Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Reduced impurity levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

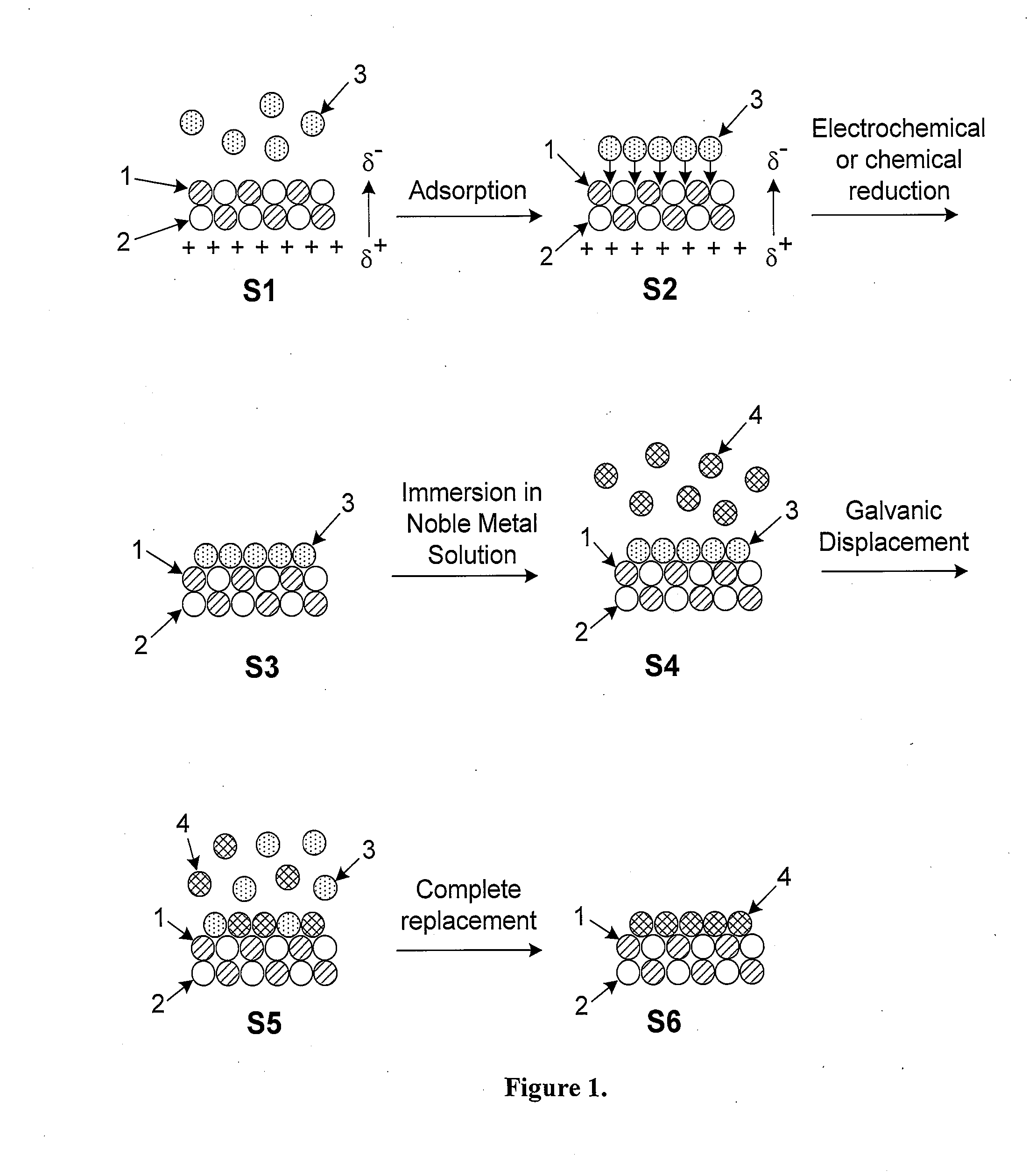

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

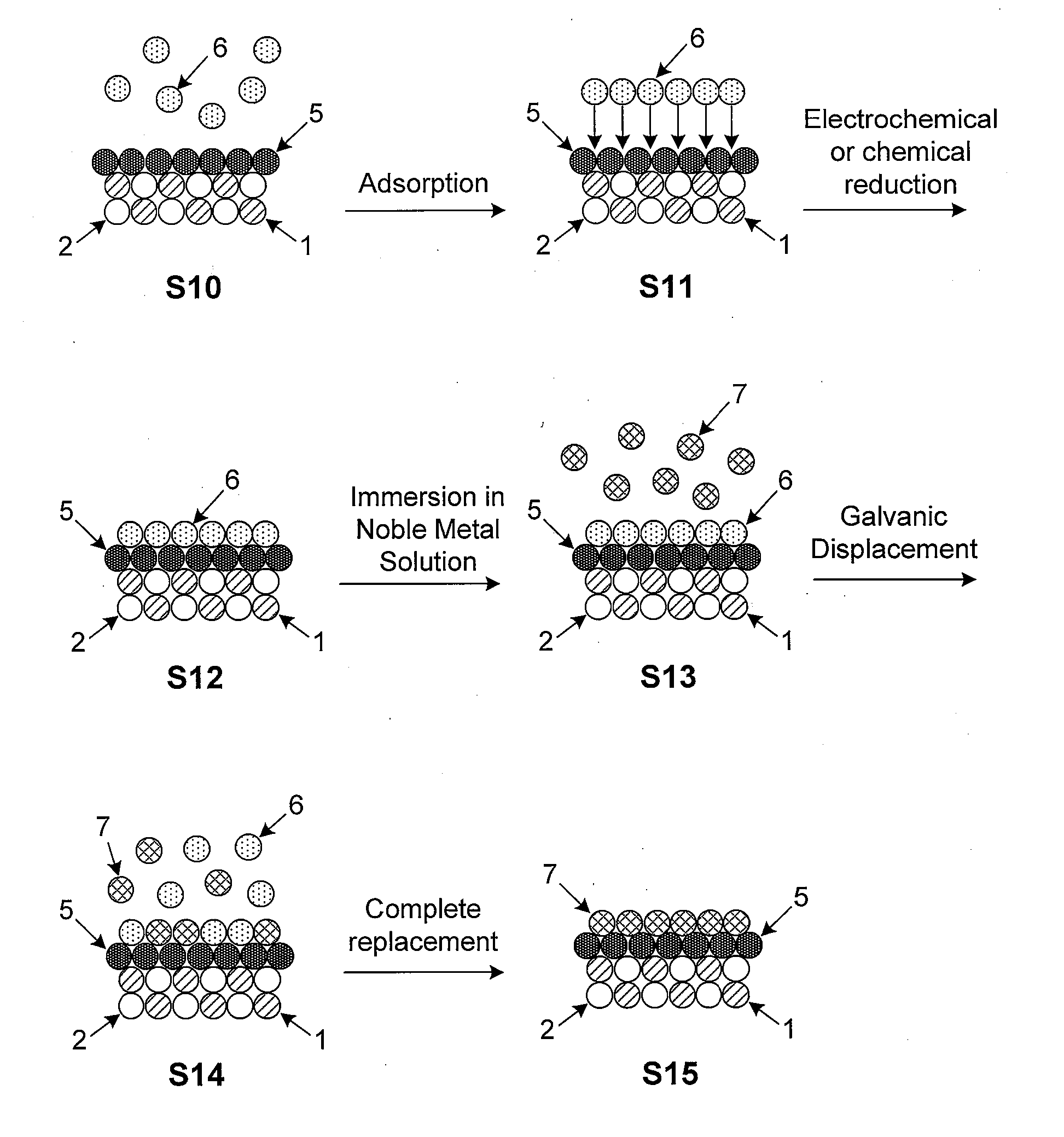

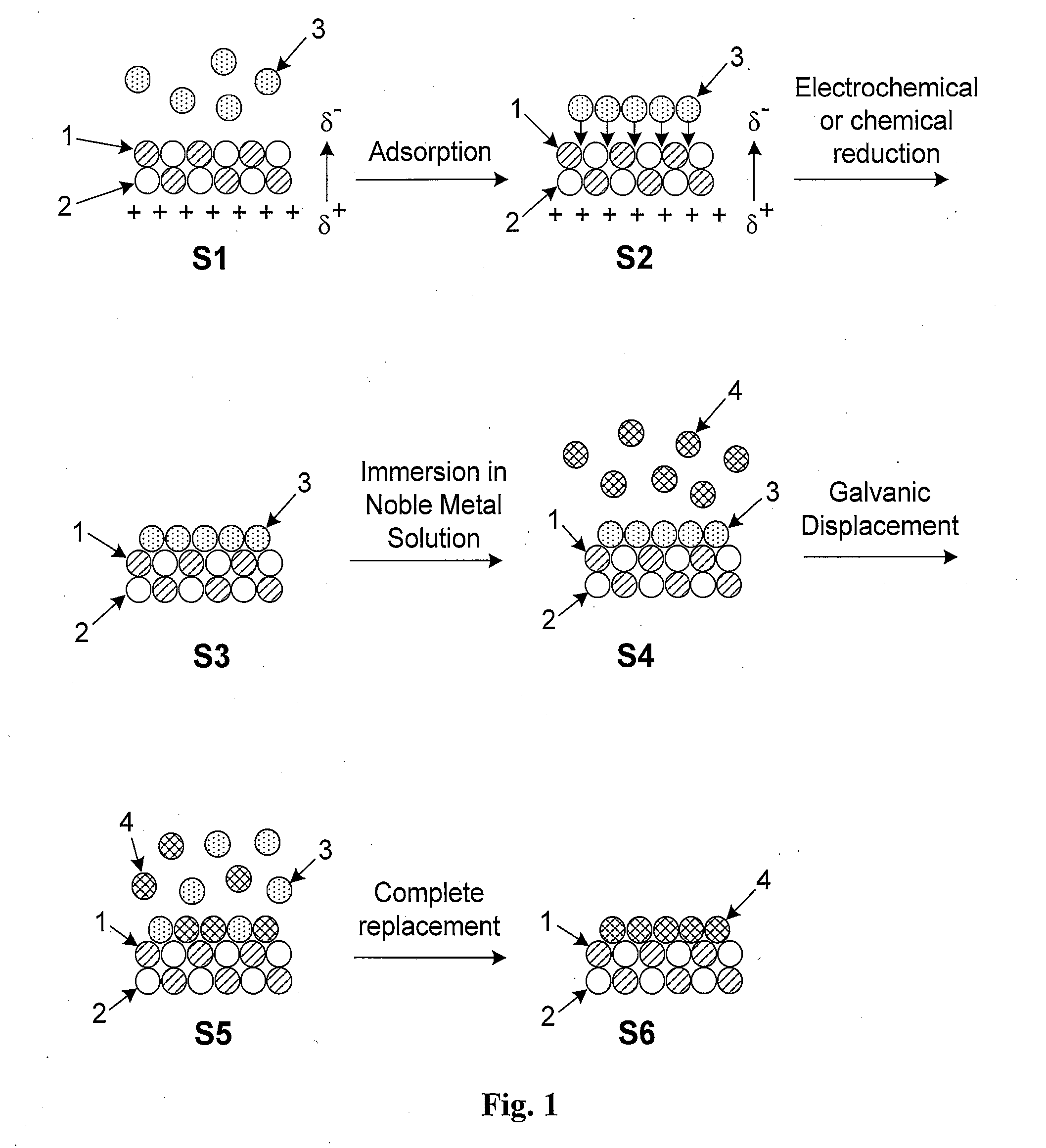

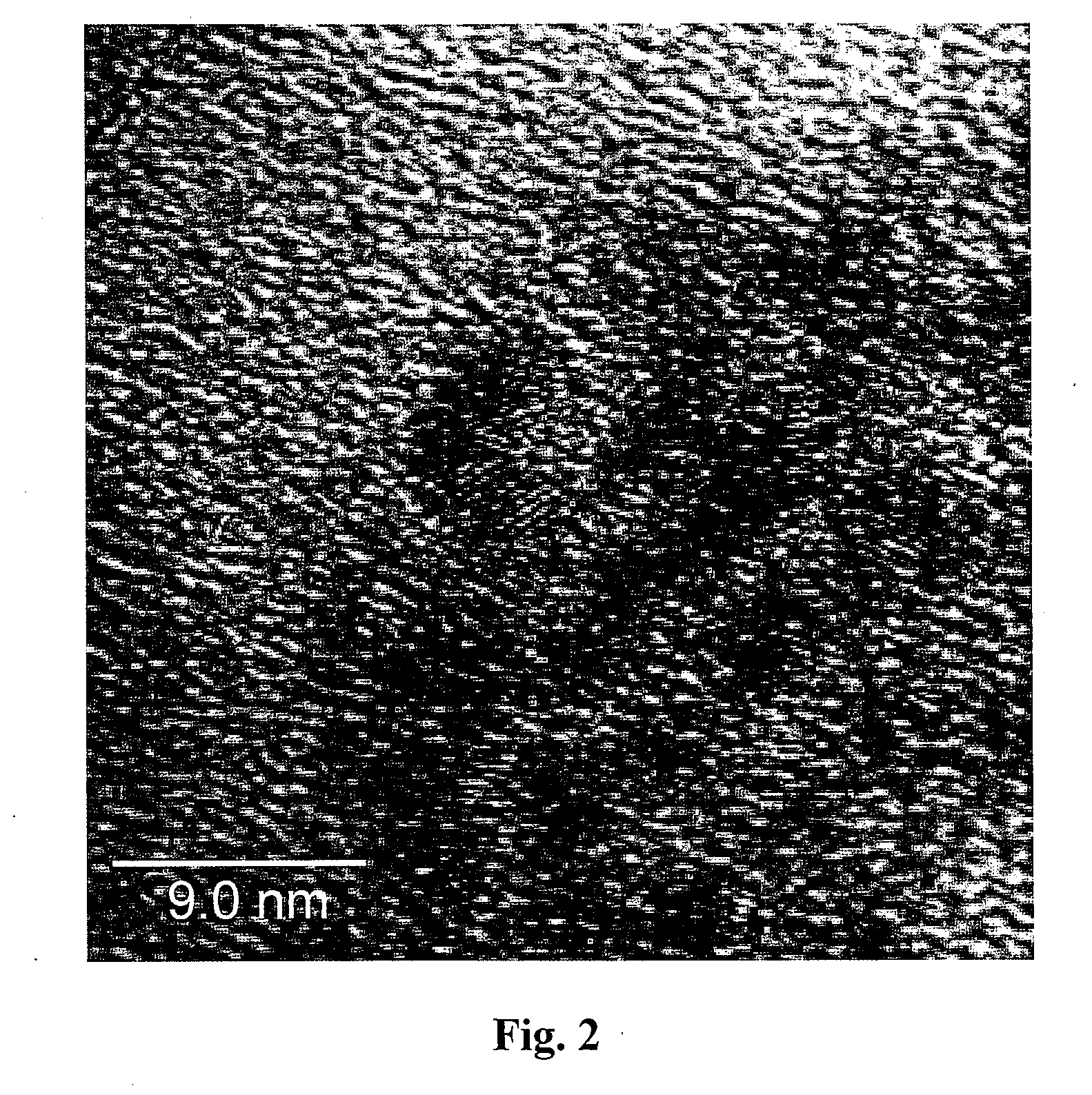

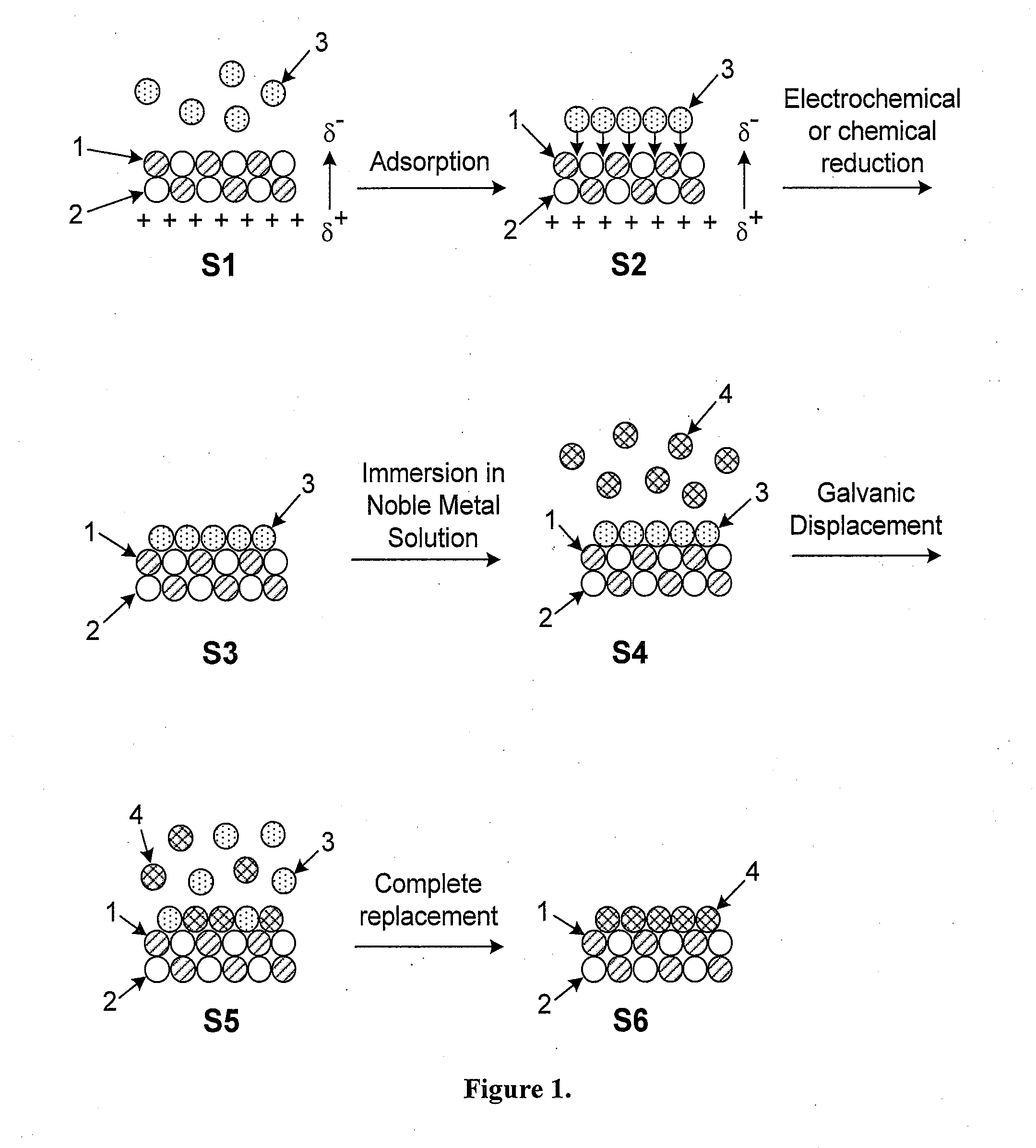

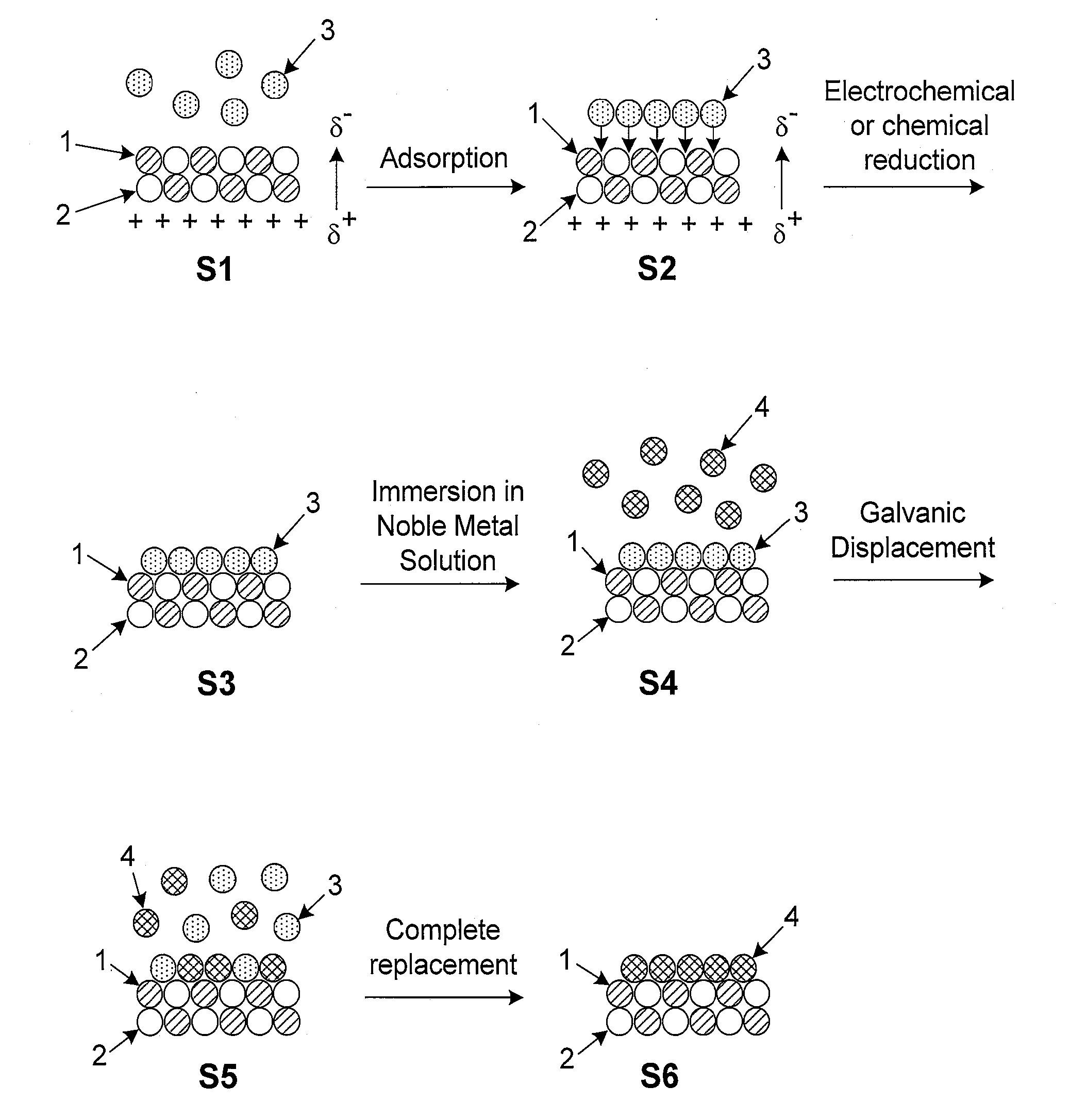

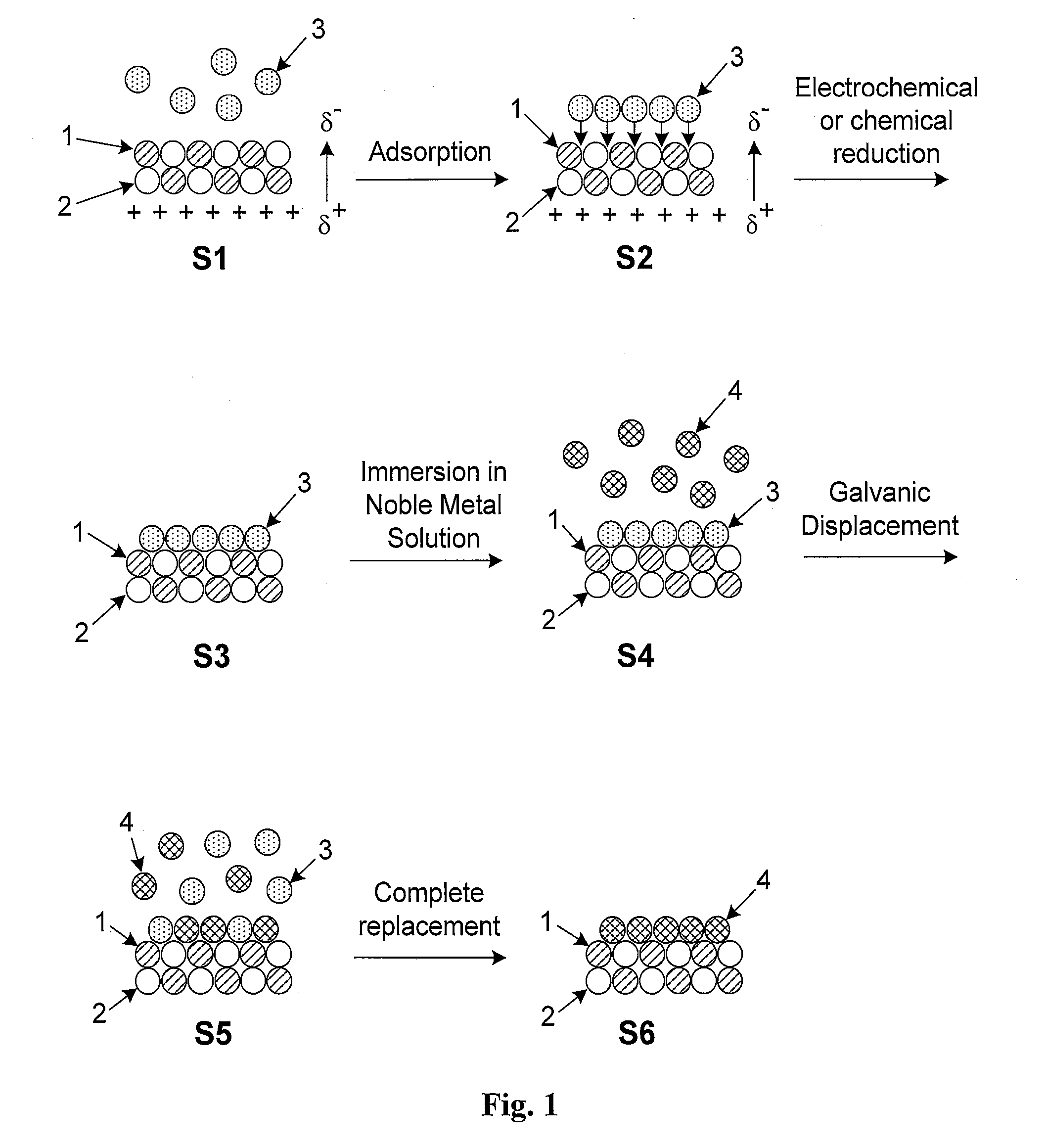

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

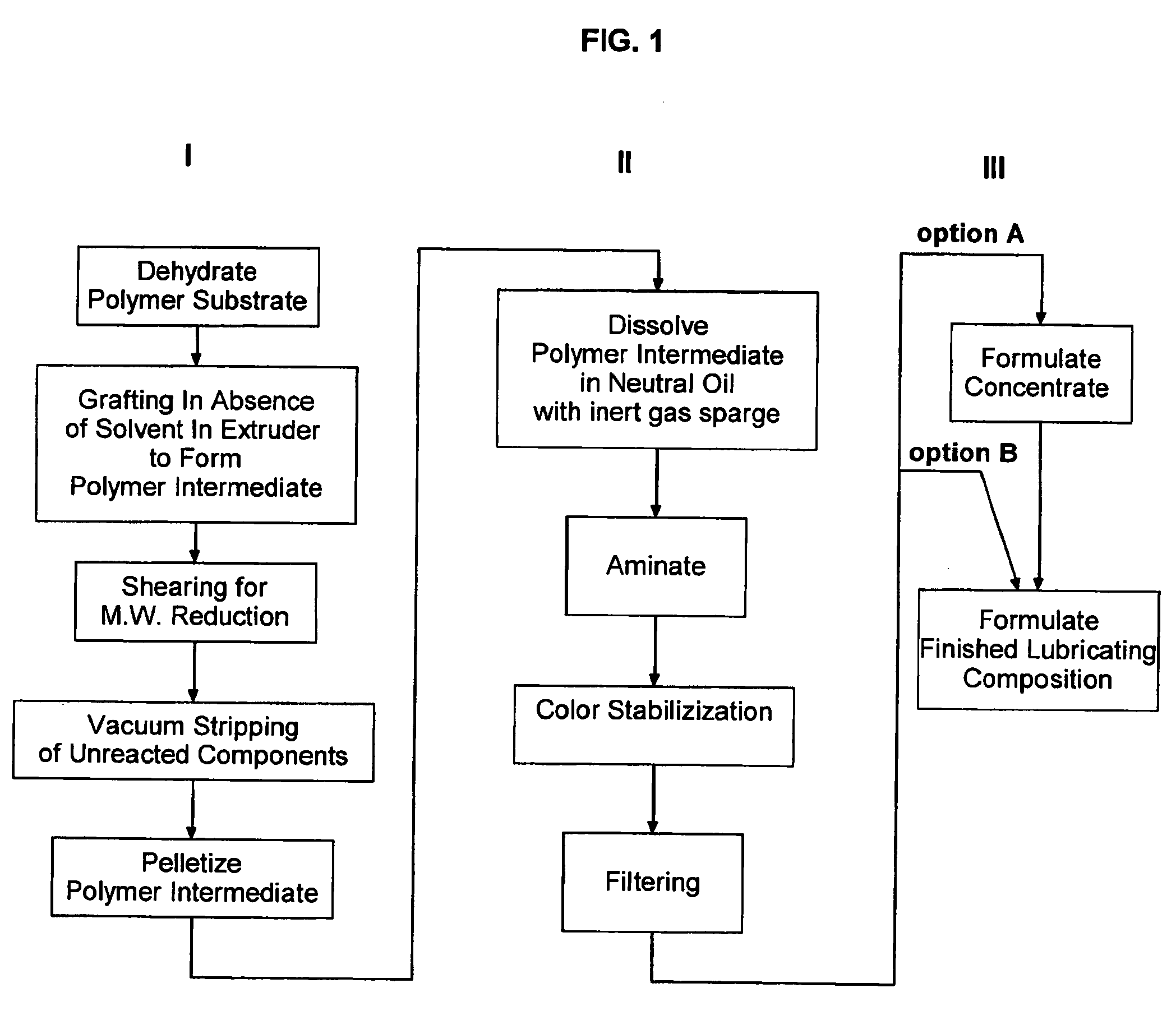

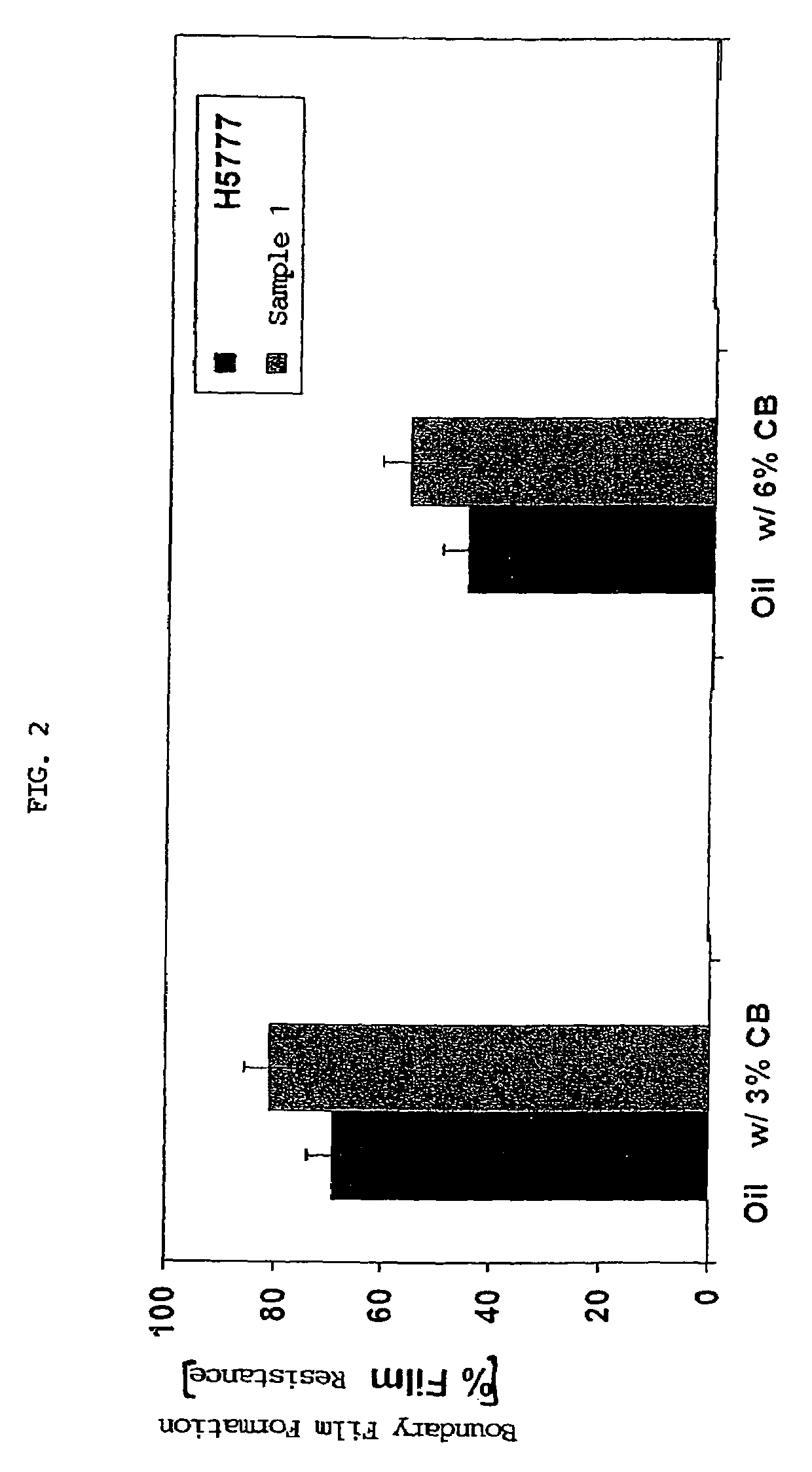

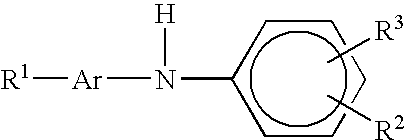

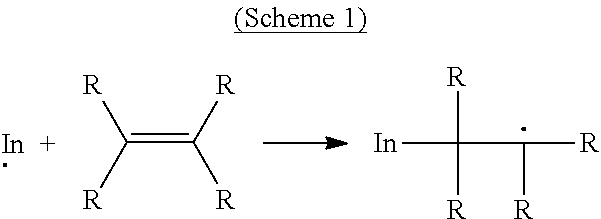

Grafted multi-functional olefin copolymer VI modifiers and uses thereof

ActiveUS7253231B2High activityImprove functionalityLiquid carbonaceous fuelsAdditivesHydrocarbon solventsCanis lupus familiaris

Owner:ARLANXEO NETHERLANDS +1

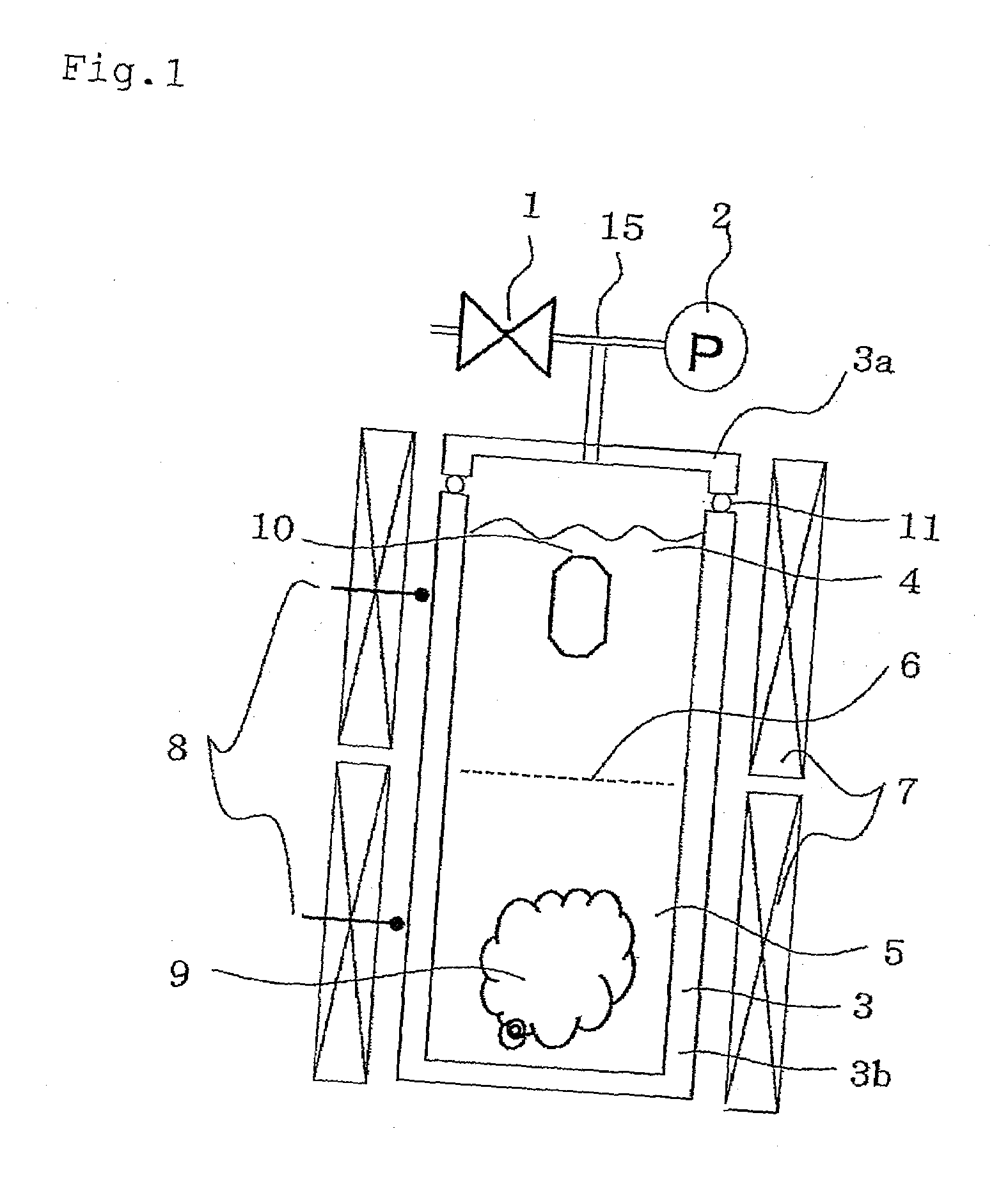

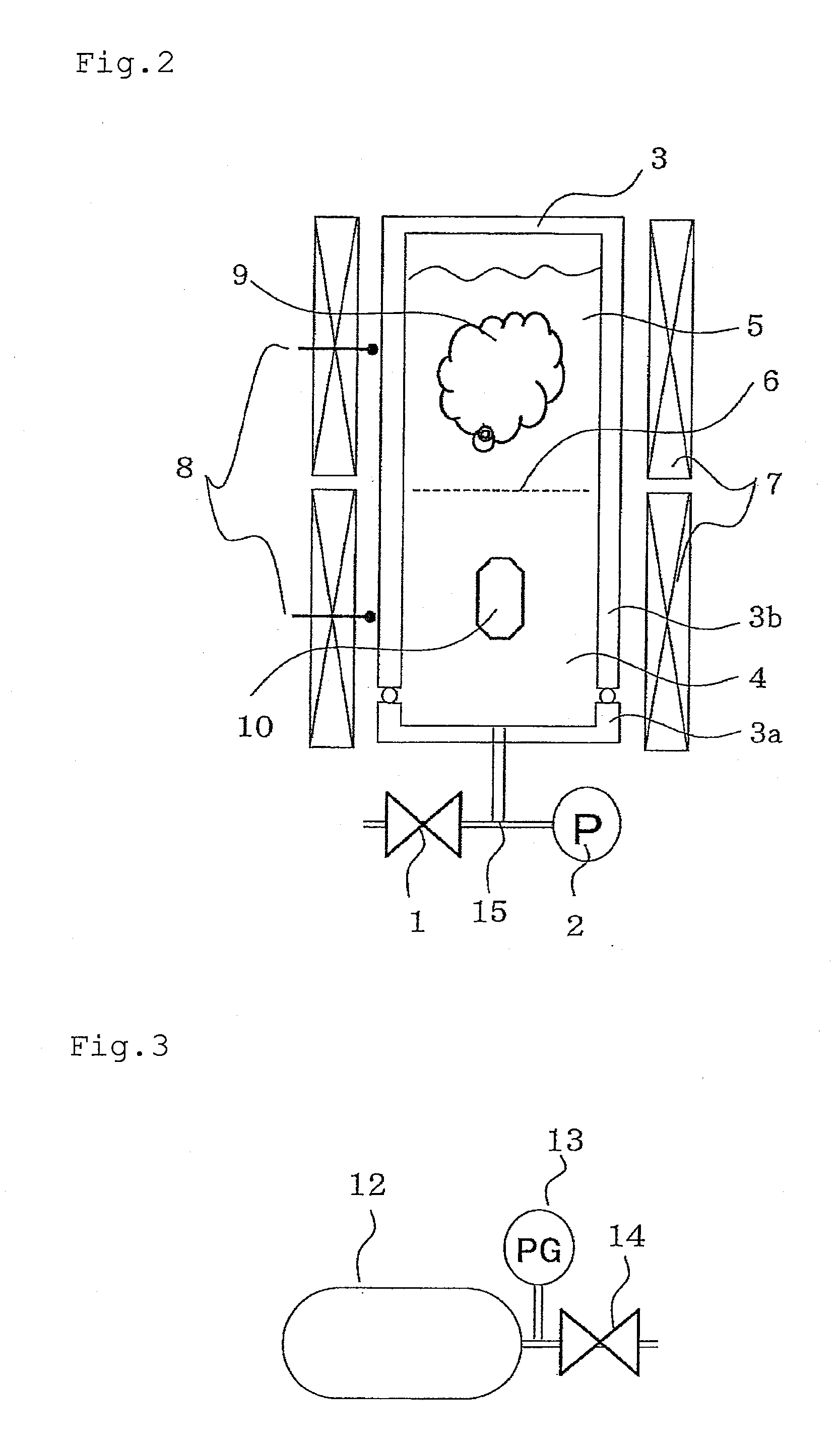

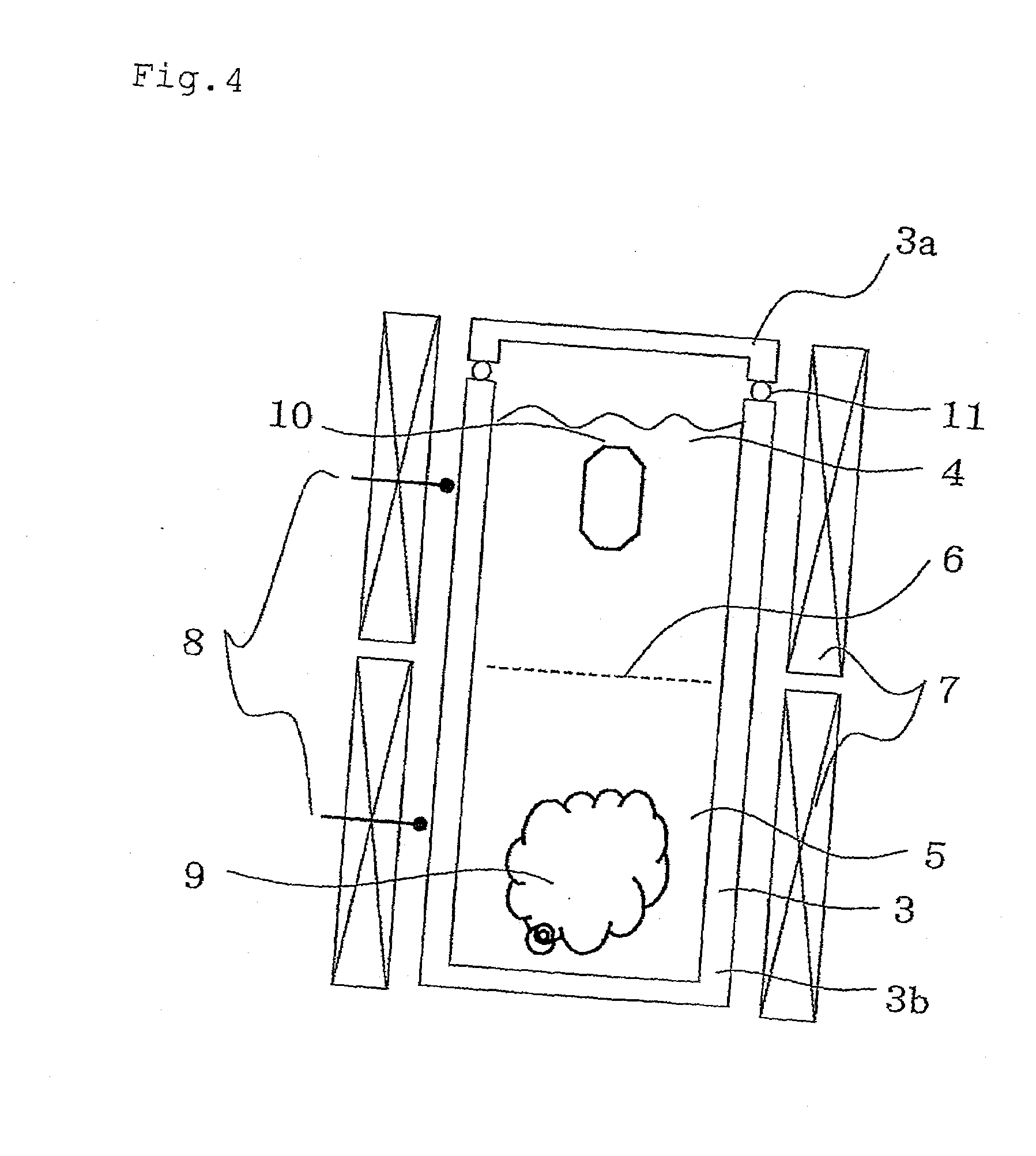

Crystal production process using supercritical solvent, crystal growth apparatus, crystal and device

InactiveUS20090092536A1Efficient productionEasy to controlPolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

To control the precipitation position of a crystal and increase the yield of the crystal by performing the crystal growth according to the solvothermal method while allowing a predetermined amount of a substance differing in the critical density from the solvent to be present in the reaction vessel; and to prevent mixing of an impurity into the crystal and improve the crystal purity.

Owner:MITSUBISHI CHEM CORP +1

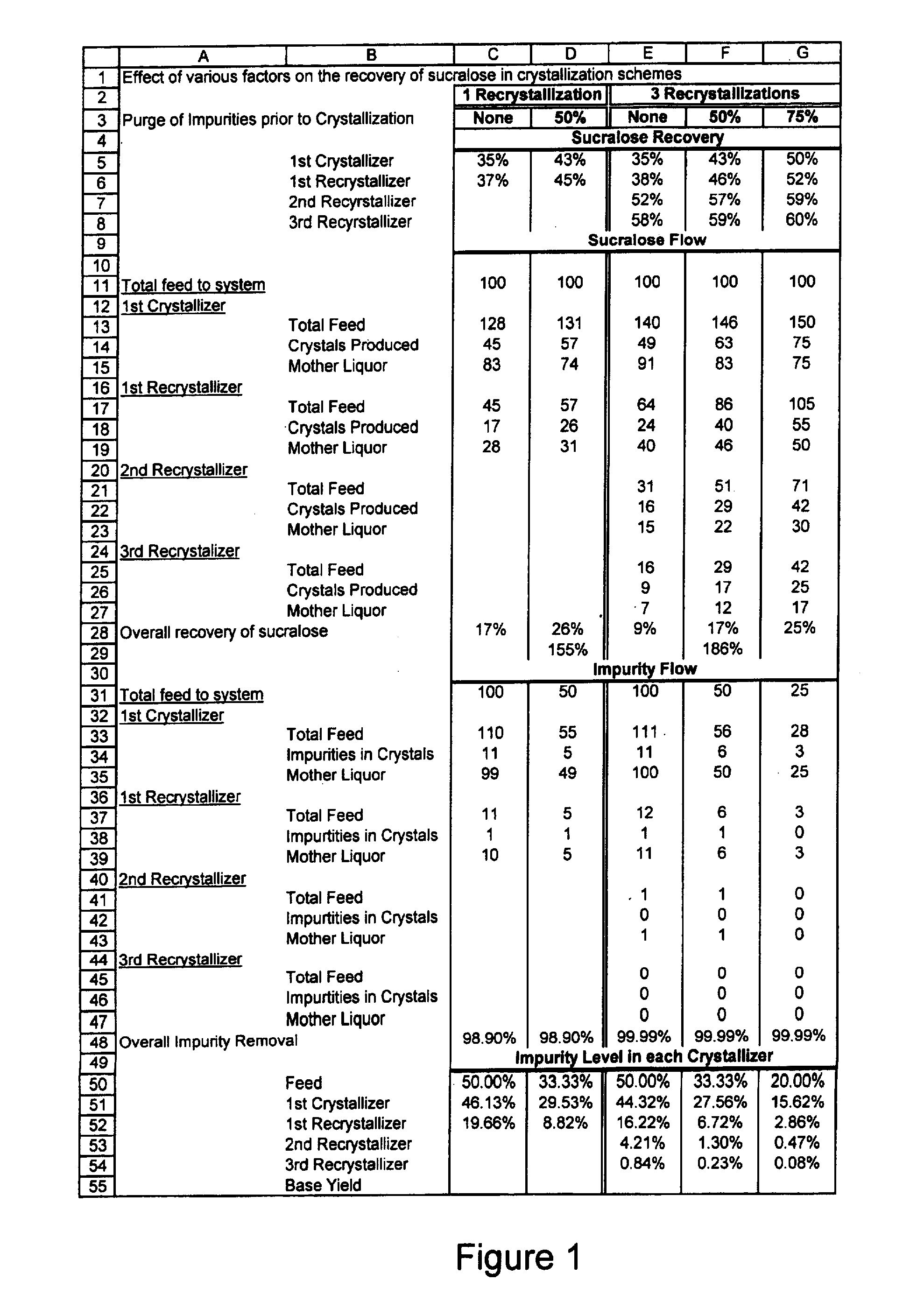

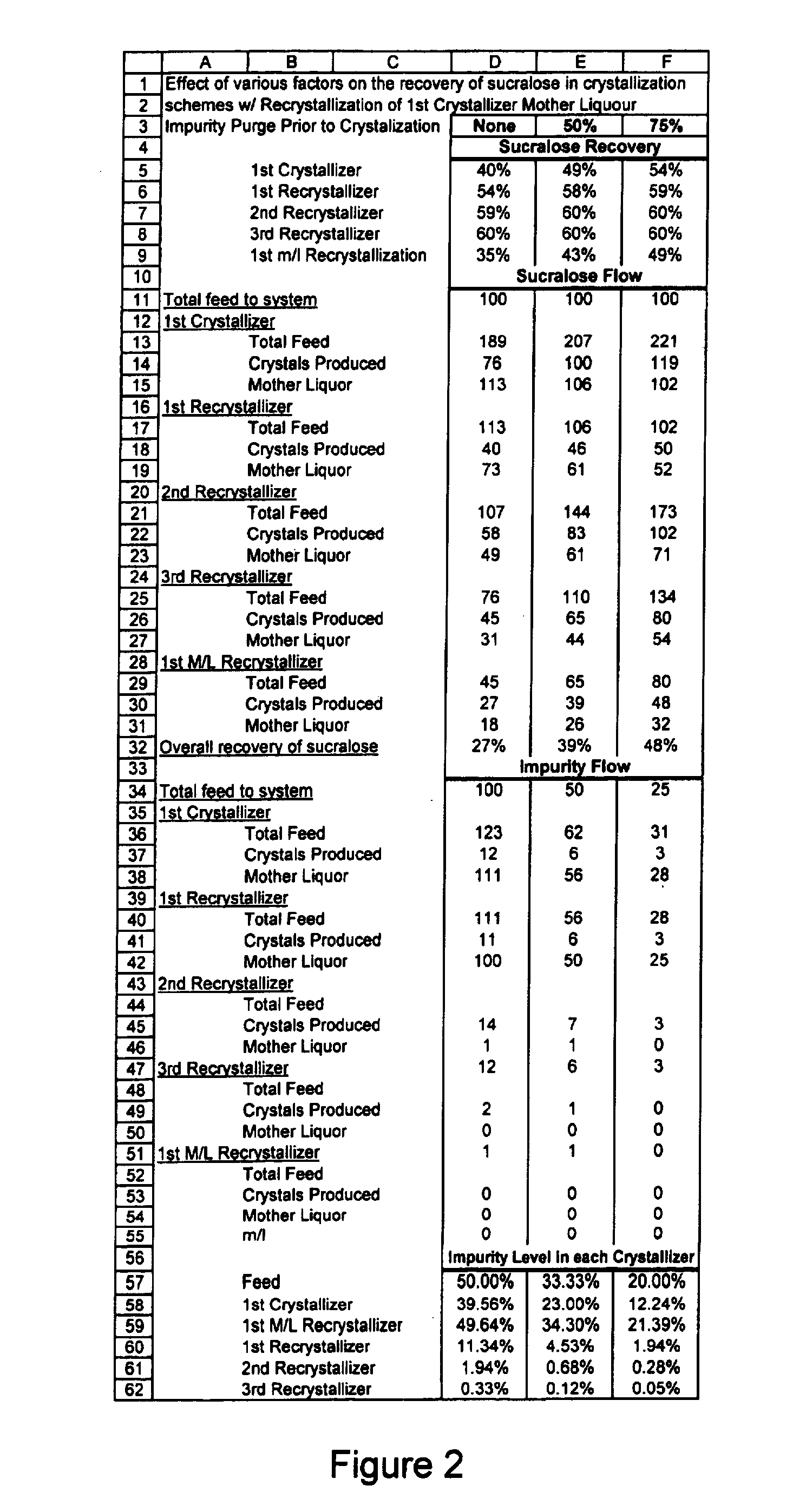

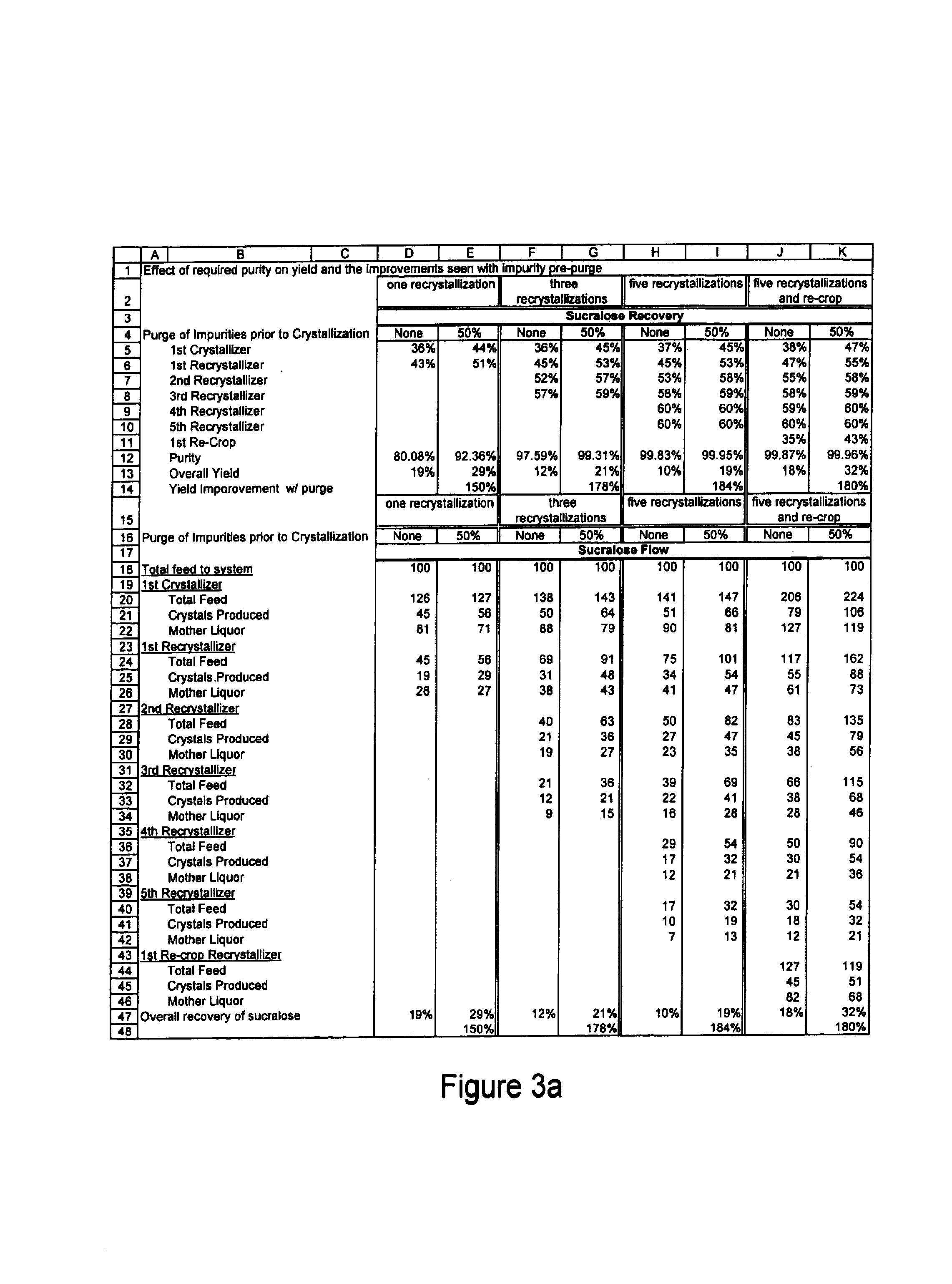

