A kind of crude enzyme preparation, its preparation method and application

A preparation and crude enzyme technology, applied in the field of bioengineering, can solve the problems of energy consumption, ATP consumption, high price, etc., and achieve the effect of reducing cost and enzyme amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

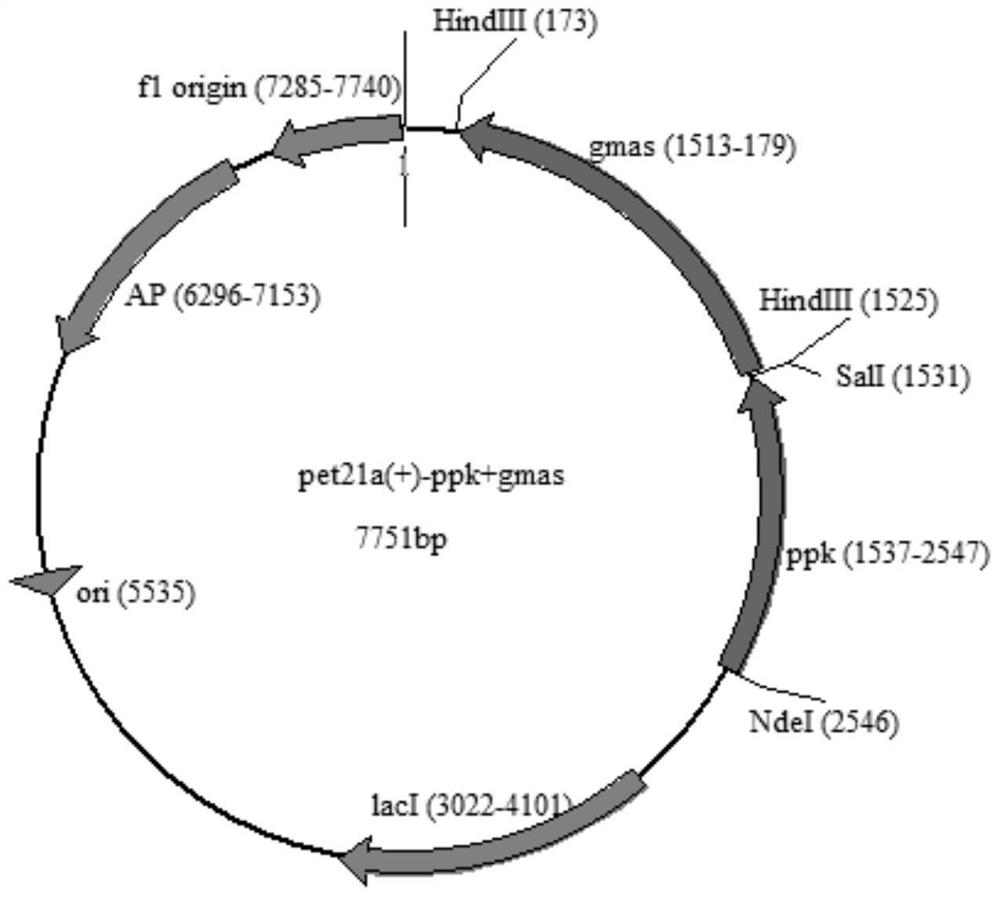

[0036] The construction of embodiment 1 genetic engineering bacterial classification

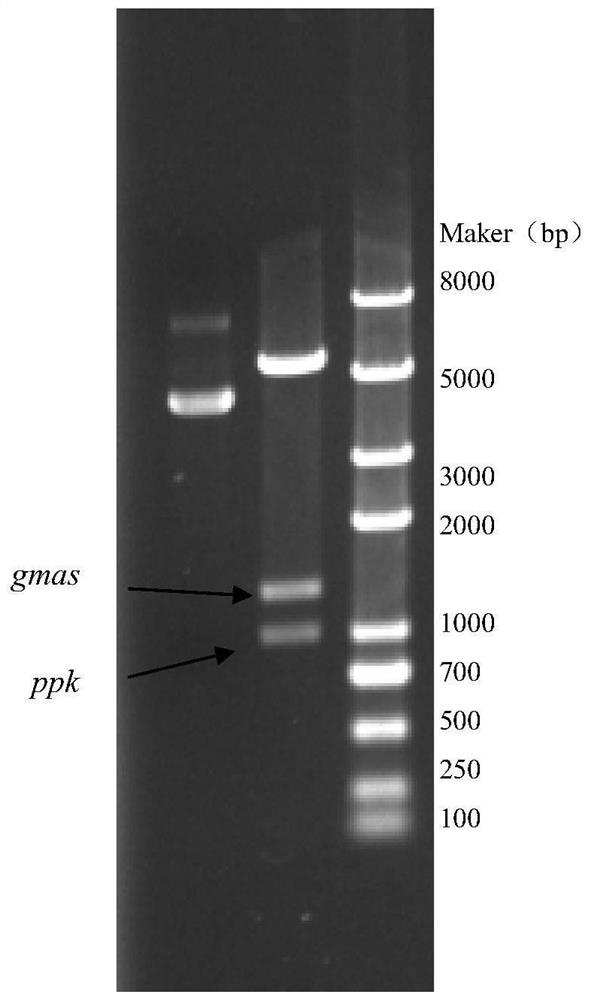

[0037] (1) Construction of pET21a(+)-ppk

[0038] Extract the plasmid pET-21a(+) with a plasmid extraction kit, and digest the plasmid with NdeI / SalI double enzymes at 37°C for 2 hours. The enzyme digestion system is: 50 μL of plasmid, 10 μL of 10×buffer, 3 μL of NdeI, 3 μL of SalI, 34 μL of water, and the 5.4 kb pET-21a (+) fragment was recovered by electrophoresis.

