact toughnessReduce consumptionWelding/soldering/cutting articlesMetal working apparatusButt weldingEngineering

The invention discloses a flange plate and web welding method for a heavy derrick Q390D steel crane beam. The method comprises the six steps of manufacturing web welding parts and flange plate welding parts with butt welding grooves, dehumidifying the web welding parts and the flange plate welding parts, welding the web welding parts in a butting and full penetration mode to form a web, welding the flange plate welding parts in a butting and full penetration mode to form a flange plate, performing heat preservation and slow cooling on a web sealing joint an a flange plate sealing joint, combing and welding the web and the flange plate in a T shape in a full penetration mode, and performing heat preservation and slow cooling on a crane beam welding joint. In the process of manufacturing the web or the flange plate, the web welding parts and the flange plate welding parts are not preheated before welding; in the crane beam manufacturing process, the web and the flange plate are not preheated before welding. According to the flange plate and web welding method, the automatic submerged arc welding multi-layer and multi-pass welding technology is adopted, the welding automation degree is high, few cold cracks exist in a welding joint structure, the welding quality is high, the labor intensity of welding work is low, the welding cost is low, and welding time is greatly shortened.

Owner:CHINA 19TH METALLURGICAL CORP

Casting welding process

InactiveCN109986182AReduce welding man-hoursSave welding materialWelding accessoriesField conditionsCurrent range

The invention discloses a casting welding process that comprises the following welding process steps: (1), cleaning a to-be-welded part: eliminating defect factors such as greasy dirt and rust; (2), preparing a welding rod: drying the welding rod for 40 minutes at the temperature of 360-380 DEG C by using an E50157 alkaline welding rod with the diameter of 3.2 mm, and putting the welding rod intoa heat preservation barrel for heat preservation for later use after the welding rod is dried; and (3), welding: selecting a direct-current electric welding machine, adopting a direct-current positiveconnection method, that is, the welding rod is connected with a cathode and a weldment is connected with an anode, wherein the current range is kept about 95-105 A. According to the invention, the casting is welded by adopting a casting cold welding process, so that the problems that the working environment of a casting hot welding process is poor and the heating temperature is difficult to meetthe requirements of the hot welding process under many field conditions are solved, the welding time is shortened, and the welding material is saved.