Process for improving sucralose purity and yield

InactiveUS6998480B2Improve efficiencyHigh purityEsterified saccharide compoundsSugar derivativesSucraloseCrystallization Purification

This invention relates to processes for purifying sucralose by the use of an initial non-crystallization purification procedure followed by three or more sequential crystallization steps and recycle of the mother liquor remaining from each crystallization step to the feed of another crystallization or purification step. This invention also relates to sucralose compositions as well as compositions comprising the sucralose compositions of the present invention. These compositions may be highly pure and have a superior taste profile.

Owner:TATE & LYLE TECH LTD

Process For Purification Of Aromatic Carboxylic Acids

InactiveUS20080103333A1Reduced level of impurityEfficient use and handlingOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsSolventCarbonyl group

Impure aromatic carboxylic acids such as are obtained by liquid phase oxidation of feed materials comprising aromatic compounds with substituent groups oxidizable to carboxylic acid groups, or comprising aromatic carboxylic acid and one or more aromatic carbonyl impurities that form hydrogenated species more soluble in aqueous solvents or with less color or color-forming tendencies than the aromatic carbonyl impurity, are purified to an aromatic carboxylic acid product with lower levels of impurities by a process comprising contacting an aqueous solution comprising the impure aromatic carboxylic acid with hydrogen at elevated temperature and pressure with an attrition-resistance, acid stable catalyst composition comprising at least one hydrogenation catalyst metal and a support comprising relatively high surface area silicon carbide.

