Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Refine matrix tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

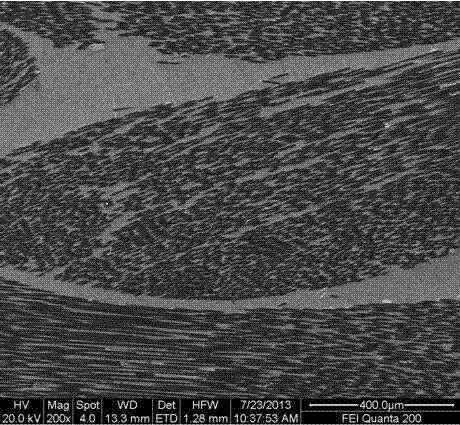

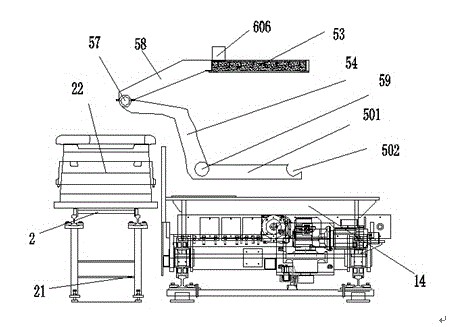

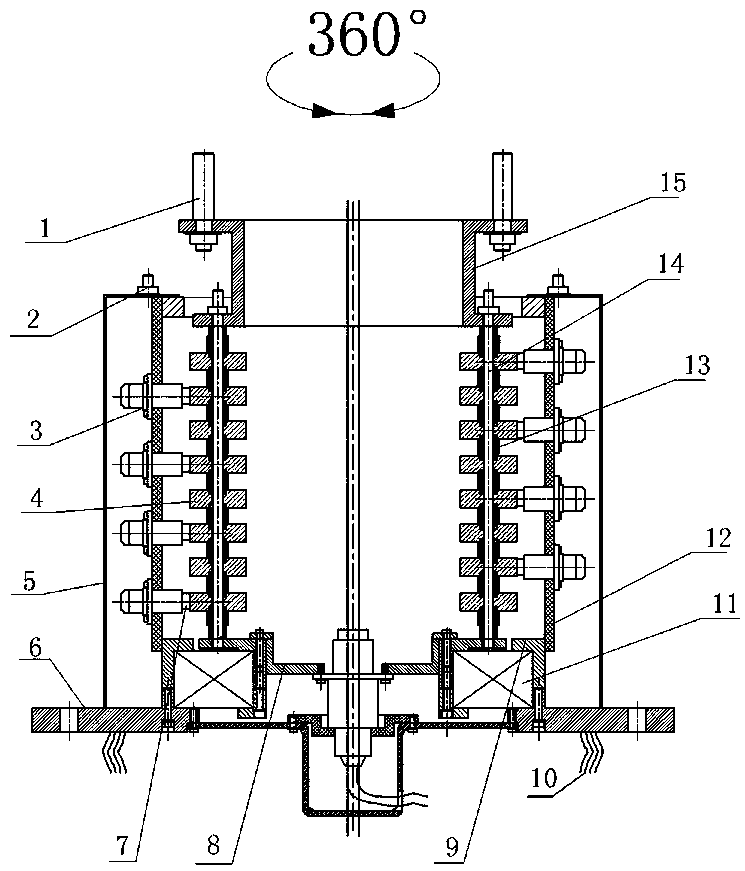

Liquid-state near-net forming method and device for continuous carbon fiber enhanced aluminum-based composite material

InactiveCN103540873ARealize hypoxic temperature control preheatingAchieve cooling rate controlFiberCarbon fibers

The invention discloses a liquid-state near-net forming method and device for a continuous carbon fiber enhanced aluminum-based composite material, namely a vacuum-assisted pressure-adjusting and infiltration casting method and device. The method comprises four procedures of smelting an alloy and pre-heating fibers, carrying out vacuum-assisted pressure-adjusting and infiltration, condensing at a high pressure and cooling rapidly. The device is composed of an alloy smelting device, a vacuum-assisted pressure-adjusting and infiltration device and a casting rapid cooling device. The liquid-state near-net forming method and device have the characteristics that (1) low-oxygen and temperature-controllable pre-heating of nickel-plated carbon fibers is realized; (2) low-pressure infiltration and high-pressure condensation of the aluminum-based composite material are realized; (3) the control of a cooling speed in the condensation of a composite material casting is realized. According to the liquid-state near-net forming method and device for the continuous carbon fiber enhanced aluminum-based composite material, oxidization and burning loss caused by pre-heating the carbon fibers, prefabricated body deformation in the infiltration process and interface reaction problems in the condensation process of the composite material are solved. The liquid-state near-net forming of the continuous carbon fiber enhanced aluminum-based composite material can be realized and the prepared composite material has the advantages of dense tissues, few interface reactions, high mechanical properties and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

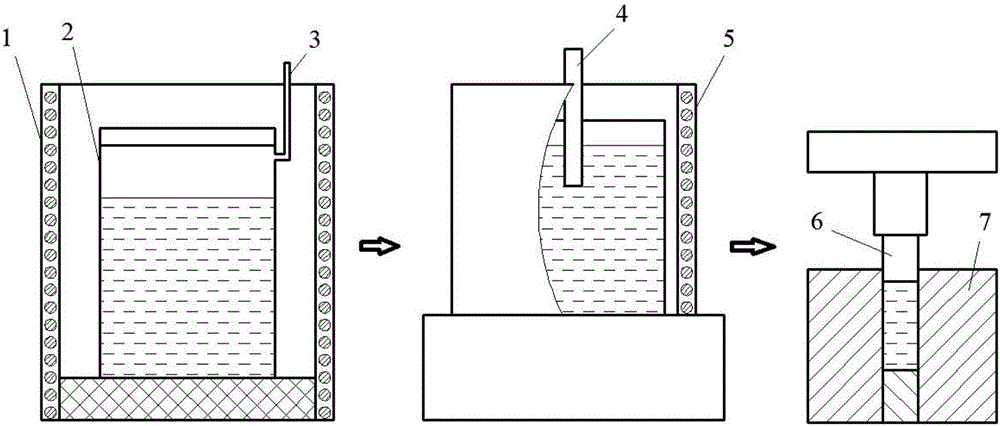

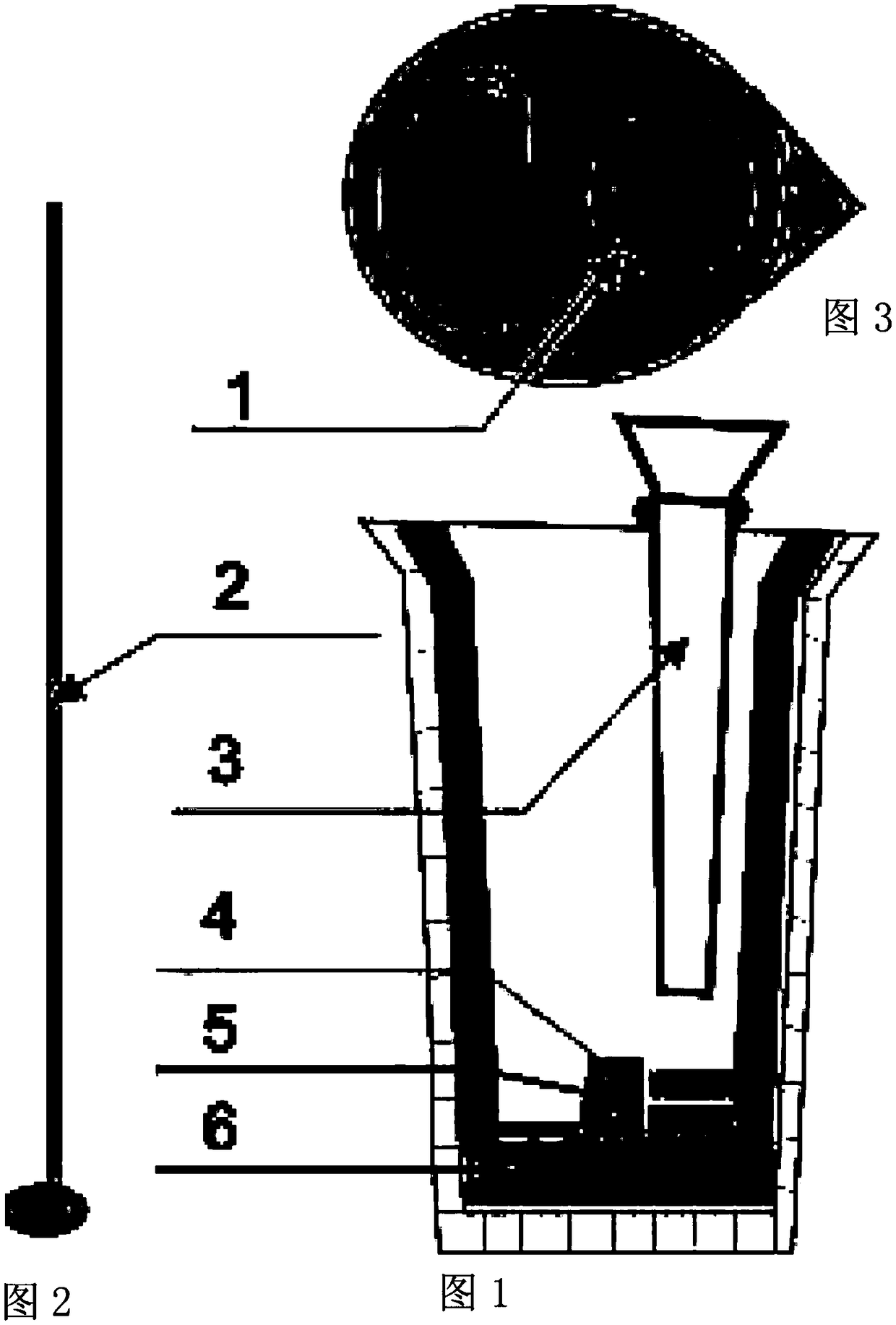

Method for adjusting and regulating long-periodic structure phase of magnesium alloy