Owner:常鑫

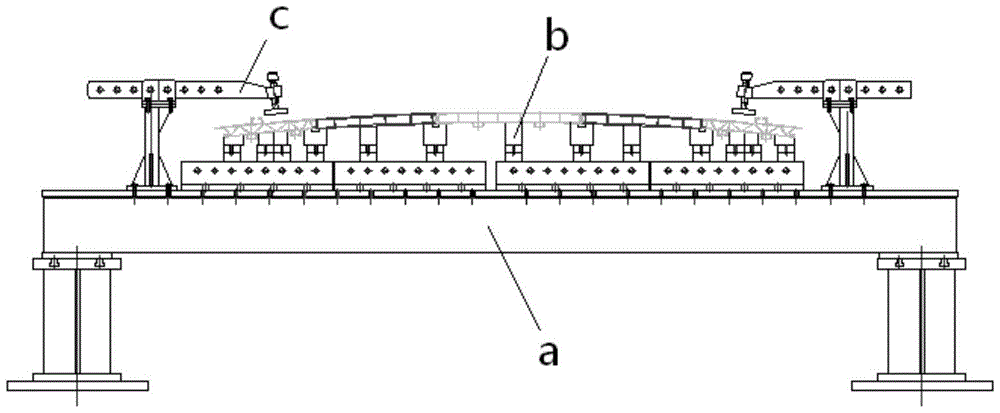

Welding Process of Aluminum Alloy Roof for Subway Cars

The invention discloses a welding technology of an aluminum alloy ceiling used for a subway compartment. The ceiling is formed by welding five subway roof plates and two subway roof edge beams, and the subway roof plates are hollow profiles, wherein the length of each subway roof plate ranges from 16 m to 20 m, the width of each subway roof plate ranges from 0.3 mm to 0.6 mm, and the wall thickness of each subway roof plate ranges from 2 mm to 3 mm. In the welding process, all the subway roof plates are firstly welded, and then the subway roof edge beams and a subway roof plate assembly are welded; the subway roof plates are welded through double-wire double-machine linkage welding, firstly, forward installation welding is performed, and then reverse installation welding is performed; the subway roof edge beams and the subway roof plate assembly are welded through single-wire double-machine linkage welding, wherein forward installation welding and reverse installation welding are also performed in sequence. The material of welded components, the steps and the technology are improved, the using requirements for the quality and size of product weld joints are completely met, the qualified rate of the product is substantially increased, and meanwhile welding working hours are reduced.

Owner:辽宁忠旺铝合金精深加工有限公司

Robot automatic welding method for forged hook tail frame

ActiveCN104148832BImprove mechanical propertiesReduce labor intensityWelding/cutting auxillary devicesArc welding apparatusControl engineeringWater circulation

Owner:南京力源轨道交通装备有限公司

Zinc-air battery pack capable of being assembled conveniently

ActiveCN103208667BFast replacementAvoid efficiency lossFuel and primary cellsCell component detailsZinc–air batteryMechanical engineering

The invention discloses a zinc-air battery pack capable of being assembled conveniently. Compared with the prior art, the zinc-air battery pack overcomes the defects that the battery replacement speed is low and the battery replacement is inconvenient. The zinc-air battery pack disclosed by the invention comprises an A-type battery (10), a B-type battery (11) and a current collector (3), wherein the A-type battery (10) is formed by putting an air pole (5) on the upper part of a battery jar (2) flatwise and spreading calamine cream (1) on the air pole through a diaphragm (4); the lower part of the current collector (3) is provided with a copper claw (8); the B-type battery (11) is formed by connecting the lower part of the A-type battery (10) with the current collector (3) by using a double-pole connector (9); the B-type battery (11) is installed on the calamine cream (1) of the A-type battery (10) through the copper claw (8); and the current collector (3) is installed on the calamine cream (1) of the B-type battery through the copper claw (8). According to the invention, the replacement speed of a zinc-air battery is increased, and the problem of reduction of battery efficiency caused when the welding is poor is solved.

Owner:AGA TECH CO LTD

Anti-abrasion tile expansion joint used for thermoelectric boiler

InactiveCN110230745AHigh strengthEasy processing and installationPipeline expansion-compensationPipe protection against damage/wearExpansion jointMachining

The invention discloses an anti-abrasion tile expansion joint used for a thermoelectric boiler. The anti-abrasion tile expansion joint is composed of a heat exchange pipe (1), a bend anti-abrasion tile (2) and a straight pipe anti-abrasion tile (3). The bend anti-abrasion tile (2) is fixed to the outer side of a bend part of the heat exchange pipe (1). The straight pipe anti-abrasion tile (3) is installed on the outer side of a straight pipe part of the heat exchange pipe (1). Part of the straight pipe anti-abrasion tile (3) stretches to the inner side of a straight shell part (2-2) of the bend anti-abrasion tile (2). By means of the anti-abrasion tile expansion joint used for the thermoelectric boiler, the bend anti-abrasion tile obtained after three times of molding is adopted, the strength is high, machining and installation are convenient, abrasion resistance is good, compared with a traditional lap joint head welding manner, welding work hours are reduced, and the service life isprolonged by 30% or higher.