Owner:BP CORP NORTH AMERICA INC

Electrodes Synthesized from Carbon Nanostructures Coated with a Smooth and Conformal Metal Adlayer

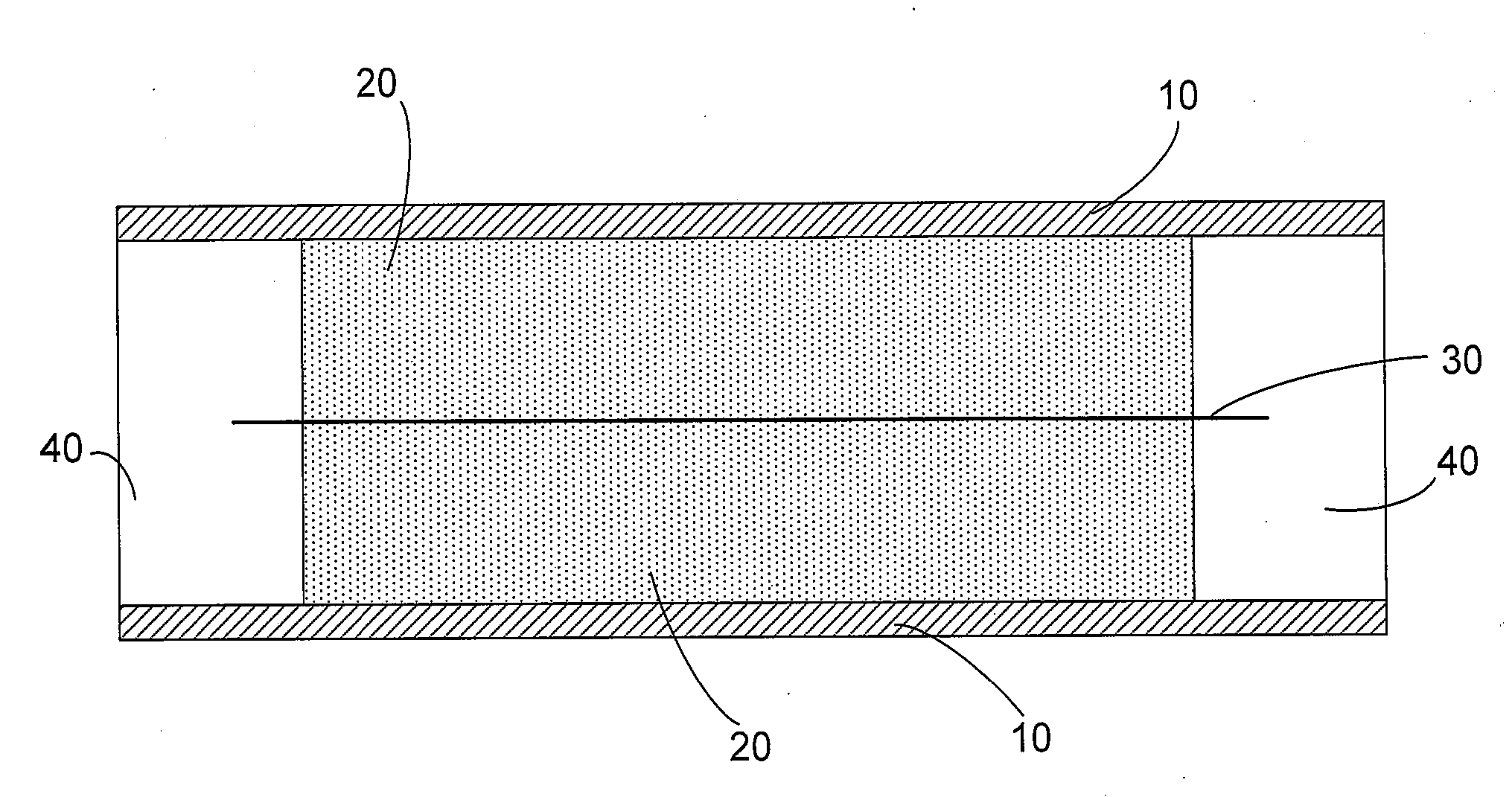

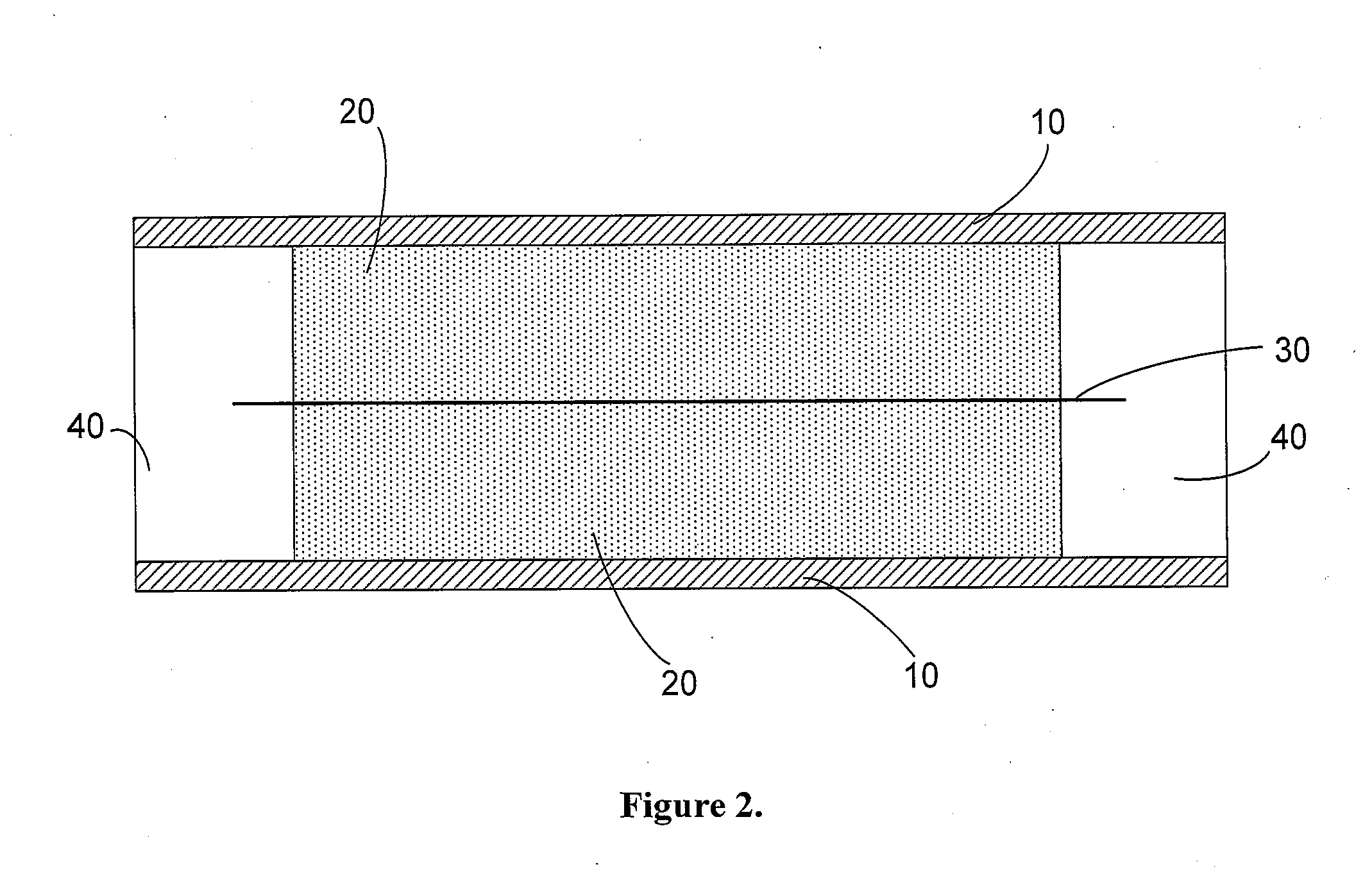

InactiveUS20100097742A1Facilitate depositionLarge pore size distributionMaterial nanotechnologyCarbon compoundsSheet filmNanostructure

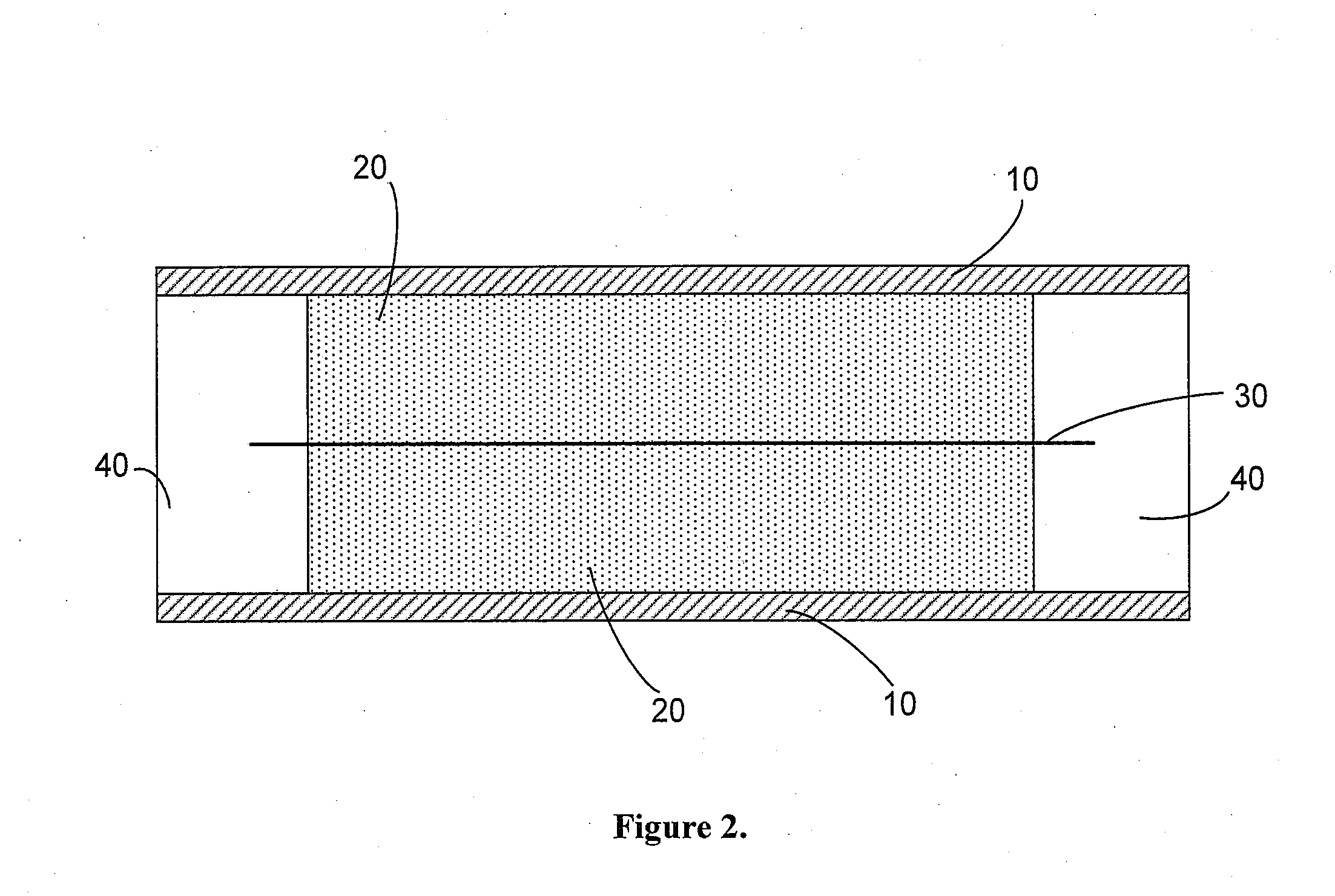

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by a surface preparation process involving immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing a suitable quantity of non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means. The nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. The process can be controlled and repeated to obtain a desired film coverage. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

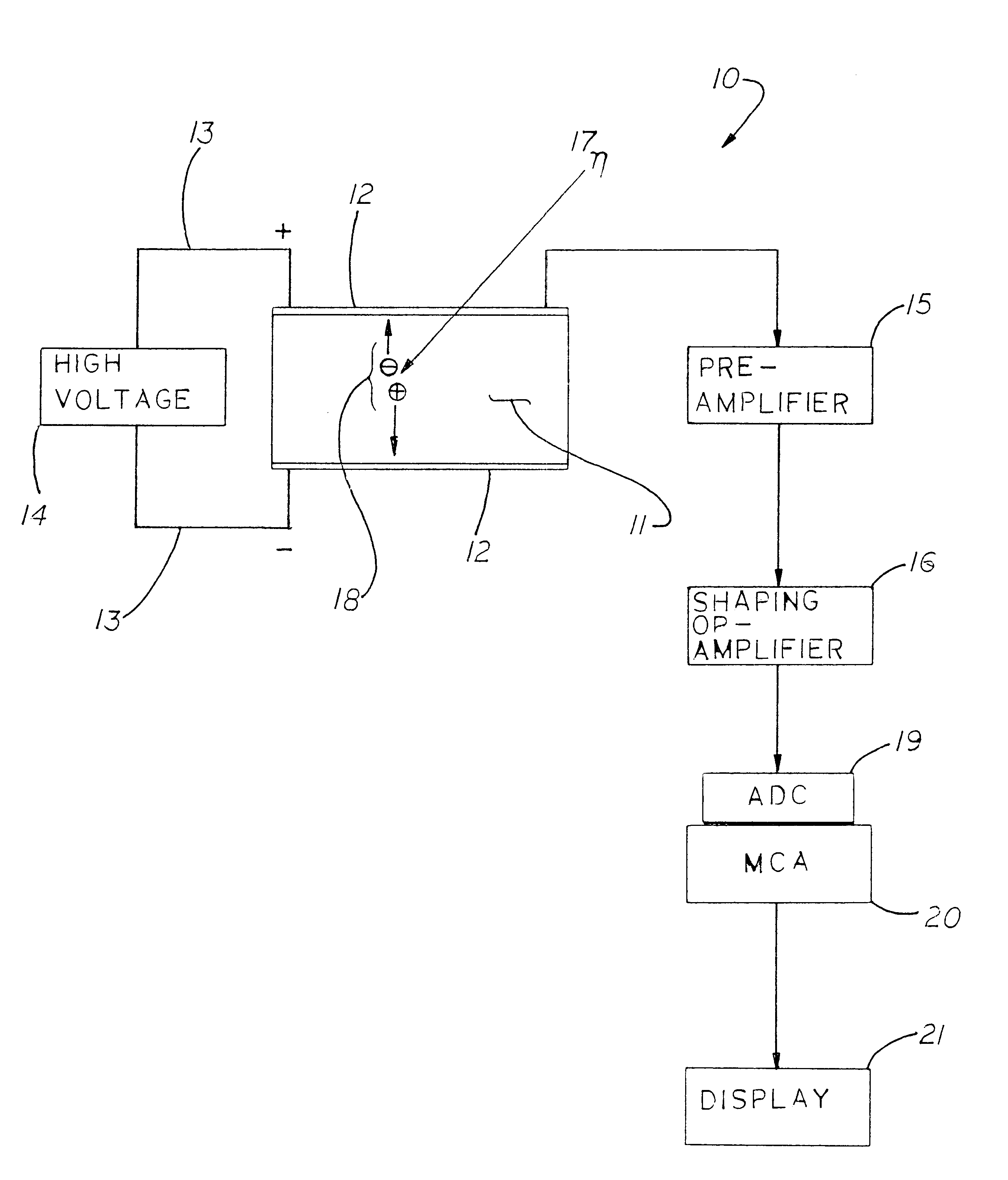

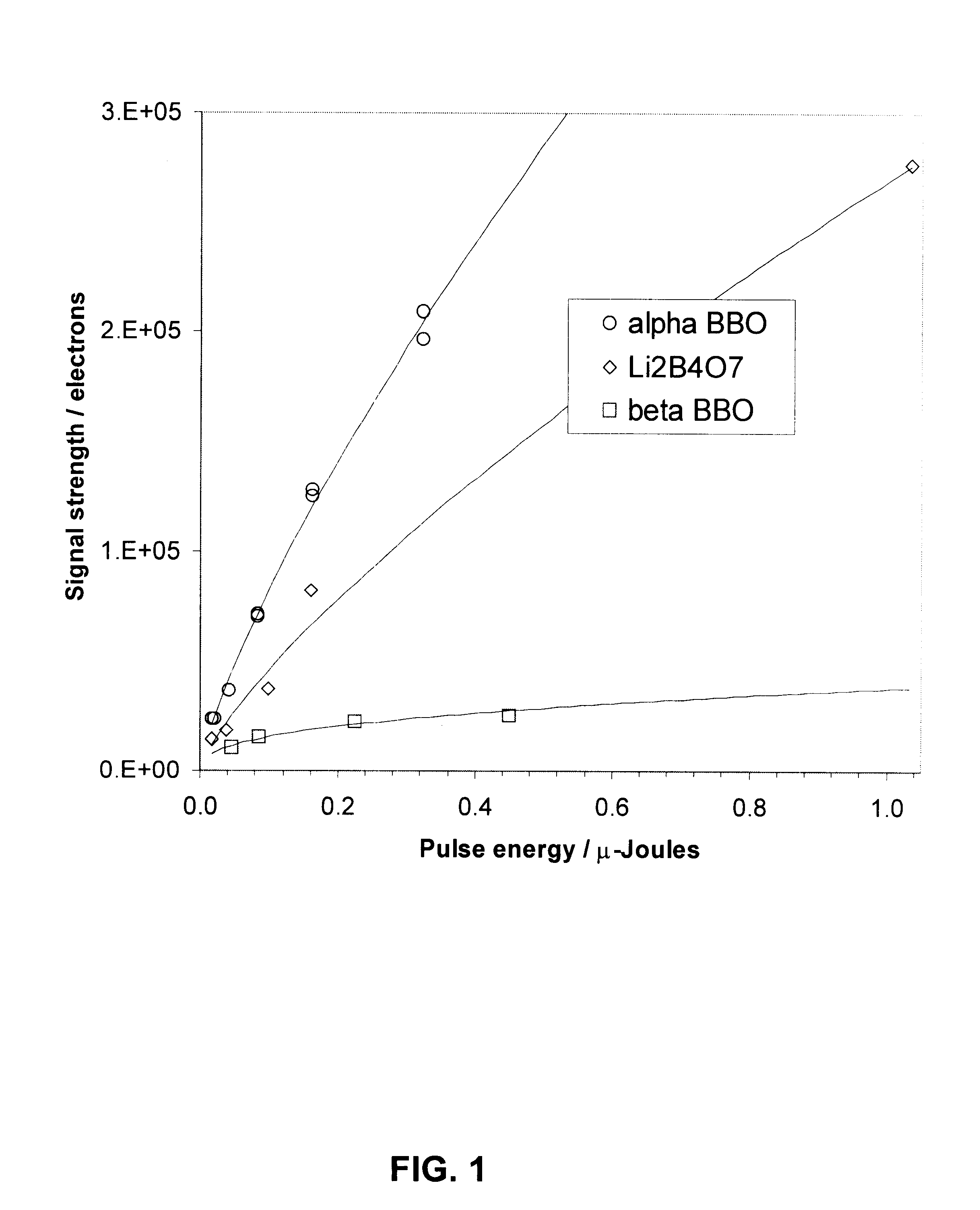

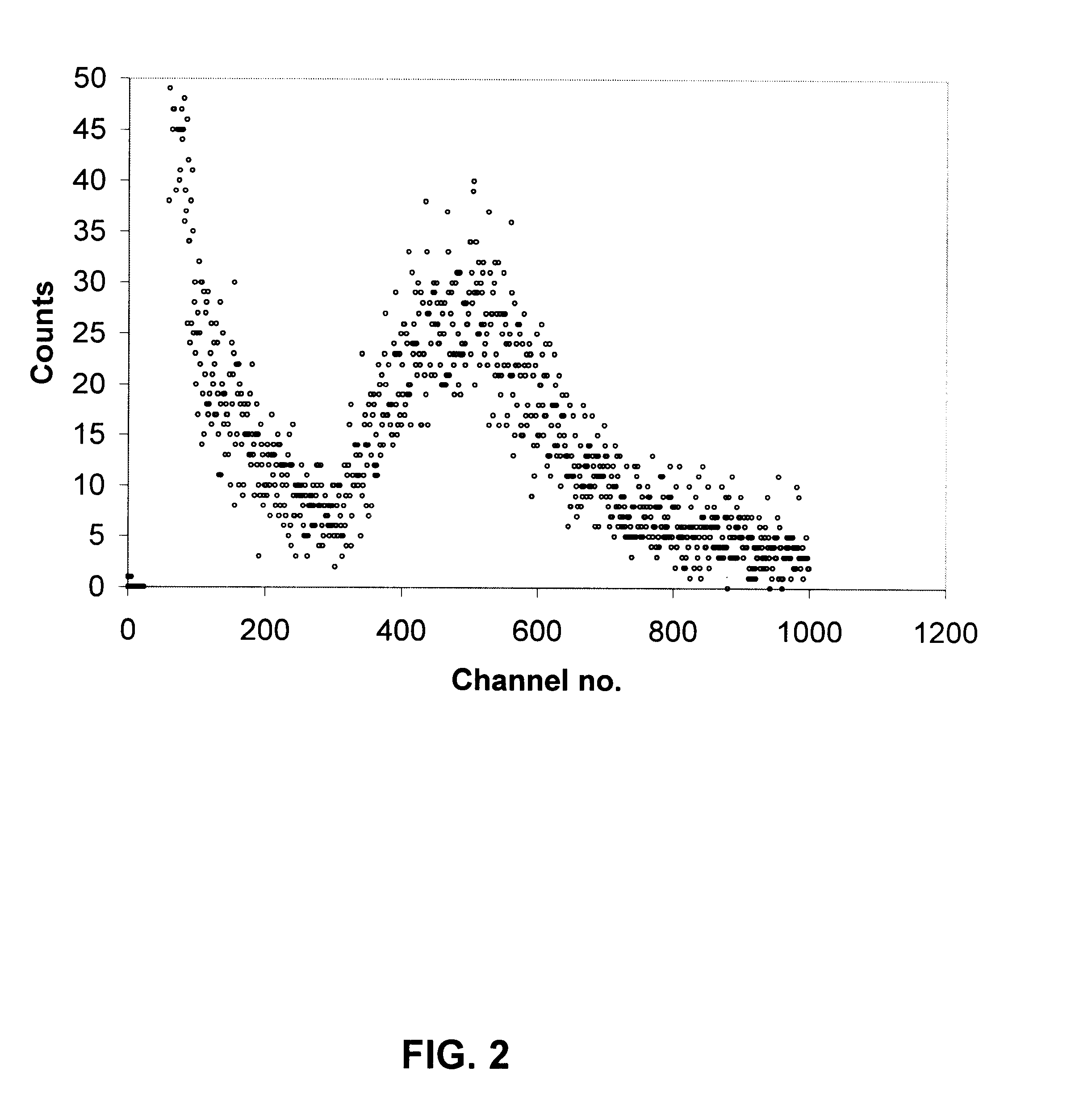

Solid state neutron detector and method for use

InactiveUS6388260B1Large cross sectionOvercome disadvantagesMaterial analysis using wave/particle radiationMeasurement with semiconductor devicesSingle crystalLithium

Crystals of lithium tetraborate or alpha-barium borate had been found to be neutron detecting materials. The crystals are prepared using known crystal growing techniques, wherein the process does not include the common practice of using a fluxing agent, such as sodium oxide or sodium fluoride, to reduce the melting temperature of the crystalline compound. Crystals prepared by this method can be sliced into thin single or polycrystalline wafers, or ground to a powder and prepared as a sintered compact or a print paste, and then configured with appropriate electronic hardware, in order to function as neutron detectors.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

