Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce oil leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

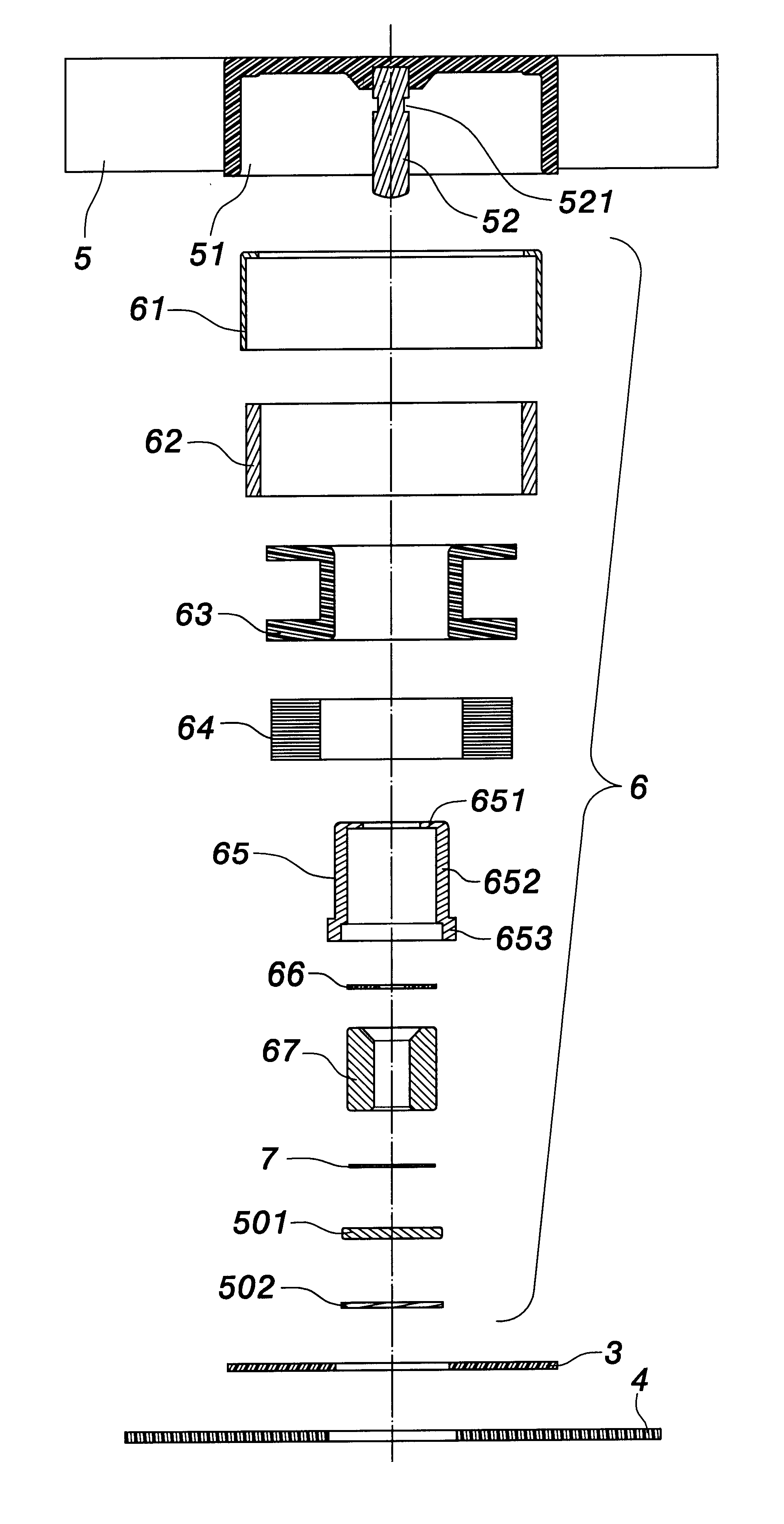

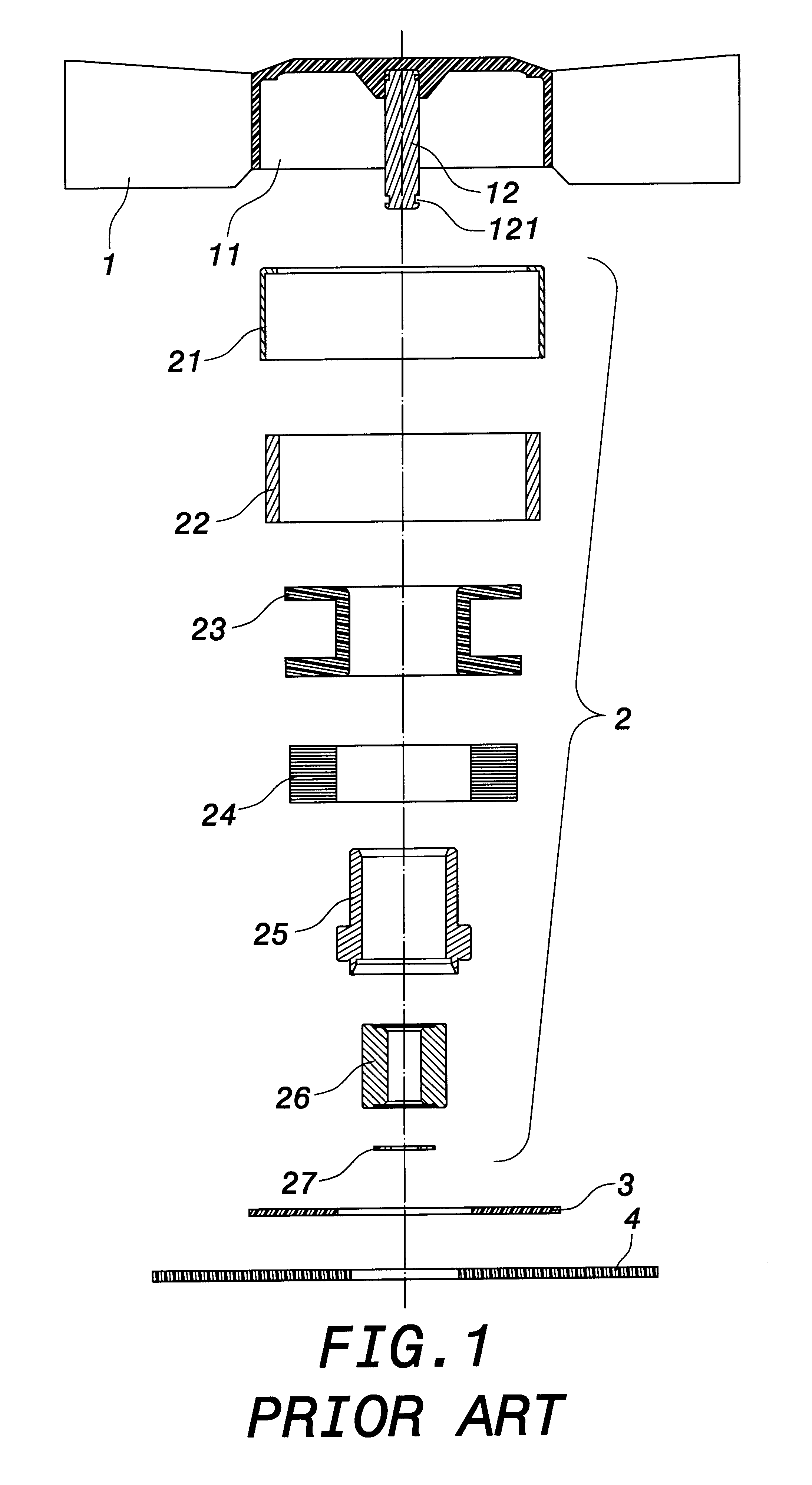

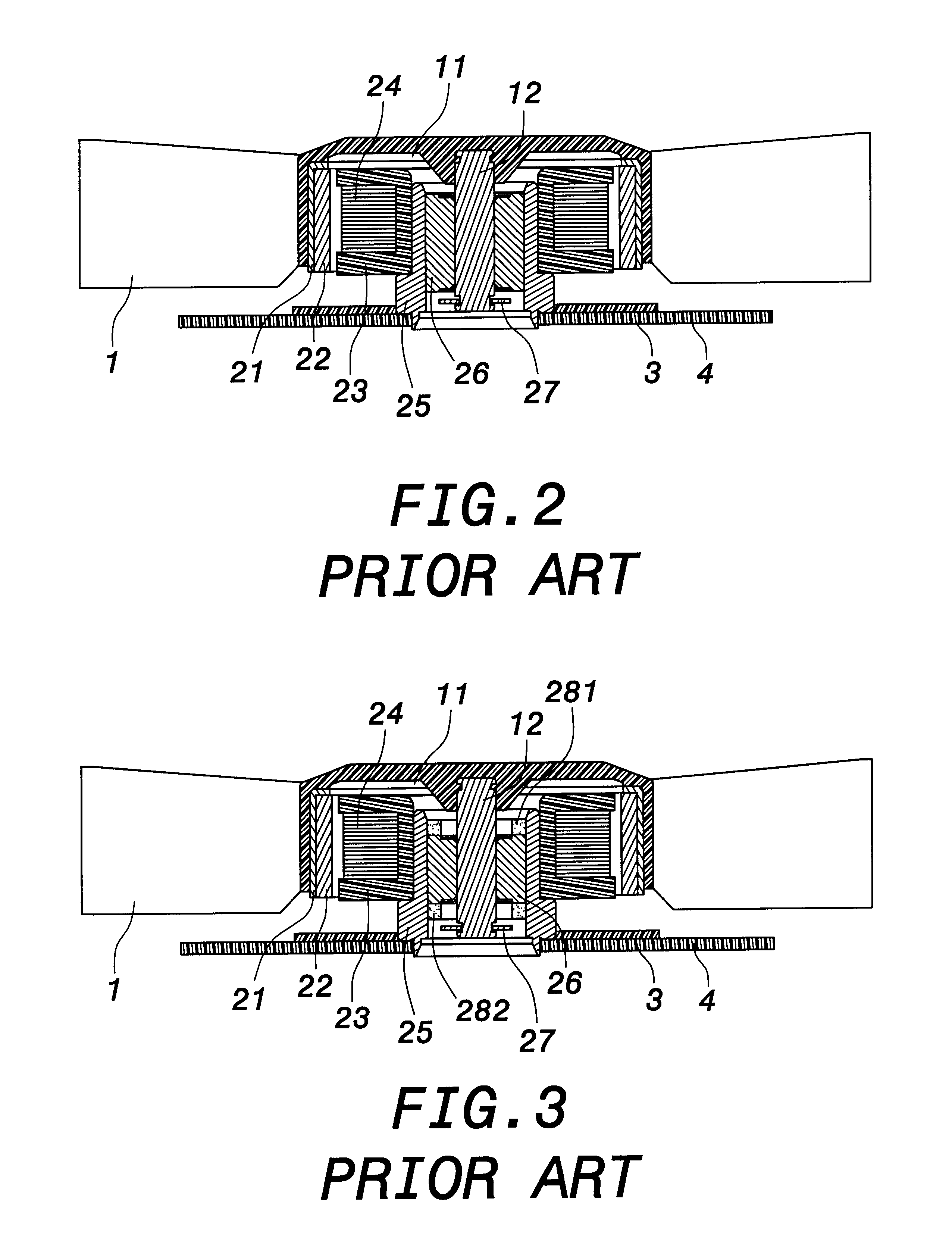

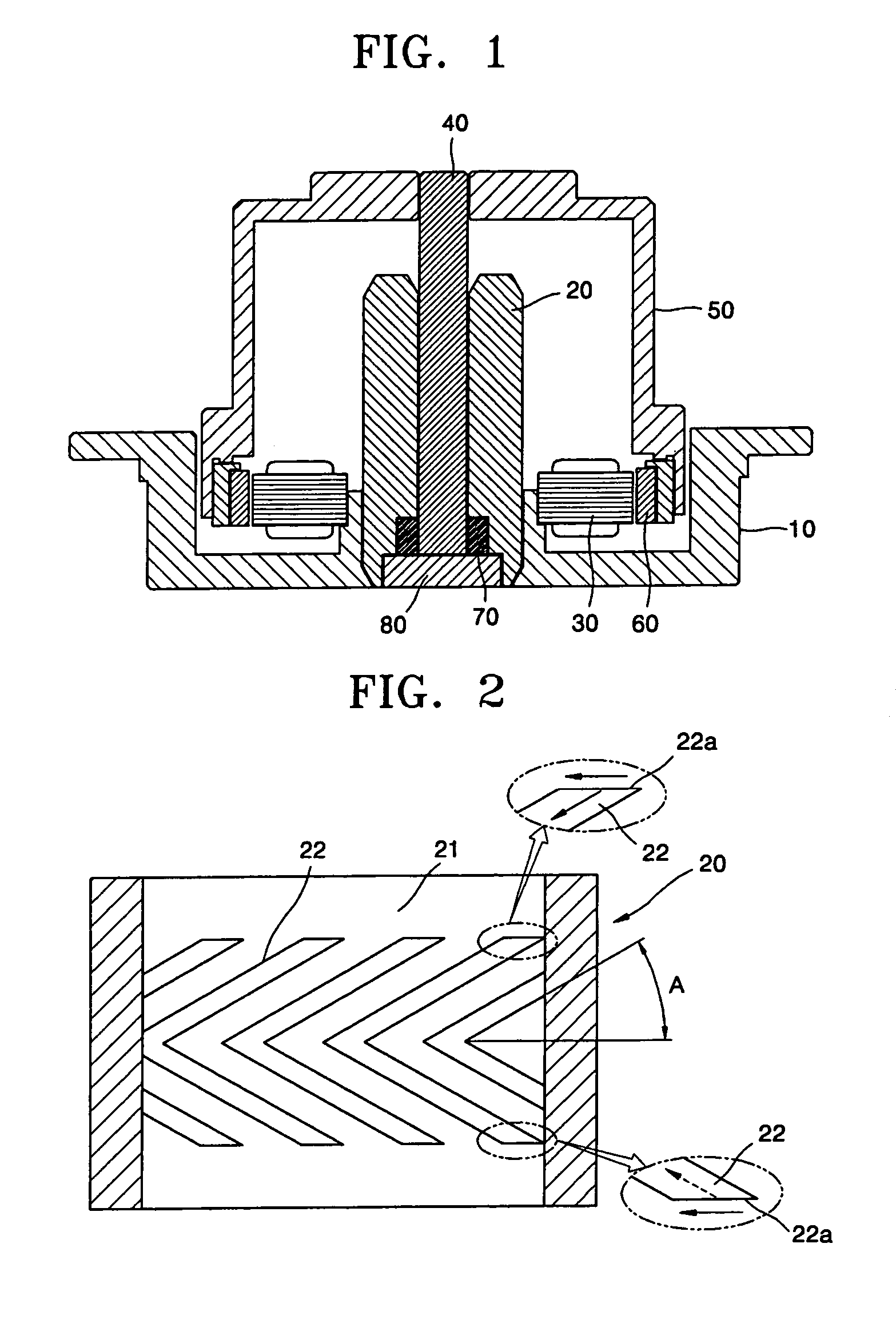

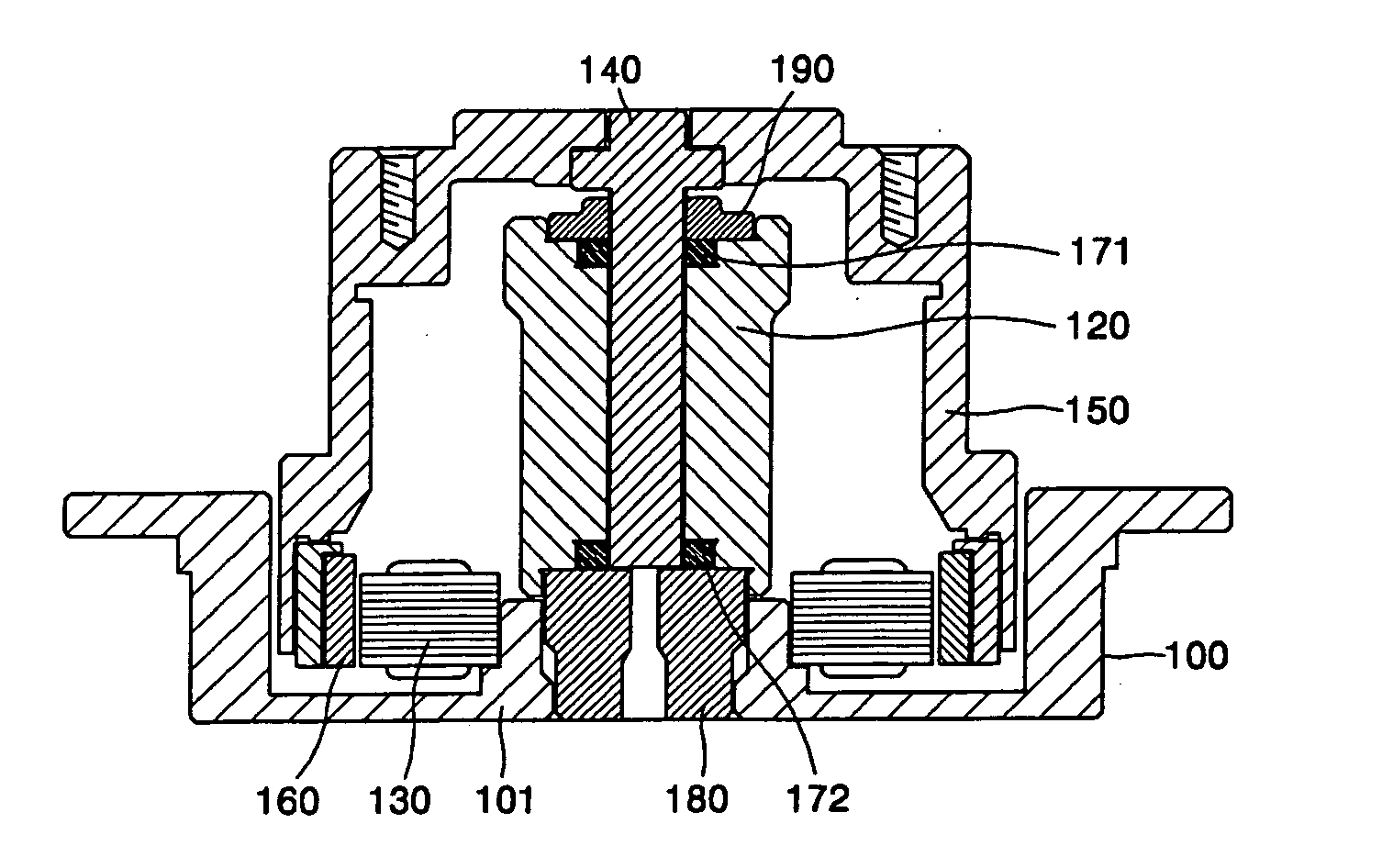

Electrical fan having an oil retaining ring to prevent loss and evaporation of lubricant oil

InactiveUS6612814B2Reduce oil leakageExtend your lifePump componentsPiston pumpsEvaporationEngineering

An electrical fan comprising a blade module and a coil module. The blade module includes a space defined therein, and a shaft. The space has a bottom where an end portion of the shaft is embedded. The coil module includes an oil-retaining bearing, an oil-retaining ring, and a shaft sleeve. The shaft sleeve has an internal flange at a top thereof. The oil-retaining bearing is mounted inside the shaft sleeve, and the oil-retaining ring is clamped between the internal flange and the oil-retaining bearing once the shaft of the blade module has penetrated through the shaft sleeve and the oil-retaining ring of the coil module. Via the oil-retaining ring, the lubricant oil is retained in the oil-retaining bearing, thereby preventing loss and evaporation of lubricant oil.

