Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Extend motor life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

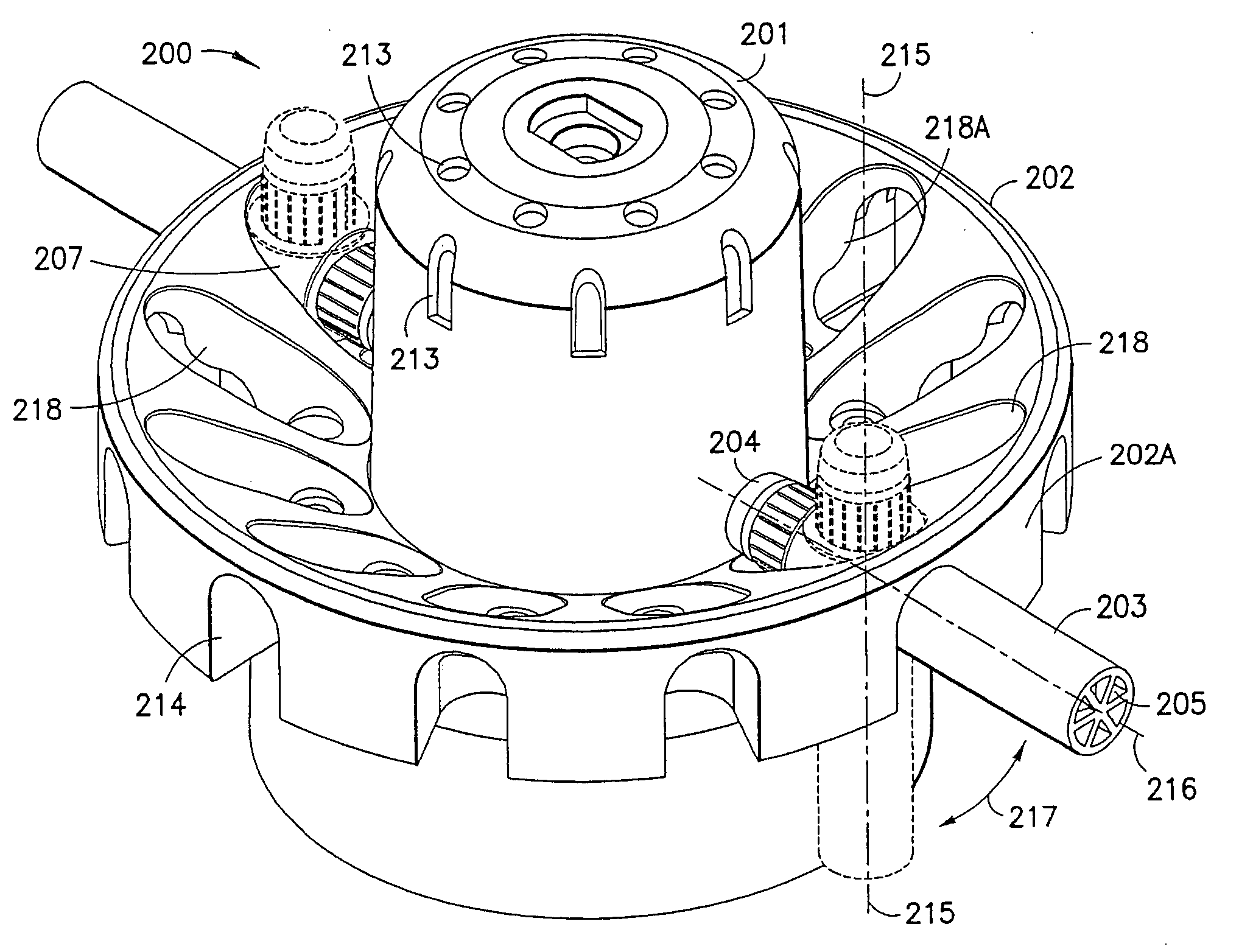

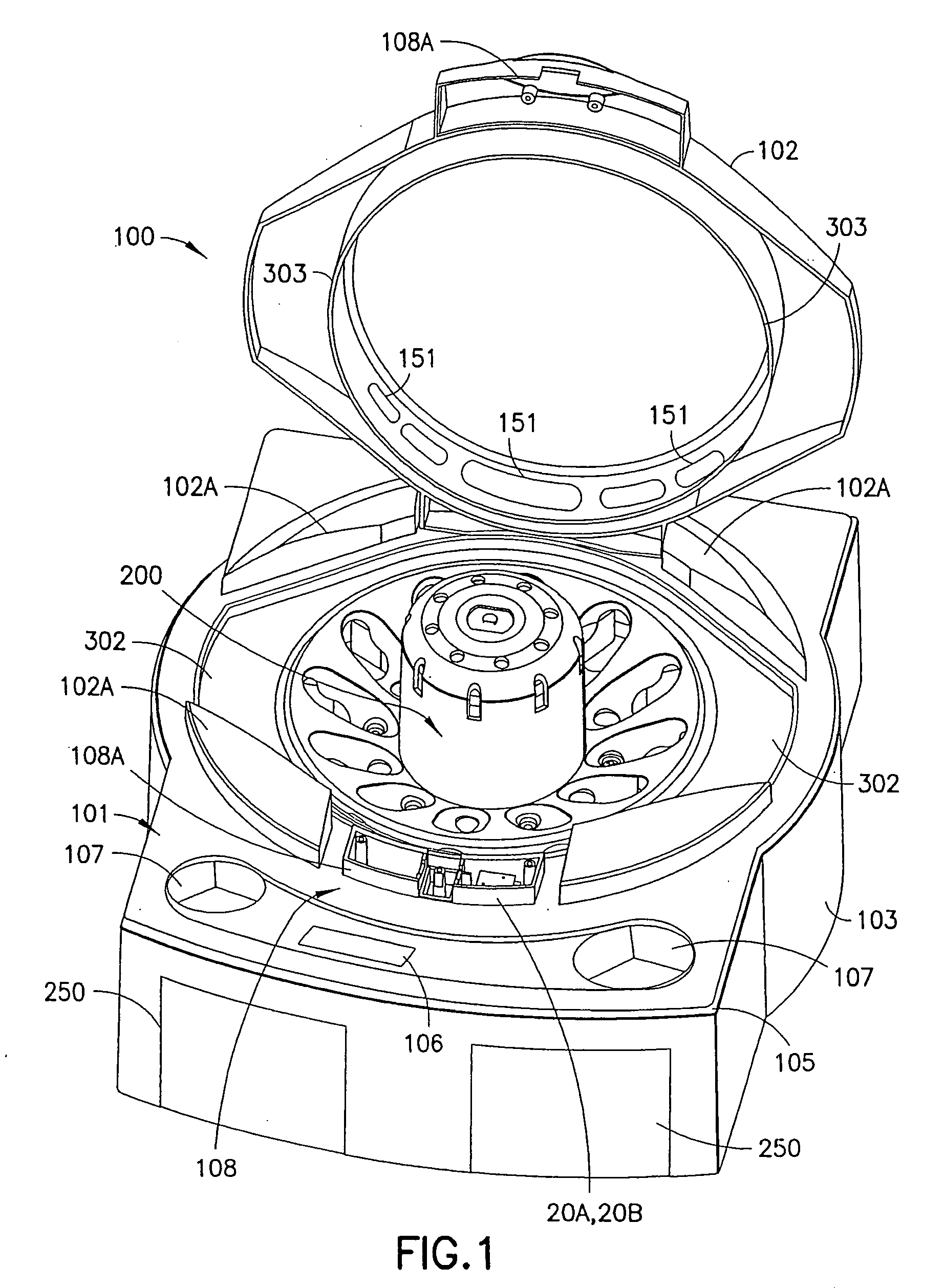

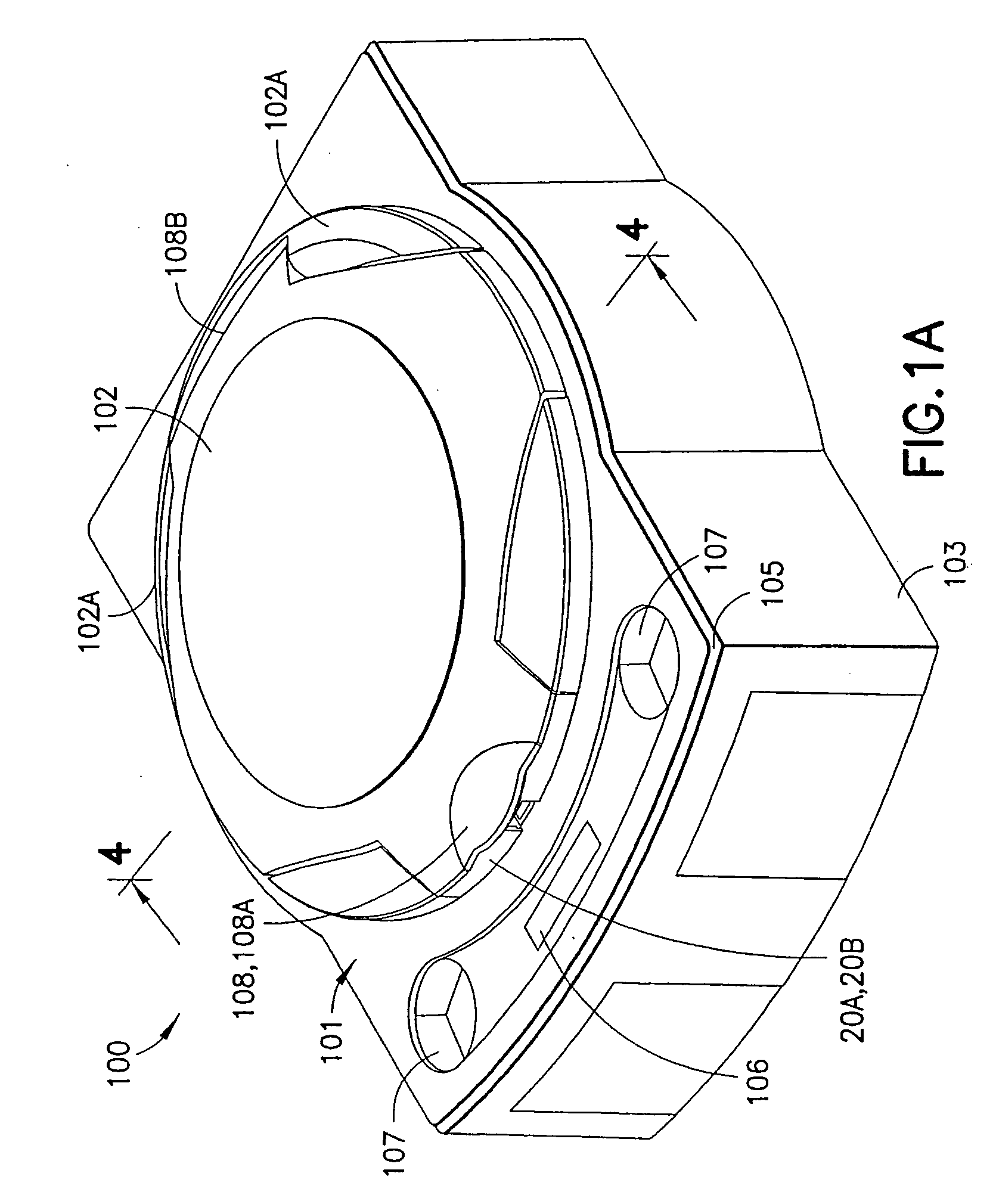

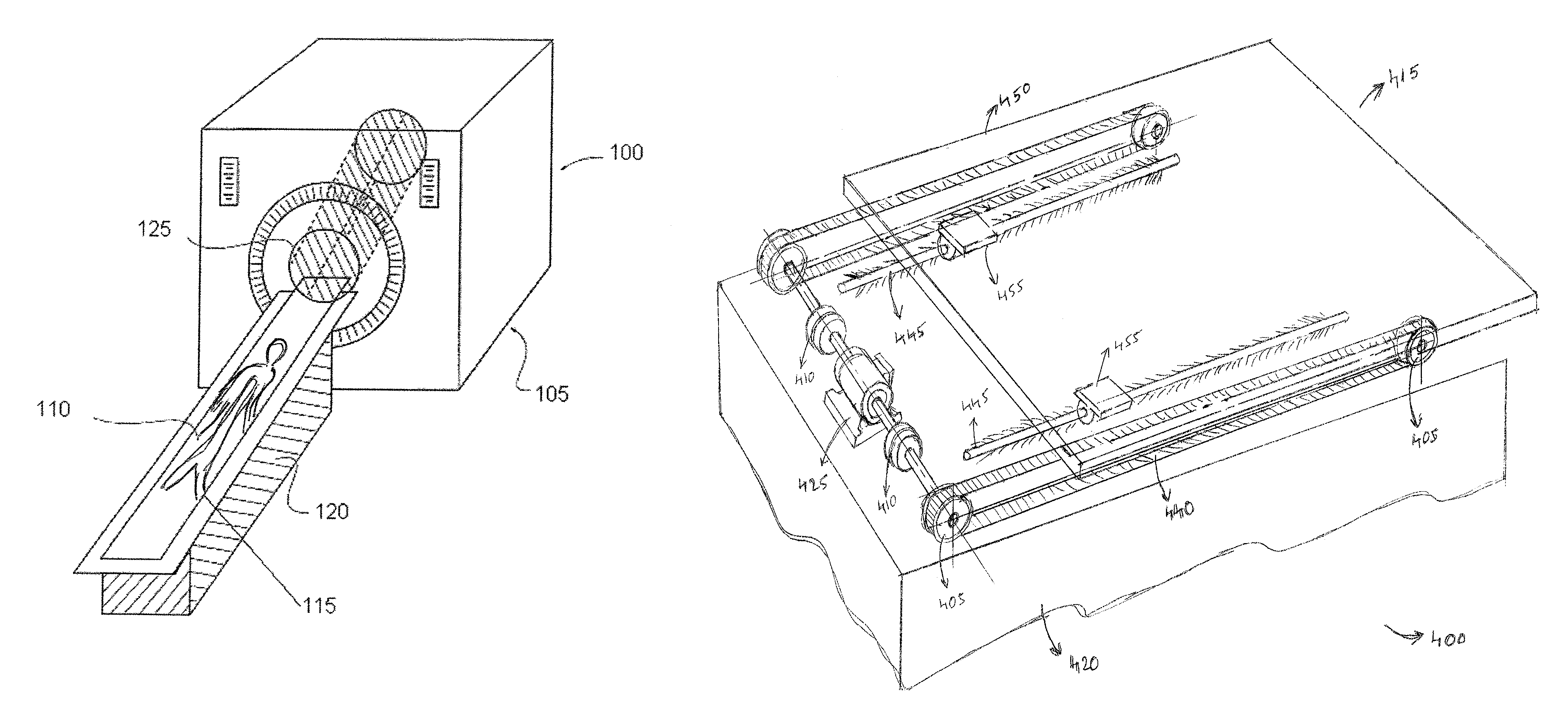

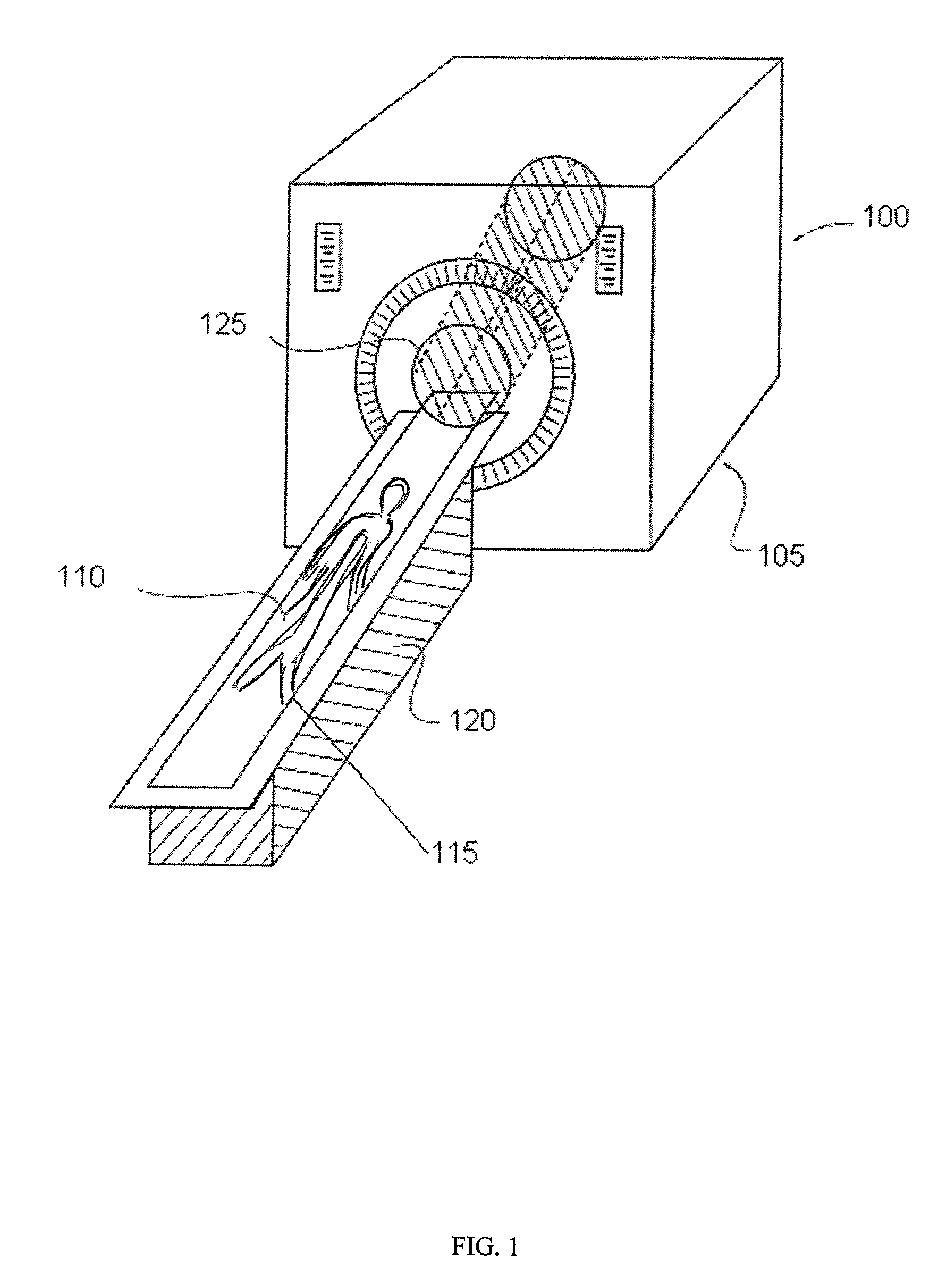

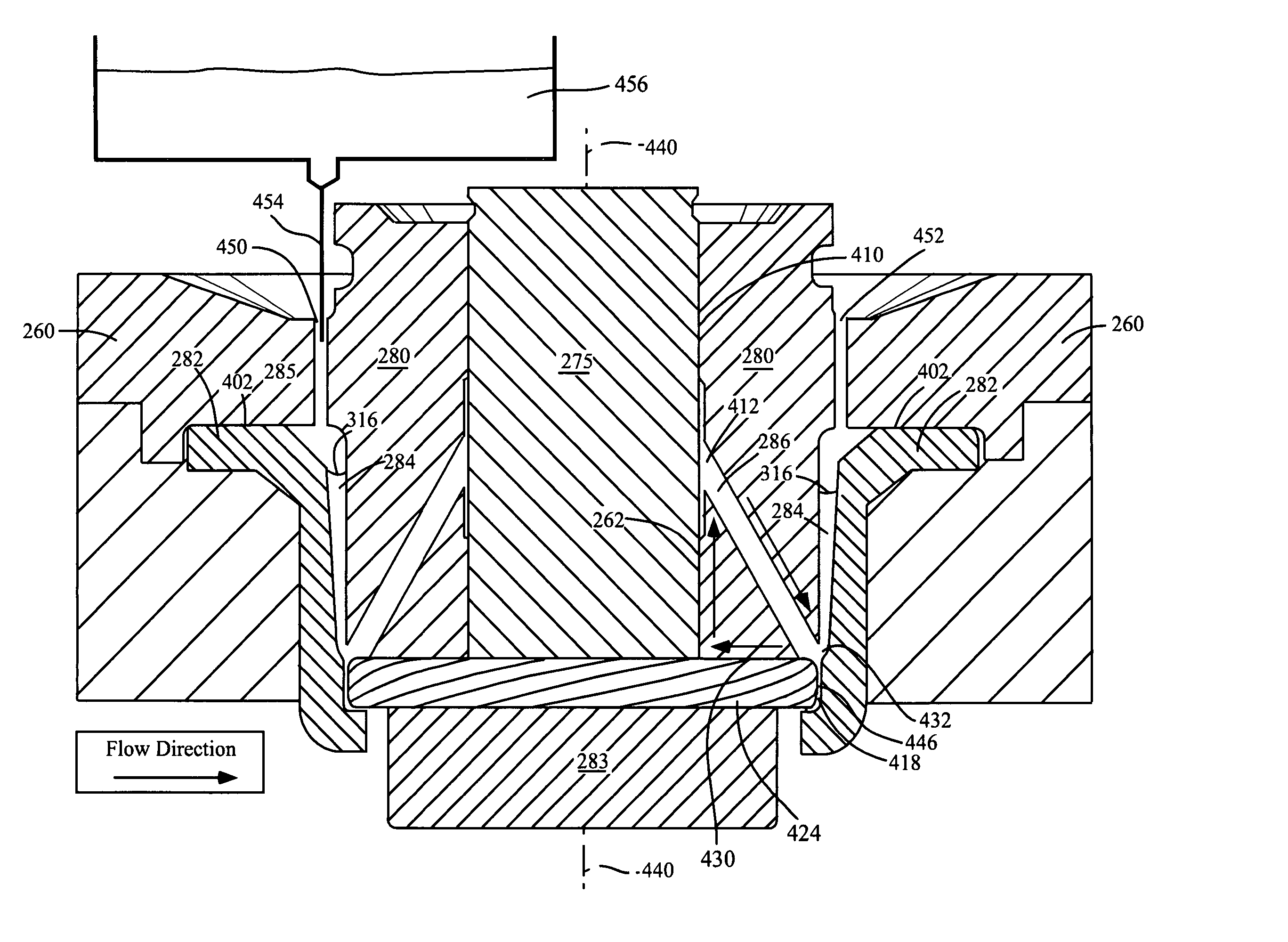

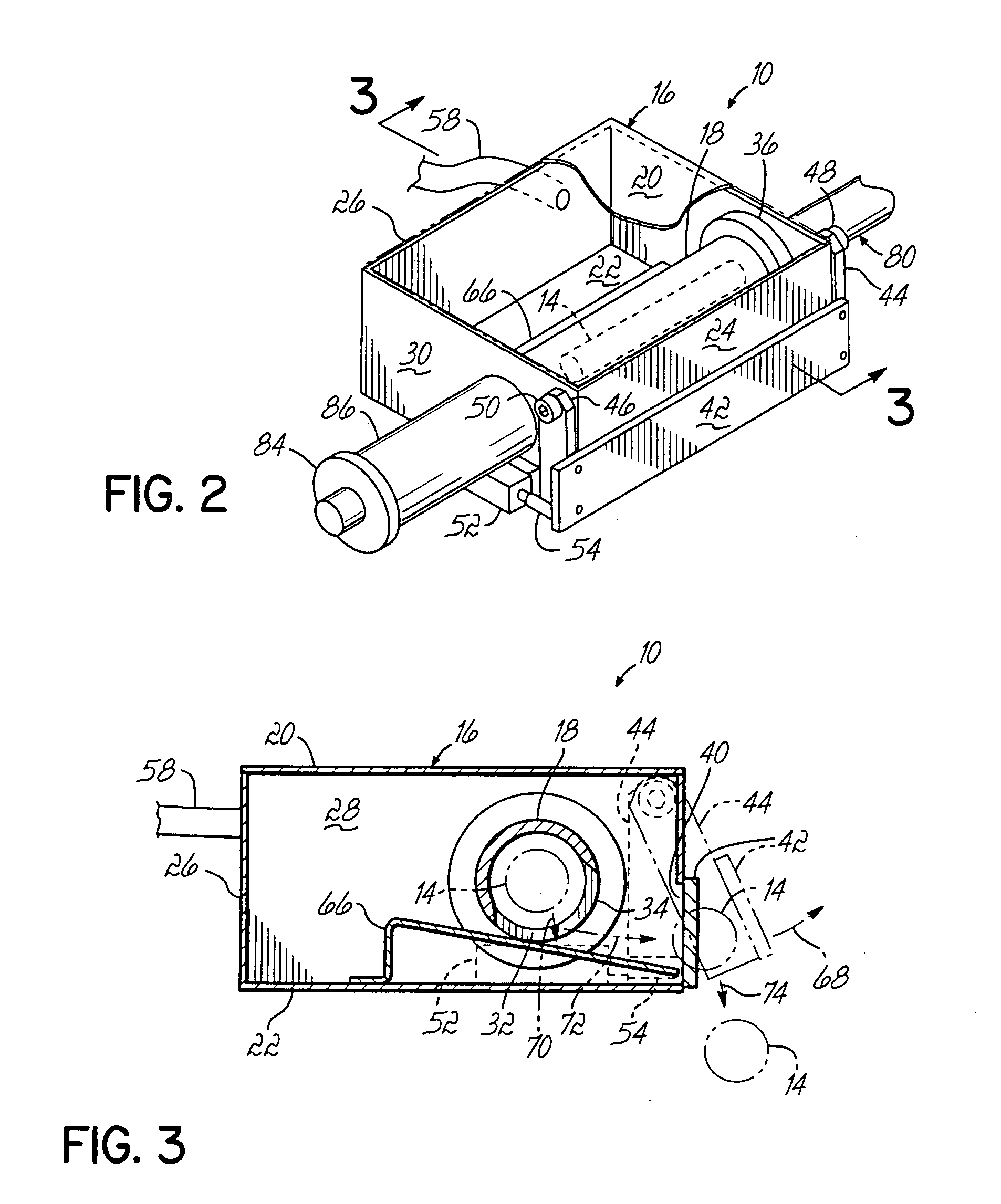

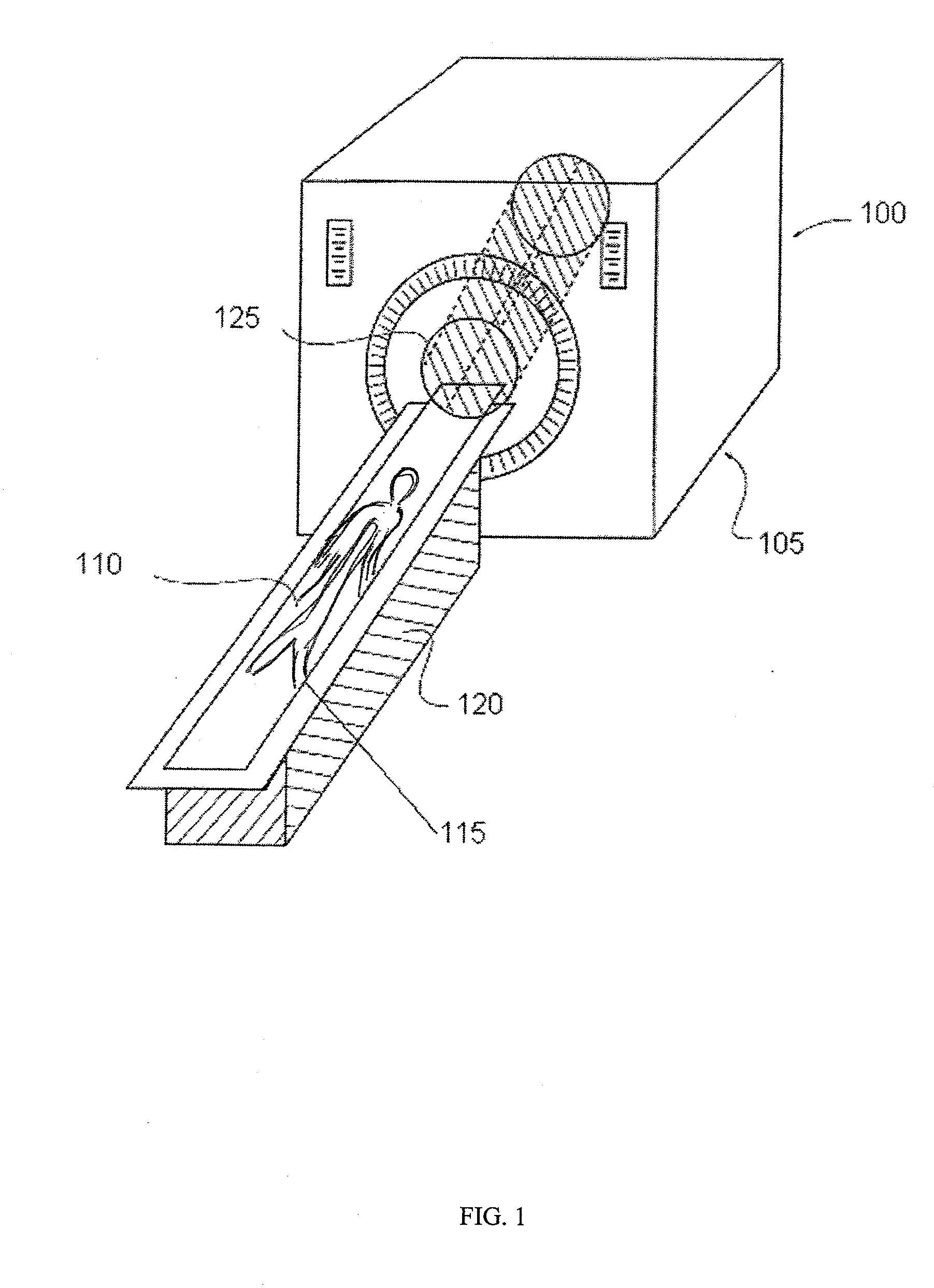

Centrifuge assembly

InactiveUS20070004577A1Minimizes detrimental forceExtend motor lifeCentrifugesAir managementMotor drive

A centrifuge system includes a drive motor mounted independently relative to a sample carrier to eliminate detrimental forces born by a motor drive shaft. The rotatable sample carrier or tray includes a rotating center operably connected to the drive motor. The drive motor cooperates with a resilient mounting system enabling self-centering, force and vibration compensation, and improving motor life. The rotatable sample tray and a sample tube holder have respective operably cooperative contoured surfaces enabling relative smooth pivoting motion in the sample tube holder during rotation, while minimizing sample vibration, and improving the desired sample separation while minimizing sample remixing. An air management system enables effective motor cooling and minimizes sample heating.

