A method for improving the purity of high-concentration starch saccharification products

A high-concentration, starch sugar technology, applied in the field of starch sugar making, can solve problems such as the decrease in the purity of saccharified products, and achieve the effects of improving the purity, improving the purity of glucose, and reducing the amount of enzymes added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] crafting process:

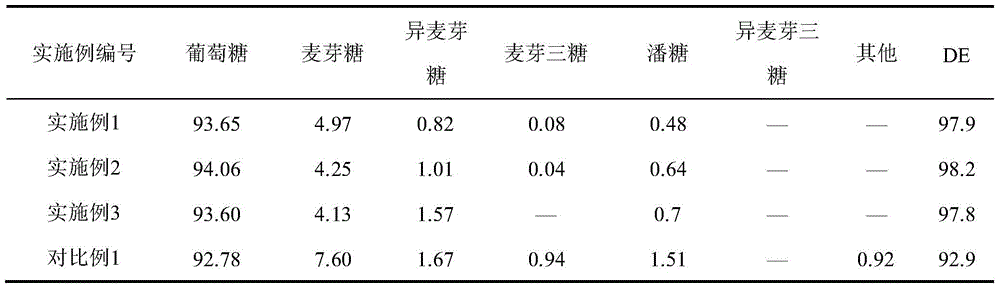

[0014] After 50% (w / w, based on starch dry basis) cornstarch milk is liquefied by high-temperature-resistant α-amylase, a starch liquefaction product with a DE value of about 15 is obtained, and the pH value is adjusted to 4.5 with hydrochloric acid, and then 4ASPU / g is added On the premise of pullulanase, 30U / g glucoamylase was added, the saccharification reaction temperature was 60°C, and the reaction time was 48h. The effect of compound enzyme addition amount on the composition of starch saccharification products was determined, and the results are shown in Table 1.

Embodiment 2

[0016] crafting process:

[0017] After 50% (w / w, based on starch dry basis) cornstarch milk is liquefied by high-temperature-resistant α-amylase, a starch liquefaction product with a DE value of about 15 is obtained, and the pH value is adjusted to 4.5 with hydrochloric acid, and then 4ASPU / g is added On the premise of pullulanase, 40 U / g glucoamylase was added, the saccharification reaction temperature was 60° C., and the reaction time was 48 hours. The effect of compound enzyme addition amount on the composition of starch saccharification products was determined, and the results are shown in Table 1.

Embodiment 3

[0019] crafting process:

[0020] After 50% (w / w, based on starch dry basis) cornstarch milk is liquefied by high-temperature-resistant α-amylase, a starch liquefaction product with a DE value of about 15 is obtained, and the pH value is adjusted to 4.5 with hydrochloric acid, and then 4ASPU / g is added On the premise of pullulanase, 50U / g glucoamylase was added, the saccharification reaction temperature was 60°C, and the reaction time was 48h. The effect of compound enzyme addition amount on the composition of starch saccharification products was determined, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com