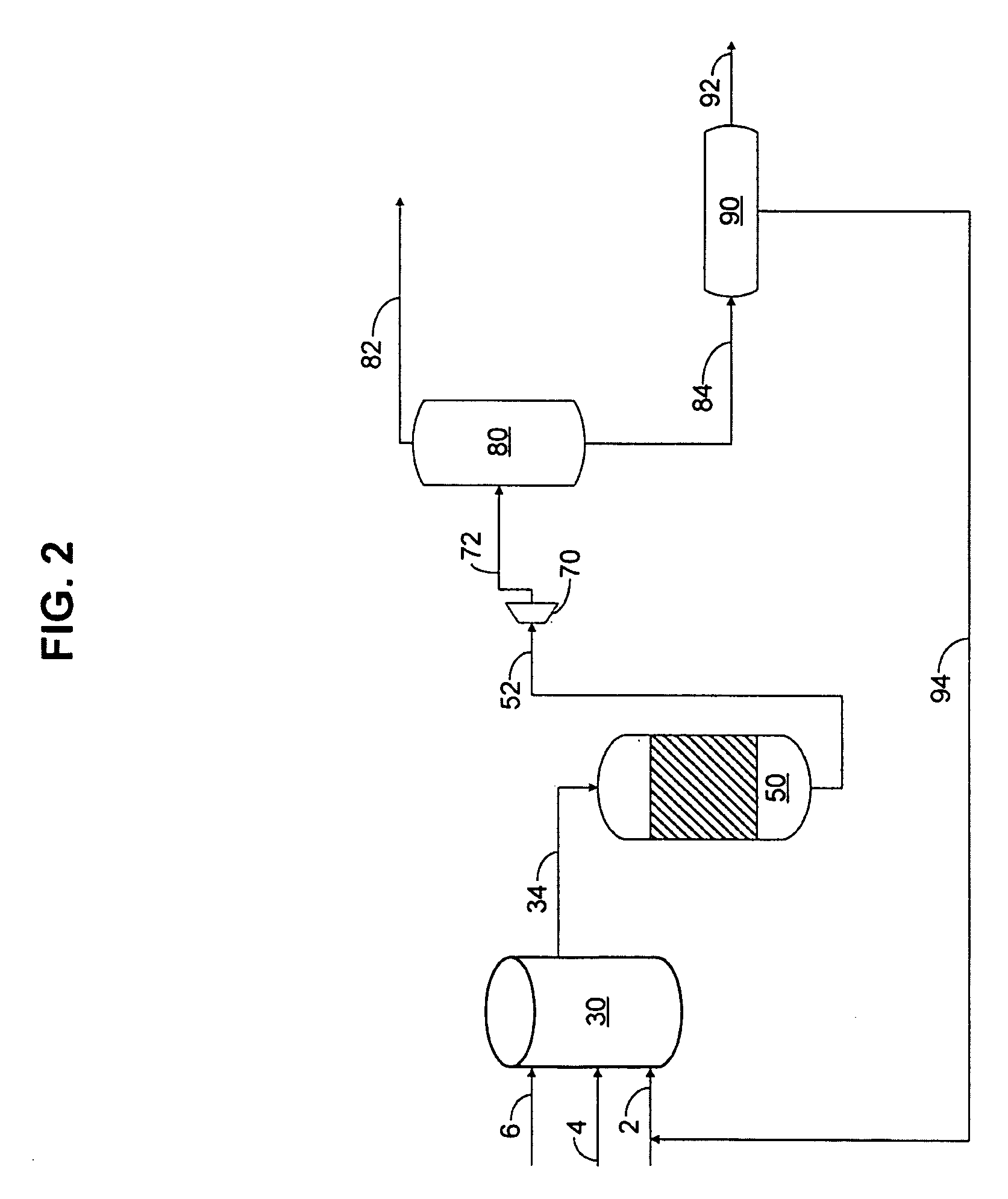

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

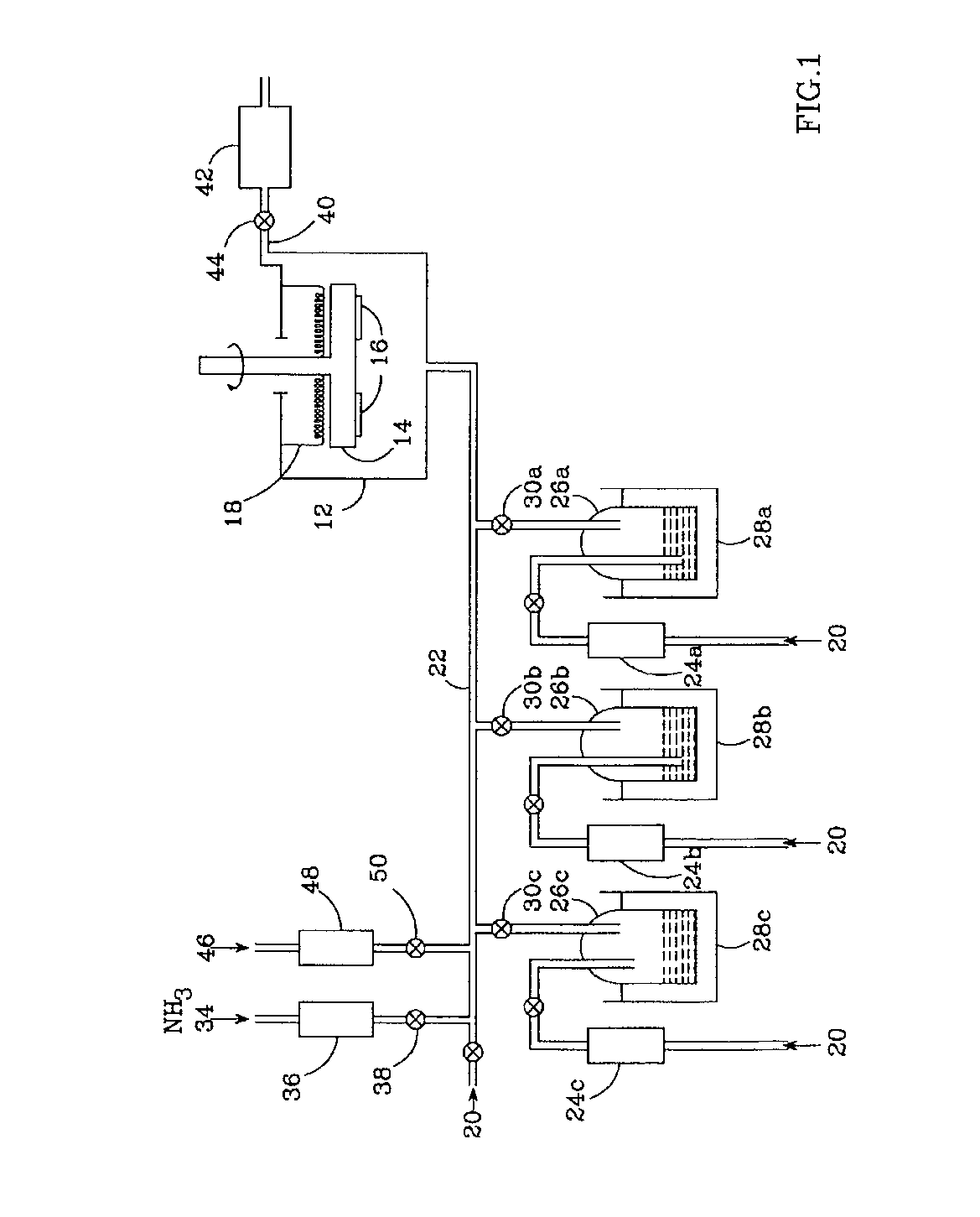

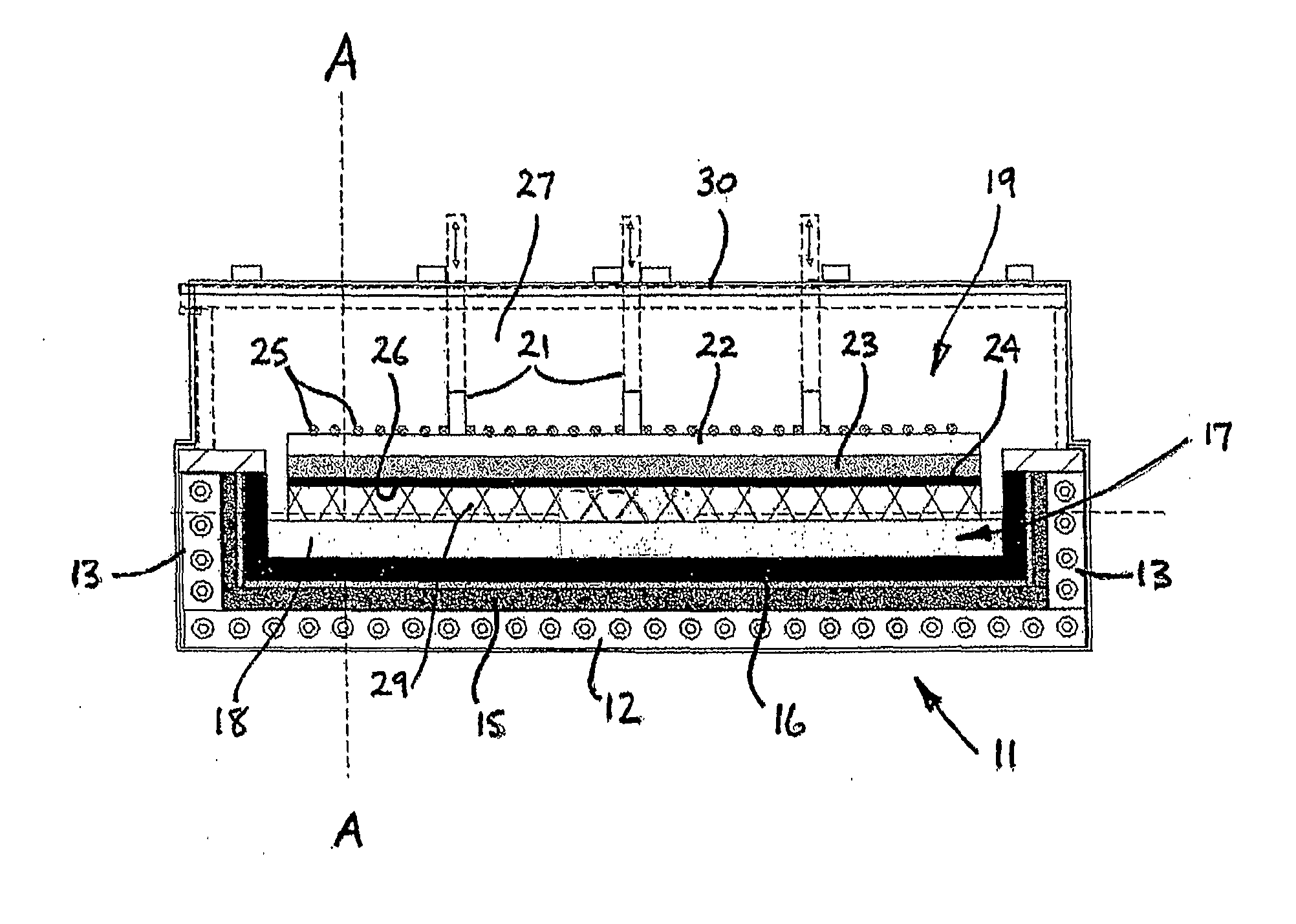

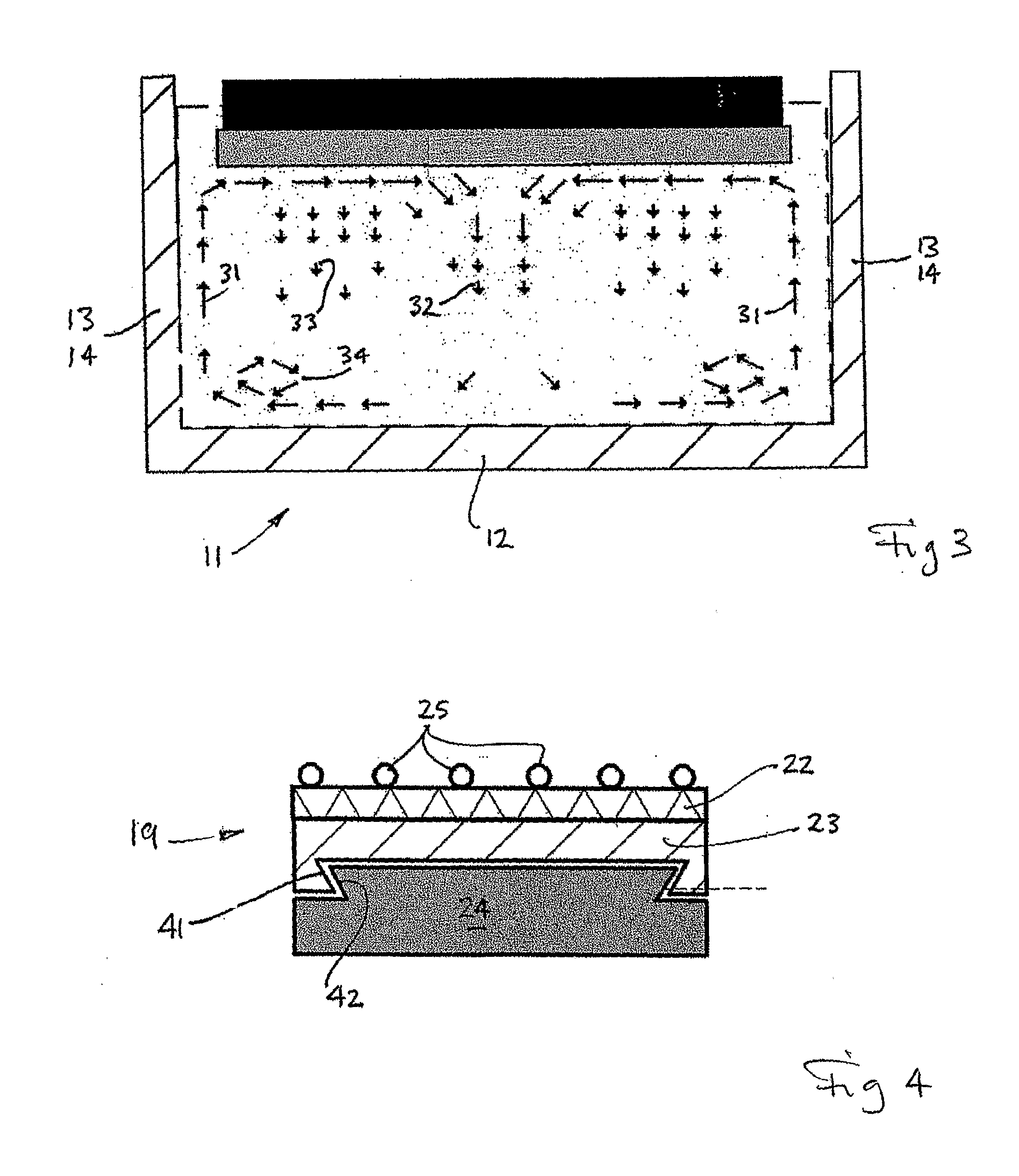

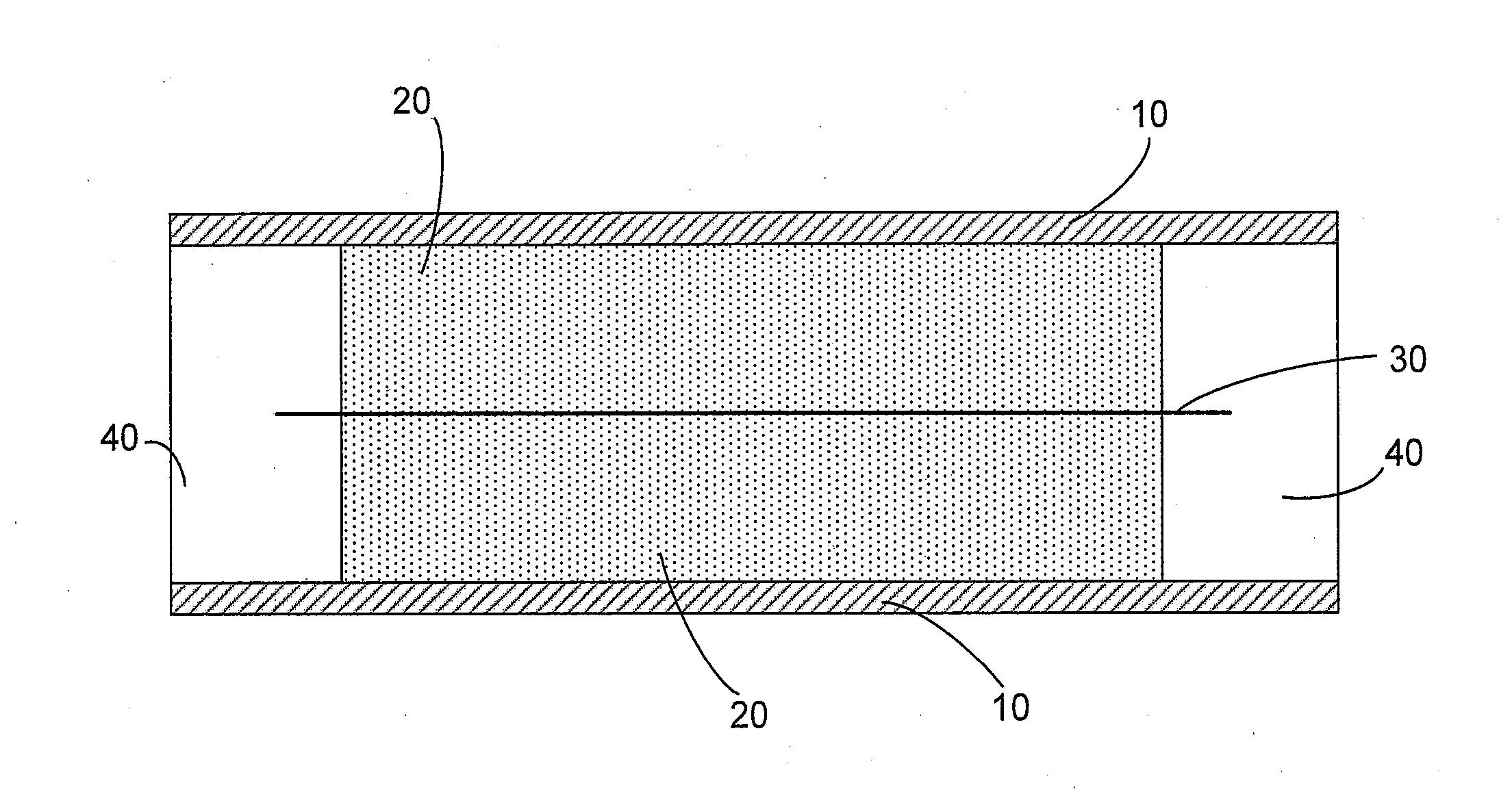

Apparatus for inverted multi-wafer MOCVD fabrication

InactiveUS8133322B2Reduce turbulenceImprove permeabilitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesDopantWafering

A semiconductor fabrication reactor according to the invention comprises a rotatable susceptor mounted to the top of a reactor chamber. One or more wafers are mounted to a surface of the susceptor and the rotation of the susceptor causes the wafers to rotate within the chamber. A heater heats the susceptor and a chamber gas inlet allows semiconductor growth gasses into the reactor chamber to deposit semiconductor material on said wafers. A chamber gas outlet is included to allow growth gasses to exit the chamber. In a preferred embodiment, the inlet is at or below the level of said wafers and the outlet is preferably at or above the level of the wafers. A semiconductor fabrication system according to the invention comprises a source of gasses for forming epitaxial layers on wafers and a source of gasses for dopants in said epitaxial layers. A gas line carries the dopant and epitaxial source gasses to a reactor for growing semiconductor devices on wafers, and the source gasses in the gas line are injected into the reactor chamber through a reactor inlet. The reactor comprises an inverted susceptor mounted in a reactor chamber that is capable of rotating. One or more wafers are mounted to a surface of the susceptor, the rotation of the susceptor causing the wafers to rotate within the chamber. A heater heats the susceptor and the source gasses deposit semiconductor material on the wafers.

Owner:CREE INC

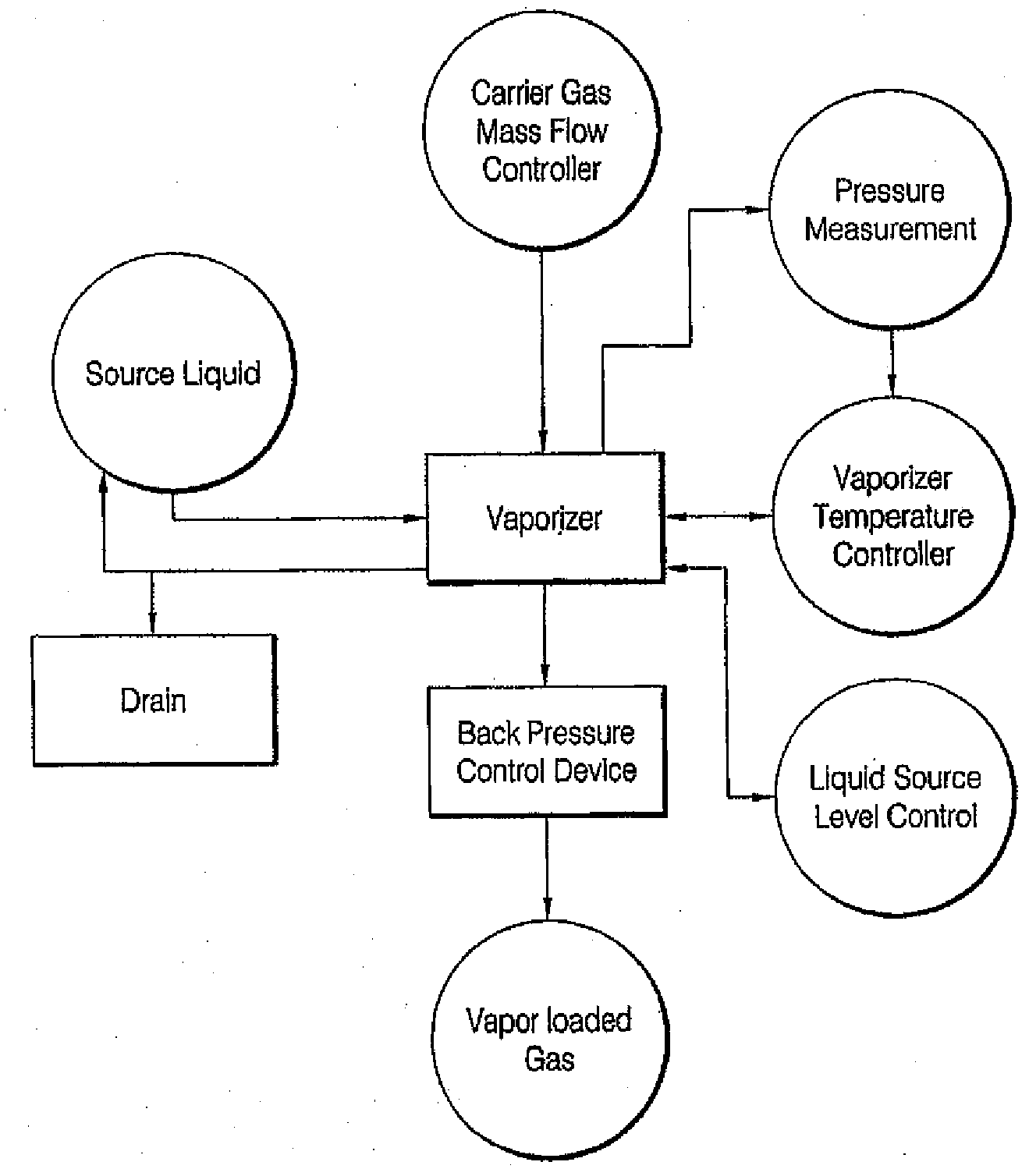

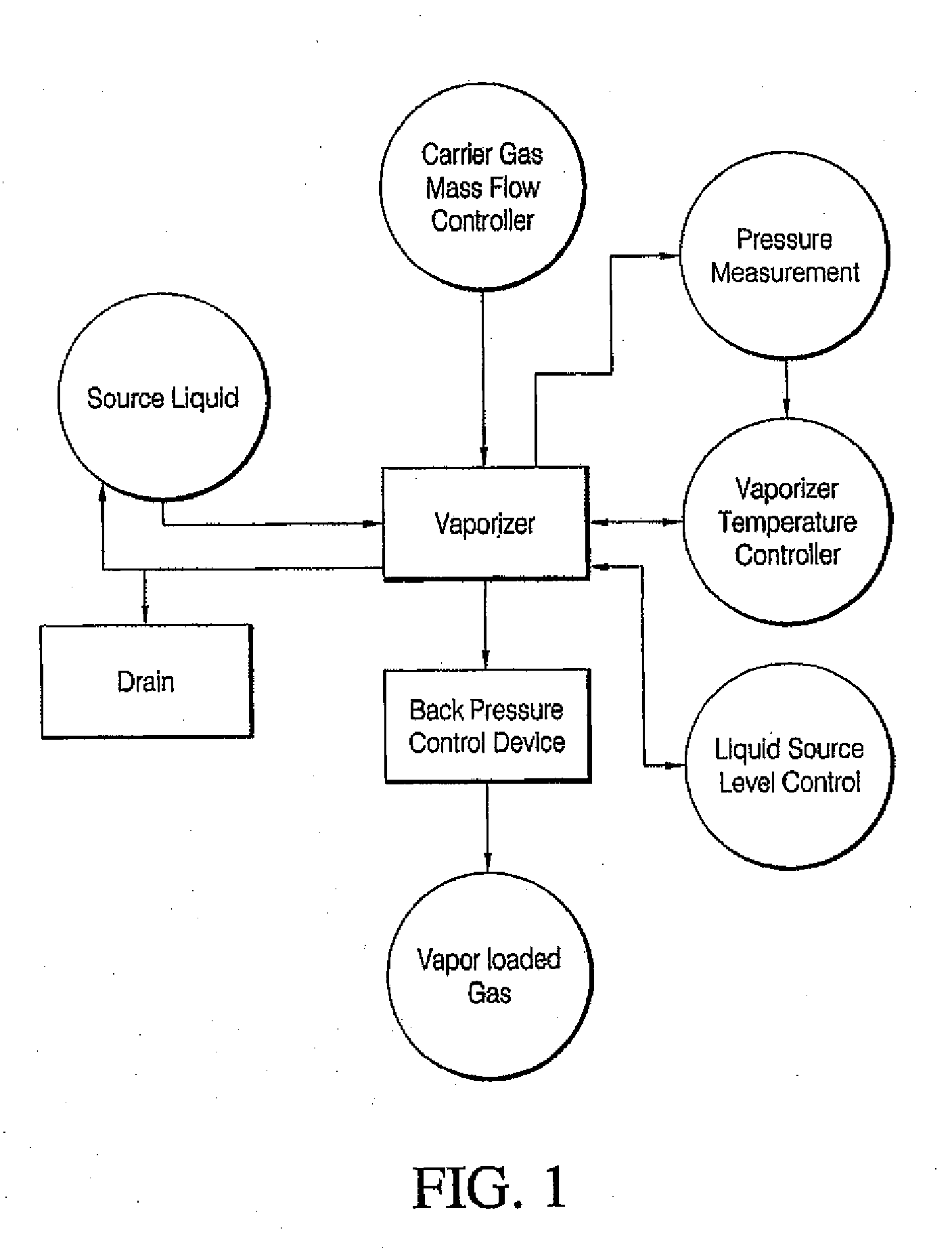

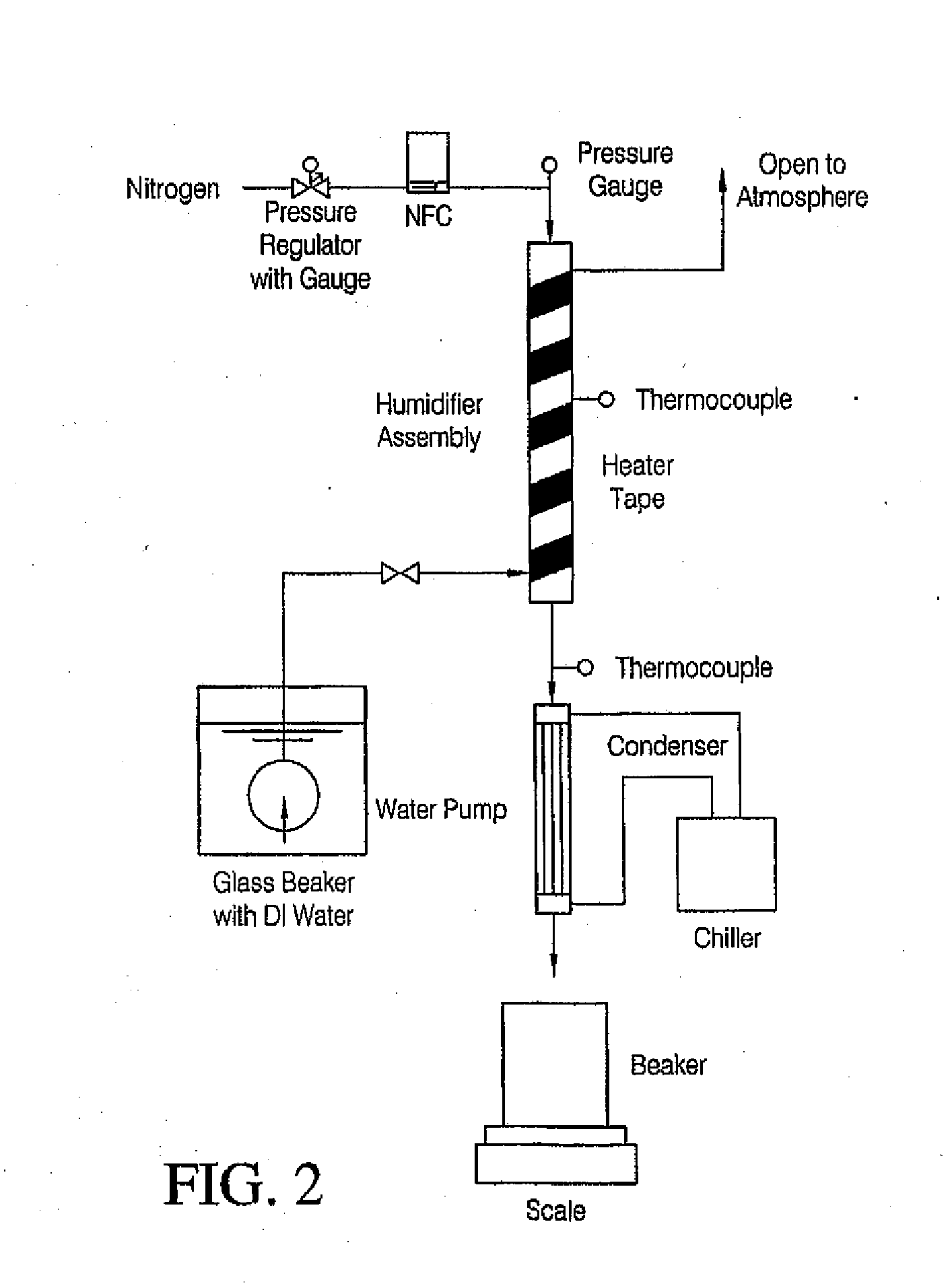

Vaporizer for delivery of low vapor pressure gases

ActiveUS20090014901A1Reduced impurity levelsLimit deliveryLighting and heating apparatusMixing methodsChemistryVapor pressure

Owner:RASIRC

Zinc oxide-based transparent conductor and sputtering target for forming the transparent conductor

ActiveUS7699965B2Reduced impurity levelsDifficult to manufacturePigmenting treatmentLayered productsDopantResource depletion

Proposed is a zinc oxide-based transparent conductor characterized in having zinc oxide as its primary component, containing an element at 1 to 10 atomic % which has a smaller ion radius than zinc in the zinc oxide and serves as an n-type dopant for the zinc oxide, and containing nitrogen in which the atomicity ratio of nitrogen in relation to the n-type dopant (nitrogen / n-type dopant) is 0.3 to 0.6. In the development of a transparent conductor that does not contain In, which is an expensive raw material with concern of resource depletion, the limit of the conventional development technique known as the single-dopant method is exceeded, a guide to dopant selection as a specific means for realizing the co-doping theory is indicated, and a transparent conductor having low resistivity is provided.