Owner:IDEAL ELETHERMAL

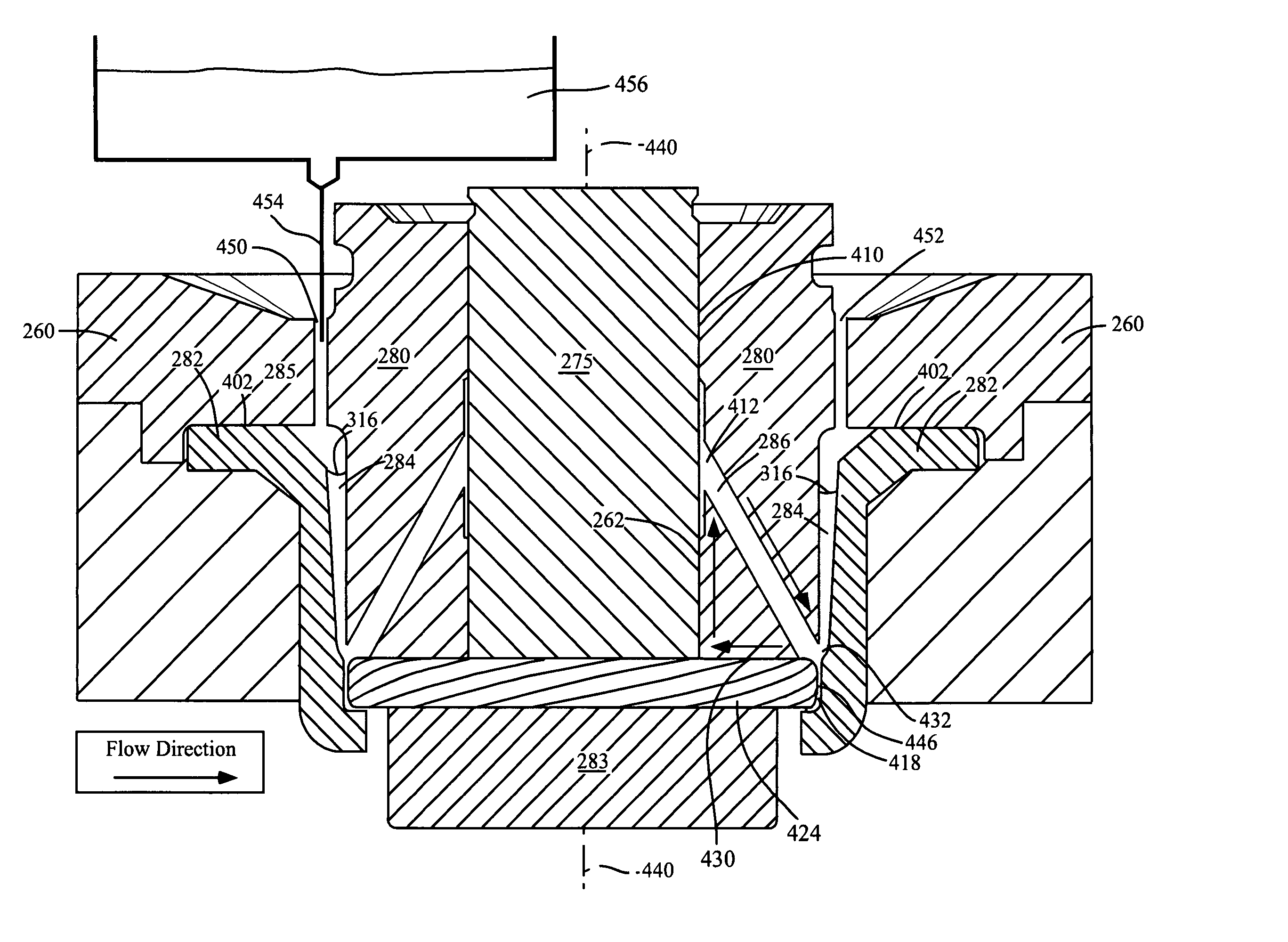

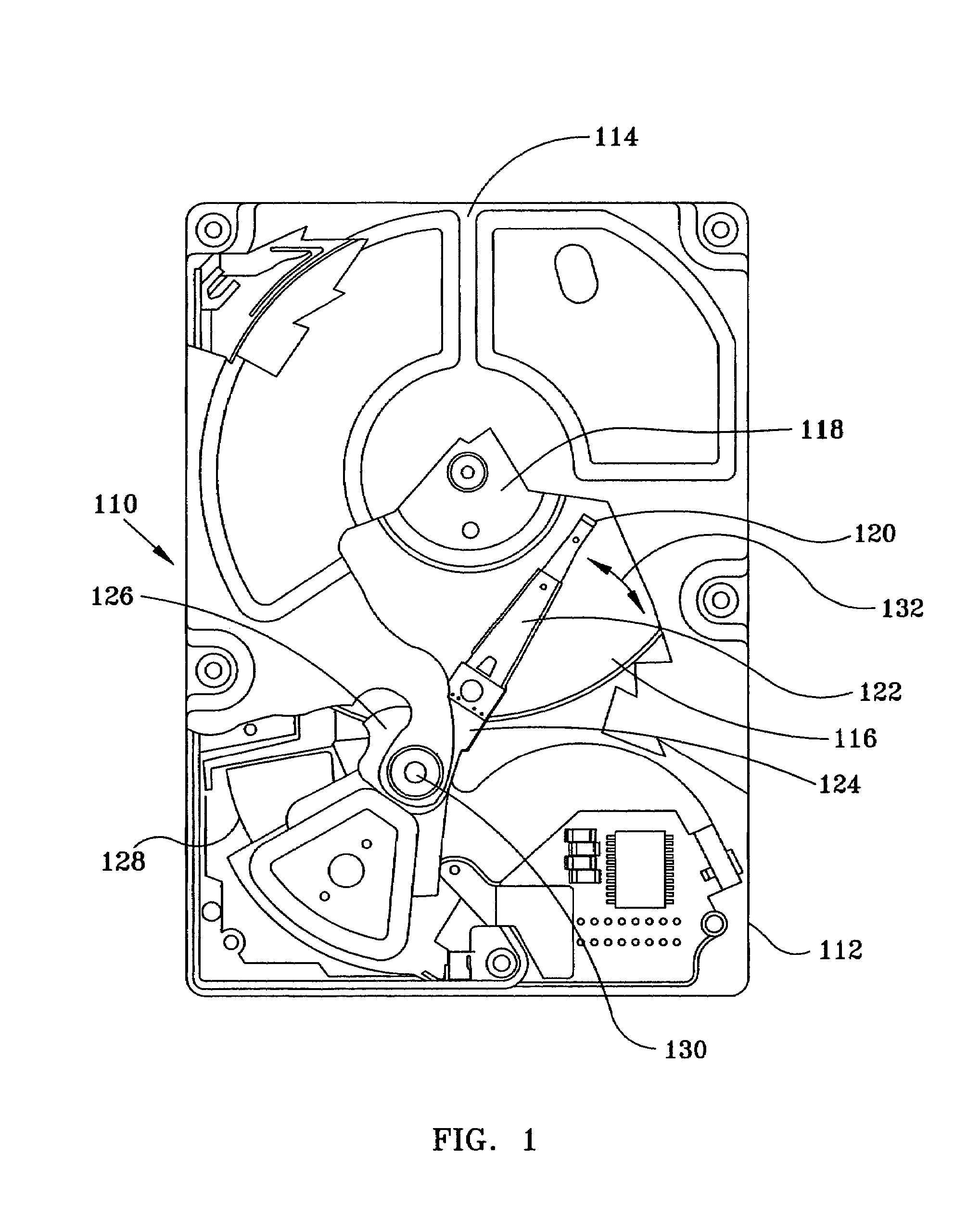

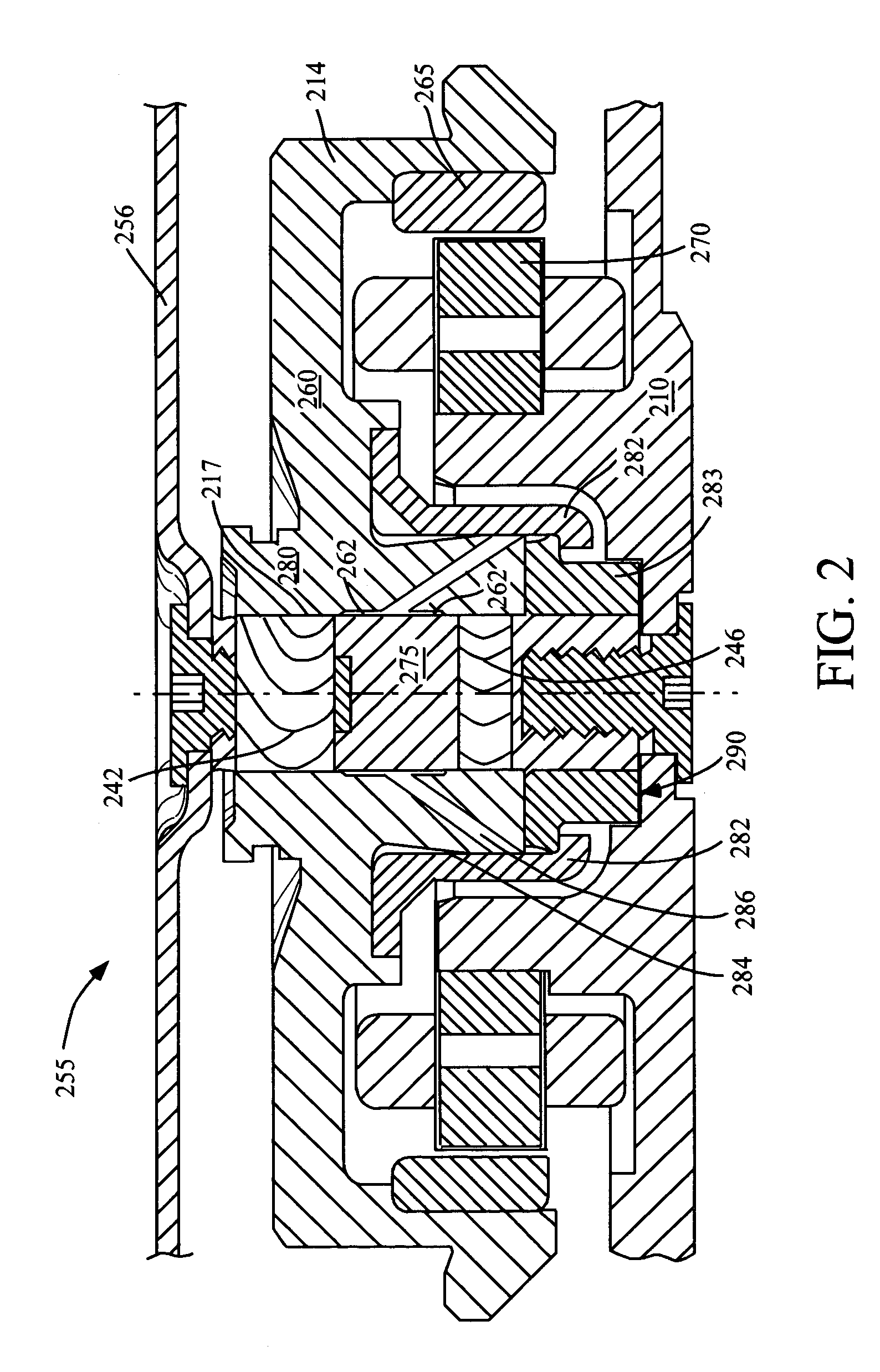

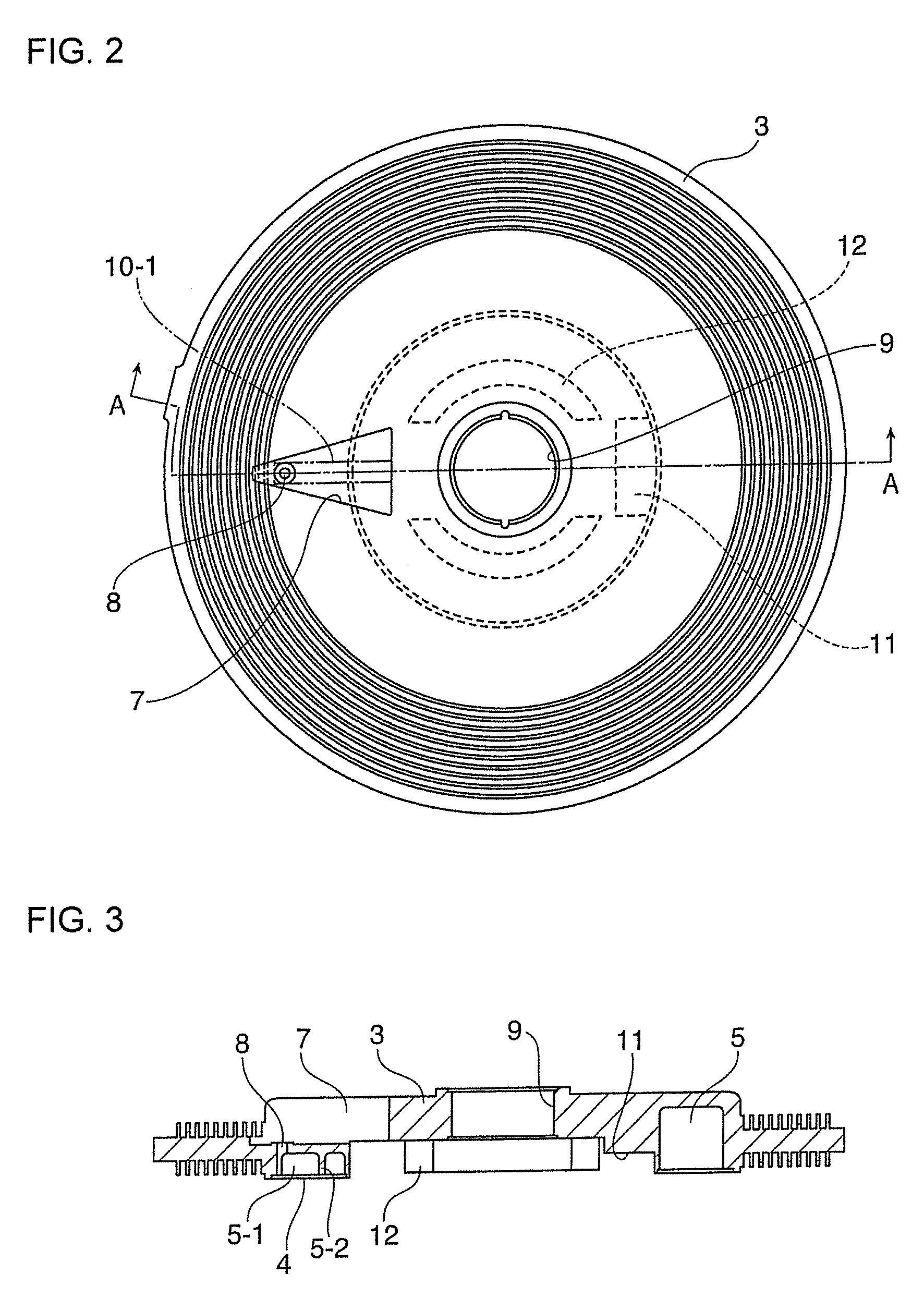

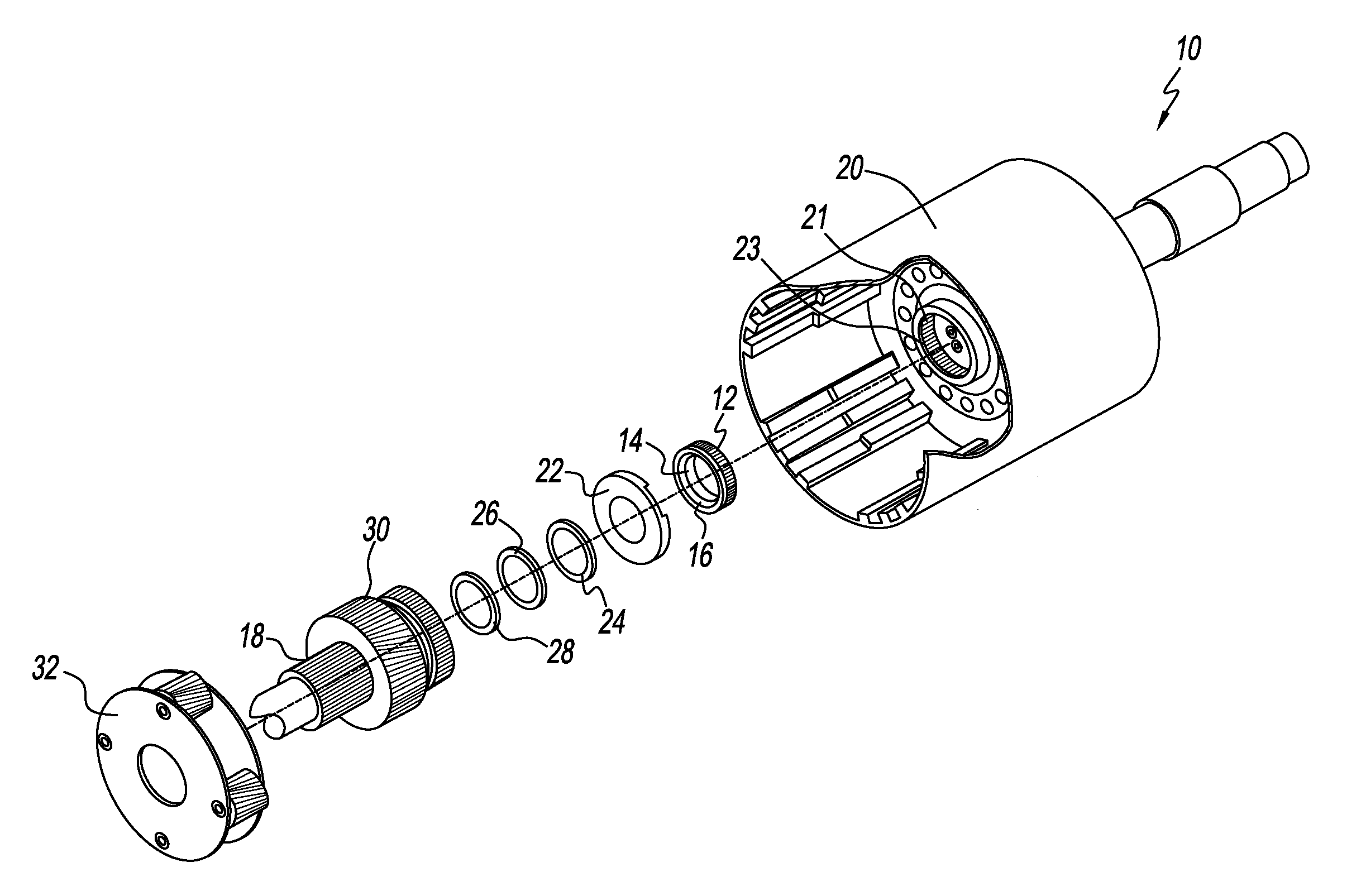

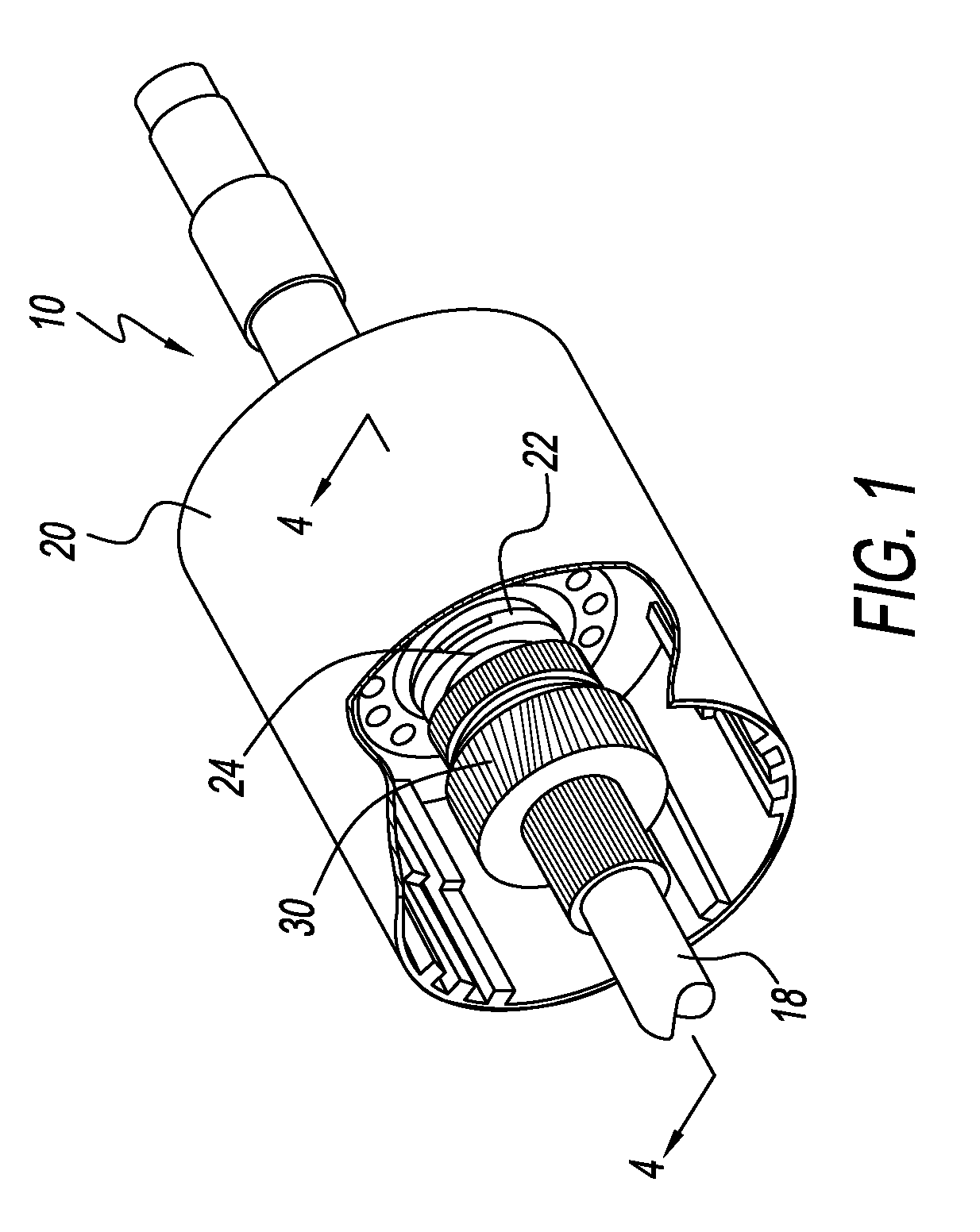

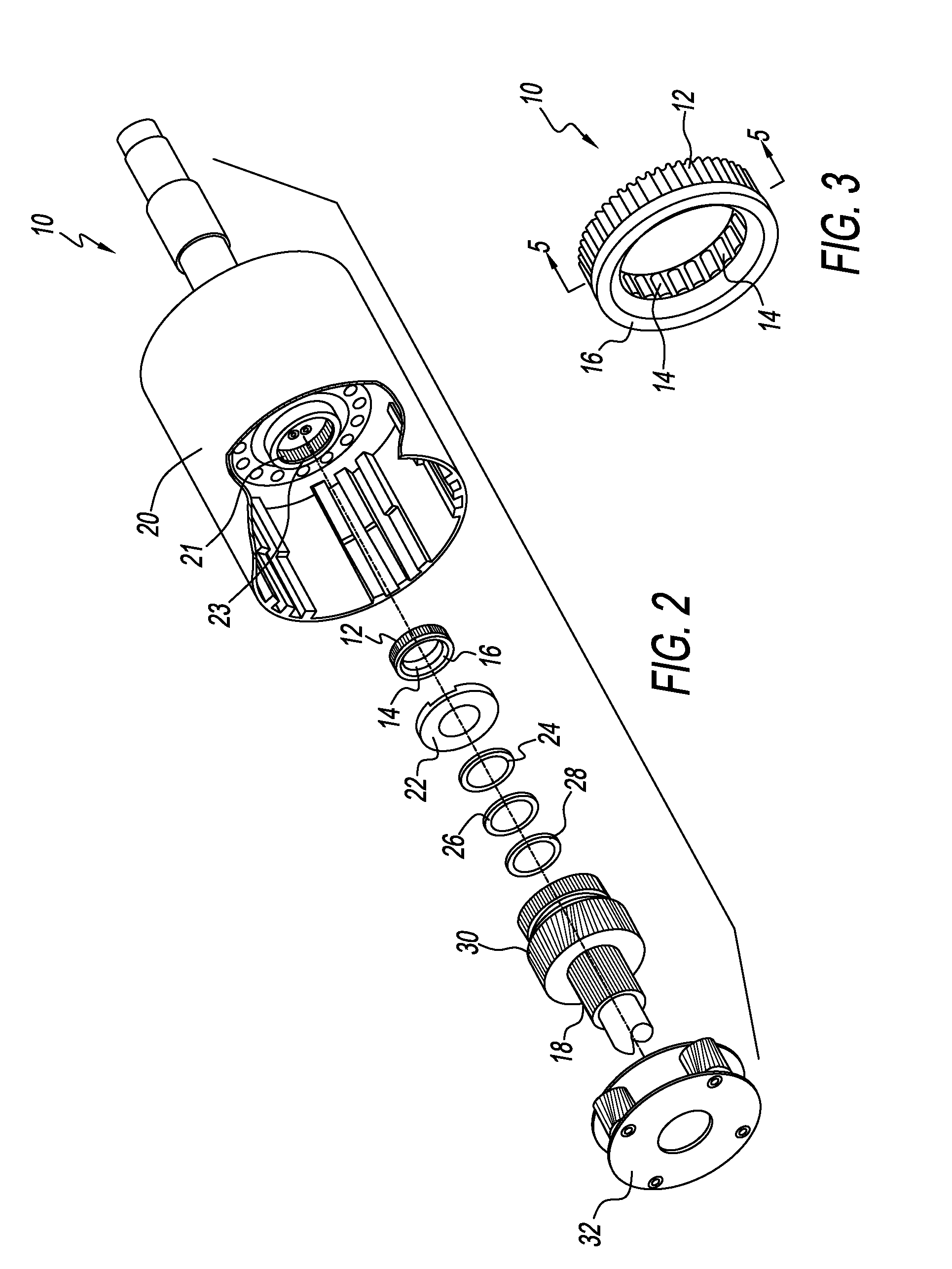

Through hub oil fill and vent for a fluid dynamic bearing motor

A through hub fill hole and air vent having an enlarged fluid diffusion path is provided for spindle motors. Oil leakage and evaporation from a motor is reduced. In an aspect, oil is retained under conditions of at least a 1000 G shock event. In an aspect, the hub fill hole has a varying diameter and geometry, and is angled, further reducing oil leakage. In an aspect, an additional cavity is employed within the hub, for maintaining rotor rotational balance. The process of filling oil into a spindle motor is made easier from a motor set up and tooling perspective. Removal of the hub and other motor components is not necessary for filling a motor. Large diameter oil fill dispenser heads, subambient and ambient fill processes, and micro dispenser fill processes may be utilized. A measured and controlled amount of oil can be dispensed, reducing variability in the motor filling process.

Owner:SEAGATE TECH LLC

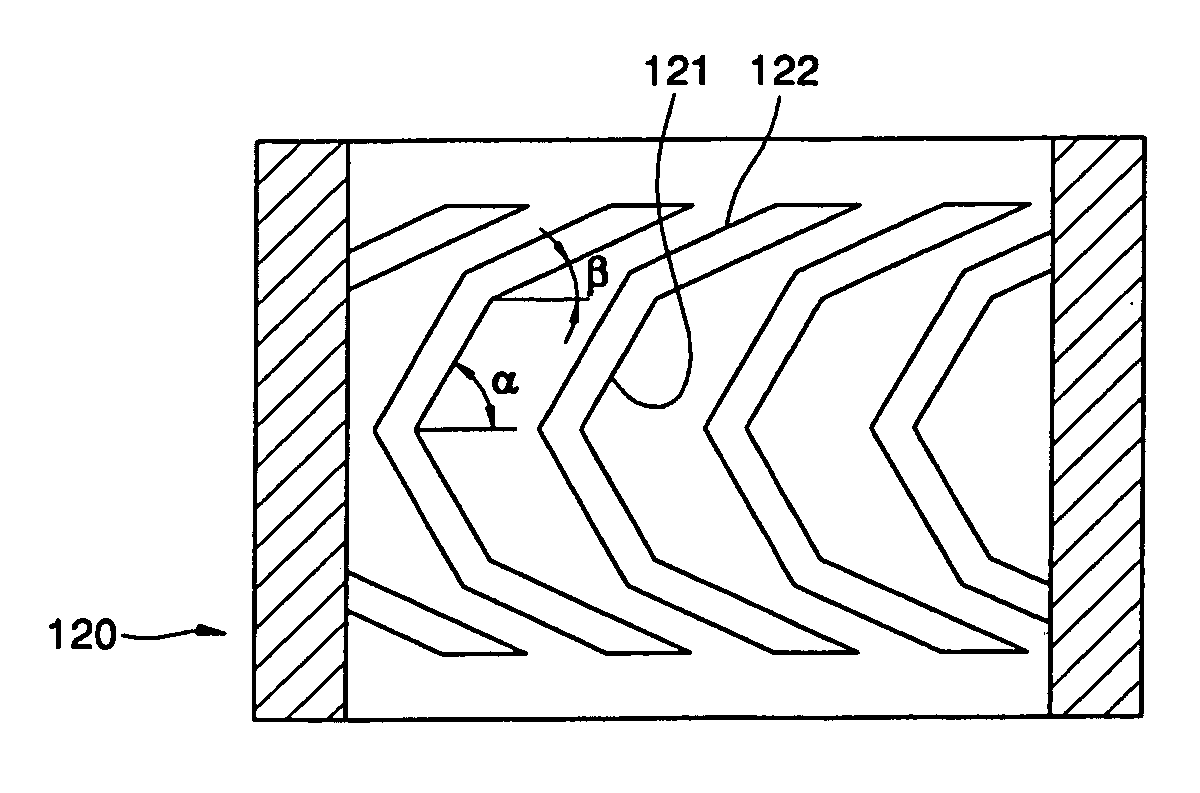

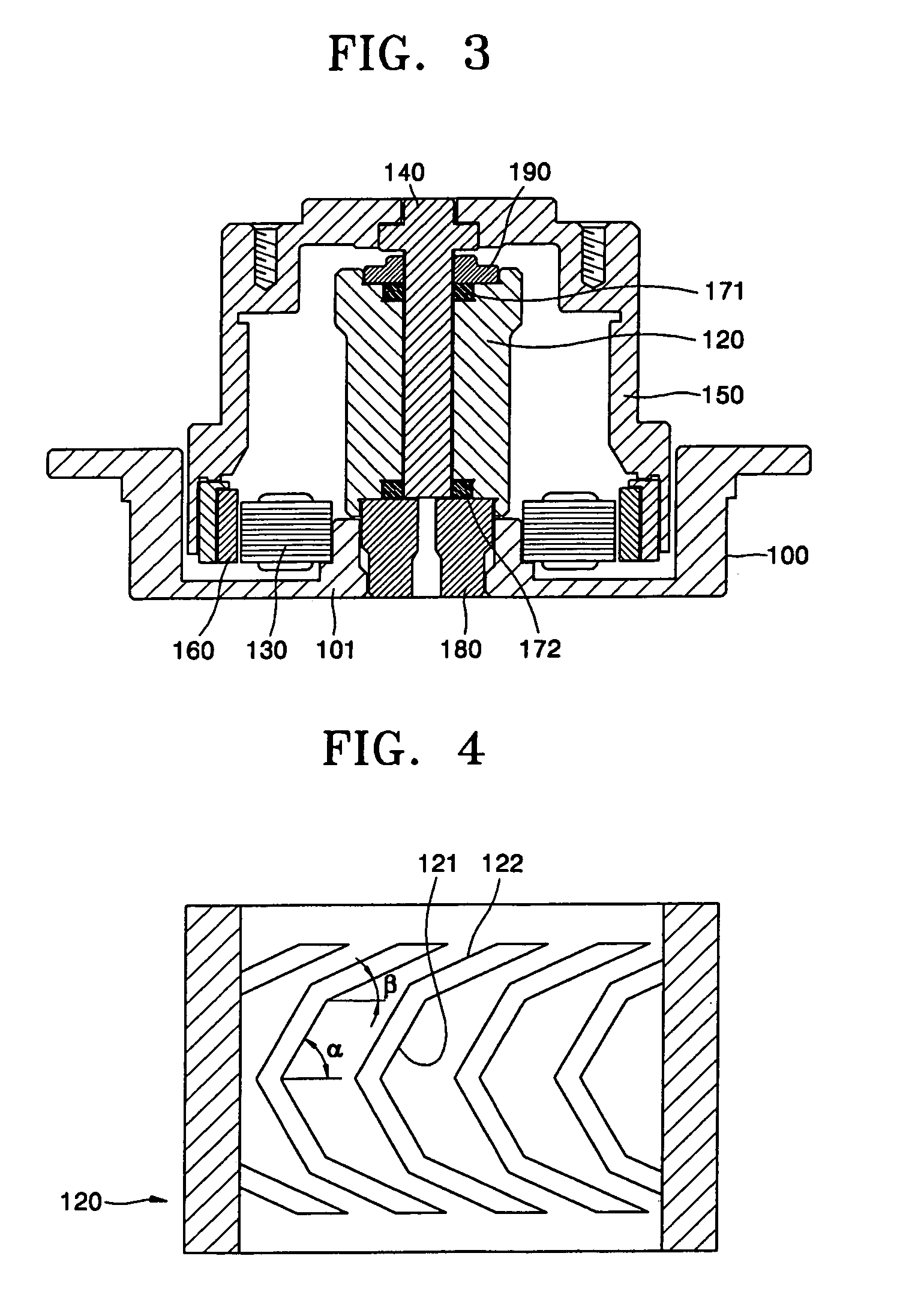

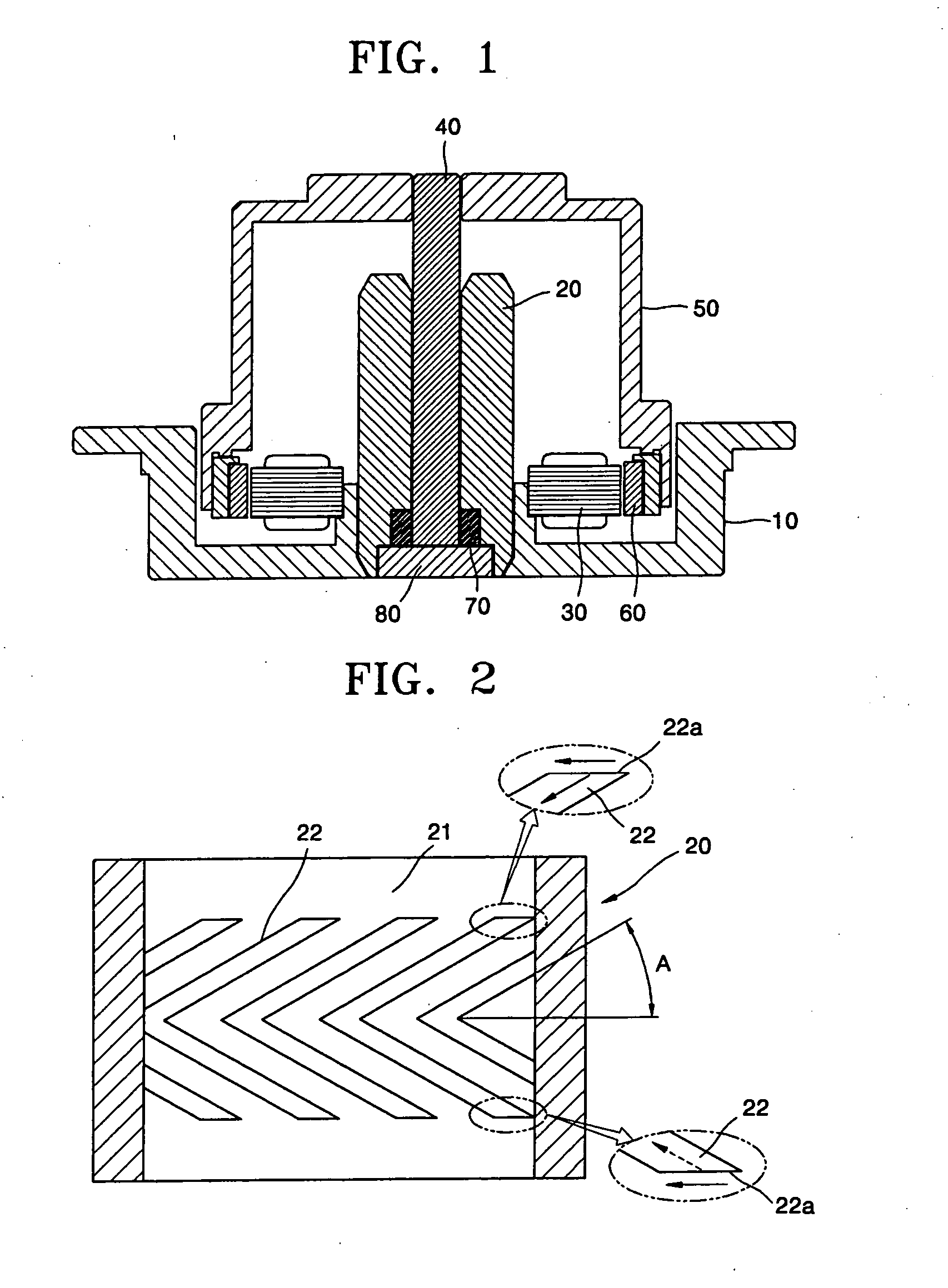

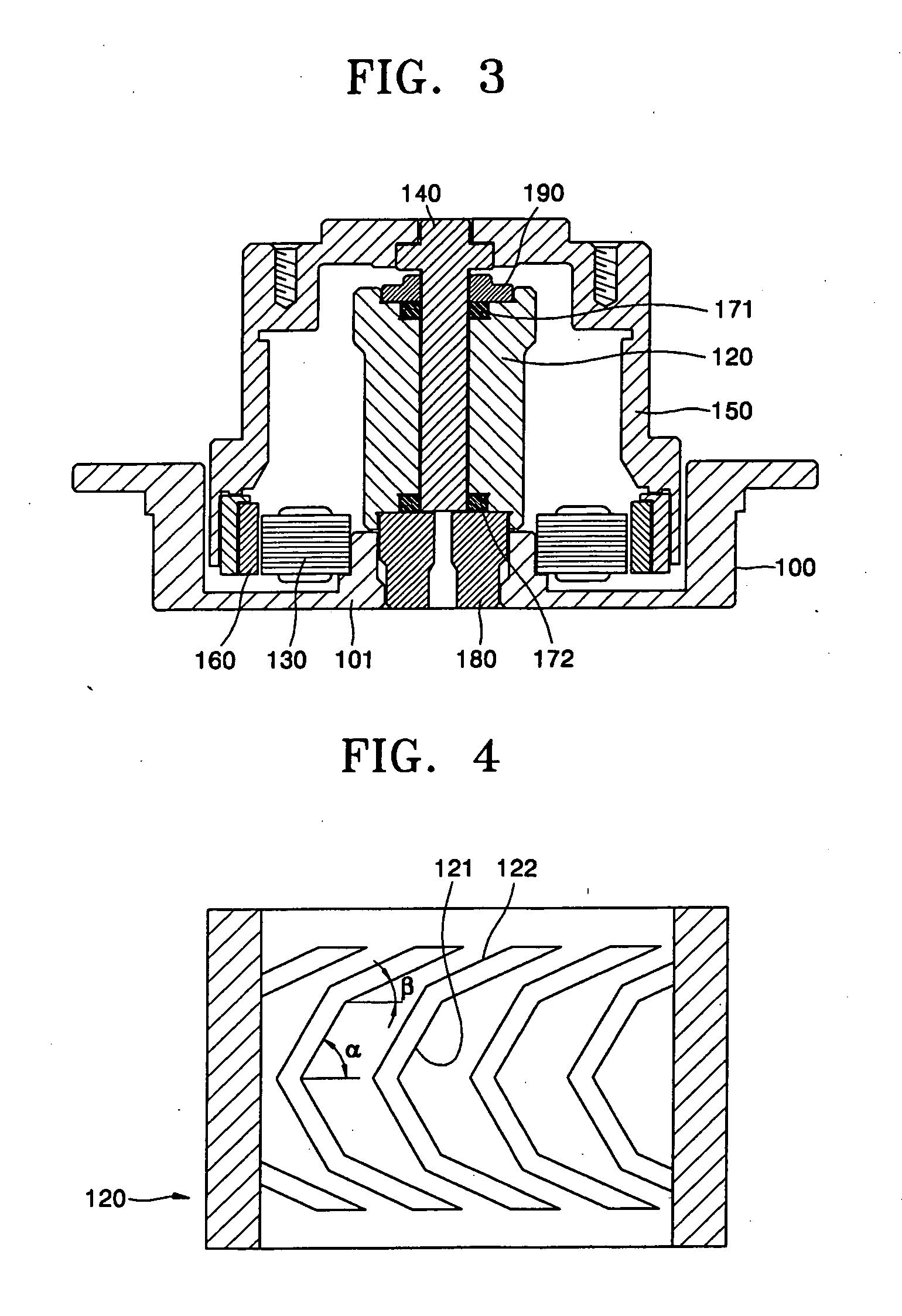

Fluid dynamic bearing motor

InactiveUS7125170B2Prevent oil leakagePrevent leakageShaftsRecord information storageEngineeringDynamic pressure

Provided is a fluid dynamic bearing motor in which a rotor is rotatably supported by forming an oil gap between the rotor and a stator to form a fluid dynamic pressure bearing and a plurality of oil grooves are formed in a surface of the rotor or stator forming the oil gap and facing each other. The oil grooves include a first oil groove inclined at a first angle with respect to a circumferential direction, and a second oil groove extending from an end portion of the first oil groove and inclined at a second angle with respect to the circumferential direction. The first angle is formed relatively greater than the second angle.

Owner:G&W TECH

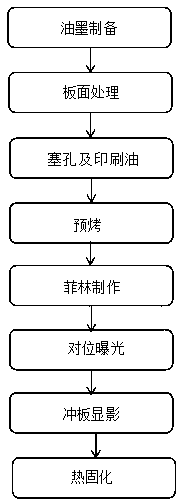

Method for preventing PCB solder mask oil leakage

InactiveCN107046774AGuaranteed developmentReduce oil leakagePrinted circuit aspectsNon-printed masksSolder maskAdverse effect

The invention provides a method for preventing PCB solder mask oil leakage. The method comprises the steps of: oil preparing, board surface processing, hole plugging and oil printing, pre-baking, film manufacturing, aligning / exposure, board punching and developing, UV curing and subsequent procedure conducting, wherein a green oil ring is additionally arranged on the periphery of a film single-side windowed region hole in the film manufacturing step, and a difference value between the diameter of the green oil ring and the diameter of the hole ranges from 2 to 5 mil. The method for preventing PCB solder mask oil leakage significantly prevents the oil leakage abnormal phenomenon at a single-side windowed position after aligning and developing, the appearance quality of the oil covering circuits and a substrate is good, and the adverse effect of plug hole oil leakage on the subsequent PCB production process is avoided.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

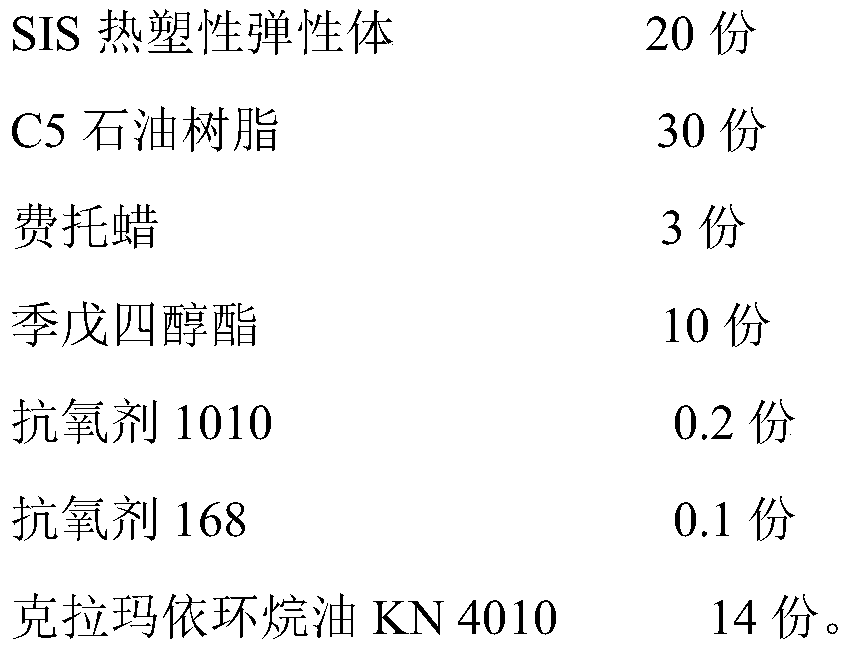

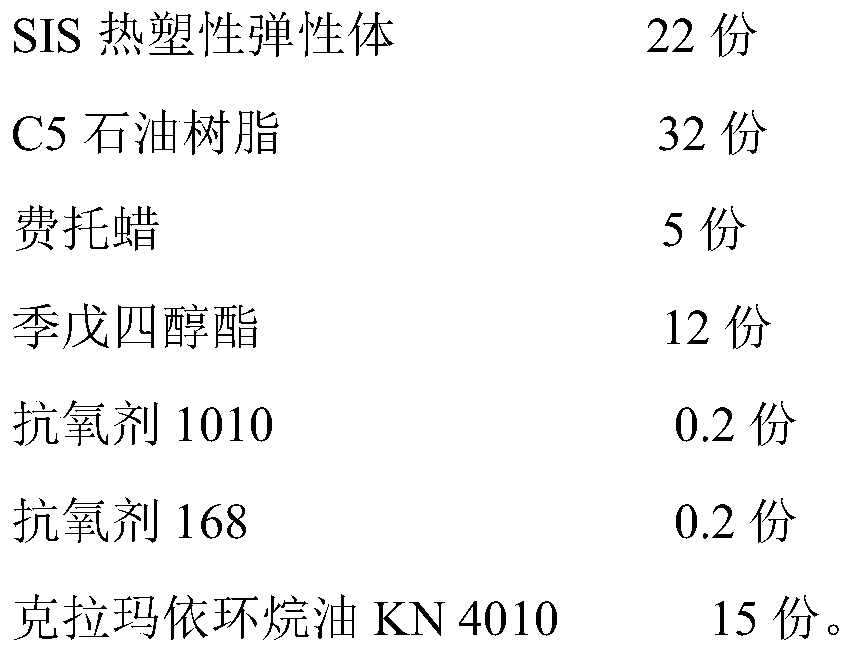

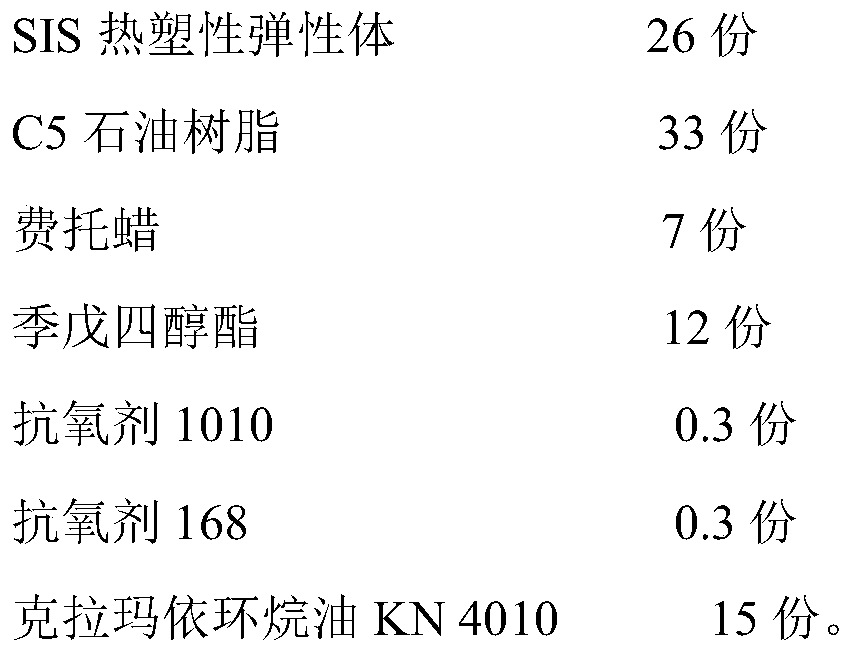

Modified hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN110734719AReduce the amount of glue remainingImprove sticking powerMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAnoxomerPolystyrene

The invention relates to a hot-melt pressure-sensitive adhesive, in particular to a modified hot-melt pressure-sensitive adhesive and a preparation method thereof. The modified hot-melt pressure-sensitive adhesive comprises the following components: a styrene thermoplastic elastomer, petroleum resin, Fischer-Tropsch wax, pentaerythritol ester, a main antioxidant, an auxiliary antioxidant and a softener; wherein the styrene thermoplastic elastomer is of an SIS linear structure, the content of styrene is 15%-21%, and the content of diblock is 50%-75%. The C5 petroleum resin and the pentaerythritol ester are dissolved in both the rubber phase (polyisoprene phase) and the hardness phase (polystyrene phase) of the thermoplastic elastomer. The two tackifying resins act together to improve the compatibility of the hot melt pressure sensitive adhesive. The raw materials cooperate with each other to obtain the hot melt pressure sensitive adhesive which has good fluidity, meets the use requirements of adhesive force, does not increase peel strength with time, and can be peeled off from the substrate cleanly.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

