Method of welding the plug in type connection nozzle and the un-orthogonal crossed connection nozzle of the cylinder

A welding method and plug-in technology, applied in welding equipment, arc welding equipment, edge parts of workpieces, etc., can solve the problems of difficult to guarantee welding quality, difficult groove processing, low utilization rate of welding electrodes, etc., to save welding materials, improve Welding efficiency and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

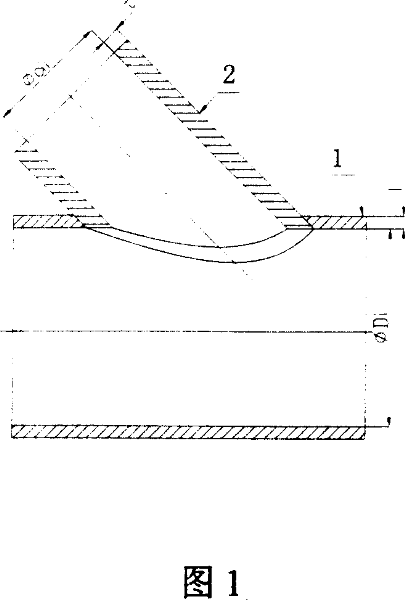

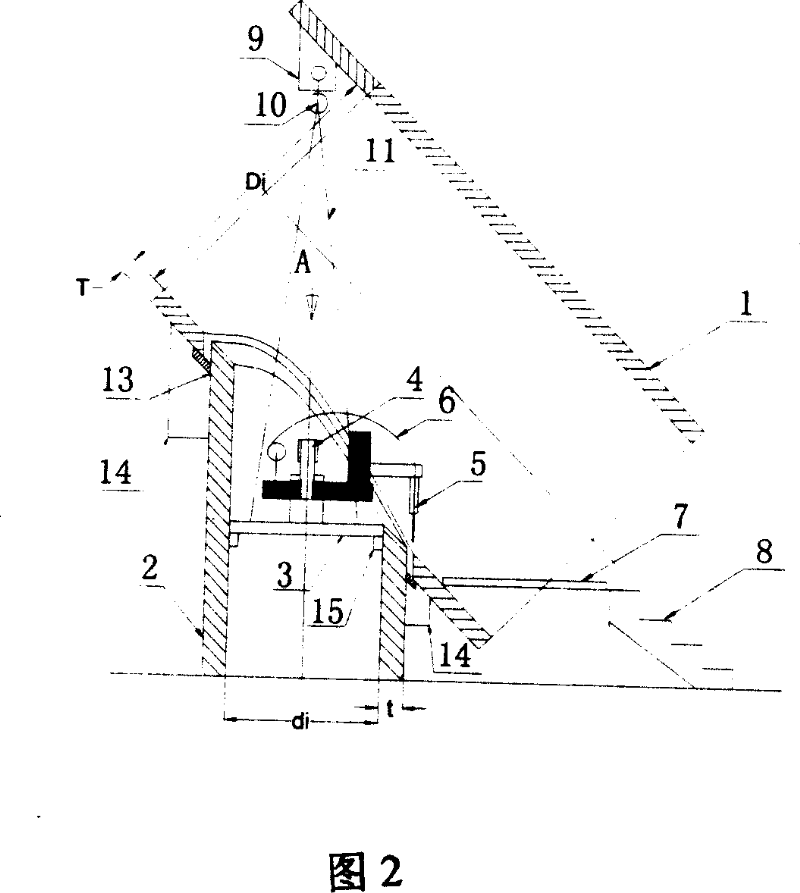

[0028] Plug-in nozzle 2 size: inner diameter 1800mm, wall thickness 280mm; barrel 1 size: inner diameter 3400mm, wall thickness 210mm; welding method:

[0029] As shown in Figure 2, it is a schematic diagram of welding the lower part of the weld. First, use a crane to insert the connecting pipe 2 into the perforated cylinder 1 and assemble it properly as required. 12 anti-deformation rigid fixed ribs 14 are uniformly arranged on the outside of the body 1 and the connecting pipe 2 and welded properly;

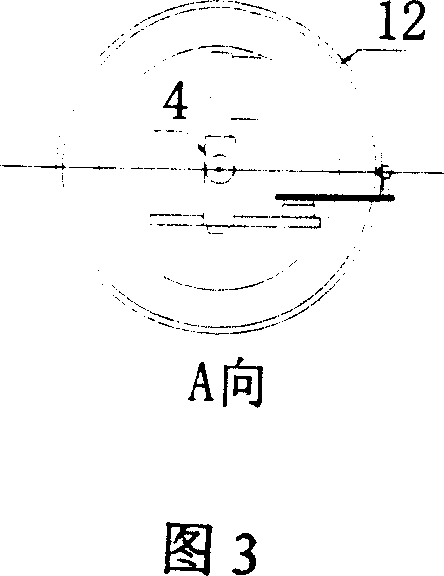

[0030] Then use a crane to place the assembled non-right-angled intersecting plug-in nozzle and the cylinder workpiece according to the orientation shown in Figure 2, that is, the nozzle 2 is vertically placed on the ground at the bottom, and the cylinder 1 is placed obliquely at the top. After the workpiece is placed and fixed, place it on the cylinder. The working platform 7 and temporary stairs 8 are installed at the lower port of the body 1, the fixed platform 3 of the hoist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com