Automobile engine cylinder cover and manufacturing method thereof

A technology of automobile engine and production method, applied in the direction of manufacturing tools, cleaning/processing machinery of casting materials, casting molding equipment, etc., can solve problems such as shrinkage cavities, shrinkage porosity, and affecting product quality, so as to improve the quality of castings, The effect of refining the matrix structure and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

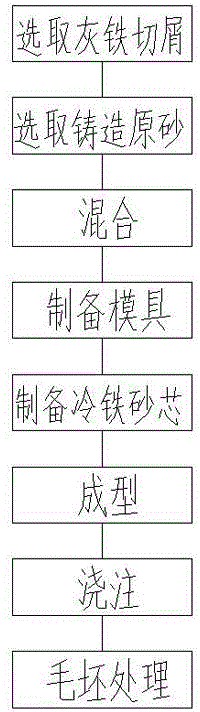

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 It is a flow chart of the automobile engine cylinder head and its manufacturing method described in the present invention, as shown in the figure, a kind of automobile engine cylinder head and its manufacturing method, the automobile engine cylinder head is a product made of the following raw materials and manufacturing methods, Its raw material composition is (weight ratio):

[0026] Gray iron chips: 90%

[0027] Foundry raw sand: 10%

[0028] Furan resin: 5%

[0029] Curing agent: 1.0%;

[0030] Production Process:

[0031] a. Take some clean gray iron shavings for later use;

[0032] b. Take some raw casting sand for spare use;

[0033] c. Put 90% of gray iron chips and 10% of raw sand into a small sand mixer and mix evenly, then add 1.0% curing agent and mix evenly, and finally add 5% furan resin and mix well, then take it out for use;

[0034] d, prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com