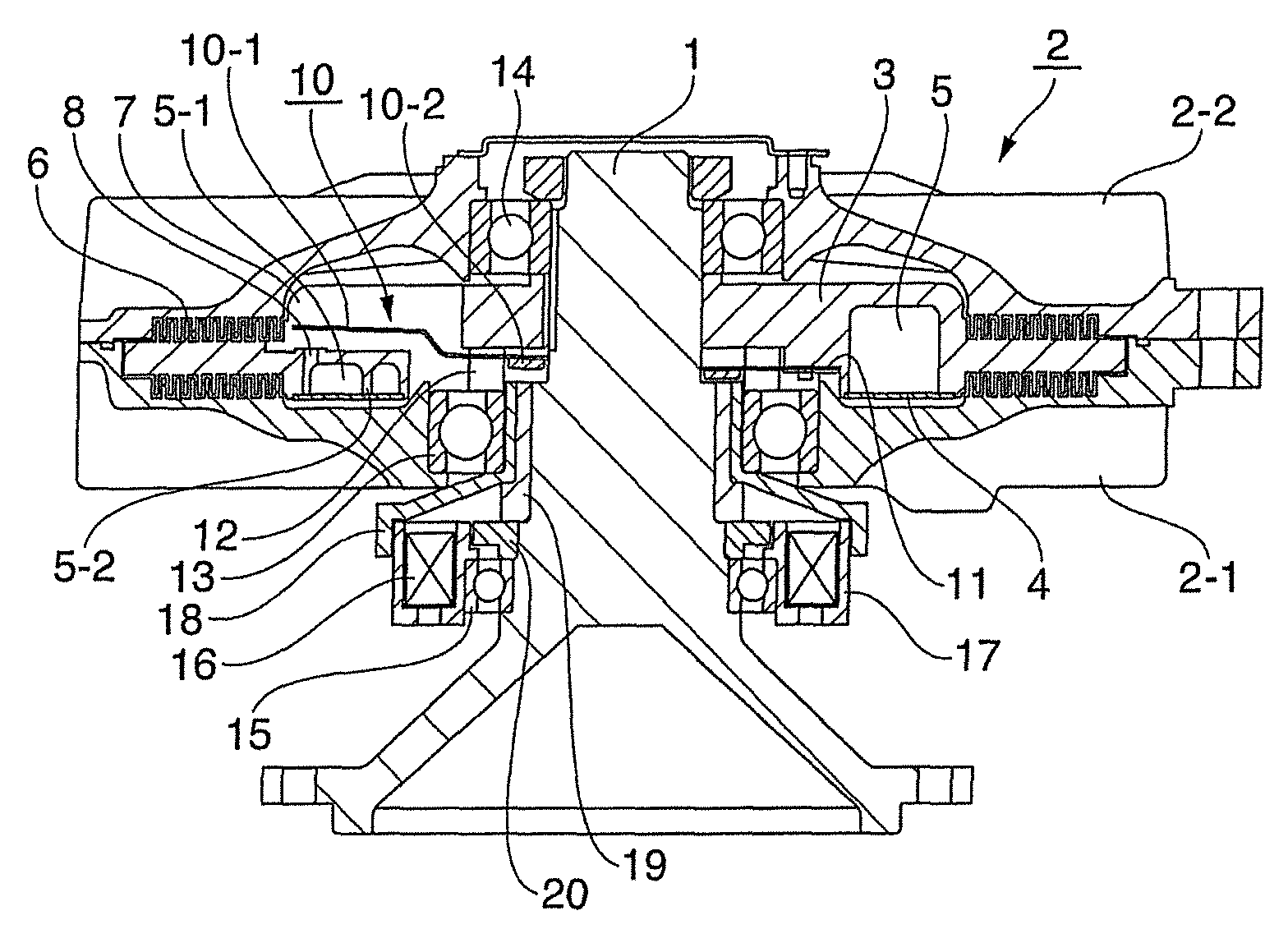

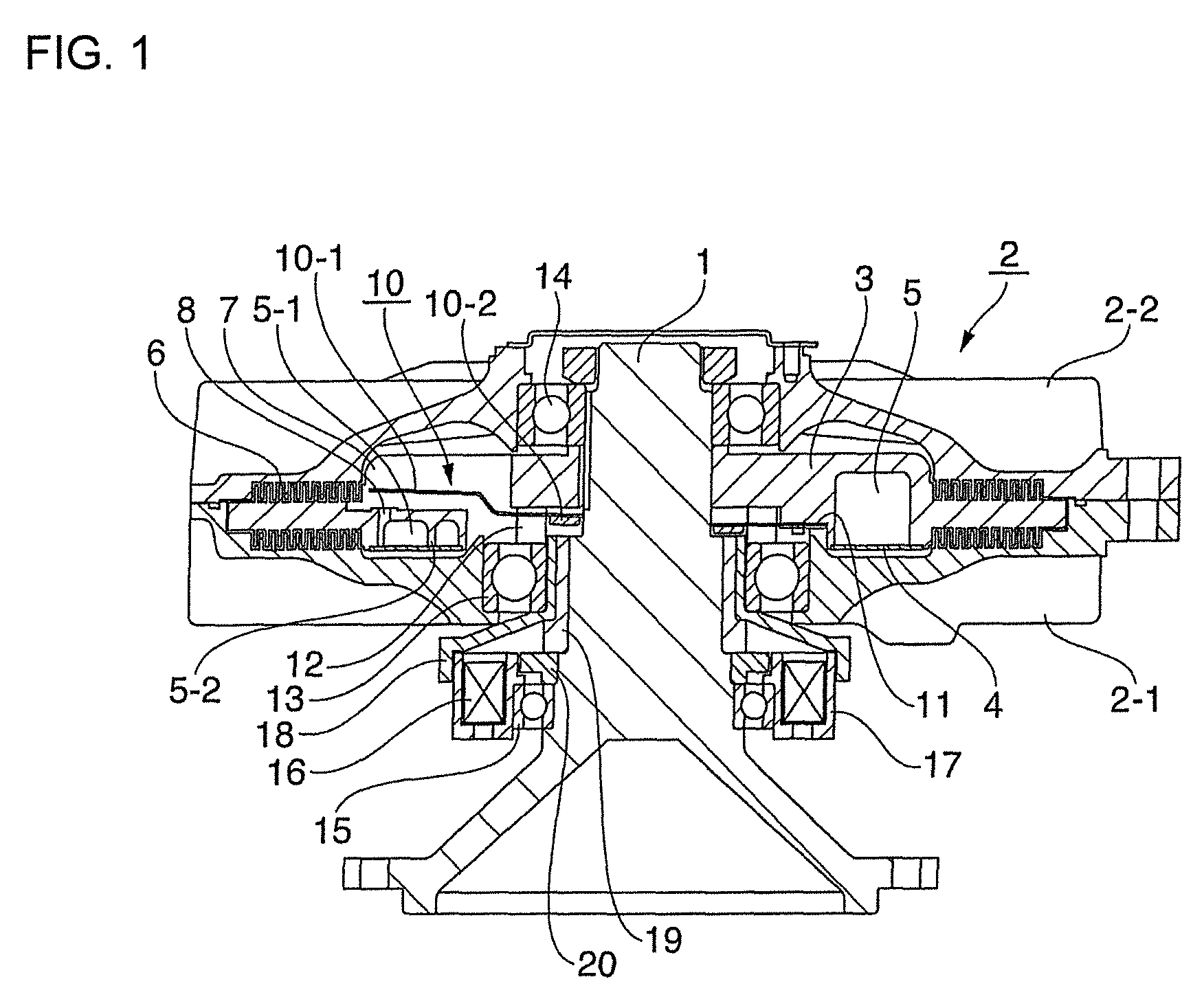

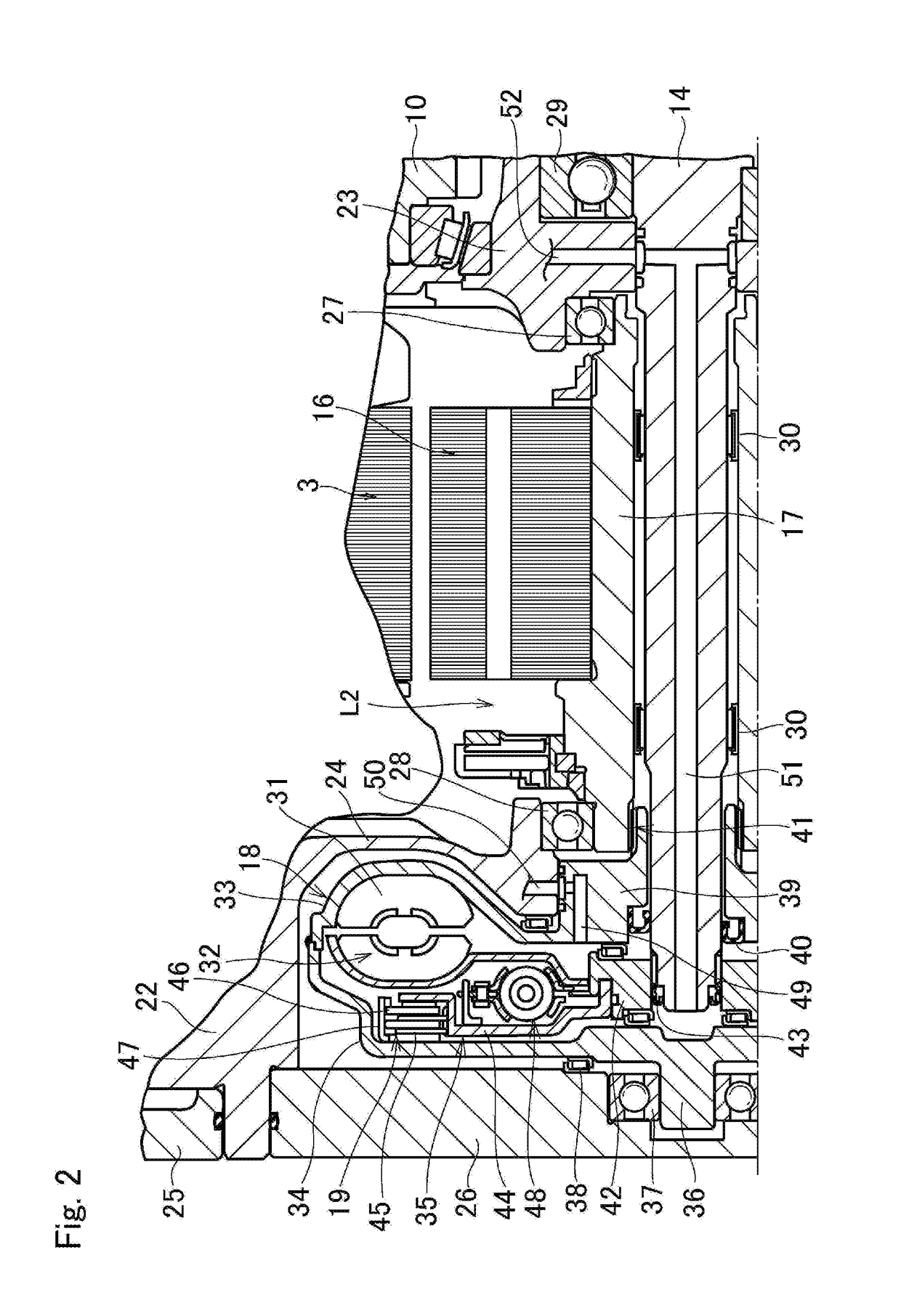

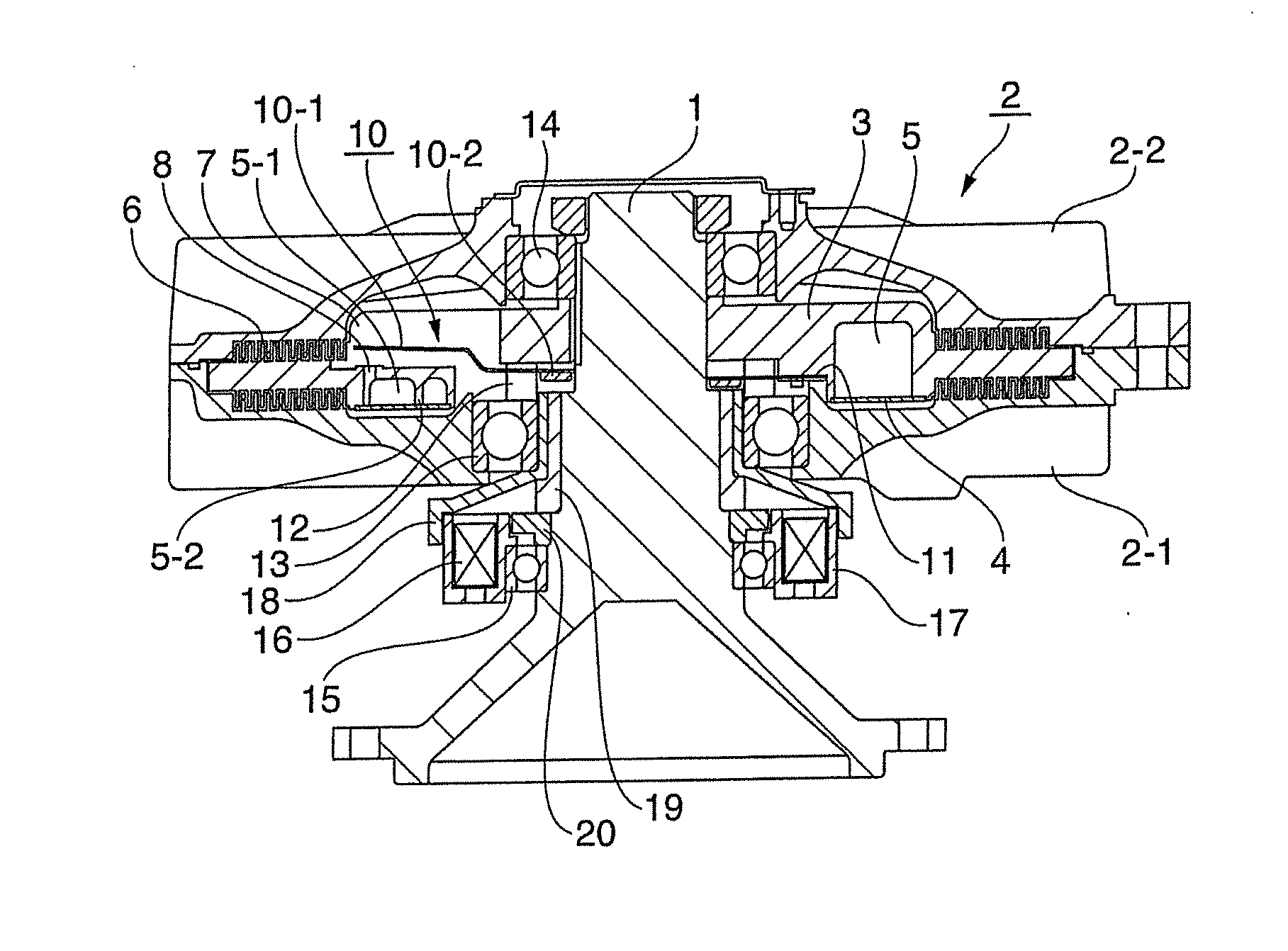

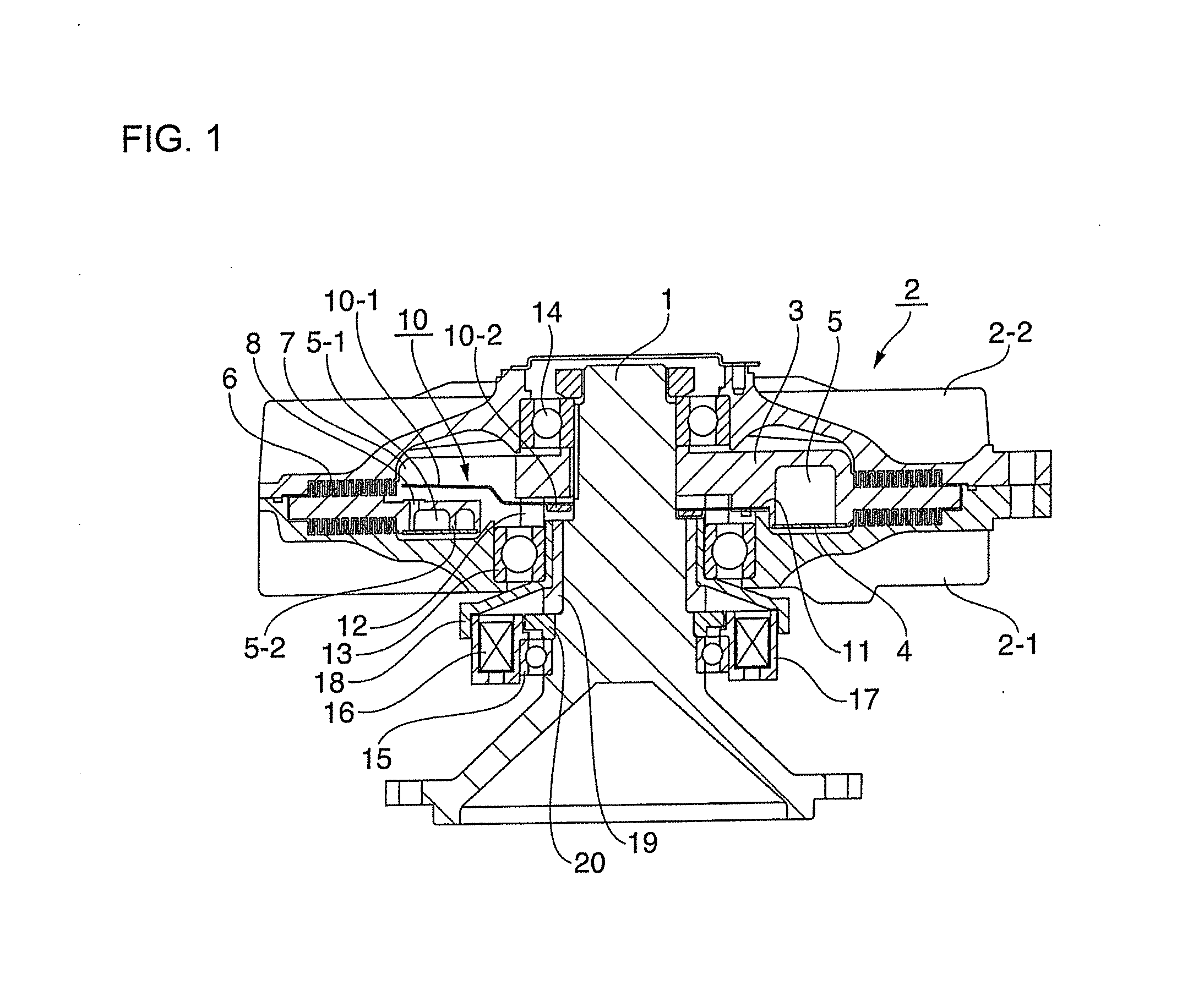

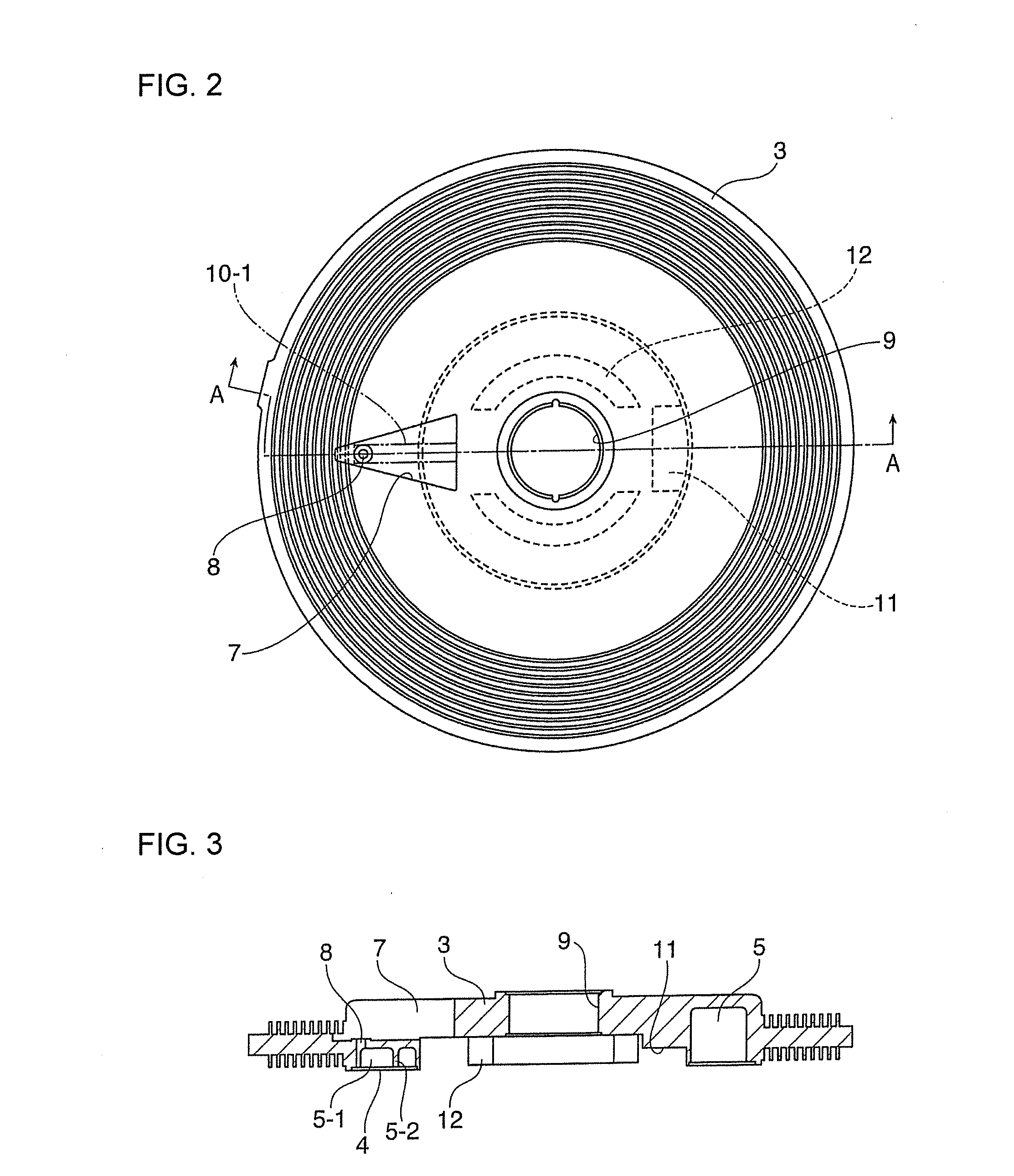

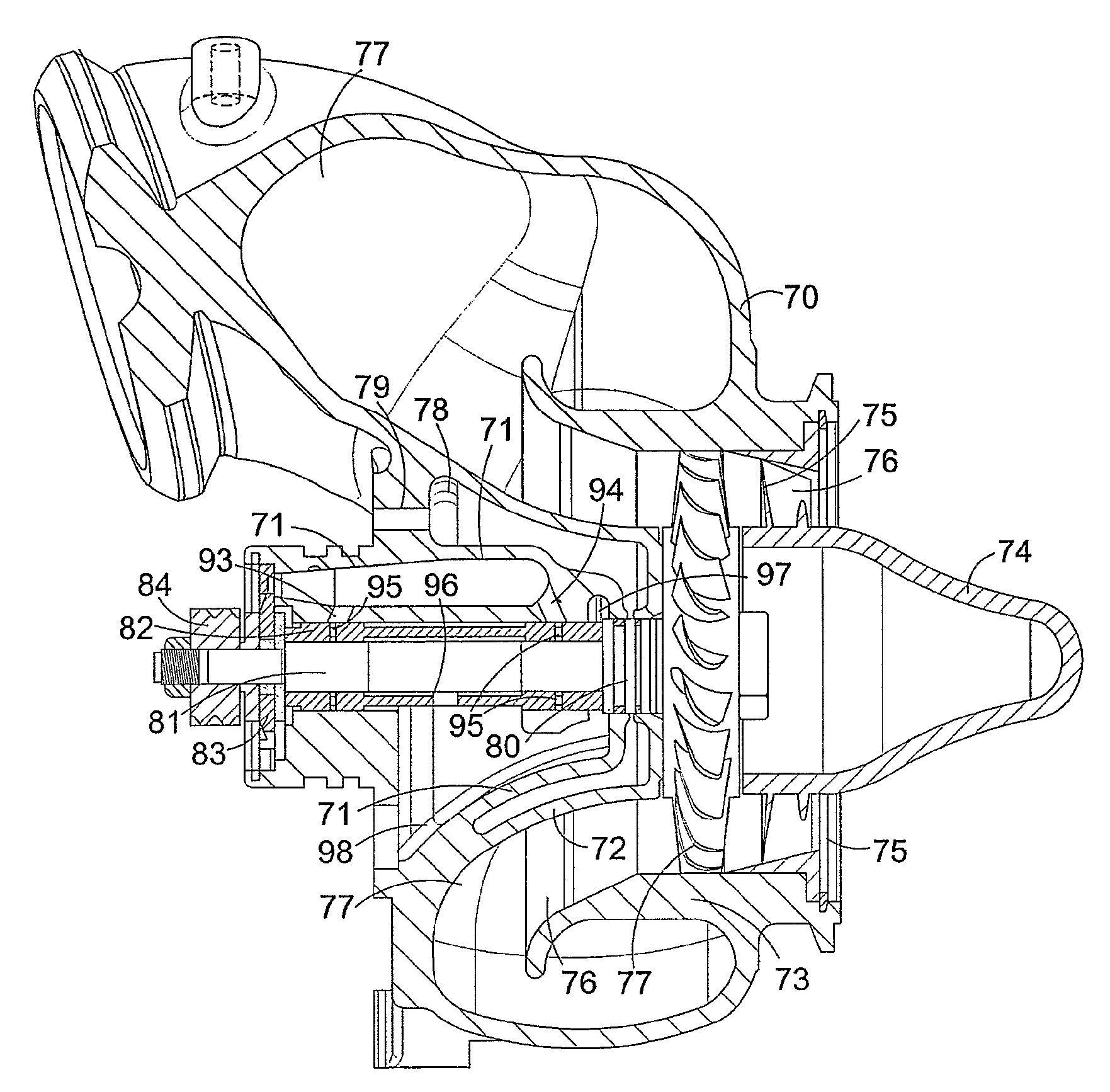

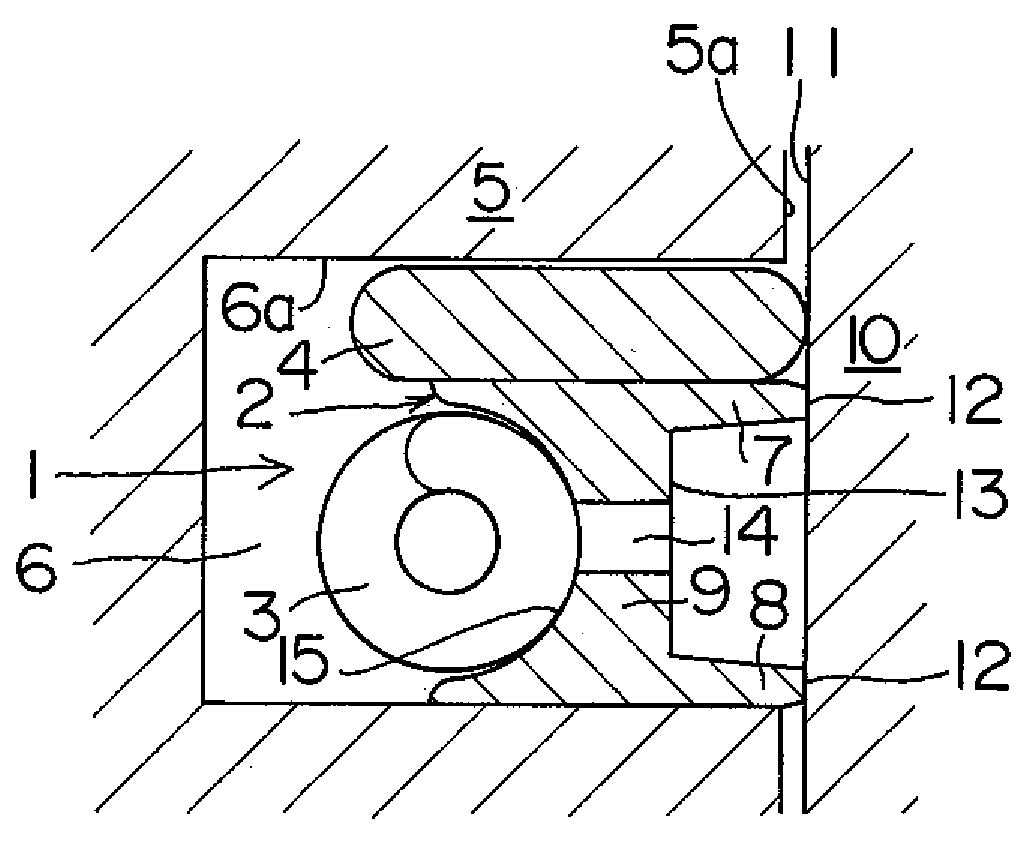

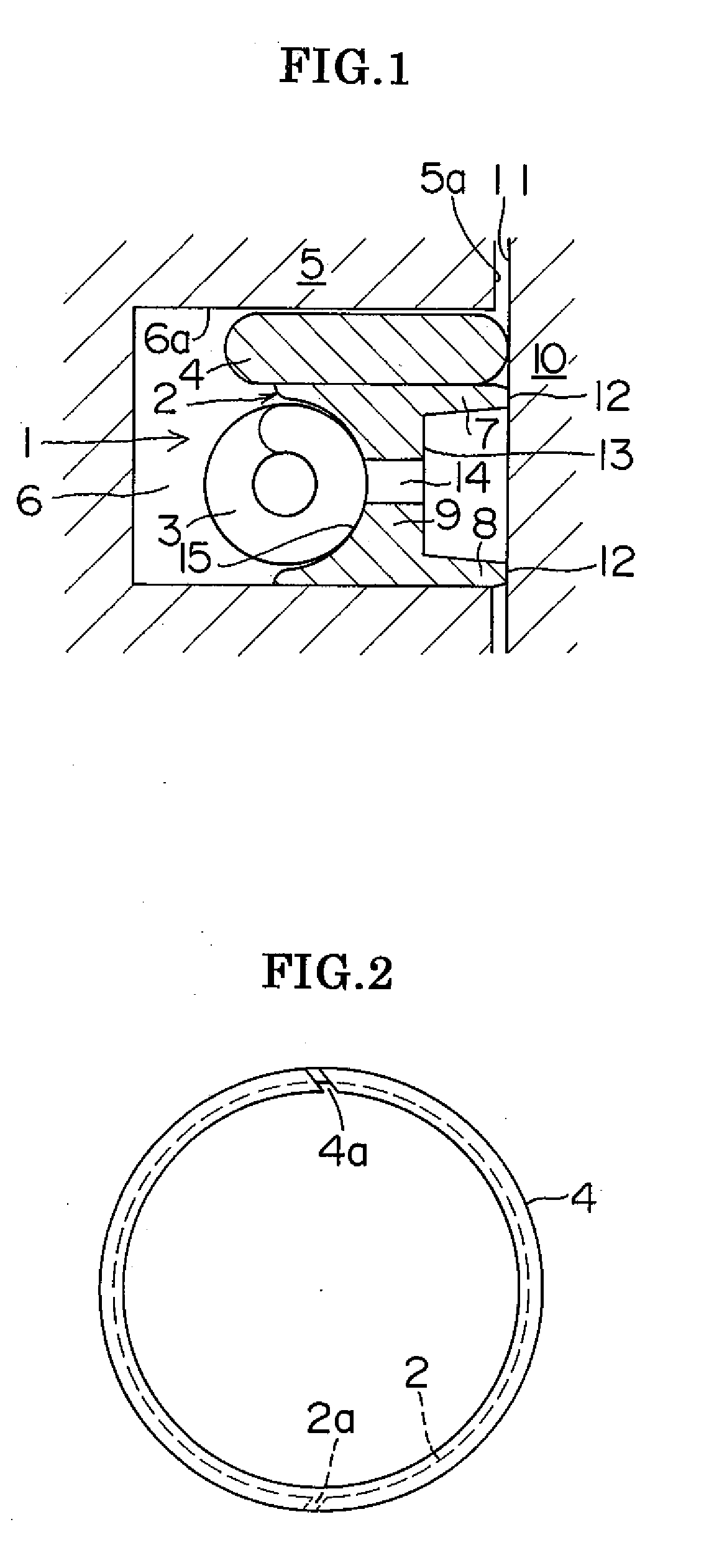

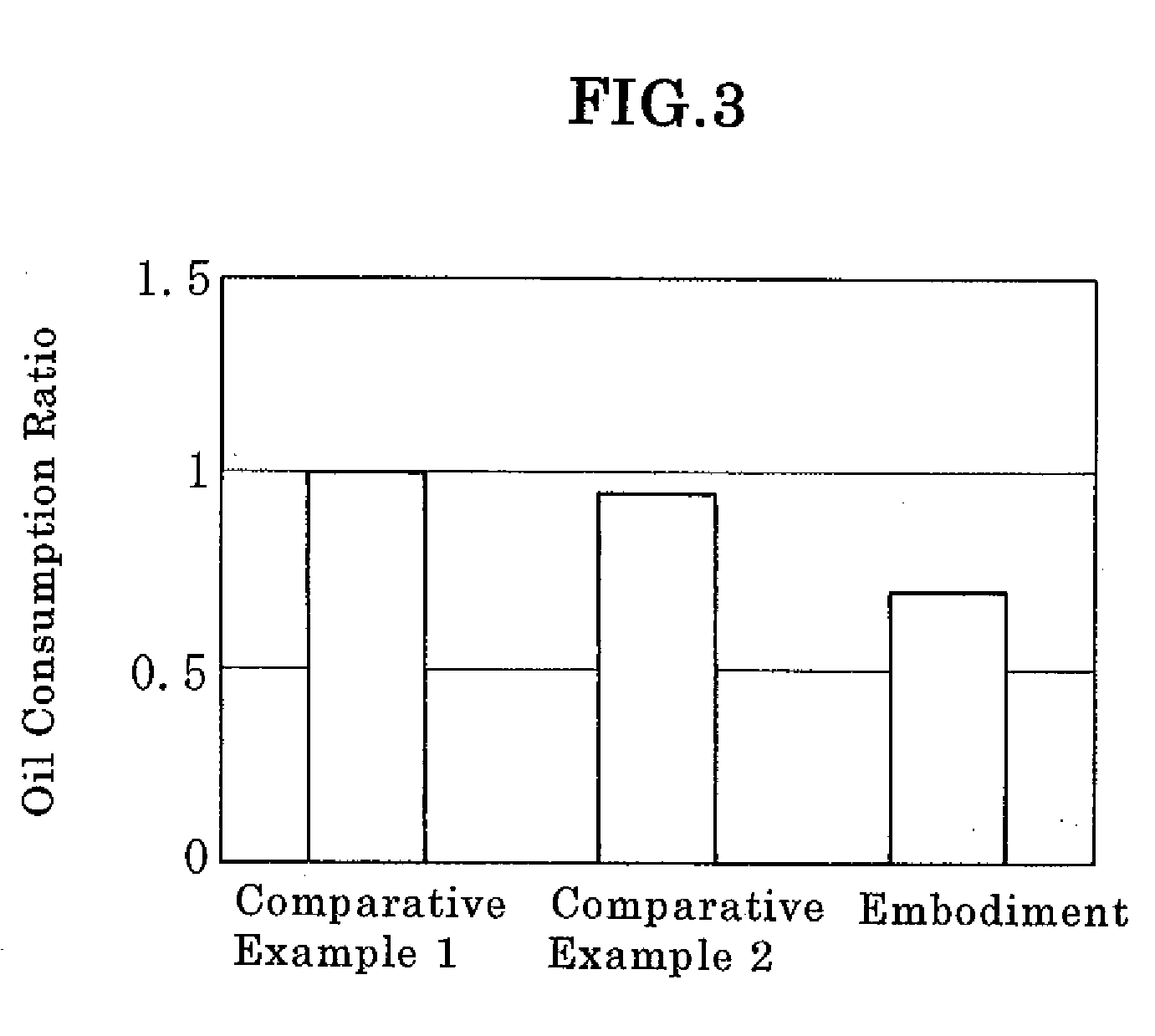

External-control type fan clutch device

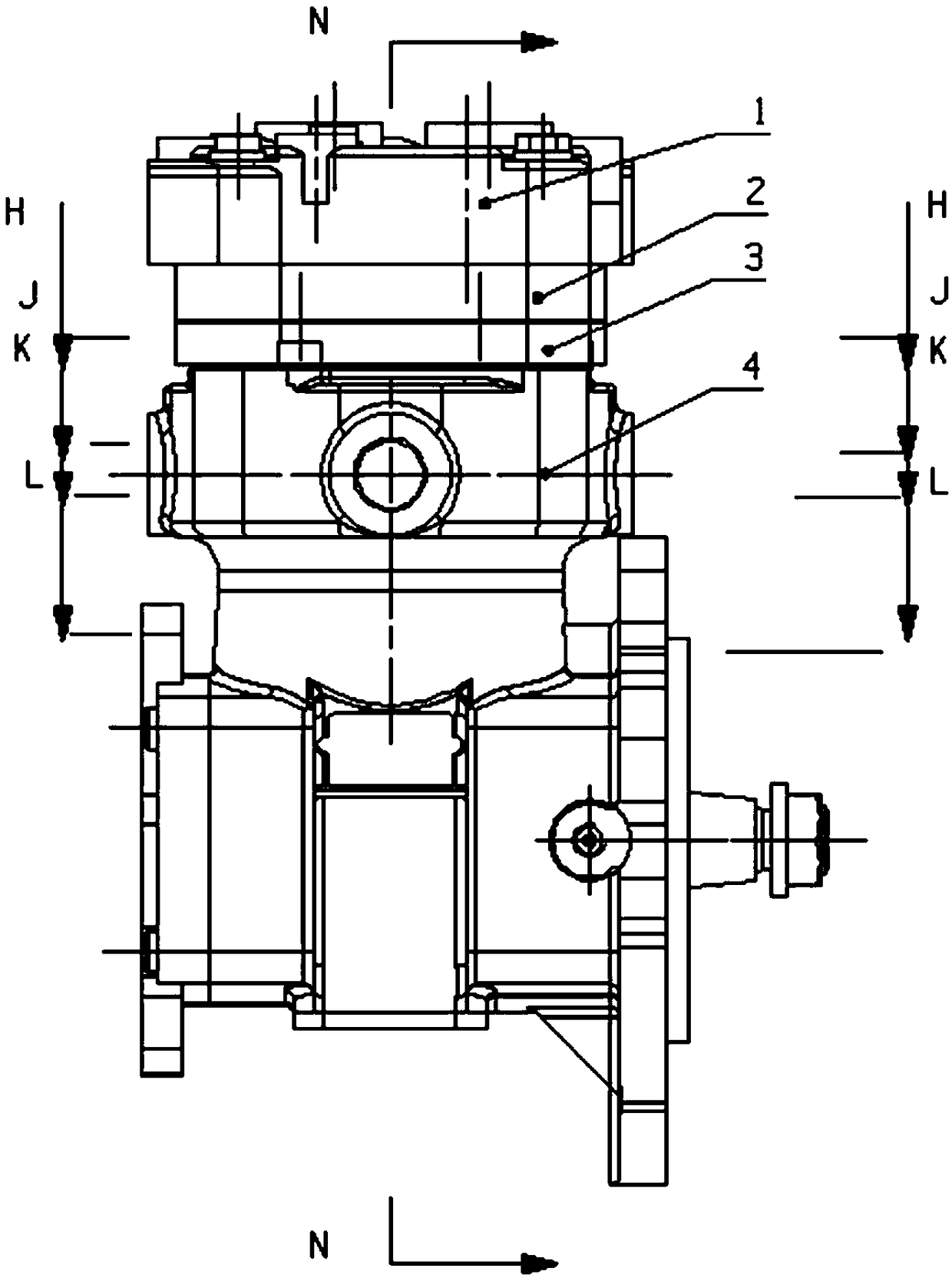

ActiveUS9328781B2Prevent rotationReduce the amount requiredCoolant flow controlFluid couplingsStop timeEngineering

