Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce the amount of enzyme" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

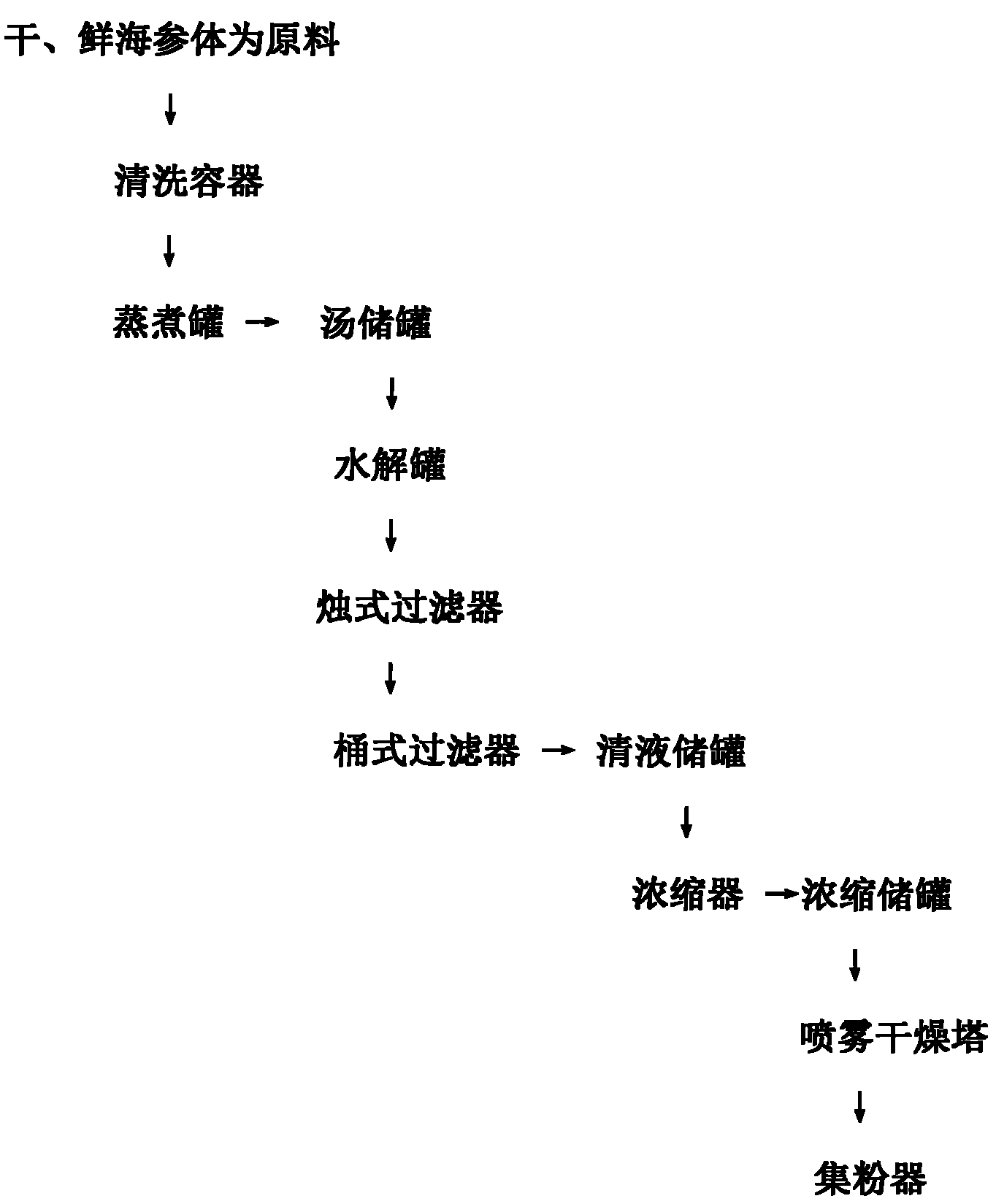

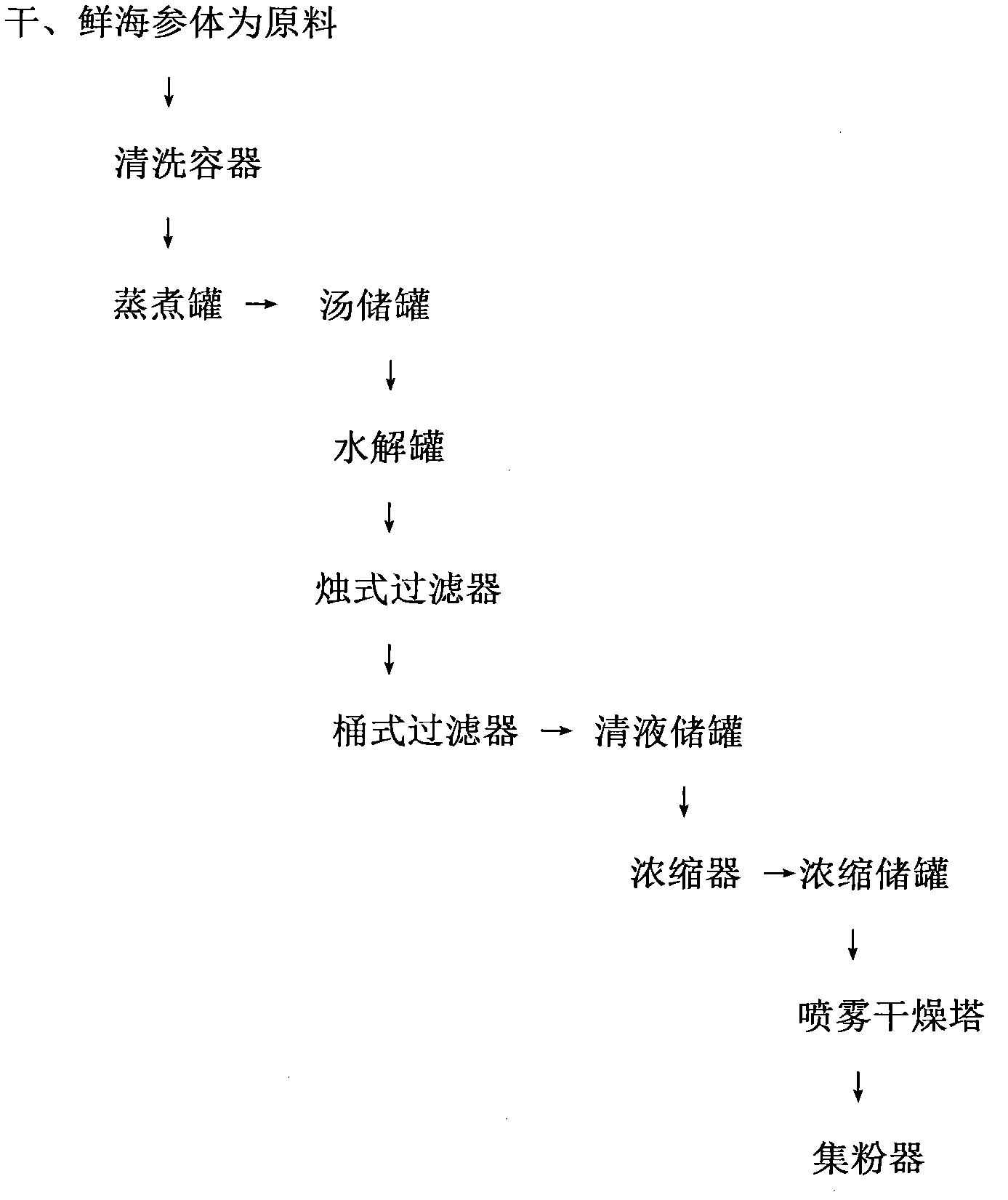

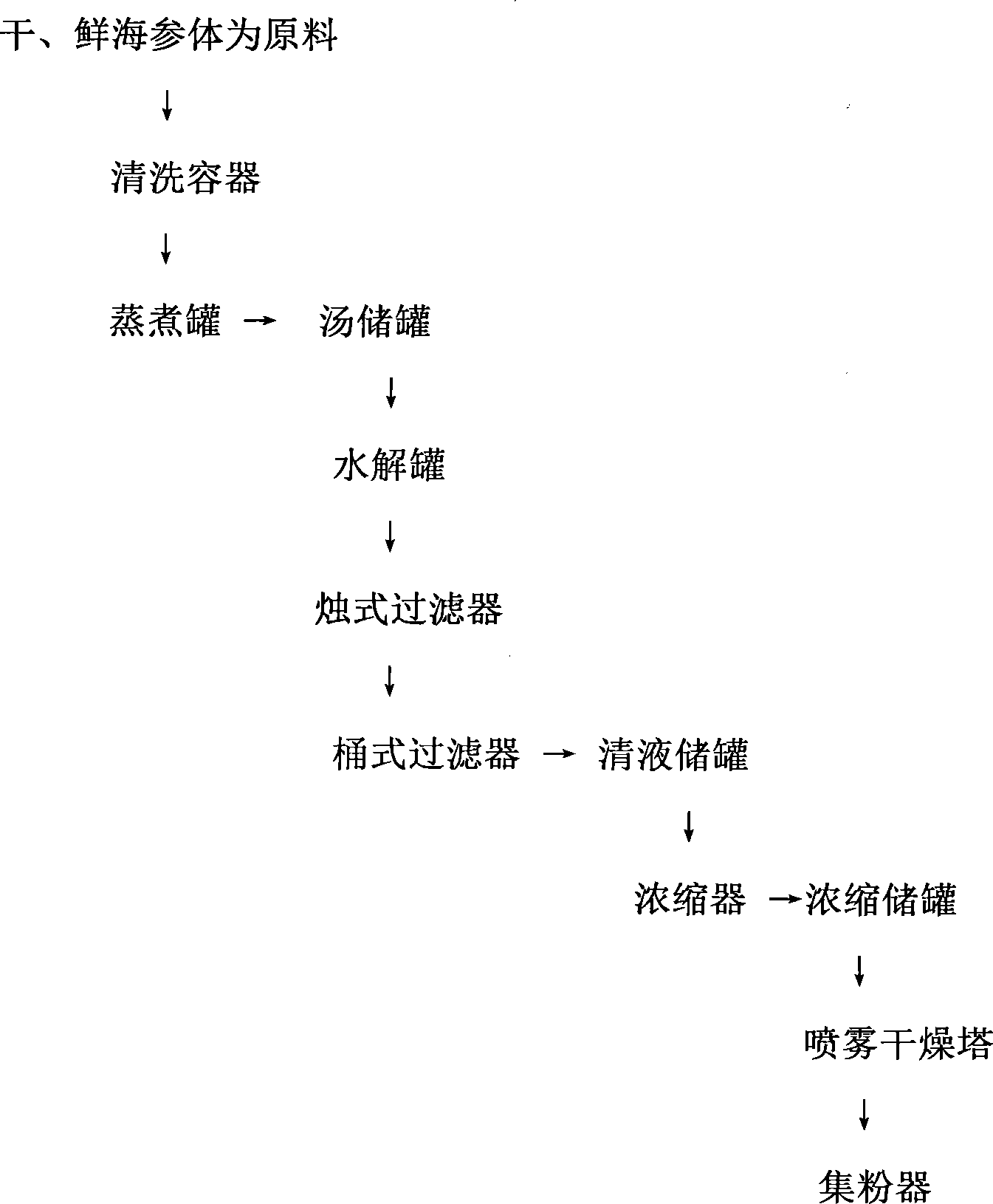

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

Method for preparing gelatin with protease degradation ossein

InactiveCN102051130AHigh purityEmission reductionGlue/gelatin preparationInorganic saltsNeutral protease

The invention discloses a method for preparing gelatin with protease degradation ossein. The method is characterized in that derosination and demineralization ossein is mainly adopted as the raw material, and acidic or neutral protease degradation ossein is used for preparing gelatin. Compared with the traditional technology, the method has the advantage that long liming period and complicated neutralization washing process are omitted, so that the production period of gelatin is shortened, and a great amount of water resource and manpower cost are saved; and compared with the new technology of preparing gelatin with skeleton grains, and the content of foreign protein and inorganic acid in gelatin is greatly reduced, so that freezing strength and viscosity of the product are improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Production method of liquid medlar

The invention discloses a production method of liquid medlar. Firstly, medlar pulp is prepared, and then liquid medlar is prepared according to the following technical steps: facilitating composite hydrolysis by ultrasonic wave, filtering, or centrifugal separating, strengthening membrane separation by ultrasonic wave, filling and sterilizing, wherein, in the process of facilitating composite enzymolysis by ultrasonic wave, ultrasonic frequency is 20 to 80 kHz, and power is 50 to 300 W, and complex enzyme which is adopted is the compound of 1 part by weight of pectase, 1.5 parts by weight of proteinase and 2.5 parts by weight of cellulase; enzyme adding amount is 0.01 to 0.15% of the total material quantity, enzymolysis temperature is 40 to 65 DEG C, and enzymolysis time is from 15 to 120 minutes. In the hydrolytic process of complex enzyme, the production method of liquid medlar is promoted by ultrasonic technology, which shortens enzymolysis reaction time for 50% and reduces enzyme adding amount by 20%, so that the production method can obviously improve enzymolysis efficiency and lower production cost.