ActiveCN106392044AImprove performanceFully exert the strengthening effectUltrasonic vibrationMagnesium alloy

The invention discloses a method for adjusting and regulating a long-periodic structure phase of magnesium alloy. The method comprises the steps of: firstly preparing Mg-Ni (or Zn)-Y alloy containing LPSO, and then adjusting and regulating form and distribution of a long-periodic structure by applying ultrasonic vibration and pressure in sequence in an alloy solidification process. The alloy preparing and processing comprises the following steps: melting the alloy under protection of mixed gas of N2 and SF6, after temperature reaches 720-730 DEG C, placing a melt in a container in a holding furnace, cooling to a temperature more than a liquidus temperature of the alloy by more than 10-50 DEG C, then performing ultrasonic vibration processing on the melt, lasting for 1-5min, after the vibration is finished, pouring into a preheated die of 200-300 DEG C for extruding to solidify under pressure, wherein an extruding pressure is 50-500 MPa, and pressure holding time is 1-3min. The LPSO phase in the alloy prepared by such method is obviously refined and uniformly distributed, and performances of the alloy are greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Abrasion-resistant lining plate for cone crusher

InactiveCN105316567AImprove toughnessImprove hardness and wear resistanceAlloy elementPrecious metal

The invention discloses an abrasion-resistant lining plate for a cone crusher and relates to the technical field of crusher lining plates. Alloy elements in the lining plate include 2.30-2.80% of C, 22.0-24.0% of Cr, 1.32-1.85% of Si, 0.15-0.23% of Mn, 0.17-0.32% of B, 0.25-0.40% of V, 0.15-0.28% of N, 0.15-0.26% of W, 0.54-0.82% of Cu, 0.02-0.06% of Ce, 0.15-0.22% of Al, 0.07-0.12% of Co, 0.22-0.35% of Ti and the balance Fe and unavoidable impurities. The ratio of the optimized elements is more reasonable and all the elements achieve the synergistic effect, so that the lining plate is high in hardness, good in tenacity and resistant to impact and abrasion; the service life of the lining plate is two to three times longer than that of a common steel abrasion-resistant material; the lining plate meets the work demands of medium and large cone crushers; besides, the raw material sources are rich, precious metal such as Mo and Ni are not contained, and the production cost is low.

Owner:ANHUI SANFANG NEW MATERIAL TECH CO LTD

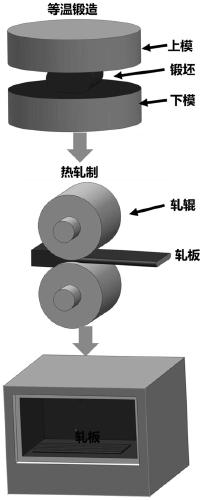

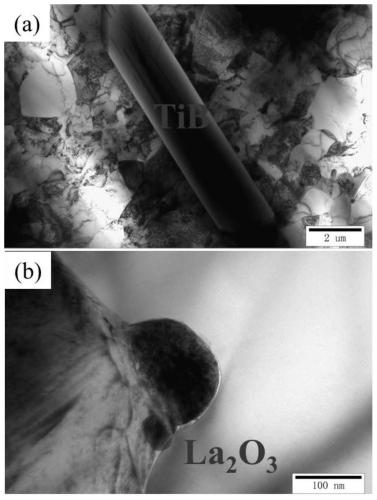

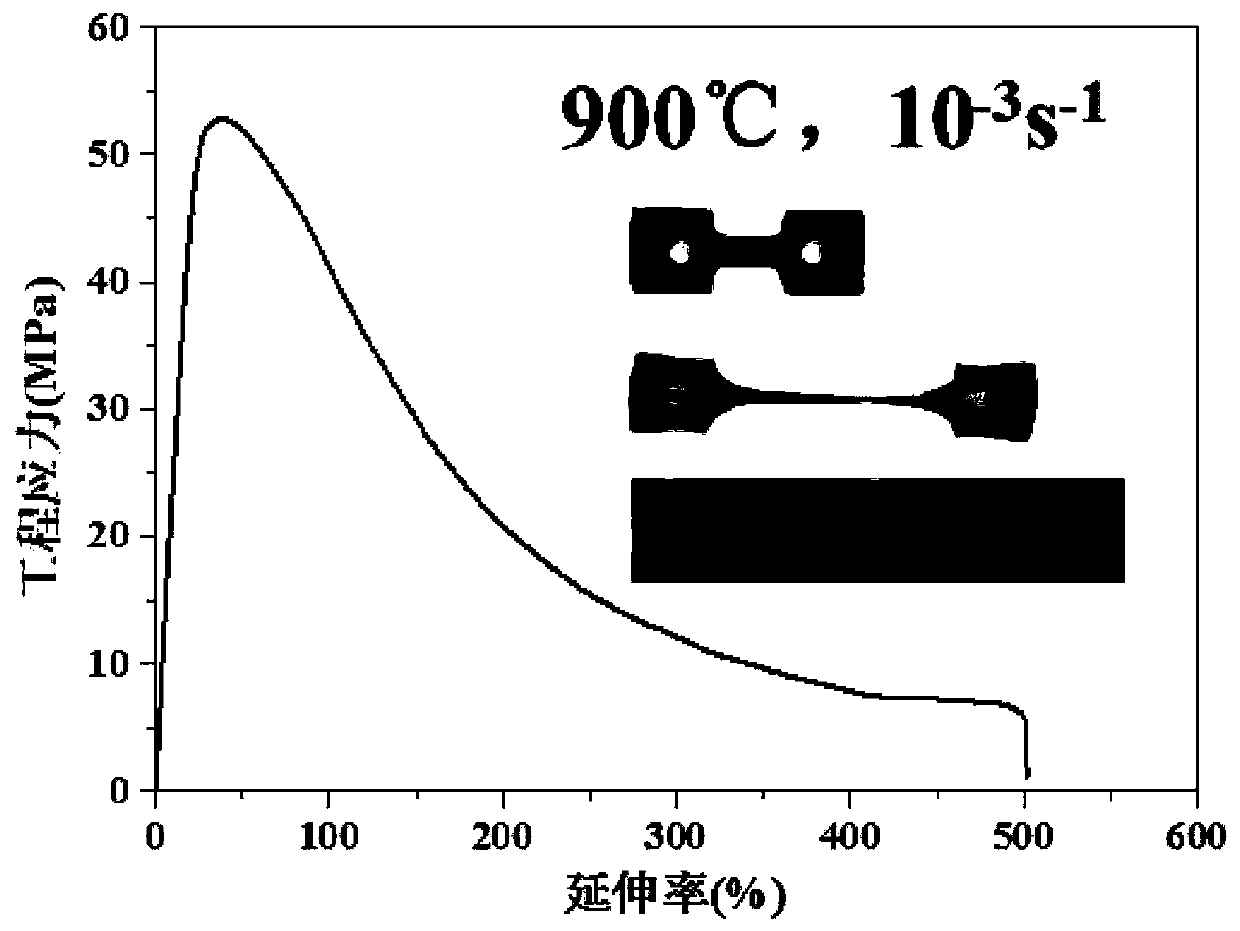

Isothermal superplastic deformation method for micro/nano particulate reinforced titanium matrix composite

