Bi-component organic silica gel and preparation method thereof

An organic silica gel, two-component technology, applied in the field of silicone rubber, can solve the problems of surface stickiness affecting hand feel, surface oil not dry, affecting product processing, etc., to achieve excellent physical properties, reduce oil phenomenon, good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

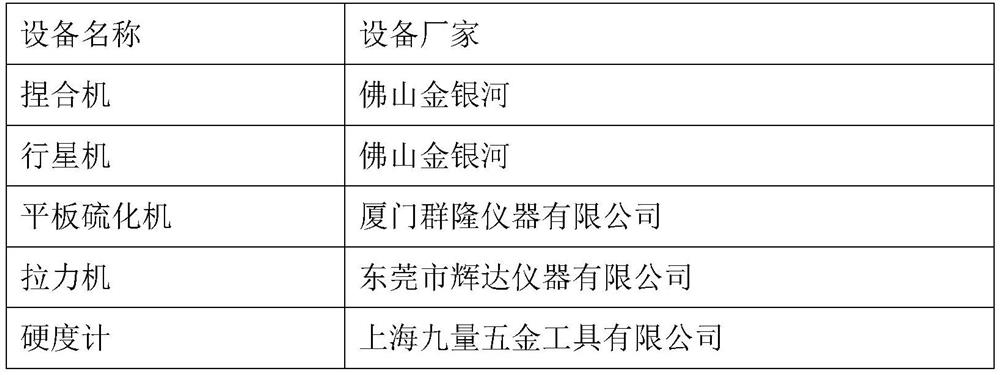

Method used

Image

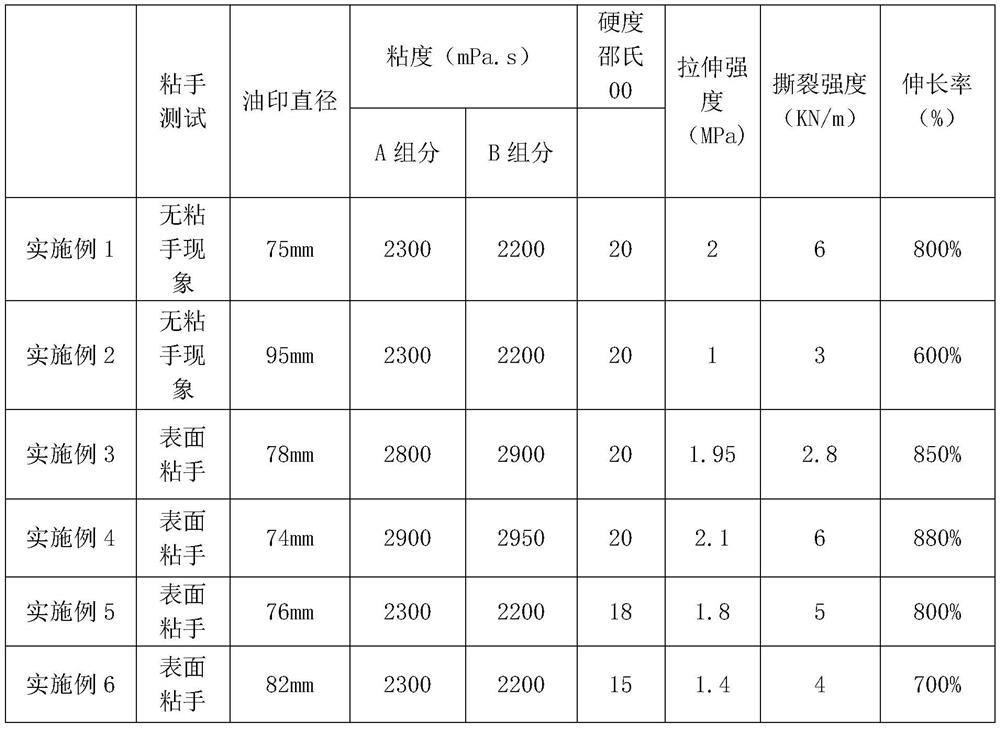

Examples

preparation example Construction

[0061] A second aspect of the present invention provides a method for preparing a two-component organic silica gel, comprising the following steps:

[0062] (1) Preparation of base rubber material A: Weigh the raw materials of component A and set aside, divide the modified hydrogen-containing silicone oil A into 3 parts by weight, and record them as A1, A2, and A3 respectively, and add A1 into the kneader 1. Knead the coupling agent for 5-15 minutes, and then add fillers in stages. After all the fillers are added, knead at room temperature for 2-4 hours, raise the temperature to 160-170°C, keep warm and vacuum banbury for 2-4 hours; then add A2, After refining evenly, the basic rubber material A is obtained and set aside;

[0063] (2) Preparation of component A: Take the basic rubber material A obtained in step (1), add A3, reinforcing resin, methyl silicone oil, and catalyst, and stir evenly in a planetary mixer to obtain component A;

[0064] (3) Preparation of base rubber ...

Embodiment 1

[0078]A two-component organic silica gel, composed of A component and B component, the raw materials of the A component include, by weight, 62 parts of modified hydrogen-containing silicone oil A, 25 parts of methyl silicone resin, methyl silicone oil 18 parts, 20 parts of filler, 0.14 parts of coupling agent, 0.2 part of catalyst; the raw materials of the B component include, in parts by weight, 62 parts of modified hydrogen-containing silicone oil B, 25 parts of methyl silicone resin, 18 parts of methyl silicone oil parts, 20 parts of fillers, 0.14 parts of coupling agents, and 0.2 parts of inhibitors;

[0079] The methyl silicone oil is Shin-Etsu KF96-1000CS;

[0080] The number average molecular weight of the methyl silicone resin is 4000;

[0081] The filler is silica powder; the average particle diameter of the silica powder is 1000 mesh;

[0082] The methyl silicone resin is purchased from Xixin Jiayi New Material Co., Ltd., and the model is XJY-8205;

[0083] The nu...

Embodiment 2

[0092] A two-component organic silica gel, consisting of A component and B component, the raw materials of the A component include, in parts by weight, 62 parts of modified hydrogen-containing silicone oil A, 18 parts of methyl silicone oil, 20 parts of filler, 0.14 parts of coupling agent, 0.2 parts of catalyst; the raw materials of the B component include, by weight, 62 parts of modified hydrogen-containing silicone oil B, 18 parts of methyl silicone oil, 20 parts of filler, 0.14 parts of coupling agent, inhibitor 0.2 copies;

[0093] The methyl silicone oil is Shin-Etsu KF96-1000CS;

[0094] The filler is silica powder; the average particle diameter of the silica powder is 1000 mesh;

[0095] The number average molecular weight of the modified hydrogen-containing silicone oil A and the modified hydrogen-containing silicone oil B is 90,000;

[0096] The hydrogen content of described modified hydrogen-containing silicone oil A is 0.22wt%; The preparation raw material of des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com