Owner:早康枸杞股份有限公司

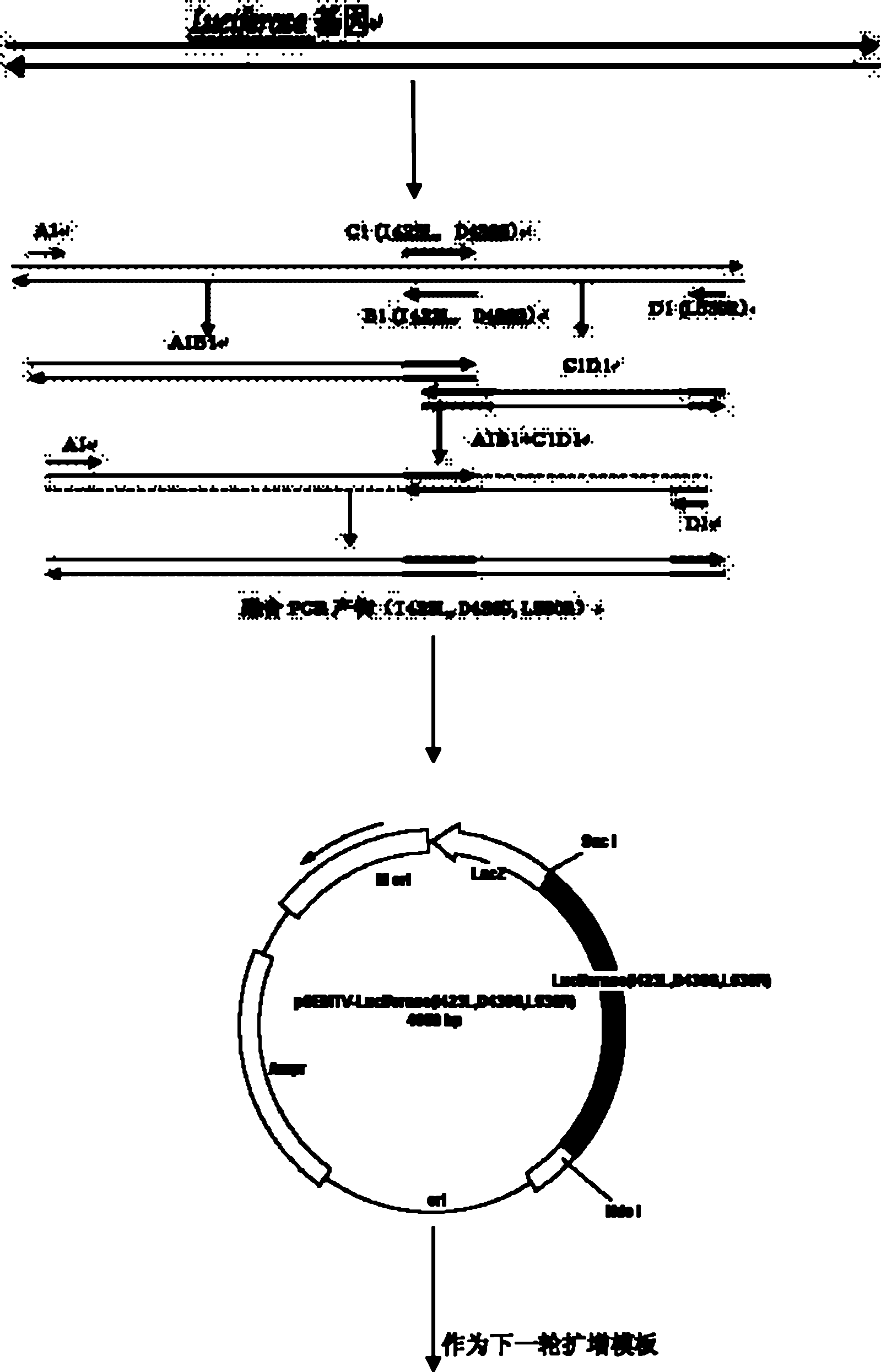

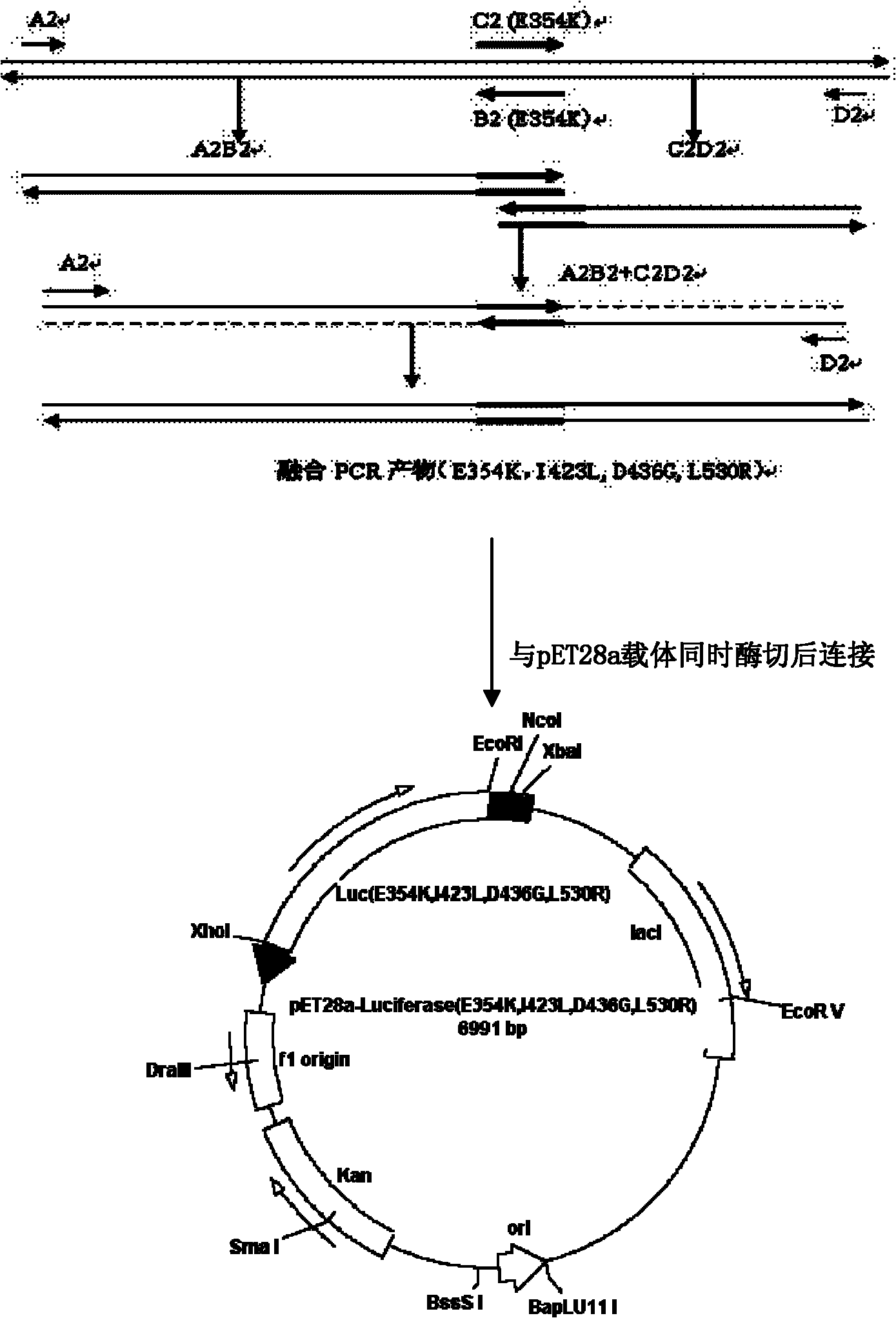

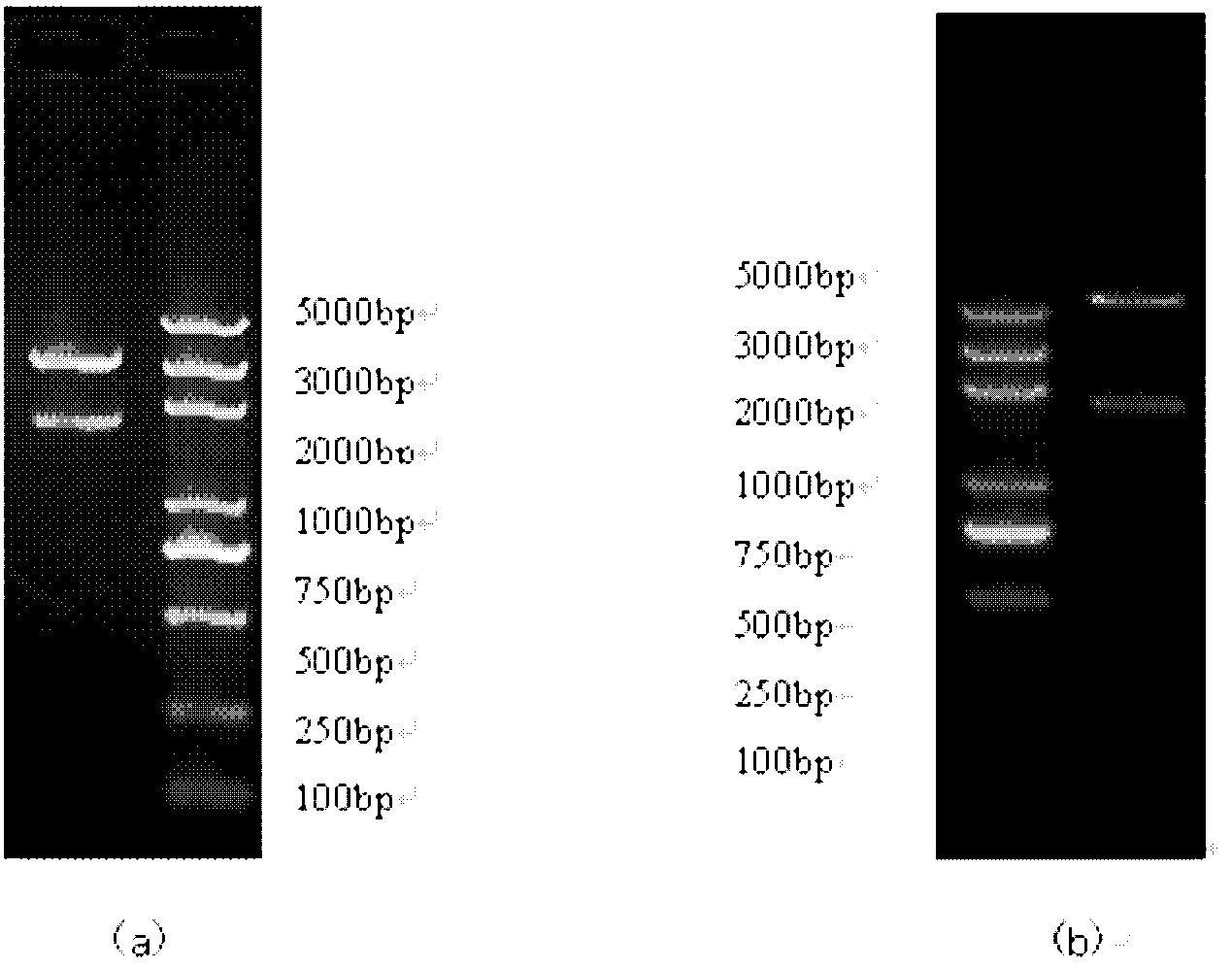

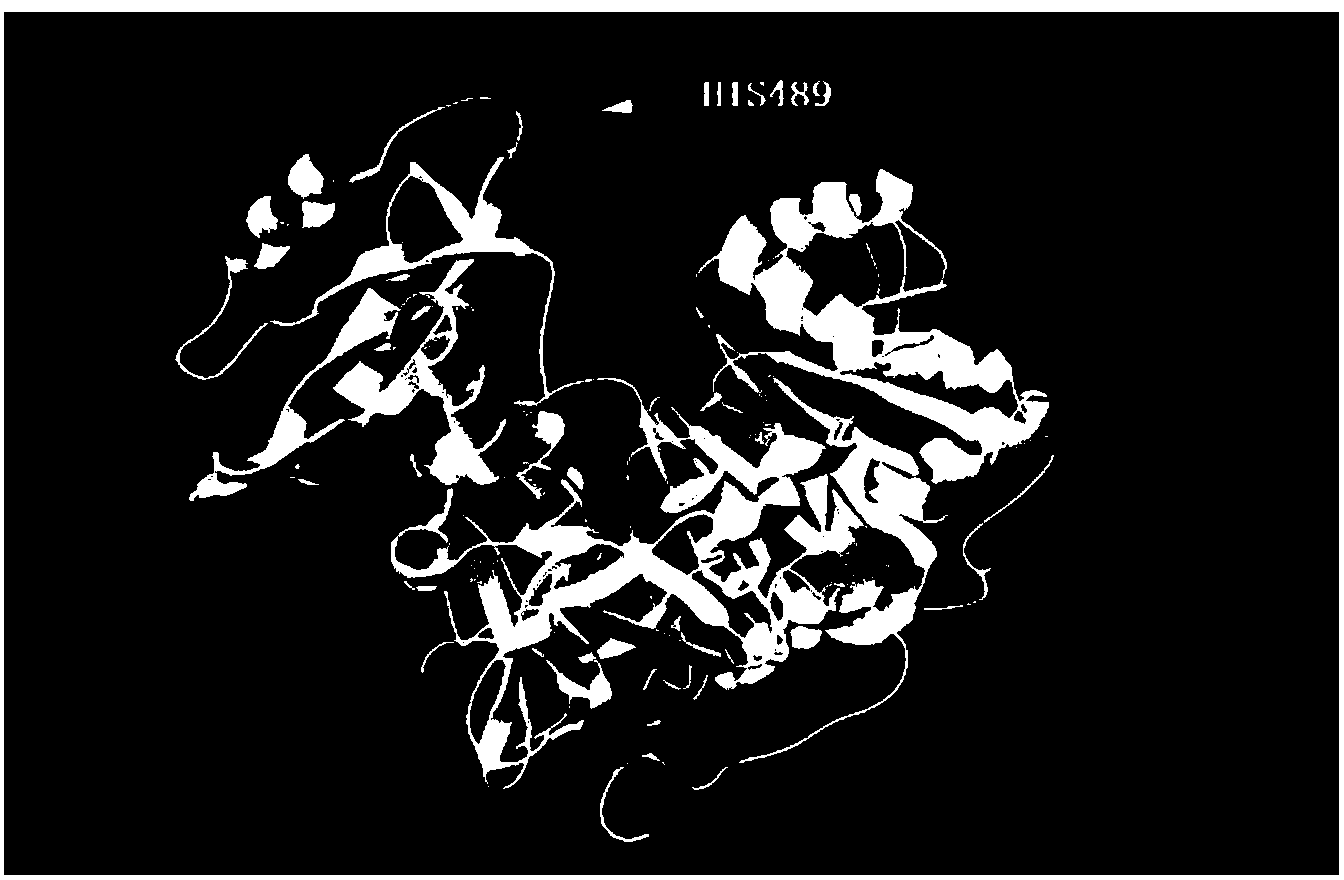

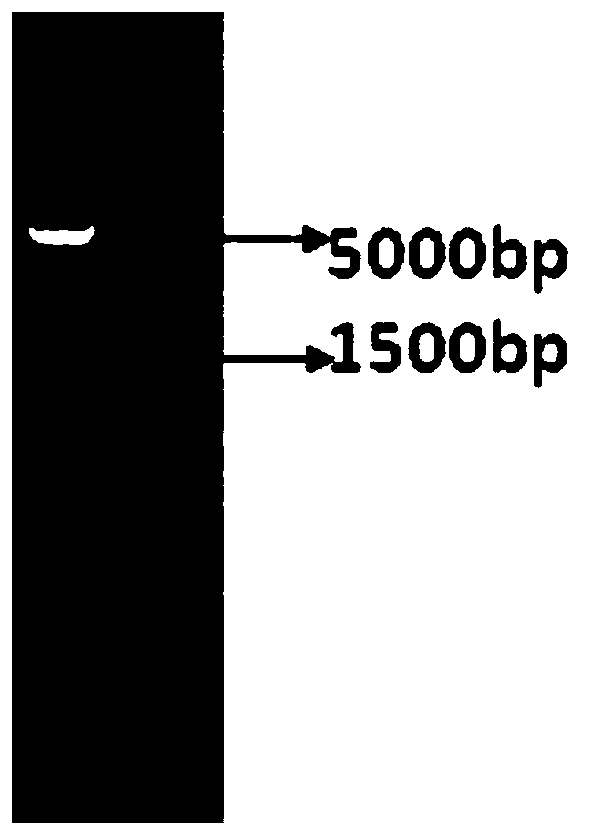

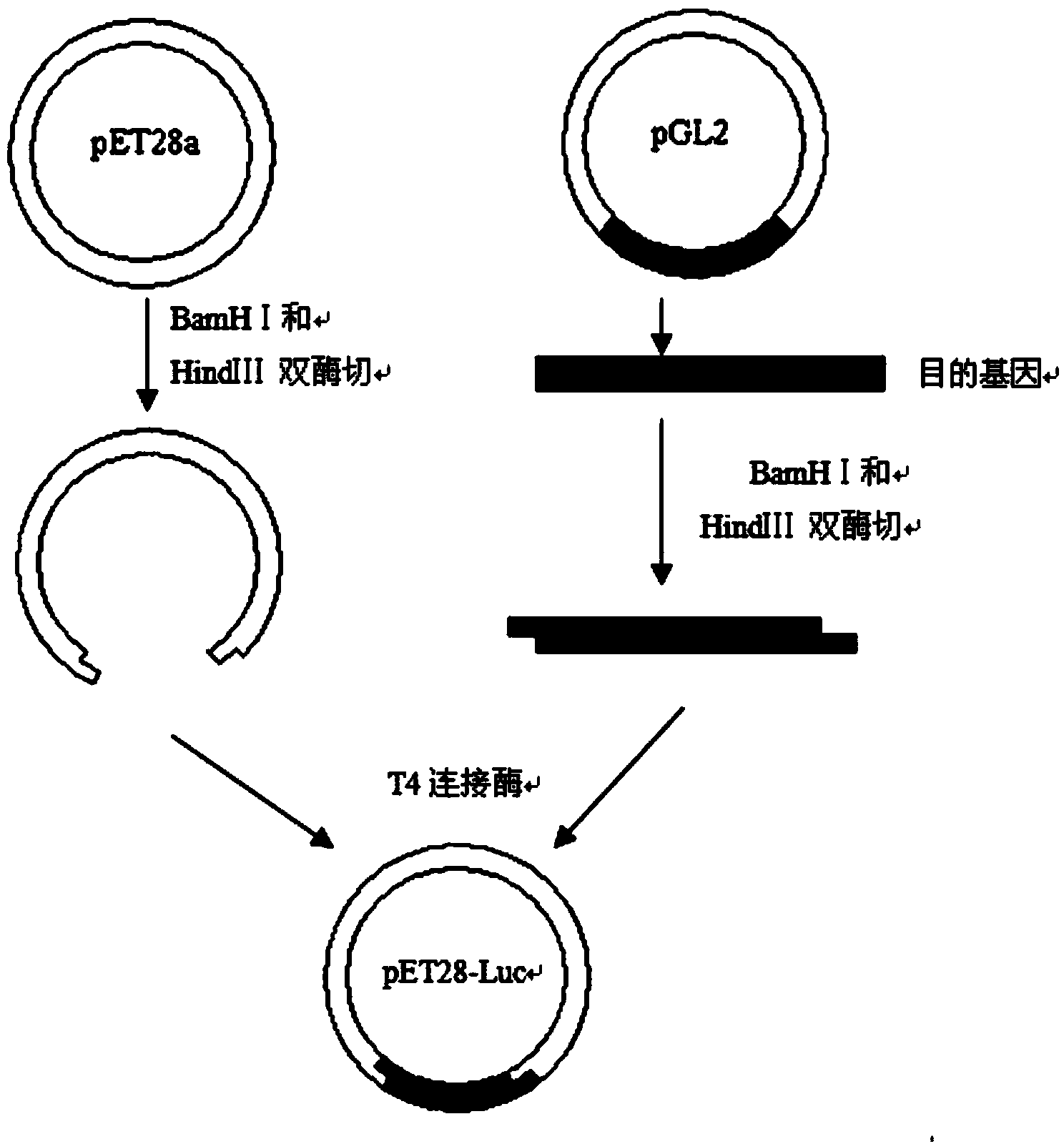

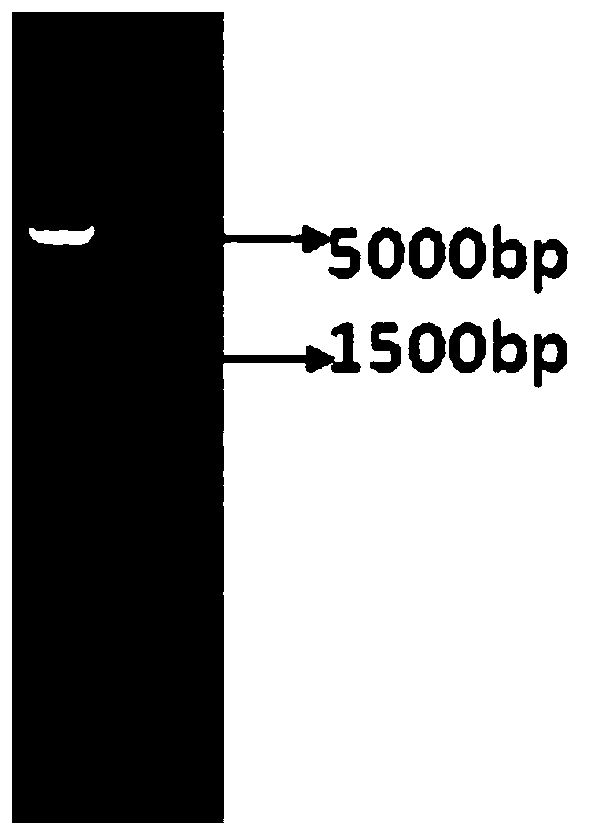

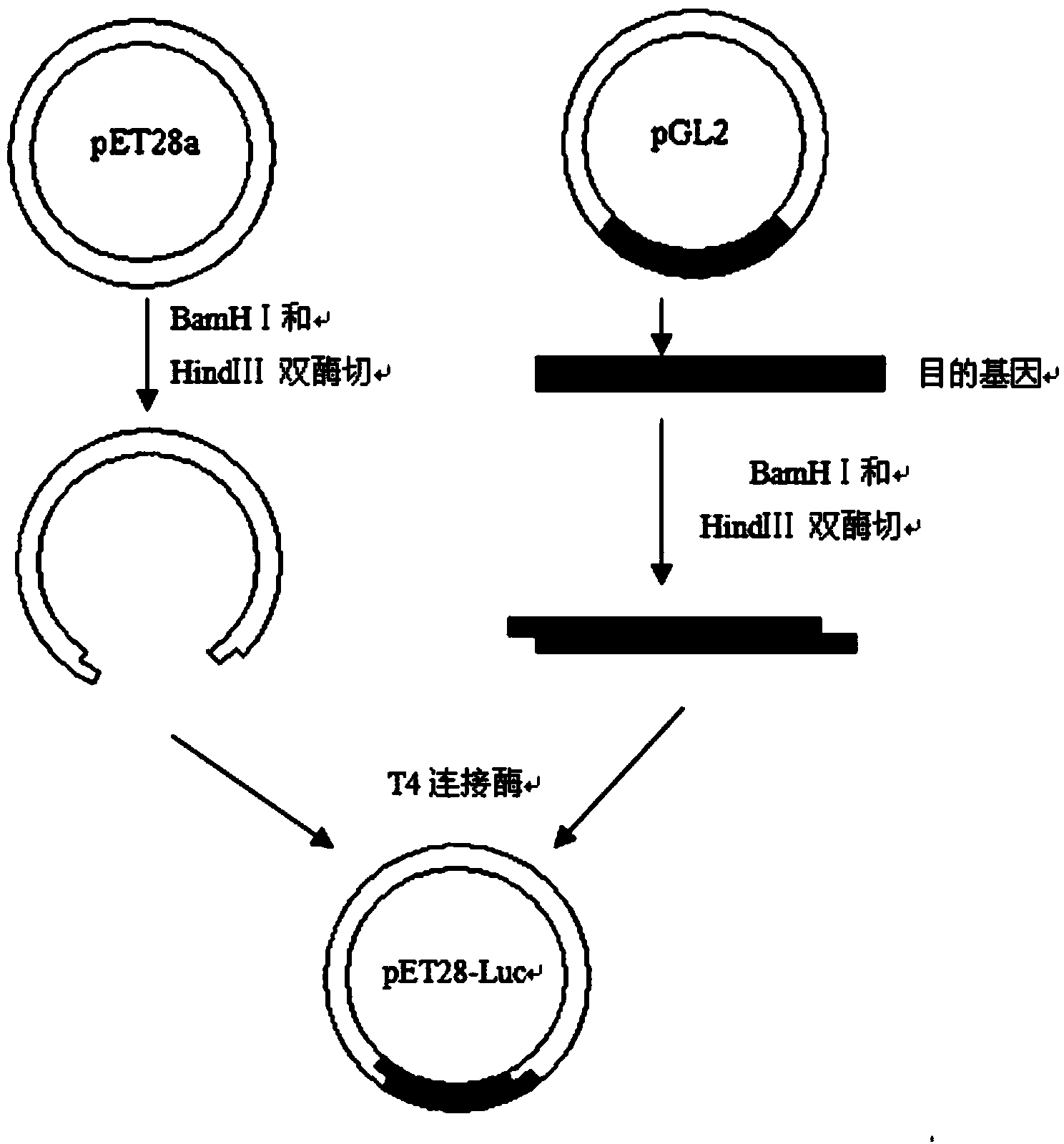

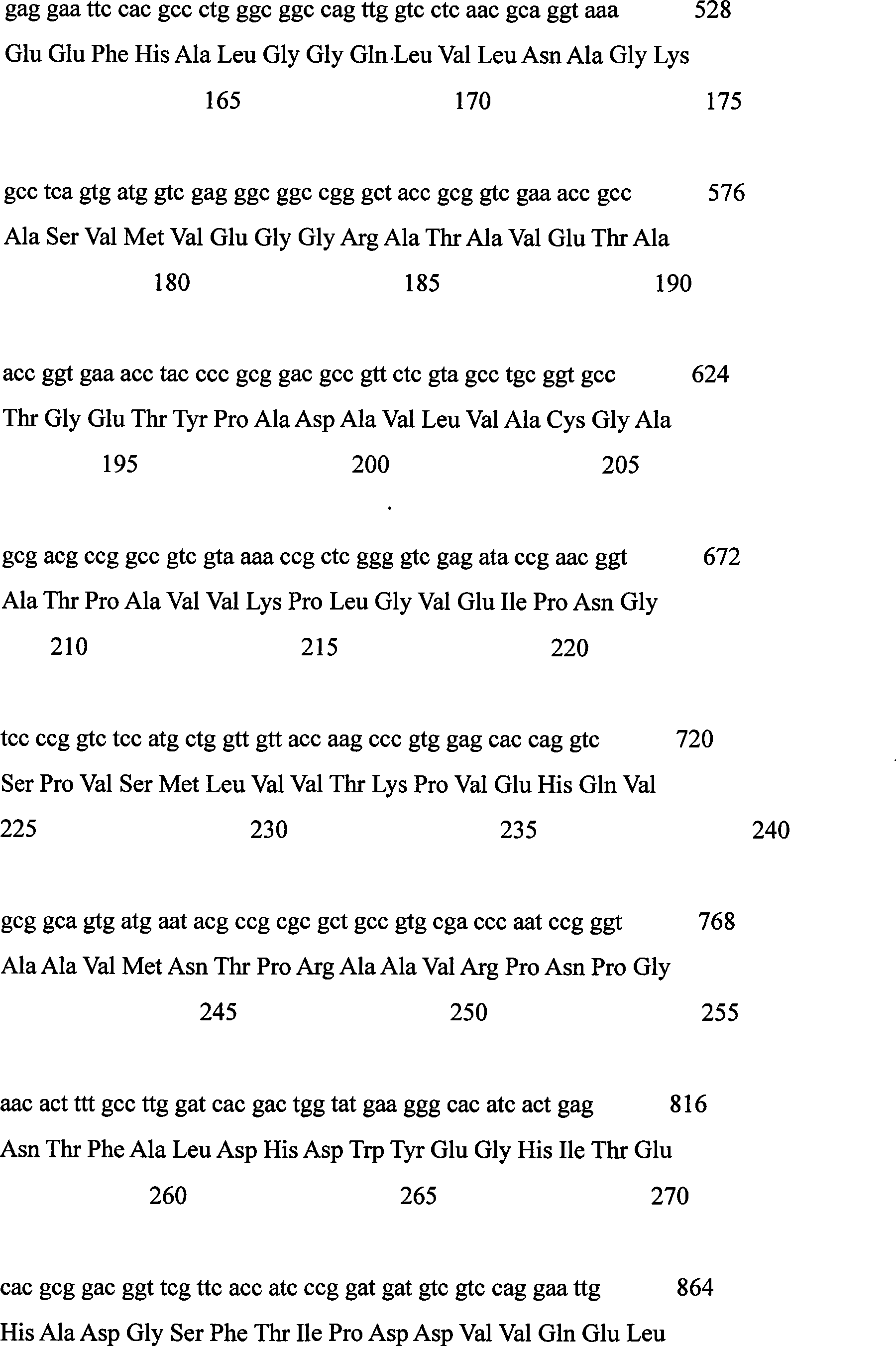

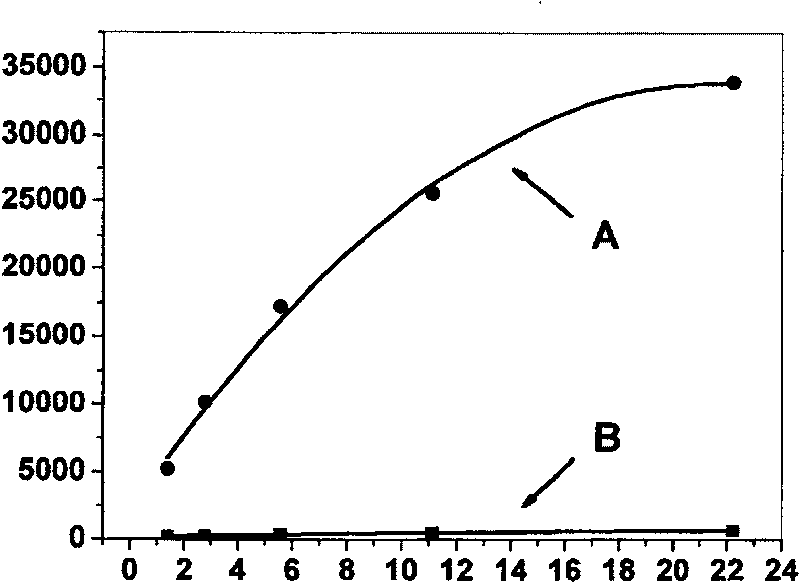

Gene encoding of firefly luciferase, its preparation method and application

InactiveCN102191213AImprove thermal stabilityMeet application requirementsBacteriaMicrobiological testing/measurementEscherichia coliCompetent cell

The invention relates to a gene encoding of firefly luciferase, its preparation method and application, which comprises the following steps: 1. introducing mutation sites of mutant enzymes; 2. identifying recombinant plasmids; 3. sequencing to obtain polymerase chain reaction (PCR) fragment with 1060 mutation sites; 4. obtaining escherichia by using restriction endonucleasecoli purifying after recovering and purifying through gel; 5. identifying recombinant plasmids to obtain a separating protein gene; 6. culturing escherichia coli, 7. converting recombinant plasmids into BL21 competent cell to obtain bacterial strain capable of expressing mutant enzymes, 8. culturing the obtained BL21 expression bacterial strain; 9. centrifuging bacteria liquid of protein, centrifuging to obtain supernatant through ultrasonic fragmentation; 10. determining to obtain firefly luciferase with high heating stability and high enzyme activity. The invention relates to application of firefly luciferase gene on foodstuff, medicine, thalline detection. The luminous intensity of the mutant enzyme is about 15 to 20 times than that of wild type, and the mutant enzyme has good heat stability than that of the wild type.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Method for producing grape skin health-care beverage

ActiveCN102138687AIncrease the juice yieldEfficient degradationFood preparationFilter materialEnzyme

The invention relates to a method for producing grape skin health-care beverage and belongs to the technical field of beverage processing. The method comprises the following steps of: selecting and cleaning fresh grape skin serving as a raw material; adding 0.02 percent of isoVc sodium and 0.15 percent of citric acid to protect color; crushing and pulping the grape skin to prepare grape skin pulp; promoting composite enzymolysis ultrasonically; filtering by using a filtering material with 100 to 350 meshes or performing centrifugal separation at 3,000 to 5,000 r / min; mixing; performing