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

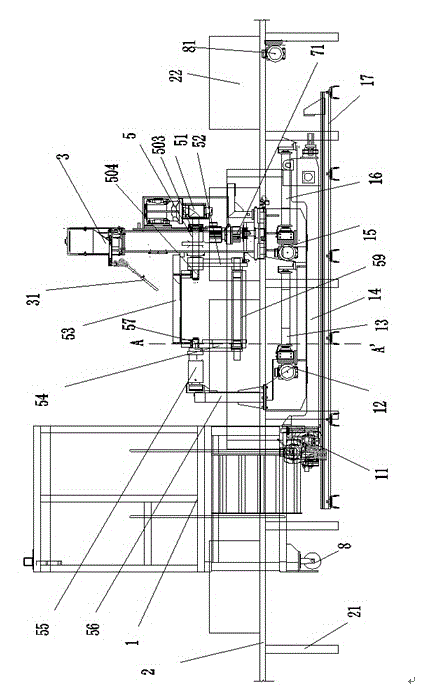

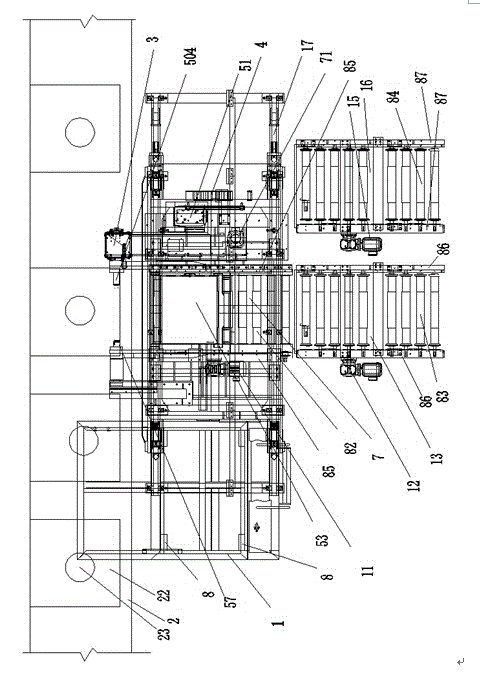

High-precision full-automatic casting machine

ActiveCN104439222AGuaranteed continuityImprove pouring qualityMolten metal supplying equipmentsMetallurgyThermal insulation

The invention discloses a high-precision full-automatic casting machine. The high-precision full-automatic casting machine comprises a casting ladle system, a casting ladle transverse moving and longitudinal moving system, a servo tilt-rotating mechanism, a detection unit and a control unit. The casting ladle system comprises a casting ladle made of thermal insulation materials and a casting ladle moving device. The casting ladle transverse moving and longitudinal moving system comprises a track system and a casting vehicle. The detection unit comprises a load sensor. The load sensor is used for detecting the weight of molten metal in the casting ladle of the casting machine and generating a signal representing the detected weight. The control unit is provided with a first arithmetic unit, a second arithmetic unit and a driving indication unit. The casting machine can effectively shorten the casting time and improve the casting stability.

Owner:山东时风(集团)有限责任公司

Preparation method of high-accuracy magnesium alloy plate

The invention discloses a preparation method of a high-accuracy magnesium alloy plate. The preparation method of the high-accuracy magnesium alloy plate comprises the steps of composition of raw materials, processing of the raw materials, smelting, cooling, machining in a pressurization mode and the like. The magnesium alloy plate prepared through the preparation method is good in corrosion resistance, largely improves physicochemical parameters such as breaking strength and ductility, has good market application value, and can be applied to the fields of automobile gearboxes and engine cases.

Owner:山东银光钰源轻金属精密成型有限公司

Casting process for crankshaft

InactiveCN105081229AOvercome the problems of many processes and heavy workloadIncrease profitFoundry mouldsFoundry coresManganeseMolten steel

The invention relates to a casting process for a crankshaft. The casting process comprises the following steps: step S01: producing a sand mould according to the design dimension requirements of the crankshaft, horizontally arranging the axis line of the sand mould, forming a direct gate and an inner gate in the sand mould, connecting the direct gate with the inner gate through a transversal channel, roasting the sand mould for 20 minutes at a high temperature of 750-900 DEG C, and then cooling to 400 DEG C; step S02: smelting a steel material in a circuit, after a temperature rises to 1400-1500 DEG C, adding a refining agent and refining for 20min to obtain molten steel in which a carbon content is 0.1-0.14%, a silicon content is 0.15-0.19%, a nickel content is 0.36-0.45% and a manganese content is 0.46-0.55%; step S03: pouring the molten steel in the step S02 into the direct gate and the inner gate of the sand mould in the step S01, controlling a pouring temperature to be 1560-1660 DEG C and controlling a pouring time to be 40s, and after the pouring is finished, insulating for 30min; and step S04: cooling to normal temperature, talking out the formed crankshaft, cleaning the surface of the crankshaft, and then polishing to obtain the crankshaft.

Owner:GUILIN CHANGXIN MACHINERY MFG

Smelting method of high-toughness and high-strength casting-state ductile cast iron

The invention relates to a smelting method of high-toughness and high-strength casting-state ductile cast iron. The smelting method comprises the steps of 1, material selection, in which pig iron, scrap steel and a melting-back material are selected as raw materials; 2, material preparation, in which 20-40% of pig iron, 30-40% of scrap steel and 20-50% of melting-back material are selected according to percent by mass; 3, smelting, in which the raw materials prepared in the step 2 are added into a medium-frequency smelting furnace, the temperature is raised, the raw materials are molten, a carburant is added to the bottom of the furnace during smelting, and the raw materials are molten to a required furnace outlet temperature; 4, nodulization and casting, in which a nodulization pack and acasting pack are pre-heated to 600-800 DEG C before nodulization, a nodulizing agent, an inoculation agent and a coverage agent are sequentially placed in the nodulization pack placement pit, and inoculation for three times is performed; and 5, box outlet. The smelting method is simple to operate; and by adding the scrap steel and the melting-back material in a large proportion, the production cost is low, and the mechanical property is improved by a reasonable proportion.