Owner:江苏汇能锅炉有限公司

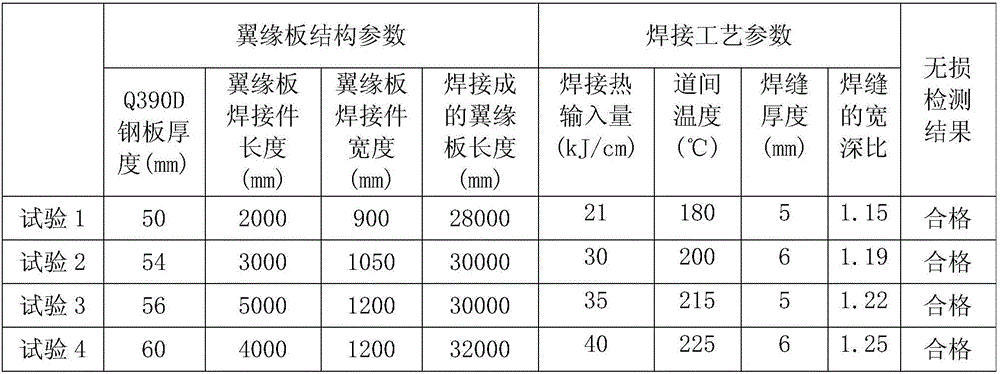

Welding method of flange plate of q390d steel crane girder in heavy work system

ActiveCN104759768BImprove impact toughnessReduce cold cracksArc welding apparatusMetal working apparatusSheet steelEngineering

The invention discloses a flange plate welding method for a heavy derrick Q390D steel crane beam. A Q390D steel plate with the thickness of 50-60 mm is cut to be flange plate welding parts for H-shaped steel, and then the flange plate welding parts are welded in a butting and full penetration mode to form a flange plate. The method comprises the five steps of manufacturing flange plate welding parts, forming grooves in a welding connector, dehumidifying the flange plate welding parts, welding the flange plate welding parts in the butting and full penetration mode to form the flange plate, and performing heat preservation and slow cooling on a welding joint. According to the flange plate welding method, no preheating working procedure performed before welding or heat preservation working procedure performed after welding is provided, the automatic submerged arc welding multi-layer and multi-pass welding technology is adopted, the welding automation degree is high, few cold cracks exist in a welding joint structure, the welding quality is high, the labor intensity of welding work is low, the welding cost is low, and welding time is greatly shortened, so that the welding technology meets the requirement for the heavy level better on the whole, particularly the heavy derrick crane beam flange plate welding requirement.