Provided is an external-control type fan clutch device that can suppress unnecessary rotation of a cooling fan at the time of activating a rotary shaft effectively regardless of stop positions of an oil supply port and an oil recover port at a stop time of the fan. The fan clutch device includes a valve member for opening / closing an oil circulating flow passage hole provided on a side wall face of the annular oil reserving chamber, wherein opening / closing of the oil circulating flow passage hole is controlled by the valve member, wherein an oil supply chamber, that is formed of a partition wall composed of an arc-like wall and a plate-like partition wall for shielding one end of the arc-like partition wall, is provided in the annular oil reserving chamber, and the oil circulating flow passage hole and an oil recovery port are arranged in the oil supply chamber.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

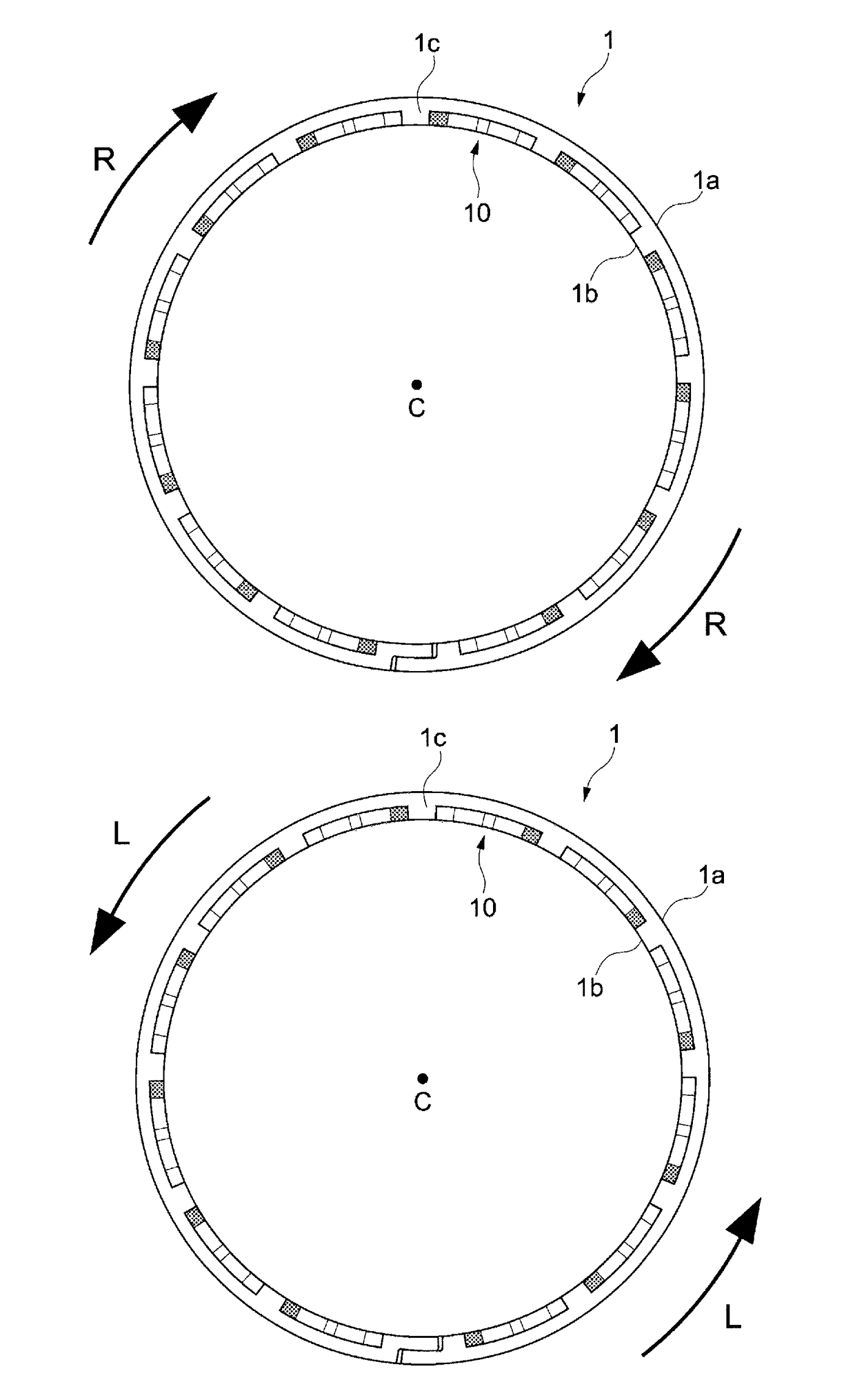

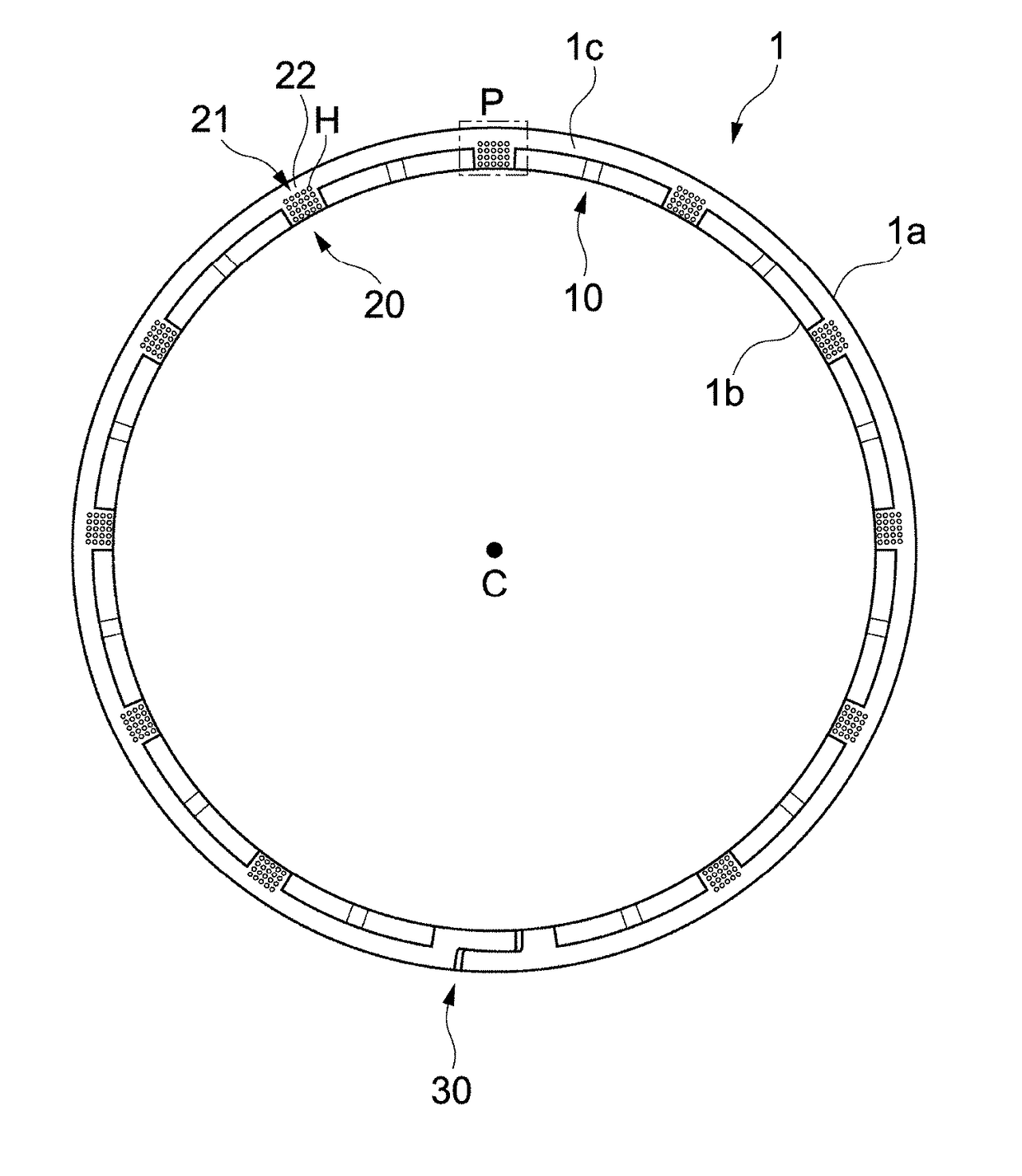

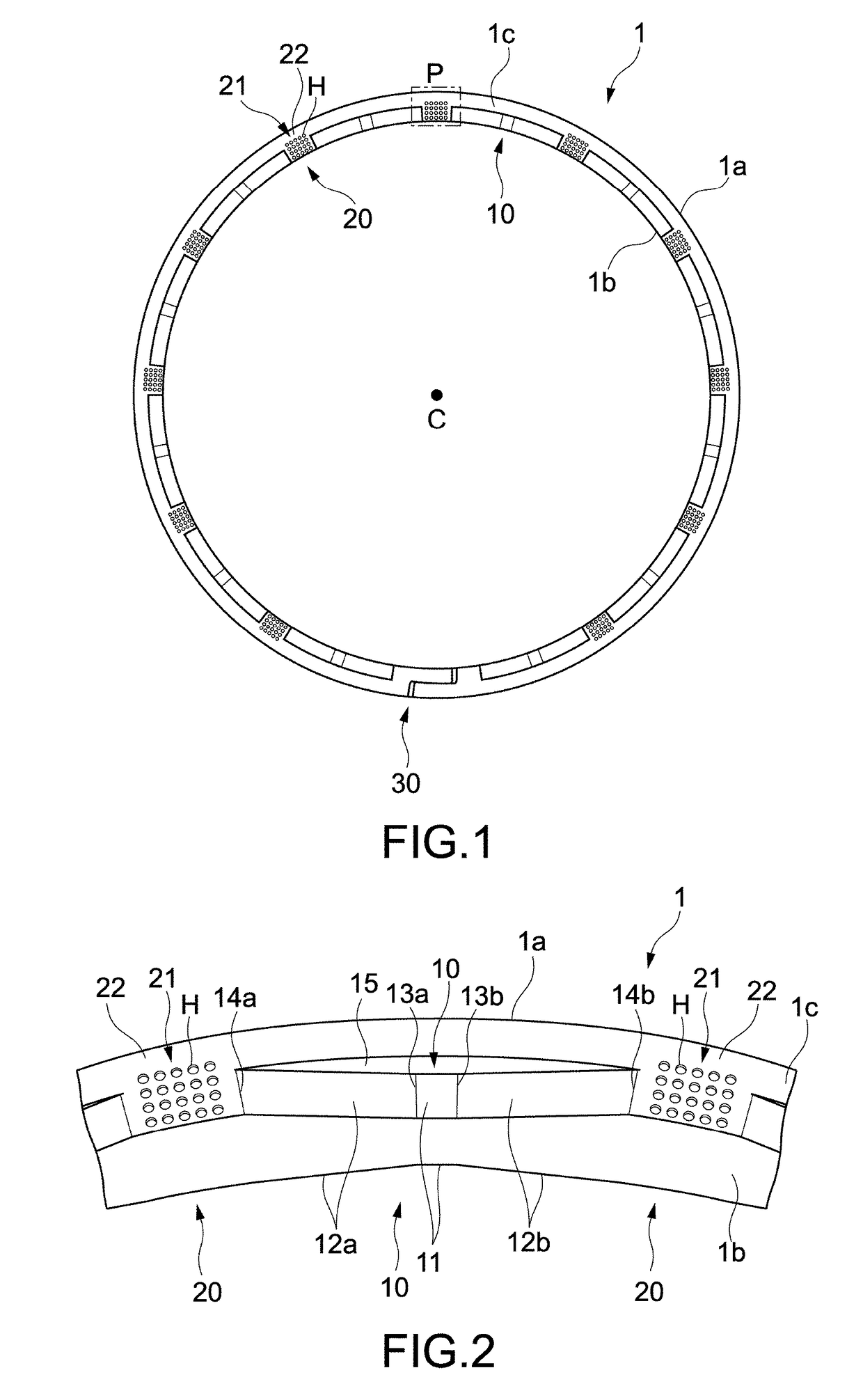

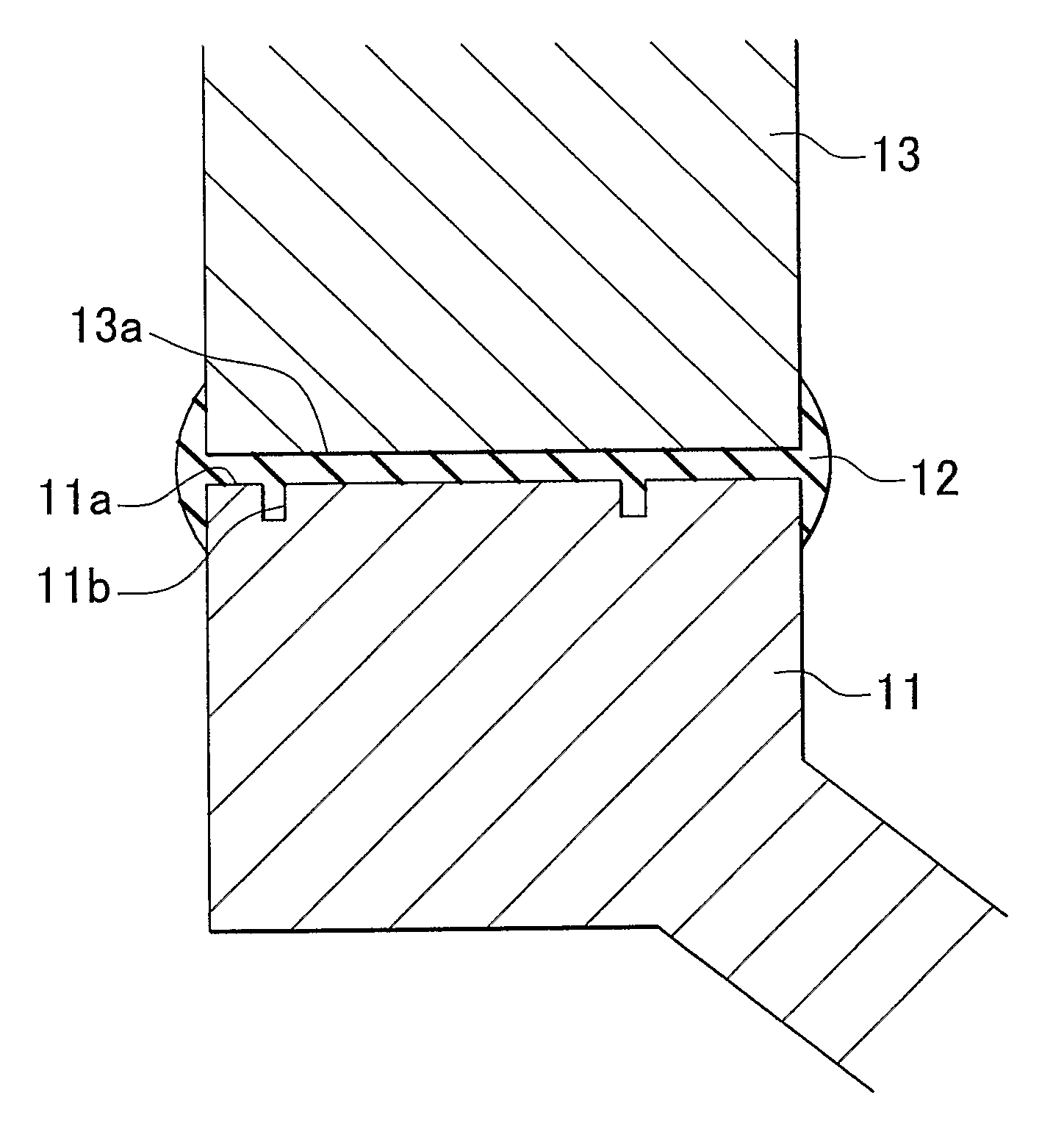

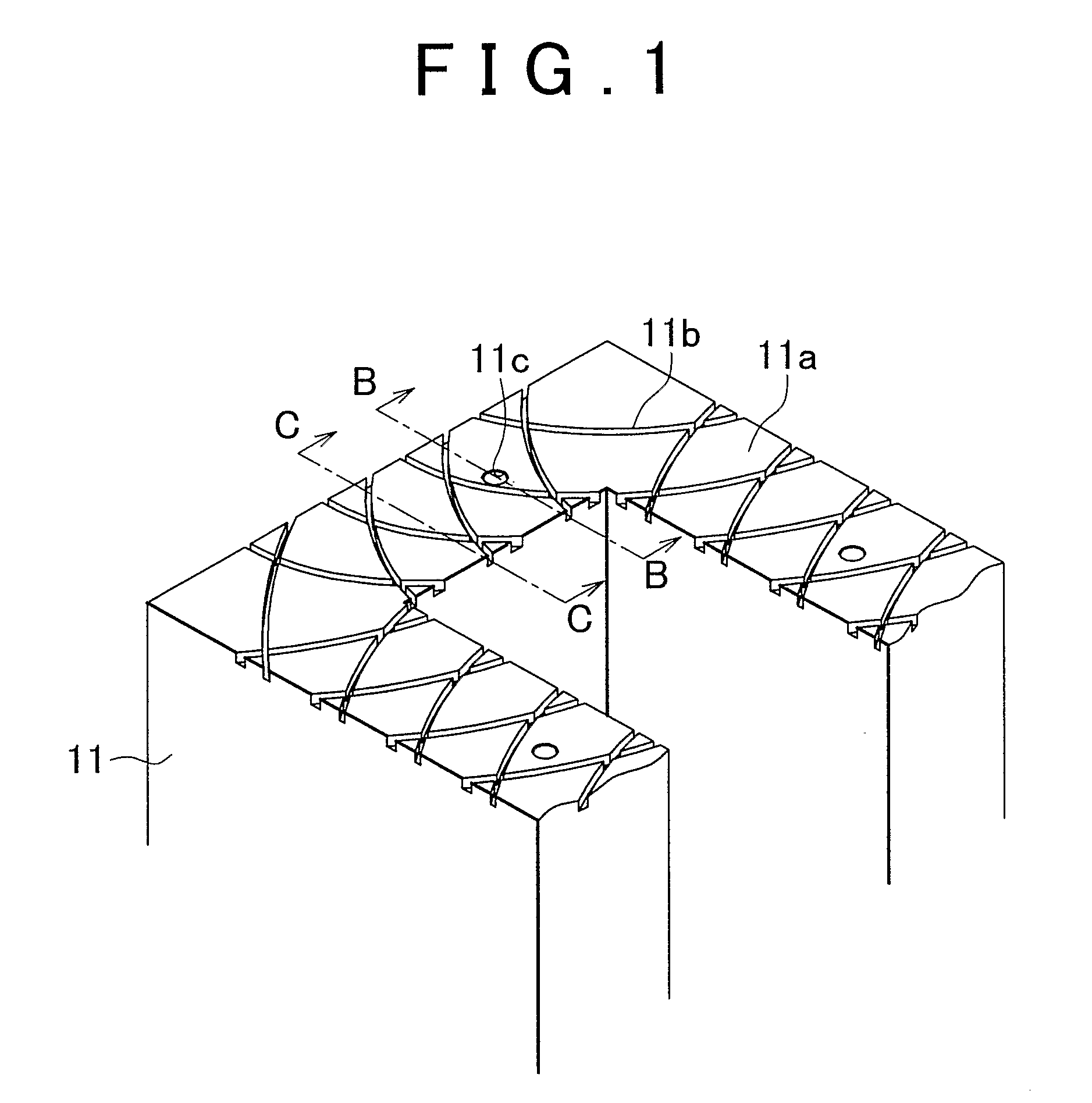

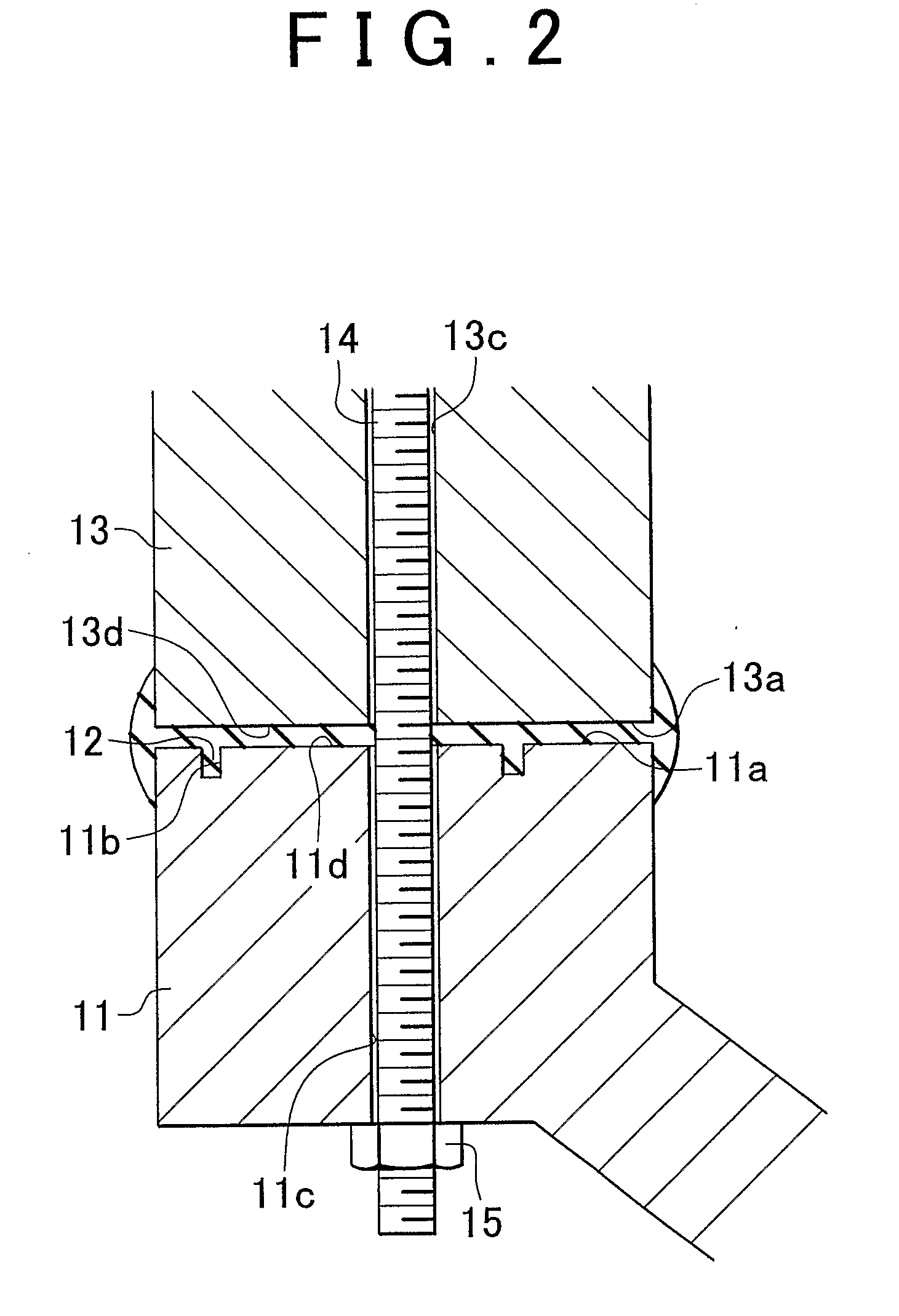

Seal ring

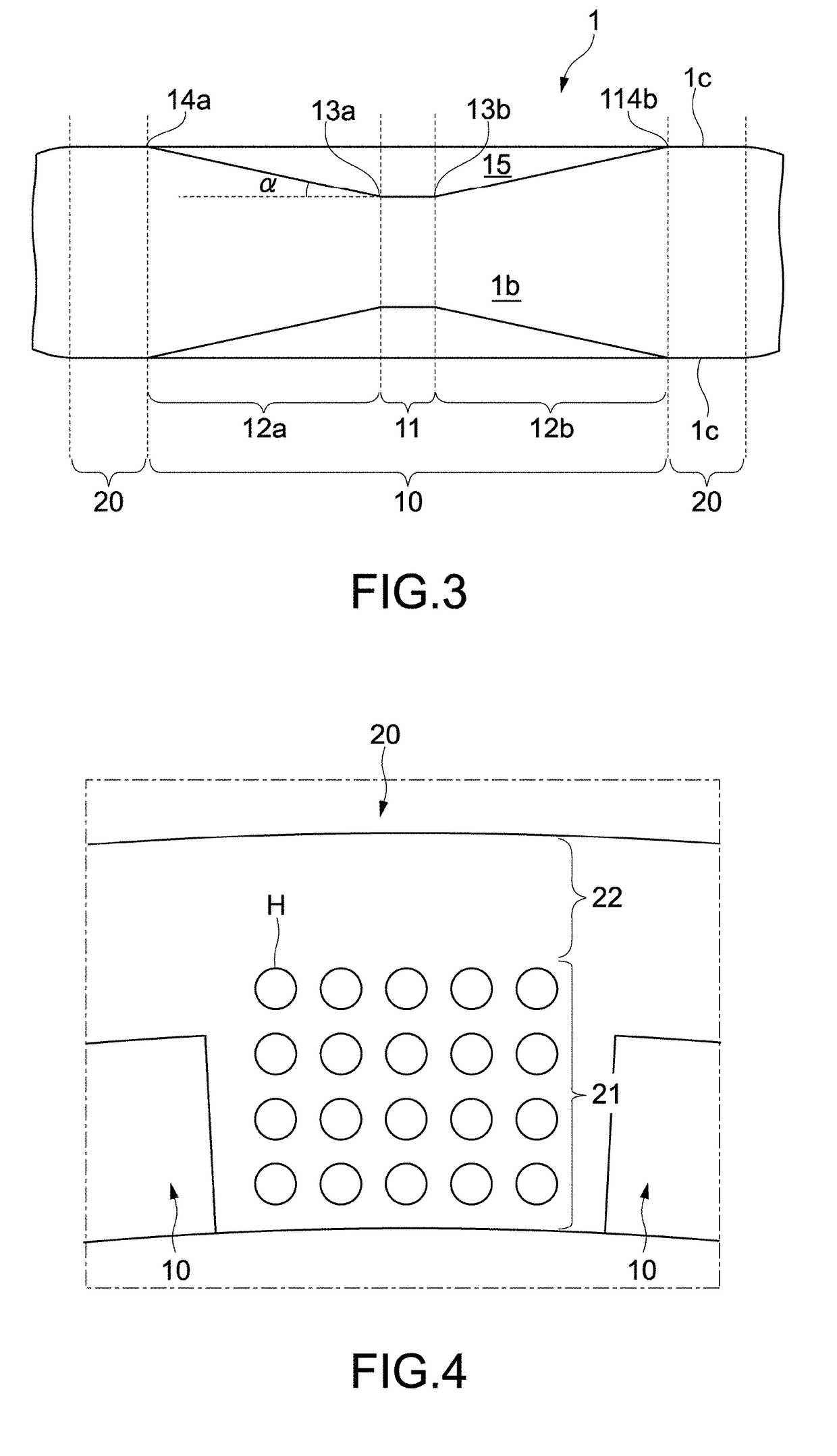

[Object] To provide a seal ring capable of both reducing a friction loss and reducing oil leakage.[Solving Means] A seal ring includes: an inner circumferential surface; an outer circumferential surface orthogonal to the inner circumferential surface; side surfaces orthogonal to the inner circumferential surface and the outer circumferential surface; and a plurality of pockets provided, spaced apart from one another in one of the side surfaces. The plurality of pockets each have a symmetrical shape in a circumferential direction and are opened on a side of the inner circumferential surface and closed on a side of the outer circumferential surface. The plurality of pockets each include circumferential end portions that are provided in end portions in the circumferential direction and are R-surfaces each having a convex shape connected to the side surface, a bottom portion provided in a central region in the circumferential direction, and inclined portions each extending between each of the circumferential end portions and the bottom portion. The inclined portions each include at least one ridge portion, a first inclined portion extending between the bottom portion and the ridge portion and forming a first angle with respect to the side surface, and a second inclined portion extending between the circumferential end portion and the ridge portion and forming a second angle smaller than the first angle with respect to the side surface.