vacuumdegassing under vacuum degree of 0.09 MPa for 20 to 25 minutes; homogenizing under 30 to 40 MPa; after performing encapsulation, performing sterilization at the temperature of between 135 and 150 DEGC for 35 to 60 seconds; cooling; performing labeling; spraying codes; and preparing the finished product after the product is inspected to be qualified. In the method, the enzymolysis reaction time is shortened by 50 percent and the enzyme adding amount is reduced by 20 percent, so that enzymolysis efficiency is improved and production cost is reduced. The processed health-care beverage has rich nutrients and good quality and is suitable for people of all ages to drink. The quality guarantee period of the beverage is more than 12 months. By the method, the grape skin is utilized at high value; waste is changed into treasure; and obvious economic, social and ecological benefits are achieved.

Owner:内蒙古云飞酒业有限公司

Method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by aqueous enzymatic method

InactiveCN105505558AEffective destructionStrong bean flavorFatty-oils/fats productionMilk substitutesFiberHydrolysate

The invention relates to a method for synchronously extracting soybean oil, soybean milk powder and soybean dietary fiber by an aqueous enzymatic method, which belongs to the technical field of plant grease processing. The method comprises the following steps: 1) dehulling soybeans and crushing the soybeans, extruding and puffing the material to obtain a puffed product; 2) adding water into an enzymatic hydrolysis reaction vessel, heating steam and adding the puffed product to obtain a mixed liquor, performing alkaline extraction on the mixed liquor, adding alkali protease for performing enzymatic hydrolysis, using a horizontal centrifuge after enzymatic hydrolysis is carried out for performing centrifugation to obtain an emulsified oil, a hydrolysate and residues; 3) using a disk centrifuge for performing centrifugation on the emulsified oil to obtain the soybean oil and a water phase, adding the water phase into the hydrolysate for concentration, and drying the material to obtain the soybean milk powder; and 4) adding water for mixing the water and the residues for homogenizing and drying a mixture to obtain the soybean dietary fiber. The method has the advantages of simple process, less enzyme usage amount, short reaction time, and low cost. The prepared high-quality soybean oil can obtain the high-nutrition partly-defatted soybean milk powder and high-oil high-protein soybean dietary fiber, and is suitable for industrial continuous production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