Owner:CHINA 19TH METALLURGICAL CORP

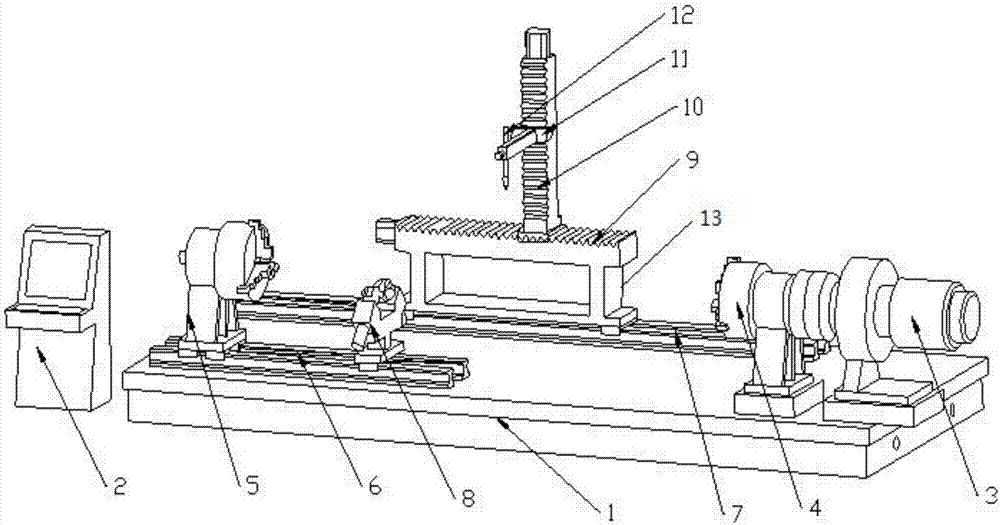

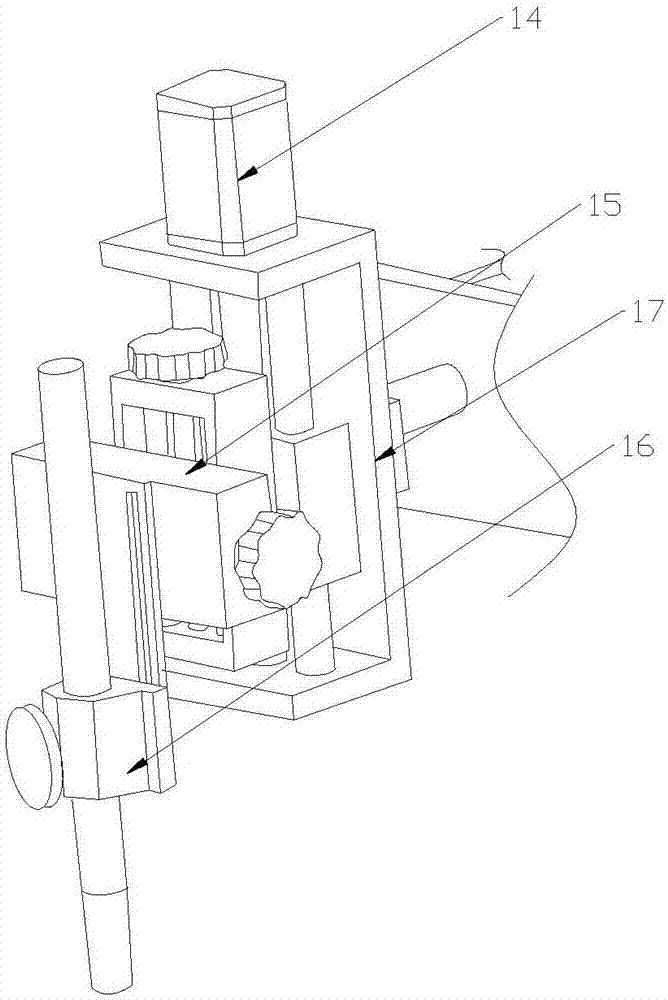

A special machine for wear-resistant surfacing welding of circular seams

ActiveCN105014193BReduce labor intensityHigh degree of automationWelding accessoriesWear resistantSlag

The invention discloses a special circular seam hardfacing machine. The special circular seam hardfacing machine comprises a platform, a control cabinet, a main shaft motor, a three-jaw head frame, a three-jaw tail frame, a first linear guide rail, a second linear guide rail and a welding device. The main shaft motor is installed in front of the right side of the platform. The three-jaw head frame is installed on the part, on the left side of the main shaft motor, of the platform. The first linear guide rail is installed on the part, on the left side of the three-jaw head frame, of the platform. The second linear guide rail is installed on the part, behind the first linear guide rail, of the platform. The welding device comprises a left-right moving beam, an up-down moving stand column, adjusting components and a welding gun. The welding gun is installed on the up-down moving stand column through the adjusting components. The adjusting components include a welding gun lifting motor, a welding gun cross-shaped fine adjusting mechanism, a welding gun clamping mechanism and a support. According to the special circular seam hardfacing machine, the welding speed can be increased by at least two times, the welding time is shortened, the productivity is increased, and the technical stability is improved; the welding quality is stable, and no defects such as welding gas holes and welding slag exist; a machine tool is of a building block combined type structure, the automation degree is high, and universality is high.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

A cob module and its manufacturing method

The application discloses a COB module and a manufacturing method thereof. The manufacturing method includes: dispensing glue on the bottom shell; assembling a plurality of COB lamp panels with the glued bottom shell; The COB lamp panel and the bottom shell that has been glued are arranged in a closed space; the closed space is vacuumized to press the bottom shell and a plurality of the COB lamp panels into shape. In this application, glue is used to connect the COB lamp board and the bottom shell, which can ensure the flatness of the light-emitting surface of the COB lamp board and the flatness between the COB modules, and avoid the inclination angle of the COB module, thereby avoiding Bright and dark lines improve the uniformity of the display. On the other hand, the screw fixing method is canceled, and there is no need to weld copper pillars on the COB light board, which reduces welding hours and improves production efficiency.