Owner:RIKEN CO LTD

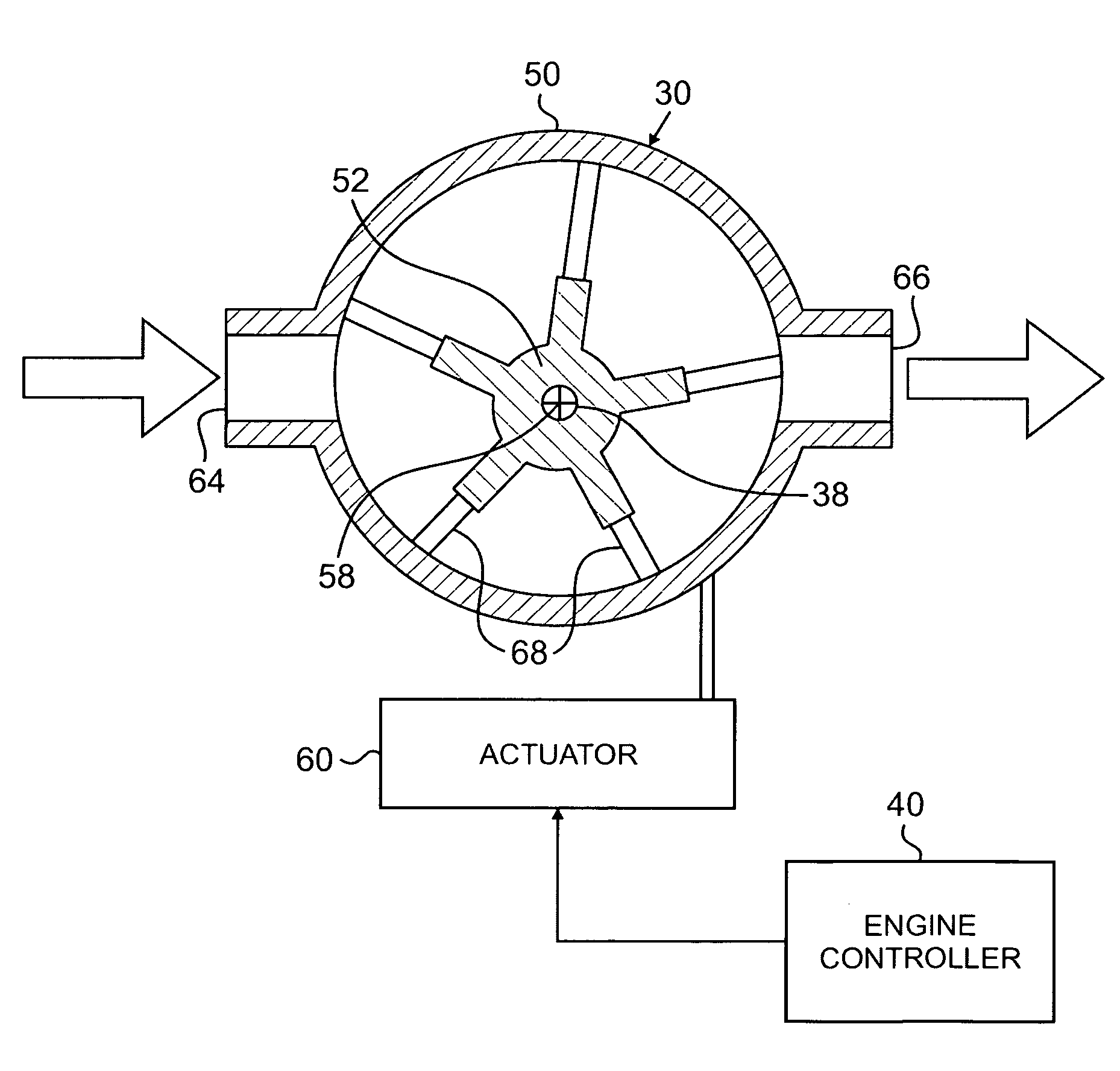

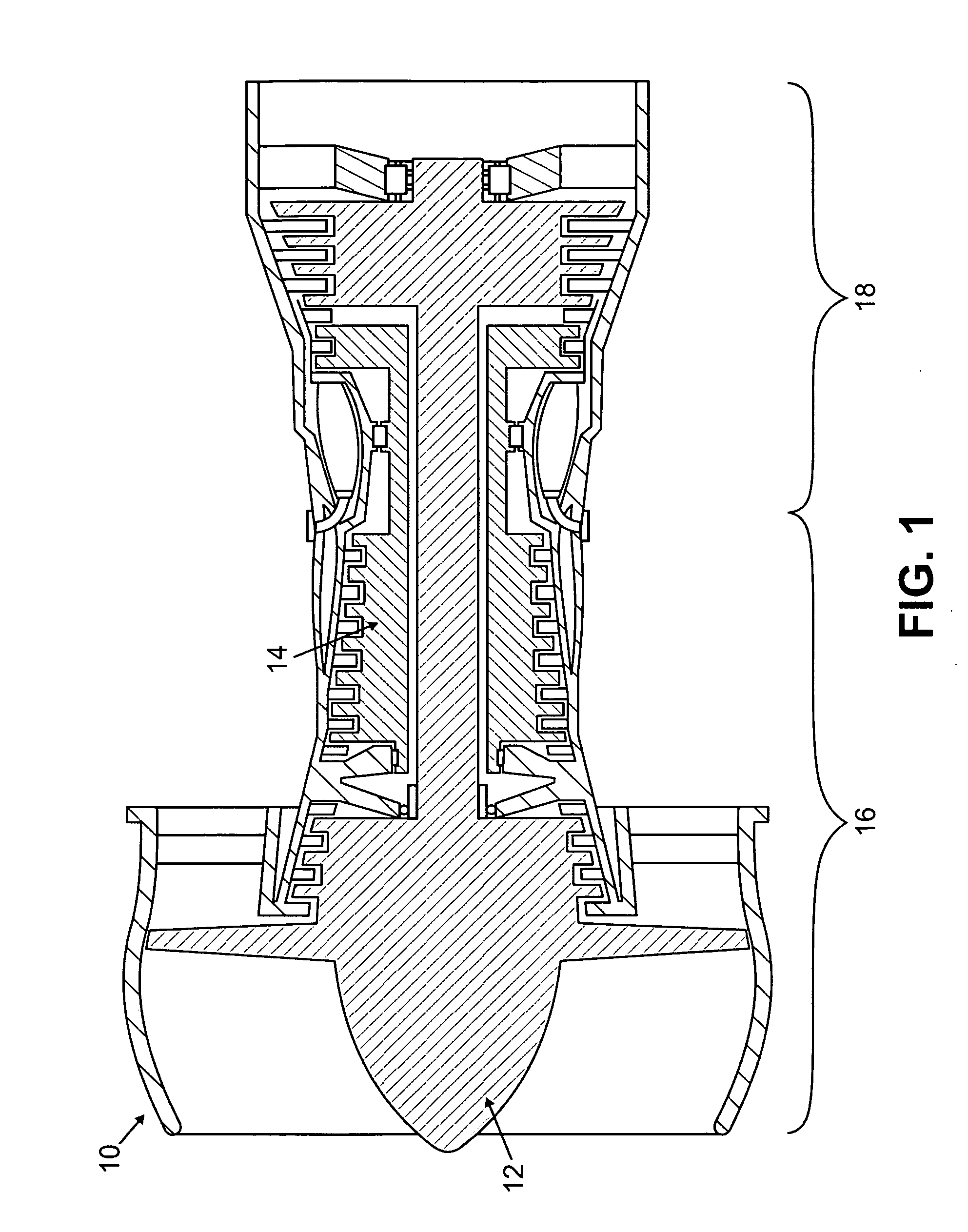

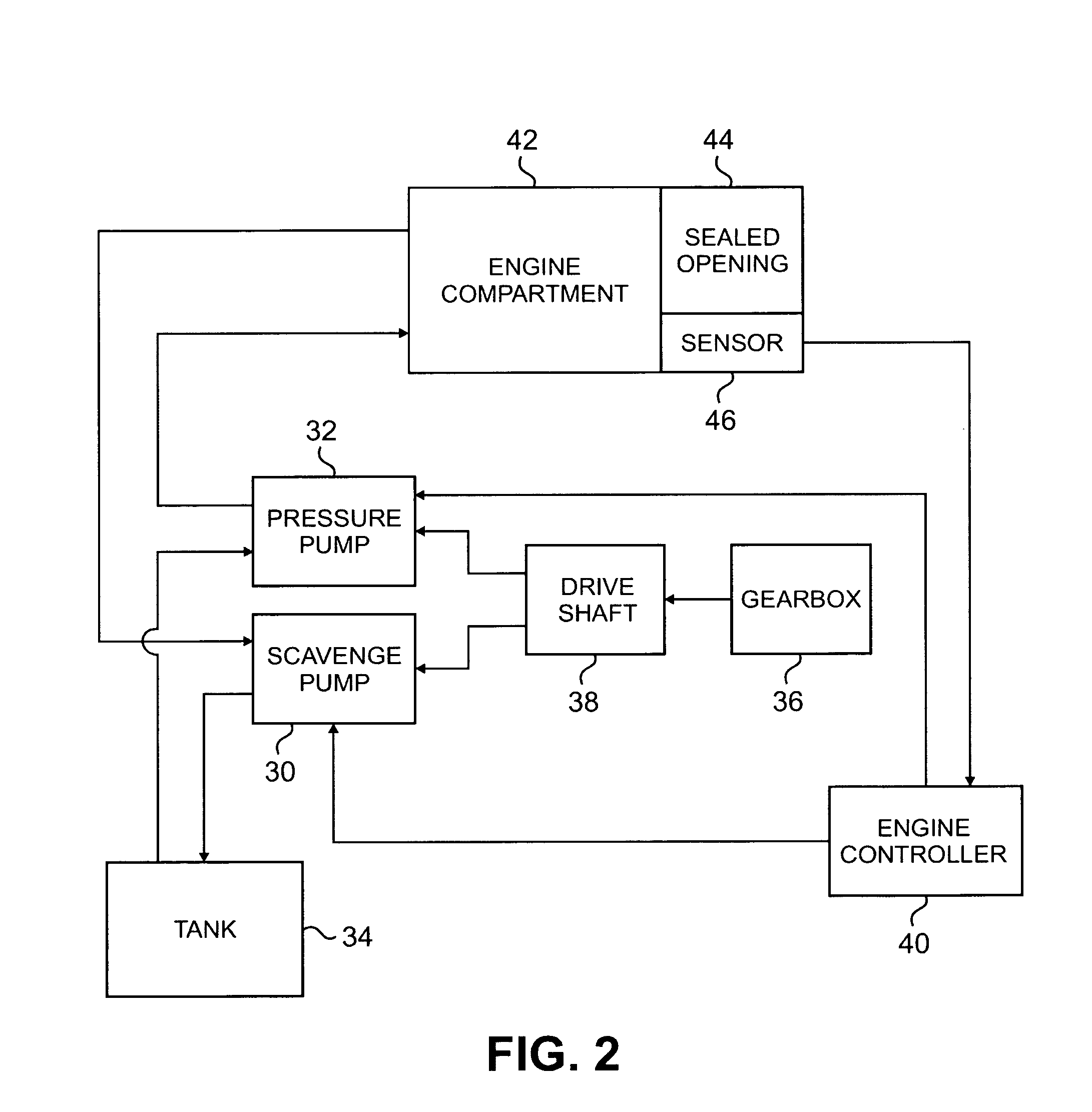

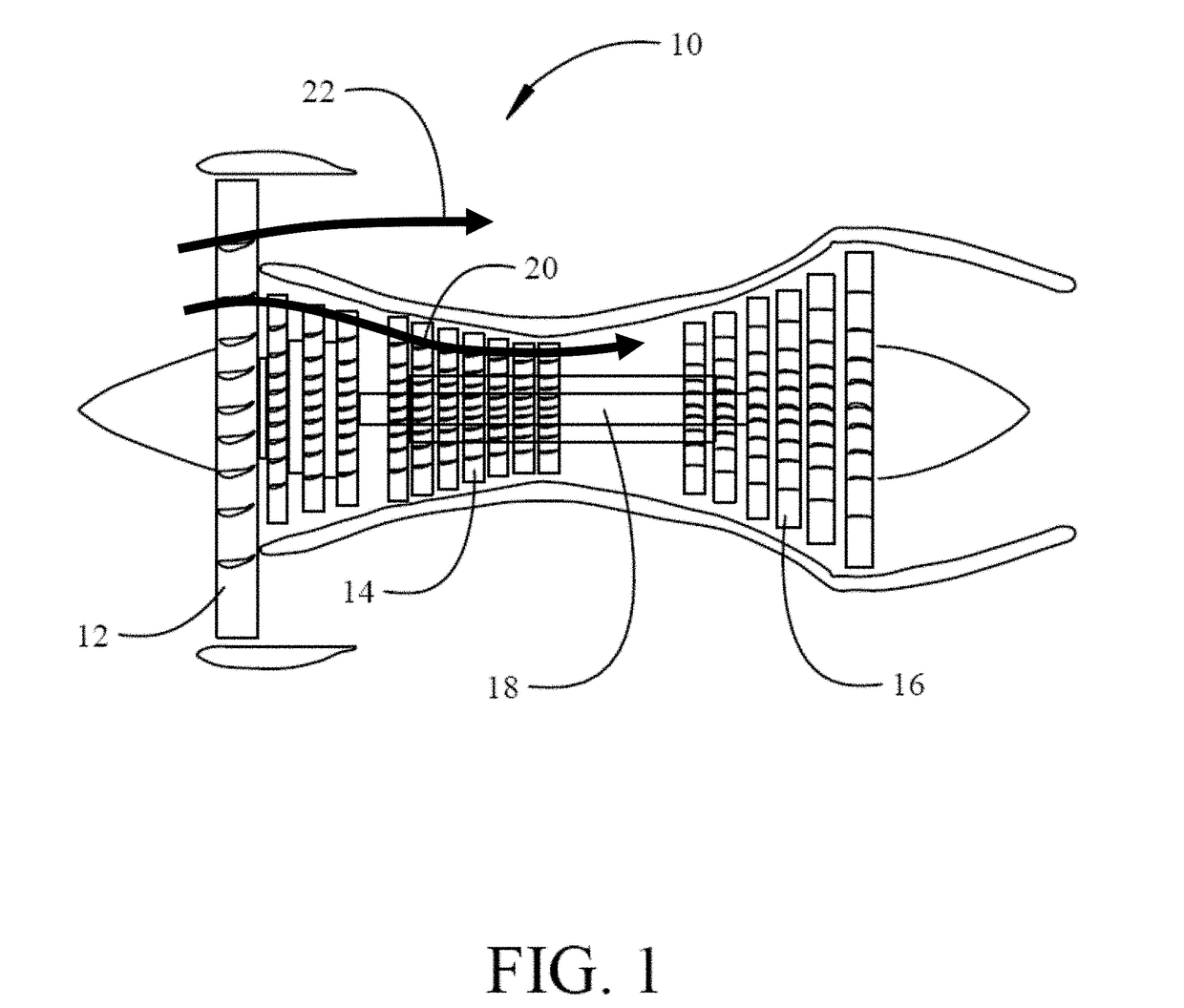

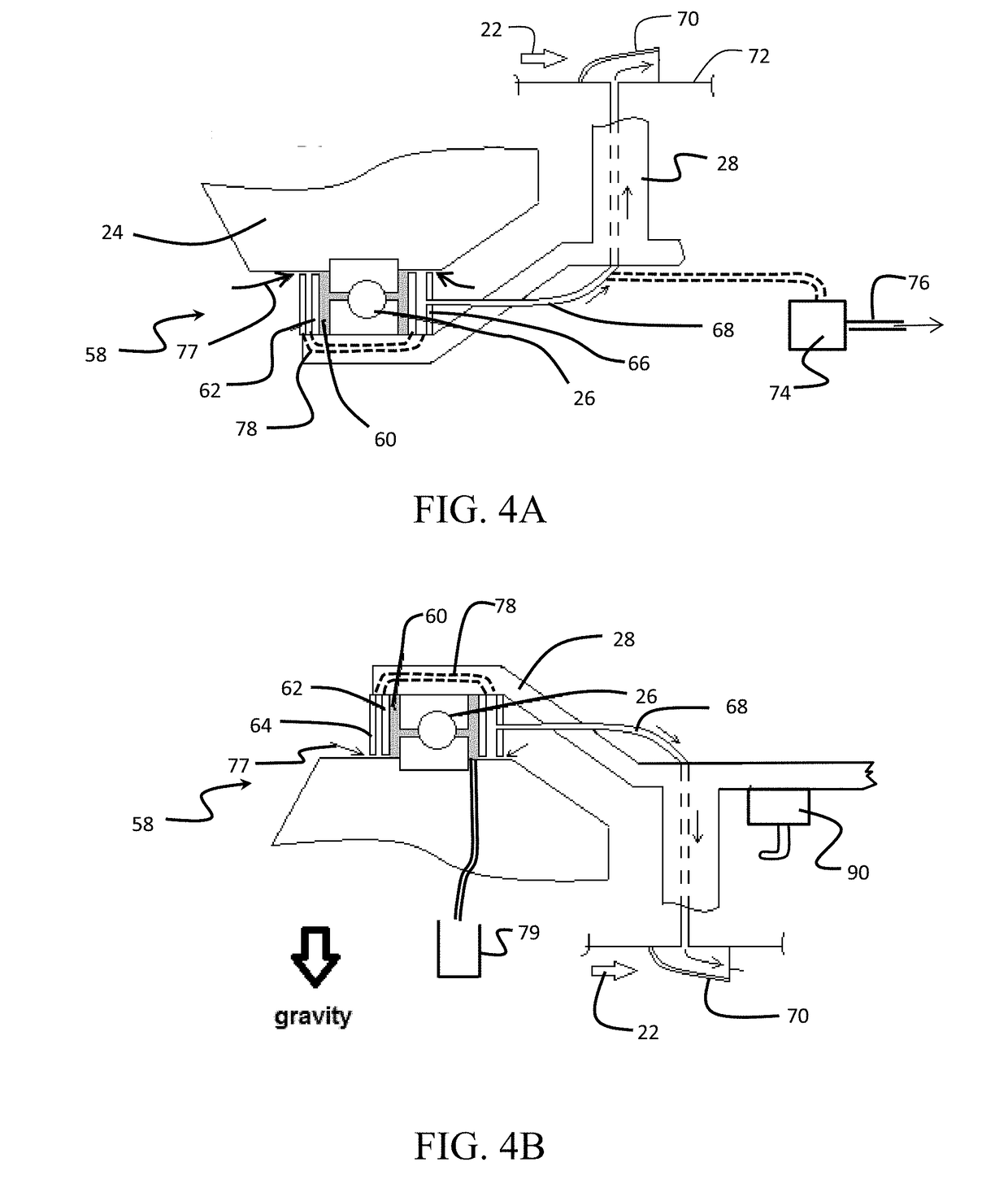

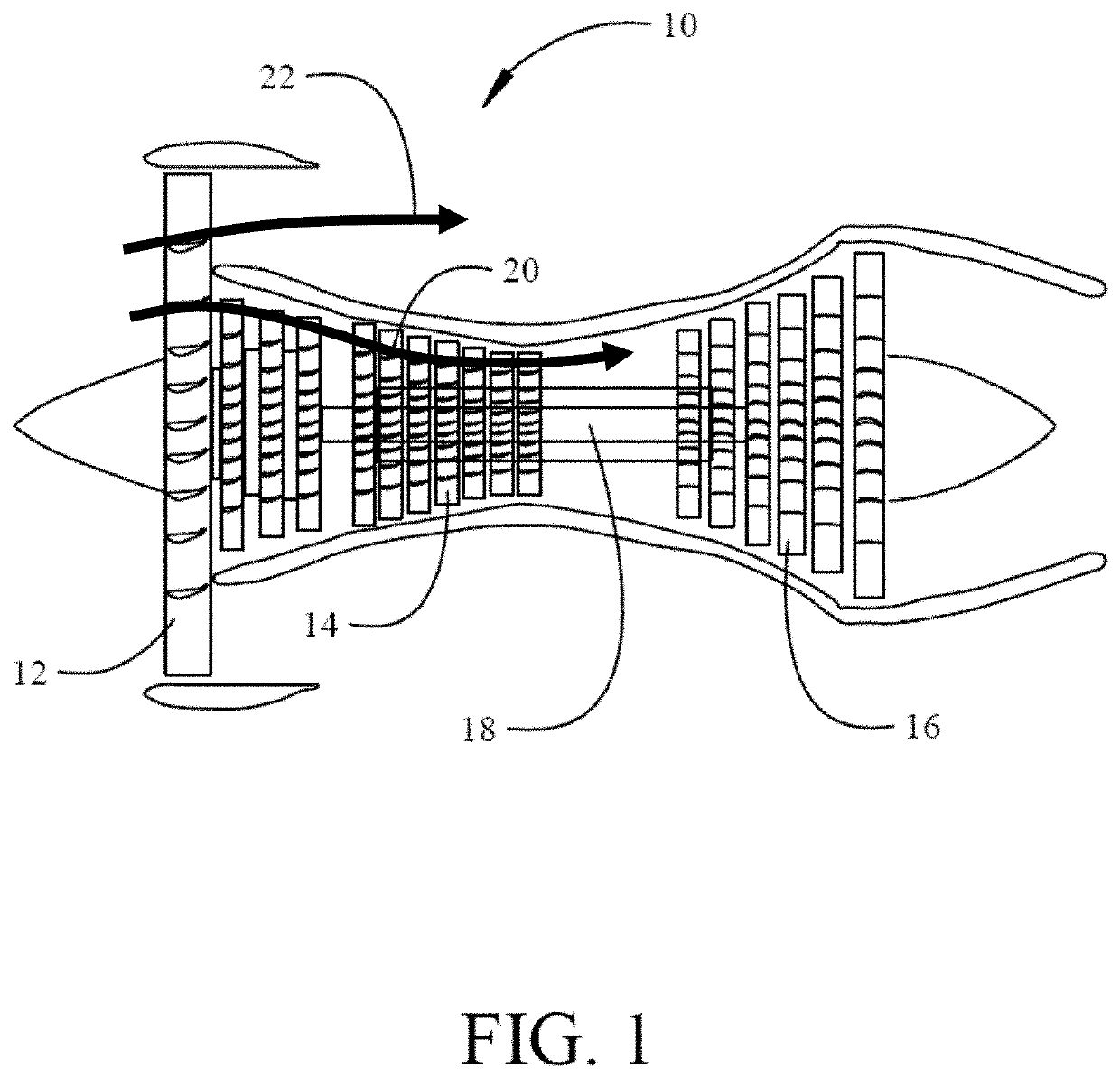

On-demand lubrication system and method for improved flow management and containment

ActiveUS20090152051A1Increase ratingsReduce oil leakageProportioning devicesEfficient propulsion technologiesFuel tankLubrication

A method of oil flow management for a gas turbine engine includes moving oil from a tank to a compartment using a pressure pump, moving oil from the compartment to the tank using a scavenge pump, and at least temporarily increasing a rate at which oil is moved with the scavenge pump by a greater amount than a rate at which oil is moved with the pressure pump to create at least a partial vacuum to negatively pressurize the compartment to reduce oil leakage.

Owner:RAYTHEON TECH CORP

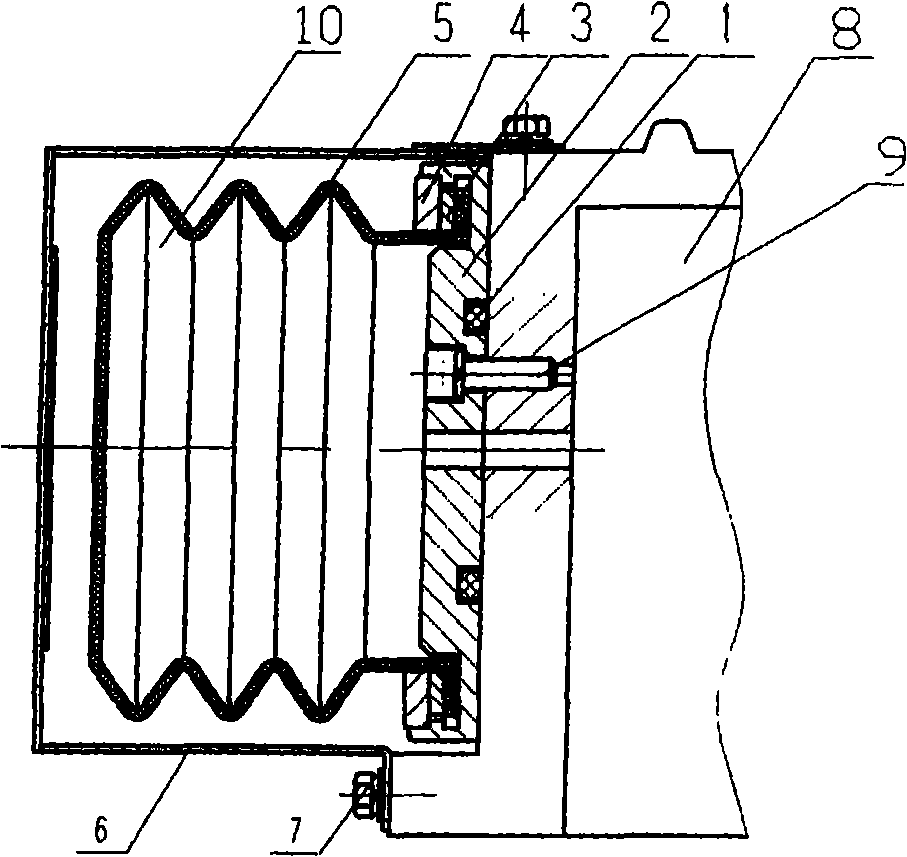

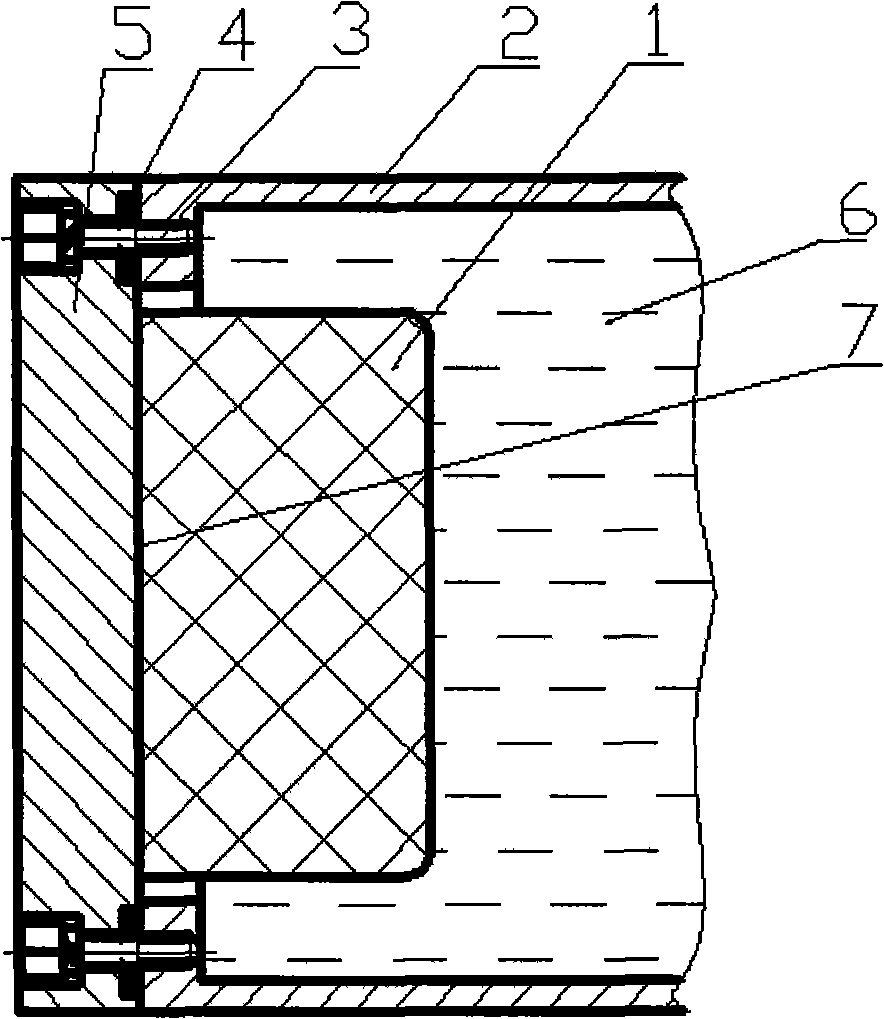

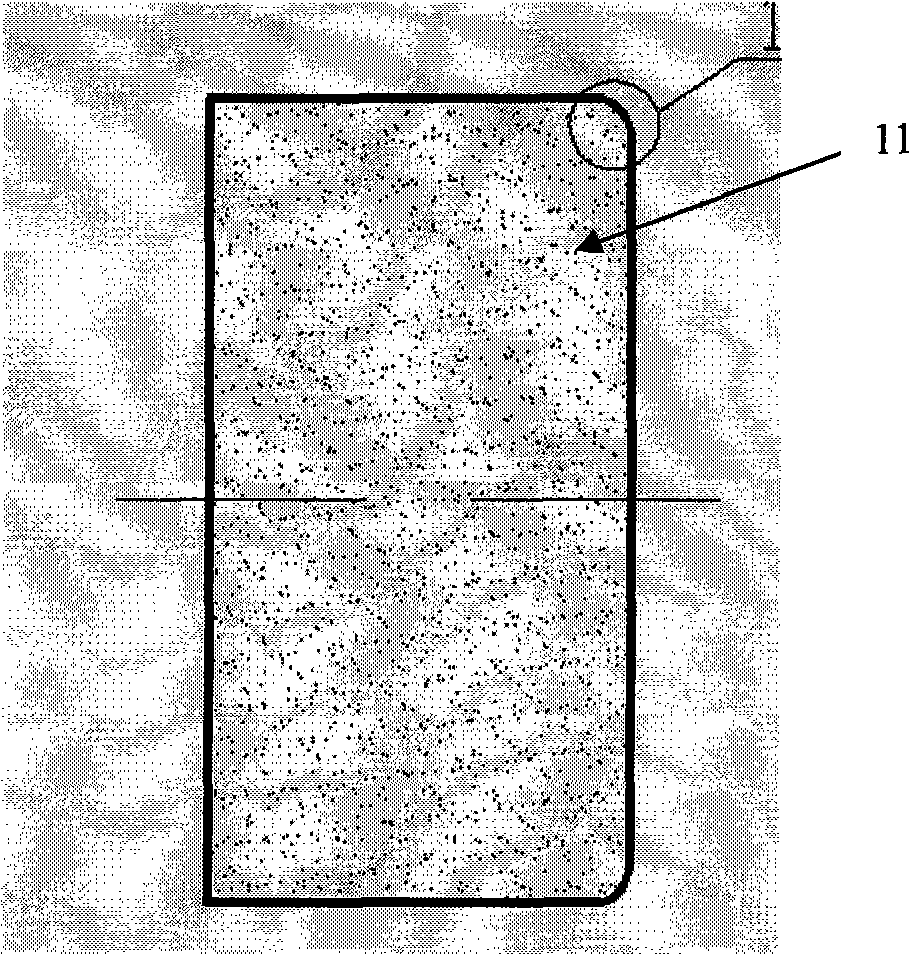

Solid state encapsulation device of X light tube for X fluorescent spectrometer

InactiveCN101286438AReduce oil leakageSimple structureMaterial analysis using wave/particle radiationX-ray tube vessels/containerEngineeringSpectrometer

The invention relates to an X-ray tube solid packaging device, comprising an X-ray tube body (2), an inner hexagon screw (3), a sealed rubber flange (4), an end face sealed flange plate (5), an insulating oil (6) and an assembly glue (7); wherein, the inner surface of the end face sealed flange plate is bonded with at least one vacuum hole pressure-reducing rubber (11); the assembly glue (7) is evenly painted at one end (1) without reversed angles of vacuum hole pressure-reducing rubber (1); the vacuum hole pressure-reducing rubber (11) is in the middle of the end face sealed flange plate (5) with sealed ring-shaped slot section; the vacuum hole pressure-reducing rubber (11) comprises a rubber base (111) and a plurality of vacuum cavity (112) therein. Compared with the expansion capsule in the prior art, the vacuum hole pressure-reducing rubber of the invention does not bear the effect of sealing, and effectively reduces the phenomenon caused by that the fatigue deformation, aging, crack and break, etc. of the expansion capsule.

Owner:JIANGSU SKYRAY INSTR

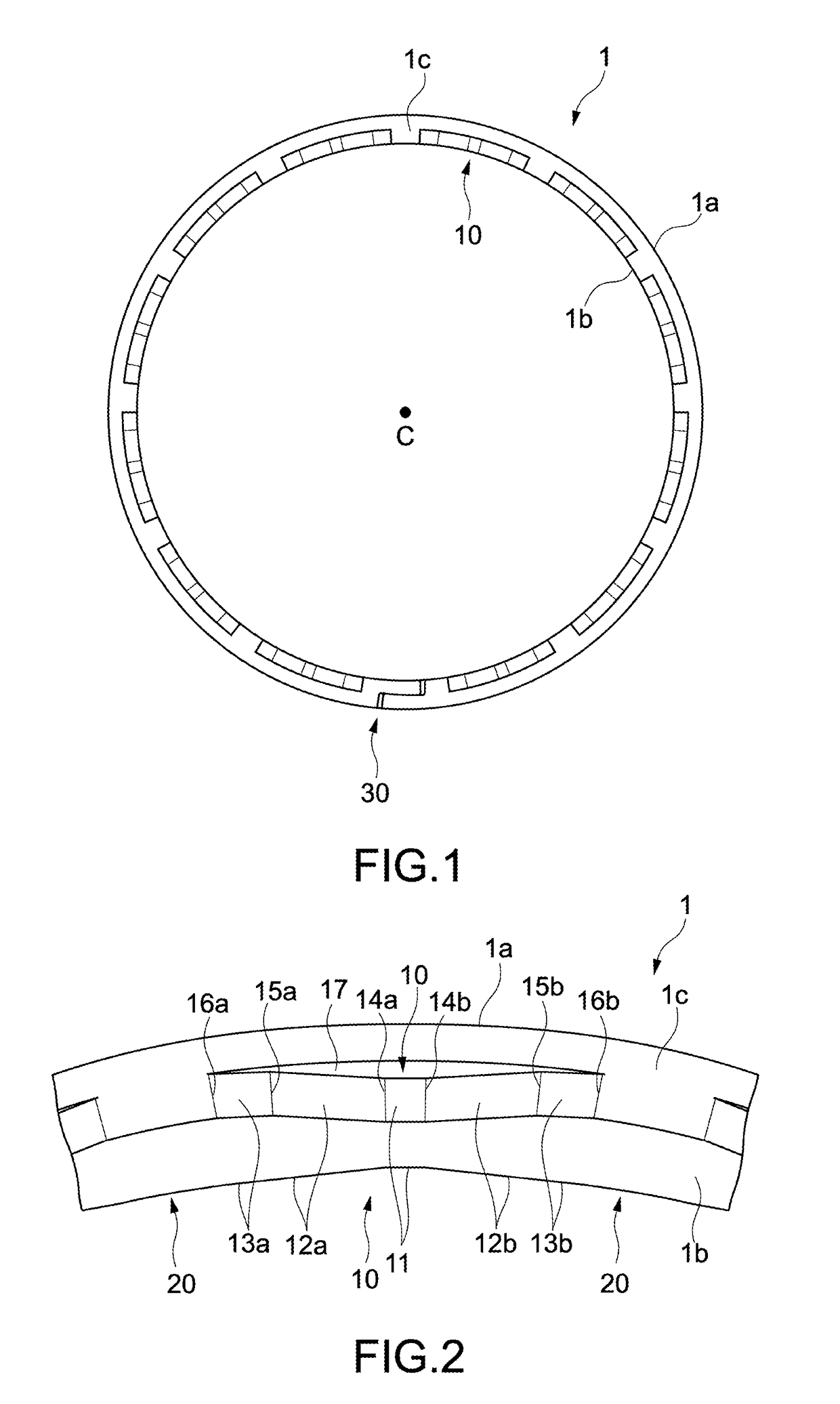

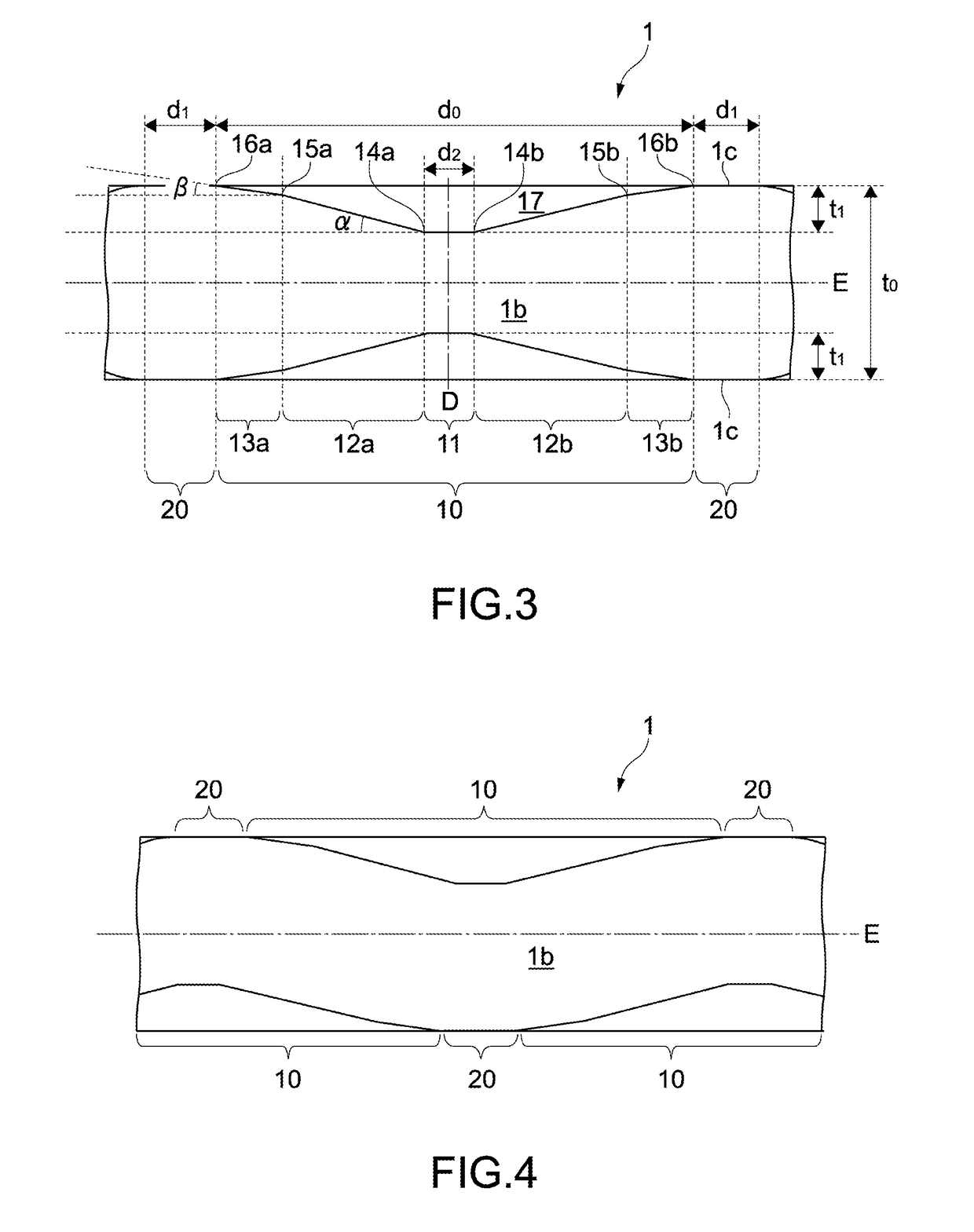

Seal Ring

Object: To provide a seal ring capable of both reducing a friction loss and reducing oil leakage.Solving Means: The seal ring includes an inner circumferential surface, an outer circumferential surface, side surfaces, a plurality of pockets, and recess regions. The outer circumferential surface is opposed to the inner circumferential surface. The side surfaces are orthogonal to the inner circumferential surface and the outer circumferential surface. The plurality of pockets are provided, spaced apart from one another in at least one of the side surfaces. The recess regions are provided in the at least one of the side surfaces and includes a plurality of independent recesses. In this seal ring, it is possible to both reduce the friction loss and reduce the oil leakage due to a function of buffering oil by the recess region.

Owner:RIKEN CO LTD

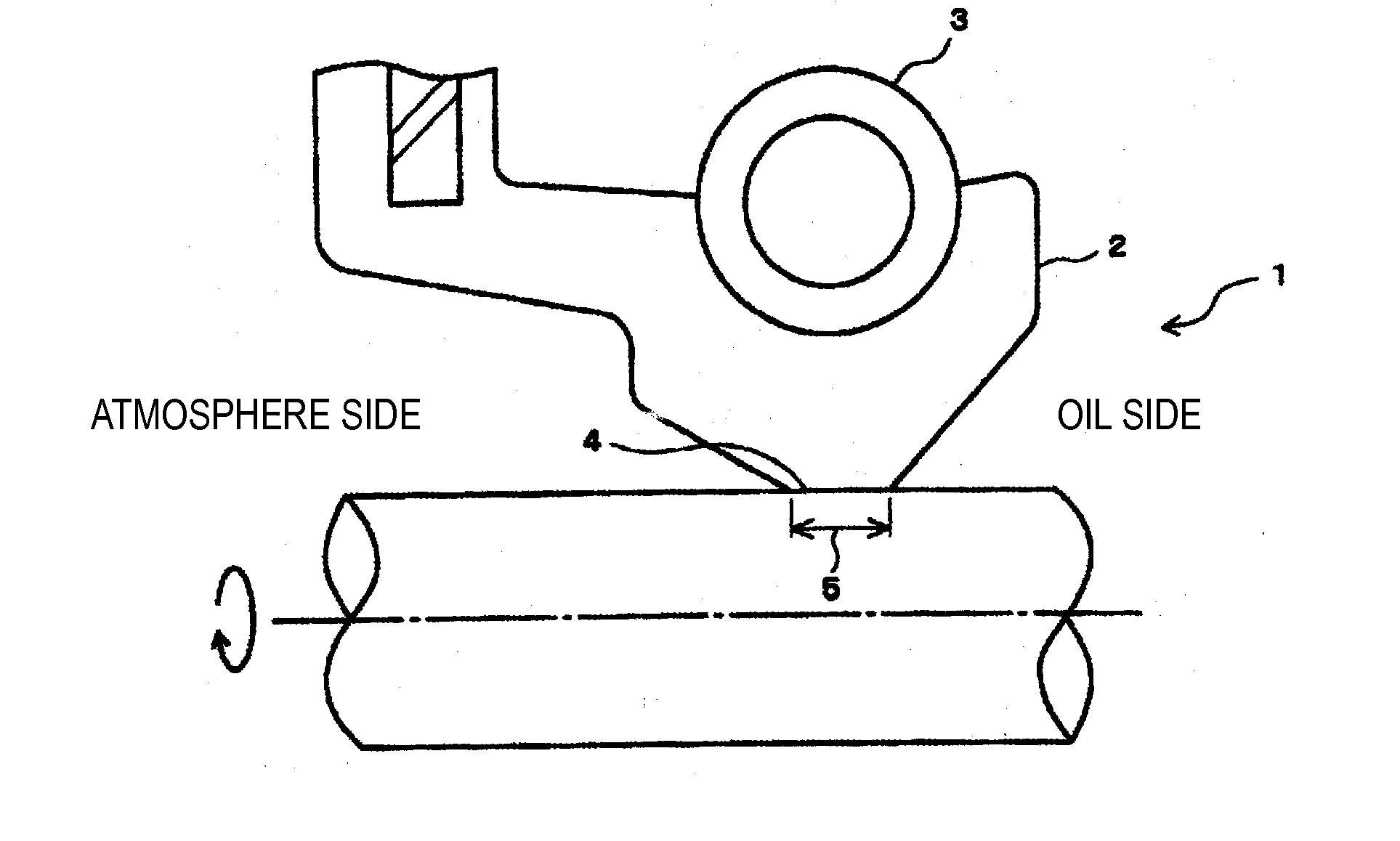

Crosslinked Fluororubber For Rotational Sliding Sealing And Method For Producing The Same

InactiveUS20100056694A1Reduce oil leakageImprove sealingOther chemical processesAlkaline-earth metal silicatesFriction reductionPolyol

Providing a crosslinked fluororubber for a rotational sliding sealing which can attain a reduction in torque (friction reduction) and is effective in diminishing oil leakage thereby improving initial properties concerning sealing properties (amount of oil pumping with sliding of sealing member) and which, even after friction and wear have occurred, can inhibit decrease of these properties and can improve conformability to eccentricity, and a method for producing the same.A crosslinked fluororubber for a rotational sliding sealing, wherein a fluororubber polymer composed of 95 to 50 wt % of a polyol-crosslinkable fluororubber polymer and 5 to 50 wt % of a liquid fluororubber polymer is obtained by crosslinking with polyol alone using a polyol crosslinking agent, and a method for producing the same.