[0039] The synthesized plasmid containing phosphokinase (US20050287627 A1, SEQ ID NO 125) encoding gene ppk was digested with NdeI / SalI double enzymes at 37°C for 2h, the digestion system was the same as above, and a 1 kb ppk fragment was recovered by electrophoresis.

[0040] The 5.4 kb pET-21a(+) fragment recovered above was ligated with the 1 kb ppk fragment under the action of T4 ligase at 22° C. for 5 h. The ligation product was transformed into competent E.coli Top10 by the calcium chloride method, and the transformant...

Embodiment 2

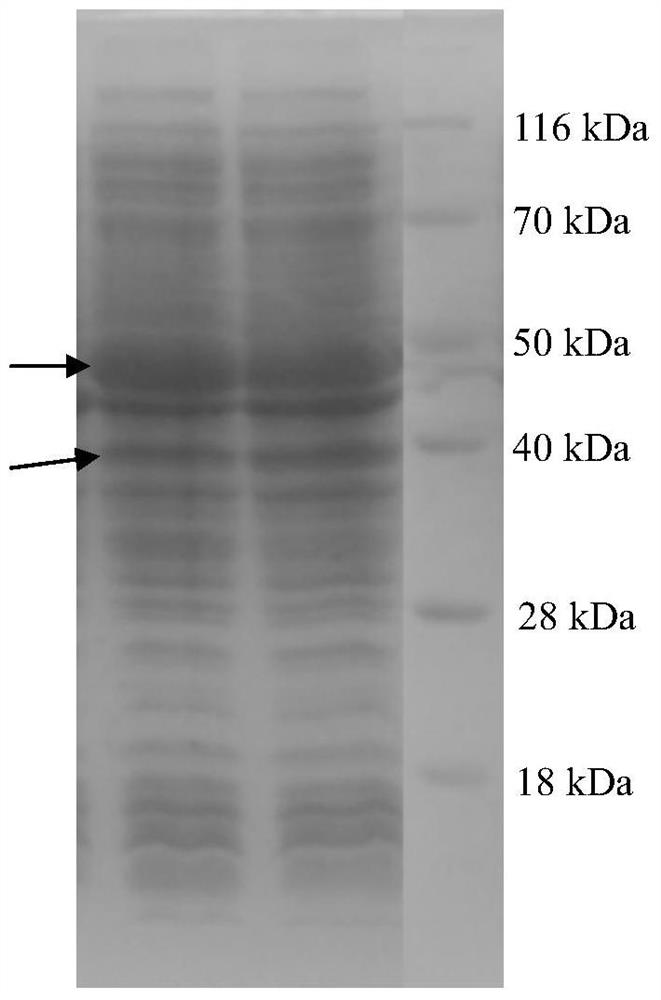

[0049] Expression of embodiment 2 recombinant protein

[0050] The recombinant bacteria BL21(DE3) / pET21a(+)-ppk+gams were picked and inoculated in LB medium containing ampicillin, and cultured overnight at 37°C with shaking. The culture was transferred to fresh LB medium containing ampicillin at 1% inoculum size, and cultured with shaking at 37°C until OD 600 =0.6-0.8, IPTG induction (final concentration 0.1mM) at 20°C overnight, centrifuged to collect cells, resuspended cells in 20mM sodium phosphate buffer (pH 8.0), ultrasonically disrupted, centrifuged and freeze-dried the supernatant to obtain a crude lyophilized powder Enzyme preparations, protein expression such as image 3 shown.

[0051] From image 3 It can be seen that the prepared crude enzyme preparation contains two proteins with sizes of 38kDa and 49kDa, respectively, which is consistent with the prediction.

Embodiment 3

[0052] Example 3 Enzyme Activity Determination

[0053] Use the following method to measure the enzyme activity of gained freeze-dried powder in embodiment 2:

[0054] The enzyme activity assay detection system of γ-glutamine synthetase is: the 3mL reaction system contains final concentrations of 50mM sodium glutamate, 15mM hydroxylamine hydrochloride, 7.5mM adenosine triphosphate disodium (ATP), 30mM magnesium chloride hexahydrate and 100mM Imidazole buffer (pH 8.0), add an appropriate amount of crude enzyme preparation enzyme solution at 30°C, react for 30 minutes, add 1mL GS color reagent (3.32g trichloroacetic acid, 6.06g ferric chloride and 5mL concentrated hydrochloric acid dissolved in water , and set the volume to 100 mL) to terminate the reaction, and measure the absorbance at 540 nm in a spectrophotometer. The amount of enzyme required to generate 1 μmol γ-glutamylhydroxamic acid per minute under these conditions was defined as 1U.

[0055] The enzyme activity dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| enantiomeric excess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com