Owner:CENTURION LLC

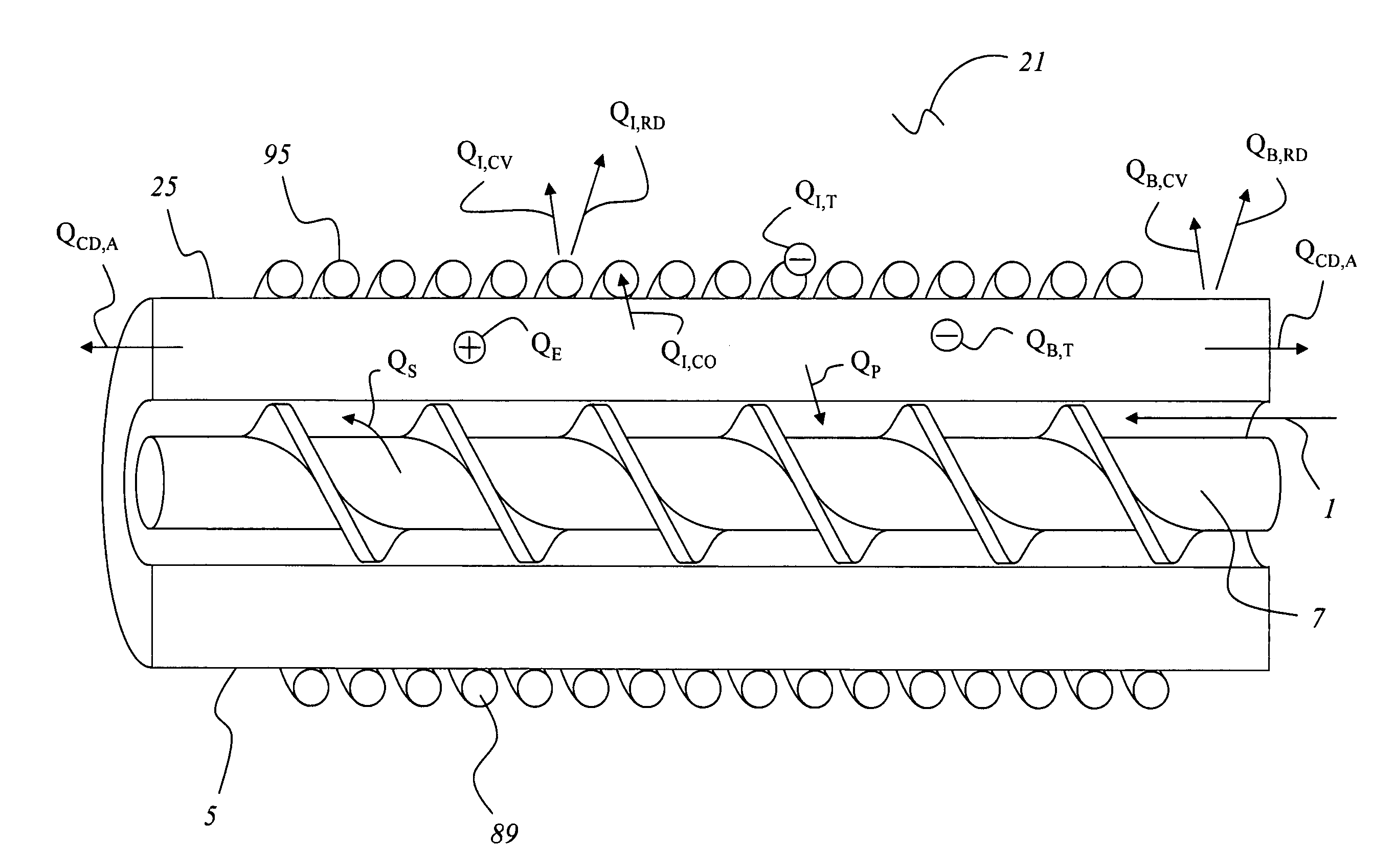

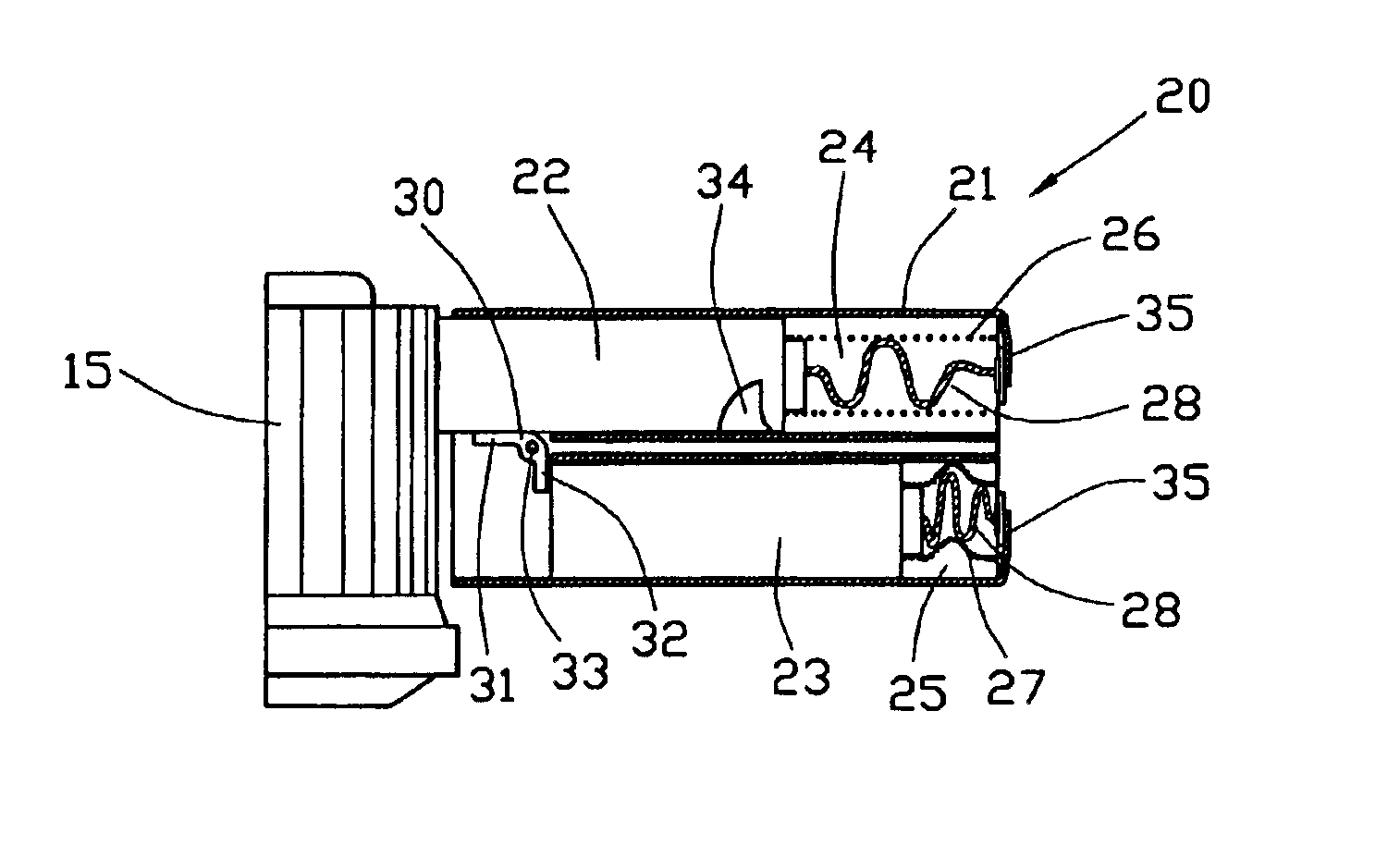

Apparatus and method for inductive heating a workpiece using an interposed thermal insulating layer

InactiveUS20080136066A1Improve heating efficiencyReduce resistanceCoil arrangementsConfectioneryThermal insulationEngineering