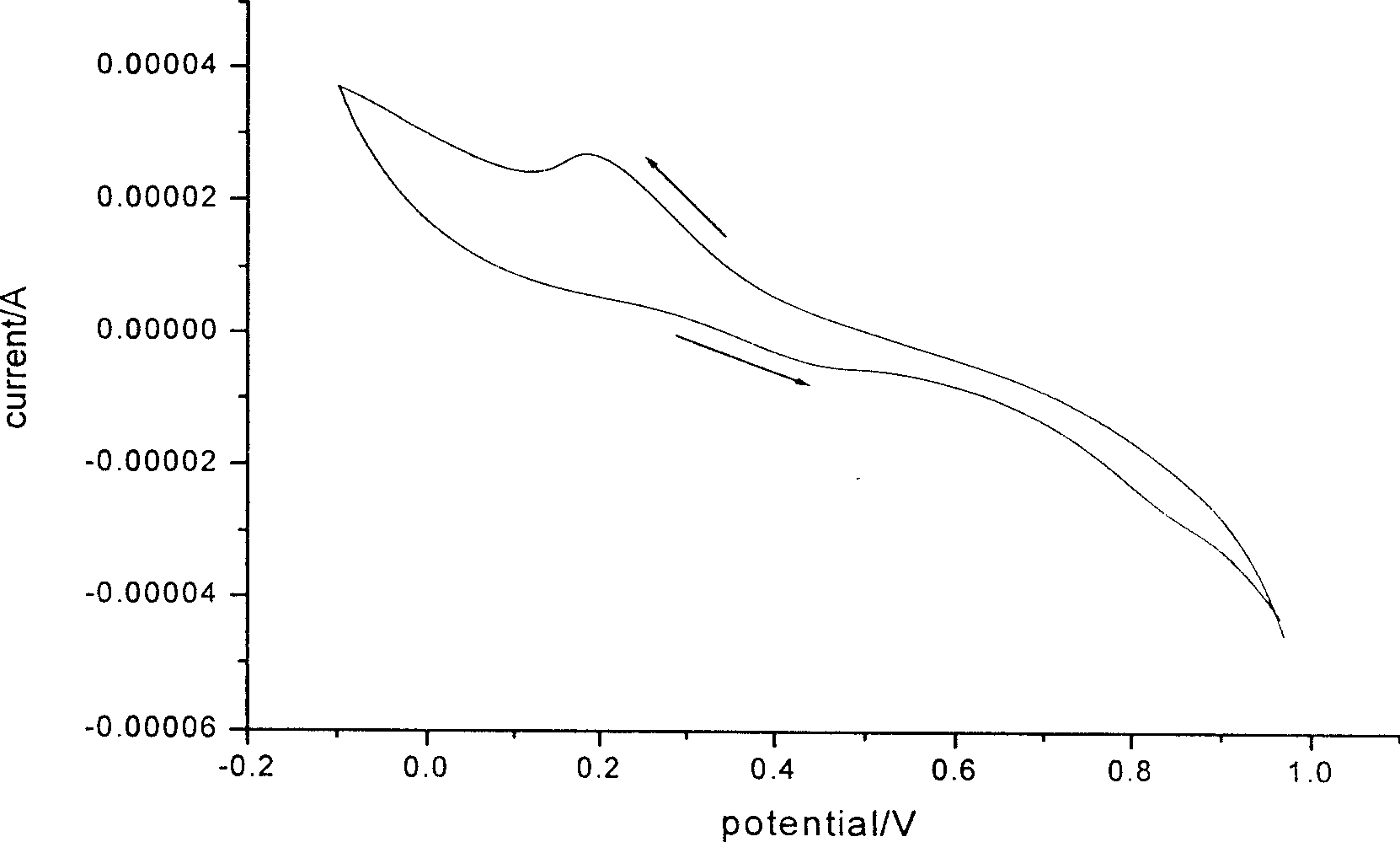

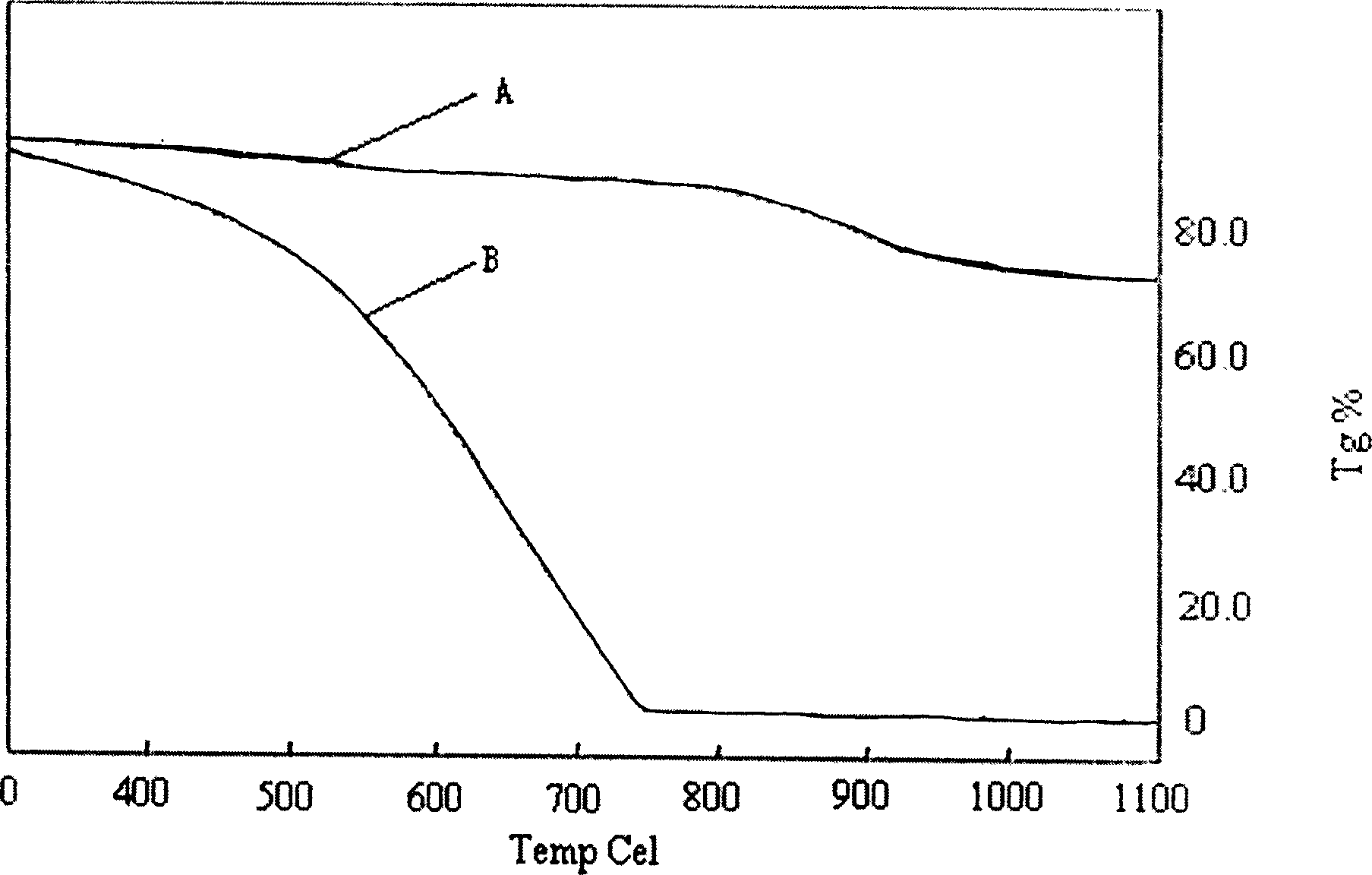

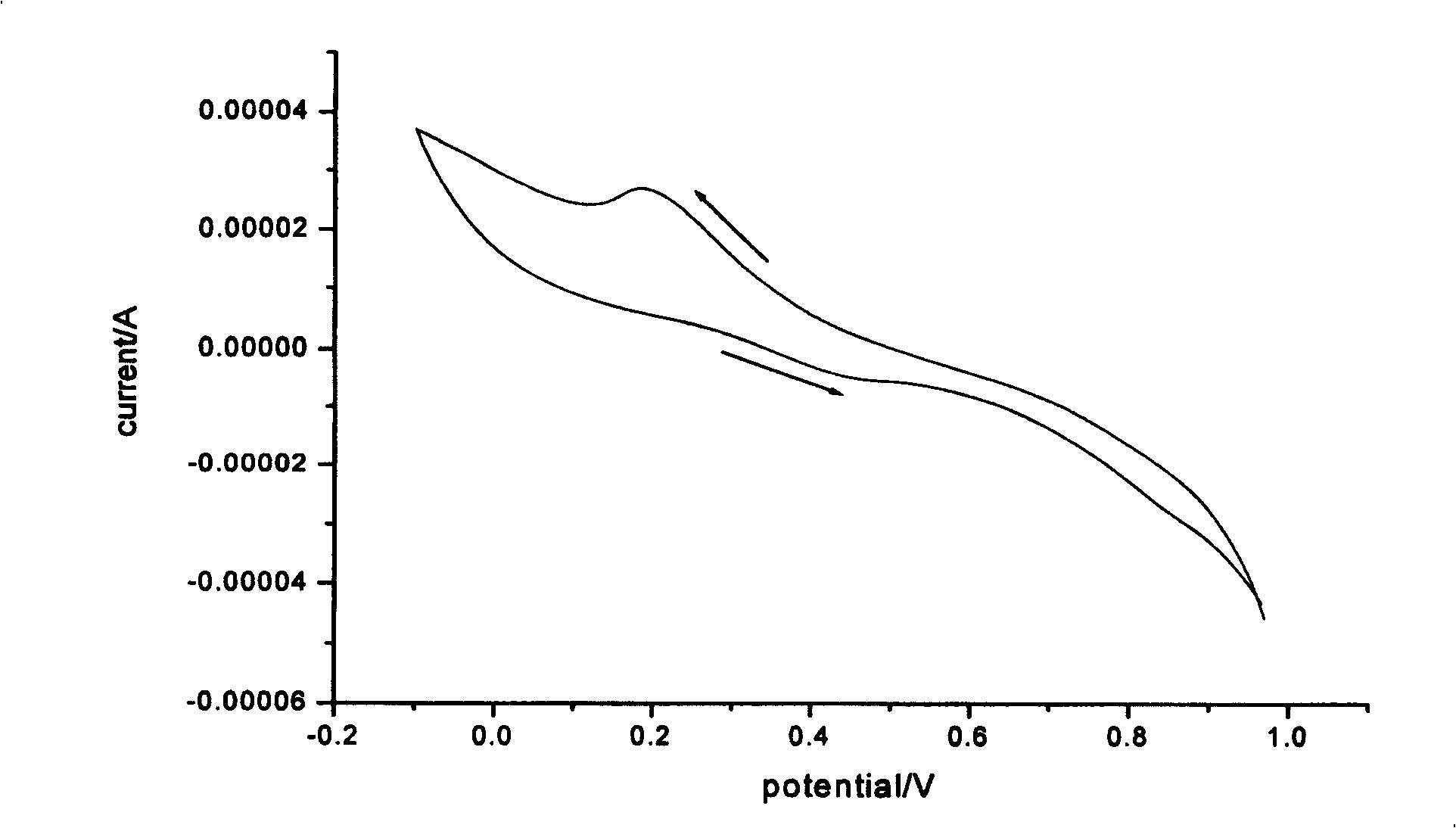

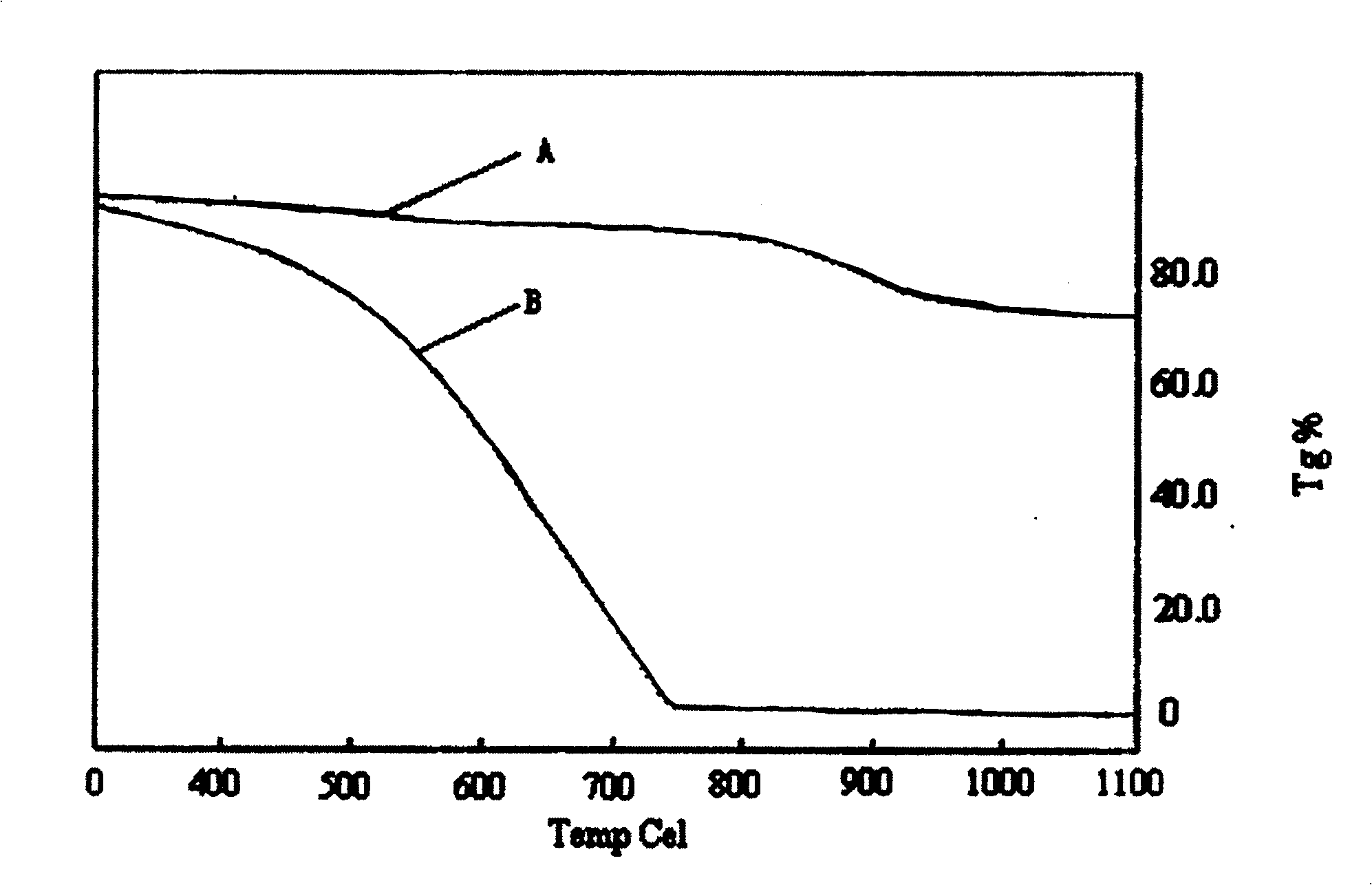

Water-soluble high temperature-resistant polyaniline conducting material and its preparation method

The invention relates to water-soluble poly amino benzenes high temperature resisting conductive material and method for preparation, wherein the material is prepared from p-phenylene diamine 54-216 parts, monomer propenoic acid 35-71 parts, horseradish peroxidase 0.05-3 parts as raw material, p-phenylene diamine and propenoic acid as monomers, deionized water as solvent, horse radish peroxidase HRP as catalyst, H2O2 as oxidation agent through copolymerization, acetone deposition and vacuum drying 48 hours at 50 deg C.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for purifying and immobilizing gamma-lactamase and splitting (+/-) gamma-lactam by one step

InactiveCN101544972ASimple purification processReduce manufacturing costOn/in organic carrierFermentationSulfolobus solfataricusGamma-lactamase

The invention belongs to the field of enzyme engineering, and particularly relates to a method for purifying and immobilizing gamma-lactamase and splitting (+ / -) gamma-lactam by one step. Gamma-lactam hydrolase is immobilized on a Ni-NTA agarose affinity column, and (+) gamma-lactam is hydrolyzed on the column so as to split the (+ / -) gamma-lactam. Plasmids of heat-resistant gamma-lactam hydrolase genes with sulfolobus solfataricus are transferred into colon bacillus to construct gene engineering bacteria capable of expressing the gamma-lactam hydrolase with histidine marks at an N end and a C end or gene engineering bacteria capable of expressing the gamma-lactam hydrolase with histidine marks at only one end of the N end and the C end. And then, the enzyme with the histidine marks is further purified and immobilized on the Ni-NTA agarose affinity column, and a (+ / -) gamma-lactam substrate is continuously converted on the column under the conditions that the pH value is 5 to 10 and the temperature is between 30 and 100 DEG C; the conversion rate can be kept at more than 80 percent; and the optical purity of a product is more than 99 percent.