Owner:JX NIPPON MINING & METALS CORP

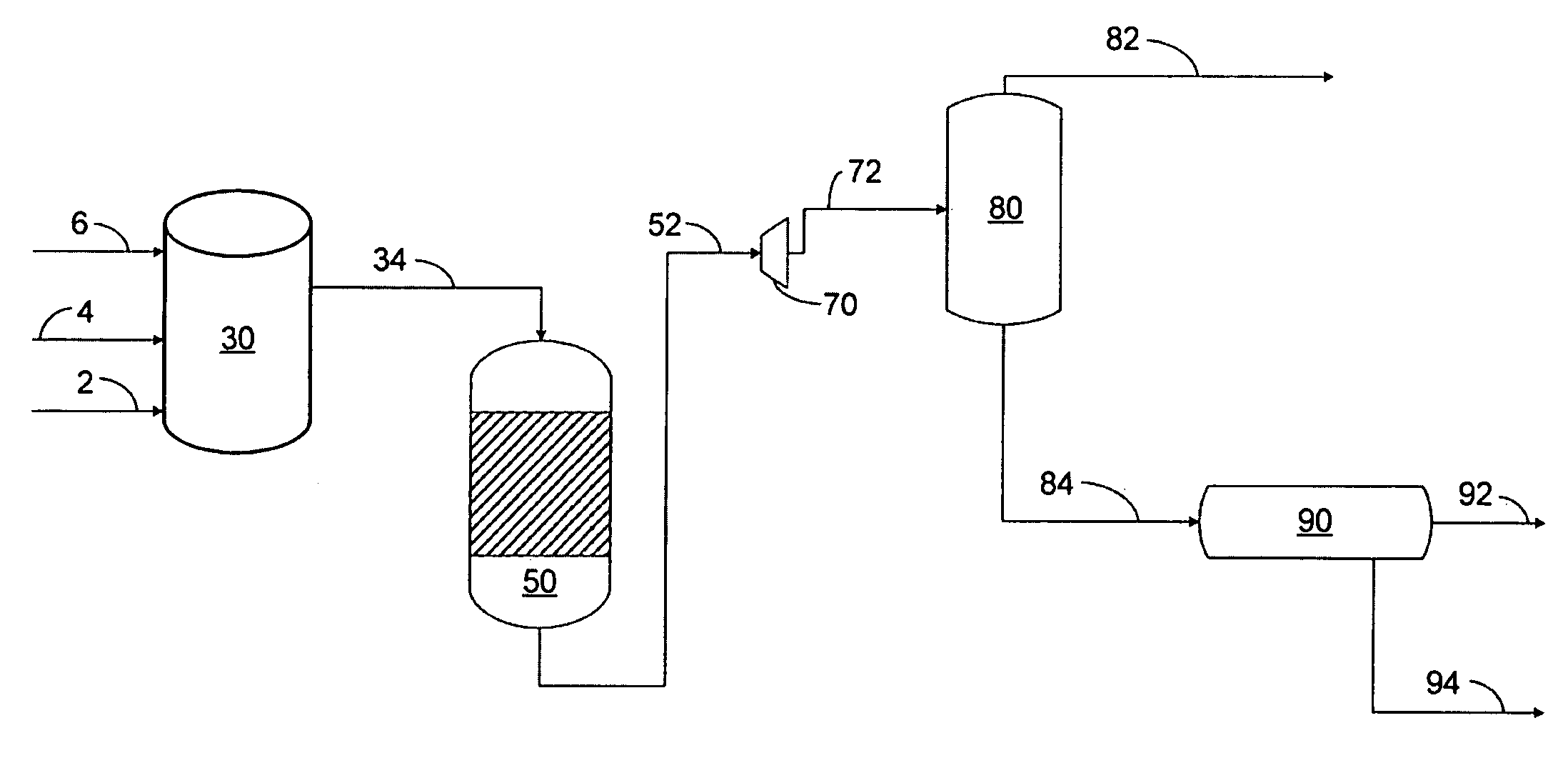

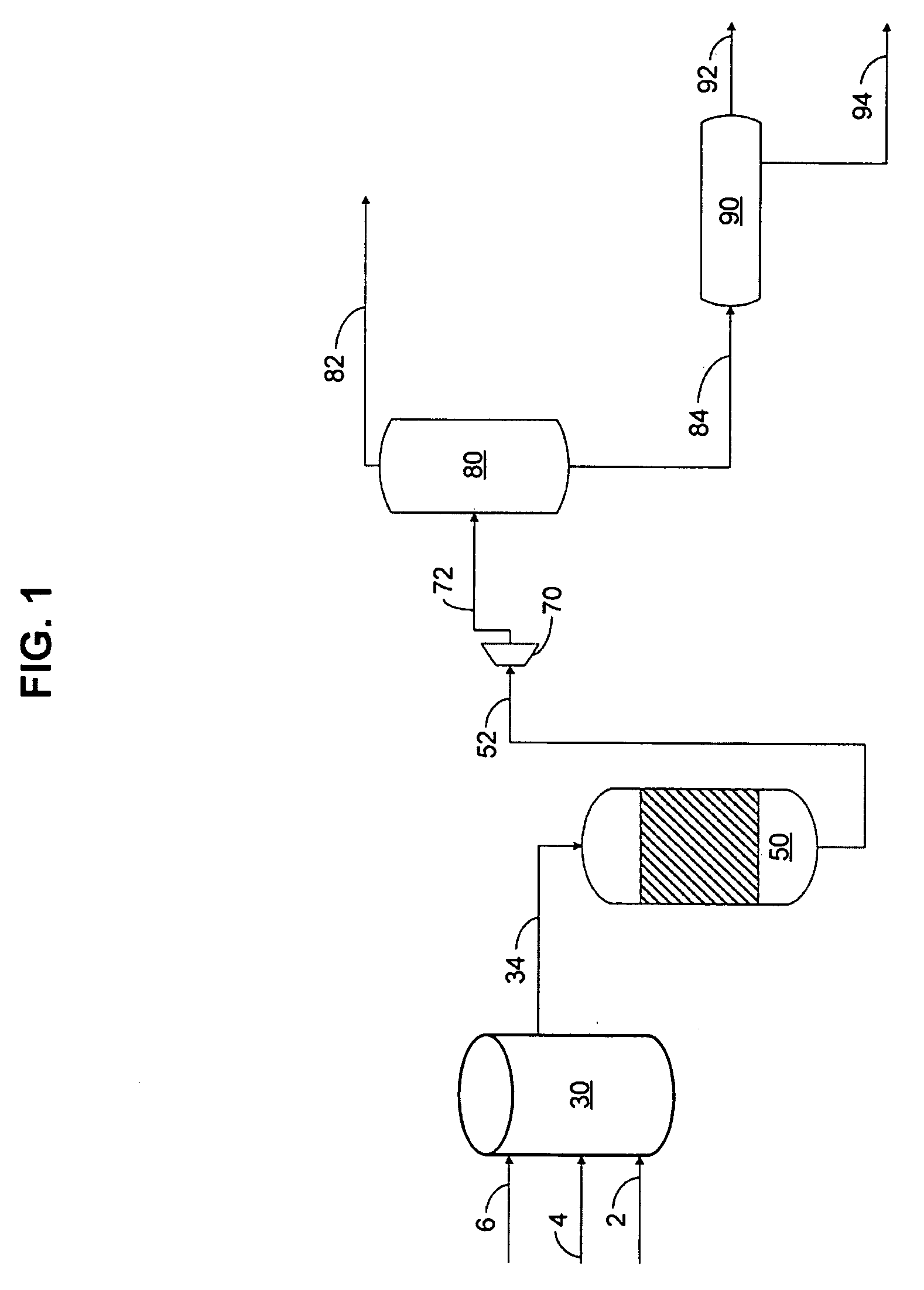

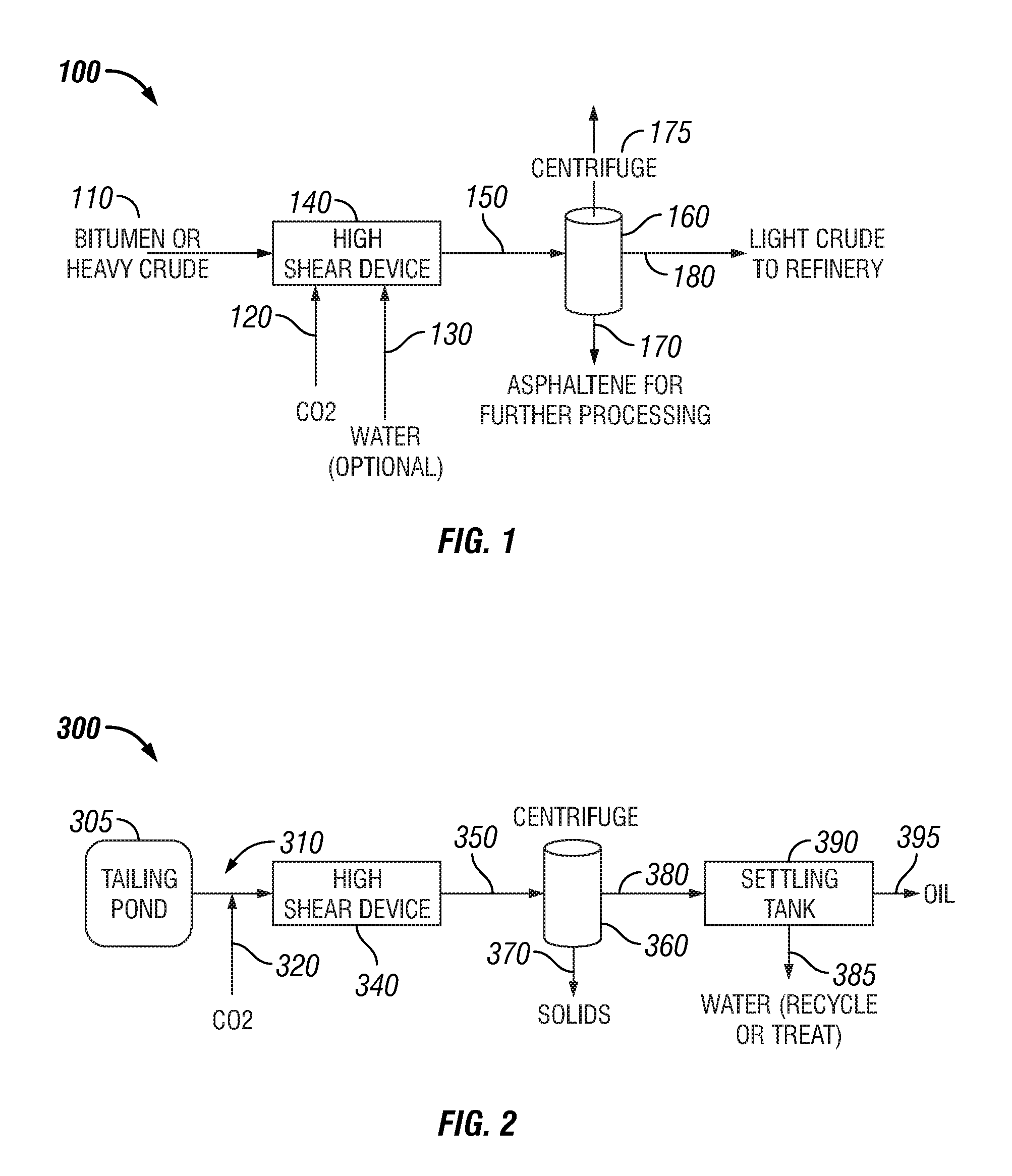

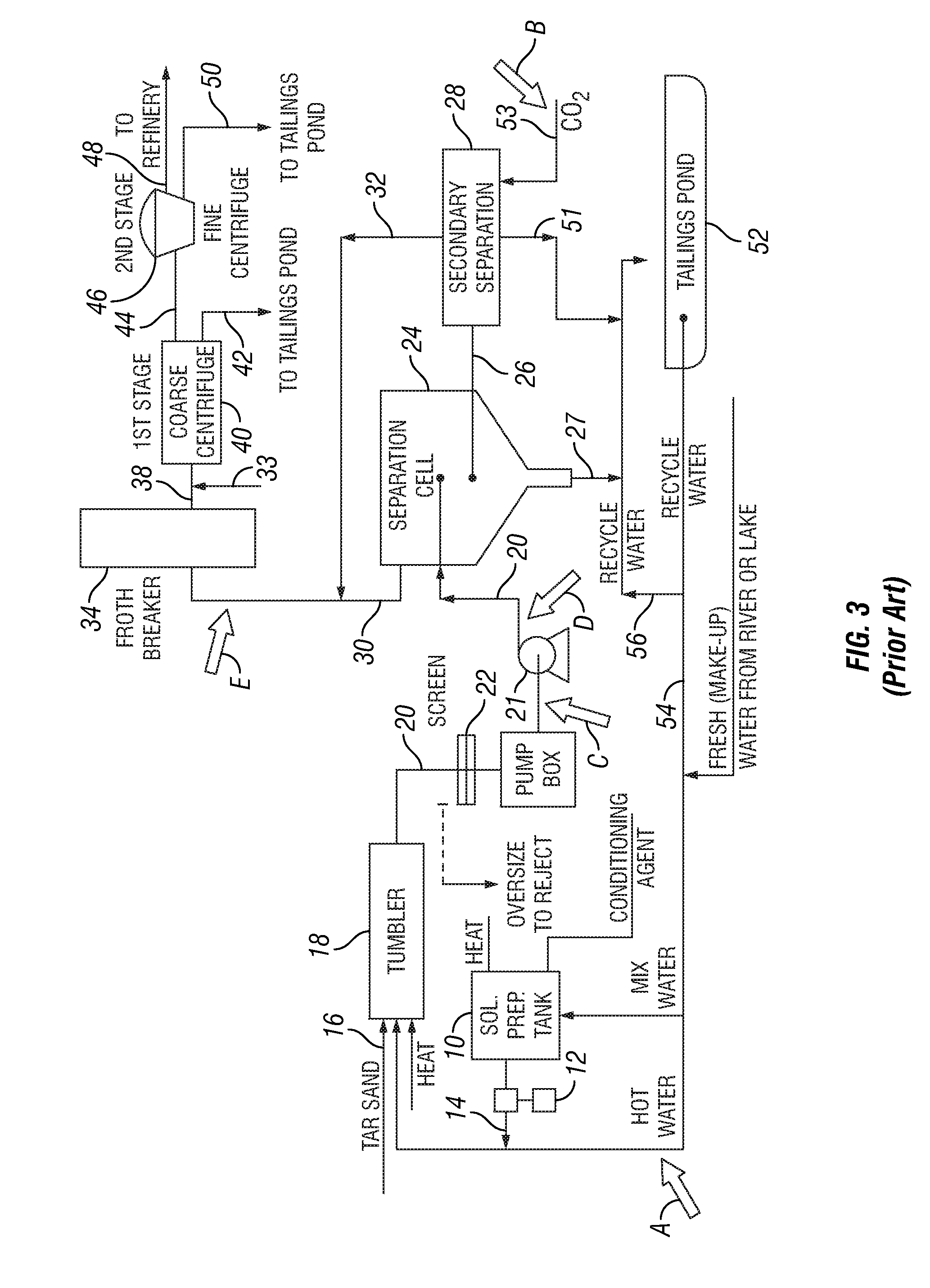

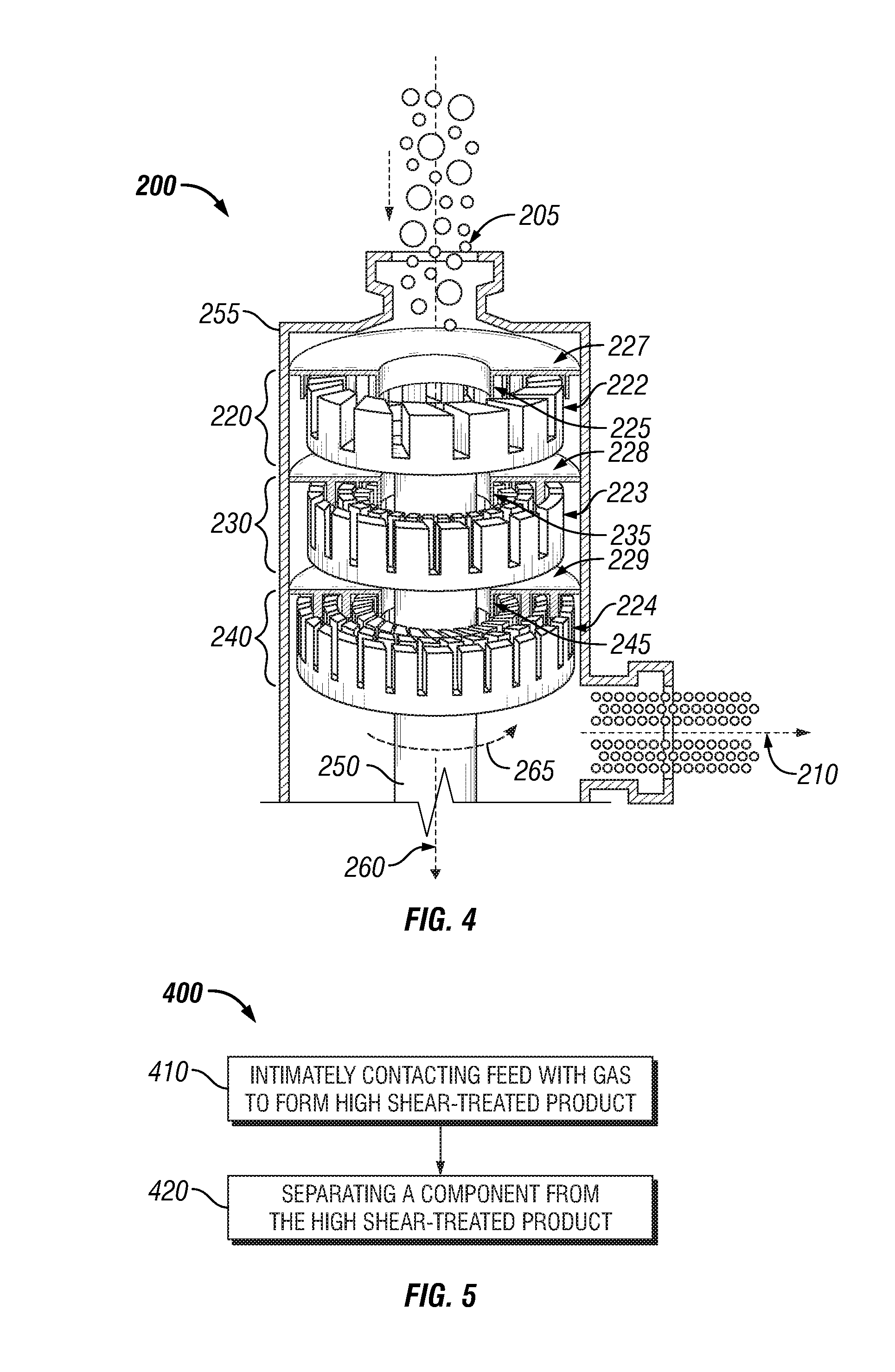

Bitumen extraction and asphaltene removal from heavy crude using high shear

InactiveUS20110266198A1Promote recoverySimple processLiquid hydrocarbon mixture productionFlotationShear rateComponents of crude oil

Herein disclosed is a method of removing at least one component from a feed by subjecting the feed to high shear in the presence of carbon dioxide to produce a high shear-treated product and separating the at least one component from the high shear-treated product to produce a component-reduced product. Also disclosed is a method of removing asphaltenes from asphaltenic oil by subjecting the asphaltenic oil to a shear rate of at least 10,000 s−1 in the presence of carbon dioxide to produce a high shear-treated product and separating asphaltenes from the high shear-treated product to produce an asphaltene-reduced product oil. Systems are also provided for carrying out the methods.

