Stator magnetic pole type electric roller vane pump

A stator magnetic pole and vane pump technology, which is applied to rotary piston/oscillating piston pump components, rotary piston pumps, pumps, etc., can solve the problem of large wear of rollers and stators, reduced service life of fuel pumps, and impact on oil pump oil. Pressure performance and other issues, to achieve the effect of increasing pump life, improving reliability, and enhancing the ability of external load mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

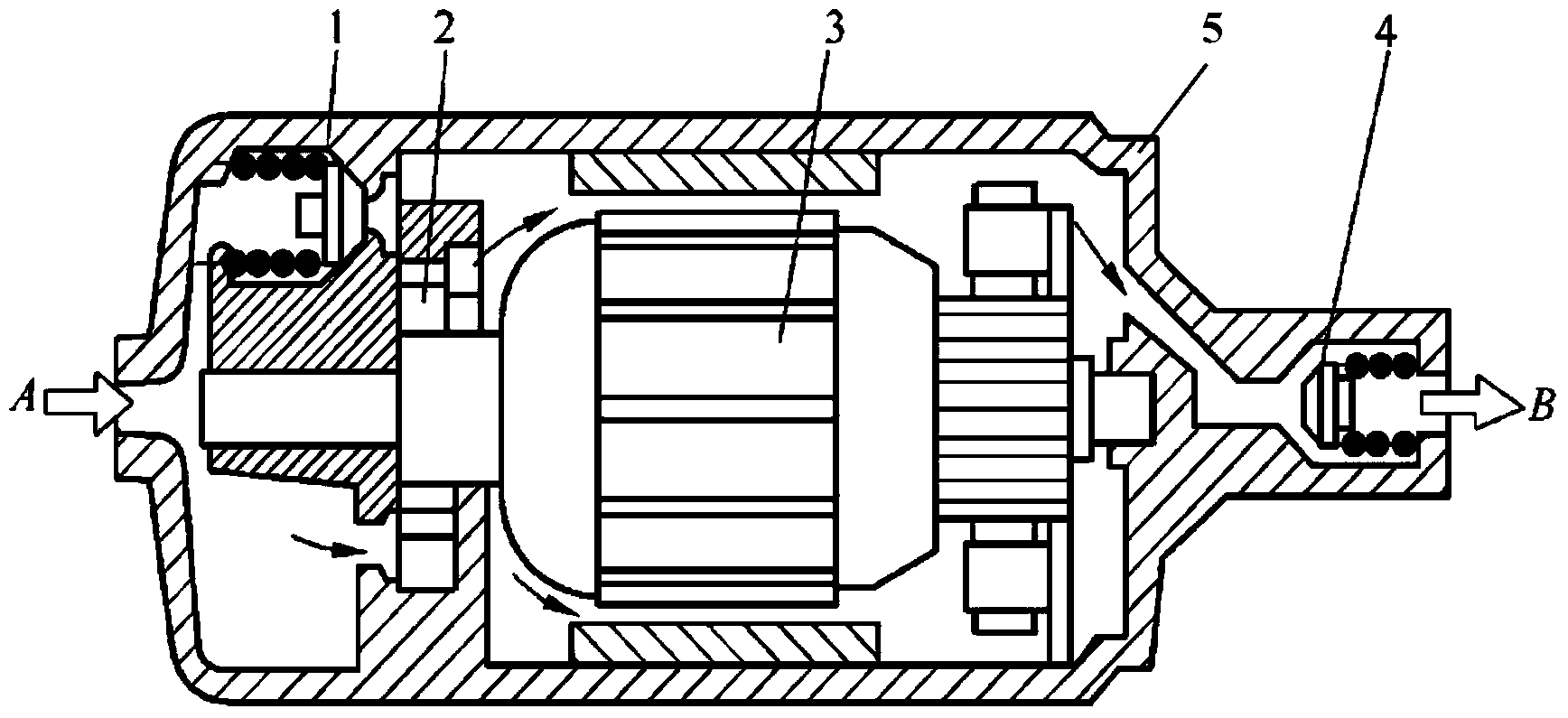

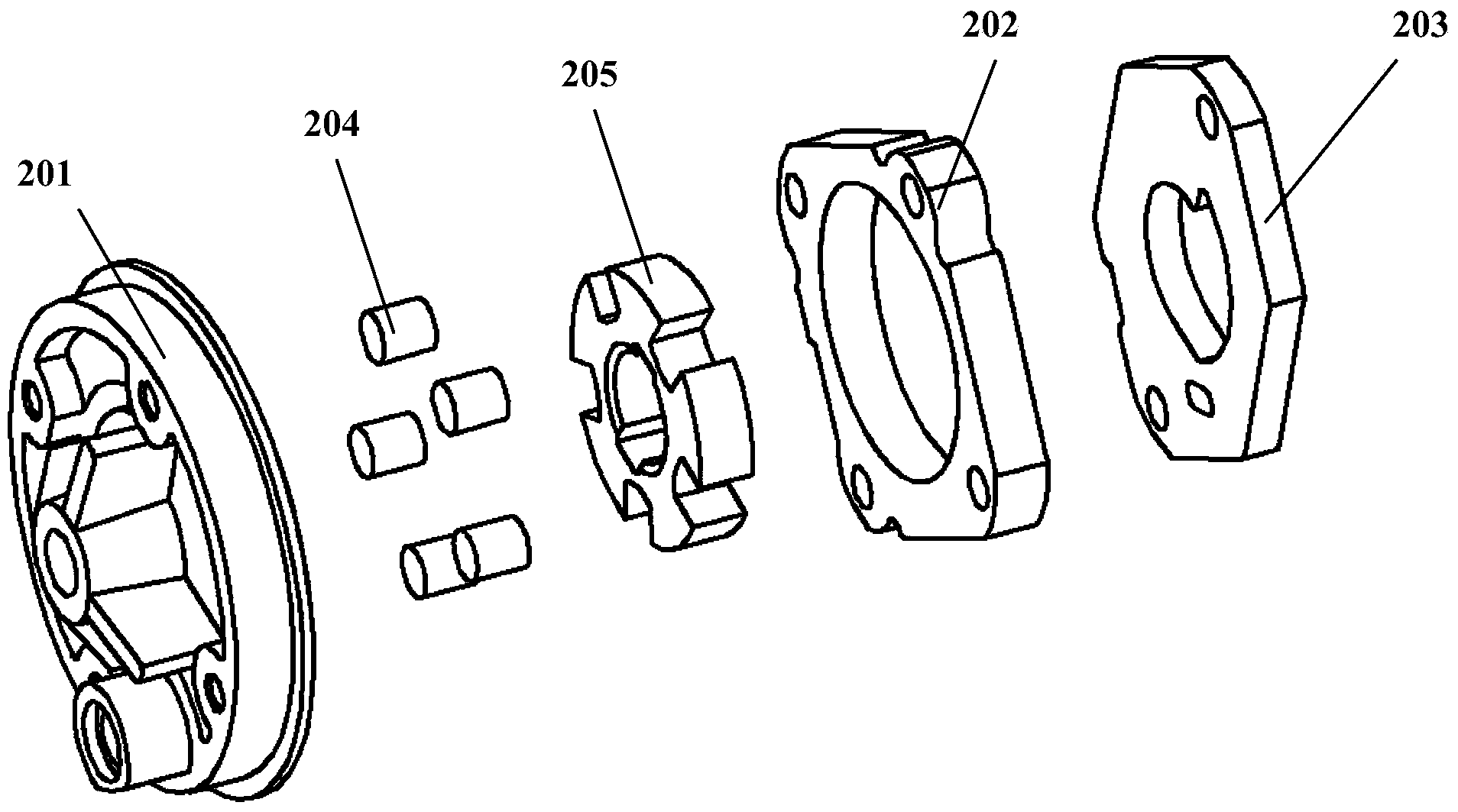

[0015] A stator magnetic pole type electric roller vane pump, including a pump casing 5, an oil inlet and an oil outlet are arranged on the pump casing 5, a DC drive motor 3 is installed inside the pump casing 5, and the oil inlet and the DC drive A pressure relief valve 1 and a roller pump 2 are installed between the motor 3, and a check valve 4 is installed in the oil outlet; the roller pump 2 includes an oil inlet cover 201 and a flow distribution plate 203, and the oil inlet cover 201 and A stator 205 is installed between the flow distribution plates 203, a rotor 205 is installed inside the stator 202, a U-shaped groove is opened on the edge of the rotor 205, and a roller 204 is installed in the U-shaped groove; the edge of the rotor 205 is uniformly opened with five U-shaped grooves, and a roller 204 is installed in each groove.

[0016] The rotor 205 rotates under the drive of the DC drive motor 3 , and under the action of centrifugal force, the roller 204 is pressed aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com