Owner:BEIJING UNIV OF CHEM TECH

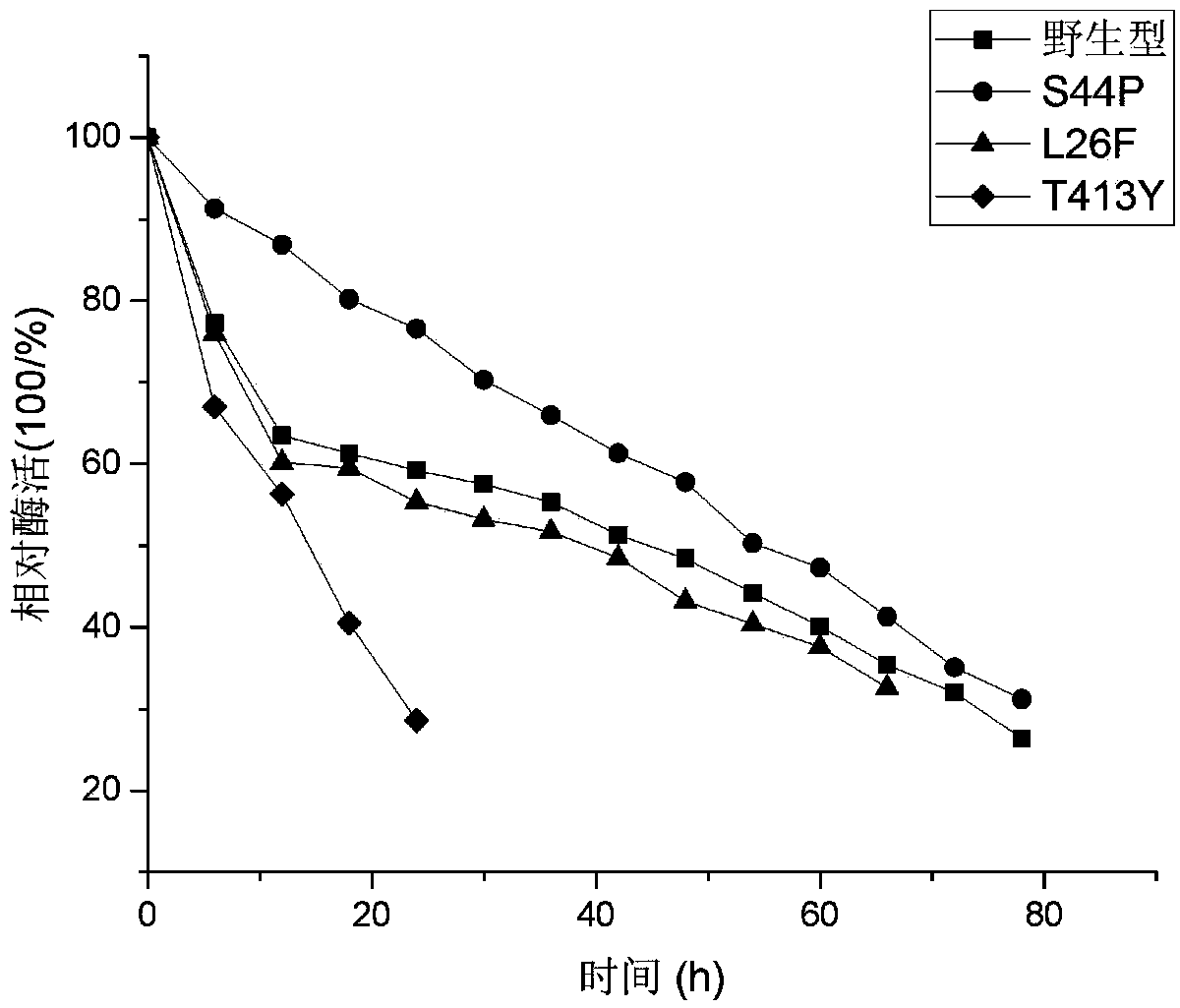

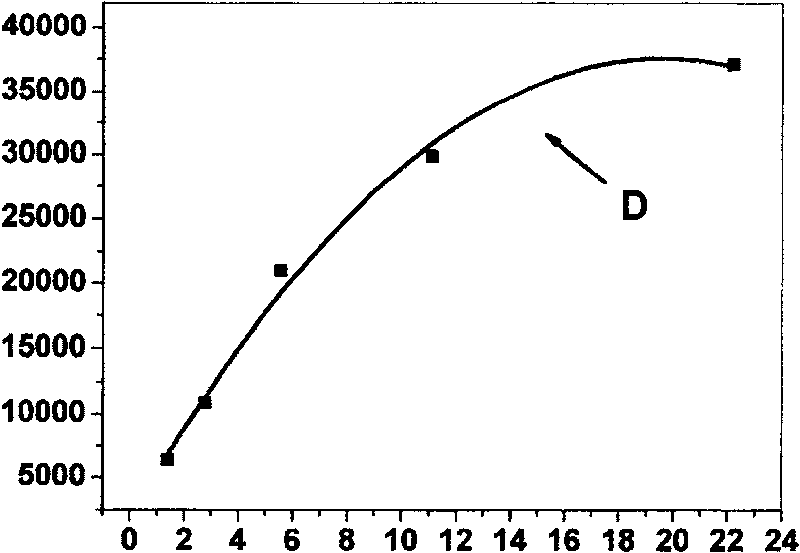

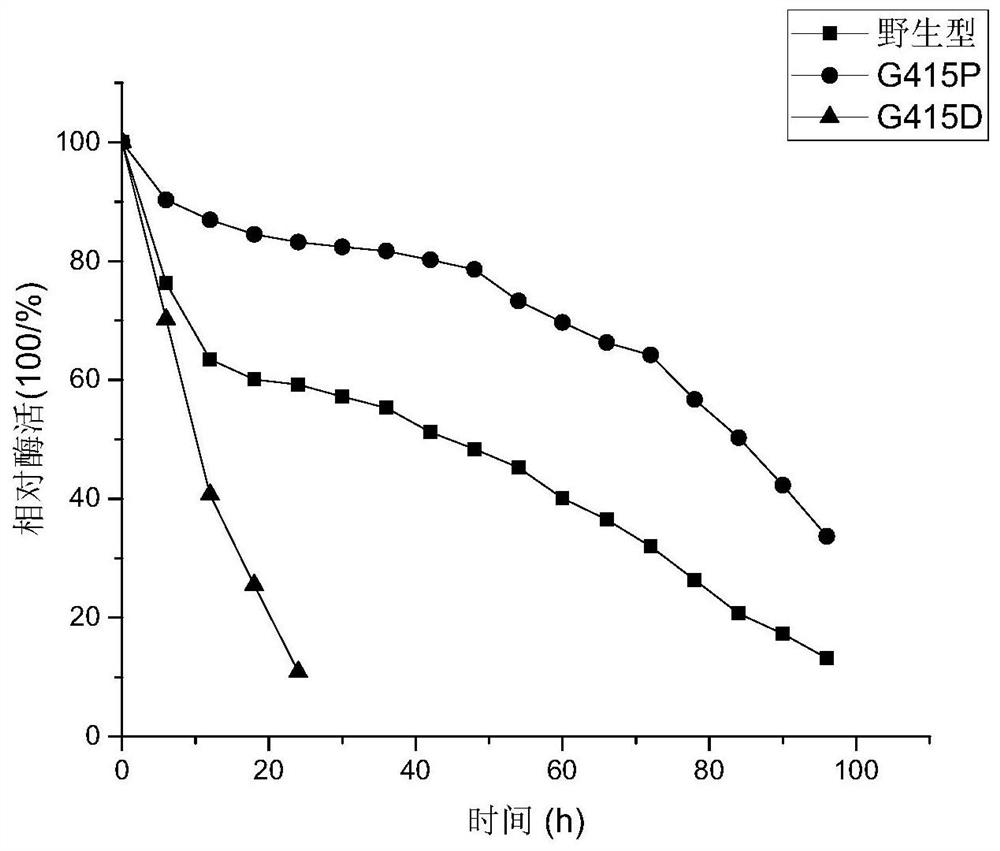

Thermal stability and trehalose yield improved MTSase mutant

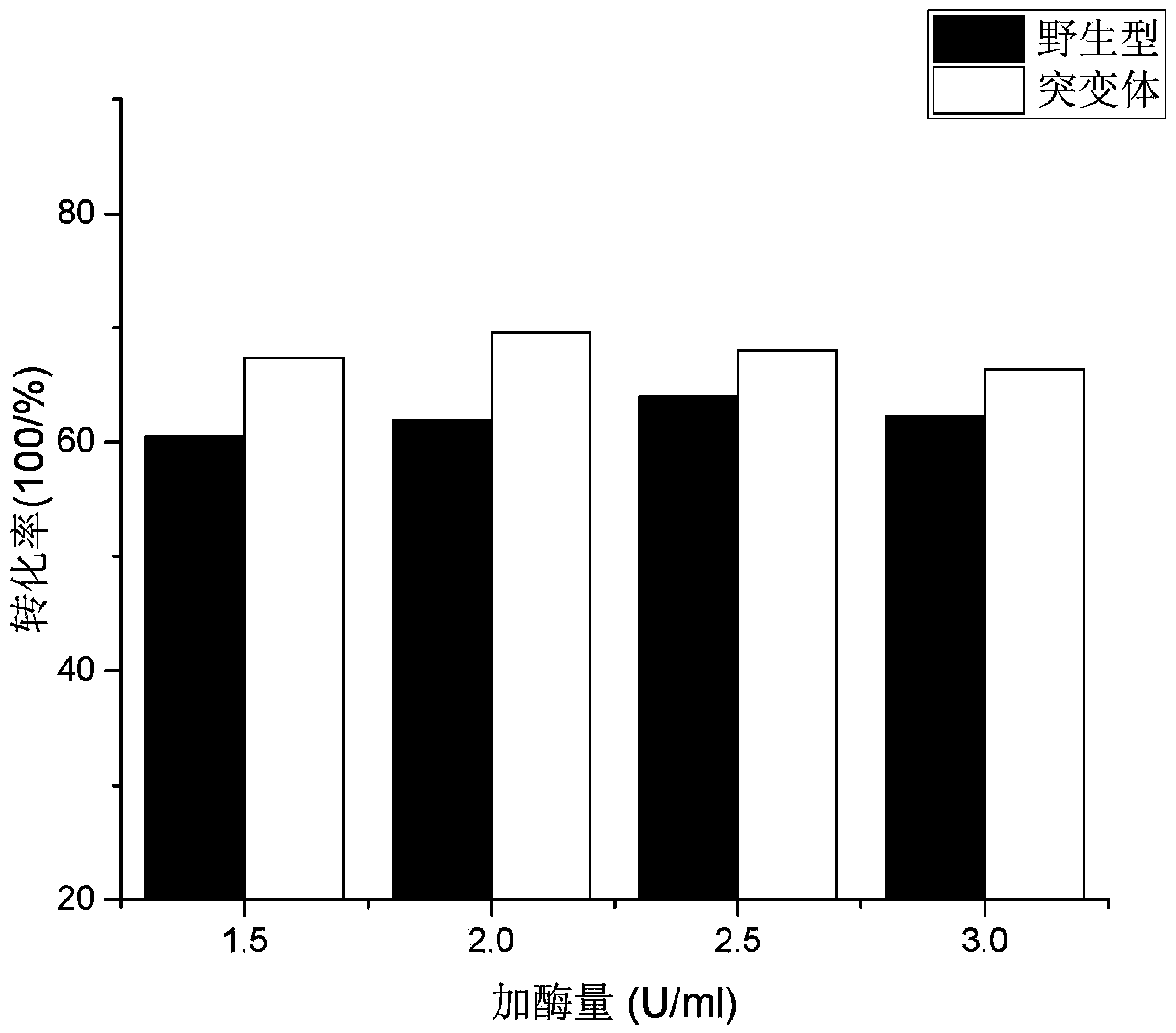

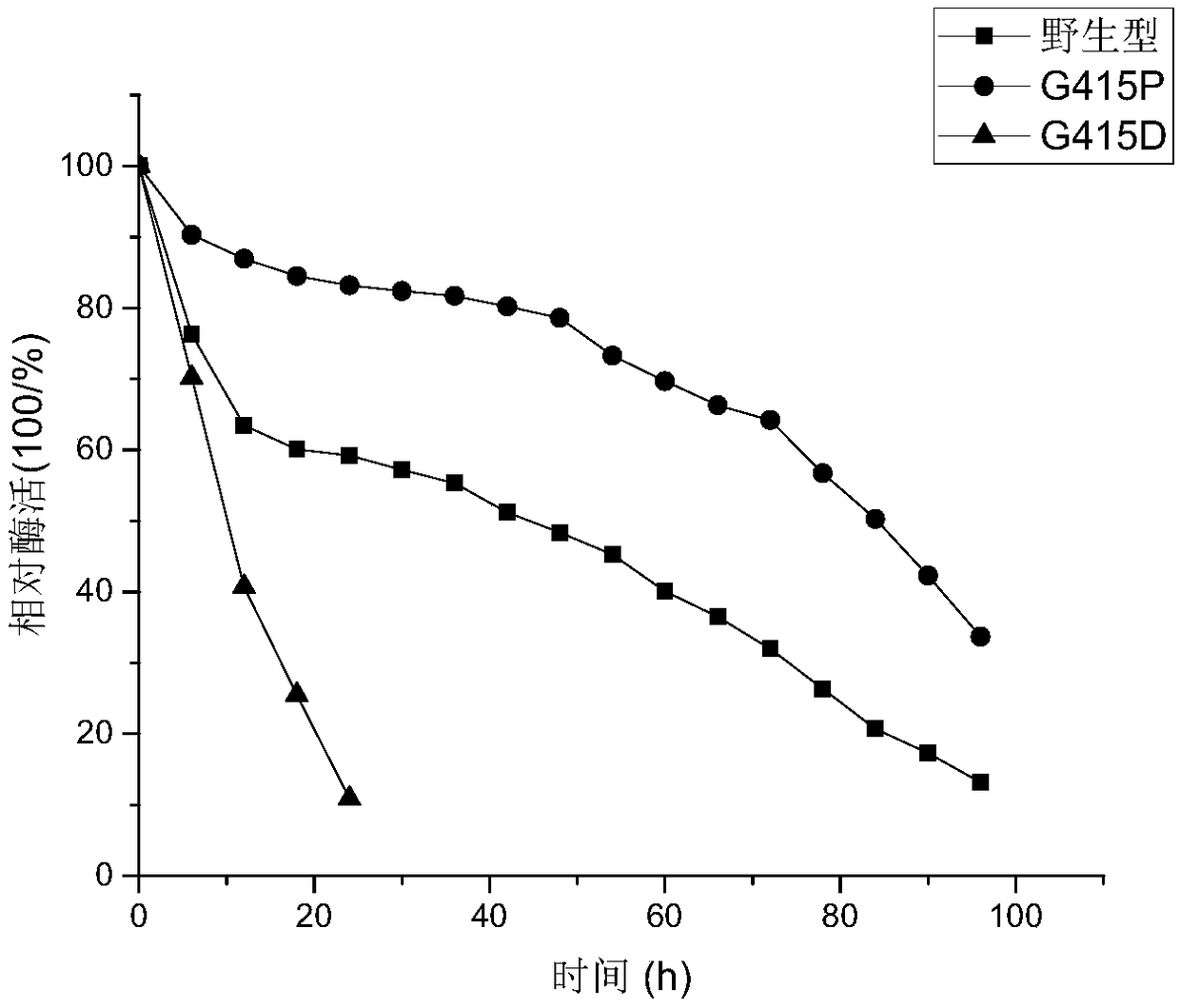

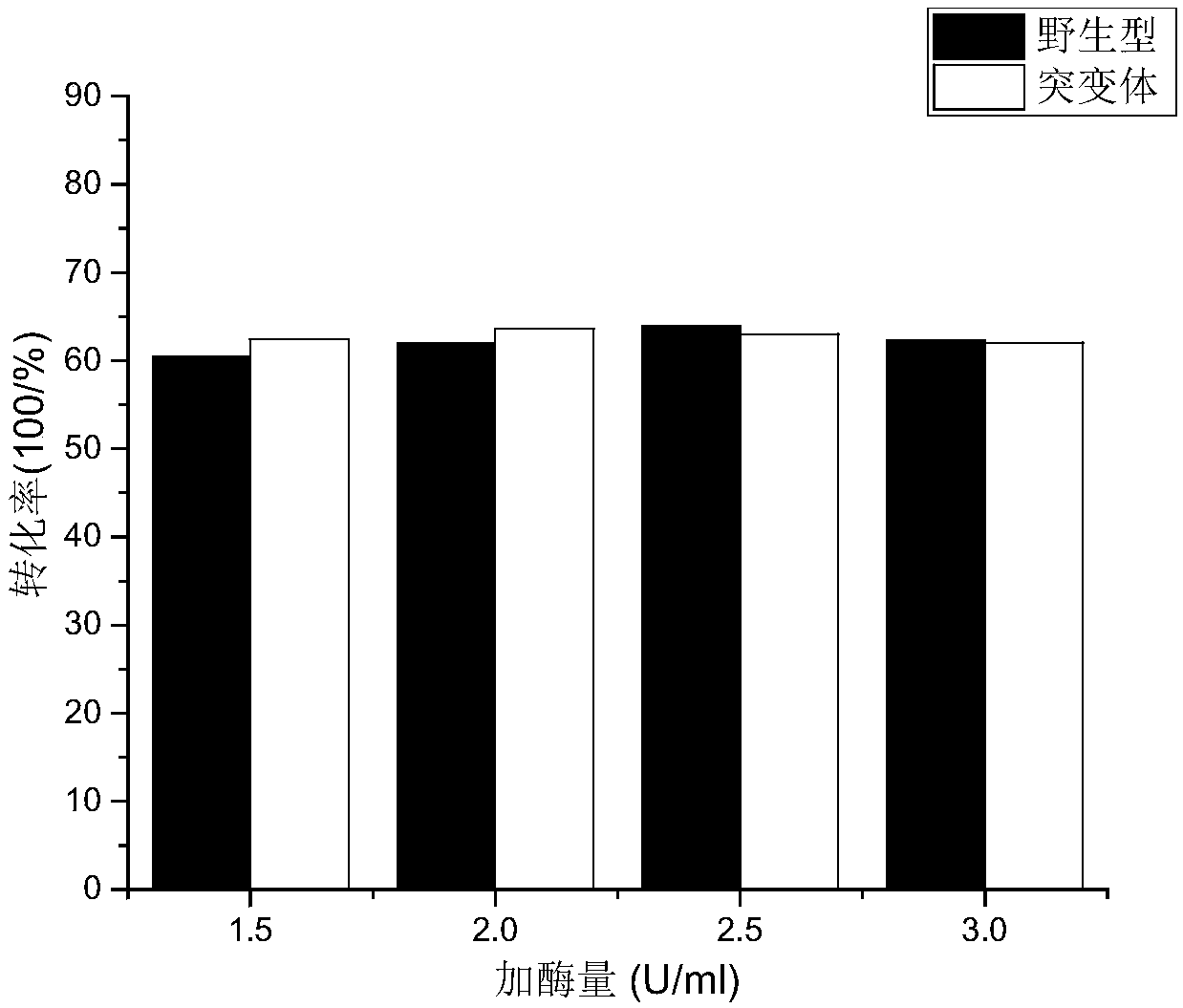

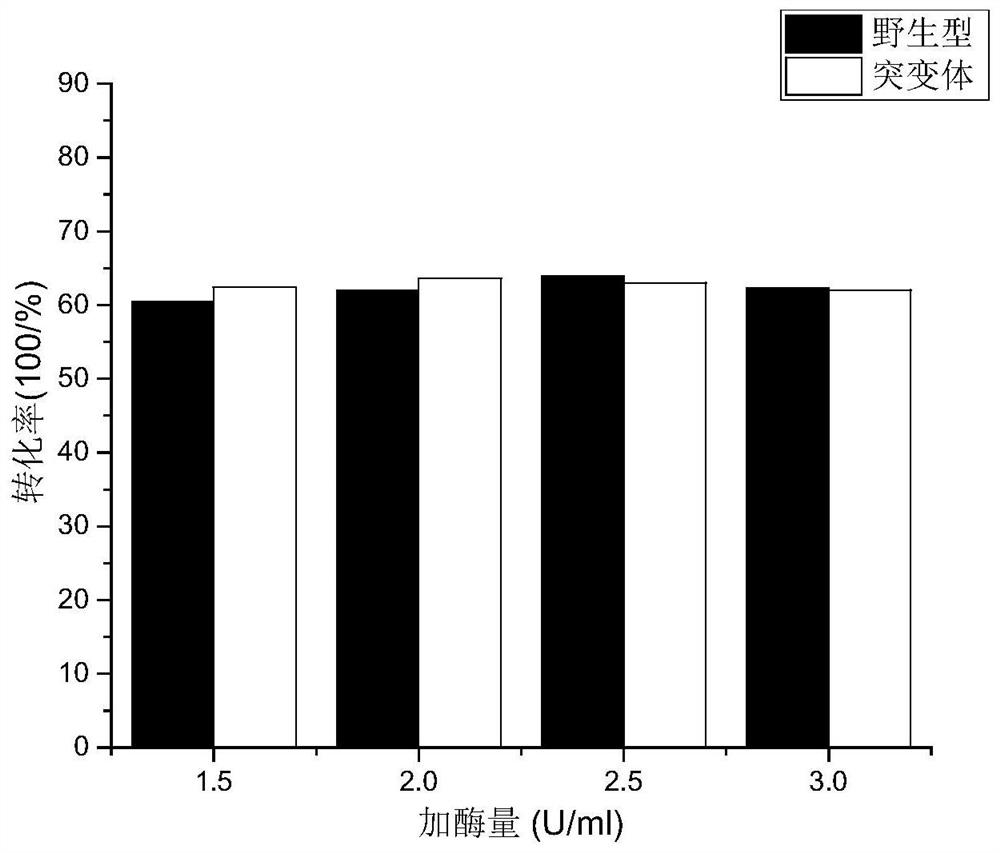

ActiveCN108753747AIncreased thermostability of synthetasesReduce the amount of enzymeGenetic engineeringFermentationHalf-lifeWild type

The invention discloses thermal stability and trehalose yield improved MTSase mutant and belongs to the technical field of enzyme engineering and protein engineering. The maltooligosyl trehalose synthase mutant disclosed by the invention is prepared by mutating one amino acid site of maltooligosyl trehalose synthase. Compared with parent maltooligosyl trehalose synthase, the prepared maltooligosyltrehalose synthase has higher thermal stability, a lower enzyme adding amount and a higher trehalose producing conversion rate. Compared with a wild type, a half-life period of the maltooligosyl trehalose synthase mutant disclosed by the invention at 50 DEG C is increased by 12 hours, and the half-life period of the maltooligosyl trehalose synthase mutant disclosed by the invention is 1.3 times of the half-life period of the wild type.

