Welding process of union melt welding small divided edge

A submerged arc automatic welding and groove welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the cutting surface accuracy is difficult to meet the requirements, affecting the quality and progress of steel components, and the welding deformation of thick plate H steel is large and other problems to achieve the effect of saving welding materials, reducing welding man-hours, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The submerged arc automatic welding small groove welding process of the present invention is carried out according to the following steps:

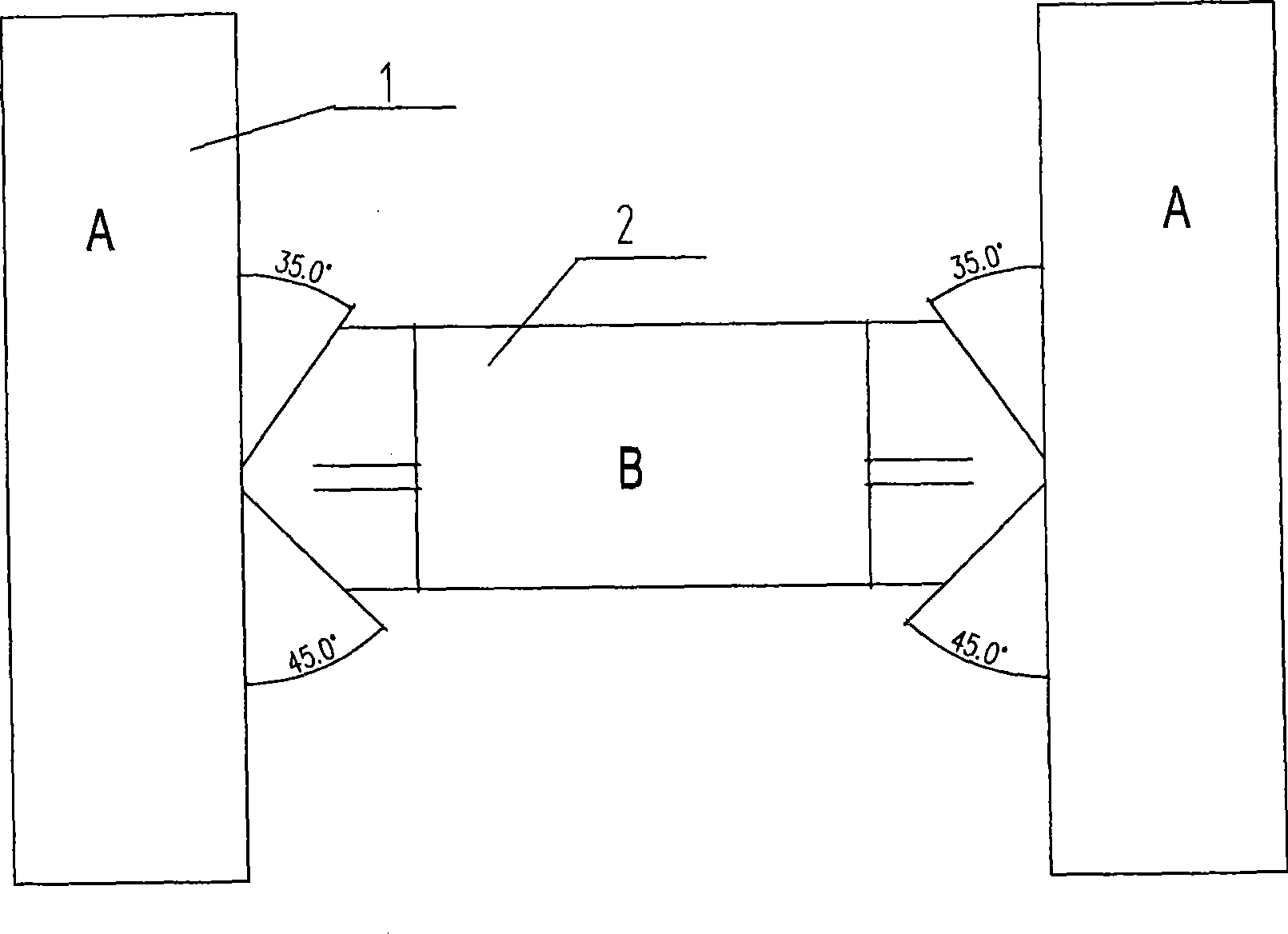

[0018] 1. Make a bevel on the weldment (B) 2. The bevel angle is 35 degrees on one side and 45 degrees on the other side. The 35-degree bevel accounts for 2 / 3-2mm of the plate thickness, and the 45-degree bevel accounts for the plate thickness. 1 / 3-2mm of the plate thickness, leave 2mm blunt edge between 1 / 3 and 2 / 3 of the plate thickness for beveling. The beveling is cut by semi-automatic precision cutting machine or mechanical processing. See the groove diagram figure 1 .