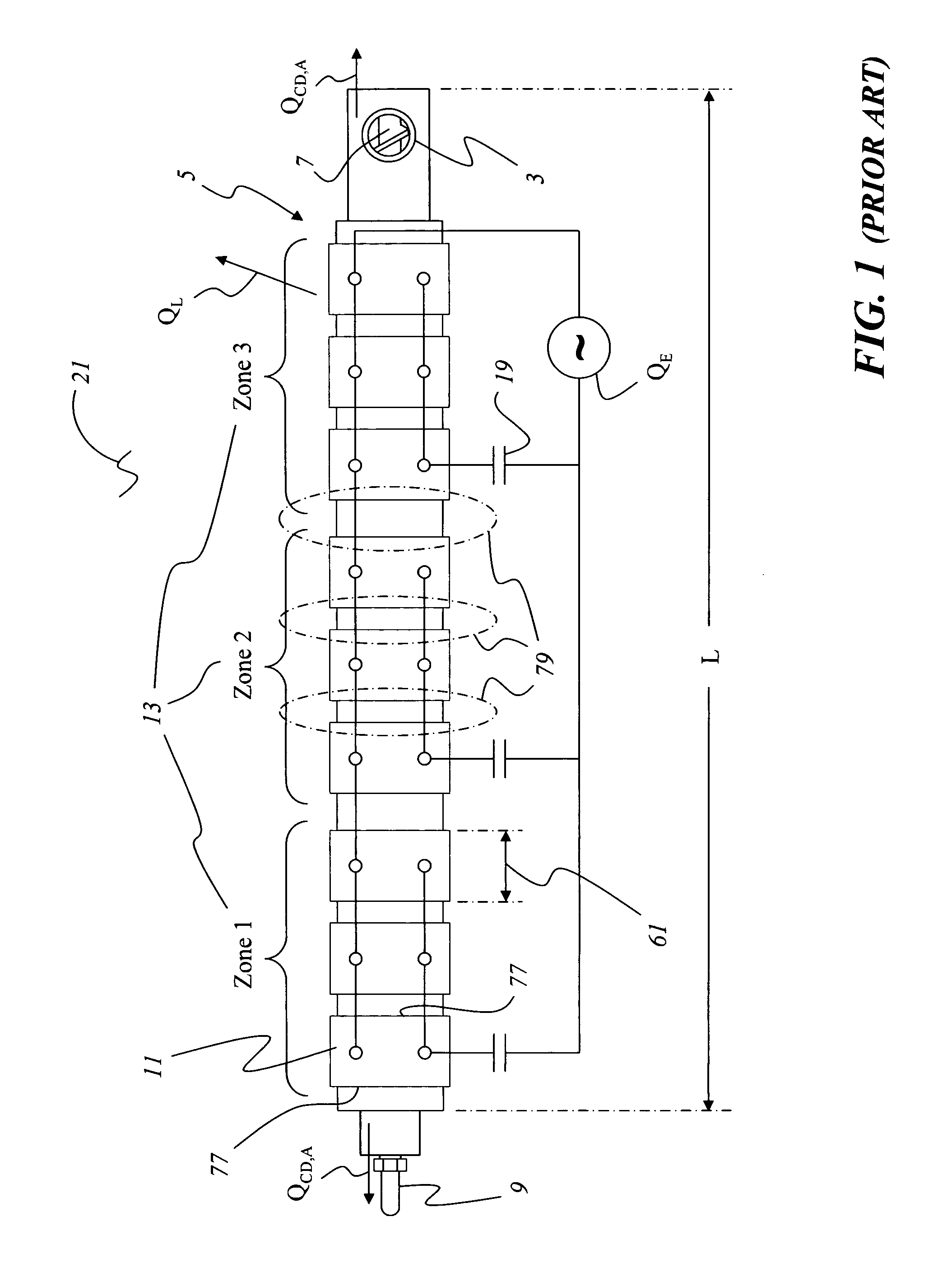

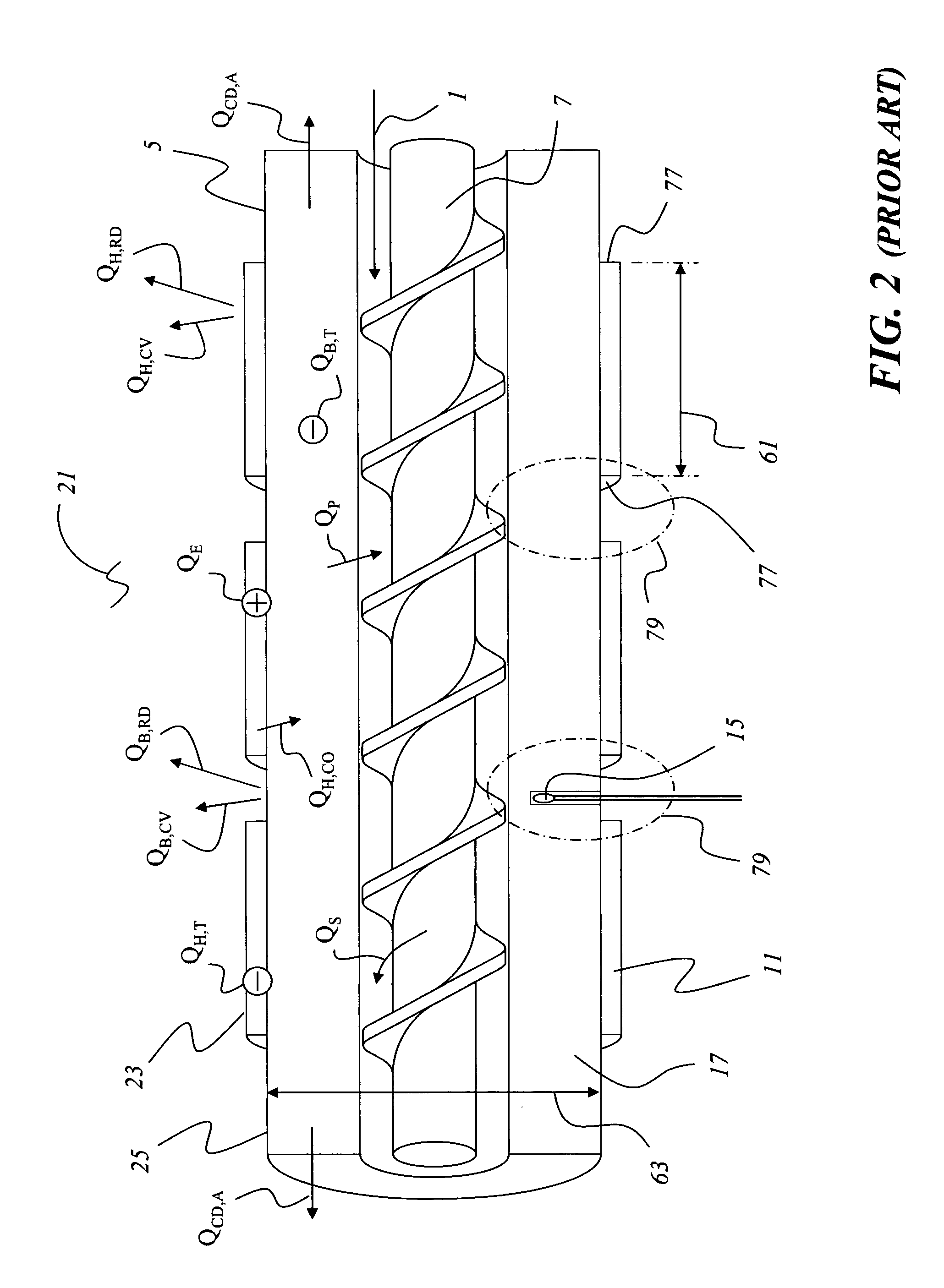

Disclosed herein is an apparatus and method with inductive heating of an electrically conductive workpiece such as a barrel used in molding or extrusion, having a layer of thermal insulation interposed between the induction windings and the workpiece, and using alternating current (AC) at an elevated frequency. Further, variable pitch induction windings may be used to generate a non-uniform and calculated heat input profile, such as to compliment the configuration of a screw for transporting material through the barrel.