Owner:SHANXI HUAXIANG GRP CO LTD

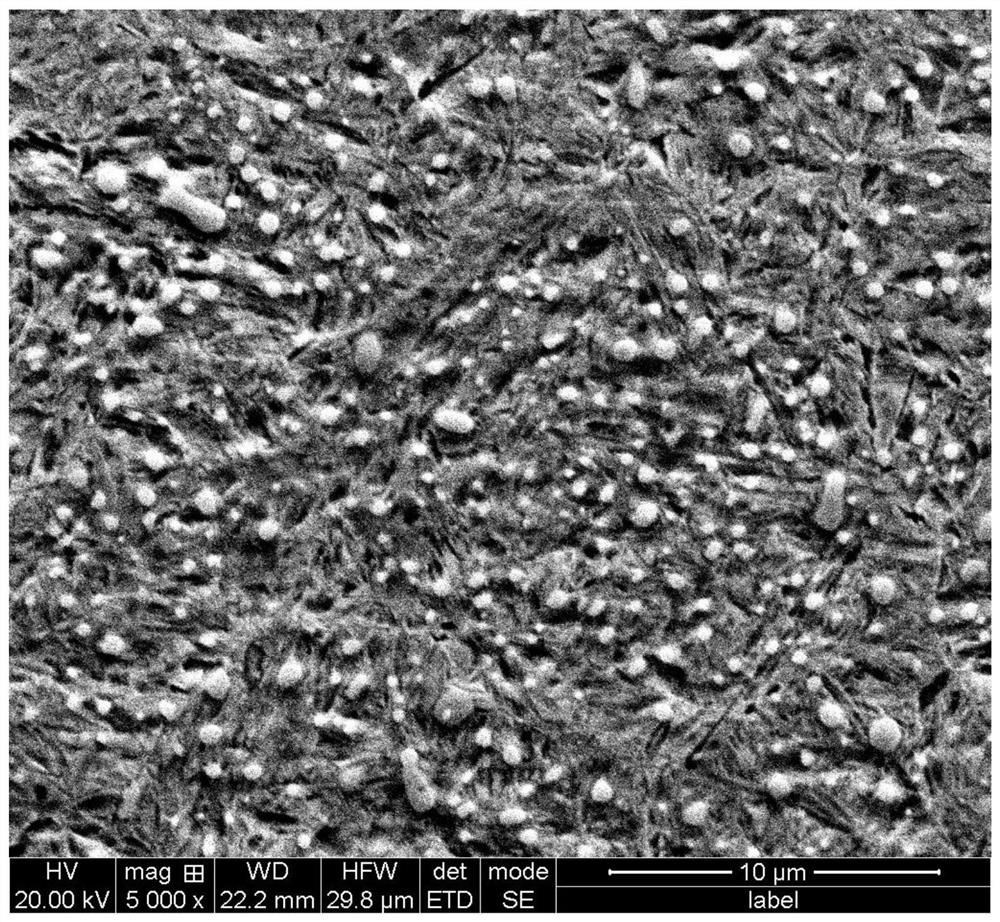

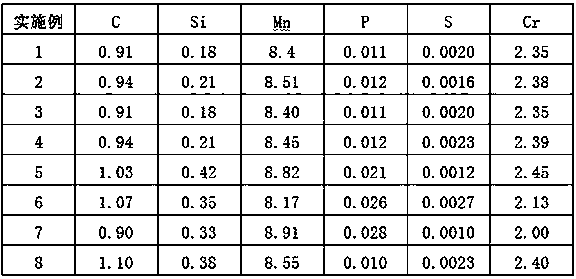

High-carbon bearing steel and preparation method thereof

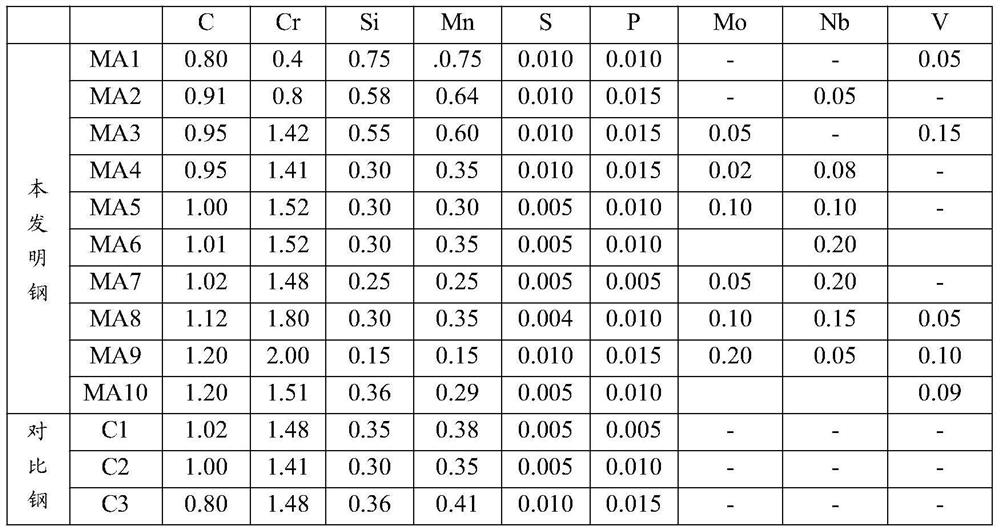

PendingCN111763889ARefine matrix tissueImprove mechanical propertiesShaftsBearing componentsCarbideNanostructured carbon

The invention relates to the technical field of structure refinement and homogenization of bearing steel, in particular to high-carbon bearing steel and a preparation method thereof. The high-carbon bearing steel comprises the following chemical components: 0.80-1.20 wt% of C, 0.40-2.0 wt% of Cr, 0.15-0.75 wt% of Mn, 0.15-0.75 wt% of Si, 0-0.20 wt% of Nb, 0-0.20 wt% of Mo, 0-0.20 wt% of V, less than or equal to 0.015 wt% of P, less than or equal to 0.01 wt% of S and the balance of Fe and inevitable impurities, wherein the contents of Nb, Mo and V are not 0 at the same time. The microalloying elements Nb, Mo and V are added into the high-carbon bearing steel and are matched with other element components, so that the matrix structure of the bearing steel can be effectively refined, a large amount of nano carbide is promoted to be separated out, and the contact fatigue life of the high-carbon bearing steel is further prolonged.

Owner:CENT IRON & STEEL RES INST

High-precision magnesium alloy sheet and preparation method thereof

The invention discloses a high-precision magnesium alloy sheet which is prepared from the following raw materials: 0.2% of yttrium, 0.06% of titanium, 0.05% of cerium, 0.05% of lanthanum, 0.02% of samarium, 0.5% of zinc, 2% of manganese and the balance of magnesium. The invention also discloses a preparation method of the magnesium alloy sheet. The magnesium alloy sheet disclosed by the invention has the advantages of favorable corrosion resistance and greatly higher physicochemical parameters (fracture strength, elongation percentage and the like), has high market application value, and can be used in the fields of automobile transmission cases, motor casings and the like.

Owner:山东银光钰源轻金属精密成型有限公司

Automobile engine cylinder cover and manufacturing method thereof

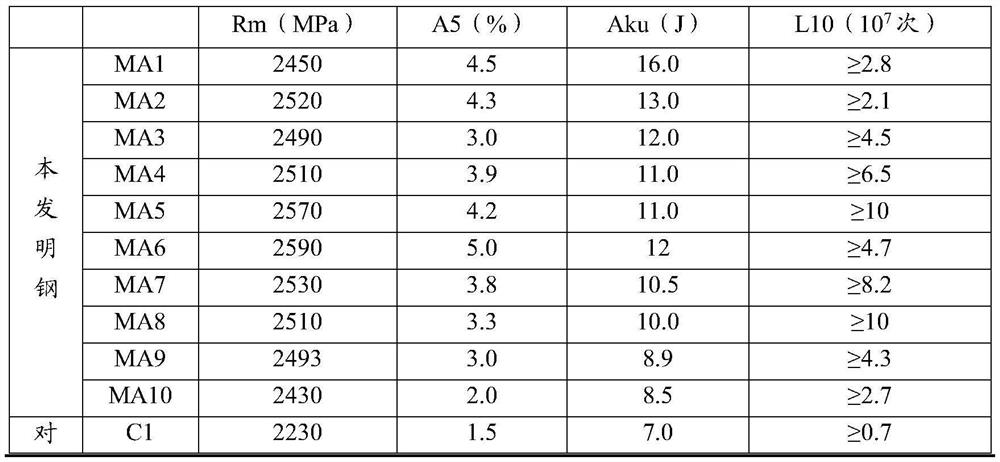

ActiveCN103949578AAdjust cooling speedPrevent shrinkageFoundry mouldsMould handling/dressing devicesCrazingMetallurgy

The invention discloses an automobile engine cylinder cover and a manufacturing method thereof. The automobile engine cylinder cover is a product prepared by the following raw materials and the manufacturing method, and comprises the raw material composition by weight: 90% of gray iron cuttings, 10% of casting roughing sand, 5% of a furan resin, and 1.0% of a curing agent. The method has the beneficial effects of effectively preventing generation of defects of casting shrinkage cavities, shrinkage porosity, deformation and cracks.

Owner:FANCHANG COUNTY JINKE CASTING

Production process of QT500-12 spheroidal graphite iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