Owner:HRD CORP

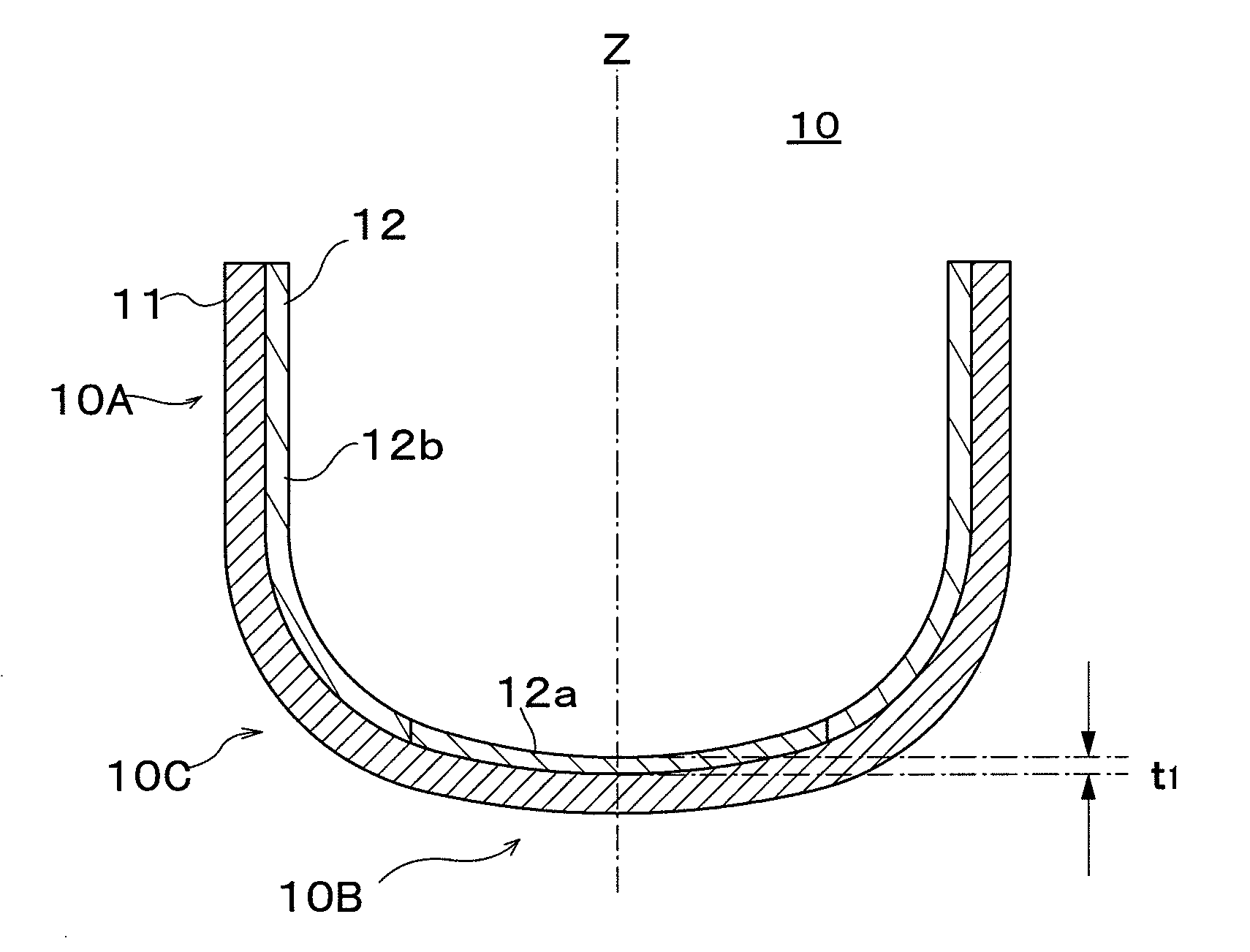

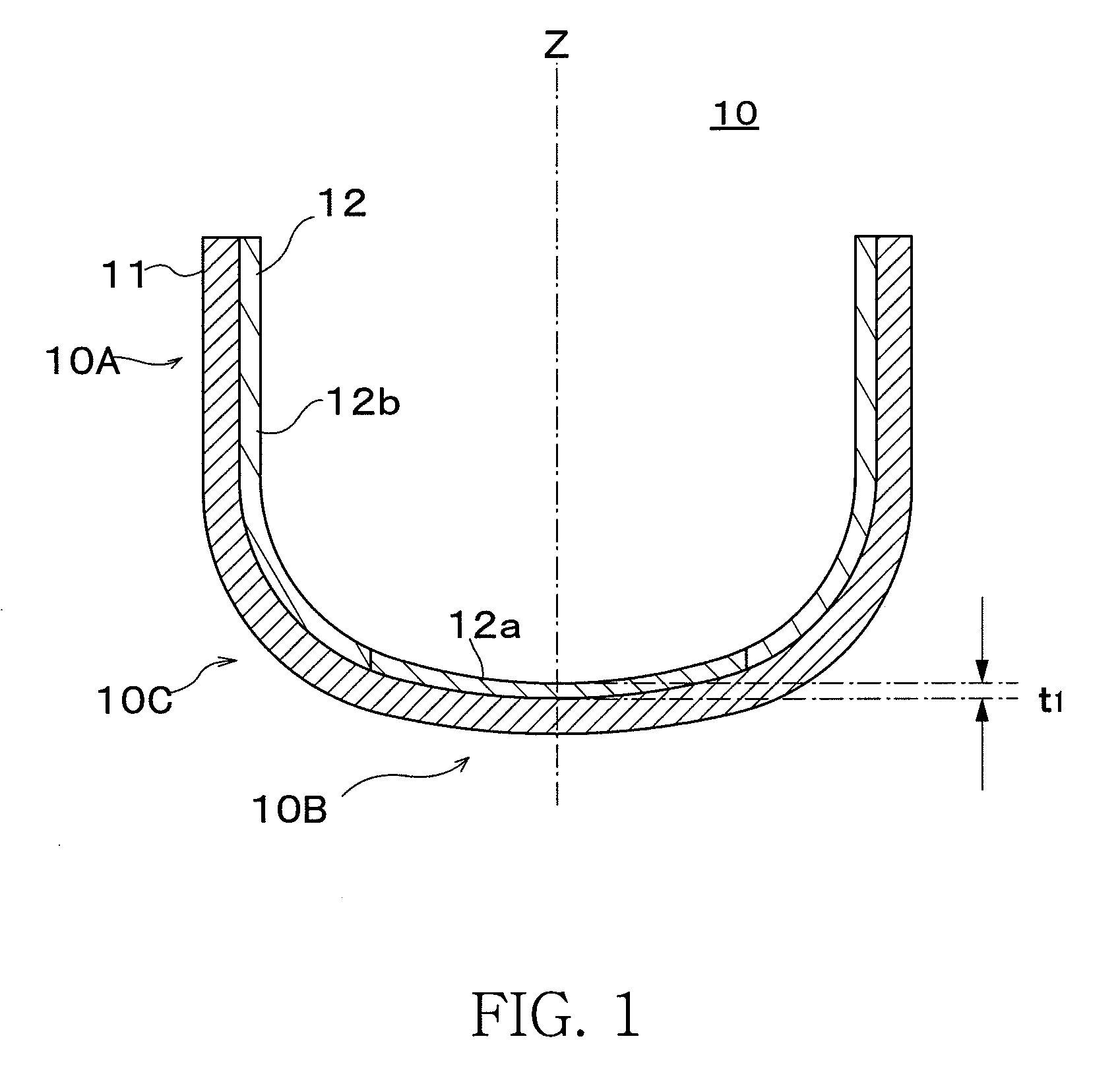

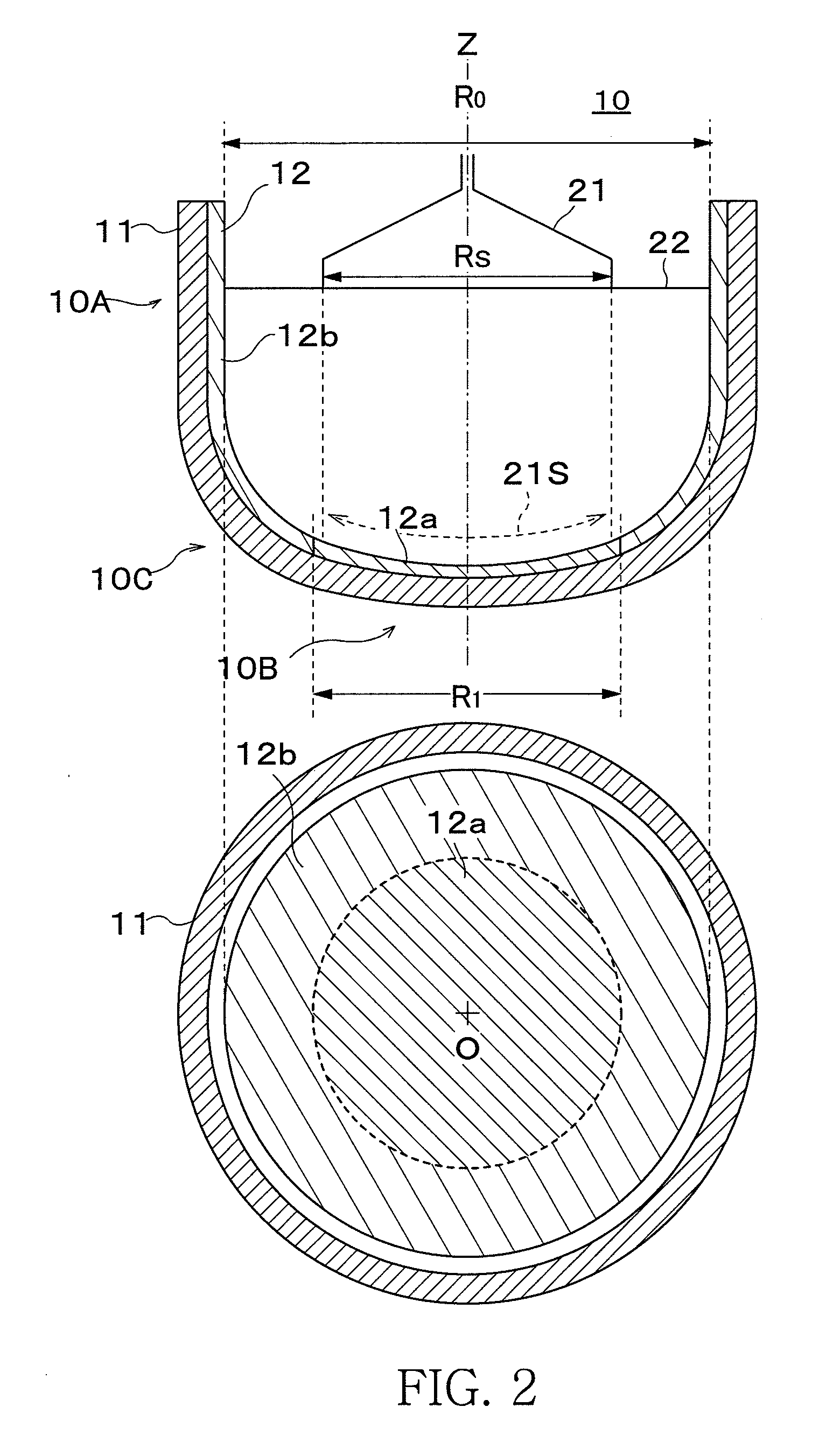

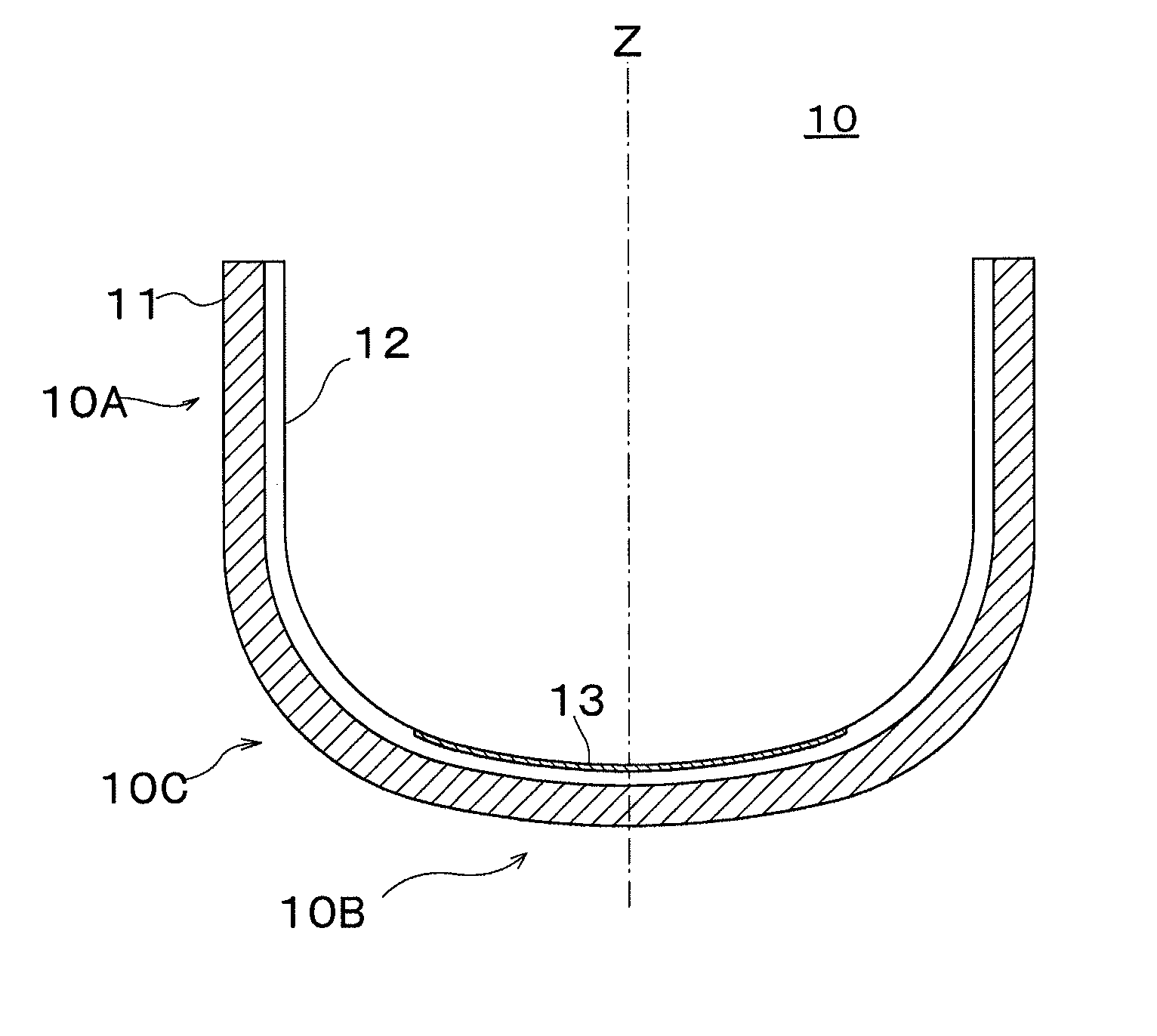

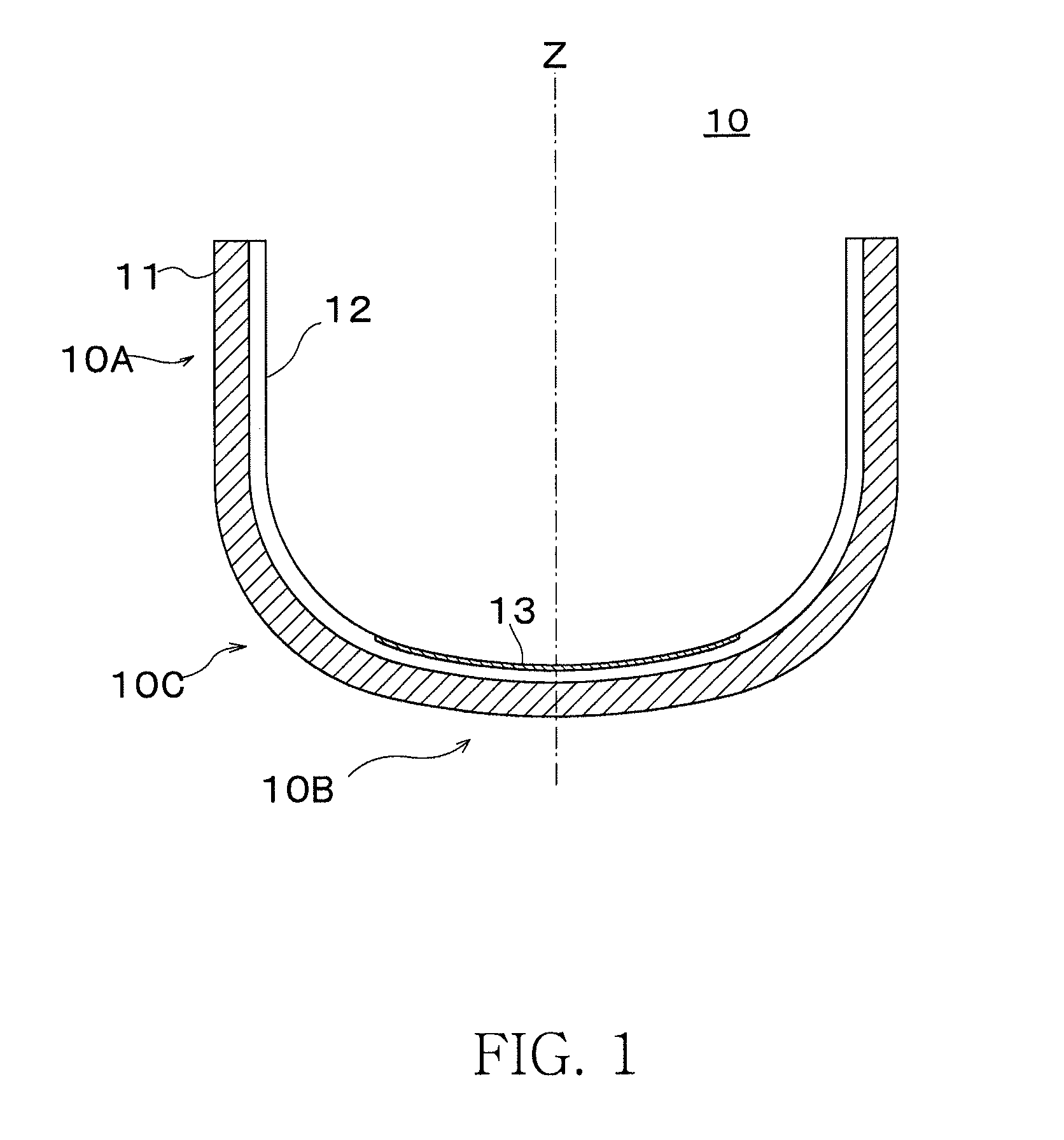

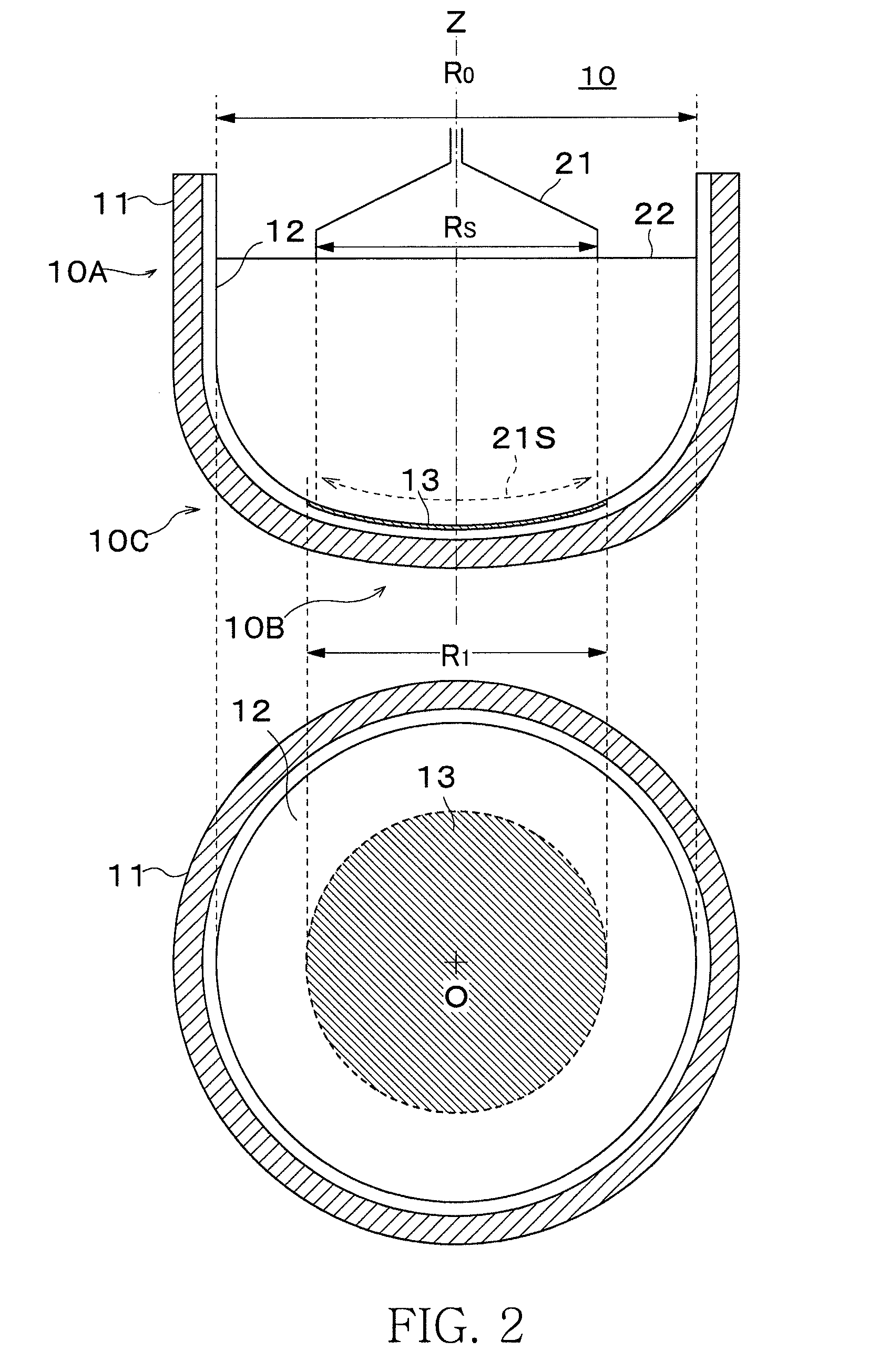

Silica glass crucible for pulling up silicon single crystal and method for manufacturing thereof

ActiveUS20100147213A1Avoid it happening againQuality improvementPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

A silica glass crucible for pulling up a silicon single crystal including an outer layer formed from a natural silica glass layer, and an inner layer formed from a synthetic silica glass layer, wherein the synthetic silica glass layer includes a first synthetic silica glass layer formed in a region within a certain range from the center of a crucible bottom section, and a second synthetic silica glass layer formed in a region which excludes the formation region of the first synthetic silica glass layer, and wherein the first synthetic silica glass layer has a thickness of 0.5 mm or more and 1.5 mm or less and a concentration of an OH group included in the first synthetic silica glass layer being 100 ppm or less.

Owner:SUMCO CORP

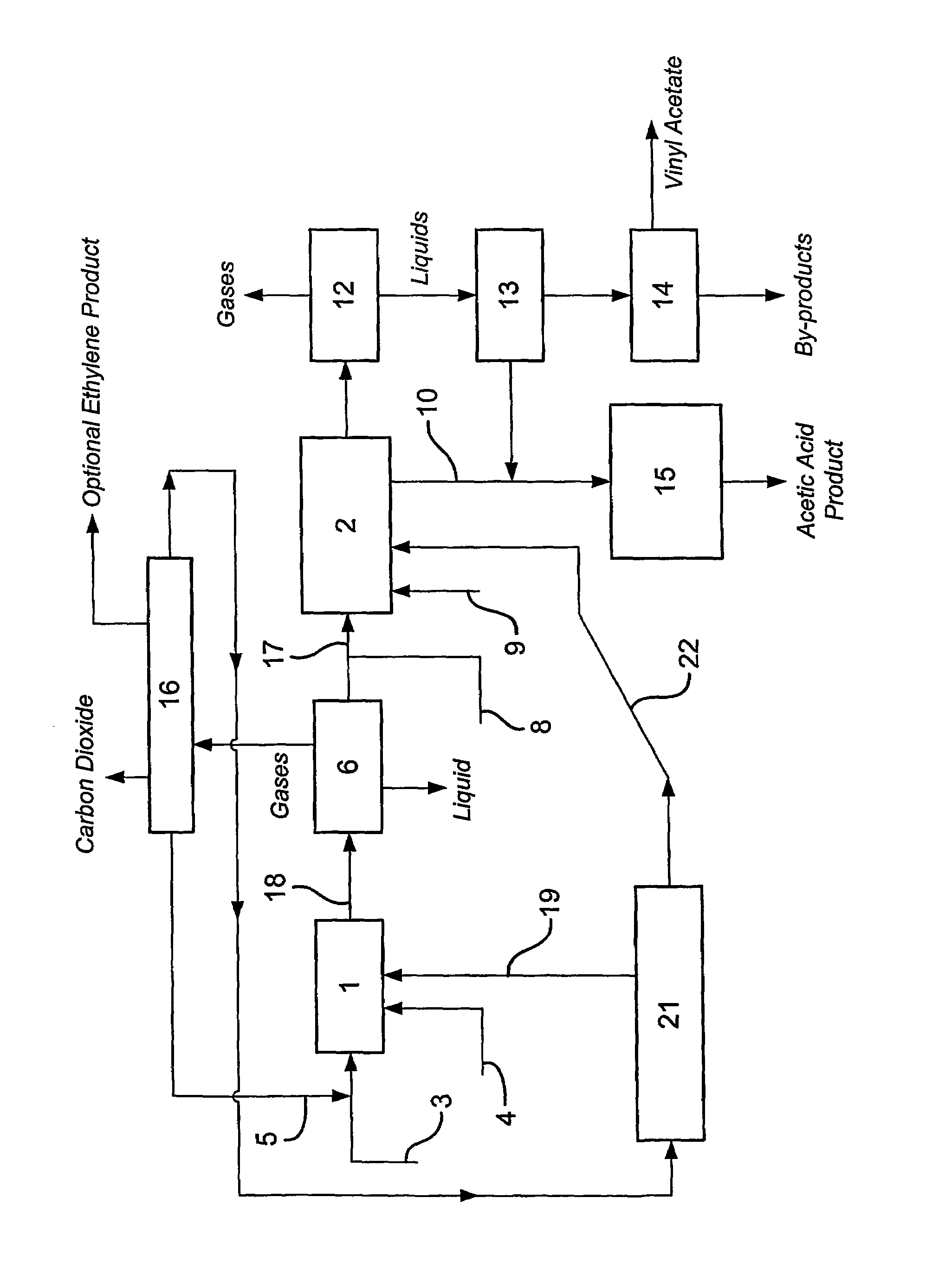

Process for the production of an alkenyl carboxylate or an alkyl carboxylate

InactiveUS7211688B2Optimal process efficiencyMaximize selectivityOrganic compound preparationOrganic chemistry methodsCarboxylateAlkene

Process for producing an alkyl carboxylate, comprising contacting in an oxidation reaction zone a C2 to C4 alkane, a molecular oxygen-containing gas, the corresponding alkene and optionally water, in the presence of at least one catalyst active for the oxidation of the alkane to the corresponding alkene and carboxylic acid, to produce a first product stream comprising alkene, unreacted alkane, carboxylic acid and water; separating in a first separation means at least a portion of the product stream produced in the oxidation reaction zone into a gaseous stream comprising alkene and unreacted alkane and a liquid stream comprising carboxylic acid and water; and separating by chemical treatment at least a portion of the gaseous stream obtained from the first separation means into respective streams rich in alkene and alkane; wherein the chemical treatment comprises the steps of: (1) contacting the alkene / alkane gaseous stream with a solution of a metal salt capable of selectively chemically absorbing the alkene to produce a chemically absorbed alkene-rich liquid stream, and (2) recovering an alkene rich stream from the metal salt solution. In a second reaction zone, at least a portion of the alkene rich stream obtained from the second separation means and a corresponding carboxylic acid are contacted, in the presence of at least one catalyst active for the production of alkyl carboxylate, to produce a second product stream comprising alkyl carboxylate.

Owner:THE BRITISH PETROLEUM CO LTD

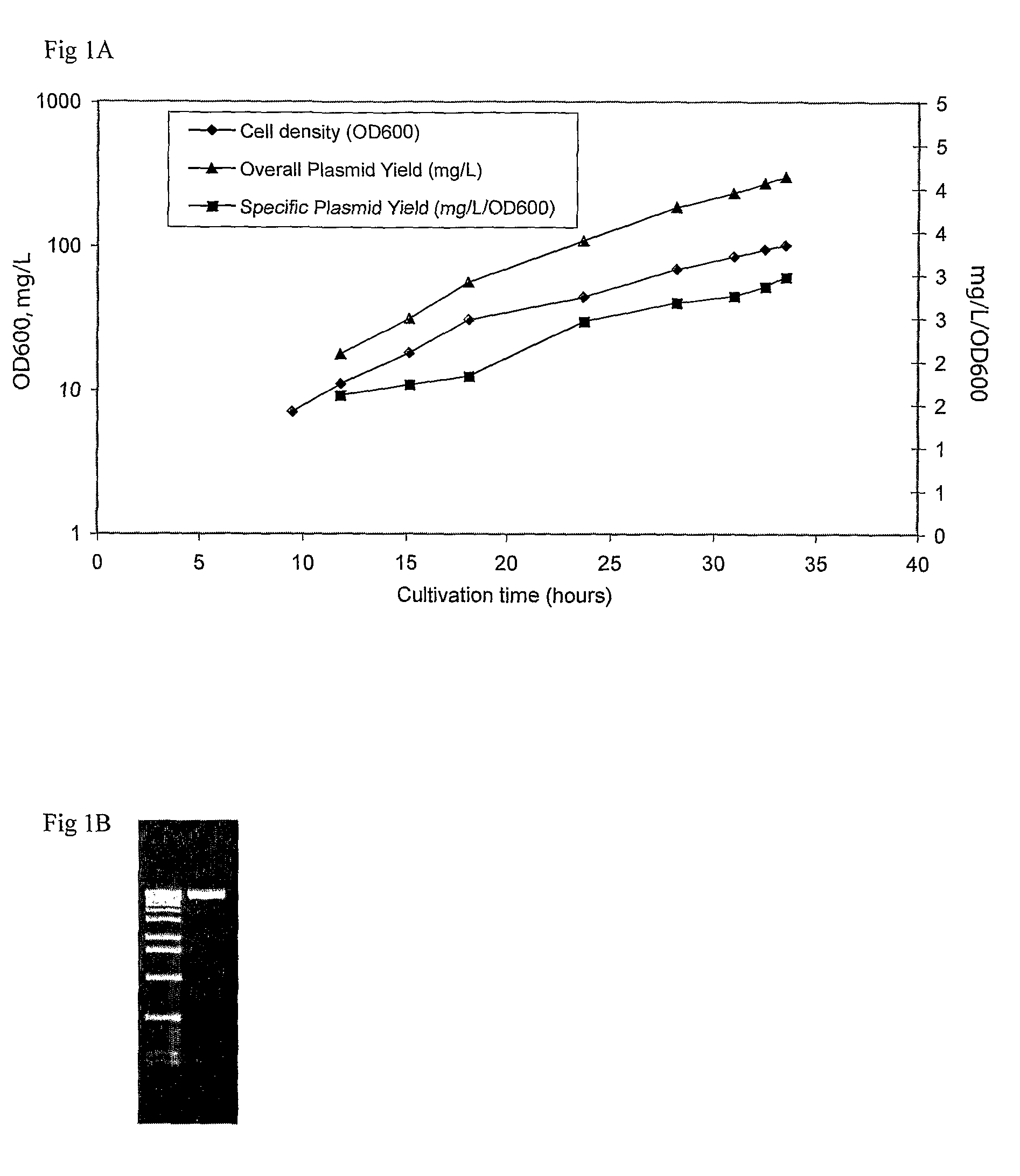

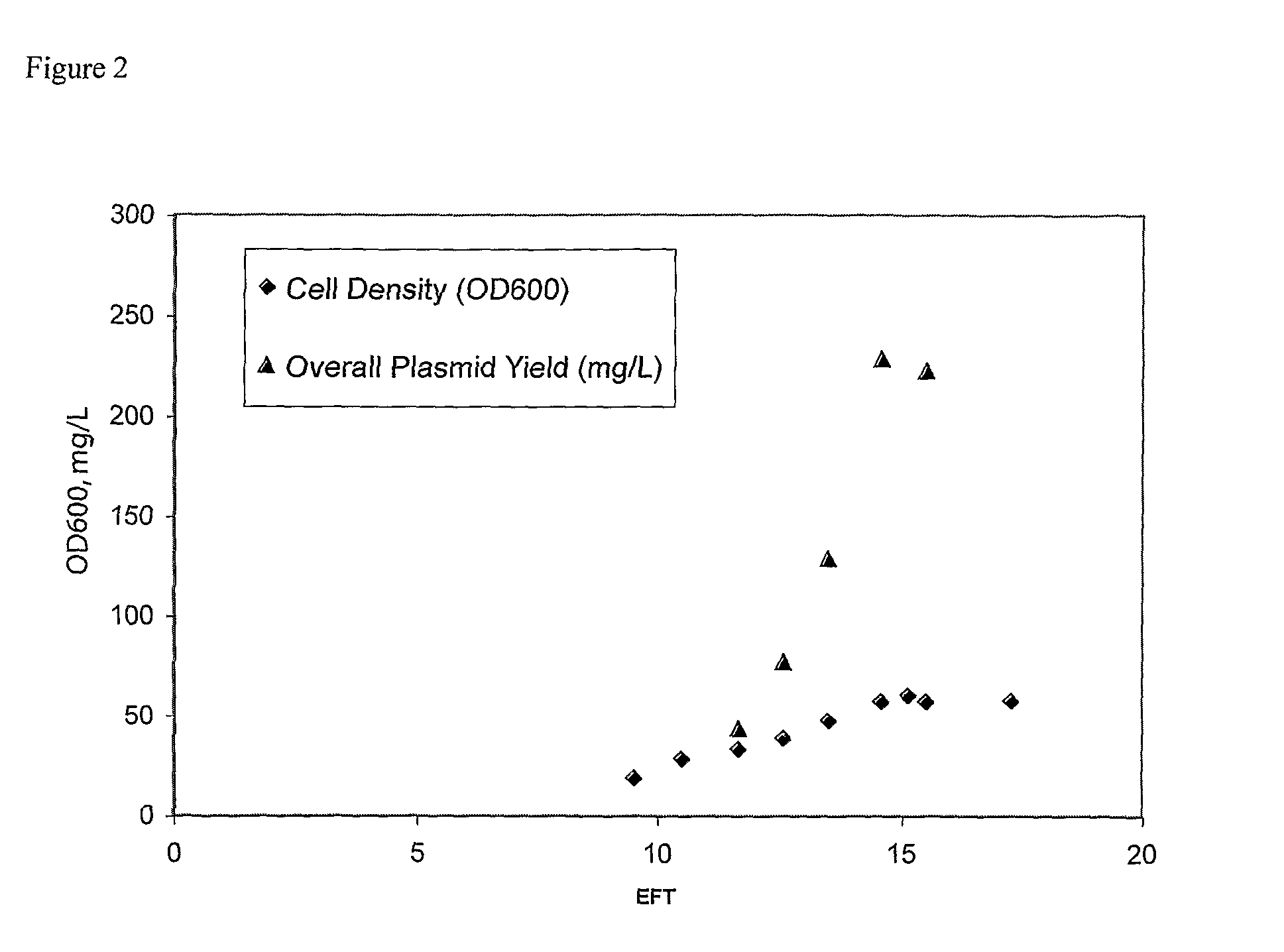

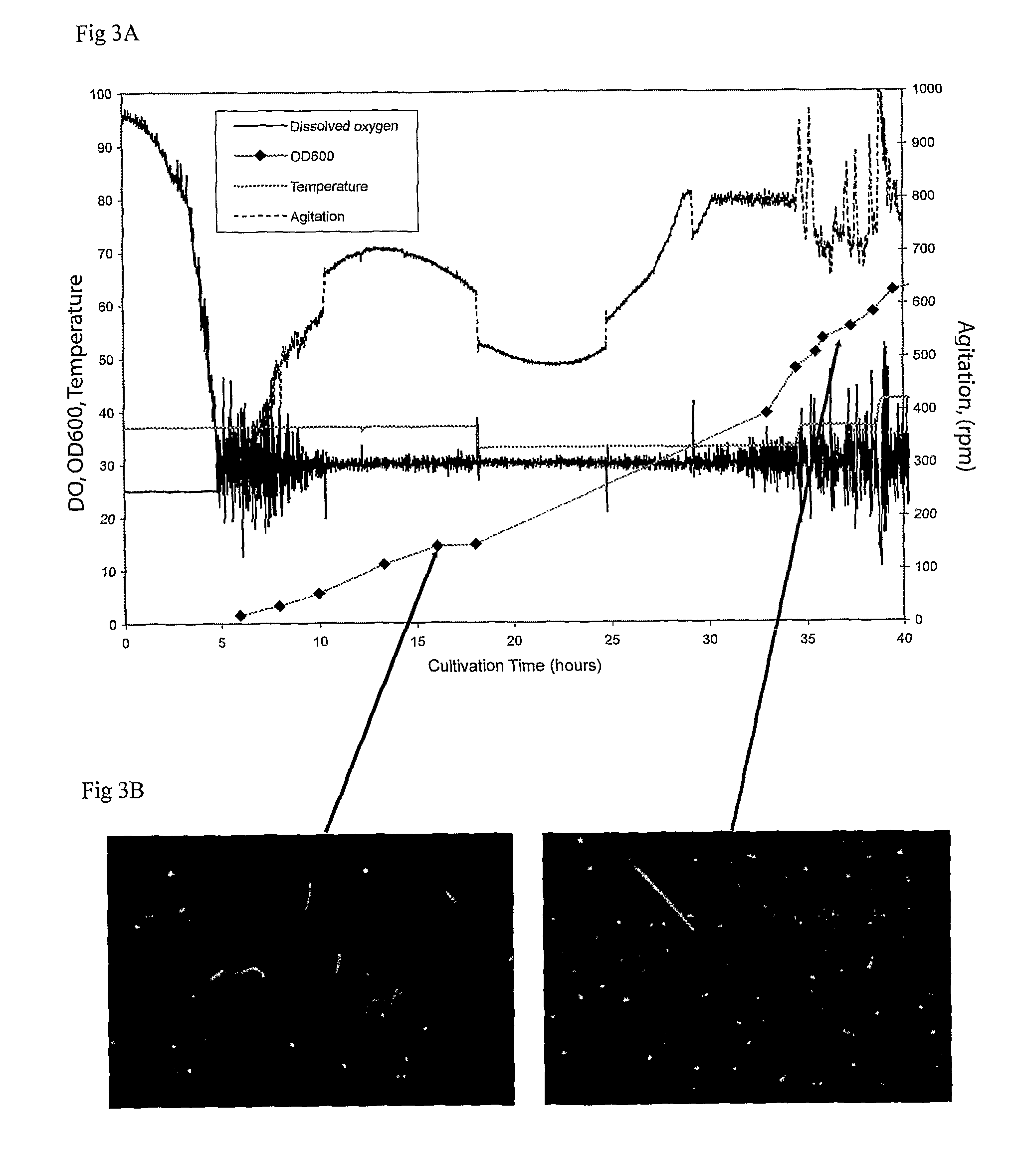

Process for plasmid DNA fermentation

ActiveUS7943377B2Improve plasmid DNA production yieldImprove plasmid DNA qualityGenetic therapy composition manufactureTissue cultureBatch fermentationPlasmid dna

Improvements in plasmid DNA production technology are needed to insure the economic feasibility of future DNA vaccines and DNA therapeutics. General methods are described, by means of which it is possible to dramatically increase plasmid DNA productivity in a fermentor. These processes feature Fed-batch fermentation strategies, combined with novel growth and induction phase temperature shifts.