Owner:COMAINTEL +1

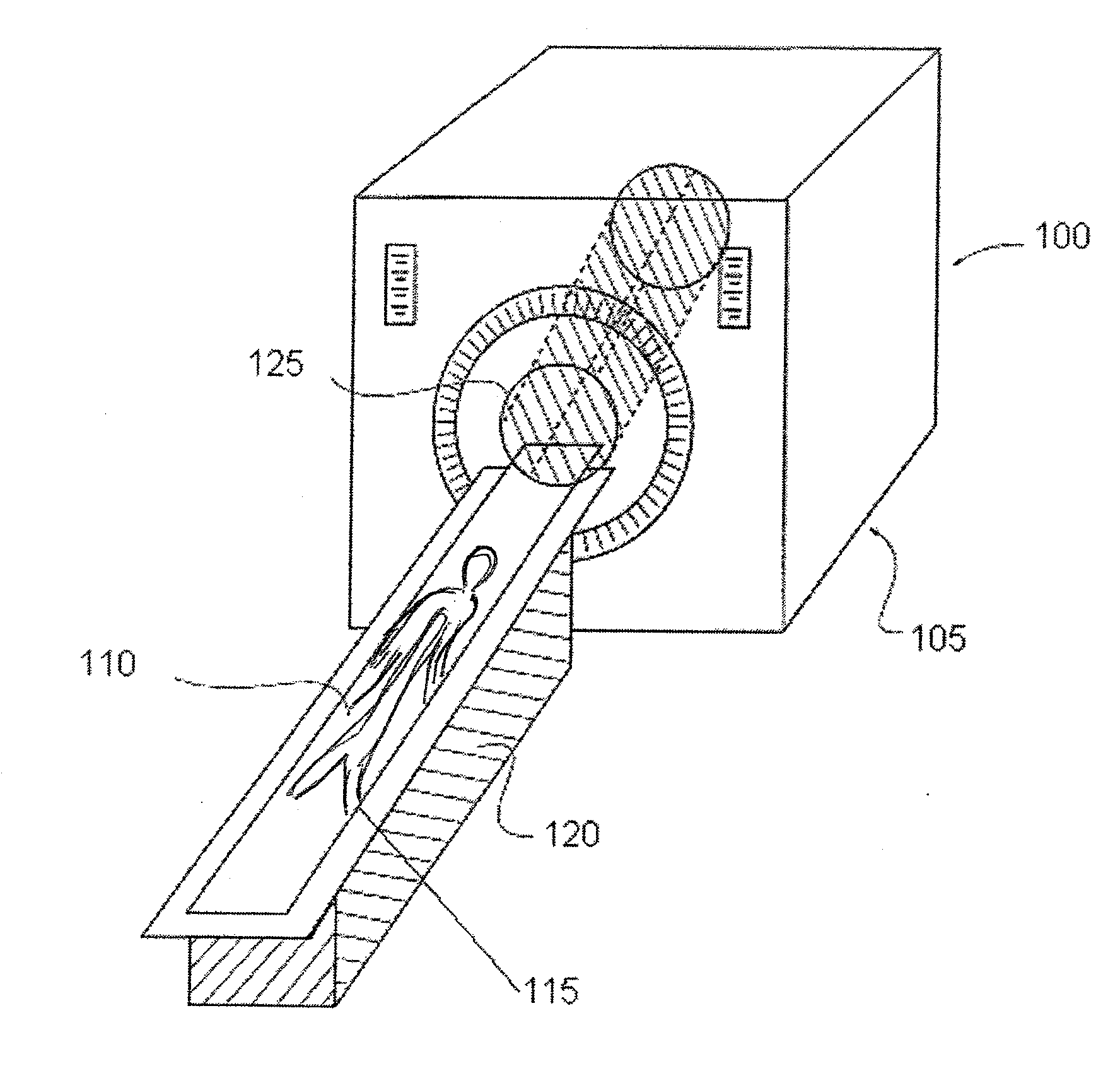

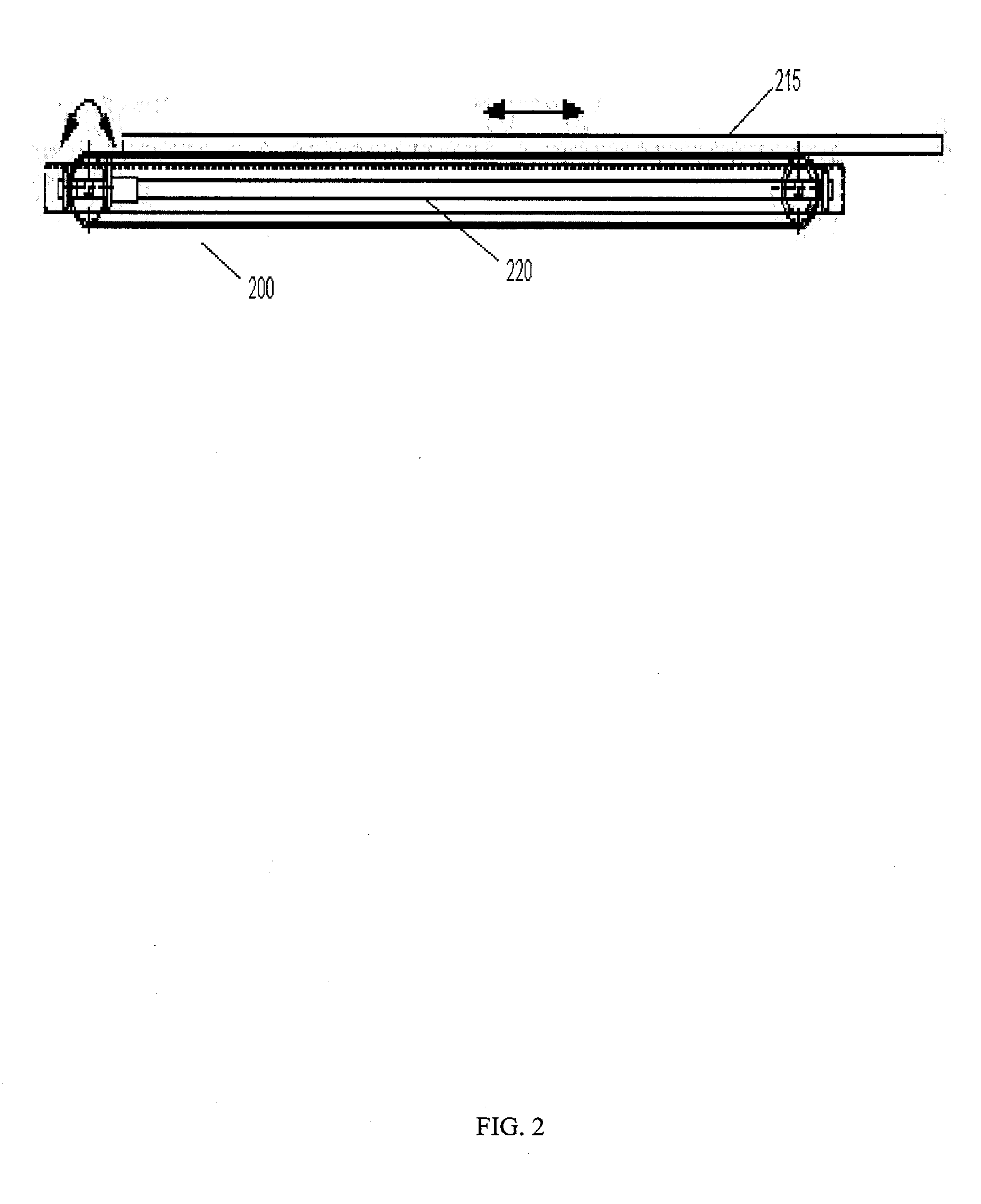

Drive system for imaging device

ActiveUS7437785B2Simple methodImprove securityStretcherPatient positioning for diagnosticsEngineeringImaging equipment

A drive system for an imaging device is provided. The drive system comprises a table assembly for engaging and supporting a patient and a driving system for moving the table assembly. The driving system can be directly coupled to the table assembly. The table assembly comprises a carrier that engages and supports a patient and at least two elongated rails placed beneath the carrier and extending between the opposing sides of the table assembly. The driving system for moving the table assembly comprises at least one double end shaft motor, at least one belt coupled to the double end shaft motor via a coupling device and at least one pair of timer pulleys coupled to the belt. Further, each timer pulley is directly coupled to a feedback device at a first end and a brake device at a second end.

