Casting die and casting process of die-casting machine rubber injection head plate

A technology of injection head plate and casting mold, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of unsatisfactory improvement, irregular casting structure, uneven thickness, etc., and achieve the elimination of shrinkage cavity and porosity Defects, reducing the probability of shrinkage, and refining the effect of the matrix structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

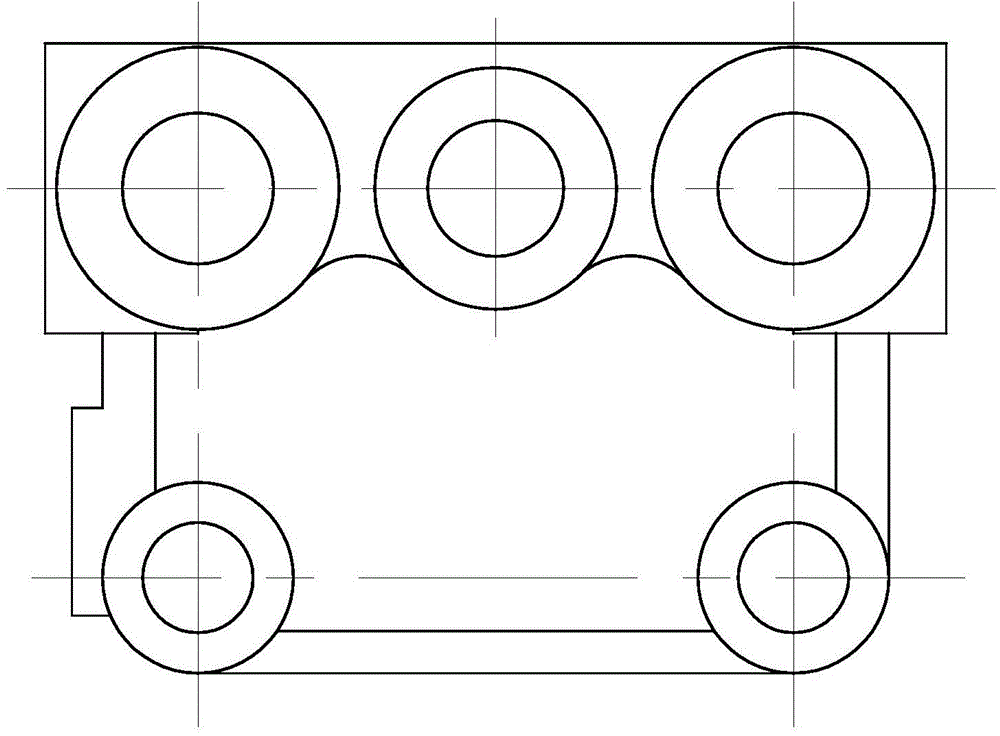

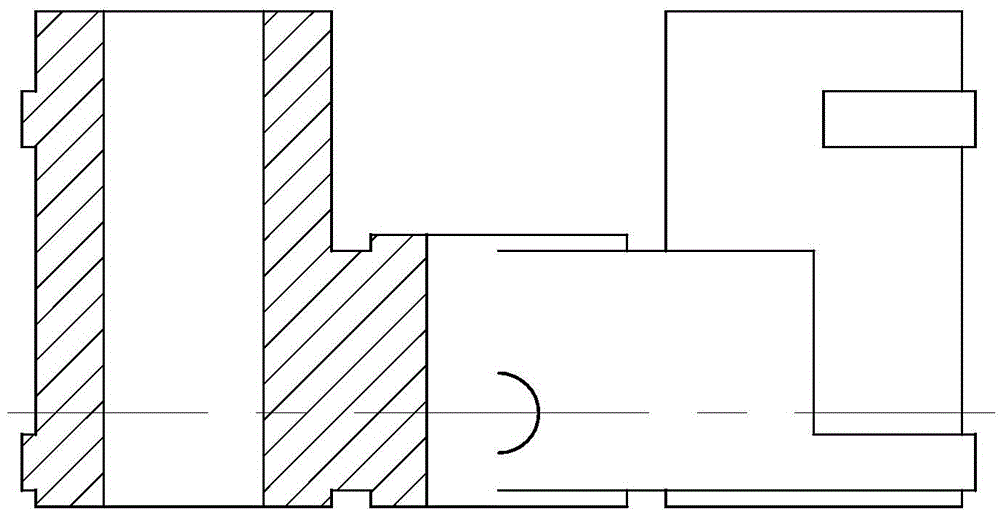

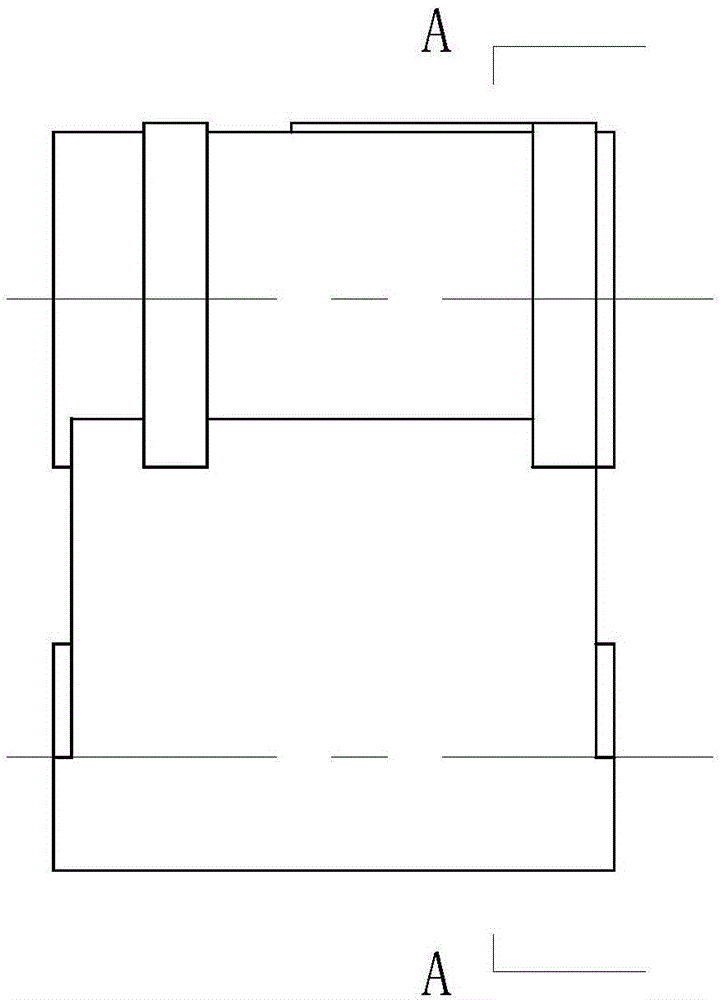

[0028] refer to Figure 7 to Figure 9 , Figure 7 to Figure 9 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the casting mold of the injection head plate of the die-casting machine includes a mold body, and the mold body includes an upper mold 1 and a lower mold 2, and the upper mold 1 and the lower mold 2 are provided with at least two cavities 3 corresponding to the injection head plate, and a sprue 51 is provided on the upper mold 1, and the sprue 51 is connected to both sides of the cavity 3 through a runner 52, In addition, two ends of the runner 52 are respectively connected to the bottoms on both sides of the cavity 3 through an inrunner 53 , and the upper end of the cavity 3 is also provided with a vent hole 54 .

[0029] Preferably, as shown in the figure, there are two cavities 3 arranged symmetrically, and the sprue and runner 52 are arranged between the two cavities 3 .

[0030] In order to balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com