Owner:JIANGNAN UNIV

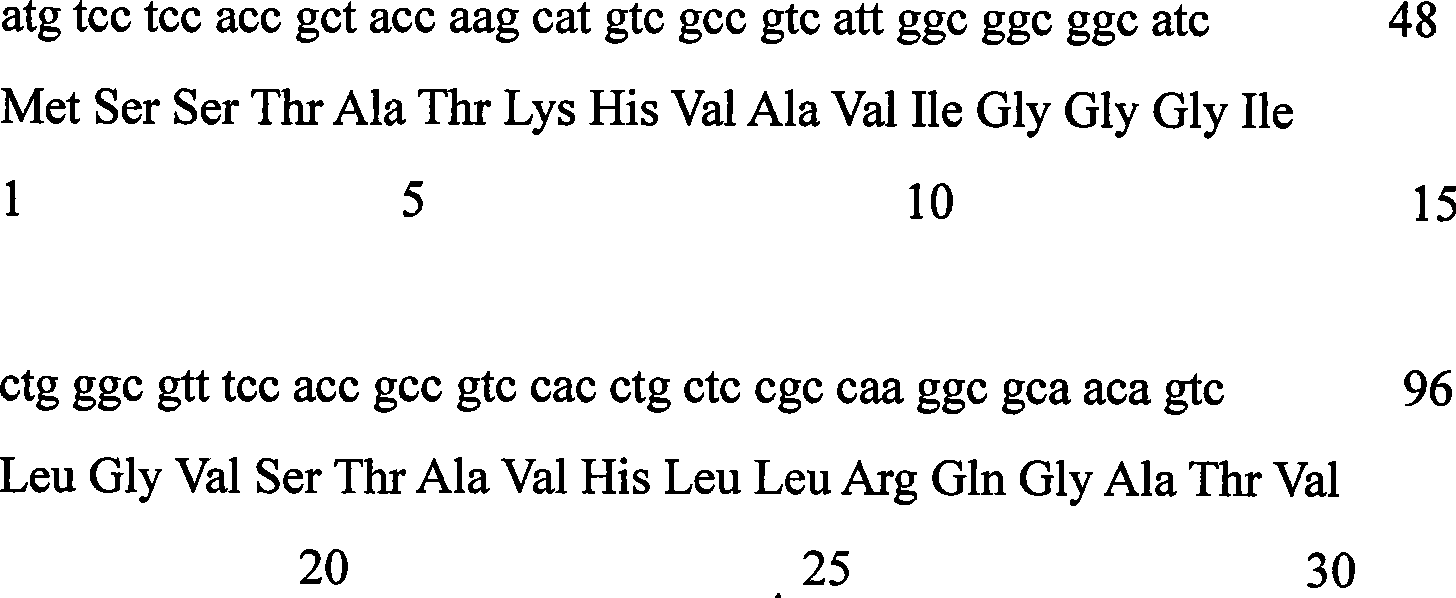

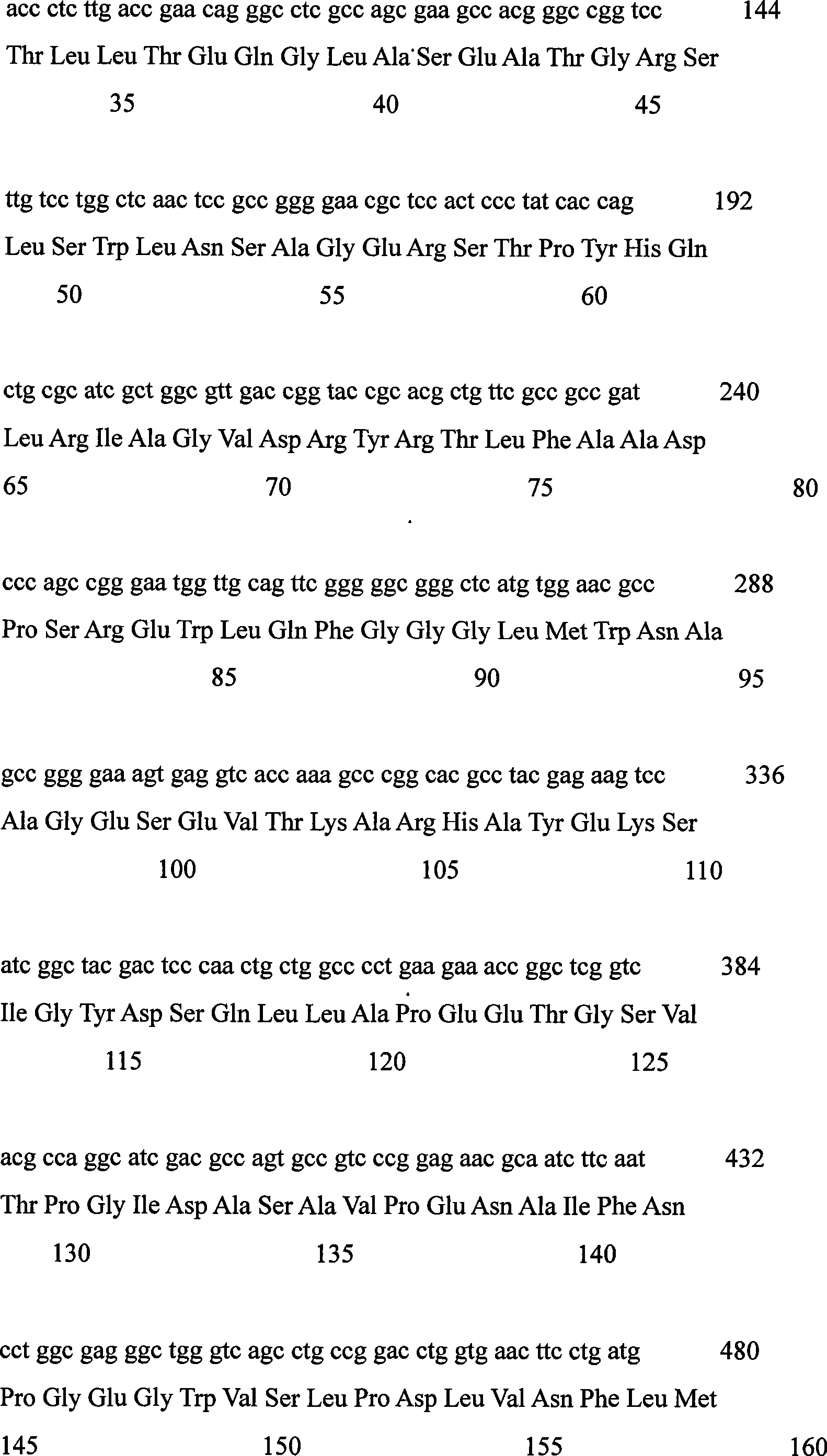

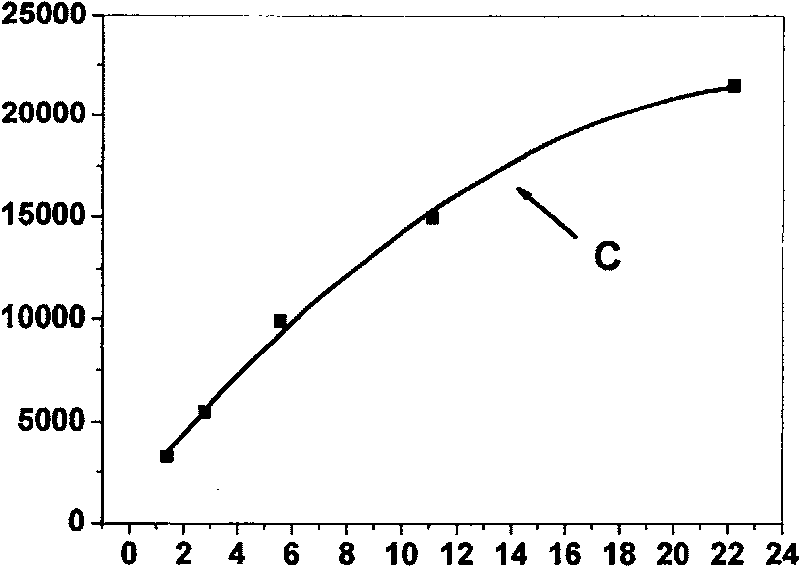

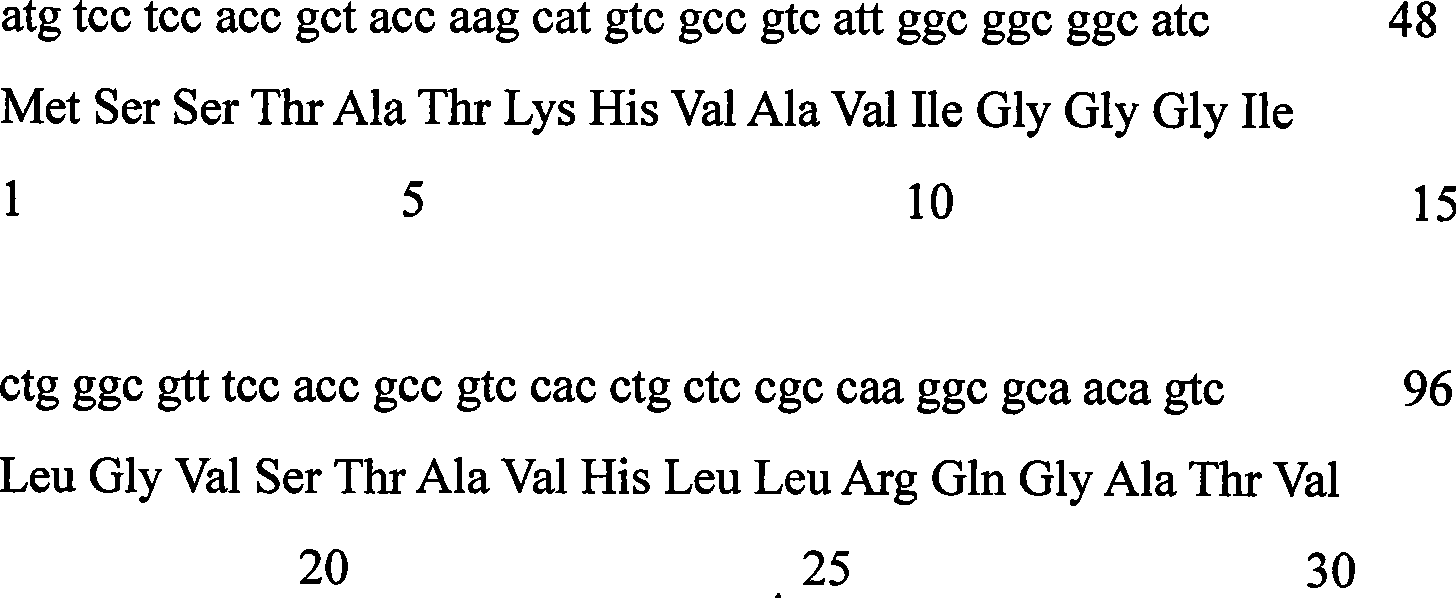

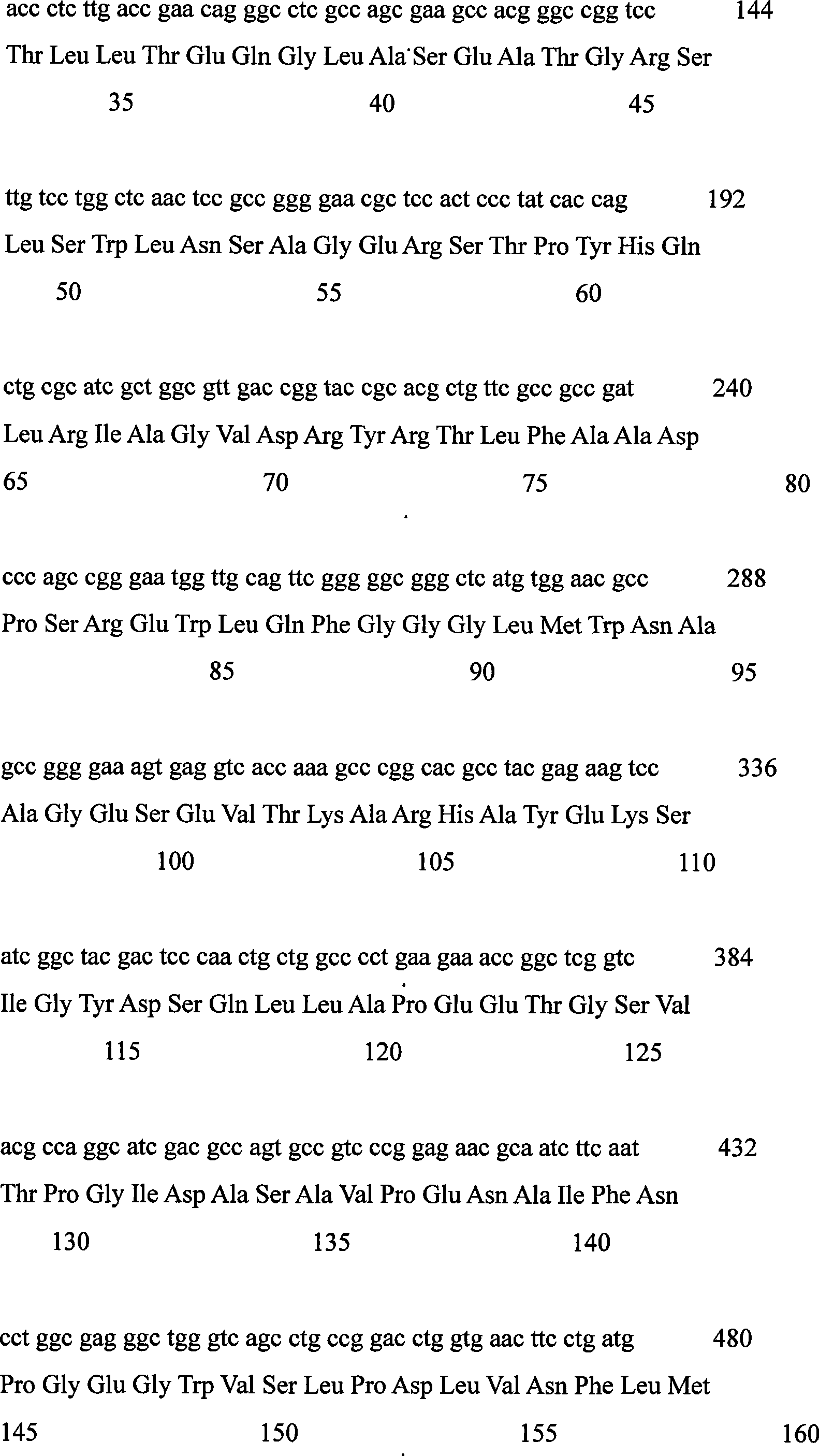

Firefly luciferase and encoding gene and obtaining method thereof

ActiveCN103409380AHigh catalytic activityHigh activityBacteriaMicroorganism based processesHeat stabilityWild type

The invention relates to firefly luciferase and an encoding gene and an obtaining method thereof. The defect that the original firefly luciferase in North America is poor in heat stability and cannot be used at a high temperature is overcome; and the original firefly luciferase in North America is mutated, so that mutative enzyme of which the heat stability is obviously improved is obtained; and the application value is improved. An amino acid sequence is SEQ ID NO.1; and a protein deoxyribonucleic acid (DNA) sequence in encoding is SEQ ID NO.2. An encoding gene and a preparation method of firefly luciferase mutant in North America are provided. By the method, a recombinant expression vector containing a wild firefly luciferase gene is built; and the protein is purified by using an affinity chromatography method. The method is simple and feasible, simple to operate, and low in cost.

Owner:TIANJIN UNIV

Thermal stability improved maltooligosyl trehalose synthase mutant

ActiveCN108753746AIncreased thermostability of synthetasesImprove stabilityBacteriaFermentationHalf-lifeWild type

The invention discloses thermal stability improved maltooligosyl trehalose synthase mutant and belongs to the technical field of enzyme engineering and protein engineering. The maltooligosyl trehalosesynthase mutant disclosed by the invention is prepared by mutating one amino acid site of maltooligosyl trehalose synthase. Compared with parent maltooligosyl trehalose synthase, the maltooligosyl trehalose synthase mutant has higher stability. Compared with a wild type, a half-life period of the maltooligosyl trehalose synthase mutant disclosed by the invention at 50 DEG C is increased by 41 hours; the half-life period of the maltooligosyl trehalose synthase mutant disclosed by the invention is 2 times of the half-life period of the wild type; namely, compared with the wild type, the stability of the maltooligosyl trehalose synthase mutant disclosed by the invention is improved by twice.

Owner:JIANGNAN UNIV

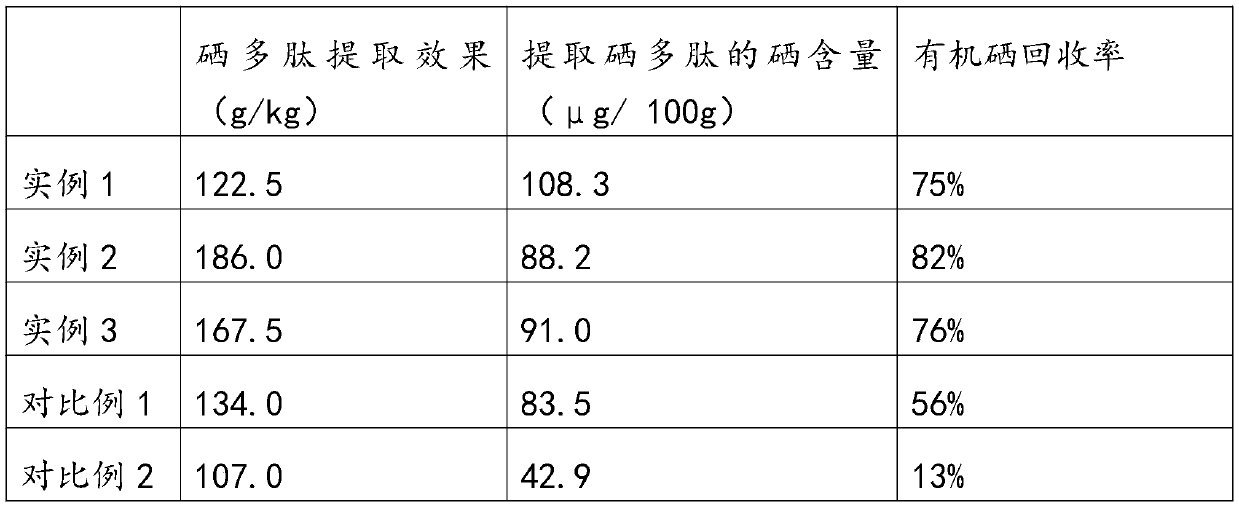

Method for extracting selenium polypeptide from selenium-rich passion fruit seeds

ActiveCN110699412AAvoid lostFew stepsPeptide preparation methodsFermentationBiotechnologyPassion fruit

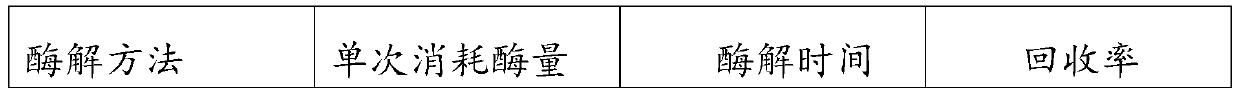

The invention discloses a method for extracting selenium polypeptide from selenium-rich passion fruit seeds. The method comprises the following steps: taking out, cleaning and drying selenium-rich passion fruit seeds, performing crushing and sieving, carrying out ultrasonic treatment, carrying out ultrasonic action to separate grease in a mixed solution, centrifugally removing oil, performing precipitating to obtain a protein mixture in the passion fruit seeds, performing homogenizing to turn proteins into a stable system, carrying out enzymolysis by using an immobilized enzyme, and carrying out centrifugal separation to obtain the purified selenium-containing polypeptide mixture of the passion fruit seeds. According to the method, the selenium polypeptide in the passion fruit seeds can berapidly extracted and utilized. Compared with traditional methods, the method has the advantages of easy operation, low cost and high extraction recovery rate, and the extracted selenium polypeptideis good in quality and remarkable in economic value effect.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Fishscale collagen production process

ActiveCN100370033CSignificant positive effectGuaranteed complete enzymatic digestionFermentationWaste materialFish scale

The invention discloses a fish scale collagen process technology that is made up from the process of twice acid process, alkali neutralized, boiling, enzymolysis, exchanging absorbing, concentrating, filtering, drying and spraying. The invention also supplies the invention to easily produce fish scale collagen produce technology. The invention has low molecular weight, stability, and low content or ash content.

Owner:YANTAI DONGCHENG PHARMA GRP

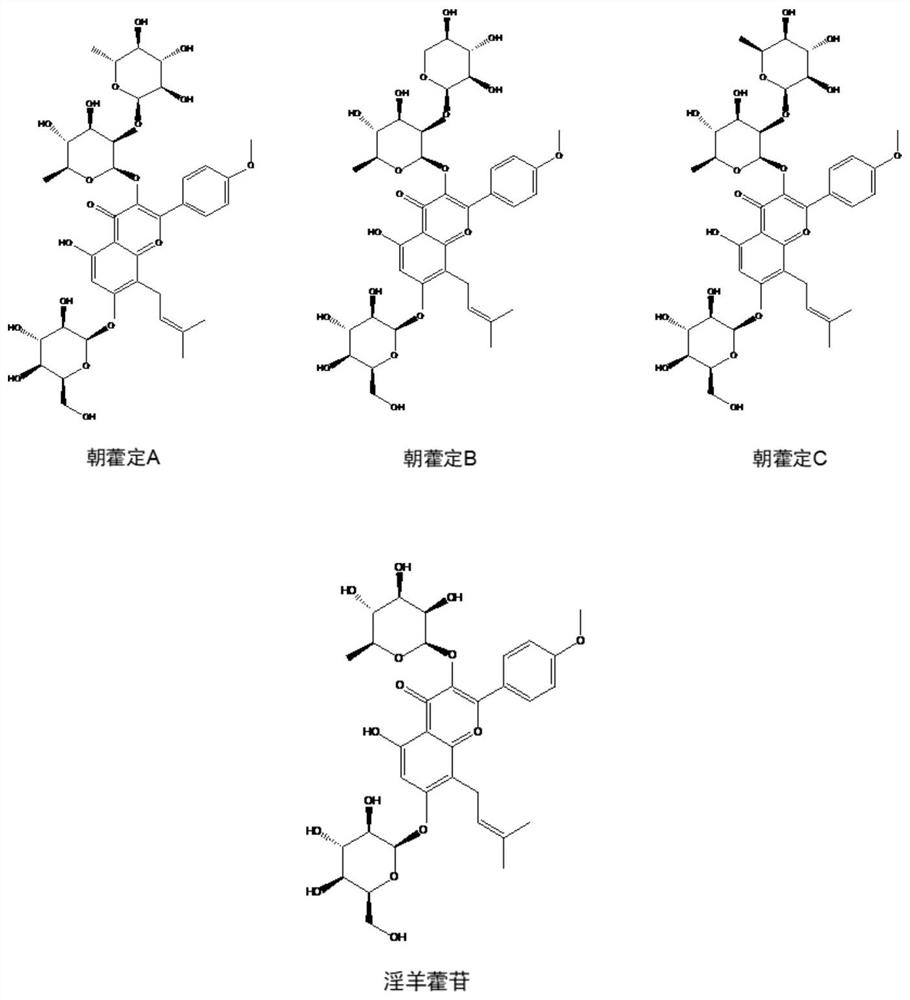

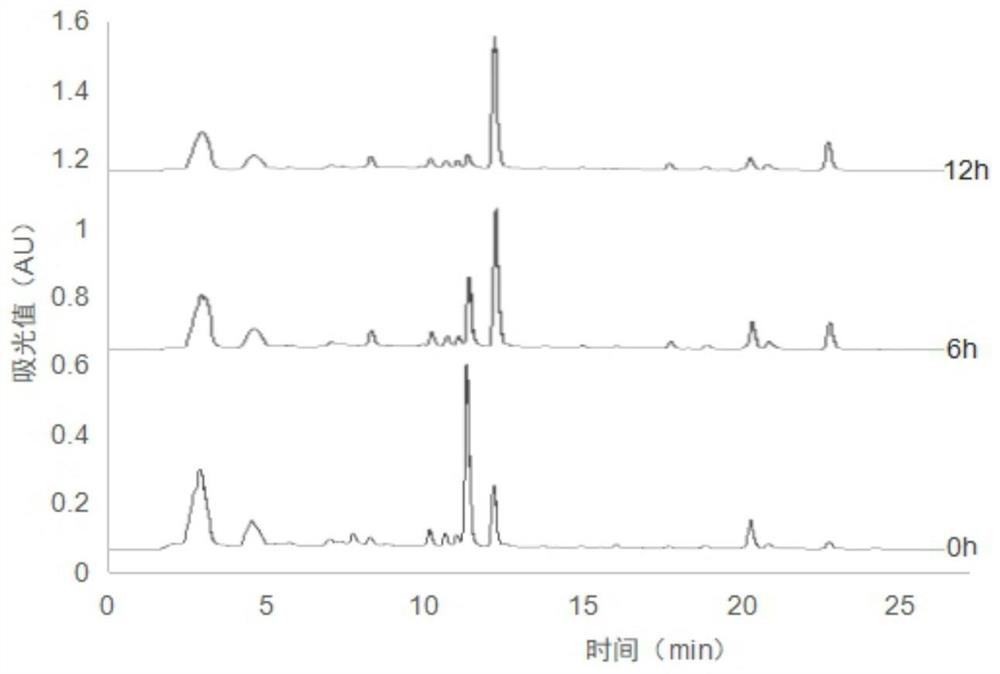

Method for preparing icariin by using biphasic enzymatic reaction

The present application relates to a method for preparing icariin using a biphasic enzymatic reaction. The reaction uses an enzyme to convert epimedin A / B / C in an epimedium extract into an enzymatic hydrolysate icariin. The method comprises the following steps: preparing an epimedium extract; carrying out the biphasic enzymatic reaction, wherein a first phase is a buffer phase and the first phase has a good solubility with respect to epimedin A / B / C in the epimedium extract, and a second phase is an organic phase and the second phase has a good solubility with respect to icariin as the enzymatic hydrolysate; and separating and purifying the product icariin, wherein an enzyme used for the biphasic enzymatic reaction is coated with non-water-soluble starch, so that the enzyme is located at the phase interface of the first phase and the second phase when the biphasic enzymatic reaction is carried out.

Owner:XIAN GIANT BIOGENE TECH CO LTD

Firefly luciferase and encoding gene and obtaining method thereof

ActiveCN103409380BHigh catalytic activityHigh activityBacteriaMicroorganism based processesLuciferase GeneMutant

The invention relates to firefly luciferase and an encoding gene and an obtaining method thereof. The defect that the original firefly luciferase in North America is poor in heat stability and cannot be used at a high temperature is overcome; and the original firefly luciferase in North America is mutated, so that mutative enzyme of which the heat stability is obviously improved is obtained; and the application value is improved. An amino acid sequence is SEQ ID NO.1; and a protein deoxyribonucleic acid (DNA) sequence in encoding is SEQ ID NO.2. An encoding gene and a preparation method of firefly luciferase mutant in North America are provided. By the method, a recombinant expression vector containing a wild firefly luciferase gene is built; and the protein is purified by using an affinity chromatography method. The method is simple and feasible, simple to operate, and low in cost.