Owner:GENERAL ELECTRIC CO

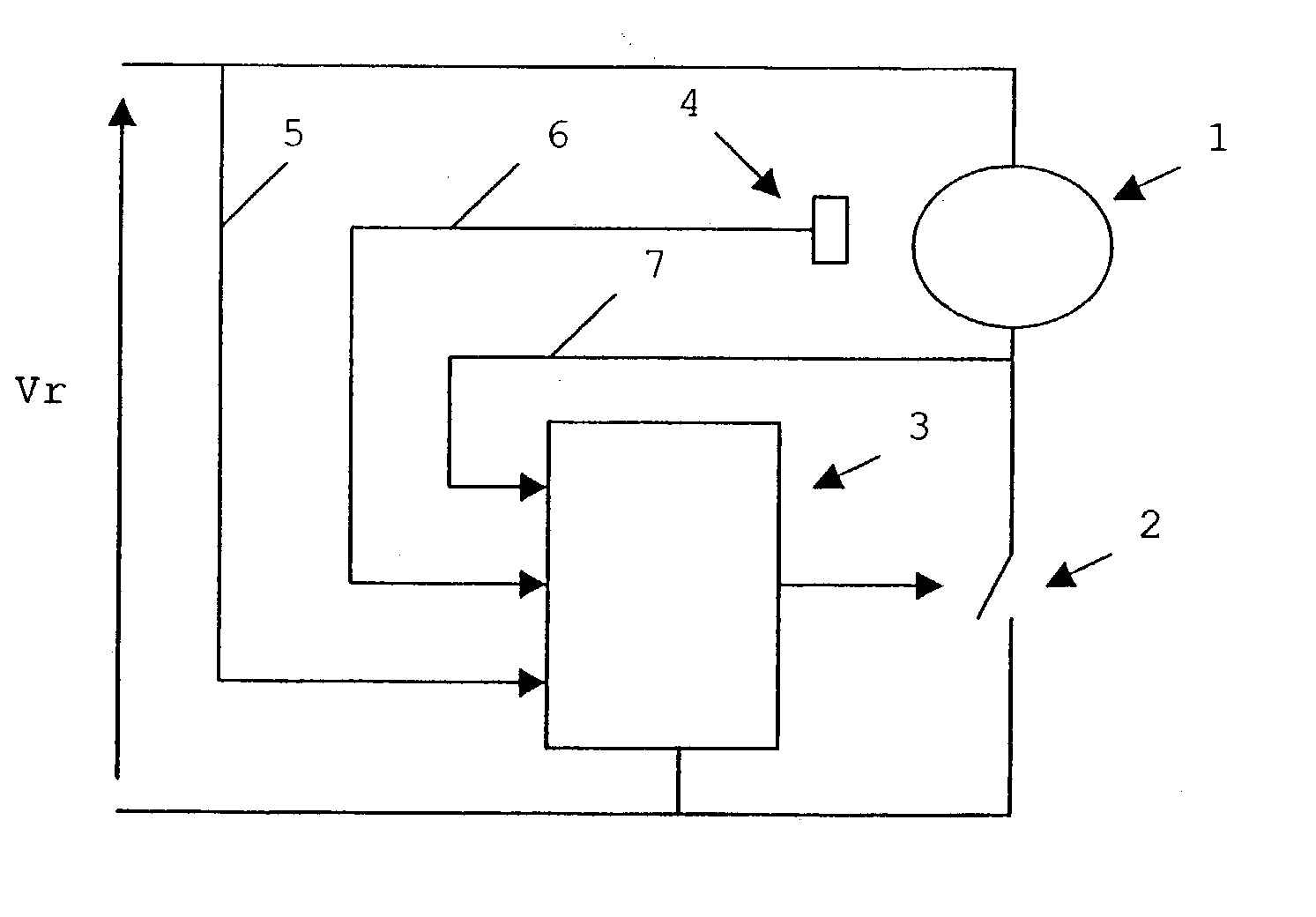

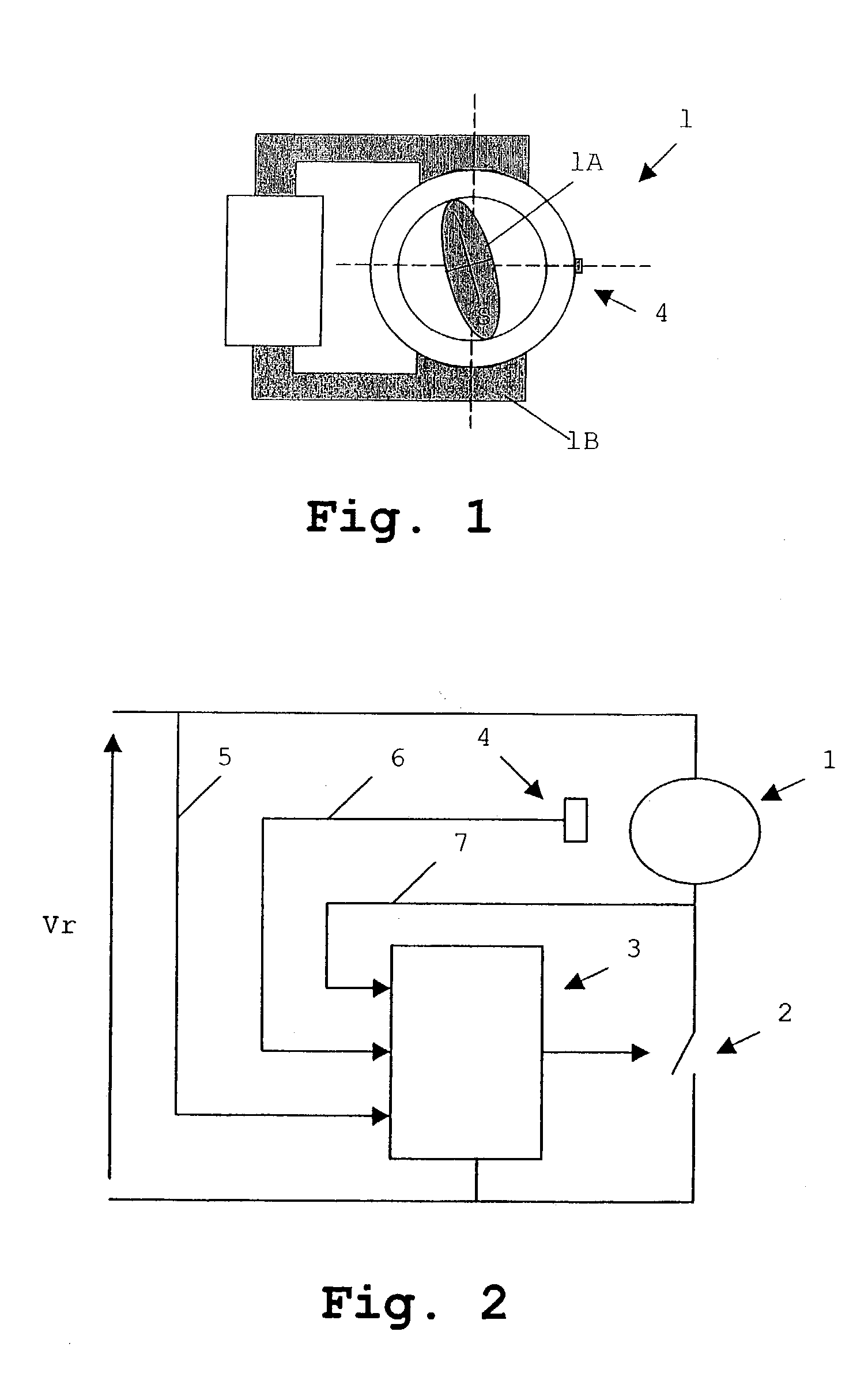