Owner:NOK CORP

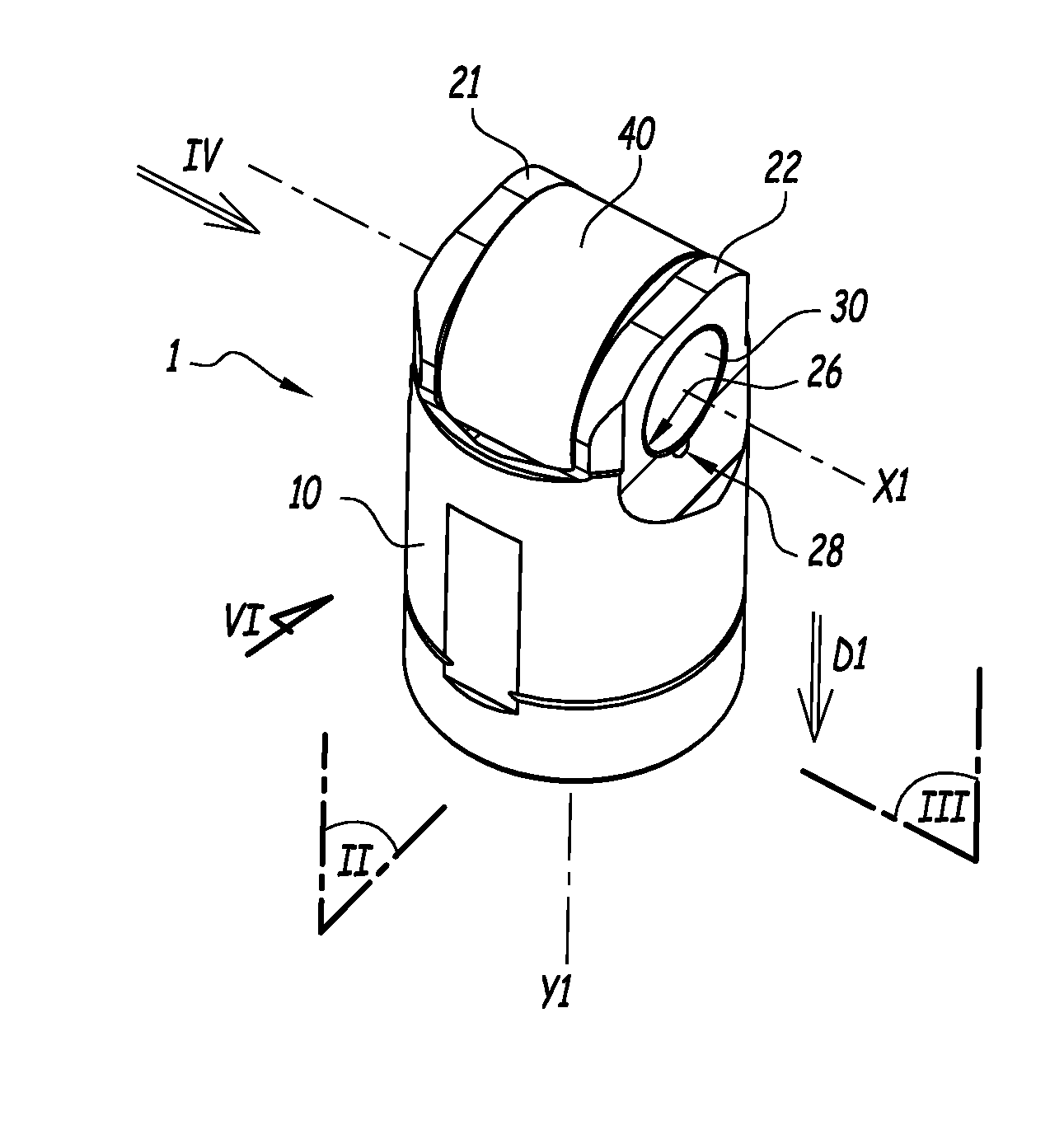

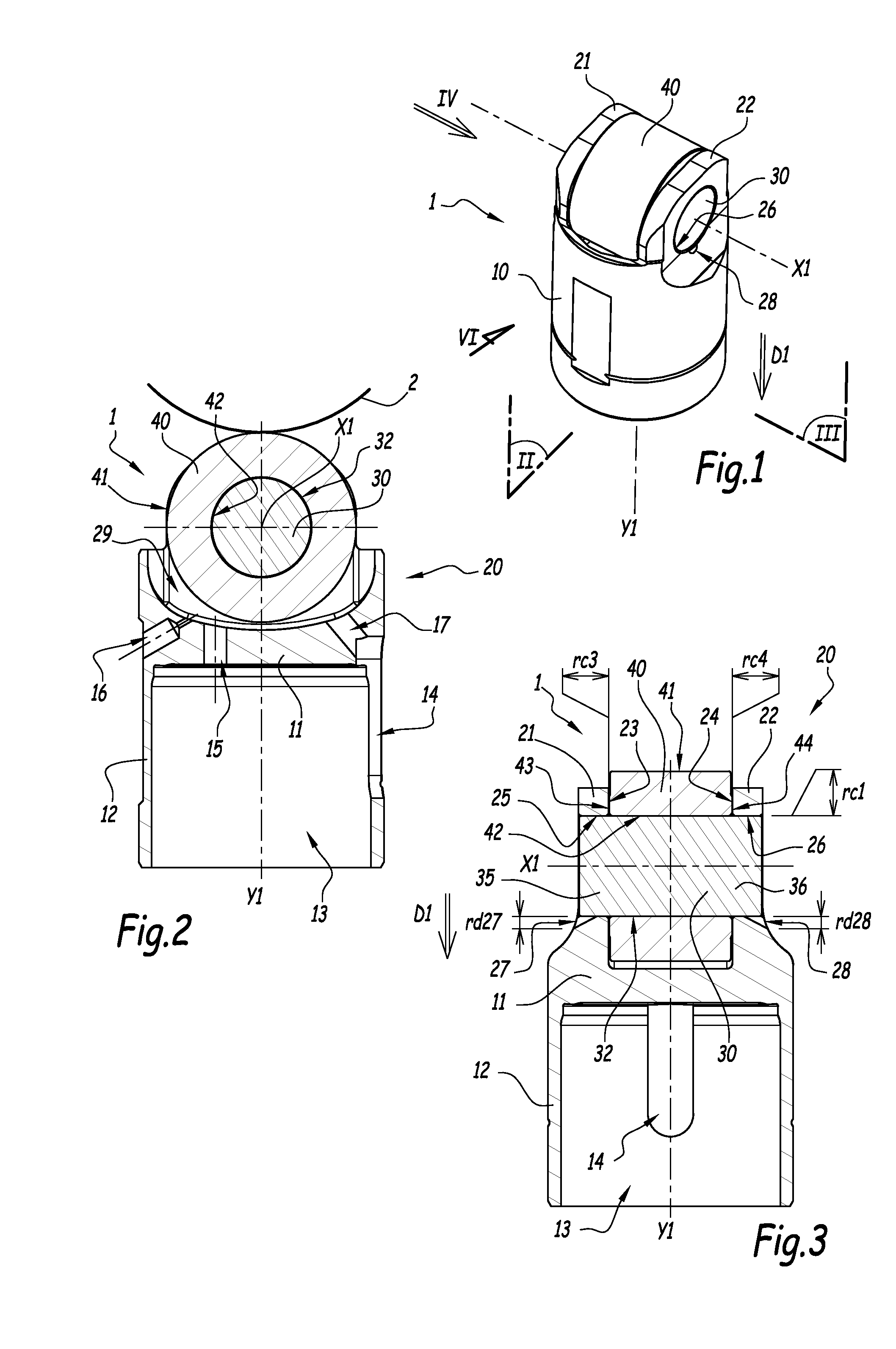

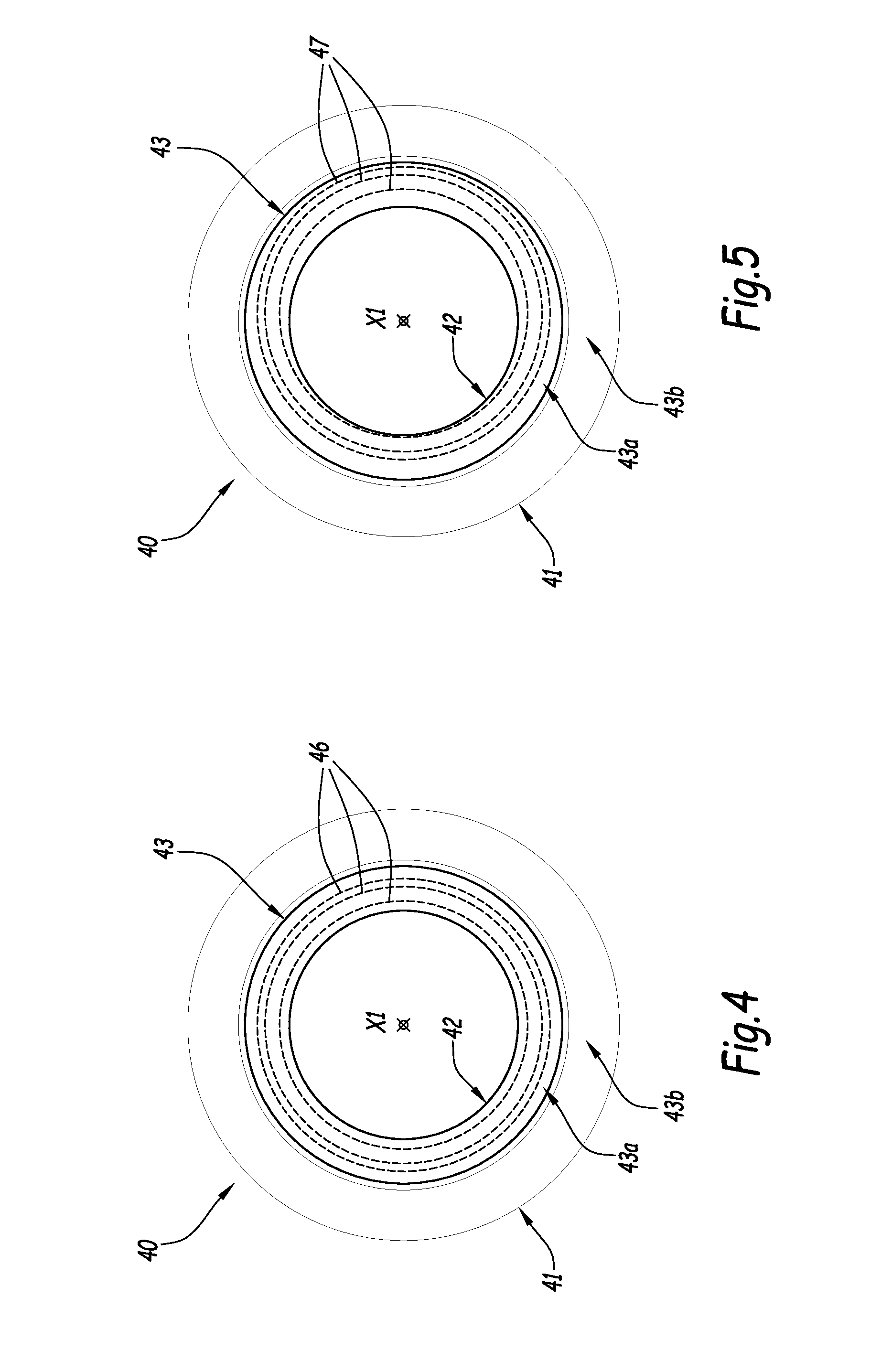

Method for manufacturing a roller, adapted to equip a mechanical system forming a cam follower or a rocker arm

ActiveUS20150330264A1Reduce frictionProlonging lifetime of mechanical systemControlling membersValve arrangementsEngineeringCam

A method for manufacturing a roller, adapted to equip a mechanical system forming a cam follower or a rocker arm. The roller is centered on a central axis and comprising: an outer cylindrical surface adapted to roll on a cam, an inner cylindrical bore adapted to receive a pin belonging to the mechanical system, and two lateral faces extending radially to the central axis. The method includes a machining step forming circular grooves that are concentric with each other on at least one of the lateral faces of the roller. The roller can be installed within a mechanical system.

Owner:AB SKF

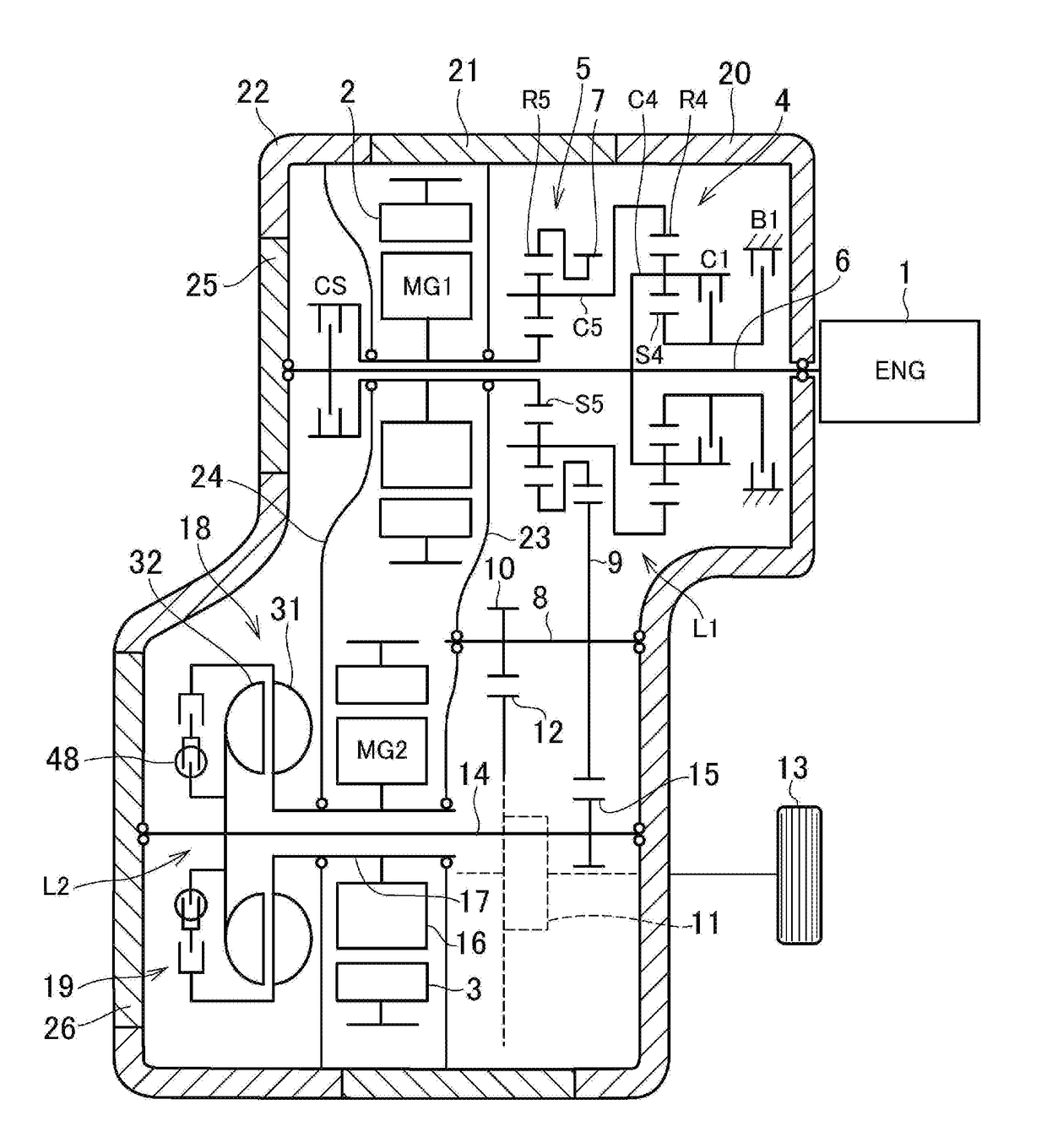

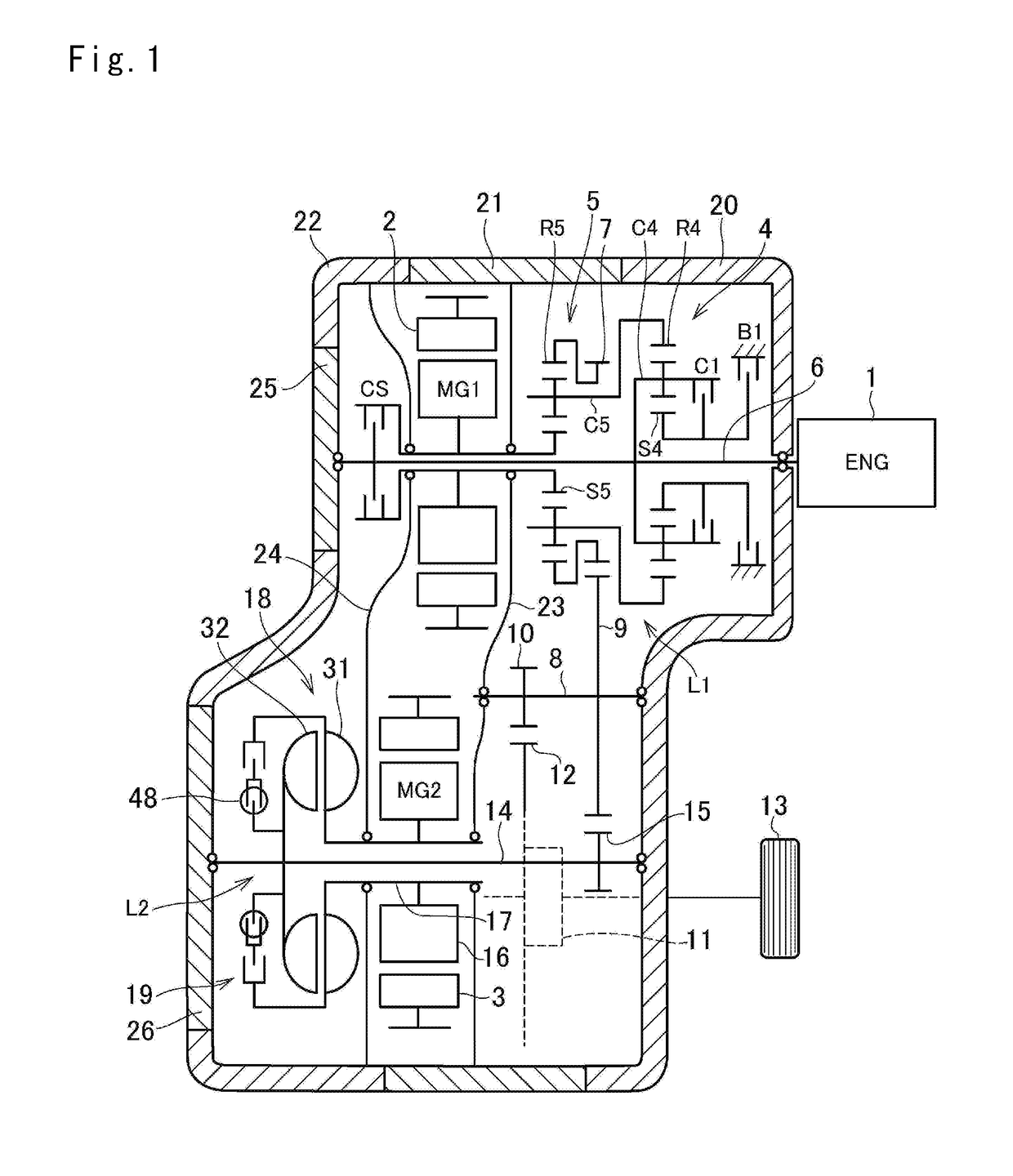

Drive unit for vehicles

ActiveUS20180208044A1Easily assembleReduce oil leakageHybrid vehiclesElectric devicesClutchSingle phase

A vehicle drive unit to prevent a single phase lock of a motor as a prime mover to limit damage is provided. The drive unit includes: a first transmission route to deliver drive force of an engine to drive wheels; and a second transmission route to deliver drive force of a motor to the drive wheels. The second transmission route comprises an intermediate shaft that transmits the drive force of the motor to the first transmission route. A fluid coupling is disposed between the motor and the intermediate shaft. A lockup clutch is arranged parallel to the fluid coupling between the motor and the intermediate shaft.