Owner:TIANJIN UNIV

Levulose valine oxidizing enzyme of high activity and method of producing the same

ActiveCN101368174AHigh activityReduce the amount of enzymeOxidoreductasesFermentationEscherichia coliFructose

The invention relates to high-activity fructose valine oxidase and a preparation method thereof, the amino acid sequence of the fructose valine oxidase is the sequence of SEQ ID. No.2, and the nucleotide sequence is shown in SEQ ID.No.1. The preparation steps are: (1) error-prone PCR amplification is carried out with the FVO gene coded sequence of Corynebacterium sp.2-4-1 as the template to establish the mutation bank of the fructose valine oxidase; (2) the mutation bank is transferred into escherichia coli and the clone, reconstruction, conversion and expression are carried out to the gene of the transferred escherichia coli; and (3) the activity of enzyme is determined by utilizing the quinine method and the high-activity fructose valine oxidase is screened out. The activity of the obtained fructose valine oxidase is about 6 times of the activity of the ordinary fructose valine oxidase, the fructose valine oxidase can be used for testing saccharification Hb kit, the used amount of enzyme is reduced, and the reaction time is shortened.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

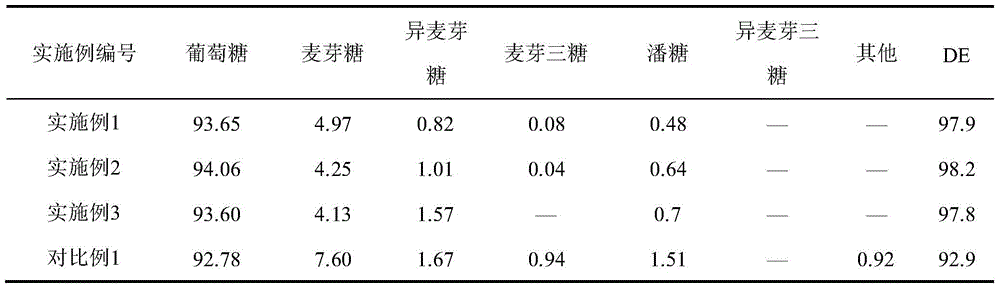

A method for improving the purity of high-concentration starch saccharification products

ActiveCN103981239BReduce the amount of enzymeReduce contentFermentationHigh concentrationGlucose-Fructose Syrup

The invention discloses a method of improving saccharification product purity of high-concentration starch and belongs to the technical field of starch saccharification. The starch is adopted as the main raw material. A starch liquefaction product is adopted as a substrate. A certain amount of pullulanase is added to replace a part of glucamylase, and participates the saccharification. High-concentration high-purity glucose syrup is finally obtained. The method increases the concentration of the substrate from 30% in industry to about 50%, and can reduce the evaporation energy consumption of glucose solutions in the later period of starch saccharification and can overcome the disadvantage that saccharification of high-concentration starch has many byproducts.

Owner:JIANGNAN UNIV

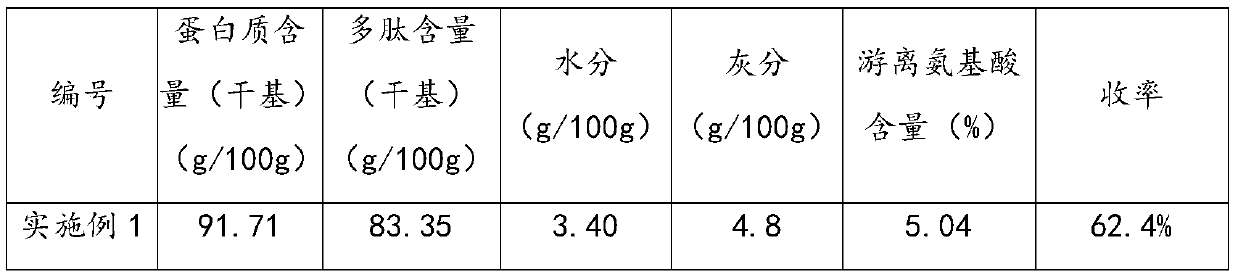

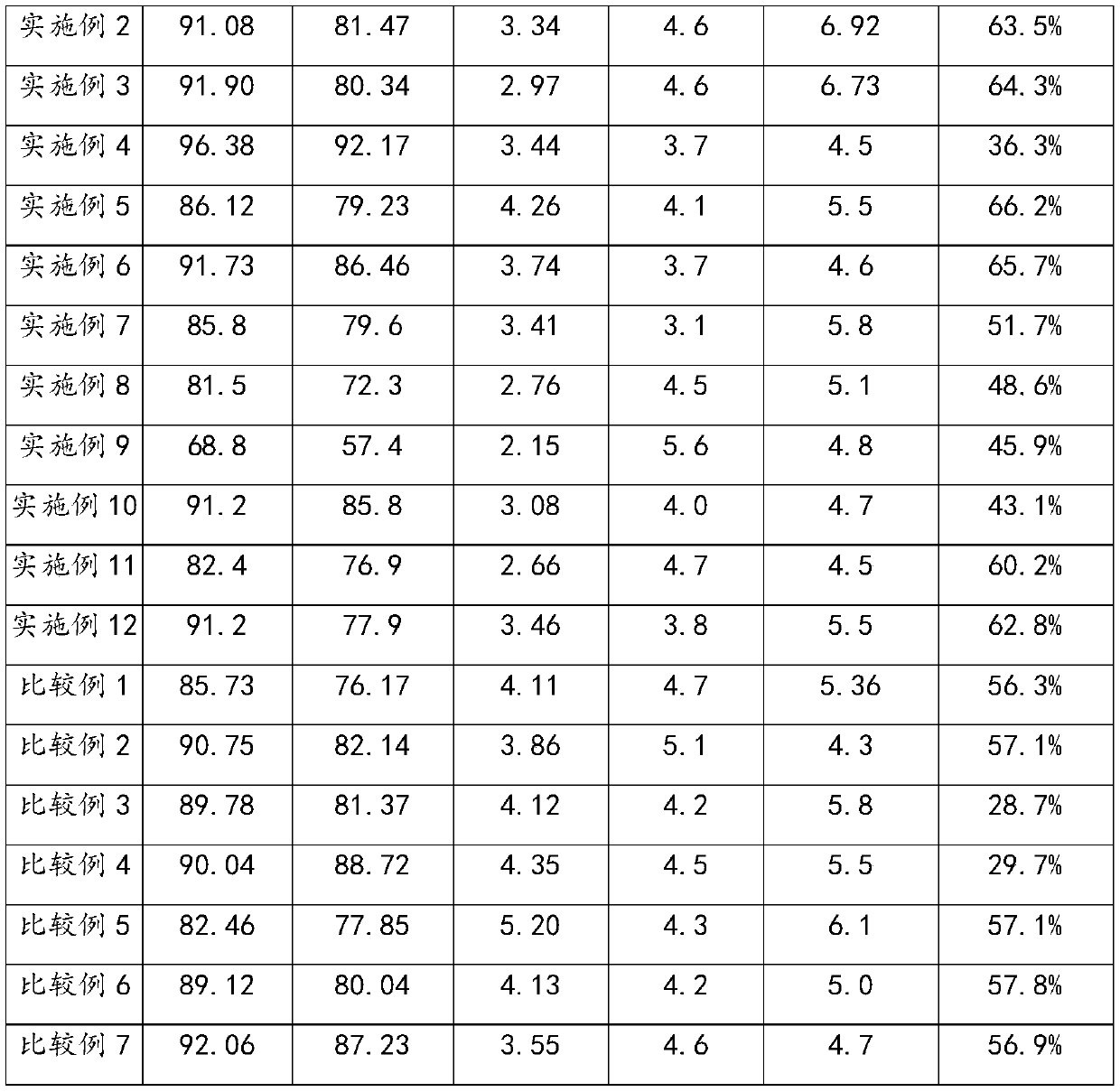

Vegetable protein peptide and preparation method thereof

The invention relates to the technical field of processing of vegetable protein, in particular to a vegetable protein peptide and a preparation method thereof. The preparation method of the vegetableprotein peptide comprises the following steps of (a) performing enzymolysis for 0.5 to 4 h on a mixture of vegetable protein and water under the vacuum condition of 50 to 55 DEG C under the effect ofan alkaline protease so as to obtain a mixed material; and (b) after the mixed material is subjected to enzymolysis for 1 to 2 h under the conditions of 50 to 55 DEG C and normal pressure under the effect of an enzyme A, performing enzymolysis for 0.5 to 2 h under the effect of a flavourzyme, wherein the enzyme A is selected from a neutral protease, a papain and a trypsin. The vegetable protein peptide and the preparation method provided by the invention have the advantages that the yield of the vegetable protein peptide can be greatly improved; the protein content and the polypeptide contentin the vegetable protein peptide are improved; the product quality is improved; the enzymolysis time can be reduced; the preparation period is shortened; pH regulation is not needed; the production cost is reduced; the production process is simplified; and the vegetable protein peptide and the preparation method can be used for mass production.

Owner:武汉天天好生物制品有限公司

Composite enzyme sensitive film containing Zn-VIA-family semiconductor nano-particle, its production and use

InactiveCN101074418BSuperiorApplicable measurementMicrobiological testing/measurementMaterial analysis by electric/magnetic meansCross-linkBio products

A high-sensitivity and stability composite enzyme functional sensitive film containing Zn-VIA family semiconductor nano-grain, its preparation and use are disclosed. The process is carried out by mixing Zn-VIA family semiconductor nano-sol with oxidizing enzyme solution, adding into polymer gel solution, agitating, adding into glutaric dialdehyde, cross-linking treating, and coating mixed solutiononto solid carrier surface to form into composite enzyme functional sensitive film containing Zn-VIA family semiconductor nano-grain. The proportion of polymer Zn-VIA family semiconductor nano-grainis 1:3.26X10-7-1:8.15X10-1, it contains oxidizing enzyme 0.1-120 active units, the grain size of Zn-VIA family semiconductor is 1-200 nm. It saves enzyme usage and has better performances. It can be used for biological sensor, biological separating film and enzyme biological catalytic engineering.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of production method of isomaltooligosaccharide

The invention discloses a production method of isomaltooligosaccharide, which comprises the following steps: slurry preparation and liquefaction, saccharification and transglycoside conversion, fermentation, refining and concentration. The invention can not only improve the purity and functional sugar content of the isomaltooligosaccharide product, but also can improve the production efficiency, shorten the production cycle, reduce the amount of enzyme preparation, save energy and reduce production costs.

Owner:GUANGZHOU SHUANGQIAO

A mutant of maltooligosaccharide-based trehalose synthase with improved thermostability

ActiveCN108753746BIncreased thermostability of synthetasesImprove stabilityBacteriaFermentationProtein engineeringTrehalose synthase

Owner:JIANGNAN UNIV

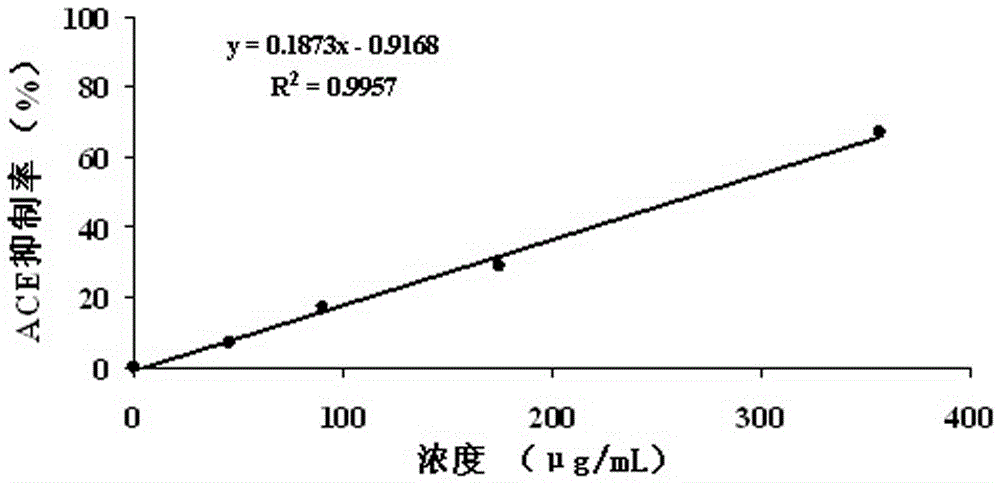

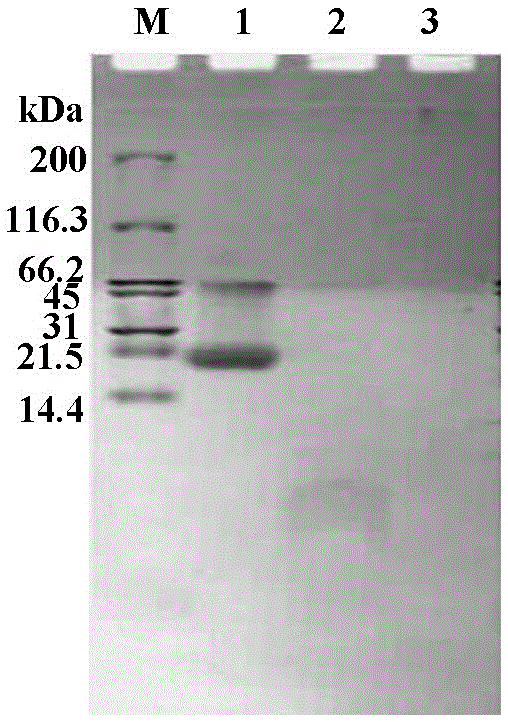

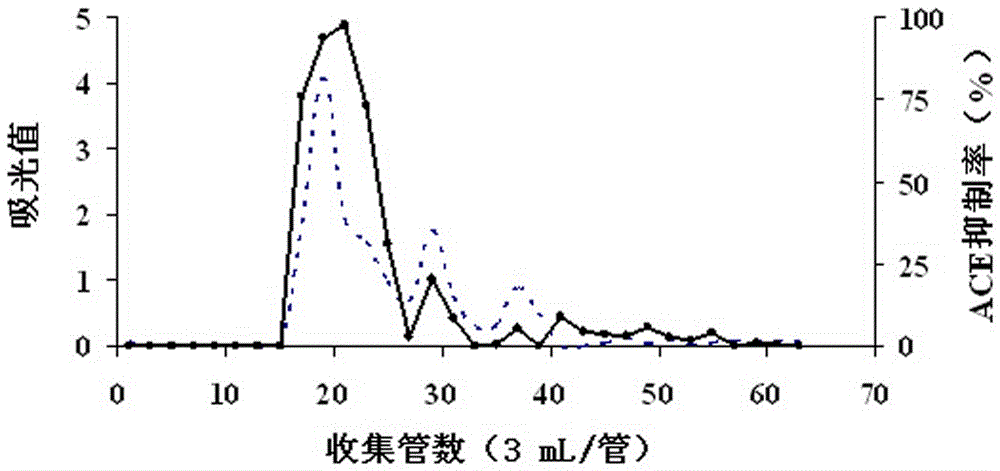

A kind of preparation method of phycoerythrin ACE inhibitory peptide

ActiveCN104131055BHigh purityAchieve a high degree of purificationPeptide preparation methodsAlgae/lichens peptidesPhycoerythrinPepsin

The invention discloses a preparation method for a phycoerythrin ACE inhibitory peptide. The method includes the steps of: extracting phycoerythrin; adding pepsin to conduct enzymolysis and then adding trypsin to perform enzymolysis; dissolving the freeze-dried powder subjected to enzymolysis in pure water, loading the obtained solution to a SephadexG-15 gel column, collecting the highest activity peak as a phycoerythrin ACE inhibitory peptide component, and further loading the obtained component to a high performance liquid chromatogram ZORBAX300SB-C18 to perform separation so as to detect phycoerythrin ACE inhibitory peptide fragments in the component and can realize preparation of high purity phycoerythrin ACE inhibitory peptide at the same time. The method provided by the invention employs pepsin and trypsin stepwise enzymolysis to prepare the ACE inhibitory peptide, can avoid inactivation of the active peptide due to degradation by gastrointestinal digestive fluid after intake by the human body, also reduces the cost, has a simple process, and can realize industrial production. The phycoerythrin ACE inhibitory peptide derives from natural vegetable protein, has a small molecular weight, is stable, safe, and easy to absorb by the human body.

Owner:JIMEI UNIV

Water-soluble high temperature-resistant polyaniline conducting material and its preparation method

InactiveCN100448916CReduce pollutionReduce the amount of enzymeOrganic conductorsConductive materialsSolvent

The invention relates to water-soluble poly amino benzenes high temperature resisting conductive material and method for preparation, wherein the material is prepared from p-phenylene diamine 54-216 parts, monomer propenoic acid 35-71 parts, horseradish peroxidase 0.05-3 parts as raw material, p-phenylene diamine and propenoic acid as monomers, deionized water as solvent, horse radish peroxidase HRP as catalyst, H2O2 as oxidation agent through copolymerization, acetone deposition and vacuum drying 48 hours at 50 deg C.

Owner:NORTHWEST NORMAL UNIVERSITY

Levulose valine oxidizing enzyme of high activity

ActiveCN101368174BHigh activityReduce the amount of enzymeOxidoreductasesFermentationEscherichia coliNucleotide

The invention relates to high-activity fructose valine oxidase and a preparation method thereof, the amino acid sequence of the fructose valine oxidase is the sequence of SEQ ID. No.2, and the nucleotide sequence is shown in SEQ ID. No.1. The preparation steps are: (1) error-prone PCR amplification is carried out with the FVO gene coded sequence of Corynebacterium sp.2-4-1 as the template to establish the mutation bank of the fructose valine oxidase; (2) the mutation bank is transferred into escherichia coli and the clone, reconstruction, conversion and expression are carried out to the gene of the transferred escherichia coli; and (3) the activity of enzyme is determined by utilizing the quinine method and the high-activity fructose valine oxidase is screened out. The activity of the obtained fructose valine oxidase is about 6 times of the activity of the ordinary fructose valine oxidase, the fructose valine oxidase can be used for testing saccharification Hb kit, the used amount of enzyme is reduced, and the reaction time is shortened.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