Compound high speed steel roll and its making process

InactiveCN100369681CImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

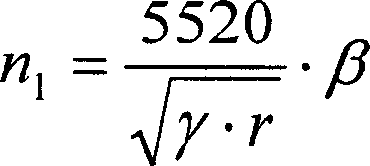

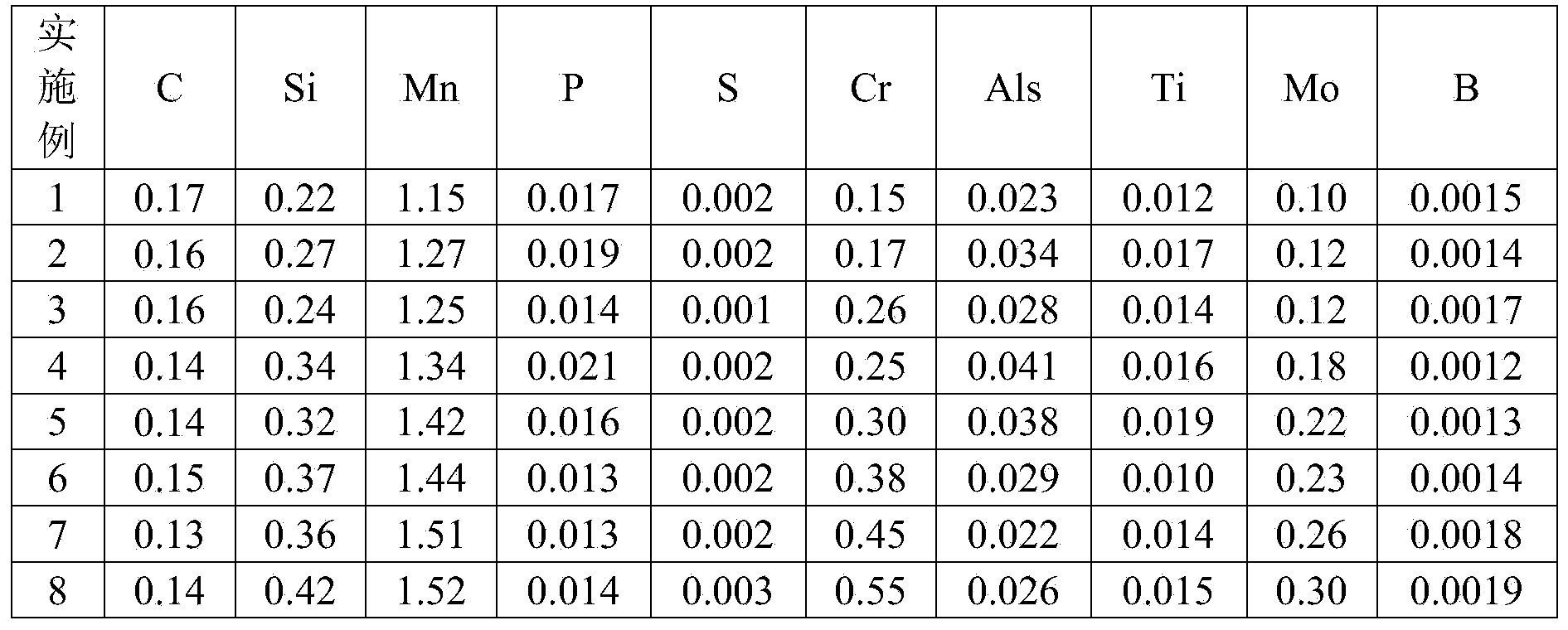

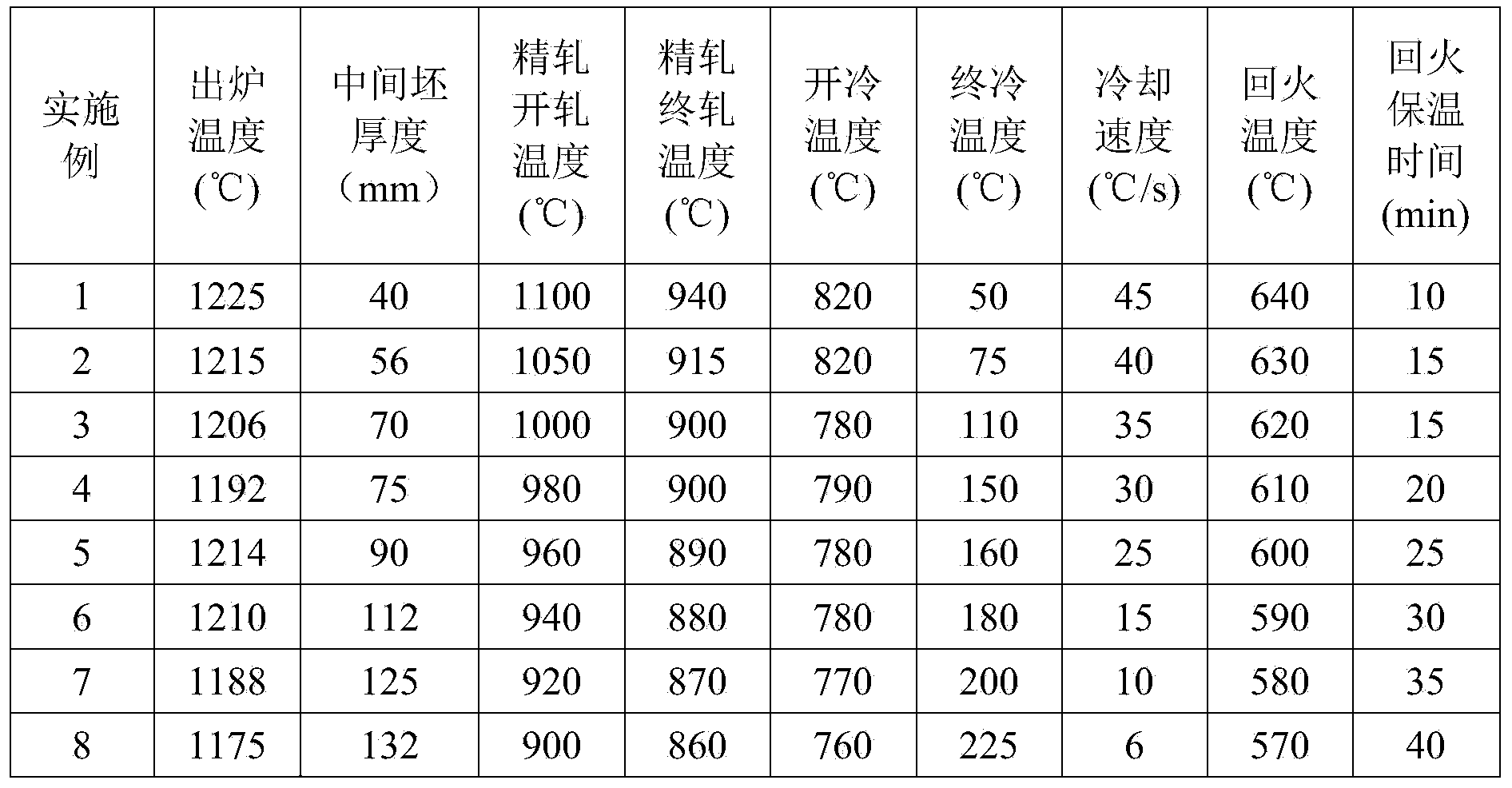

Steel plate with thickness of smaller than 60mm and yield strength of 690MPa and preparation method of steel plate

InactiveCN104278206AEasy to produceReduce manufacturing costUltimate tensile strengthMechanical property

The invention belongs to the field of steel and iron and particularly relates to a steel plate with the thickness of smaller than 60mm and the yield strength of 690MPa. The steel plate contains the following chemical components in percentage by weight: 0.10-0.20% of C, 0.15-0.50% of Si, 1.00-1.60% of Mn, 0.10-0.60% of Cr, 0.015-0.050% of Als, 0.008-0.025% of Ti, 0.10-0.30% of Mo, 0.0008-0.0030% of B, less than or equal to 0.025% of P, less than or equal to 0.008% of S, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 2ppm of H and the balance of Fe and unavoidable impurities. The steel plate provided by the invention has favorable mechanical properties, plasticity and toughness, has the yield strength of larger than or equal to 690MPa, and can be applied to manufacture of large engineering machines or steel structures such as hydraulic supports for coal mines, heavy engineering machines, ocean platforms and the like.

Owner:SHANDONG IRON & STEEL CO LTD

Al-Mn pipe alloy of household air conditioner heat exchanger and preparation method of Al-Mn pipe alloy

The invention belongs to the technical field of metal materials and metallurgy, and discloses an Al-Mn pipe alloy of a household air conditioner heat exchanger and a preparation method of the Al-Mn pipe alloy. The Al-Mn pipe alloy comprises, by weight: Mn: 0.5-1.0%, Mg: 0.1-0.5%, Zn: 0.1-0.4%, Fe: 0.1-0.4%, Si: 0.05-0.4%, Cu: 0.01-0.15%, Ti: 0.02-0.3%, Cr: 0.05-0.4%, Zr: 0.02-0.3%, and the balanceAl and impurities. The preparation method comprises the steps of melting an aluminum ingot into an aluminum melt; adding a magnesium ingot and an intermediate alloy into the aluminum melt; stirring to form an alloy melt; casting the alloy melt into a casting; and extruding, drawing and annealing the casting to obtain the Al-Mn pipe alloy of the household air conditioner heat exchanger. Accordingto the Al-Mn pipe alloy of the household air conditioner heat exchanger and the preparation method of the Al-Mn pipe alloy, the corrosion resistance, strength and toughness of the alloy is improved, and the product quality of the household air conditioner heat exchanger is favorably improved.

Owner:河南誉金技术服务有限公司

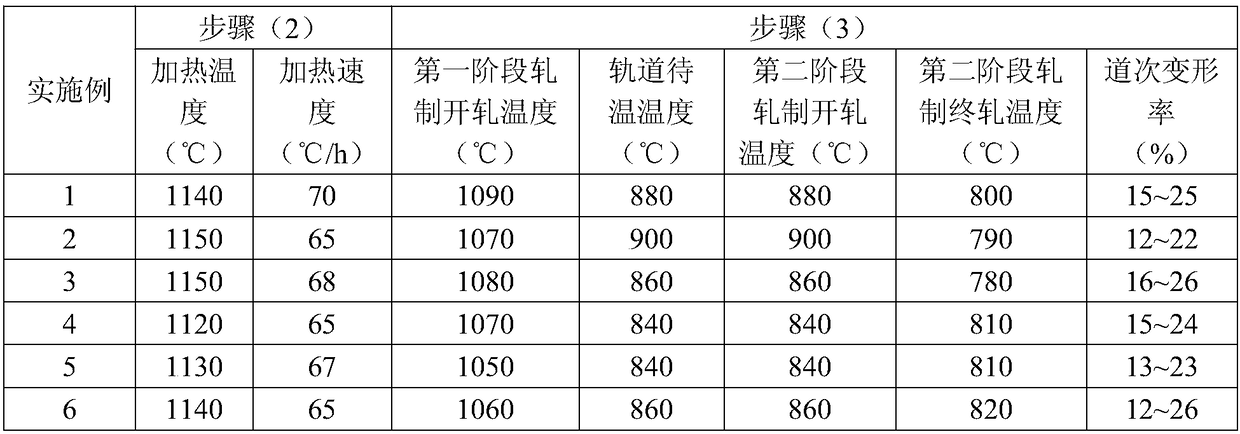

Microalloyed high-strength high-plasticity non-magnetic steel plate and manufacturing method thereof

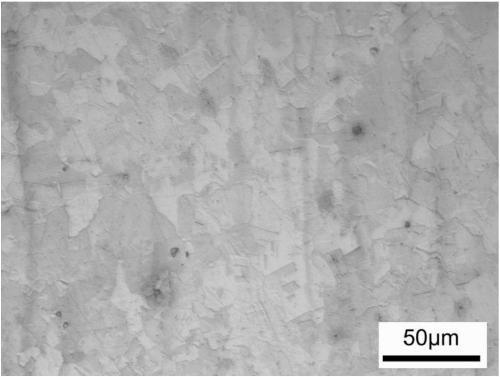

The invention discloses a microalloyed high-strength high-plasticity non-magnetic steel plate. The non-magnetic steel plate comprises the following chemical elements by mass: 0.10 to 0.20% of C, morethan 0 and no more than 0.4% of Si, 20 to 26% of Mn, 2.0 to 3.0% of Al, 0.01 to 0.02% of Ti and 0.04 to 0.09% of Nb, with the balance being Fe and unavoidable impurities. The matrix structure of the non-magnetic steel plate is fine deformed austenite crystal grains. Accordingly, the invention also discloses a manufacturing method for the non-magnetic steel plate. The manufacturing method comprisesthe following steps: (1) smelting and casting; (2) heating, wherein a heating temperature is 1120 to 1170 DEG C; (3) rolling; and (4) cooling after rolling. The non-magnetic steel plate of the invention adopts a microalloying design, so the non-magnetic steel plate has high strength and good plasticity, with yield strength being 450-510 MPa and tensile strength being 660-710 MPa.