Owner:TOYOTA JIDOSHA KK

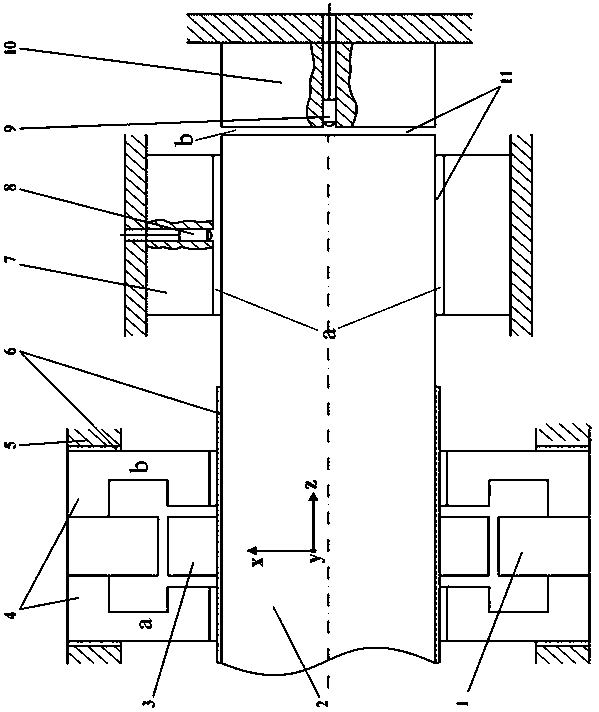

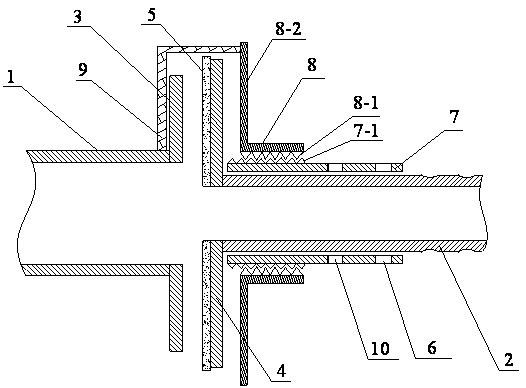

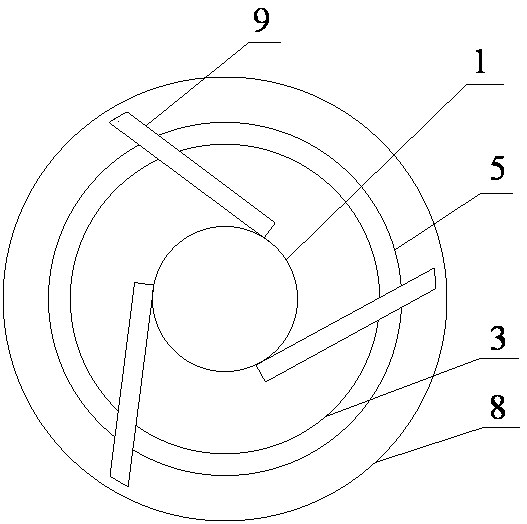

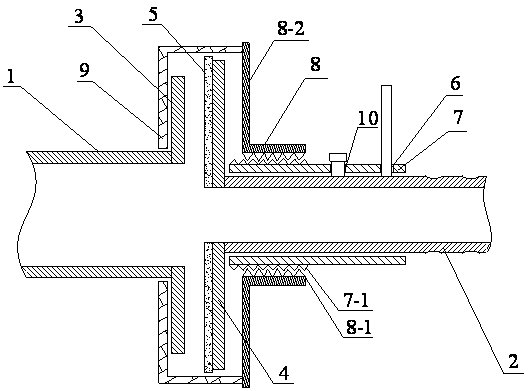

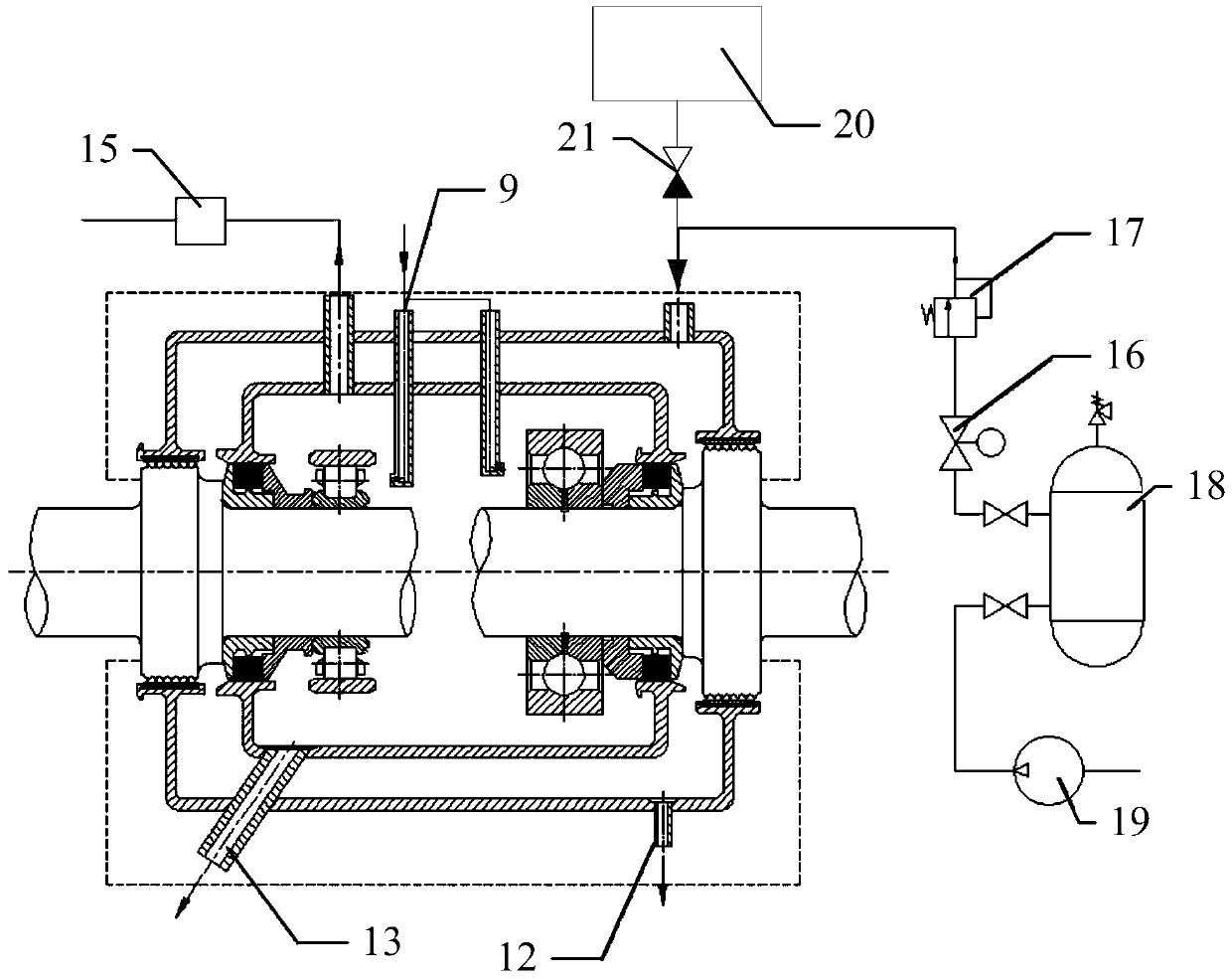

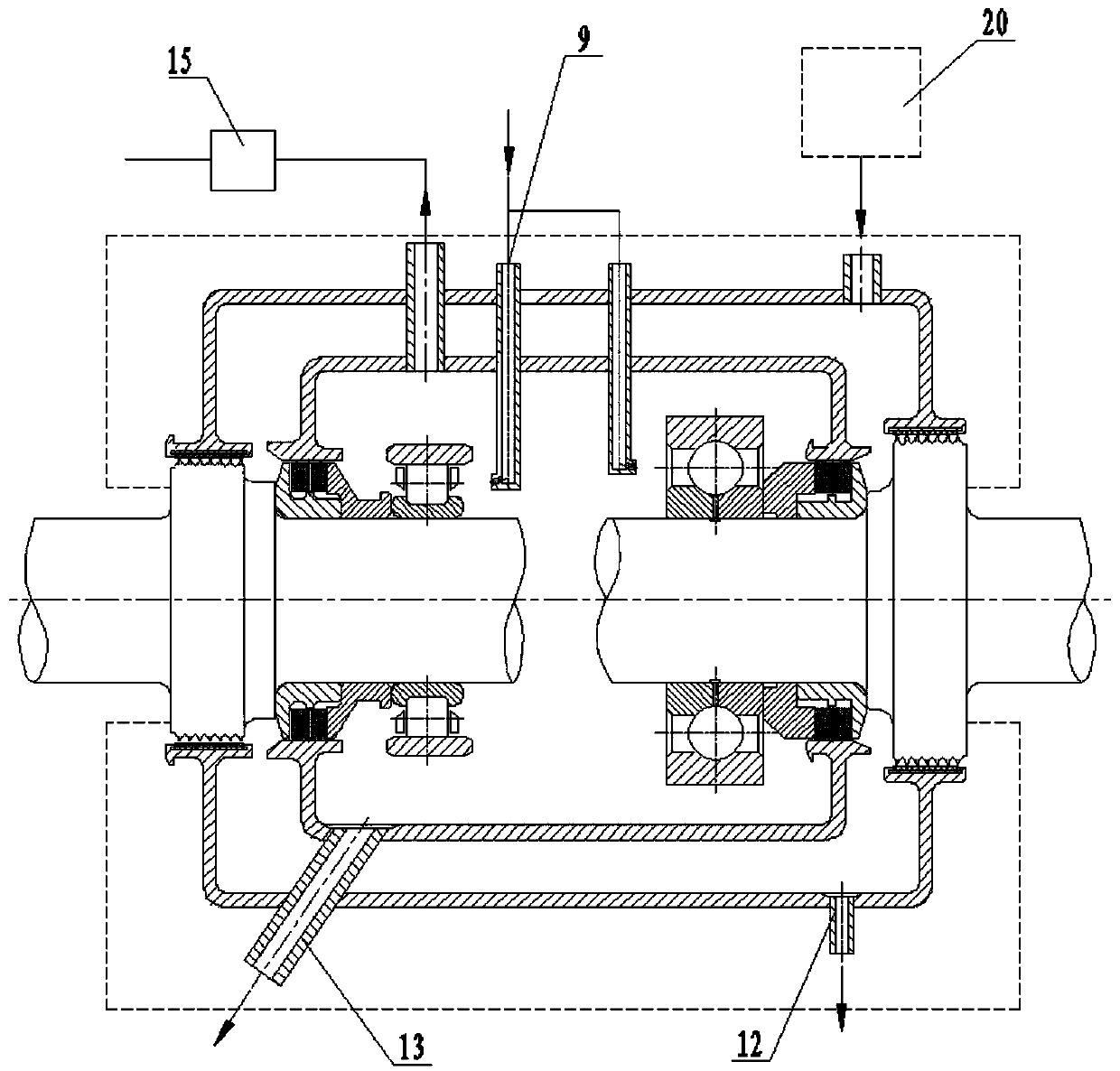

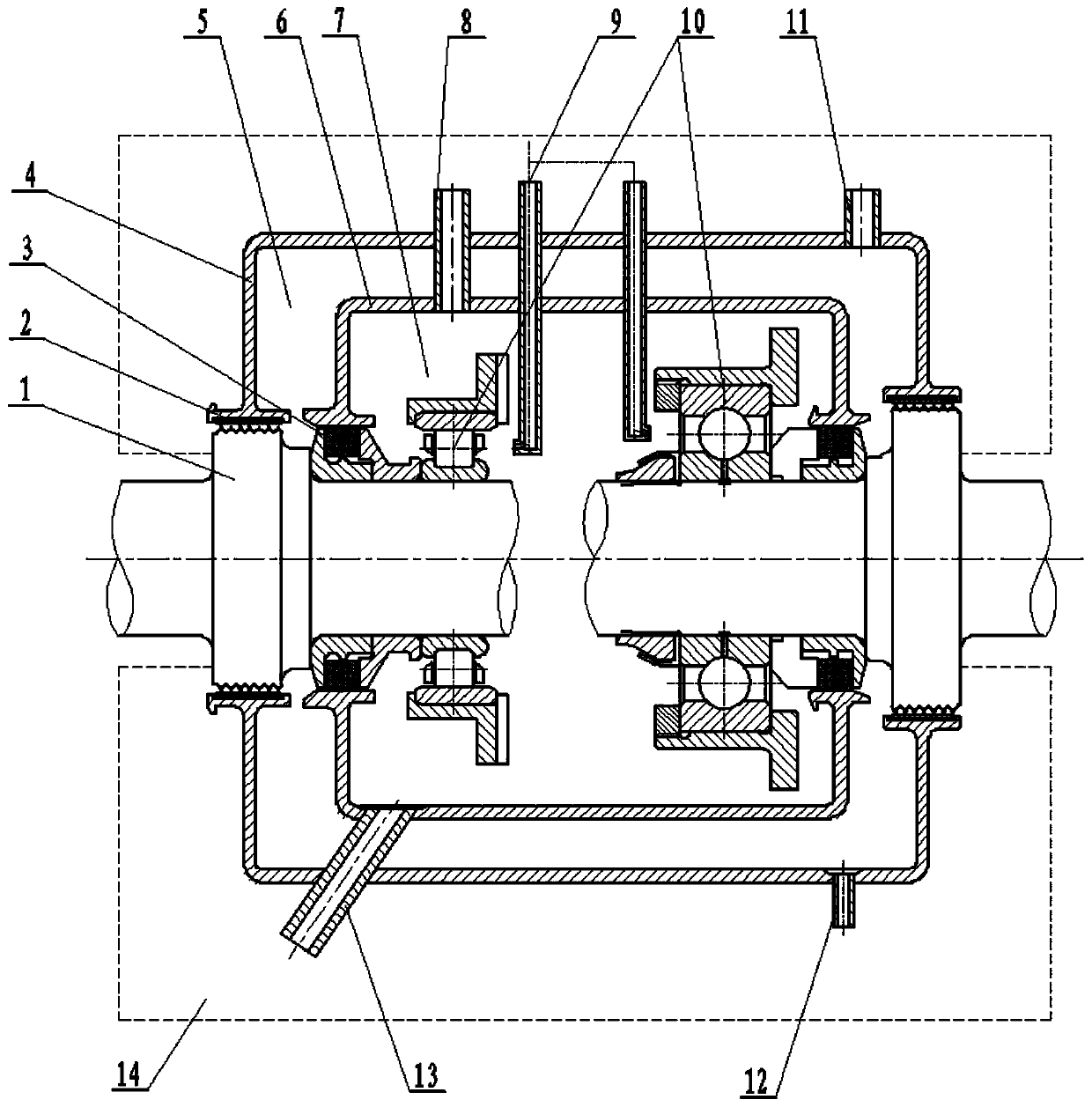

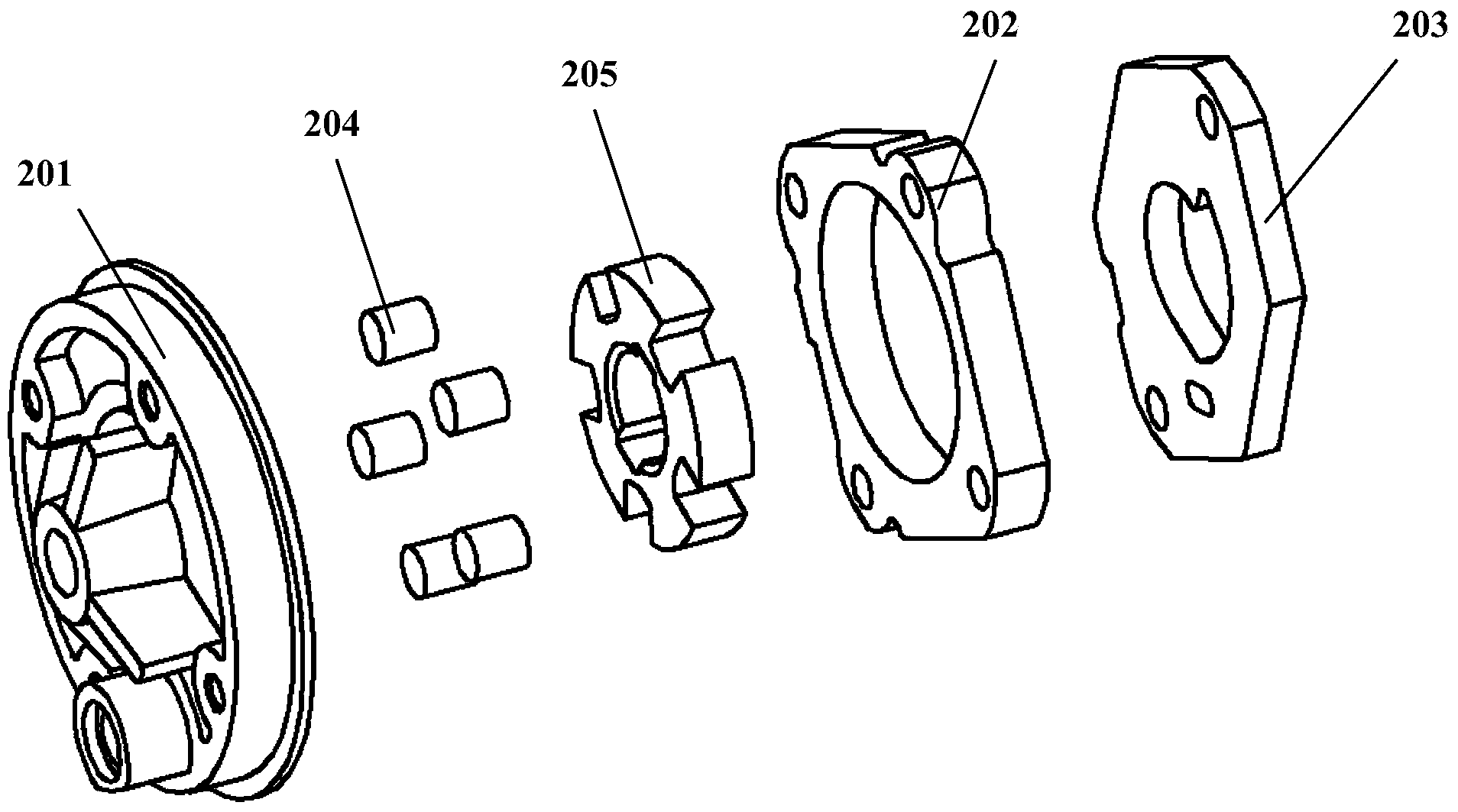

Fluid magnetic vector support applied to hydraulic element

The invention provides a fluid magnetic vector support applied to a hydraulic element, and belongs to the field of friction pair coupling parts in hydraulic elements. According to the fluid magnetic vector support applied to the hydraulic element, closed-loop control is further carried out over the thickness of a high-pressure fluid film by adjusting the magnetic force of axial magnetic force units and a radial magnetic force unit, a friction pair can be prevented from being worn, meanwhile, oil leaking is reduced to the greatest degree, the efficiency of the hydraulic element is improved, andthe service life of the hydraulic element is prolonged. An iron core is mounted on the side face of a friction pair motion coupling part, the radial magnetic force unit is arranged at the position right facing the iron core, the axial magnetic force units are symmetrically arranged on the two sides of the radial magnetic force unit, and a magnetic force unit set is formed jointly. A radial displacement sensor and an axial displacement sensor are mounted on a radial friction pair static coupling part and an axial friction pair static coupling part correspondingly and are used for monitoring the thickness of the high-pressure fluid film, the change information of the high-pressure fluid film is fed back to the radial magnetic force unit and the axial magnetic force units, a magnetic field generated by the high-pressure fluid film is weakened or reinforced, and the thickness of the high-pressure fluid film is kept within the ideal range.

Owner:HARBIN INST OF TECH

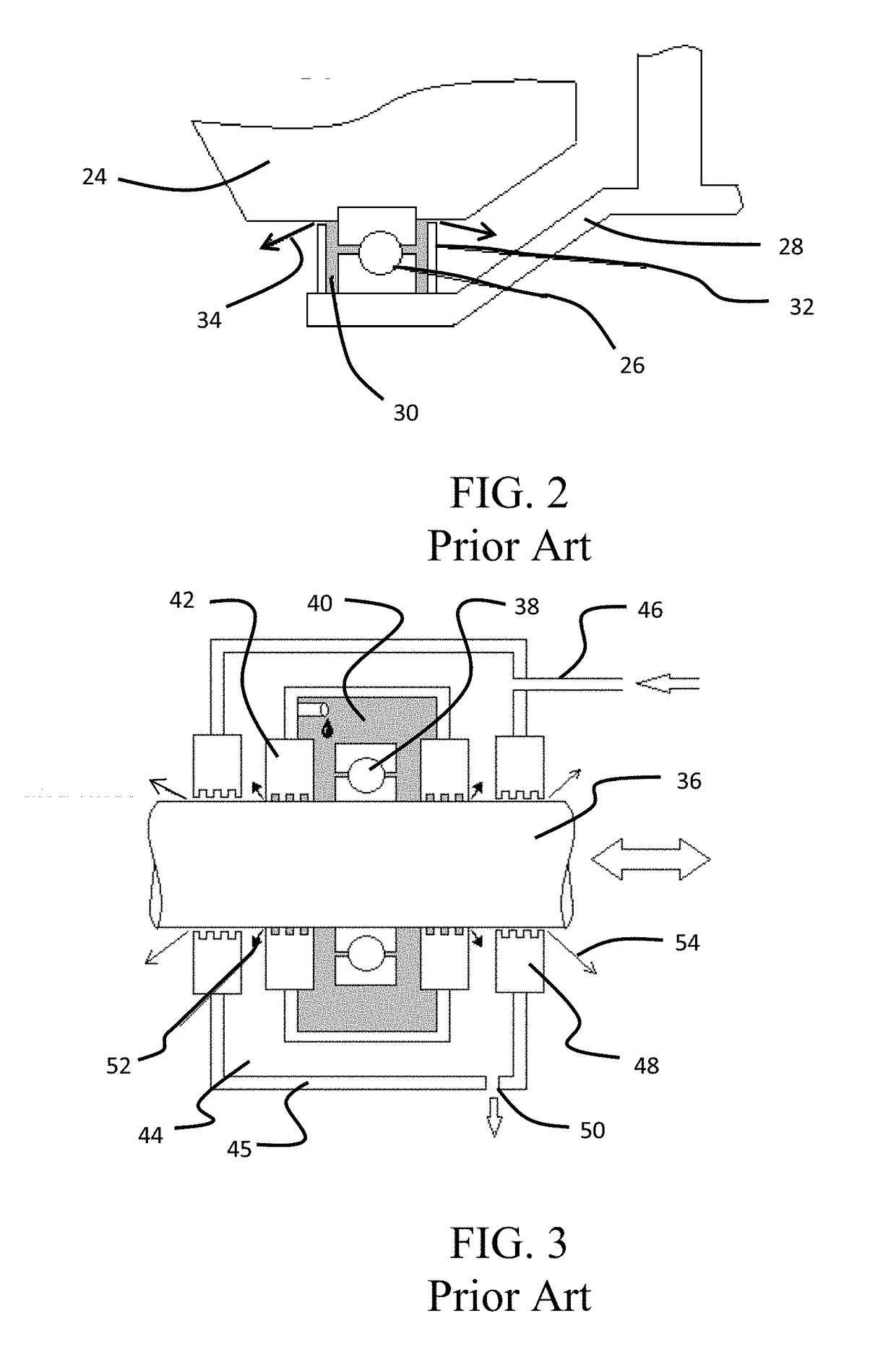

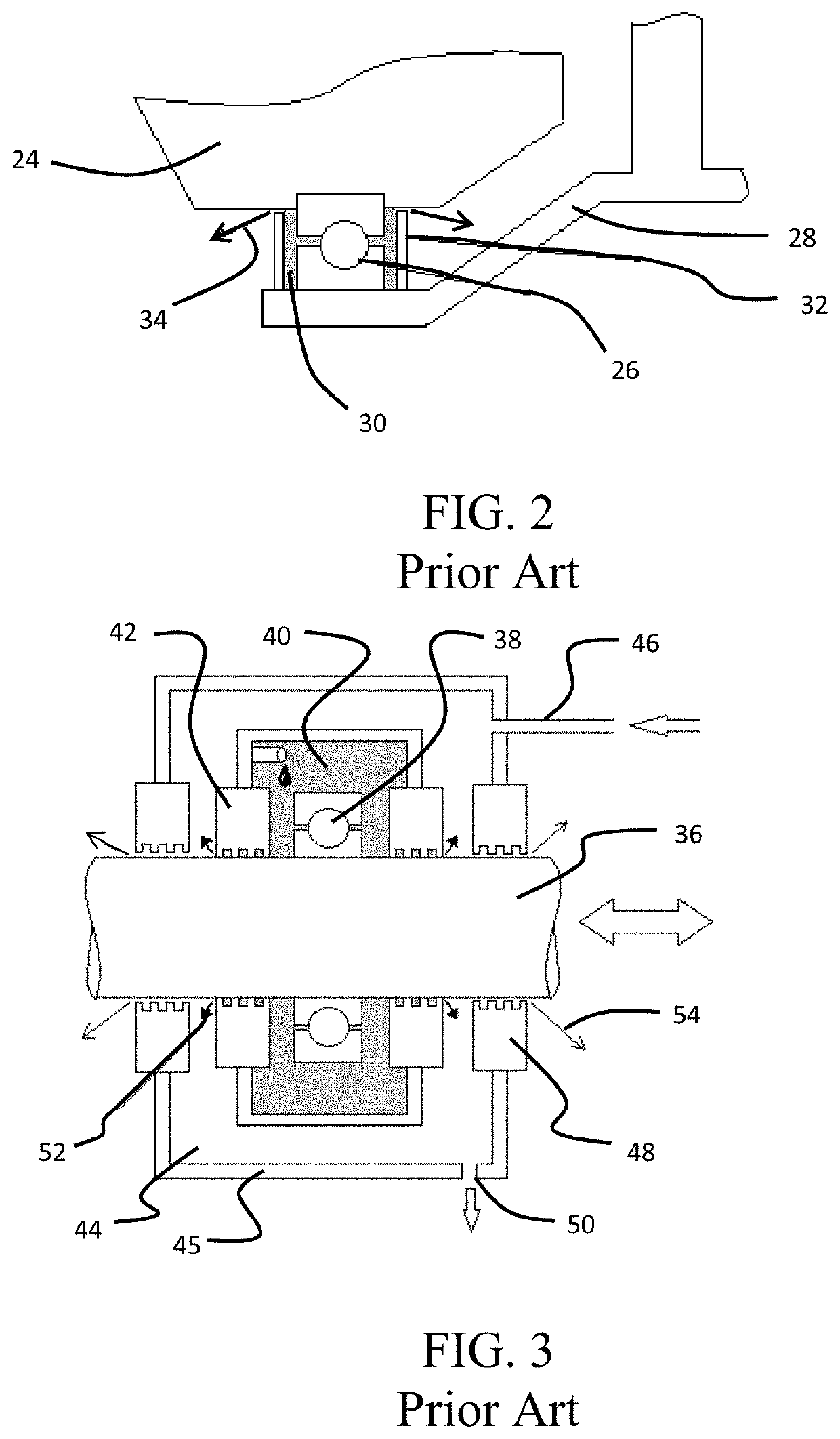

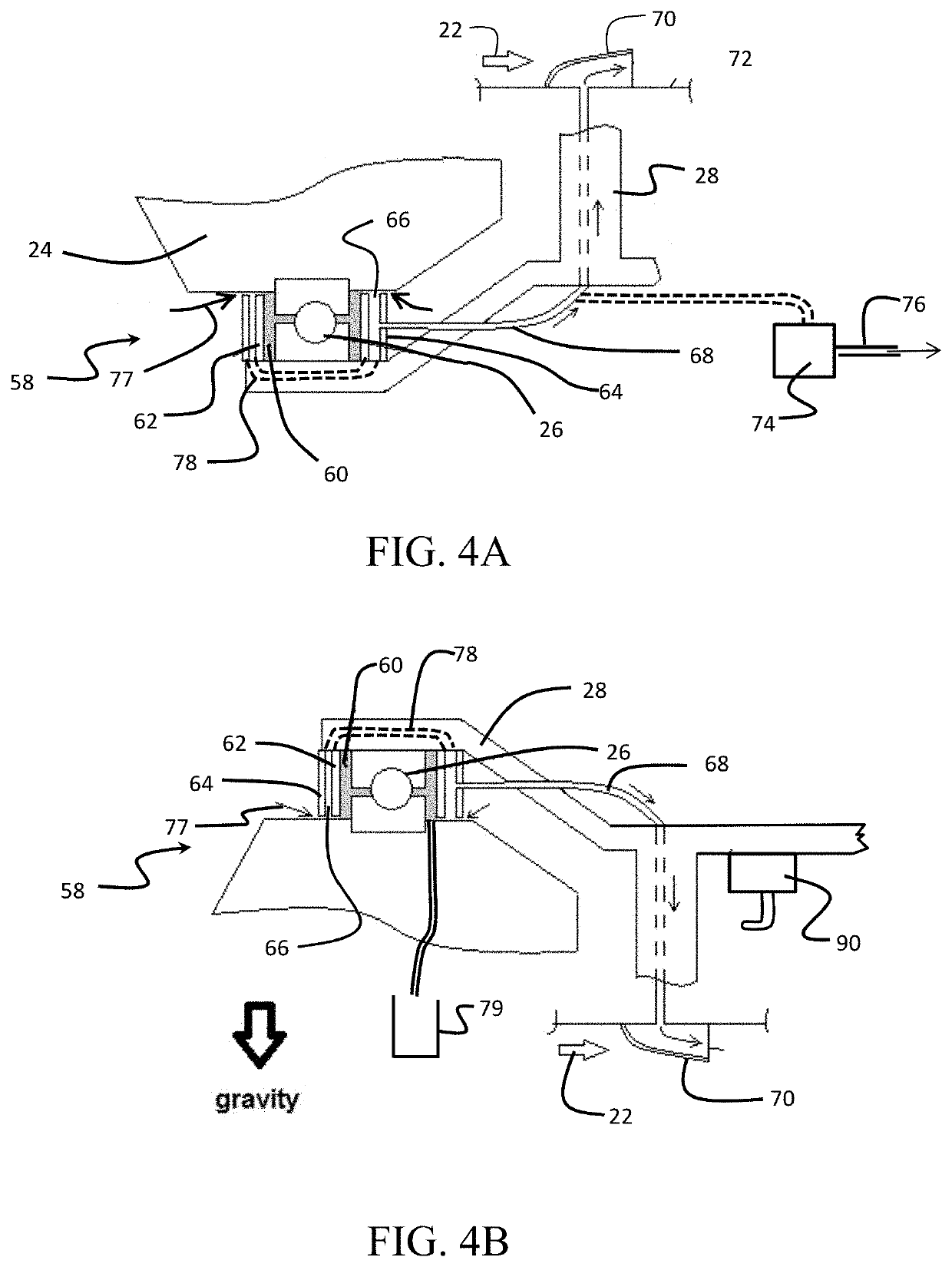

Seal assembly and method for reducing aircraft engine oil leakage

A seal assembly for a gas turbine engine employs a first seal forming an oil chamber around a bearing. The first seal is configured to maintain the oil chamber at a first pressure. A second seal forms a ventilating cavity around the oil chamber. The second seal is configured to maintain the ventilating cavity at a second pressure, the second pressure being less than the first pressure and less than an ambient pressure of a primary flow path in the engine. A pressure reducing device is coupled to the ventilating cavity. The pressure reducing device is configured to maintain the second pressure.

Owner:THE BOEING CO

Flange plate rapid-connecting device and operation method thereof

ActiveCN105371031APrevent oil leakageAvoid vibrationFlanged jointsTransformer oilUltimate tensile strength

The invention provides a flange plate rapid-connecting device and an operation method thereof and belongs to the technical field of flange plate sealing and connecting of oil feeding and draining valves of transformers. The flange plate rapid-connecting device comprises a transformer oil feeding and draining pipe, an oil pipe self-sealing connector, a transformer oil feeding and draining valve flange, an oil pipe connector flange, a sealing gasket, an adjusting steel pipe, a chuck and buckles. The adjusting steel pipe is arranged coaxially outside the oil pipe self-sealing connector. A plurality of assistant member connecting holes and a plurality of threaded holes are formed in the adjusting steel pipe. The adjusting steel pipe is provided with an external threaded face. The chuck is provided with an internal threaded face which is matched and connected with the external threaded face, and a vertical face perpendicular to the internal threaded face. The multiple buckles are connected to the end of the vertical face through hinges. The flange plate rapid connecting device is safe, reliable, suitable for oil feeding and draining operations of oil outlets with all sizes of the transformers, rapid, convenient and capable of greatly shortening sealing and connecting time of flange plates of the transformers, relieving the work intensity of maintainers and improving the working efficiency, and the maintenance frequency is greatly reduced at the same time.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

More Durable Bearing & Oil Seal Design For The GM 700R4 Family of Automatic Transmissions

InactiveUS20110211785A1Keep the forceLess movementBearing assemblyShaft assemblyAutomatic transmissionEngineering

The present invention relates to automatic transmissions. In particular, the present invention relates to the GM 700r4 automatic transmission. More particularly, the invention relates to a novel bearing / oil seal designed to replace the OEM input to output oil seal in the GM 700r4 transmission which is known to have oil seal failure history. The OEM input and output shafts of transmissions produce substantial movement relative to each other. Excessive movement between the shafts causes rapid oil seal wear, oil loss, and transmission failures. The new bearing / oil seal design of the present invention serves to couple the shafts together, and provide a vertical sealing face for a more durable seal. The benefits from the new bearing / oil seal are less movement throughout the drive train, longer oil seal life, less binding of the ¾ clutch pack, longer transmission shelf life, and increasing overall durability.

Owner:DEANS LUTHER PRESTON

External-control type fan clutch device

ActiveUS20150219168A1Reduce oil leakageReduce the amount requiredFluid couplingsCoolant flow controlStop timeEngineering

Provided is an external-control type fan clutch device that can suppress unnecessary rotation of a cooling fan at the time of activating a rotary shaft effectively regardless of stop positions of an oil supply port and an oil recover port at a stop time of the fan. The fan clutch device includes a valve member for opening / closing an oil circulating flow passage hole provided on a side wall face of the annular oil reserving chamber, wherein opening / closing of the oil circulating flow passage hole is controlled by the valve member, wherein an oil supply chamber, that is formed of a partition wall composed of an arc-like wall and a plate-like partition wall for shielding one end of the arc-like partition wall, is provided in the annular oil reserving chamber, and the oil circulating flow passage hole and an oil recovery port are arranged in the oil supply chamber.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

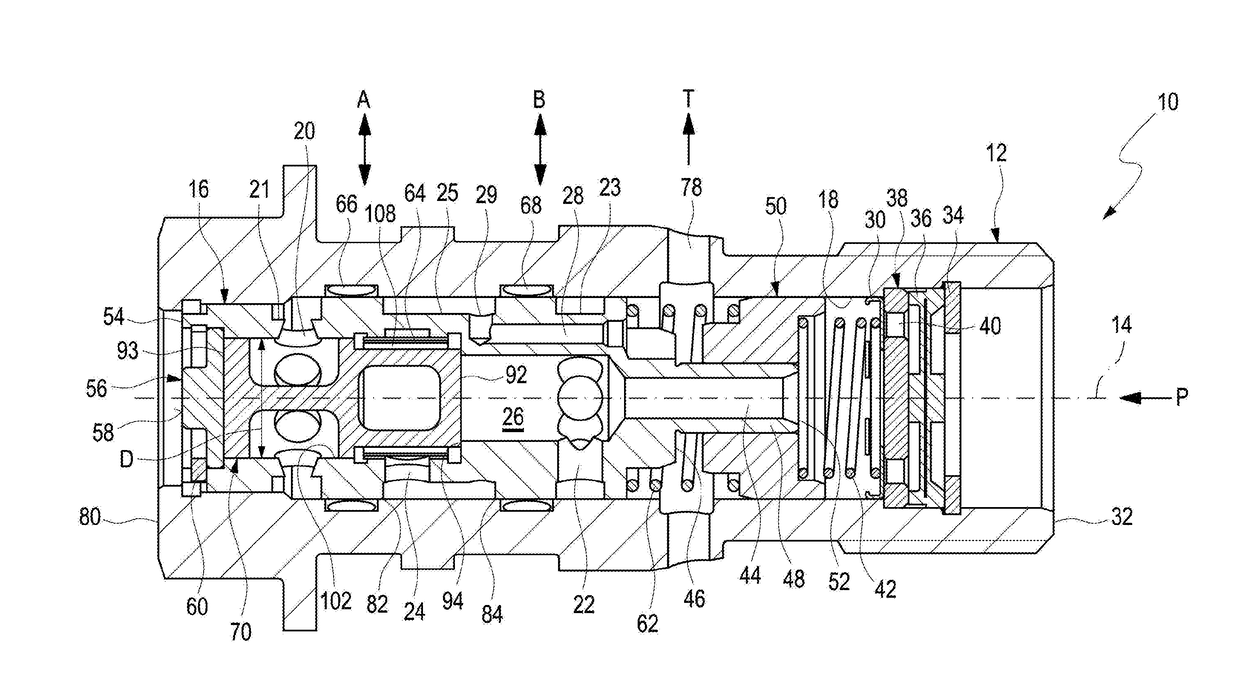

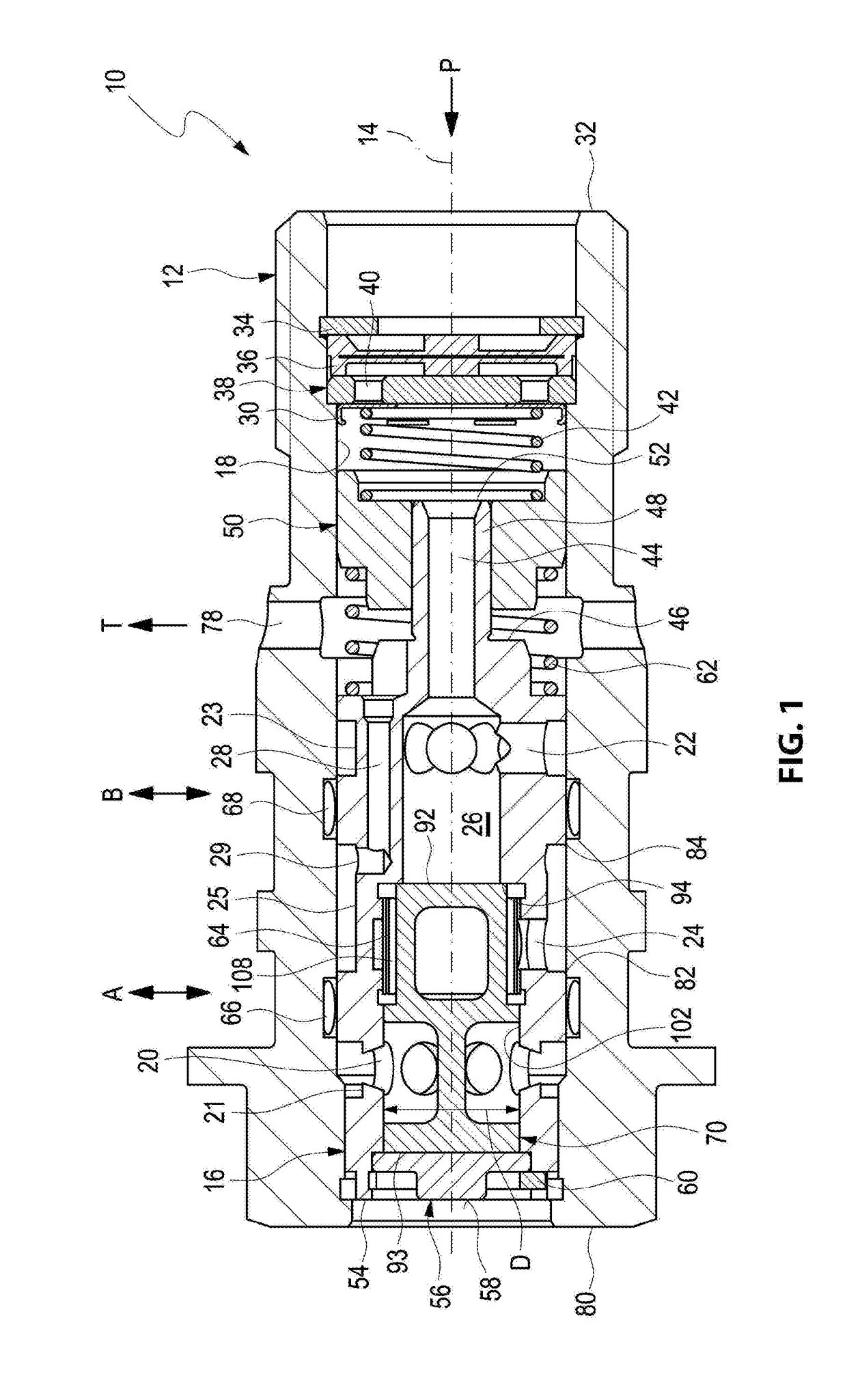

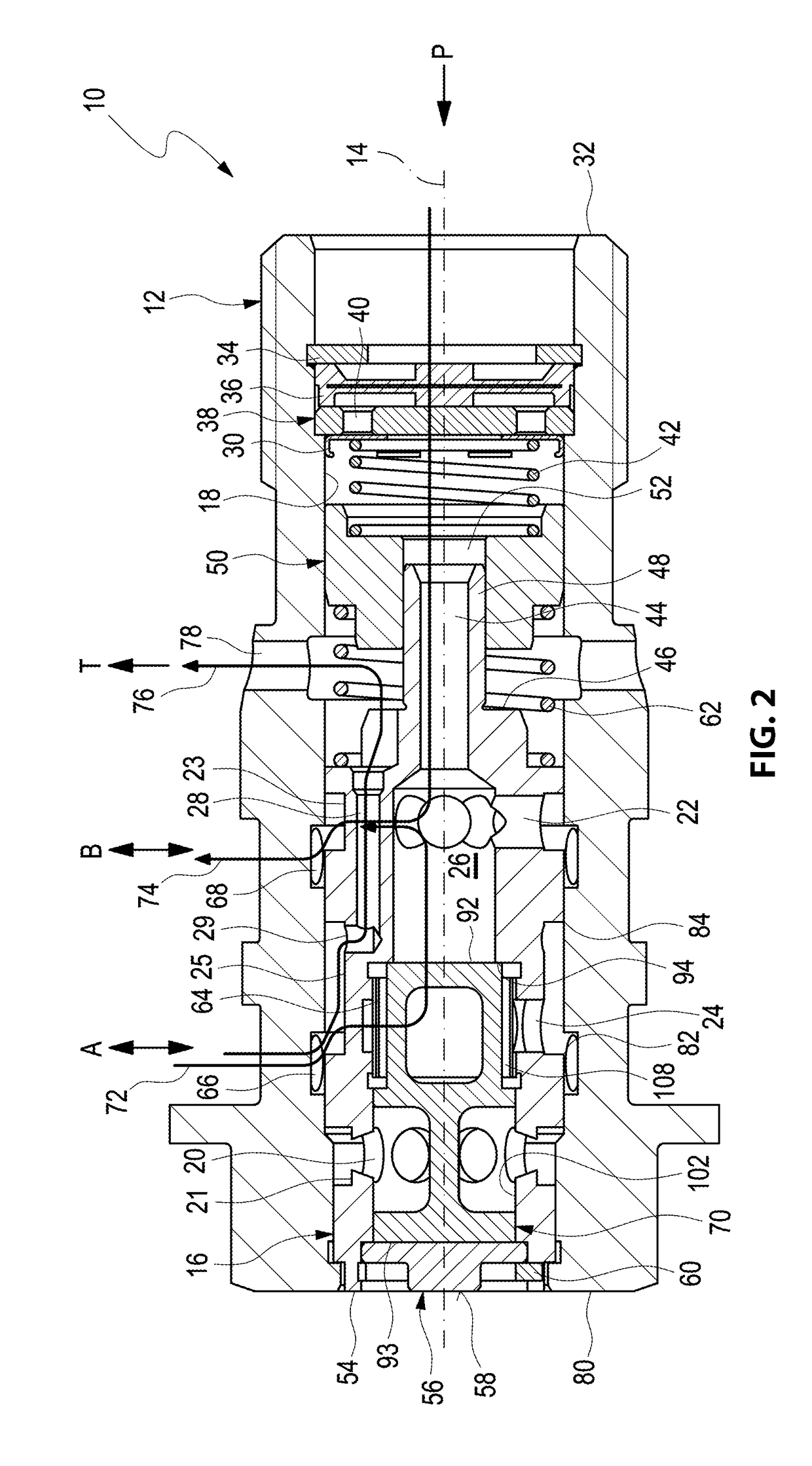

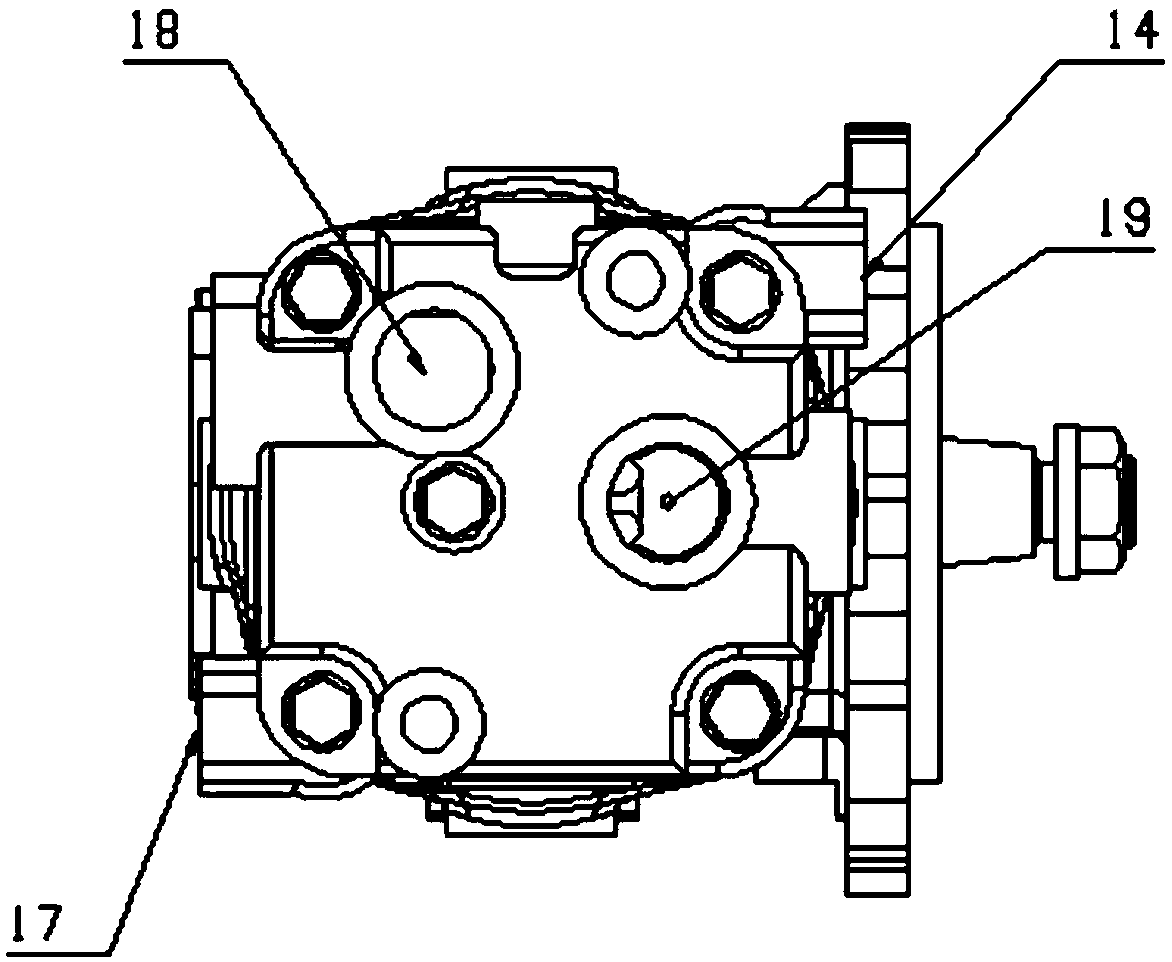

Hydraulic valve for a cam phaser

ActiveUS20180283229A1Reduce oil leakageReduce weightValve arrangementsMachines/enginesPistonInterior space

A hydraulic valve for a cam phaser and including a housing; a hollow cylindrical piston which is supported axially movable in a central opening extending along a longitudinal axis of the housing; a supply connection feeding a hydraulic fluid; and at least a first operating connection, a second operating connection and a tank connection, wherein one of the first operating connection or the second operating connection is connectable through an interior space of the piston with the supply connection and another of the first operating connection or the second operating connection is connectable with the tank connection as a function of a position of a position of the piston along the longitudinal axis of the housing, wherein the piston includes a first flow through opening and a second flow through opening connecting the interior space of the piston with the first operating connection and the second operating connection.

Owner:ECO HLDG 1 GMBH

Method for improving solder resist oil leakage of PCB

PendingCN111385979AImprove cleanlinessLow costNon-metallic protective coating applicationPhysical chemistryEngineering

The invention relates to a method for improving solder resist oil leakage of a PCB, which comprises the steps of ink preparation, PCB processing, hole plugging and oil printing, pre-baking, film manufacturing, alignment exposure and thermocuring. The method solves the problem of solder resist oil leakage of the PCB by controlling various parameters.

Owner:惠东县建祥电子科技有限公司

Joining Surface Structure for a Plurality of Cases

InactiveUS20080315532A1Reduce oil leakageMaintain strengthEngine sealsEngine lubricationEngineeringSurface structure

A joining surface of a lower case including a plurality of grooves and bolt holes. The plurality of grooves are formed with a substantially arced shape and intersect with each other. The bolt holes are used for tightening. The grooves intersect with each other, and connecting sections of the grooves form a continuous groove that separates the inside of the case from the outside of the case. A liquid gasket is filled in the grooves.

