Vegetable protein peptide and preparation method thereof

A plant protein peptide and plant protein technology, which is applied in the field of plant protein processing, can solve the problems of low efficiency and high production cost, and achieve the effects of reducing enzymatic hydrolysis time, improving quality and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

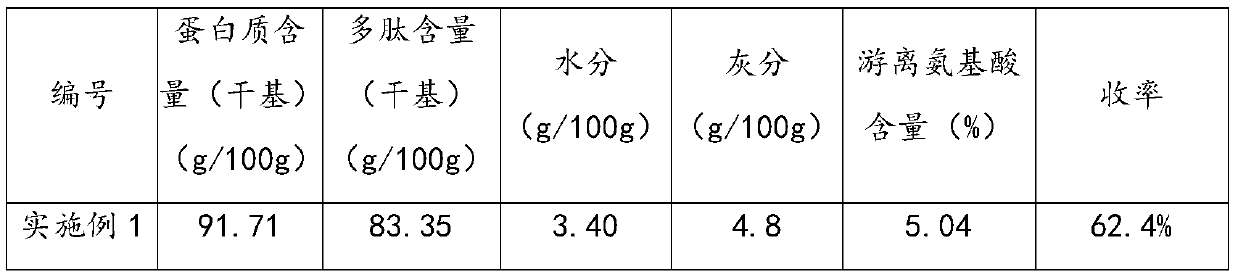

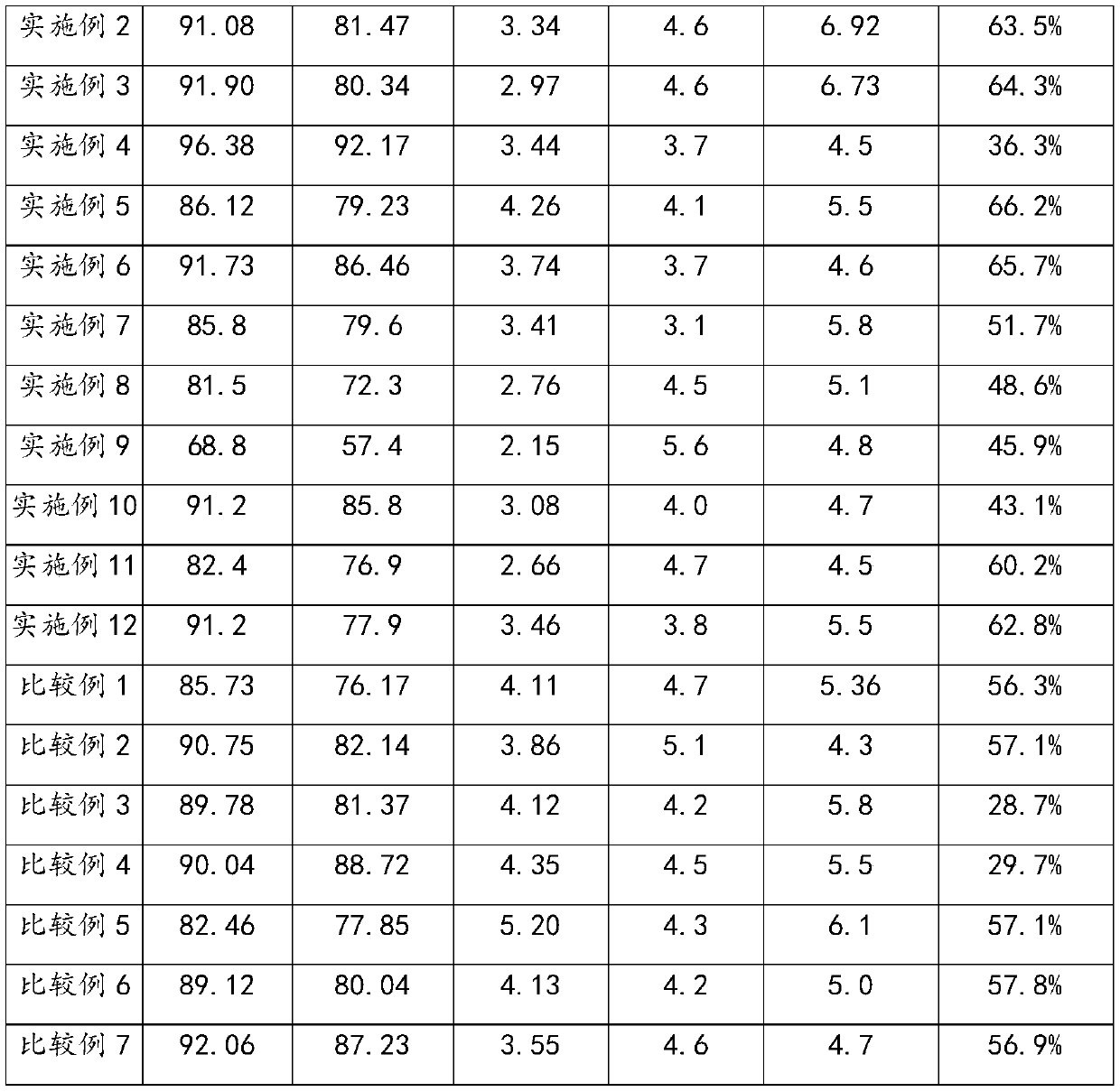

Examples

Embodiment 1

[0057] The present embodiment provides a kind of preparation method of vegetable protein peptide, comprises the following steps:

[0058] (1) Send 5kg of soybean protein isolate and 75kg of water into the enzymolysis reaction tank, stir fully, the stirring speed is 60rpm, open the steam valve to raise the temperature and keep the temperature to 55°C, turn on the vacuum pump to make the vacuum degree in the reaction tank reach and maintain at 0.07 MPa, then add 0.075kg alkaline protease, enzymatic hydrolysis for 1h, turn off the vacuum pump, return to normal pressure, and obtain the mixed material;

[0059] (2) Add 0.1 kg of neutral protease to the mixed material in step (1), and after enzymolysis for 2 hours, add 0.05 kg of flavor protease for enzymolysis for 1 hour;

[0060] (3) Warm up the mixture obtained after enzymolysis in step (2) to 95°C, inactivate the enzyme for 15 minutes; then lower the temperature to 70°C, filter with plates and frames, and collect the filtrate; ...

Embodiment 2

[0064] The present embodiment provides a kind of preparation method of vegetable protein peptide, comprises the following steps:

[0065] (1) Send 5kg of soybean protein isolate and 100kg of water into the enzymolysis reaction tank, stir fully, the stirring speed is 60rpm, open the steam valve to raise the temperature and keep the temperature at 55°C, turn on the vacuum pump to make the vacuum degree in the reaction tank reach and maintain at 0.07 MPa, then add 0.1kg alkaline protease, enzymatically hydrolyze for 2h, turn off the vacuum pump, return to normal pressure, and obtain the mixed material;

[0066] (2) Add 0.025 kg of neutral protease to the mixed material of step (1), and after enzymatic hydrolysis for 2 hours, add 0.01 kg of flavor protease, and perform enzymatic hydrolysis for 1 hour;

[0067] (3) Warm up the mixture obtained after enzymolysis in step (2) to 95°C, inactivate the enzyme for 15 minutes; then lower the temperature to 70°C, filter with plates and fram...

Embodiment 3

[0071] The present embodiment provides a kind of preparation method of vegetable protein peptide, comprises the following steps:

[0072] (1) Send 5kg of soybean protein isolate and 50kg of water into the enzymolysis reaction tank, stir fully, the stirring speed is 60rpm, open the steam valve to heat up and keep the temperature at 55°C, turn on the vacuum pump to make the vacuum degree in the reaction tank reach and maintain at 0.07 MPa, then add 0.15kg alkaline protease, enzymatic hydrolysis for 1h, turn off the vacuum pump, return to normal pressure, and obtain the mixed material;

[0073] (2) Add 0.1 kg of neutral protease to the mixed material in step (1), and after enzymolysis for 2 hours, add 0.05 kg of flavor protease for enzymolysis for 1 hour;

[0074] (3) Warm up the mixture obtained after enzymolysis in step (2) to 95°C, inactivate the enzyme for 15 minutes; then lower the temperature to 70°C, filter with plates and frames, and collect the filtrate;

[0075] (4) Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com