Owner:BAOSHAN IRON & STEEL CO LTD

High-chromium alloy cast ball and casting method thereof

InactiveCN110527901AHigh hardnessImprove mechanical propertiesFurnace typesHeat treatment furnacesHardnessInduction furnace

The invention provides a high-chromium alloy cast ball and a casting method thereof. The high-chromium alloy cast ball comprises the following components in percentage by weight:1.6-2.5% of C, 15-19%of Cr, 0.7-1.1% of Cu, 0.2-0.7% of Mn, 0.4-0.8% of Mo, 0.02-0.05% of V, 0.1-0.4% of Y, 0.7-1.2% of B, 0.004-0.009% of Nb, 0.002-0.007% of Ta, less than 0.02% of P, less than 0.01% of S and the balanceof Fe. The casting method comprises the following steps: (1) raw material smelting: adding the raw materials calculated in proportion into a high-frequency induction furnace for high-temperature smelting, adding a deslagging agent for deslagging after furnace charge is completely molten, adding 0.05% of aluminum for deoxidation, discharging, and adding an inoculant along with flow in the discharging process; 2, pouring moulding: setting the pouring temperature from 1420 DEG C to 1440 DEG C, setting the pouring time from 5 min to 9 min, and obtaining the high-chromium alloy cast ball primary finished product; 3, enabling the high-chromium alloy cast ball primary finished product to be subjected to heat treatment to obtain the high-chromium alloy cast ball finished product. The high-chromium alloy cast ball has excellent abrasion resistance and impact resistance, high hardness and long service life.

Owner:马鞍山常裕机械设备股份有限公司

Method for producing nodular cast iron from low-manganese steel scrap accessories

The invention discloses a method for producing nodular cast iron from low-manganese steel scrap accessories. The method comprises the steps as follows: low-manganese steel scrap, recirculated iron andadditives are matched in percentage by weight, and the additives include a nodulizer, 75SiFe and a carburant and are added as per the percentage of the total weight of the low-manganese steel scrap and the recirculated iron; the recirculated iron, the carburant and the low-manganese steel scrap are sequentially added to an electric medium-frequency induction furnace, heating is stopped after thetemperature rises to 1,500-1,530 DEG C, and slag is cleaned through raking; the nodulizer and 75SiFe are sequentially placed into a nodulizing ladle reaction chamber, and the chamber is covered with an upper cover; the molten iron discharging temperature is controlled to be 1,520+ / -10 DEG C, molten iron in the electric furnace is poured into the nodulizing ladle reaction chamber from a liquid inlet in the upper cover, and the nodulizing reaction time is controlled to range from 60 s to 120 s; the pouring temperature is controlled to range from 1,390 DEG C to 1,410 DEG C, and pouring is performed in a manufactured sand mold cavity. The method has the beneficial effects as follows: produced castings have the good density; the method is convenient to operate and master; the production cost can be reduced; the low-manganese steel scrap has the stable source and is convenient to buy, resources can be saved, and the energy consumption can be reduced.

Owner:KAZUO PENGDA CASTING

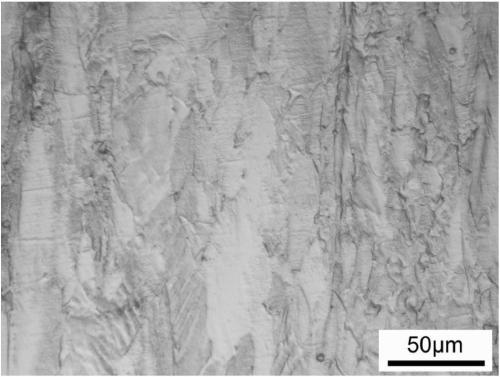

A Method for Isothermal Superplastic Deformation of Micro/Nano Particle Reinforced Titanium Matrix Composites

ActiveCN110284089BEvenly distributedEnhanced interface bindingTitanium matrix compositesIsothermal forging

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

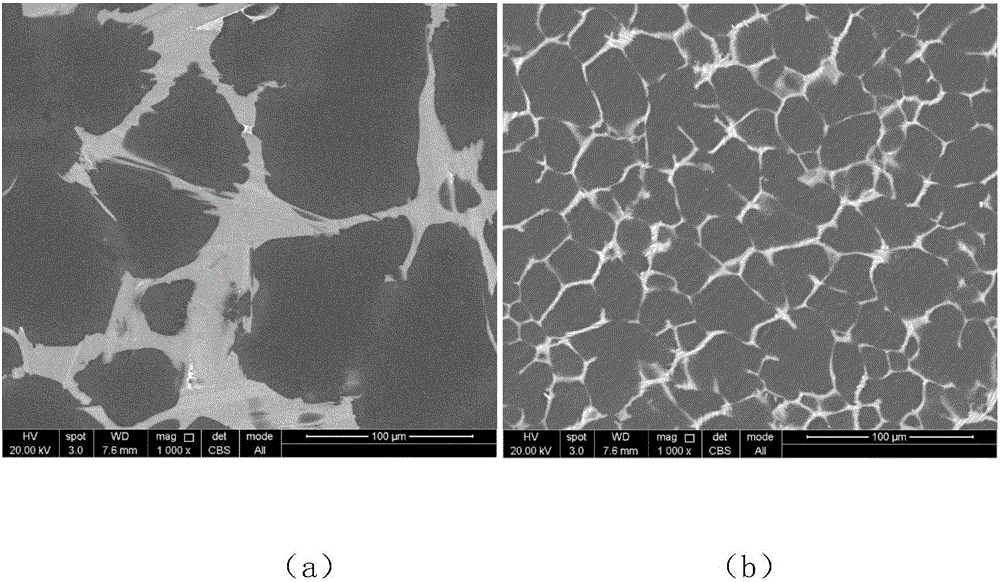

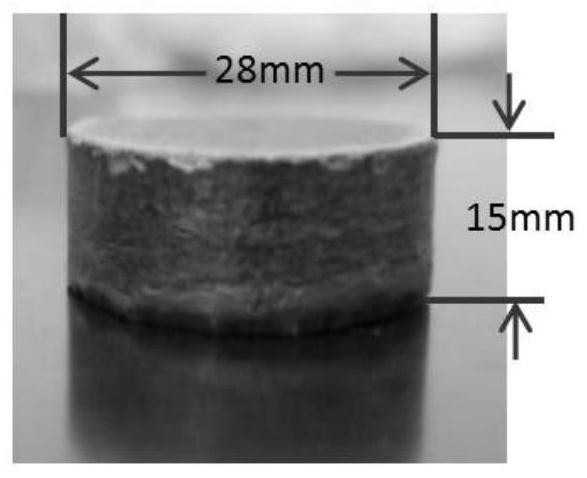

Cast production method of heavy truck front axle

InactiveCN104630606ASpeed up coolingRefine matrix tissueFoundry mouldsFoundry coresDuctile ironQuenching

The invention provides a cast production method of a heavy truck front axle, and belongs to machinery. Copper-nickel alloying isothermal quenching ductile iron is adopted in the method, has higher strength and toughness when compared with conventional copper-molybdenum alloying isothermal quenching ductile iron, and can prolong the service life of the front axle. The blank of the front axle is cast through an iron-mould coated sand technology method; and a tundish pouring method is employed during spheroidizing and enables the spheroidising more stable. Machining is employed before isothermal quenching in the method, and the front axle is prevented from deformation. The isothermal quenching treatment is carried out on a salt furnace production line containing a protective atmosphere, and a matrix structure of austenite+acicular ferrite is generated, so that the toughness of the front axle is greatly improved. The cast production method is advantaged in that material revolution of replacing forging with casting and replacing steel with iron is realized; heavy forging equipment and die investment are saved; a production cycle is shortened; and the cast production method has obvious economic benefits and social benefits.