Owner:ALDEVRON LLC

Method And Apparatus For Refining A Molten Material

ActiveUS20080196209A1Nucleation is simplifiedReduced impurity levelsBy zone-melting liquidsBy pulling from meltIngotDirectional solidification

Owner:REC SOLAR NORWAY AS

Electrodes Synthesized from Carbon Nanostructures Coated with a Smooth and Conformal Metal Adlayer

InactiveUS20130045328A1High reactivityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructureHigh surface area

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by a surface preparation process involving immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing a suitable quantity of non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means. The nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. The process can be controlled and repeated to obtain a desired film coverage. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

Platinum-based electrocatalysts synthesized by depositing contiguous adlayers on carbon nanostructures

InactiveUS8404613B2High reactivityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

Owner:BROOKHAVEN SCI ASSOCS

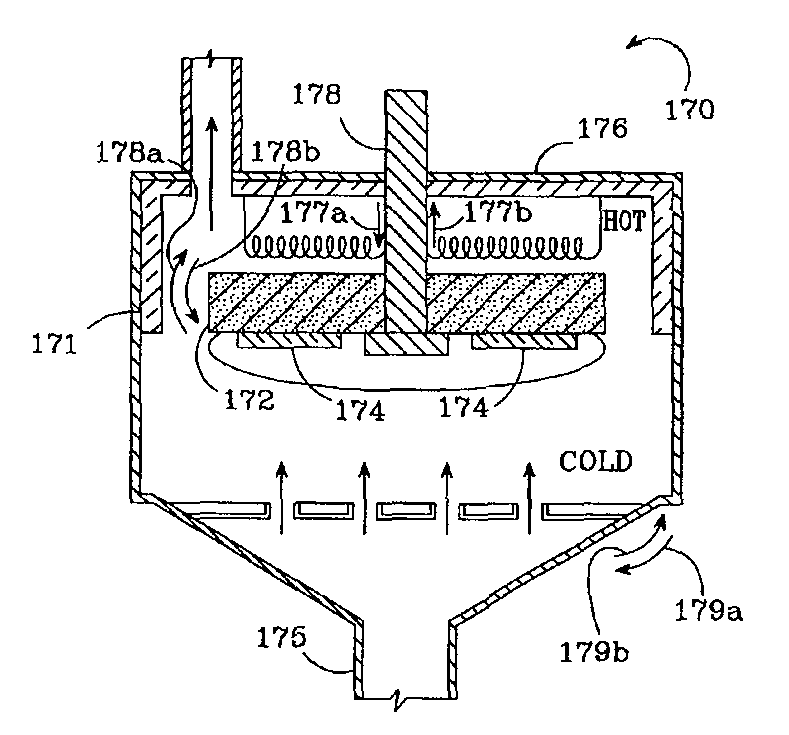

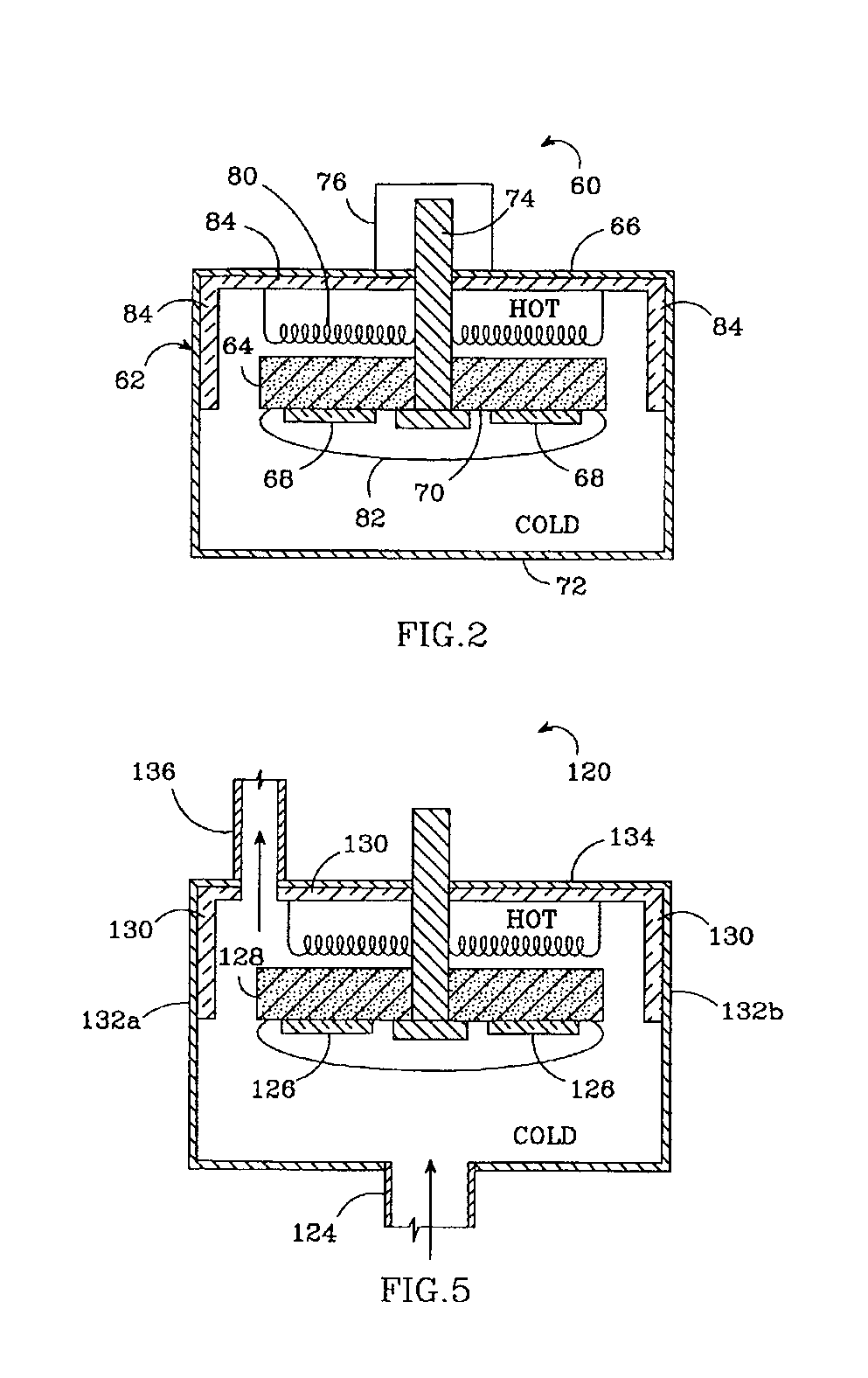

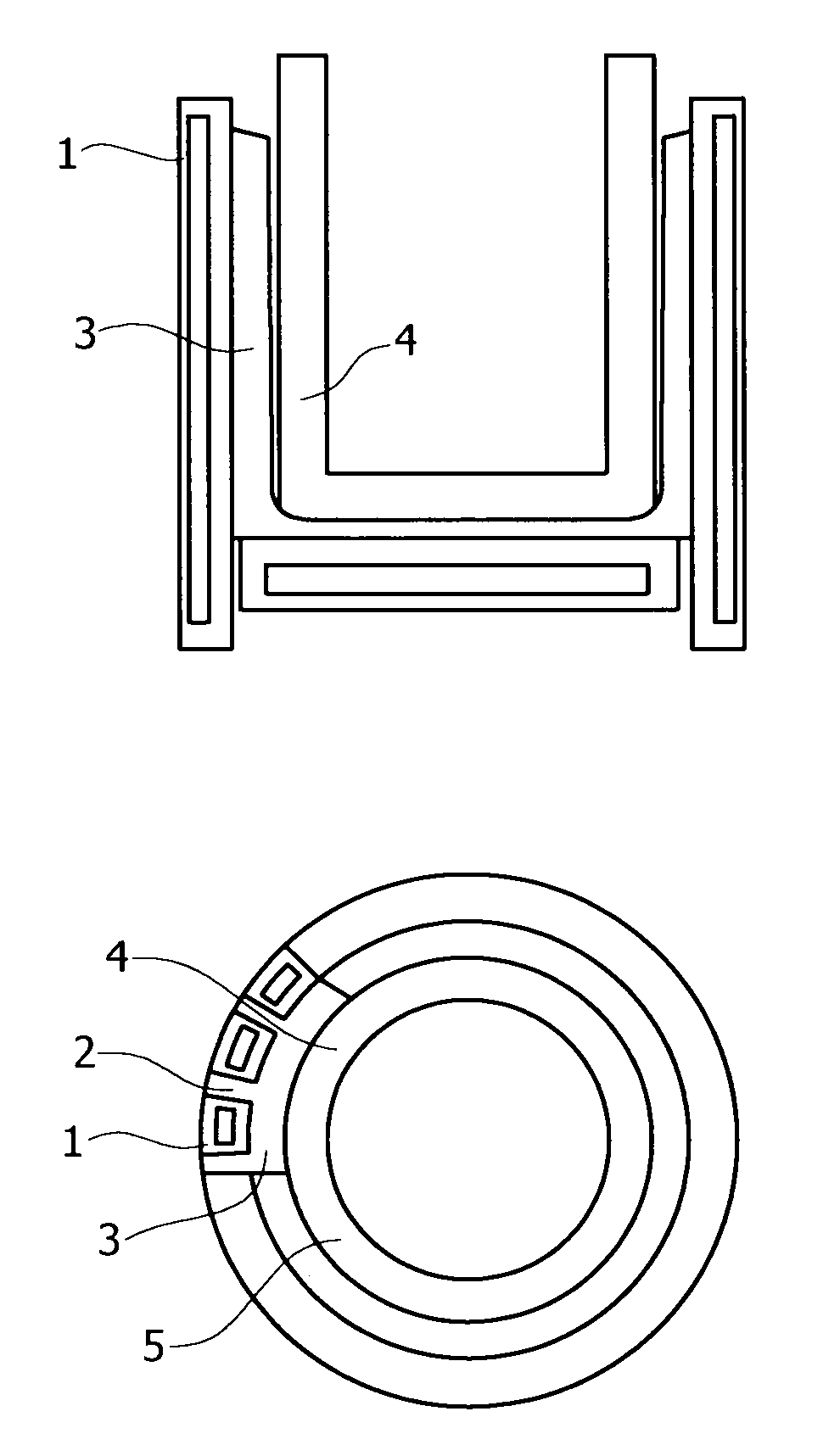

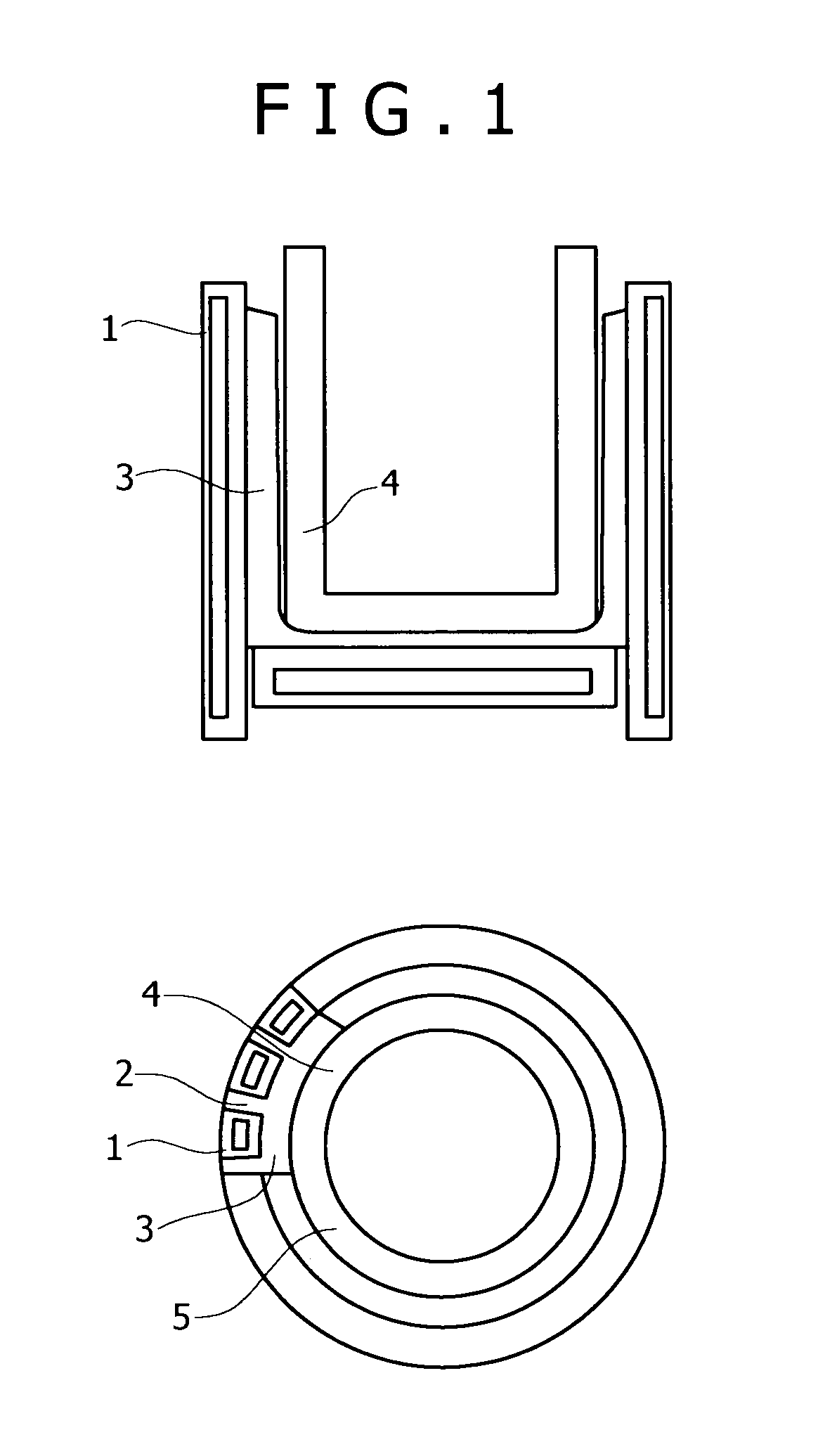

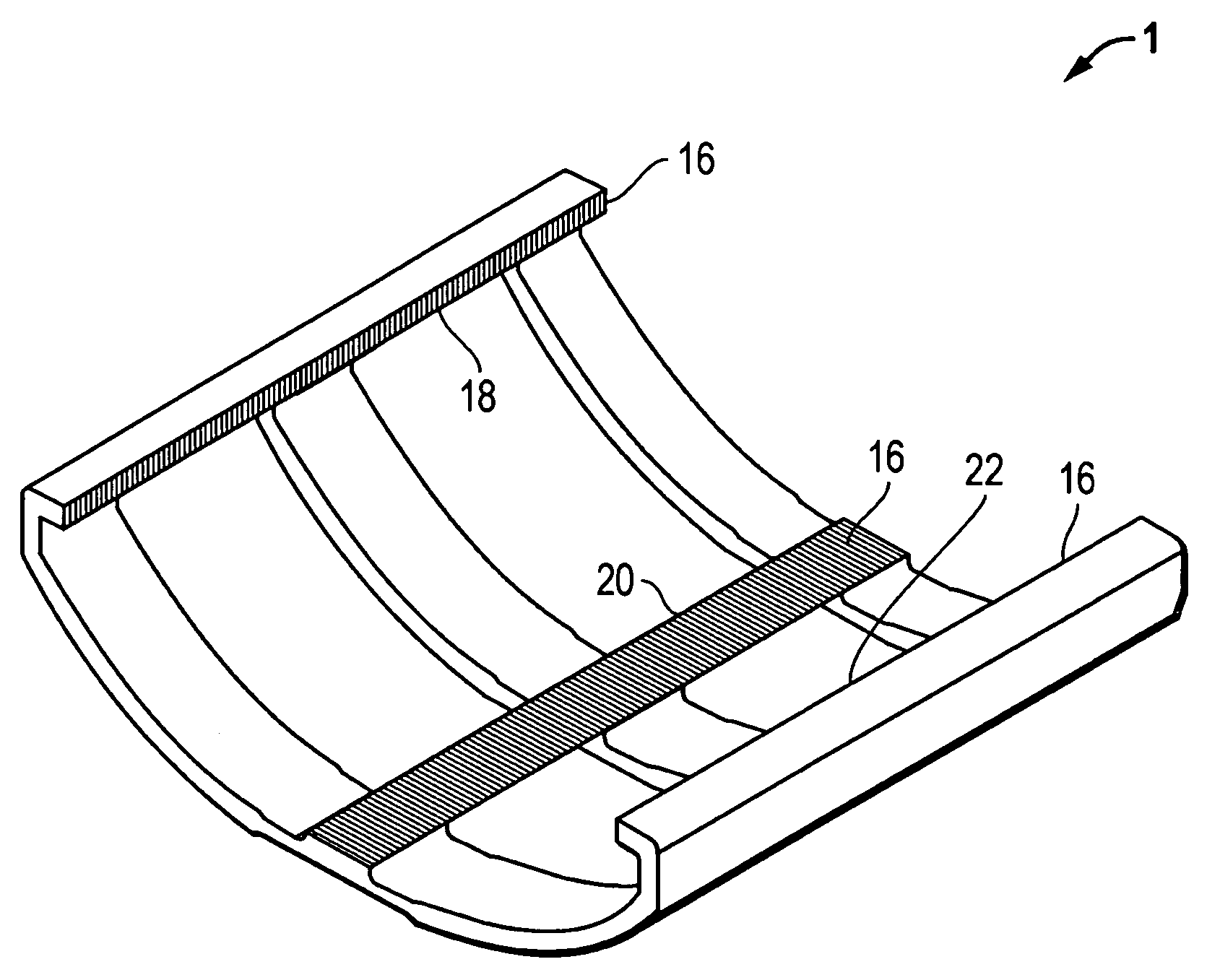

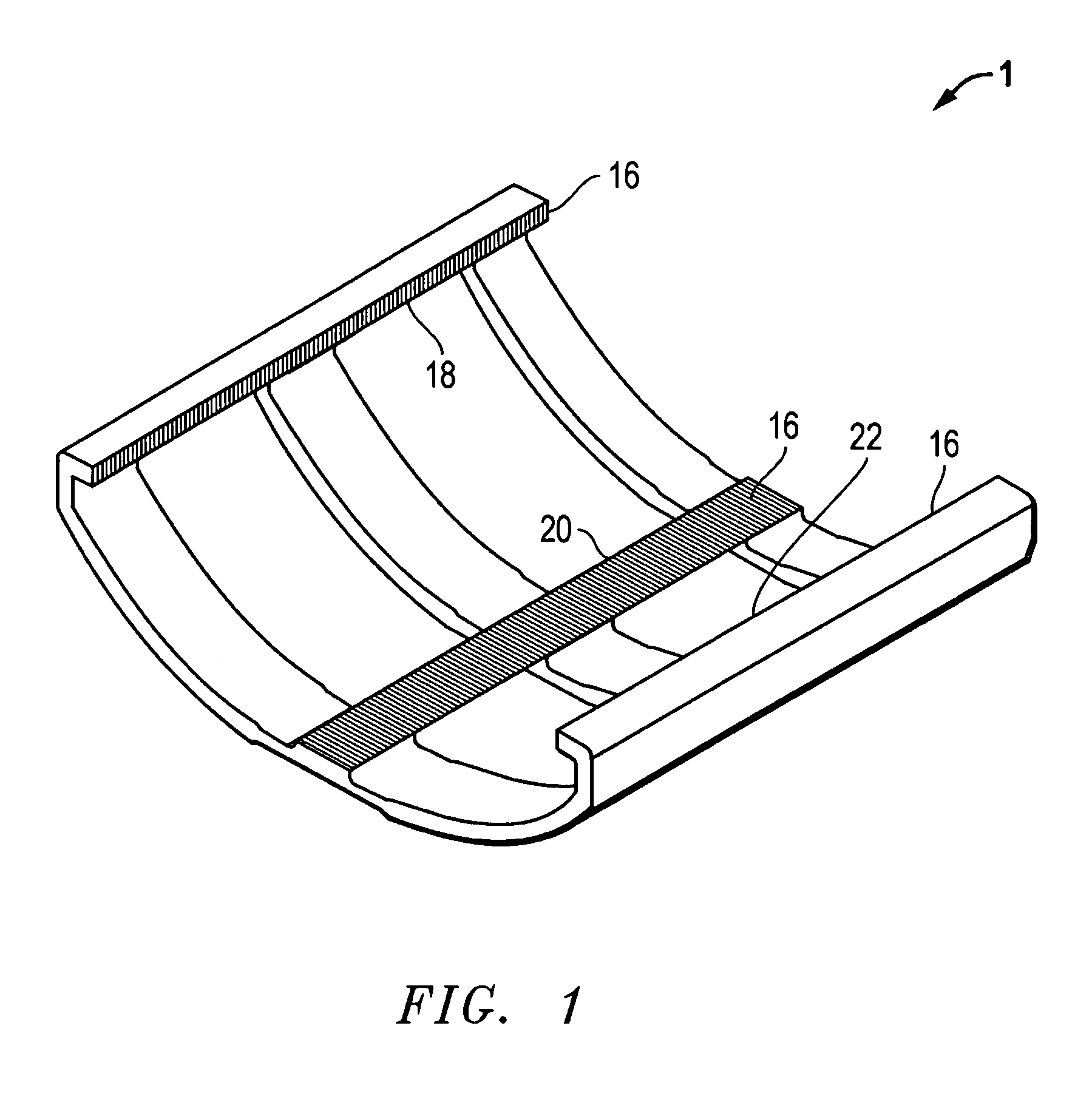

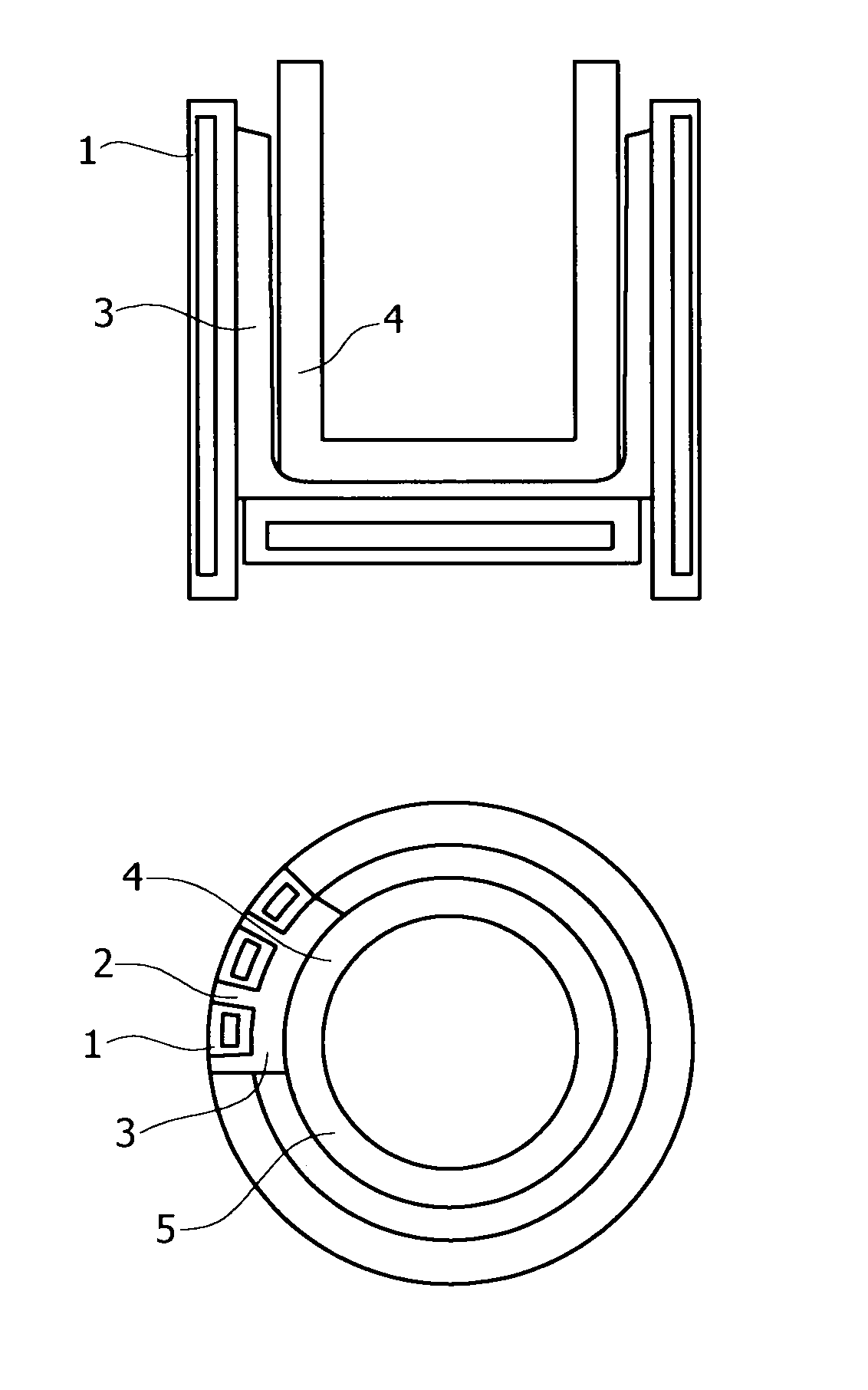

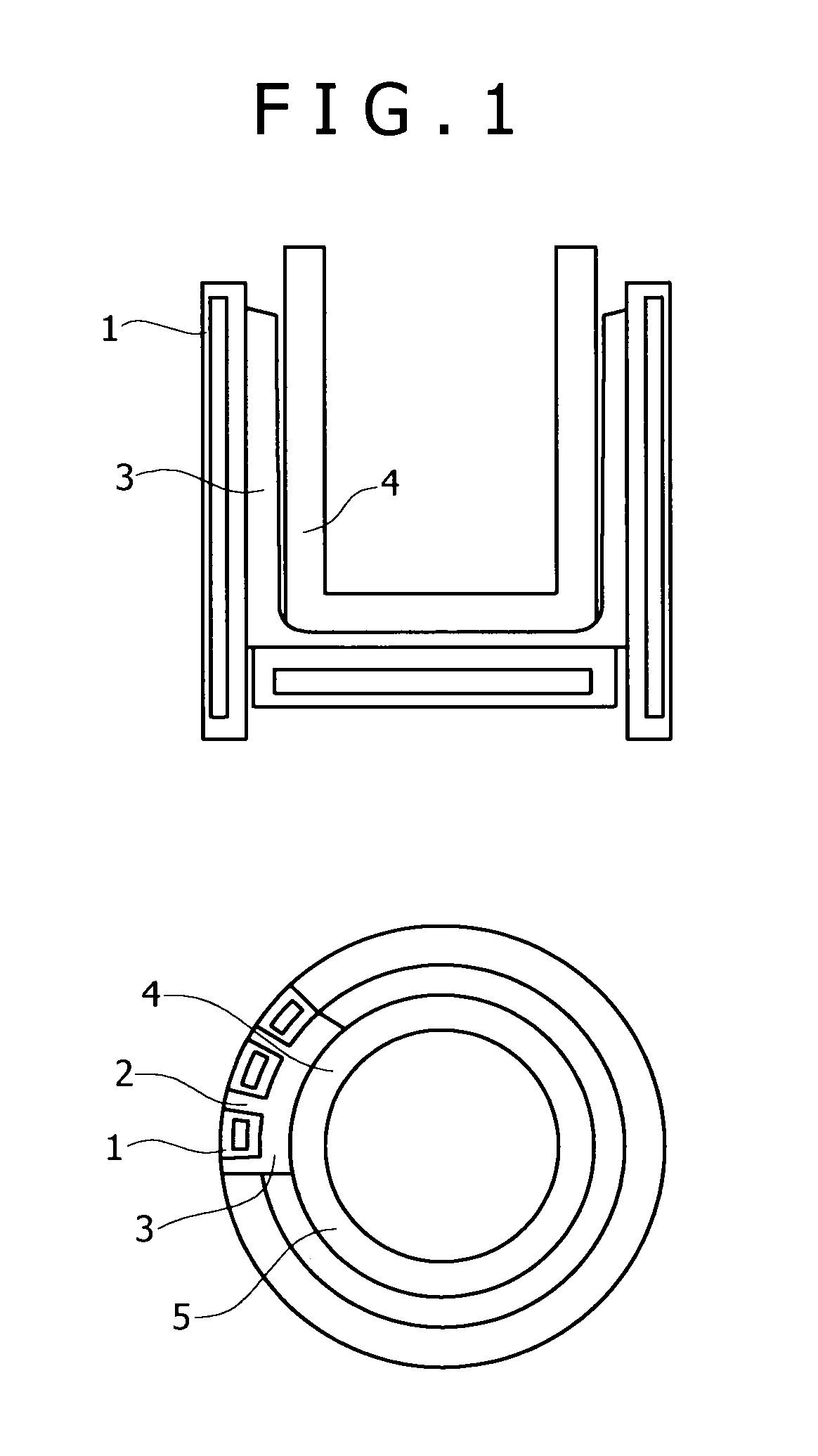

Induction melting apparatus employing halide type crucible, process for producing the crucible, method of induction melting, and process for producing ingot of ultrahigh-purity fe-, ni-, or co-based alloy material

InactiveUS20090038772A1Improve performanceIncrease the scope of applicationFurnaces without endless coreCoil arrangementsMolten stateChemical element

There is provided an induction-melting apparatus capable of exhibiting high refining performance without inflicting damage to a crucible even if a halide-compound base refining flux is used upon induction-melting of an ultrahigh-purity high melting-point metal, having a melting point reaching 1500° C., and a method for induction-melting using the same. There is also provided a melting method for enabling production of ultrahigh-purity Fe-base, Ni-base, and Co-base alloying materials, each having an impurity level of (C+O+N+S+P)<100 ppm, and Ca<10 ppm, and in the form of a large ingot. Further, with the induction-melting apparatus, a plurality of tubular segments are disposed so as to be cylindrical in shape, a gap in a range of 1.5 to 15 mm in distance is provided between the respective tubular segments adjacent to each other, and a layer composed of any substance selected from the group consisting of single chemical elements of halides of metal elements of the specific of the Periodic Table of the Elements, or from mixtures of the halides, oxides, and carbides, or nitrides of the metal elements is formed in each of the gaps, and on an inner peripheral surface of a peripheral body part of a crucible. There is also provided method for induction-melting an Fe-base alloy, and so forth, using a halide-base flux while forcibly cooling the crucible. A refining flux composed of any selected from the group consisting of metal elements of the Groups IA, IIA, or IIIA of the Periodic Table of the Elements, oxides thereof, halides thereof, halide single elements or halides selected from the group of halides, or mixtures of the metal elements, and the oxides thereof is added to be thereby turned into a molten state, primary melting is executed by holding a state of a molten metal being in contact with the refining flux before tapping, the molten metal is caused to undergo solidification inside a mold, thereby producing a primary ingot and subsequently secondary melting is executed by an electron-beam melting method whereby while the primary ingot is sequentially melted in a water-cooled copper mold at a low pressure, the molten metal as-solidified state is pulled out from an outlet side of the water-cooled copper mold, thereby forming an ingot product.