A kind of crude enzyme preparation, its preparation method and application

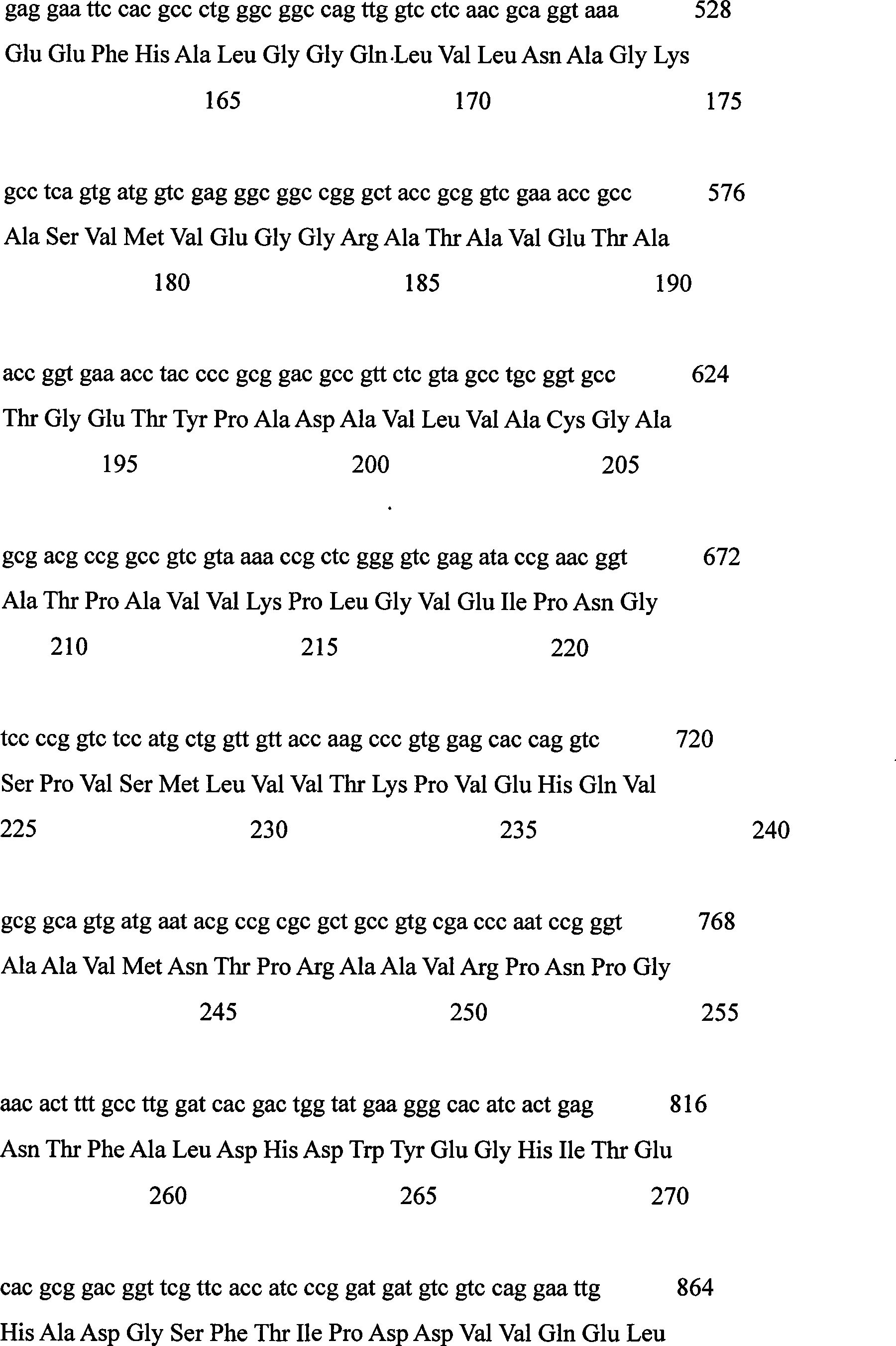

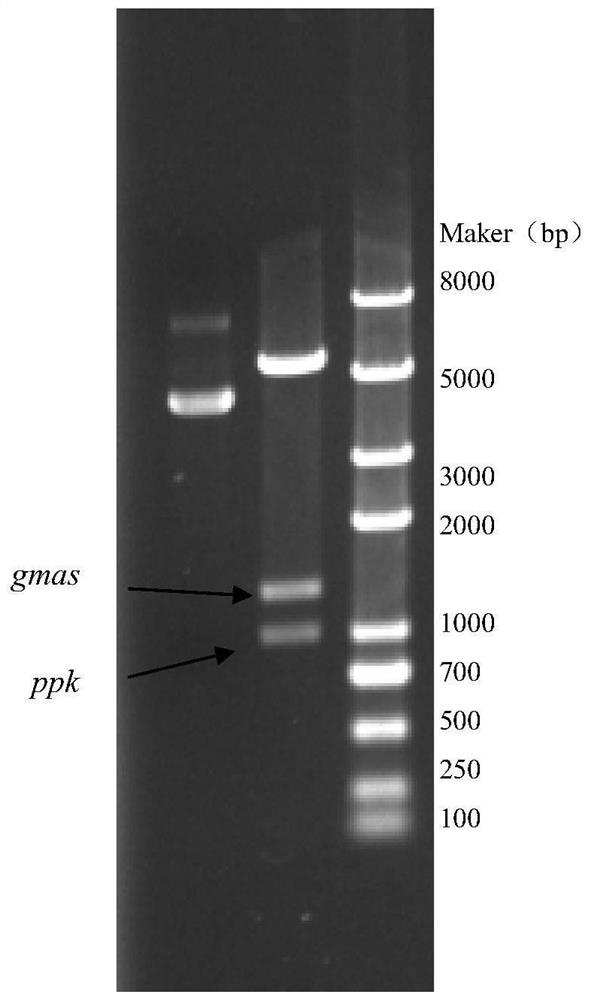

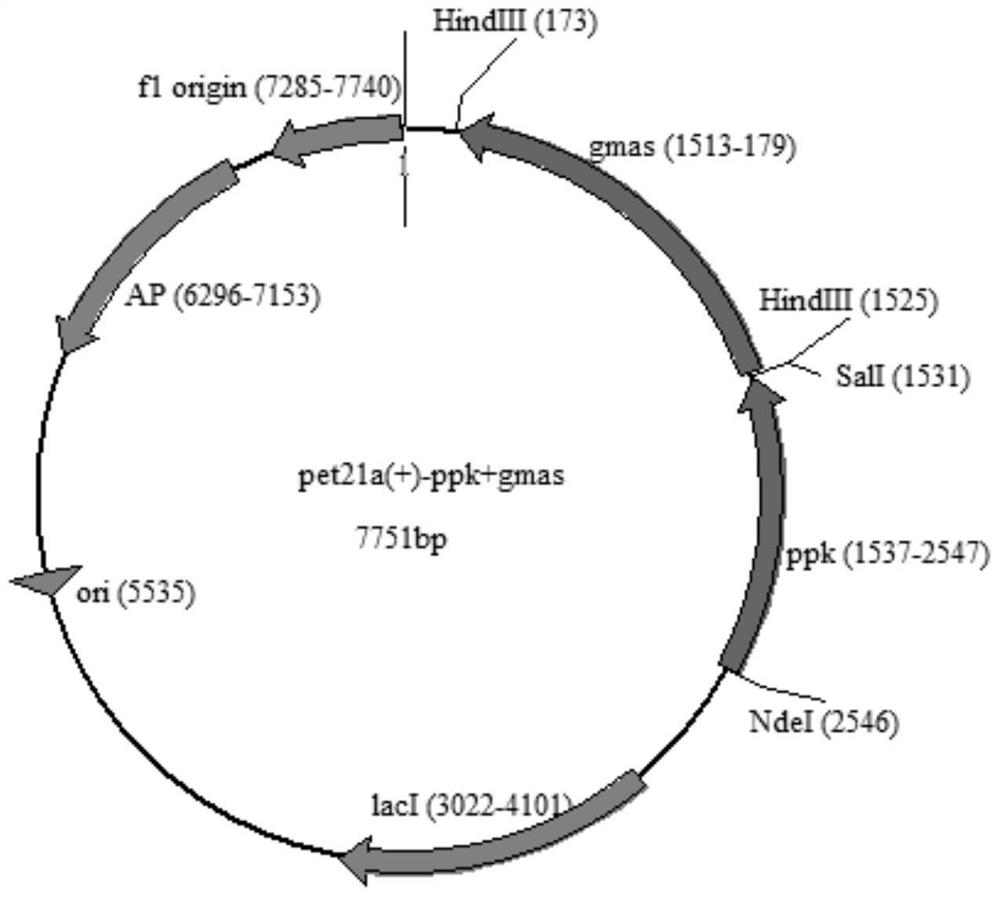

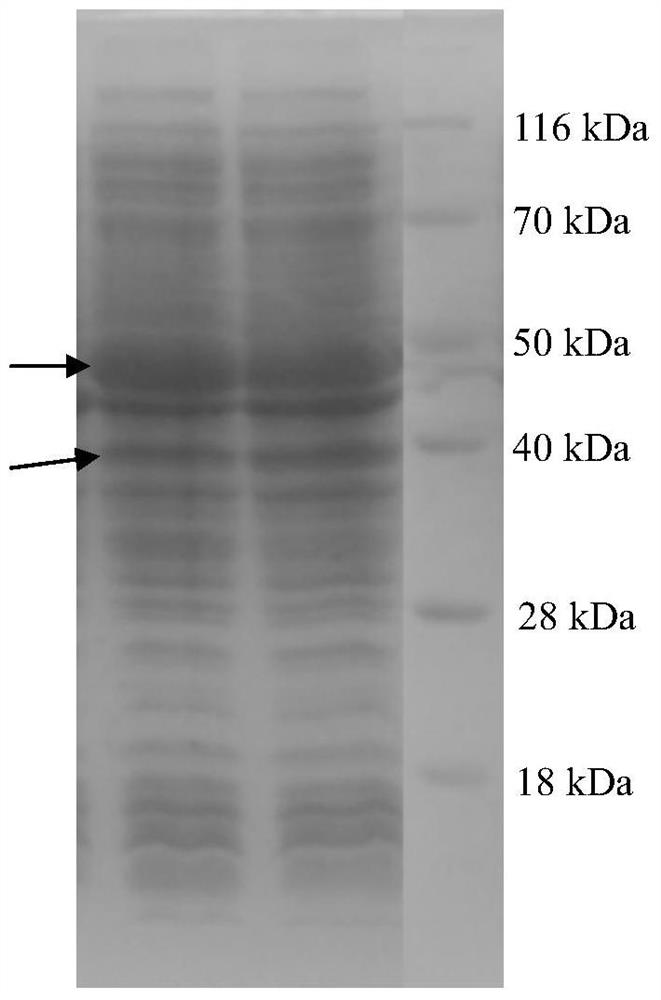

The invention relates to the technical field of biological engineering and particularly relates to a crude enzyme preparation as well as a preparation method and application thereof. The crude enzyme preparation comprises gamma-glutamyl-methylamine synthetase and phosphokinase, wherein genes of the gamma-glutamyl-methylamine synthetase and the phosphokinase are cloned on one expression vector. According to the crude enzyme preparation provided by the invention, a recombinant vector containing a gamma-glutamyl-methylamine synthetase encoding gene and a phosphokinase encoding gene is constructed for the first time; the recombinant vector is used for converting host bacteria to obtain an engineering strain; and when the engineering strain is fermented, the crude enzyme preparation containing the gamma-glutamyl-methylamine synthetase and the phosphokinase can be obtained.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

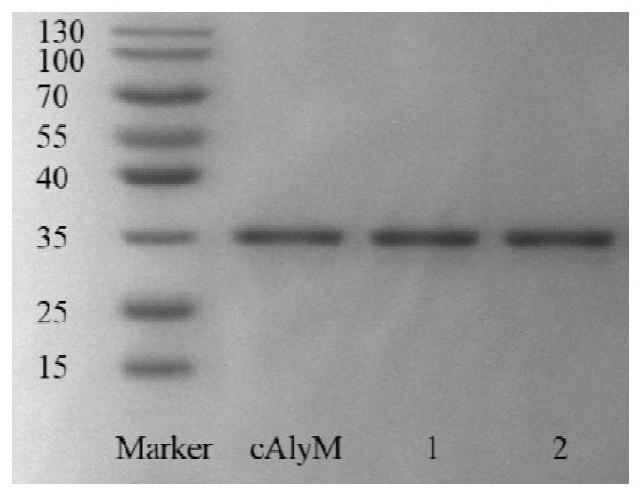

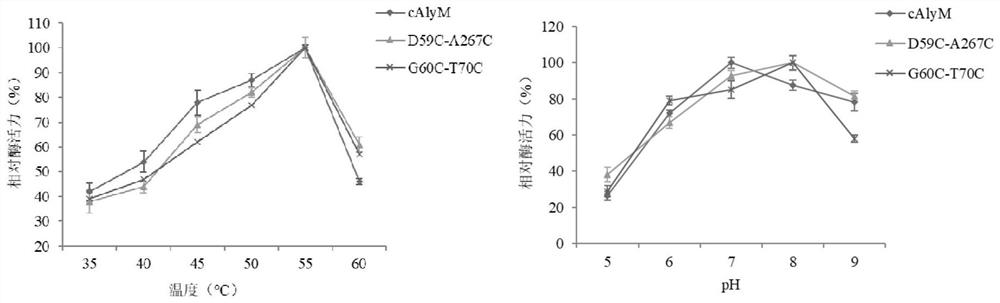

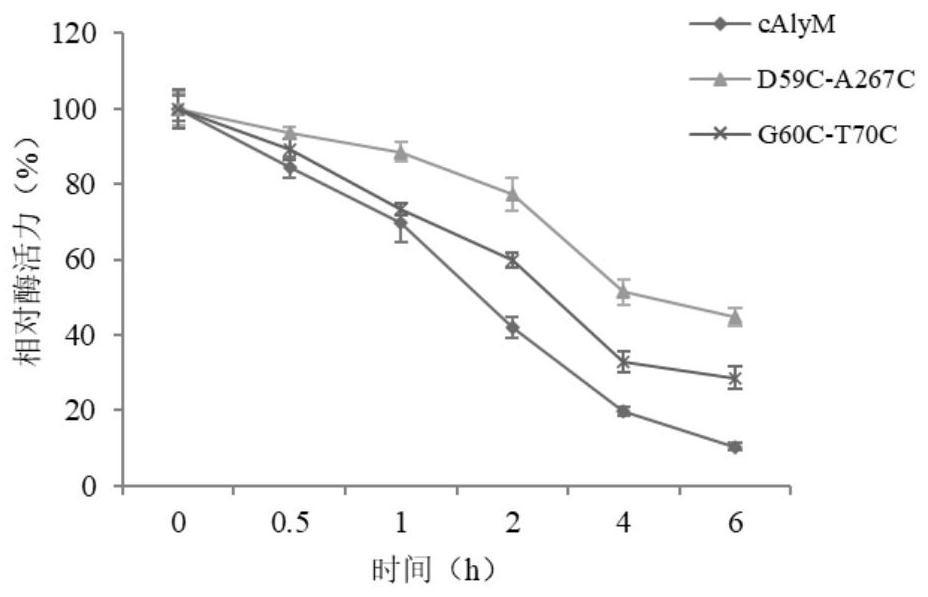

A thermal stability and high enzyme activity recombinant alginate lyase and its application

ActiveCN112574980BImprove immunityOvercoming destructive shortcomingsBacteriaMicroorganism based processesLyaseAlginate lyase

The present invention provides a alginate lyase with better thermal stability and high enzyme activity, the amino acid sequence of which is SEQ ID NO:3 or SEQ ID NO5; the mutant enzyme provided by the present invention is used to prepare alginate oligosaccharides . The present invention utilizes the genetically modified recombinant alginate lyase to prepare algin oligosaccharides in a directional manner. Compared with the existing method of preparing alginate oligosaccharides by acid hydrolysis, it overcomes the disadvantage of large destructiveness. Compared with the existing method of enzymatic hydrolysis Compared with the method for preparing algin oligosaccharides, the modified recombinant algin lyase can reduce the amount of enzyme added, shorten the enzymatic hydrolysis time, and improve the enzymatic hydrolysis efficiency. The enzyme of the invention has high enzyme activity and high thermal stability, and is more suitable for industrial enzymatic hydrolysis of alginate to prepare alginate oligosaccharides. The prepared alginate oligosaccharide has the effects of anti-tumor, anti-inflammation, lowering blood fat, improving immunity, etc., can be used in the field of food and health care products, and has broad application prospects.

Owner:OCEAN UNIV OF CHINA +1

Extraction method of sea cucumber polypeptide

ActiveCN102488073BIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

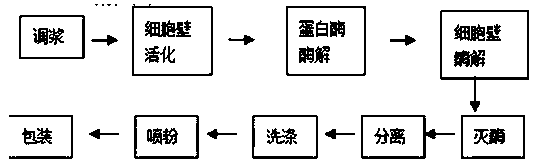

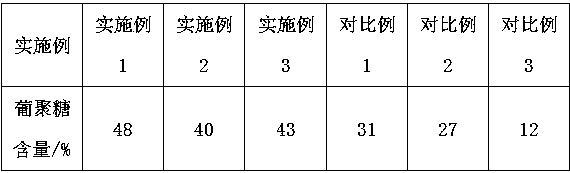

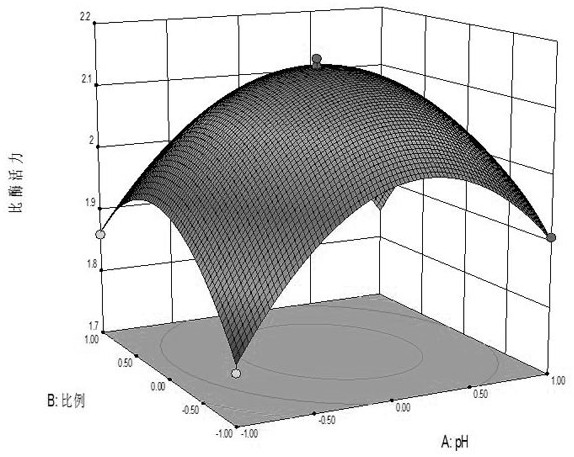

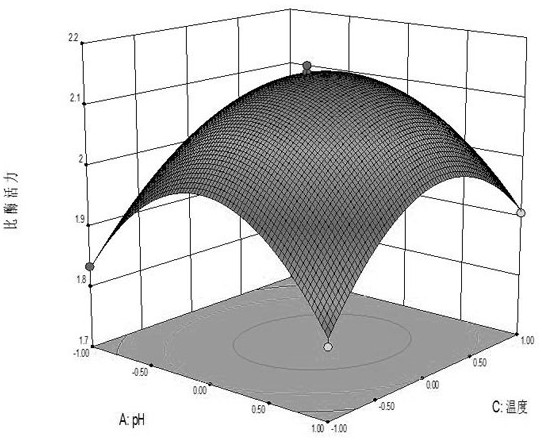

Preparation method of cell wall with high glucan content

The invention provides a method for preparing a high-glucan cell wall product. The method adopts a flow path shown as a figure 1 in the specification. The cell wall product prepared with the method has a stable glucan content of 40% or above, which is greatly higher than that of the existing product in the market; in addition, a raw material used in the invention is a byproduct obtained during yeast cell extraction, and is low in cost; the cell wall product with high glucan content is widely applied to the fields of feed, food and the like; therefore, the method has a great economic prospect.

Owner:SHANDONG BIO SUNKEEN

Method for producing high maltose syrup by utilizing mpeg-mal5000-β-amylase

ActiveCN108690858BEnzymolysis temperature is lowReduce manufacturing costFermentationAmylaseEnzymatic hydrolysis

The invention discloses a method for producing high maltose syrup with mPEG-Mal5000-β-amylase: ①Mix starch and water into starch slurry, add high-temperature-resistant α-amylase, keep warm at 90°C for 3 minutes, and inactivate the enzyme; ②Inactivate the enzyme Add mPEG‑Mal5000‑β‑amylase to the final starch solution, after enzymatic hydrolysis, boil and centrifuge to obtain high maltose syrup. Compared with unmodified β-amylase, the application of mPEG-Mal5000-β-amylase to produce high maltose syrup, the amount of enzyme added was reduced from 200 U / g to 120 U / g, and the usage was reduced by 40%; the saccharification time was reduced from 28h Reduced to 16h; yield increased from 73.29% to 85.67%. For enzymatic hydrolysis of corn starch, the amount of enzyme added was reduced from 200 U / g to 100 U / g, and the usage was reduced by 50%; the saccharification time was reduced from 27h to 14h; the yield increased from 76.53% to 86.34%.

Owner:HENAN INST OF SCI & TECH

Compound enzyme preparation and its preparation method and application

ActiveCN105296316BEliminate Cold HazeImprove temperature stabilityHydrolasesAlcoholic beverage preparationSodium edetateSolvent

The invention provides a compound enzyme preparation, which comprises the following components: papain 1-2.5×104U / liter, bromelain 1000-3000U / liter, proline endonuclease 0.1-10PPU / liter, benzene Sodium formate 0.1-1%, ascorbic acid 0.1-1%, sodium edetate 0.1-1%, glycerin 20-50%, solvent is deionized water. The compound enzyme preparation has good stability, long shelf life, long-lasting and obvious effect of eliminating cold turbidity, can greatly reduce the dosage of enzyme preparation, and has extremely high commercial and promotional value.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com