A kind of preparation method of phycoerythrin ACE inhibitory peptide

A technology of phycoerythrin and inhibitory peptides, which is applied in the field of preparation of phycoerythrin ACE inhibitory peptides, can solve the problems of loss of activity, complicated purification steps, unfavorable large-scale production, etc., and achieve reduced enzyme amount, low molecular weight, and technical parameters Effective and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

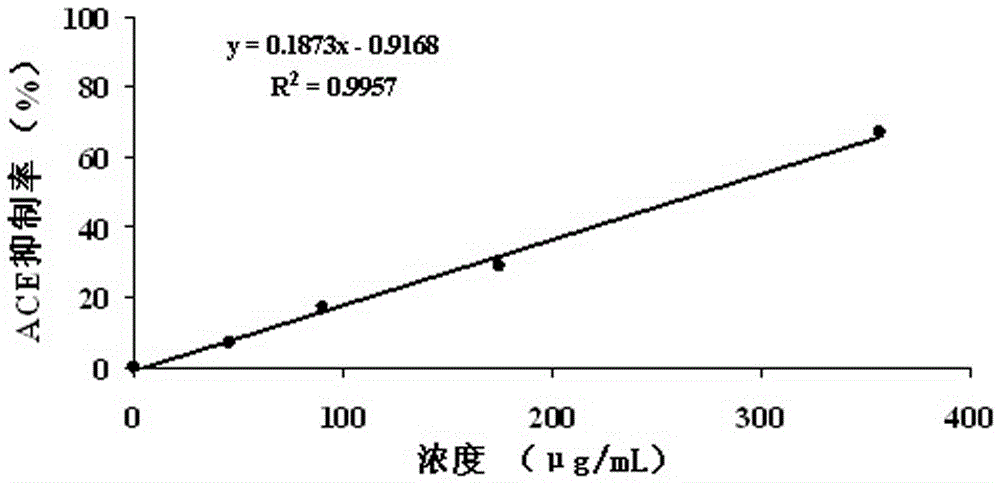

[0029] 1) Extraction of phycoerythrin: take 200 g red algae as raw material, wash and dry at 40 ℃, and crush. Add 20 times the volume of distilled water to make a seaweed suspension, and freeze and thaw three times at -20 °C and 4 °C to break the cells. After 20 min of homogenization, the tissue was sonicated for 10 min. After centrifugation, take the supernatant and carry out 35~50% ammonium sulfate salting out. The salted-out precipitate was dialyzed and loaded onto a DEAE-Sepharose anion exchange column, and was washed with 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under weak light conditions 2 PO 4 Solution (containing 200 mmol / L NaCl) was mixed for linear elution. The eluted fractions with A565 / A280> 3.0 were collected, freeze-dried to make phycoerythrin powder, and stored away from light. Phycoerythrin solutions with different concentrations were prepared to measure the ACE inhibitory activity. like figure 1 As shown, the ACE inhibitory ac...

Embodiment 2

[0034] 1) Extraction of phycoerythrin: 200 g laver was used as raw material, washed and dried at 40 °C, and crushed. Add 30 times the volume of distilled water to make a seaweed suspension, and freeze and thaw five times at -20 °C and 4 °C to break the cells. After 20 min of homogenization, the tissue was sonicated for 20 min. After centrifugation, take the supernatant and carry out 35~50% ammonium sulfate salting out. The salted-out precipitate was dialyzed and loaded onto a DEAE-Sepharose anion exchange column, and was washed with 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under weak light conditions 2 PO 4 The solution (containing 200 mmol / L NaCl) was mixed for linear elution at a flow rate of 1 mL / min. The eluted fractions with A565 / A280> 3.0 were collected, freeze-dried to make phycoerythrin powder, and stored away from light. Prepare different concentrations of phycoerythrin solutions to measure ACE inhibitory activity;

[0035] 2) Enzymatic...

Embodiment 3

[0038] 1) Extraction of phycoerythrin: 1 kg of red hair algae was used as raw material, washed and dried at 40 ℃, and pulverized. Add 20 times the volume of distilled water to make a seaweed suspension, and freeze and thaw five times at -20 °C and 4 °C to break the cells. After 40 min of homogenization, the tissue was sonicated for 30 min. After centrifugation, take the supernatant and carry out 35~50% ammonium sulfate salting out. The salted-out precipitate was dialyzed and loaded onto a DEAE-Sepharose anion exchange column, and was washed with 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under weak light conditions 2 PO 4 The solution (containing 200 mmol / L NaCl) was mixed for linear elution at a flow rate of 1 mL / min. The eluted fractions with A565 / A280> 3.0 were collected, freeze-dried to make phycoerythrin powder, and stored away from light. Prepare different concentrations of phycoerythrin solutions to measure ACE inhibitory activity;

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com