Owner:KOBE STEEL LTD

Silica glass crucible for pulling up silicon single crystal and method for manufacturing thereof

ActiveUS20100162947A1Inhibit productionQuality improvementAfter-treatment apparatusPolycrystalline material growthCrucibleSingle crystal

A silica glass crucible used for pulling up a silicon single crystal and made from natural silica a raw material is provided with a region within a certain range from the center of a bottom section of the crucible and up to 0.5 mm deep from an inner surface and which substantially does not include gas bubbles, wherein an average value of a concentration of Al included in a region within the certain range from the center of the bottom section of the crucible and up to 0.5 mm deep from the inner surface is 30 ppm or more and 150 ppm or less. In the case where the inner layer of the crucible bottom section is formed in this way, dents in the inner surface are prevented and the generation of gas bubbles is reduced.

Owner:JAPAN SUPER QUARTZ CORP

Hydrocarbon synthesis catalyst and process

InactiveUS6844370B2Extended service lifePrevent excessive expansionHydrocarbon from carbon oxidesOrganic compound preparationGramFerric

According to the present invention there is provided a hydrocarbon synthesis catalyst comprising a precipitated iron product and a catalyst promotor. The catalyst has a surface area of below 60 m2 per gram of catalyst in the reduced form or below 100 m2 per gram of catalyst in the non-reduced form. According to the invention there is also provided a process for preparing the catalyst and the use thereof in the synthesis of hydrocarbons.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

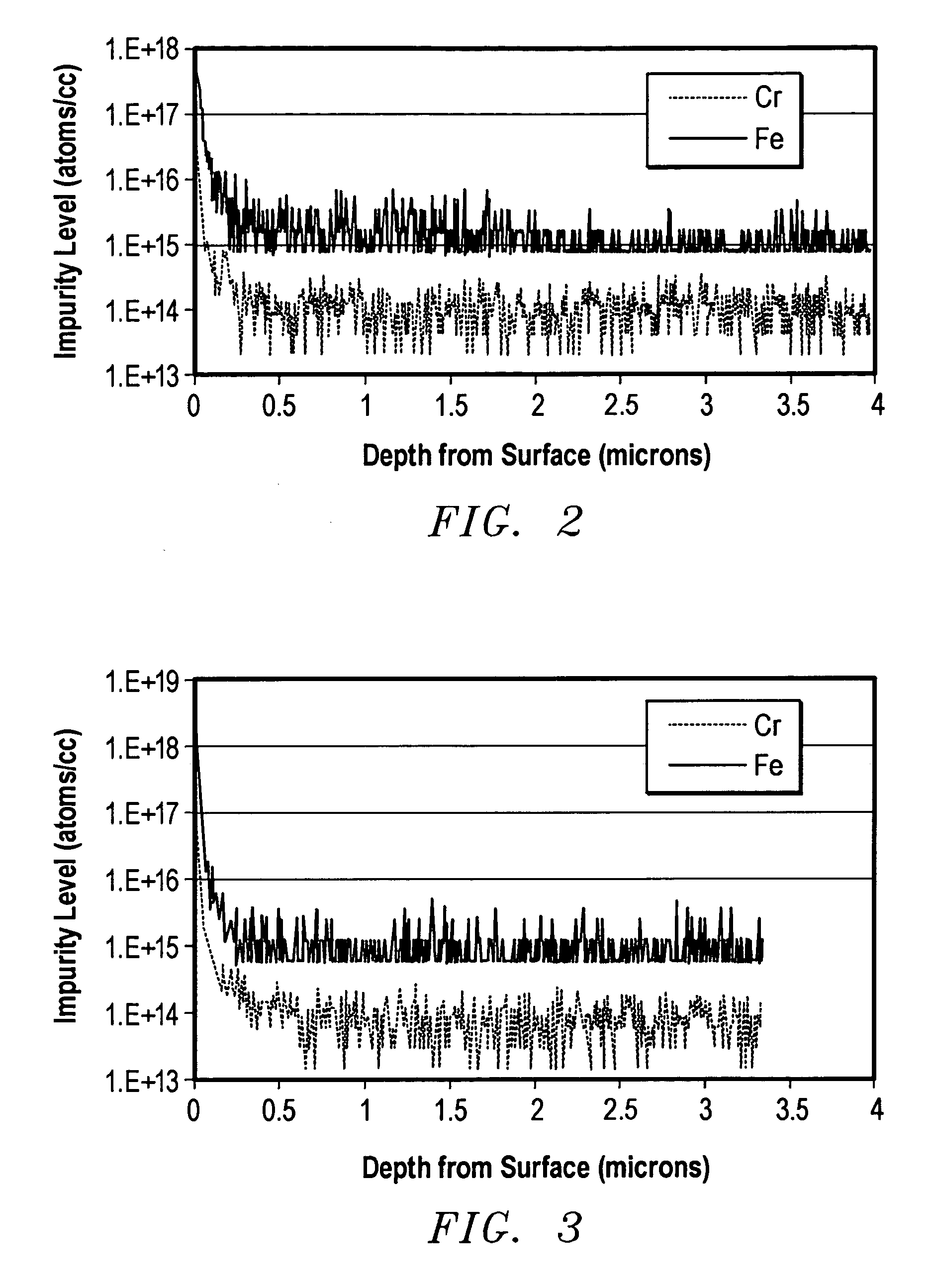

Method for treating semiconductor processing components and components formed thereby

InactiveUS20040235231A1Reduced impurity levelsSemiconductor/solid-state device manufacturingSilicon carbideSemiconductorImpurity

A semiconductor processing component formed of SiC, wherein an outer surface portion of the component has a surface impurity level that is not greater than ten times a bulk impurity level of the outer surface portion.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method of purifying macrolides

InactiveUS7220357B2Reduced impurity levelsReduce the presence of impuritiesIon-exchange process apparatusSugar derivativesMacrolide resistanceSorption

Provided is a method of purifying a macrolide, especially tacrolimus, that includes loading macrolide onto a bed of sorption resin and elting with a suitable eluent such as a combination of water and tetrahydrofuran.

Owner:TEVA PHARM USA INC +1

Induction melting apparatus employing halide type crucible, process for producing the crucible, method of induction melting, and process for producing ingot of ultrahigh-purity Fe-, Ni-, or Co-based alloy material

InactiveUS7967057B2Maintain securityPromoting secondary refiningFurnaces without endless coreCoil arrangementsCrucibleIngot

There is described a method for producing ultrahigh-purity Fe-base, Ni-base, and Co-base alloying materials to achieve impurity levels of (C+O+N+S+P)<100 ppm, and Ca<10 ppm, in the form of a large ingot, using a refining flux while forcibly cooling the crucible. A refining flux selected from the group consisting of metal elements of the Groups IA, IIA, and IIIA of the Periodic Table, oxides thereof, halides thereof, and mixtures thereof, is added to the molten metal during primary melting and the molten metal is held in contact with the refining flux for at least 5 minutes before tapping. Thereafter, the molten metal is caused to undergo solidification inside a mold, thereby producing a primary ingot. Subsequently, secondary melting is executed by an electron-beam melting method whereby while the primary ingot is sequentially melted in a water-cooled copper mold at a low pressure, the molten metal as-solidified state is pulled out from an outlet side of the water-cooled copper mold, thereby forming an ingot product.

Owner:KOBE STEEL LTD

Titaniferous ore beneficiation

ActiveUS20080241026A1Reduced impurity levelsIncrease contentTitanium dioxideTitanium halidesAlkaline earth metalChloride

This invention relates to a process for beneficiating a titaniferous ore. The process comprises calcining the titaniferous ore, at least one alkali or alkaline earth metal salt, and at least one alumina-containing material in the presence of oxygen to form a calcined ore mixture, then leaching the calcined ore mixture with a solution comprising ammonium, sodium or magnesium chloride in the presence of oxygen to form a leached ore mixture, and contacting the leached ore with an acid to form a beneficiated ore.

Owner:UNIV OF LEEDS

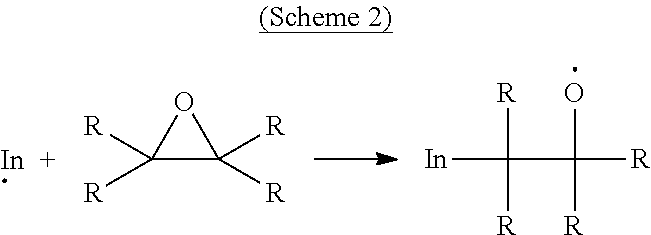

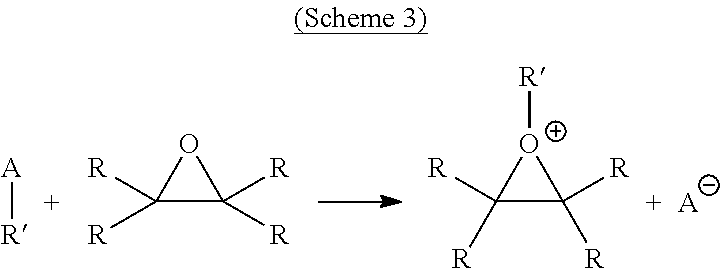

Curable formulation

InactiveUS20120220684A1Raise the ratioImprove solubilityOrganic chemistryRosin coatingsCross-linkReactive diluent

Disclosed is a curable formulation comprising a resin; all, or a substantial part, of which comprises one or more fatty acid esters, or their derivatives, obtained from plant oils. Due to the high viscosity of known curable resin materials, and in particular cationically photocurable and thermally curable resins epoxy resins, reactive diluents are conventionally added in order to reduce viscosity and render them suitable for certain methods of application, such as flexography and inkjet printing. However, if an excessive amount of reactive diluent is added to a formulation, the concentration of resin may be so low as to prevent a formulation from curing to form a cured, cross-linked material with acceptable properties. Thus the minimum viscosity of known formulations is limited by the amount of low viscosity reactive diluent which may be added to comparatively high viscosity resins. Formulations of the present invention comprise resins of lower viscosity and therefore may be prepared having a lower viscosity than has been previously possible.

Owner:AKCROS CHEM

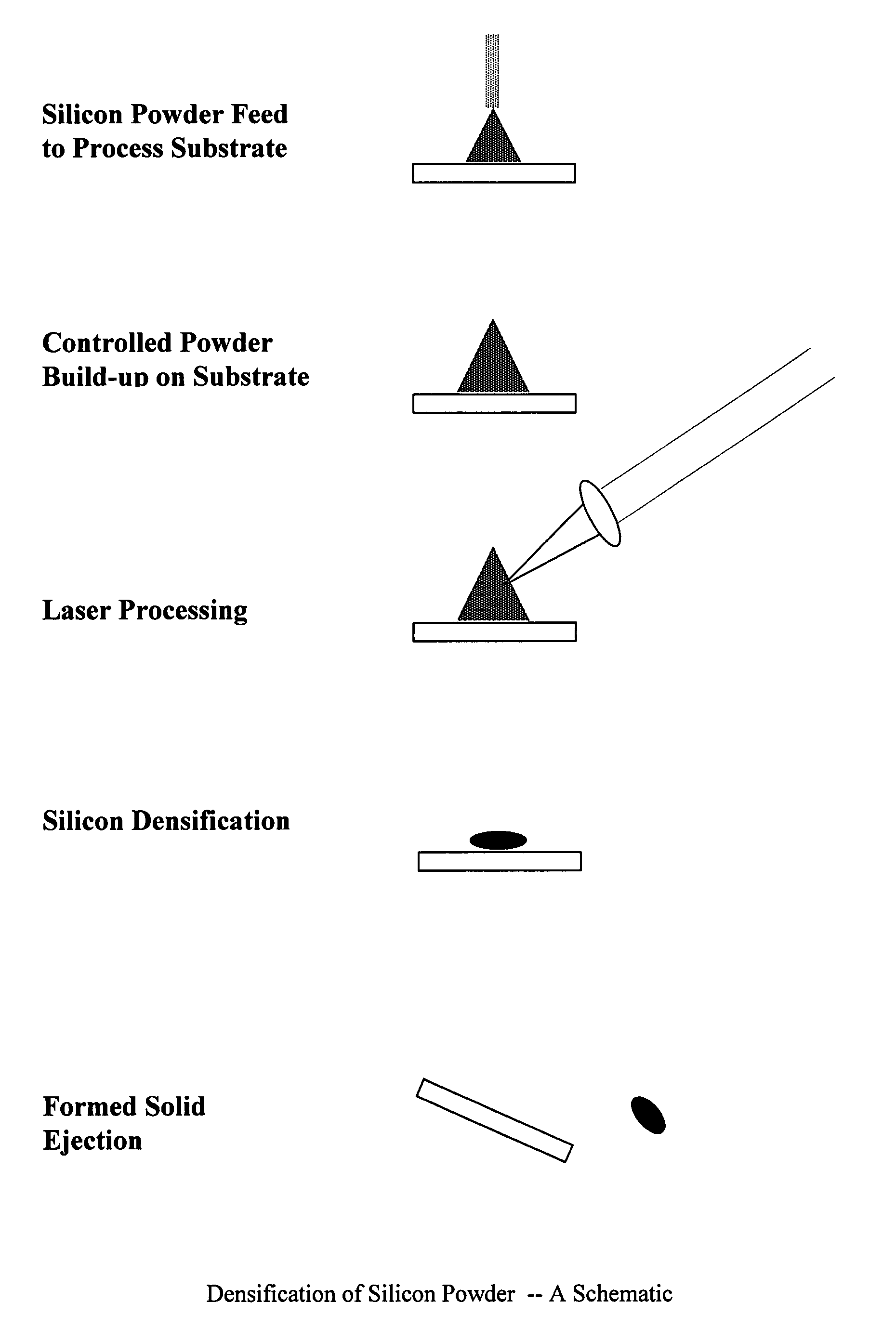

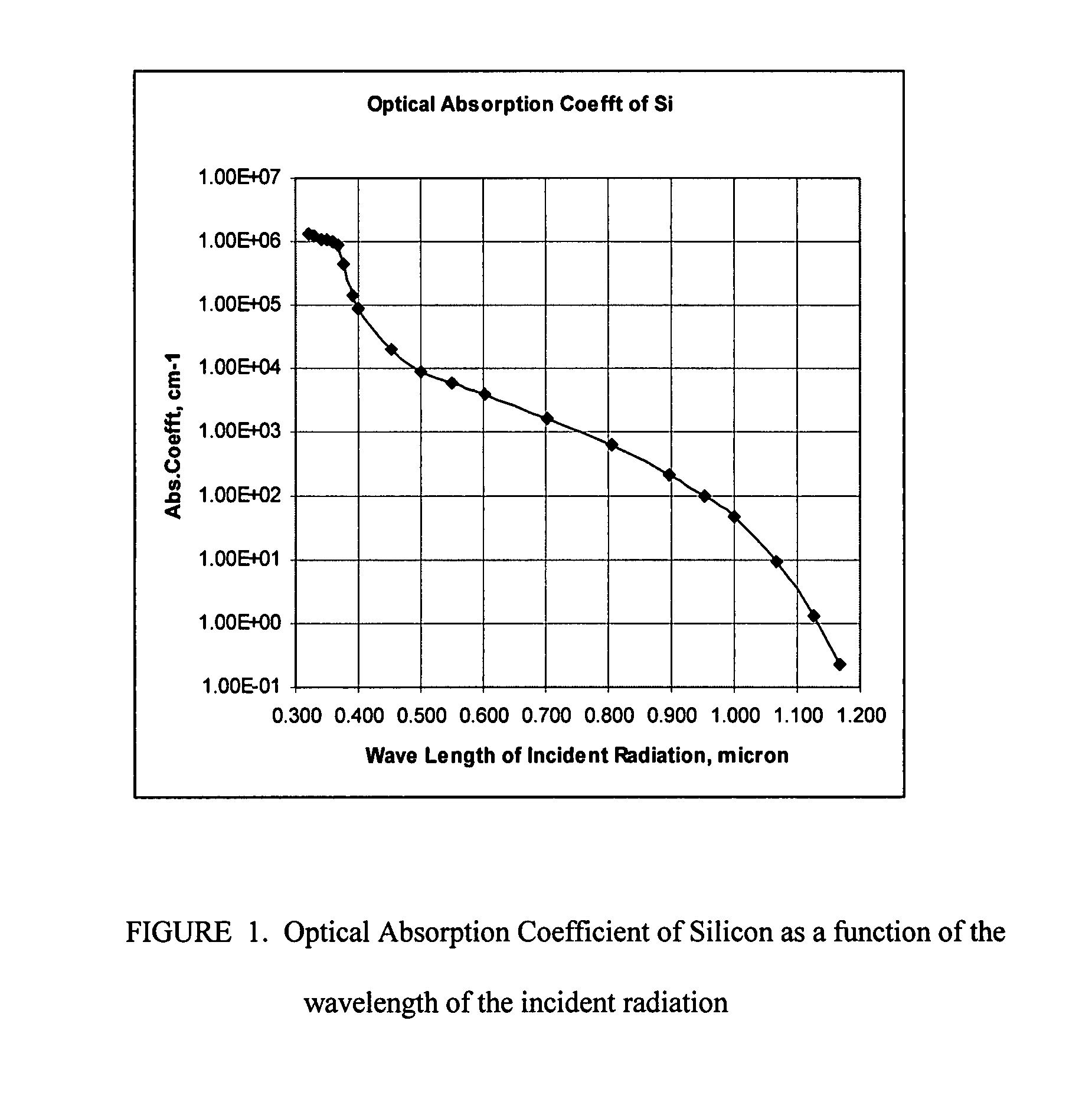

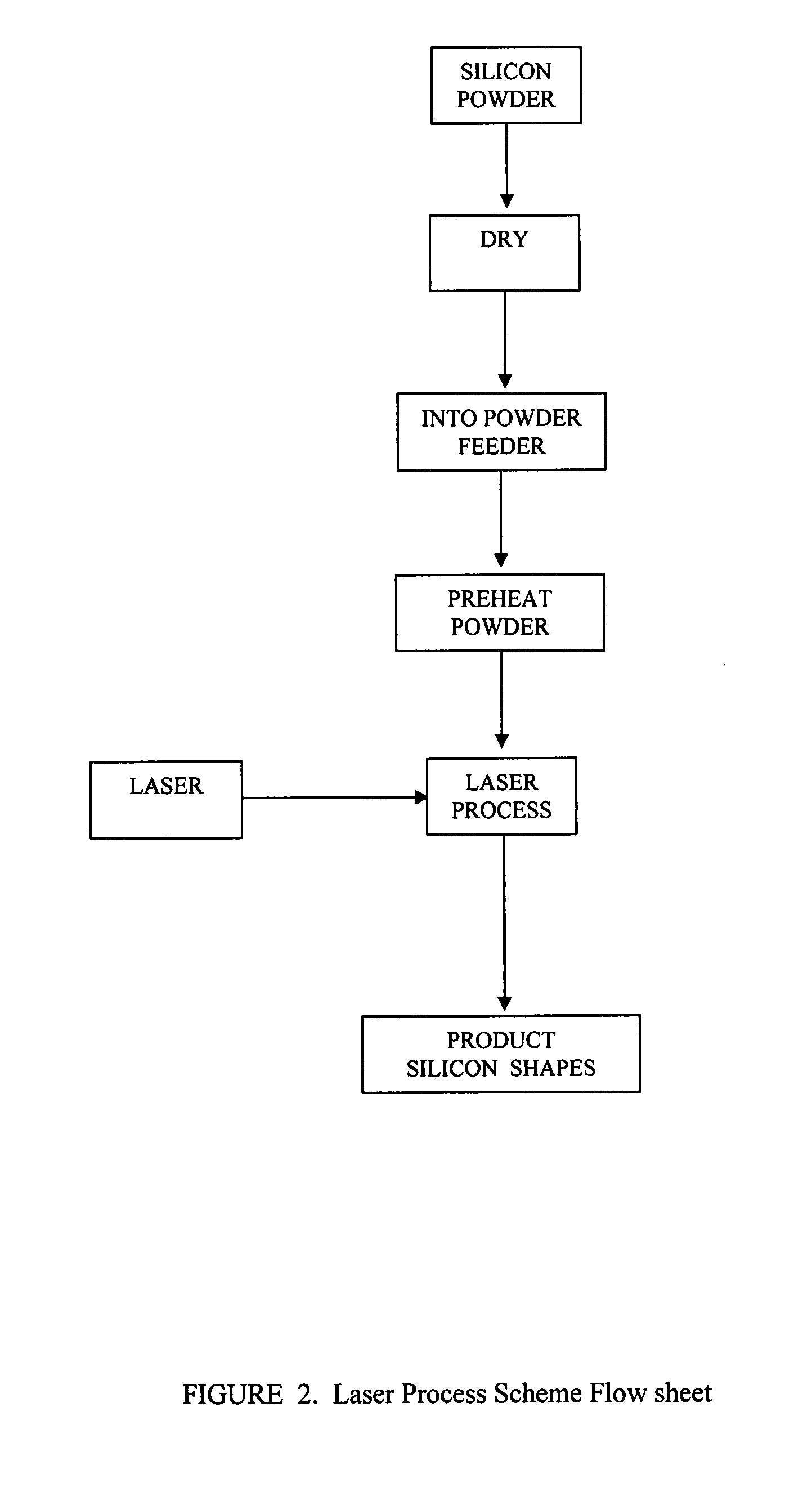

Laser conversion of high purity silicon powder to densified granular forms

InactiveUS9067792B1Easy to manufactureEasy to transportPolycrystalline material growthSiliconUltra fineLength wave

The present invention relates to a direct method to convert fine and ultra fine silicon powder from polysilicon manufacturing sources such as fluid bed and free space reactors into densified granular forms. This conversion process is effected by the use of lasers of selective wavelengths from solid state diode or optically-pumped YAG sources to locally heat, melt and densify a controlled quantity of silicon powder, and comprises the steps of distributing dry silicon powder on an inert substrate, subjecting the silicon charge to a focused laser beam to realize melted and densified granular forms, and discharging the product. When adapted to high purity silicon powder, the end use for the densified silicon granular forms is primarily as feedstock for silicon-based semiconductor and photovoltaic manufacturing industries. The process, suitably modified, is adaptable to form other silicon body shapes and components.

Owner:HARIHARAN ALLEPPEY V +1

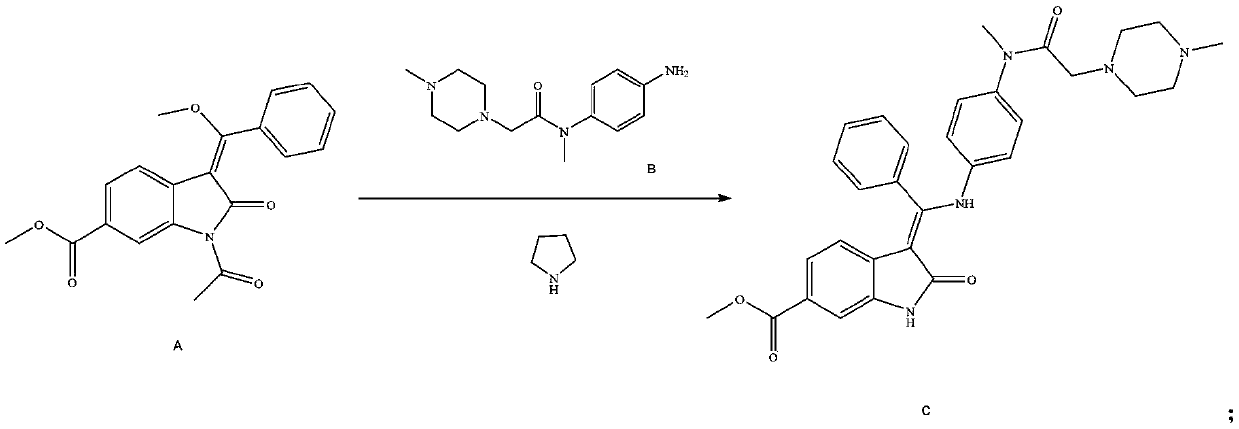

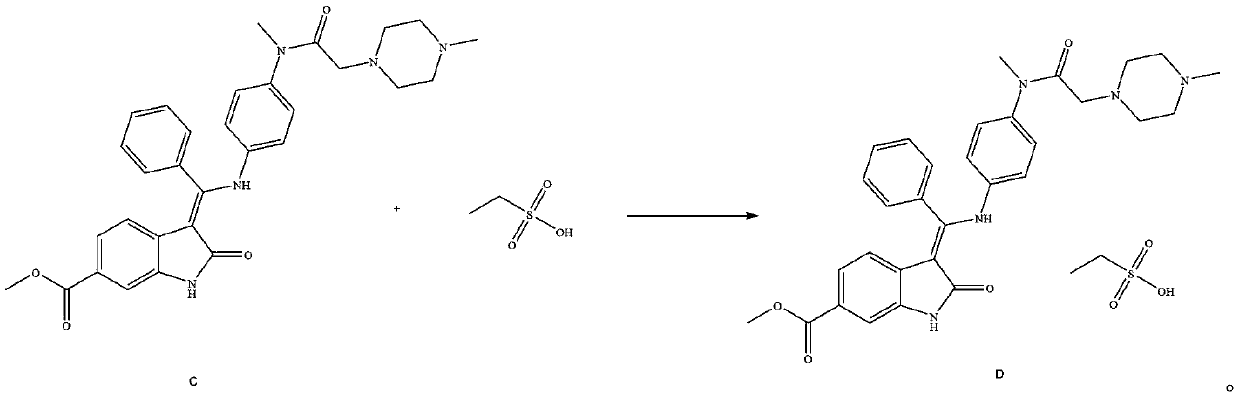

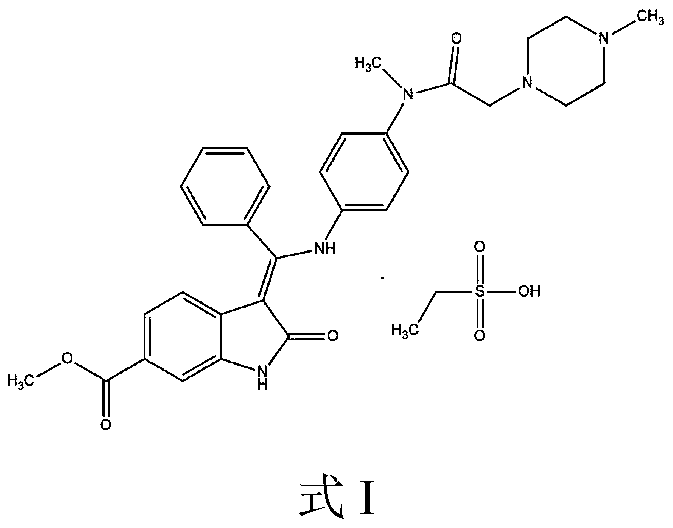

Method for preparing Nintedanib ethylsulfonate

ActiveCN109988094AHigh purityHigh yieldOrganic compound preparationSulfonic acids salts preparationPyrrolidineSolvent

The invention relates to a method for preparing Nintedanib ethylsulfonate. The method comprises the following steps: (1) adding 1-acetyl-3-[methoxy(phenyl)methylene]-2-oxo-indolinyl-6-methyl formate (compound A) into a reaction solvent to react with N-(4-amino phenyl)-N,4-dimethyl-1-piperazinyl acetamide (compound B), adding pyrrolidine for continuous reaction after the reaction ends up, carryingout crystallization, carrying out stirring washing with a mixed solvent, and carrying out drying, so as to produce (3Z)-3-{[(4-{methyl-[(4-methyl piperazin-1-yl)acetyl]amino}phenyl)amino]-(phenyl)methylene} -2-oxo-2,3-indolinyl-6-methyl formate (compound C); and (2) subjecting the compound C to a reaction with ethyl sulfonic acid, carrying out crystallization, carrying out filtering, and carryingout drying, thereby producing the Nintedanib ethylsulfonate. According to the method, the Nintedanib ethylsulfonate with high purity, good yield and low impurity level is obtained through reactions oftwo steps.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

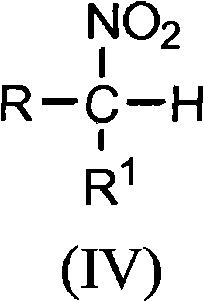

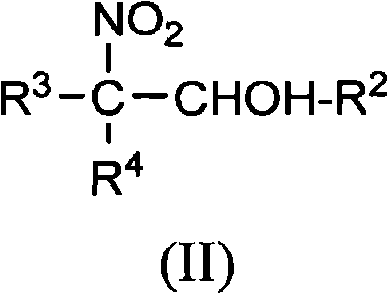

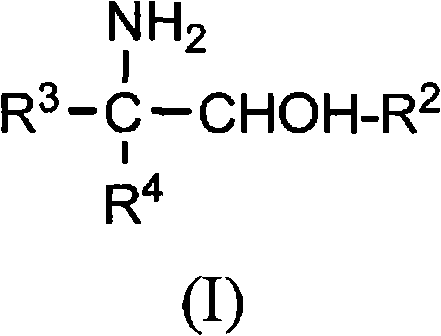

Process for making aminoalcohol compounds

InactiveCN102803201AReduced impurity levelsOrganic compound preparationAmino-hyroxy compound preparationScavengerNitroalkane

Provided is a process for making an aminoalcohol compound. The process comprises using an excess amount of aliphatic aldehyde in a condensation step between the aldehyde and a nitroalkane, and using an aldehyde scavenger in a reductive hydrogenation step. The process yields aminoalcohol compounds exhibiting reduced color and odor.

Owner:ANGUS CHEM CO

Titaniferous ore beneficiation

InactiveUS7625536B2Reduced impurity levelsTitanium halidesProcess efficiency improvementTitaniumCalcination

This invention relates to a process for beneficiating a titaniferous ore. The process comprises leaching the titaniferous ore with sulfuric acid to form a leached ore, calcining the leached ore in the presence of oxygen to form a calcined ore, and leaching the calcined ore with sulfuric acid, hydrochloric acid, and / or nitric acid to form a beneficiated ore. The leached ore is not reduced prior to or following calcination.

Owner:TRONOX LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com