Owner:深德彩智能科技(东莞)有限公司

Welding Process of Aluminum Alloy Roof Beam for Subway

ActiveCN106271145BSimple processImprove work efficiencyWelding apparatusStructural engineeringMachine

The invention discloses a welding process of an aluminum alloy vehicle roof edge beam for a metro and belongs to the technical field of aluminum alloy welding. The vehicle roof edge beam is formed by welding two edge beam profiles. Welding is conducted in two phases. Firstly, manual tack welding is conducted; and then, automatic welding is conducted through a robot, wherein the manual tack welding process comprises the steps of front assembling and pairing, front side tack welding and reverse side tack welding; and the process of automatic welding conducted through the robot comprises the steps of front assembling and welding, reverse assembling and fixation and reverse assembling and welding. According to the welding process of the aluminum alloy vehicle roof edge beam for the metro, the steps and process of a welding machine are improved; welding quality and dimensional requirements of an obtained product completely meet the use requirements; the product percentage of pass is remarkably increased; and meanwhile the labor-hour of the welding machine is reduced.

Owner:辽宁忠旺铝合金精深加工有限公司

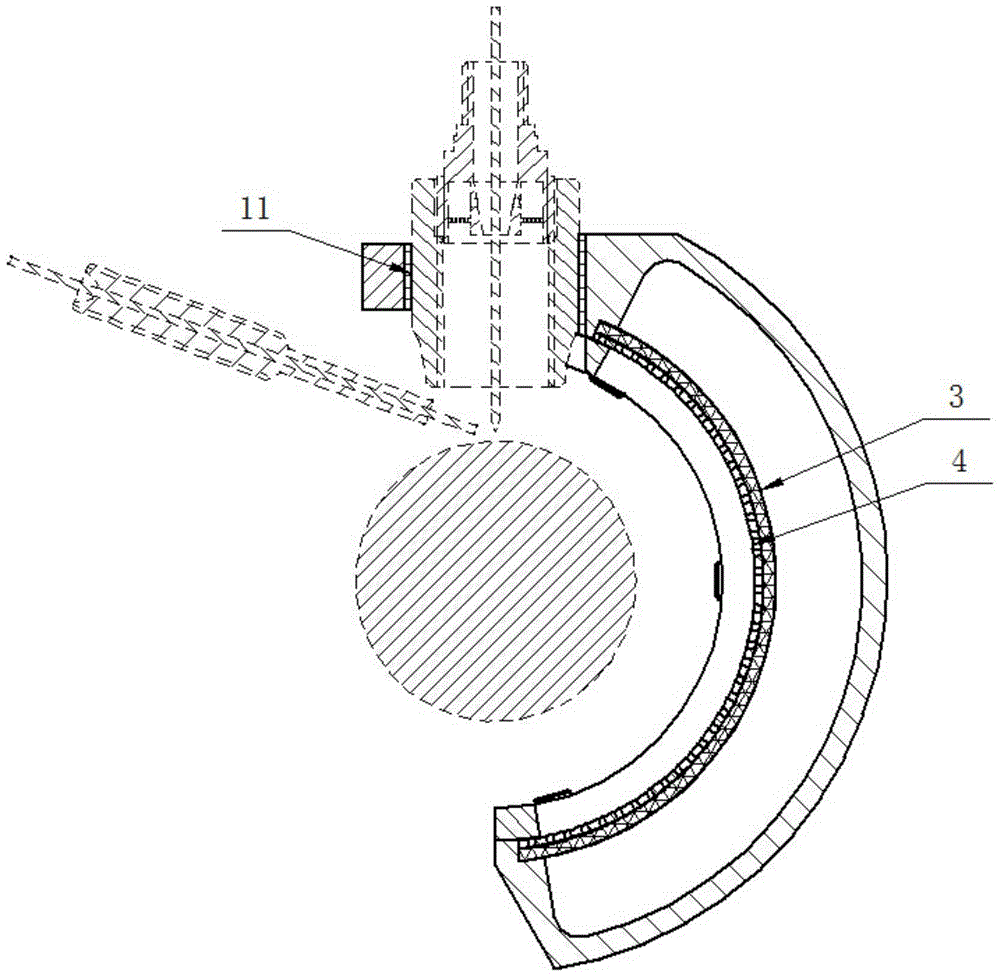

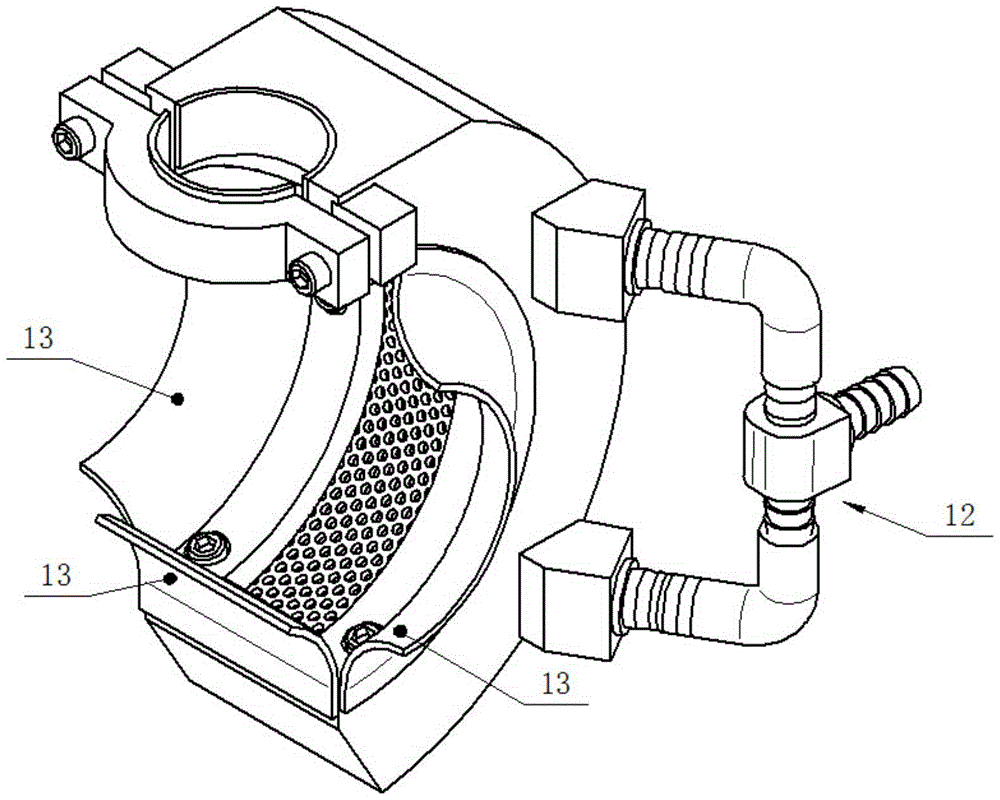

Arc-shaped semi-closed gas protective hood for pipeline welding and welding method

ActiveCN104551353BReasonable designSimple structureMetal working apparatusTubular articlesHeat-affected zoneEngineering

The invention relates to an arc semi-closed gas protection cover for welding a pipeline and a welding method. The arc semi-closed gas protection cover comprises an arc shell, an arc pressing ring, a stainless steel silk screen layer, an arc baffle plate, a fixed lug, a buffer layer and an air inlet assembly, wherein the arc baffle plate and the stainless steel silk screen layer are arranged in a clamping groove of the arc shell; the arc pressing ring is arranged on the inner surface of the arc shell; one end of the arc shell is fixedly connected with a welding gun through the fixed lug, and the buffer layer is arranged between the arc shell and the welding gun and used as a transitional layer; the air inlet assembly is arranged on the radial side wall of the arc shell. The arc semi-closed gas protection cover is reasonable in design, simple in structure and easy to operate; a connector seam and a hot influence area can be ensured to stay at a protective state, so that a weld seam with silver-white surface, excellent quality and mechanic property meeting the requirement can be obtained.

Owner:BEIJING XINGTONG SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com