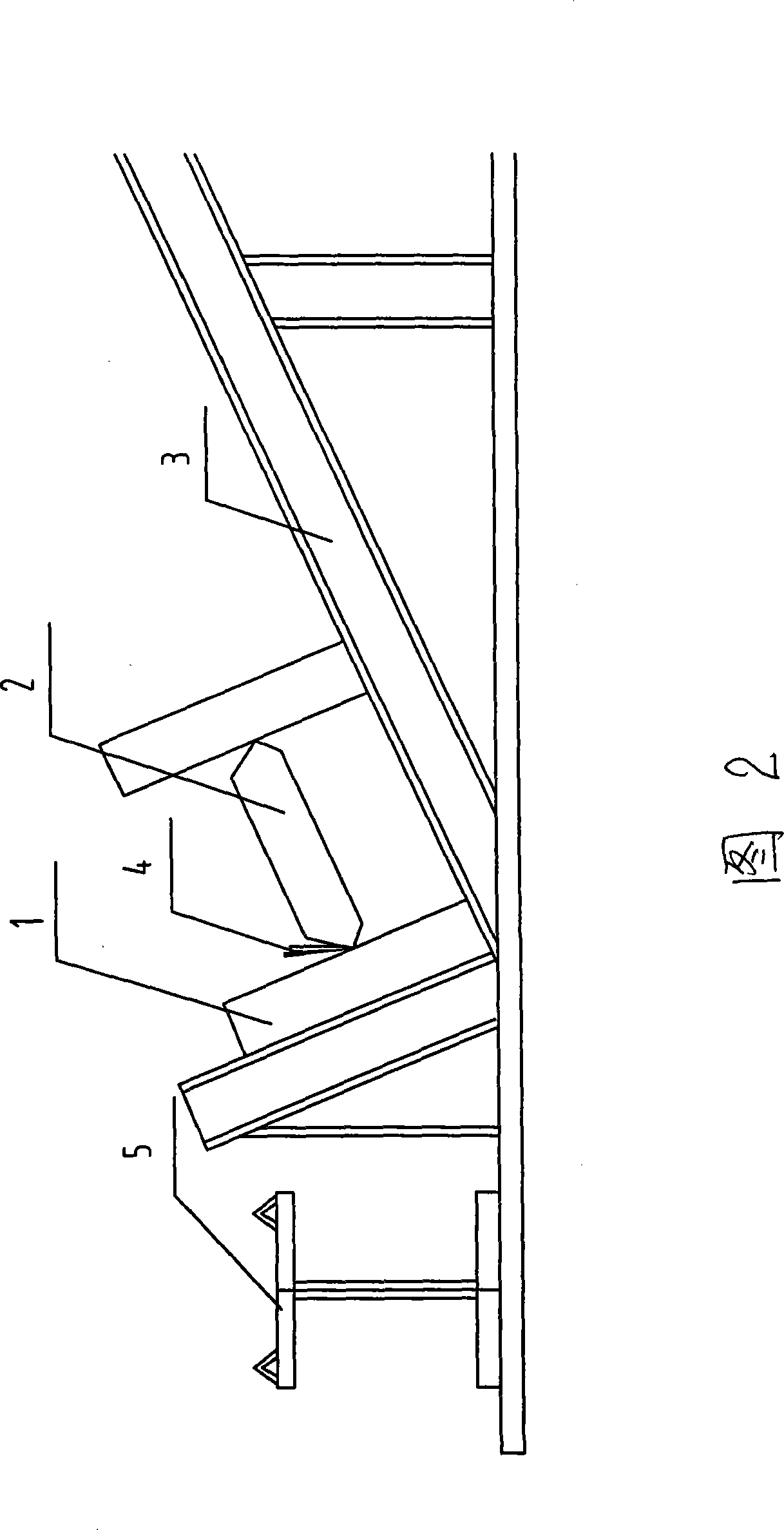

[0019] 2. Do a good job of preheating before butt welding, and use the welding mold 3 shown in Figure 2 according to the requirements of the groove angle.

[0020] 3. Carry out H-group pairing of weldment (A) 1 and weldment (B) 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com