Owner:QINGDAO XUSHENG HEAD

Production method of steel wear-resisting plate BTW for coal mine

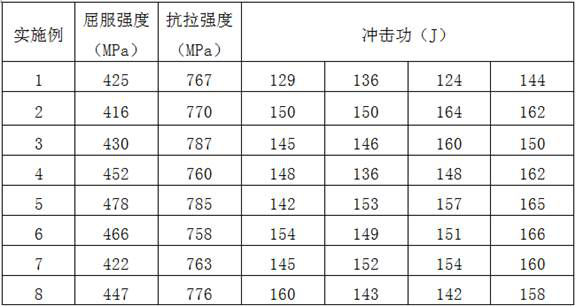

The invention discloses a production method of a steel wear-resisting plate BTW for a coal mine. The production method comprises the procedures of steel ingot cogging, blank heating, high-pressure water dephosphorization, rolling, cooling and straightening. Through heating curve control and rolling schedule design optimization, rapid cooling control is achieved after rolling, and the steel wear-resisting plate BTW for the coal mine is obtained and is widely applied to the coal mine field, wherein the surface quality of the steel wear-resisting plate BTW for the coal mine is good, and strengthand wear resistance of the steel wear-resisting plate BTW for the coal mine meet user requirements. The thickness specification of the obtained steel wear-resisting plate BTW for the coal mine rangesfrom 15 mm to 50 mm; and after use performance is agreed by users, tensile strength is larger than or equal to 700 MPa, yield strength ranges from 400 MPa to 480 MPa, and ballistic work is larger thanor equal to 80 J. The plate shape of the wear-resisting plate BTW is level, flatness is smaller than or equal to 5 mm / 1 m, surface quality meets class B of GB / T14977 requirements, and zero-coping delivery of the steel plate is achieved.

Owner:WUYANG IRON & STEEL

Preparation method for reinforcing Ti2AlNb composite material by using graphene

The invention belongs to the technical field of metal matrix composite materials and preparation thereof, and particularly relates to a preparation method for reinforcing a Ti2AlNb composite materialby using graphene. The preparation method adopts the graphene to reinforce a Ti2AlNb alloy, optimizes the properties of the Ti2AlNb alloy, and adopts the graphene to reinforce the Ti2AlNb composite material prepared by spark plasma sintering, it is found that the graphene is evenly distributed in the composite material, the relative density of the composite material reaches 98% or above, and whenthe content of the graphene is 0.5 wt.%, the fracture toughness and elongation of the composite material are improved by 70% and 51% correspondingly; the preparation method fully shows that the graphene has very remarkable toughening and plasticizing effects on the Ti2AlNb alloy, and when the the Ti2AlNb alloy is applied to the field of aviation starting, the combat performance of an aircraft canbe greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

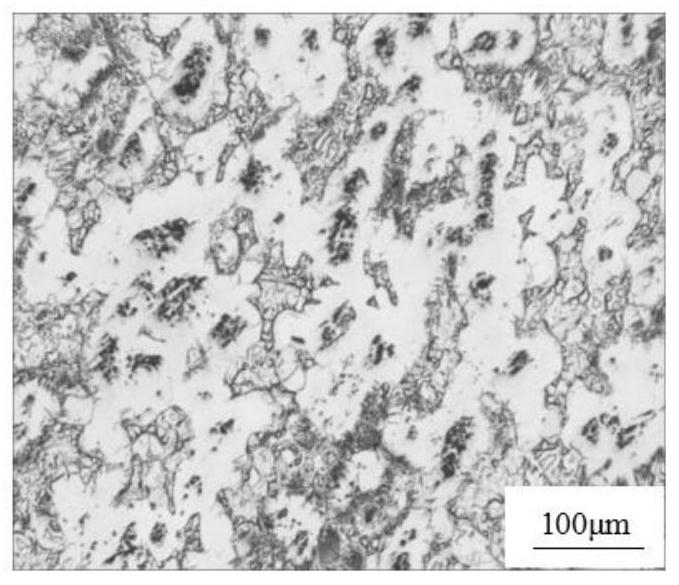

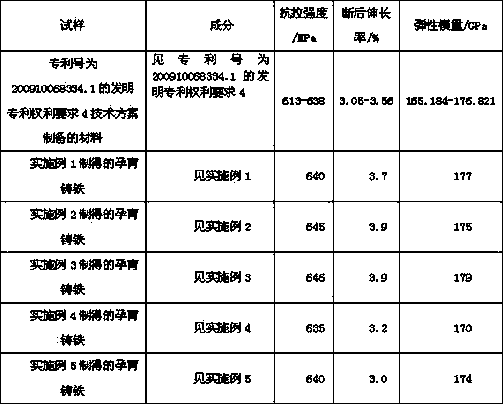

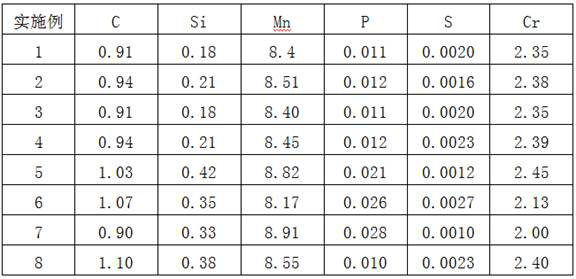

Inoculated cast iron and preparation method thereof

The invention provides inoculated cast iron and a preparation method thereof and belongs to the field of metal materials. The inoculated cast iron comprises, by weight, C 3.3-3.5%, Si 1.3-1.5%, Mn 1.3-16%, P 0.03-0.05%, S 0.06-0.07%, Cr 21-23%, Nd 0.25-0.29%, Sn 0.25-0.29%, Ti 0.25-0.29%, Se 0.25-0.29% and the balance Fe. The preparation method comprises the steps of weighing raw materials, preparing molten alloy, adding Nd-Sn-Se-Ti-Zn into the molten alloy, casting a mixture into casting ingots, and performing heating, heat preservation, air quenching and tempering to obtain the inoculated cast iron. The inoculated cast iron has good comprehensive performance, the material cost is low, and the preparation method is simple.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

A kind of production method of steel wear-resistant plate btw for coal mine

The invention discloses a production method of a steel wear-resistant plate BTW for coal mines. The production method comprises the steps of steel ingot billeting, billet heating, high-pressure water dephosphorization, rolling, cooling and straightening. The invention controls the heating curve, optimizes the design of the rolling schedule, and controls the rapid cooling after rolling to obtain the steel wear-resistant plate BTW for coal mines with good surface quality, and the strength and wear resistance meet the requirements of users, and is widely used in the field of coal mines. The BTW thickness specification of the steel wear-resistant plate for coal mine obtained in the present invention is 15-50mm, and after the use performance is agreed with the user: the guaranteed tensile strength is ≥700MPa, the yield strength is 400-480MPa, and the impact energy is ≥80J; the wear-resistant plate BTW has a flat shape, Flatness ≤ 5mm / 1m, surface quality meets the requirements of GB / T14977 Class B, steel plate delivery without grinding.

Owner:WUYANG IRON & STEEL

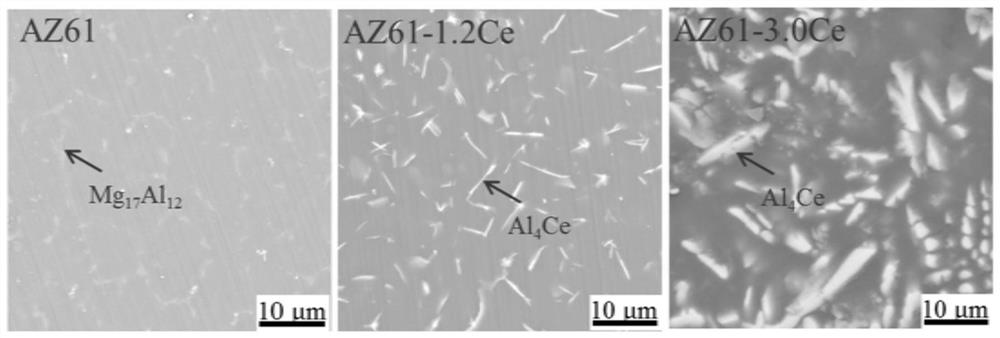

A method for preparing needle-like second phases to improve the degradation resistance of medical magnesium alloys

ActiveCN110722168BReduce transfer rateHigh affinityAdditive manufacturingTransportation and packagingImplantGalvanic corrosion