Owner:TOYOTA JIDOSHA KK

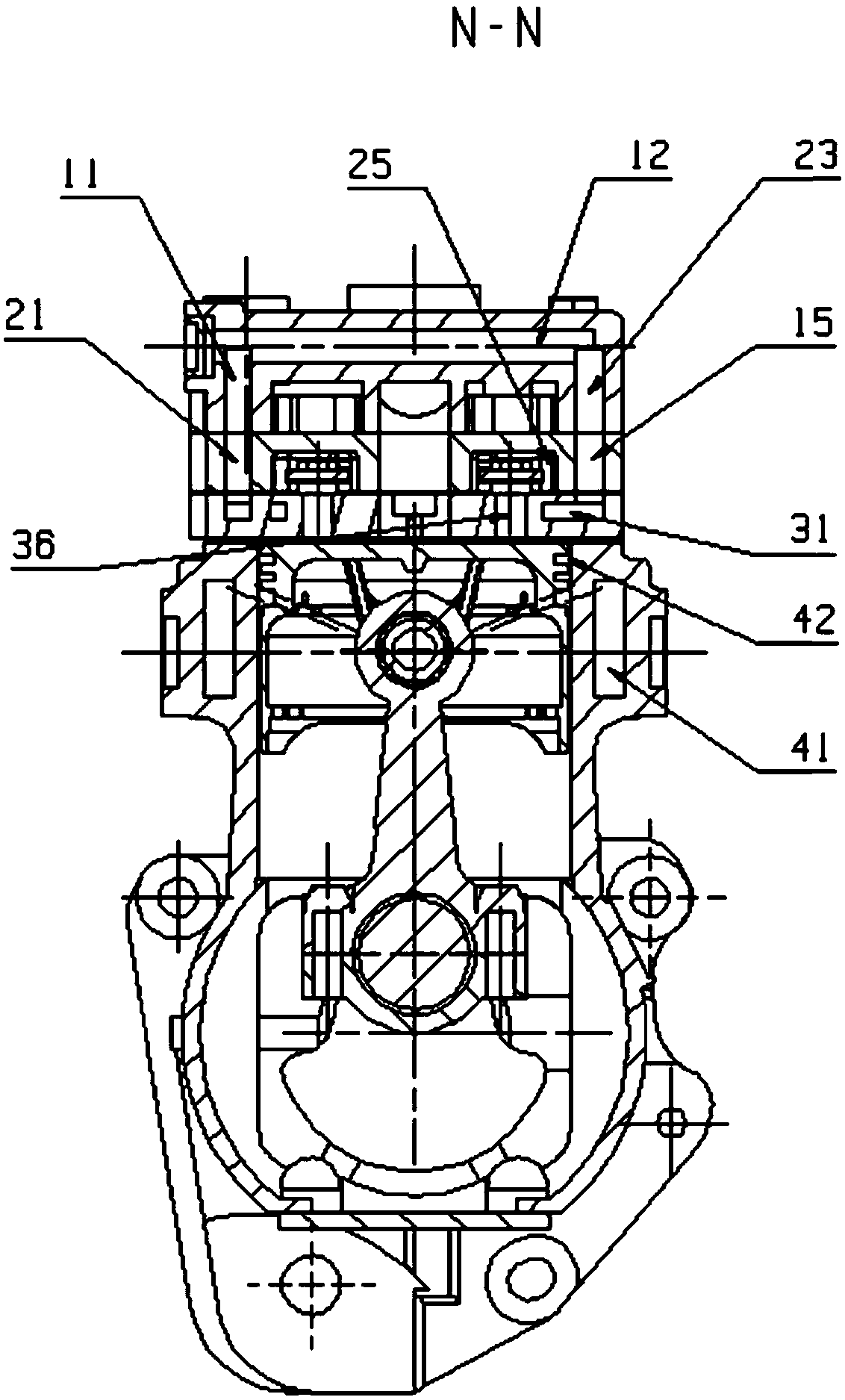

All-water cooling air compressor

PendingCN109185099AReduce oil leakageReduce the temperaturePositive displacement pump componentsPositive-displacement liquid enginesGas compressorEngineering

The invention discloses an all-water cooling air compressor. The all-water cooling air compressor comprises a cylinder cover, a valve plate, a supercooling plate and a cylinder jacket, wherein a firstcylinder cover water way, a second cylinder cover water way, a third cylinder cover water way, an inlet, a fourth cylinder cover water way, a fifth cylinder cover water way and an outlet are arrangedin the cylinder cover; the second cylinder cover water way is used as a water outlet of the first cylinder cover water way, and communicates with the fourth cylinder cover water way; a first valve plate water way, a second valve plate water way, a third valve plate water way and a fourth valve plate water way are arranged in the valve plate; a first supercooling plate water way, a second supercooling plate water way, a third supercooling plate water way, a fourth supercooling plate water way and a fifth supercooling plate water way are arranged in the supercooling plate; and a cylinder jacketwater way is arranged in the cylinder jacket. The all-water cooling air compressor further lowers the temperature of compressed air to reduce the oil moving quantity; and in addition, the supercooling plate and the valve plate are basically consistent in appearance, and can be directly added on a traditional water cooling air compressor.

Owner:GUANGXI YUCHAI MASCH CO LTD

Fluid dynamic bearing motor

InactiveUS20050094909A1Simple structurePrevent oil leakageShaftsRecord information storageEngineeringMechanical engineering

Provided is a fluid dynamic bearing motor in which a rotor is rotatably supported by forming an oil gap between the rotor and a stator to form a fluid dynamic pressure bearing and a plurality of oil grooves are formed in a surface of the rotor or stator forming the oil gap and facing each other. The oil grooves include a first oil groove inclined at a first angle with respect to a circumferential direction, and a second oil groove extending from an end portion of the first oil groove and inclined at a second angle with respect to the circumferential direction. The first angle is formed relatively greater than the second angle.

Owner:G&W TECH

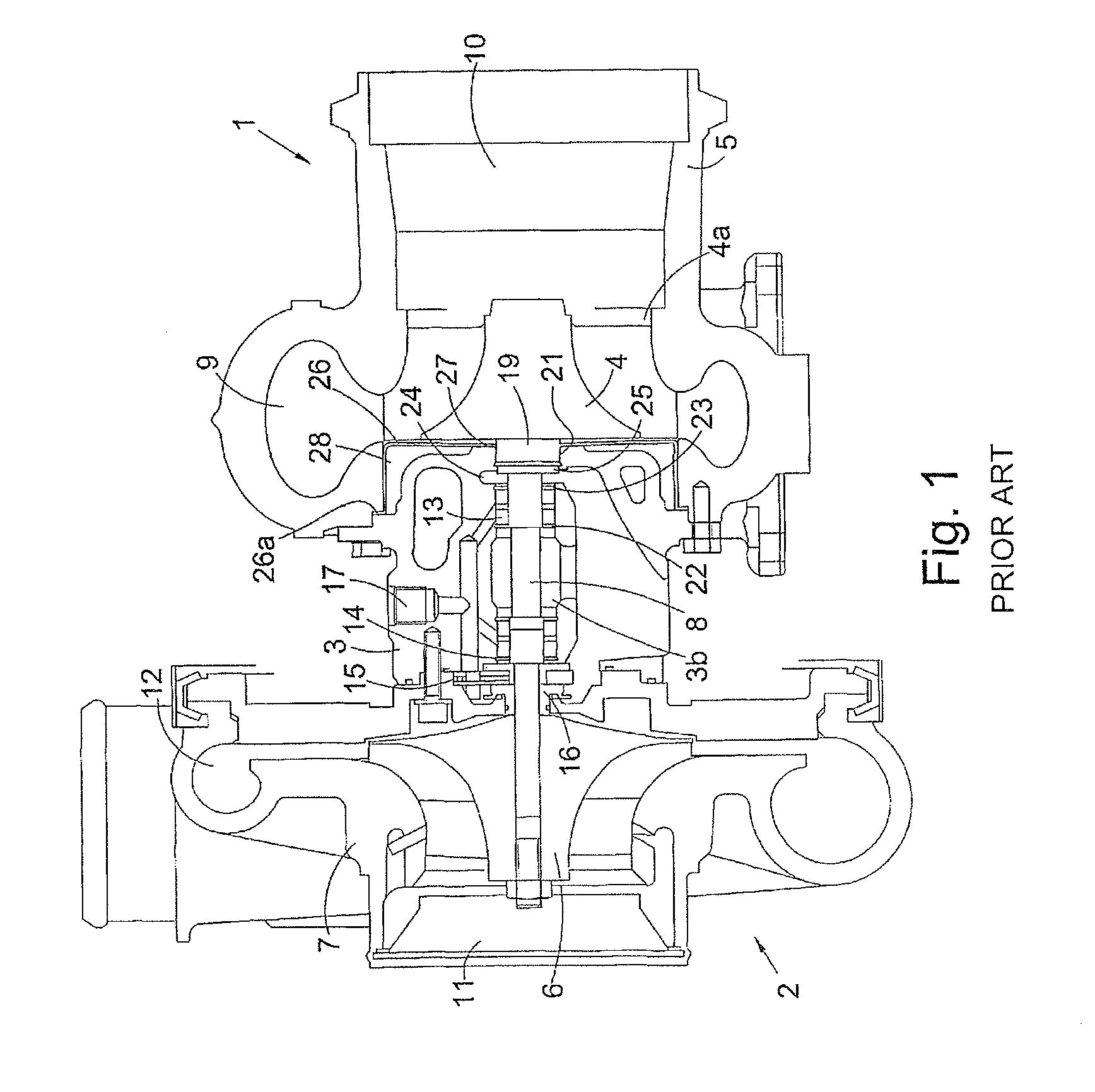

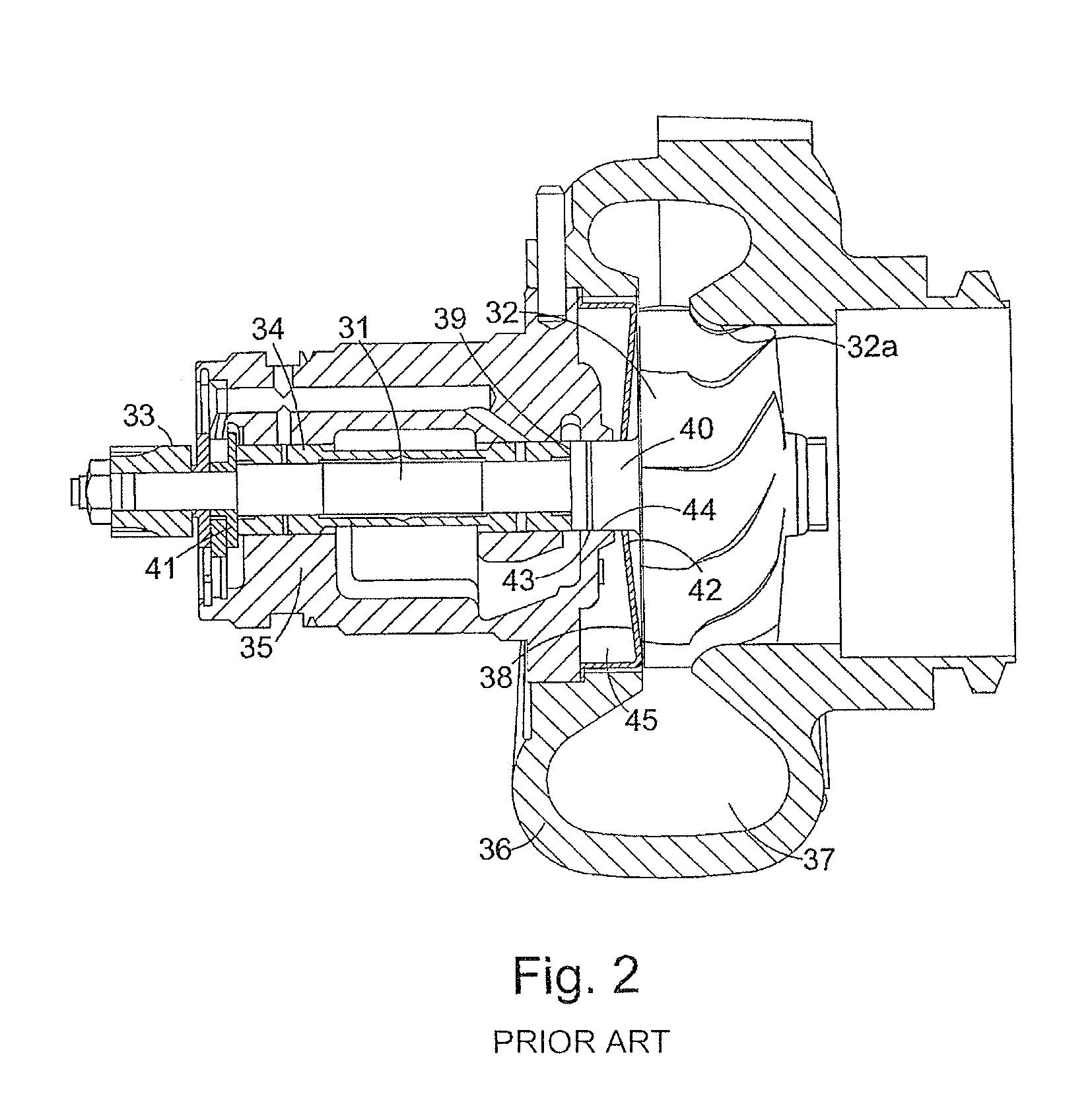

Turbomachine

A turbomachine comprising a housing defining a bearing cavity and a turbine chamber separated by a first wall, a heat shield disposed between the first wall and the turbine wheel, a heat shield cavity defined between the first wall and the heat shield. The shaft extends through a passage defined in part by a first aperture in the wall and a second aperture in the heat shield. A first seal is provided between the shaft and the first aperture. The housing defines a first gas channel communicating with the heat shield cavity for connection to a pressure source for raising pressure within the heat shield cavity. A second channel is provided between the heat shield cavity and the passage, the second channel opening to the passage on the opposite side of the first seal to the bearing assembly. A second seal is provided between the shaft and the second aperture.

Owner:CUMMINS TURBO TECH

Sealing system for reducing leakage of lubricating oil of gas turbine

PendingCN110056431AReduce oil leakageReduce leakageGas turbine plantsJet propulsion plantsMain bearingGas turbines

The invention relates to the technical field of gas turbines, in particular to a sealing system for reducing leakage of lubricating oil of a gas turbine. The sealing system aims to solve the problemsthat when the existing gas turbine is in a low working condition, the oil is leaked, the oil consumption is large, the temperature of a lubricating oil is too high, a main bearing cannot be protected,and a lubricating system cannot work normally. The sealing system comprises a lubricating oil sealing device body and a pressurizing air guiding system, an air outlet end of the pressurizing air guiding system is in communication with a sealing air cavity of the lubricating oil sealing device body through a sealing air cavity air supply pipe of the lubricating oil sealing device body, a one-way valve is arranged on the passage between the pressurizing air guiding system and the sealing air cavity, and the air outlet end of the air pressurizing system is in communication with the sealing air cavity through the sealing air cavity air supply pipe of the lubricating oil sealing device body. The sealing system is used for preventing the lubricating oil from leaking under the action of a low working condition of the gas turbine.

Owner:中国船舶重工集团公司第七0三研究所

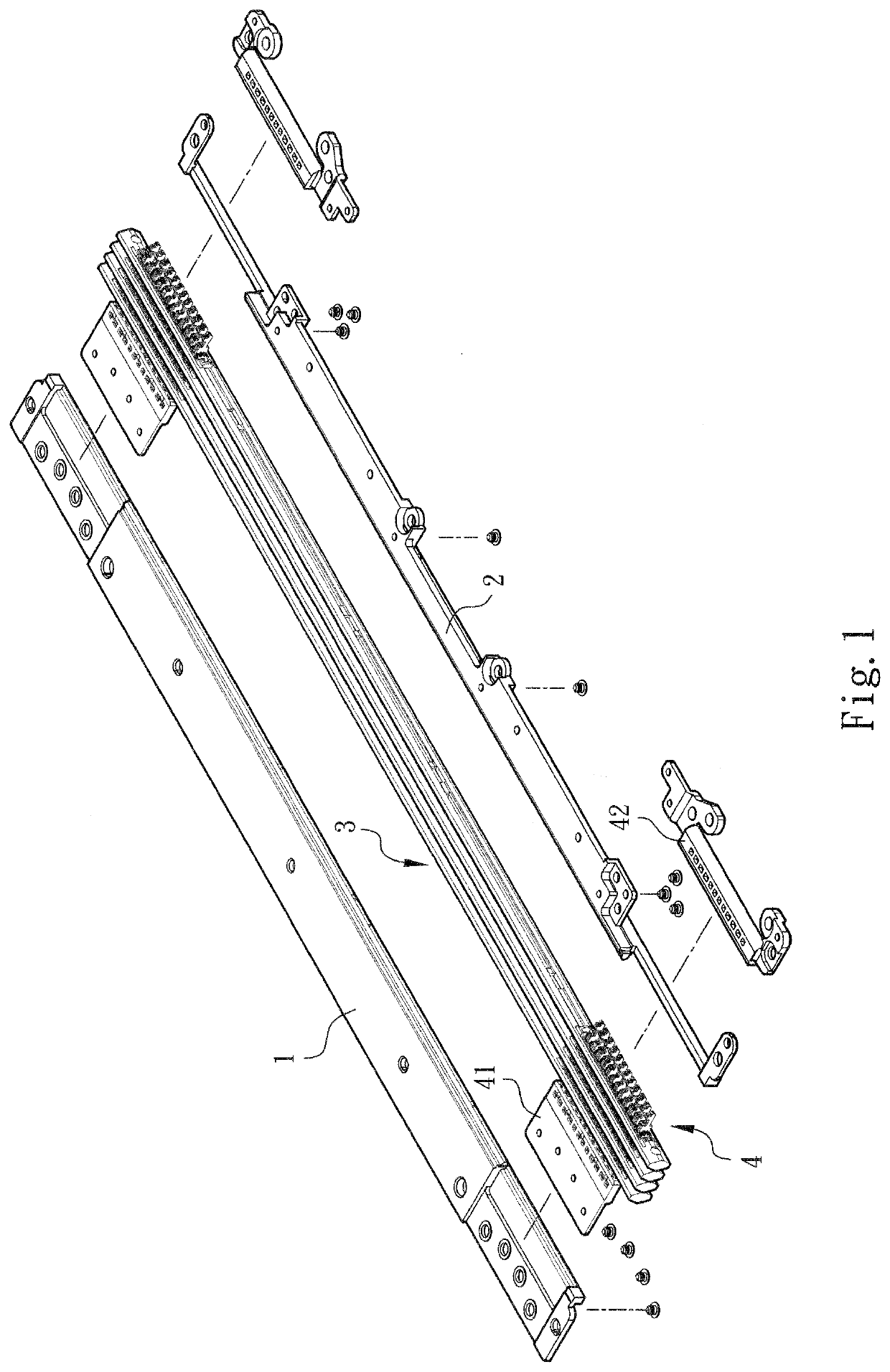

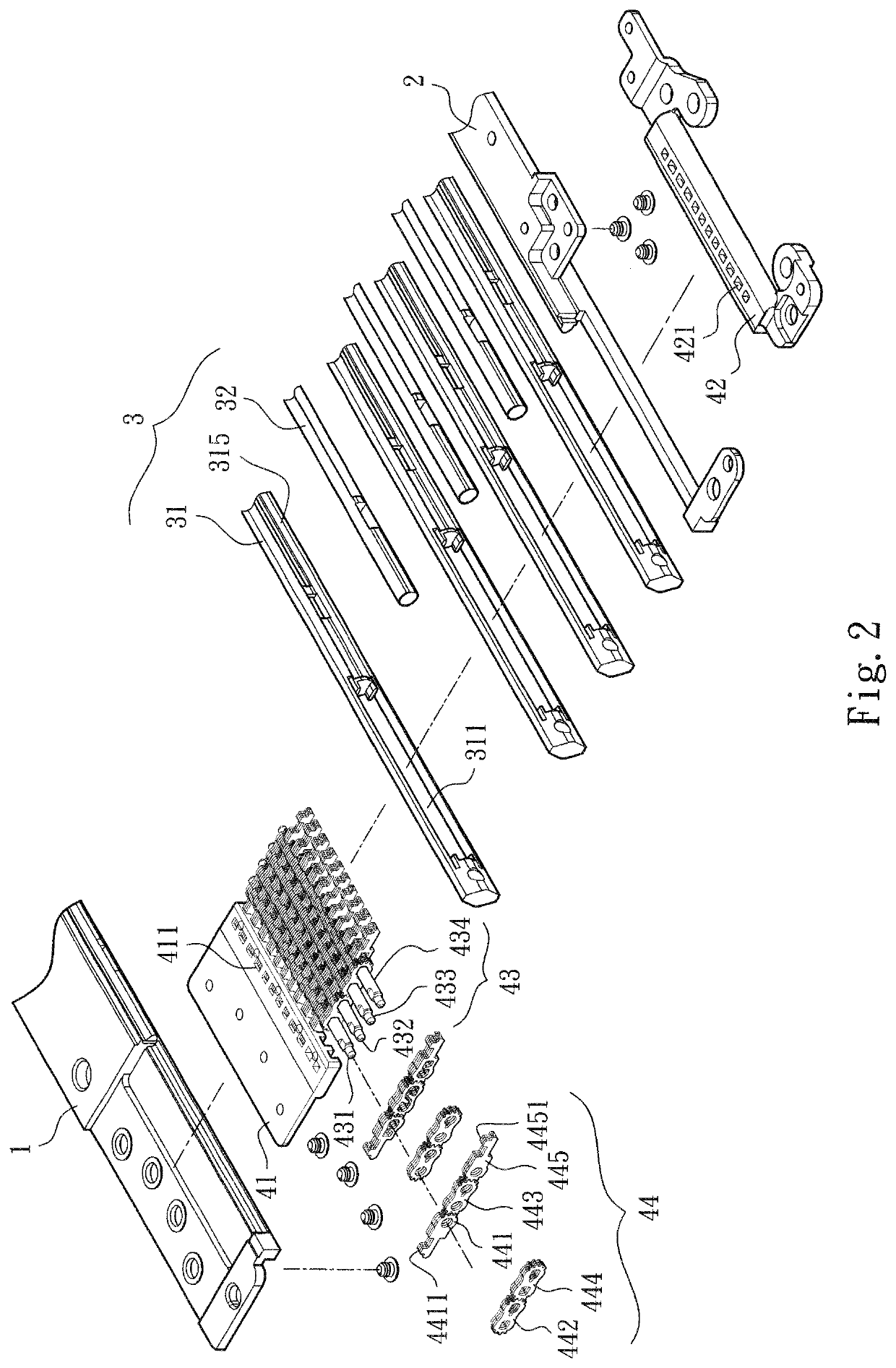

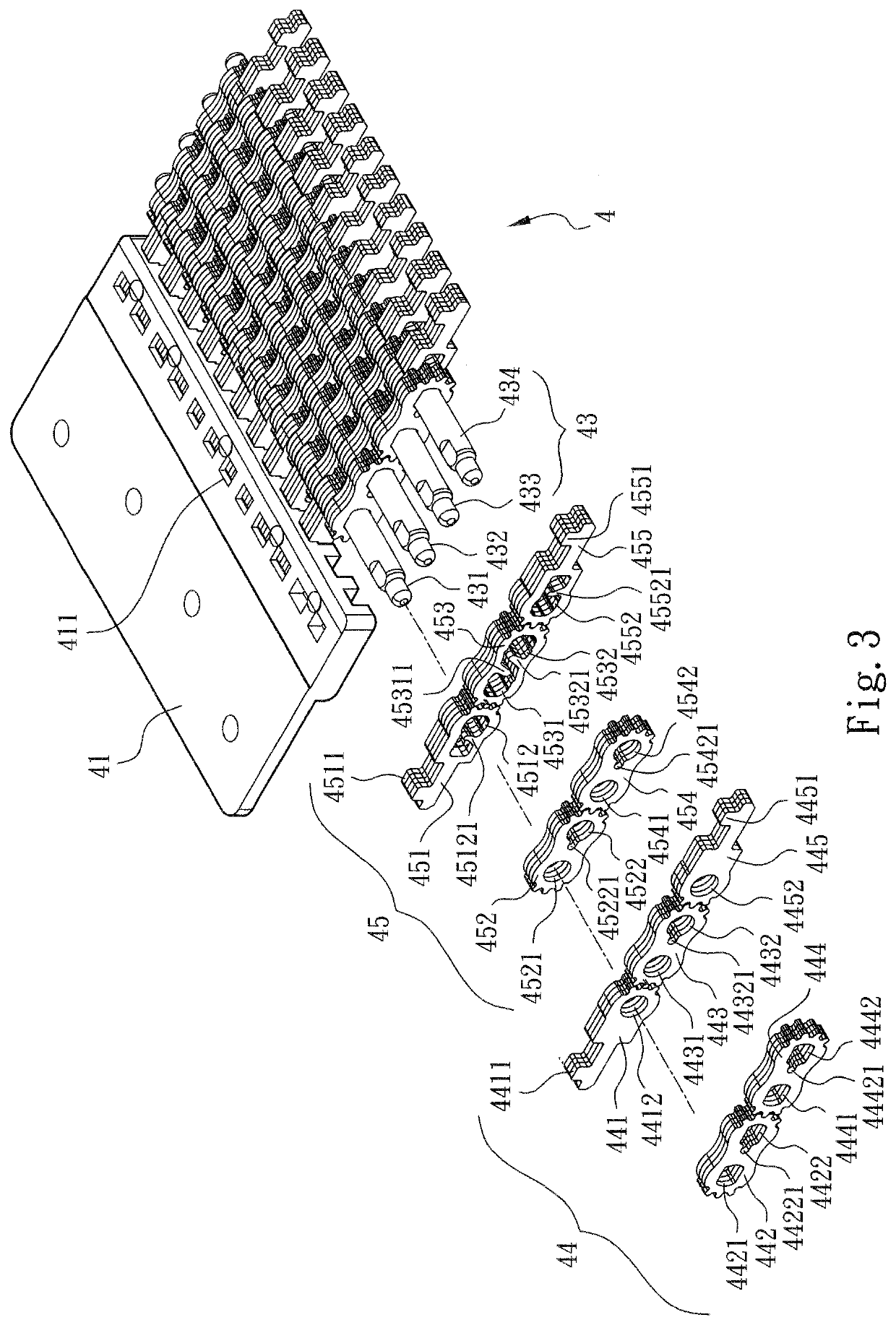

Rotary shaft link assembly structure

ActiveUS20210200275A1Reduce dropped powderReduce oil leakageWing accessoriesDetails for portable computersFriction reductionClassical mechanics

A rotary shaft link assembly structure is connected between a first support and a second support of two articles. The rotary shaft link assembly structure has a rotary shaft assembly and at least one synchronous rotational assembly. The rotary shaft assembly has multiple connection members side-by-side disposed between the first and second supports. Each connection member is correspondingly formed with at least one hollow section. The synchronous rotational assembly passes through the hollow sections of the connection members to respectively connect with the first and second supports, whereby the connection members are transversely serially connected to drivingly bend and connect along with the synchronous rotational assembly. The connection members respectively shield a part of the synchronous rotational assembly to provide a protection effect and reduce the dropped powder and oil leakage caused by the friction.

Owner:FIRST DOME

Combined oil ring

InactiveUS20090273142A1Reduce oil leakageReduce fuel consumptionPiston ringsBraking action transmissionPetroleum engineering

Owner:TEIKOKU PISTON RING CO LTD

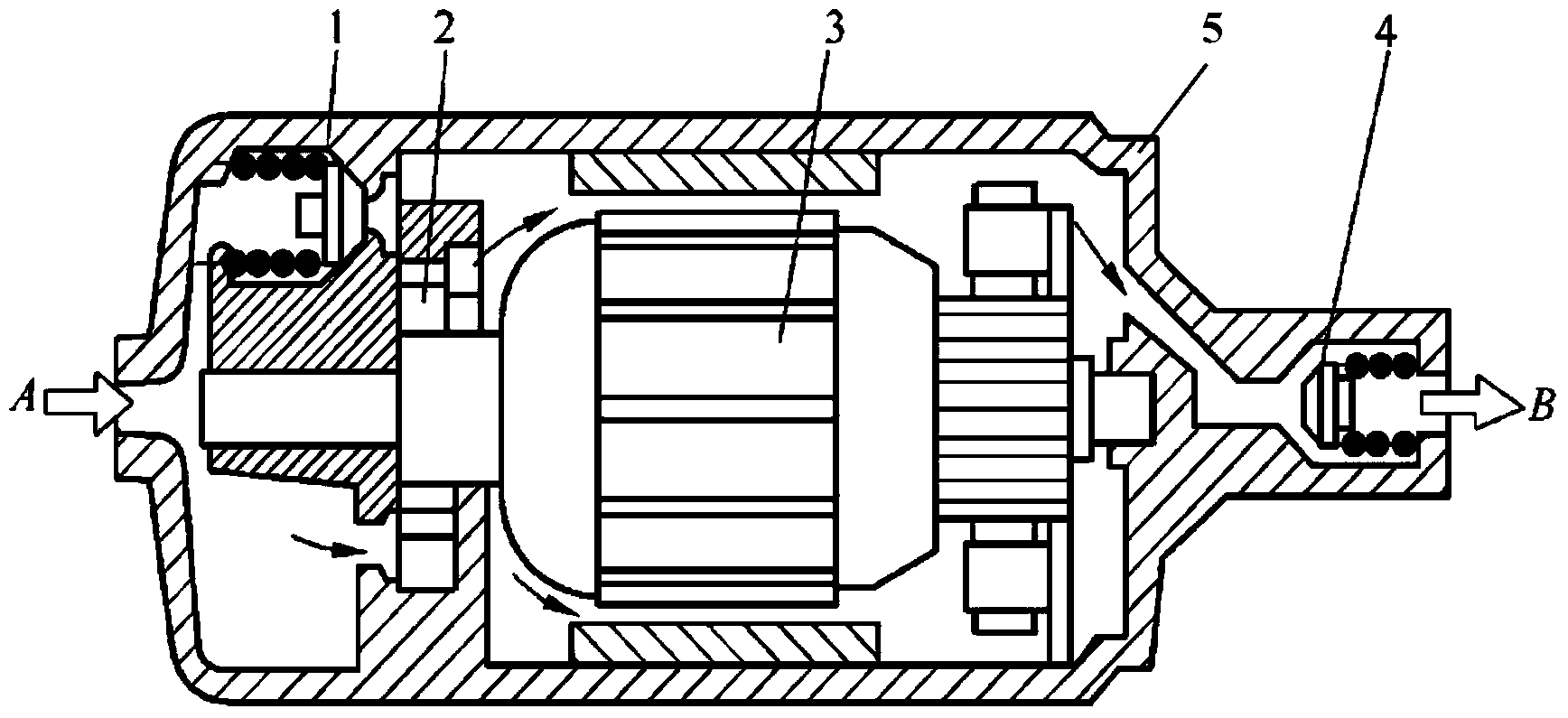

Stator magnetic pole type electric roller vane pump

InactiveCN103527475AReduce oil leakageIncreased pump volumetric and mechanical efficiencyRotary piston pumpsRotary piston liquid enginesDrive motorRelief valve

The invention discloses a stator magnetic pole type electric roller vane pump, which comprises a pump shell, wherein the pump shell is provided with an oil inlet and an oil outlet; a direct current(DC) drive motor is arranged in the pump shell; a relief valve and a roller pump are arranged between the oil inlet and the DC drive motor; an one-way valve is arranged in the oil outlet; the roller pump comprises an oil intake end, a stator, a rotor, a plurality of rollers and a port plate, wherein the stator is arranged between the cap of the oil intake end and the port plate; the rotor is arranged in the stator; an U-shaped groove is formed in the edge of the rotor and the rollers are arranged in the U-shaped groove. The stator magnetic pole type electric roller vane pump, disclosed by the invention, has the beneficial effects that the impact abrasion to the sidewall of the stator caused by the rollers in the roller pump due to the action of start centrifugal force is avoided; the tight contact among the magnetic sidewall of the stator, the rollers and the groove of the rotor can relieve oil fluid leakage, thereby increasing volumetric efficiency and mechanical efficiency of the pump; the ability of resisting external load sudden change is greatly augmented; the reliability is improved, meanwhile, the service time of the pump is prolonged and low costs of good quality products are realized.

Owner:WENZHOU PUMP VALVE ENG RES INSTOF LANZHOU UNIV OF TECH +1

Seal assembly and method for reducing aircraft engine oil leakage

A seal assembly for a gas turbine engine employs a first seal forming an oil chamber around a bearing. The first seal is configured to maintain the oil chamber at a first pressure. A second seal forms a ventilating cavity around the oil chamber. The second seal is configured to maintain the ventilating cavity at a second pressure, the second pressure being less than the first pressure and less than an ambient pressure of a primary flow path in the engine. A pressure reducing device is coupled to the ventilating cavity. The pressure reducing device is configured to maintain the second pressure.

Owner:THE BOEING CO

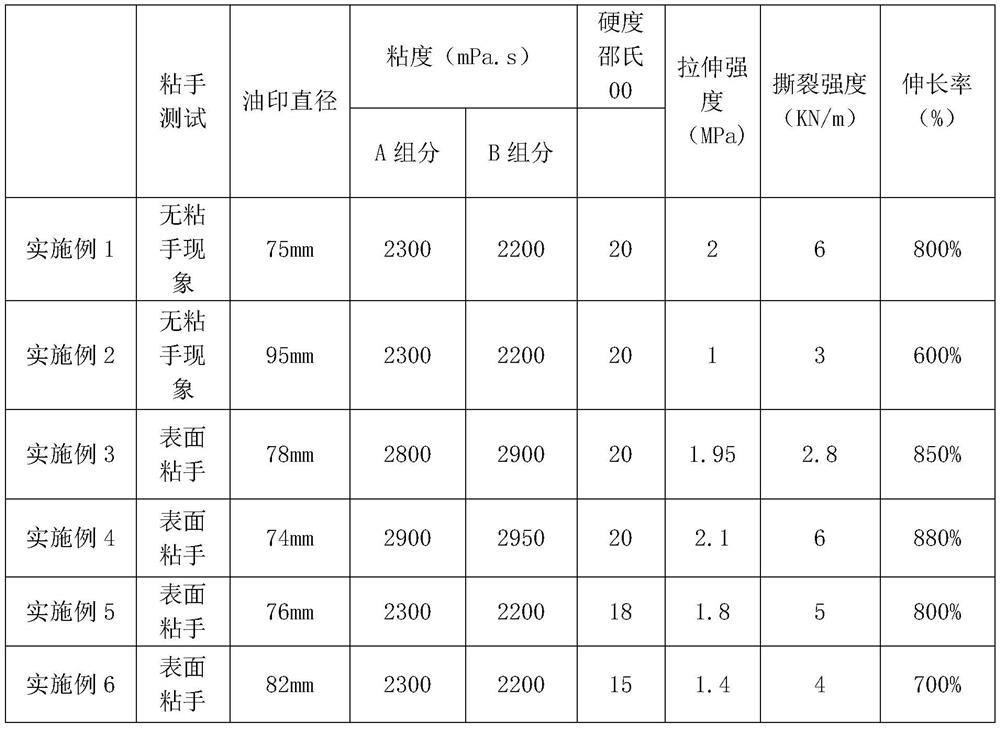

Bi-component organic silica gel and preparation method thereof

The invention relates to the technical field of silicone rubber, in particular to bi-component organic silica gel and a preparation method thereof. The bi-component organic silica gel is composed of a component A and a component B. The component A is prepared from the following raw materials in parts by weight: 40-70 parts of modified hydrogen-containing silicone oil A, 20-30 parts of reinforcing resin, 10-25 parts of methyl silicone oil, 15-25 parts of filler and 0.01-0.5 part of a catalyst. The component B is prepared from the following raw materials in parts by weight: 40 to 70 parts of modified hydrogen-containing silicone oil B, 20 to 30 parts of reinforcing resin, 10 to 25 parts of methyl silicone oil, 15 to 25 parts of filler and 0.01 to 1 part of an inhibitor. Specific modified hydrogen-containing silicone oil is prepared by selecting specific raw materials, and the low-viscosity bi-component silica gel which is good in physical performance, free of oil leakage and hand sticking and ultralow in hardness (Shore C zero degree) is prepared.

Owner:东莞市天之韵新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com