Owner:CENT SOUTH UNIV

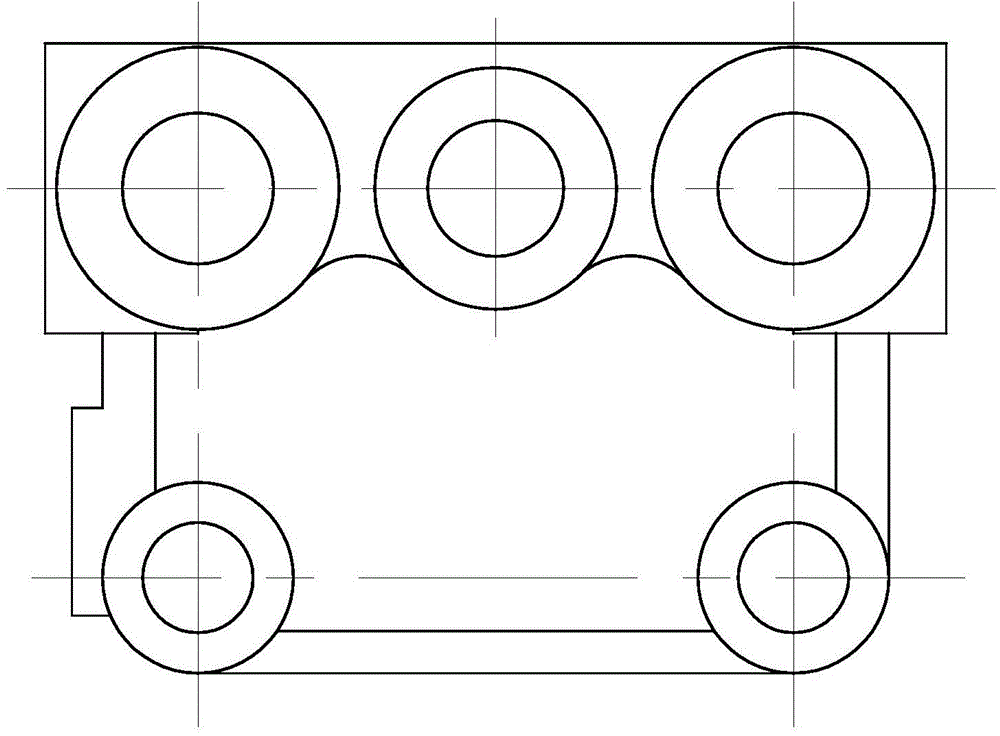

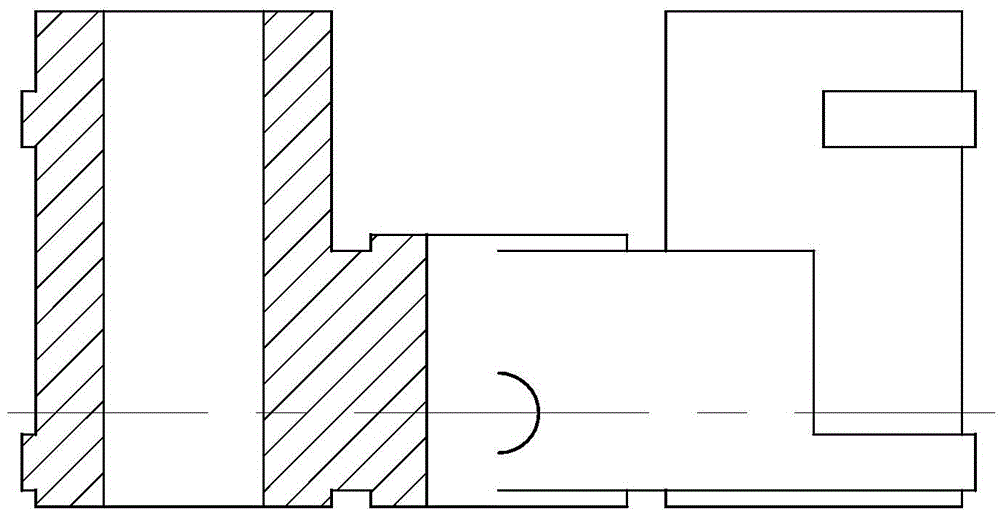

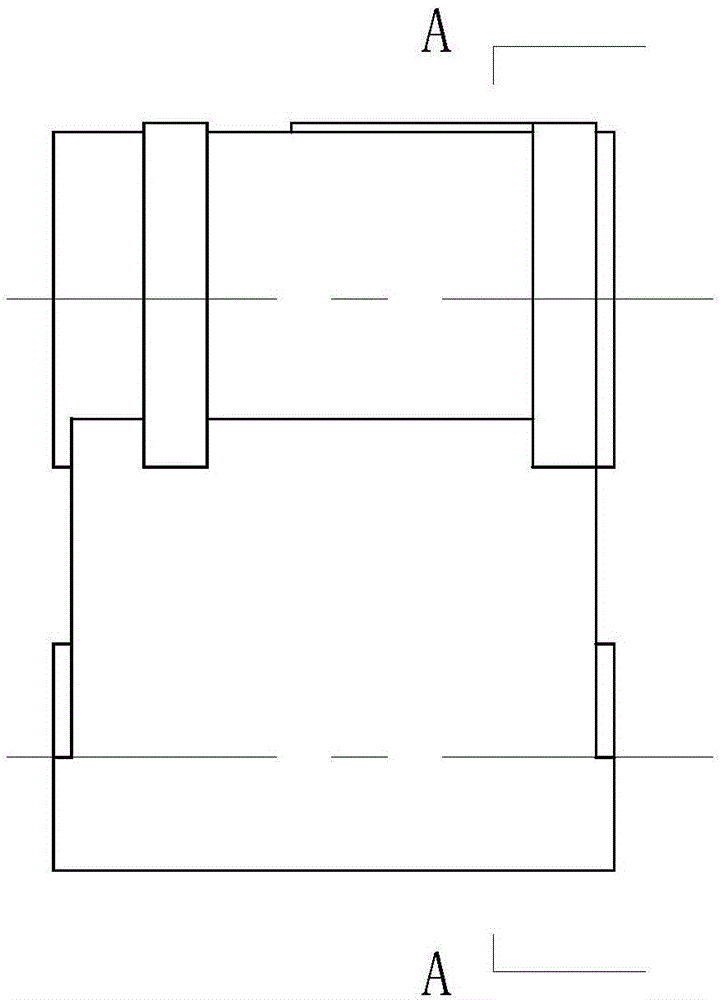

Casting die and casting process of die-casting machine rubber injection head plate

ActiveCN104785713ASimultaneous coagulation effectRefine matrix tissueFoundry mouldsFoundry coresShrinkage rateDie casting

The invention discloses a casting die and a casting process of a die-casting machine rubber injection head plate. The casting die comprises a die body, wherein the die body comprises an upper die and a lower die; at least two cavities which correspond to the rubber injection head plate are formed between the upper die and the lower die; a gate sprue is formed in the upper die, and is communicated with two sides of the cavities through cross gates; two ends of each cross gate are respectively communicated with the bottoms of two sides of the cavities through the ingates; and exhaust holes are also formed in the upper ends of the cavities. The ingates are communicated with the side surfaces of the cavities, and the walls corresponding to the ingates are not thick, so that cooling balance is formed, and the simultaneous solidification effect is reached. Through utilization of an instantaneous flow inoculation process, the matrix structure is refined; the compactness is improved; and the shrinkage rate is reduced. Due to the adoption of the improved process, the defect of shrinkage of shrinkage cavities is basically removed; the oil leakage rate after installation is only 1%-1.5%; the yield is greatly improved; and obvious economic benefits are obtained.

Owner:GUANGDONG HENGCHENG TECH

A maintenance-free slip ring with high current and high power

ActiveCN106486875BHigh strengthIncrease relative volatilityRotary current collectorEngineeringElectrical current

Owner:LINYI HAINA ELECTRONICS

Aluminum alloy die-casting door panel and manufacturing method thereof

The invention belongs to the field of machining of alloy materials and discloses an aluminum alloy pressure-cast door plank. The aluminum alloy pressure-cast door plank is prepared from the following raw materials in percentage by weight: 4.1%-4.3% of magnesium, 1.8%-2.1% of manganese, 0.8%-0.9% of zinc, 0.6%-0.7% of copper, 0.3%-0.4% of nickel, 0.1%-0.2% of white graphite, 0.04-0.05% of cerium, 0.04%-0.05% of yttrium, 0.02%-0.03% of samarium, 0.01%-0.02% of silicon dioxide and the balance of aluminum. The aluminum alloy pressure-cast door plank is high in mechanical strength, can resist corrosion and is unlikely to be oxidized and change color; the preparation method is simple, feasible and suitable for large-scale production.

Owner:宋守宝

Melting method of as-cast high-toughness and high-strength nodular cast iron

The invention relates to a smelting method of high-toughness and high-strength casting-state ductile cast iron. The smelting method comprises the steps of 1, material selection, in which pig iron, scrap steel and a melting-back material are selected as raw materials; 2, material preparation, in which 20-40% of pig iron, 30-40% of scrap steel and 20-50% of melting-back material are selected according to percent by mass; 3, smelting, in which the raw materials prepared in the step 2 are added into a medium-frequency smelting furnace, the temperature is raised, the raw materials are molten, a carburant is added to the bottom of the furnace during smelting, and the raw materials are molten to a required furnace outlet temperature; 4, nodulization and casting, in which a nodulization pack and acasting pack are pre-heated to 600-800 DEG C before nodulization, a nodulizing agent, an inoculation agent and a coverage agent are sequentially placed in the nodulization pack placement pit, and inoculation for three times is performed; and 5, box outlet. The smelting method is simple to operate; and by adding the scrap steel and the melting-back material in a large proportion, the production cost is low, and the mechanical property is improved by a reasonable proportion.

Owner:SHANXI HUAXIANG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com