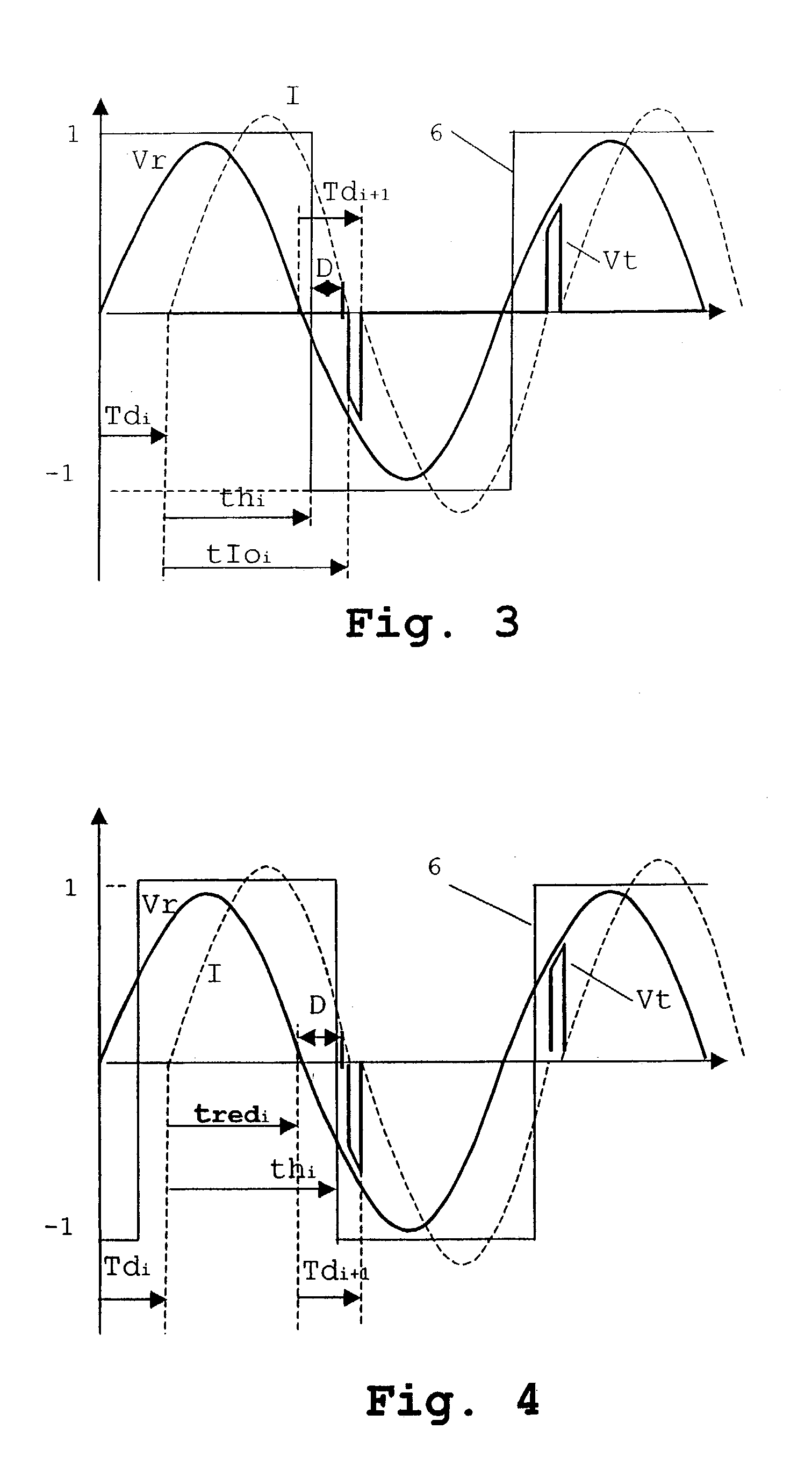

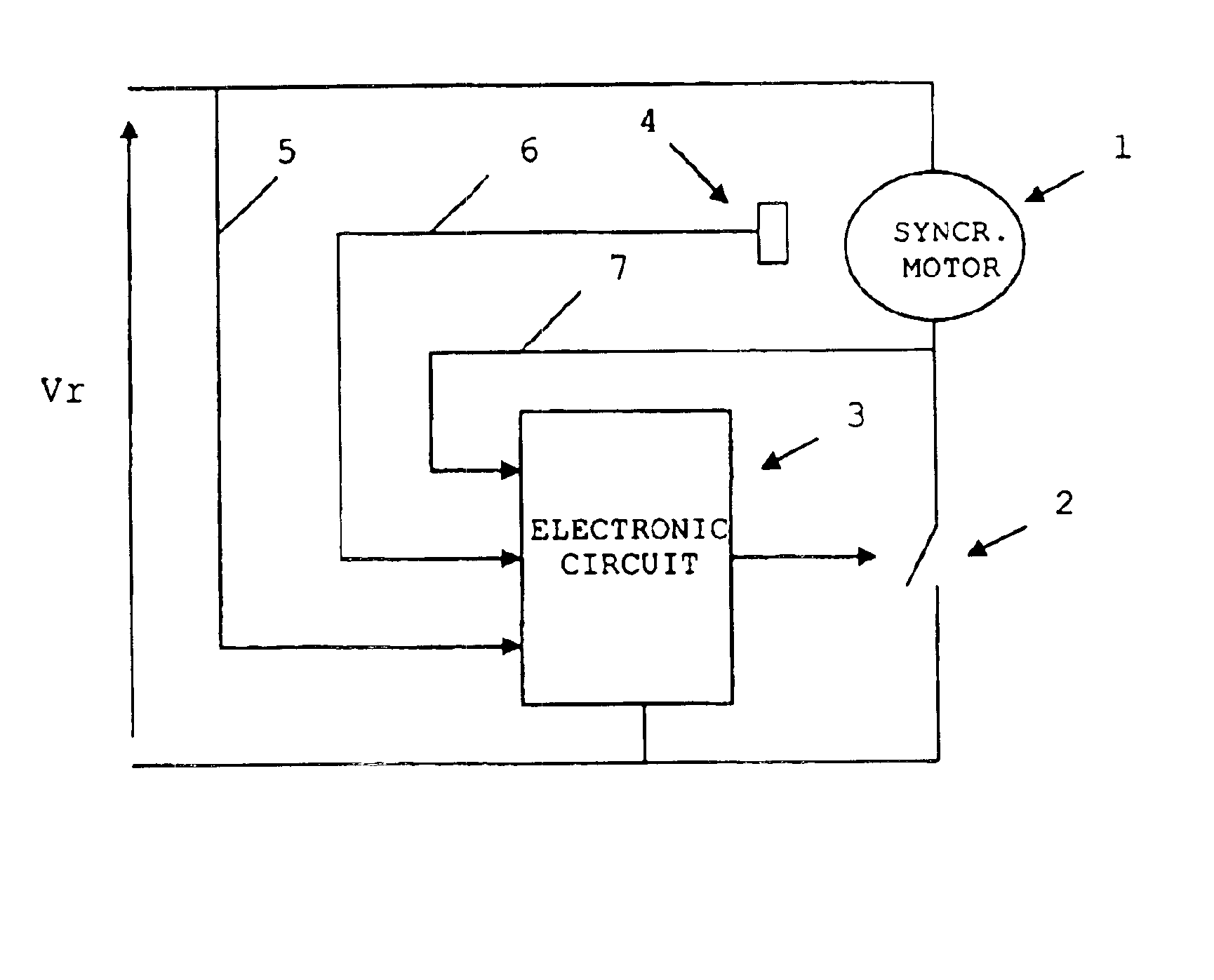

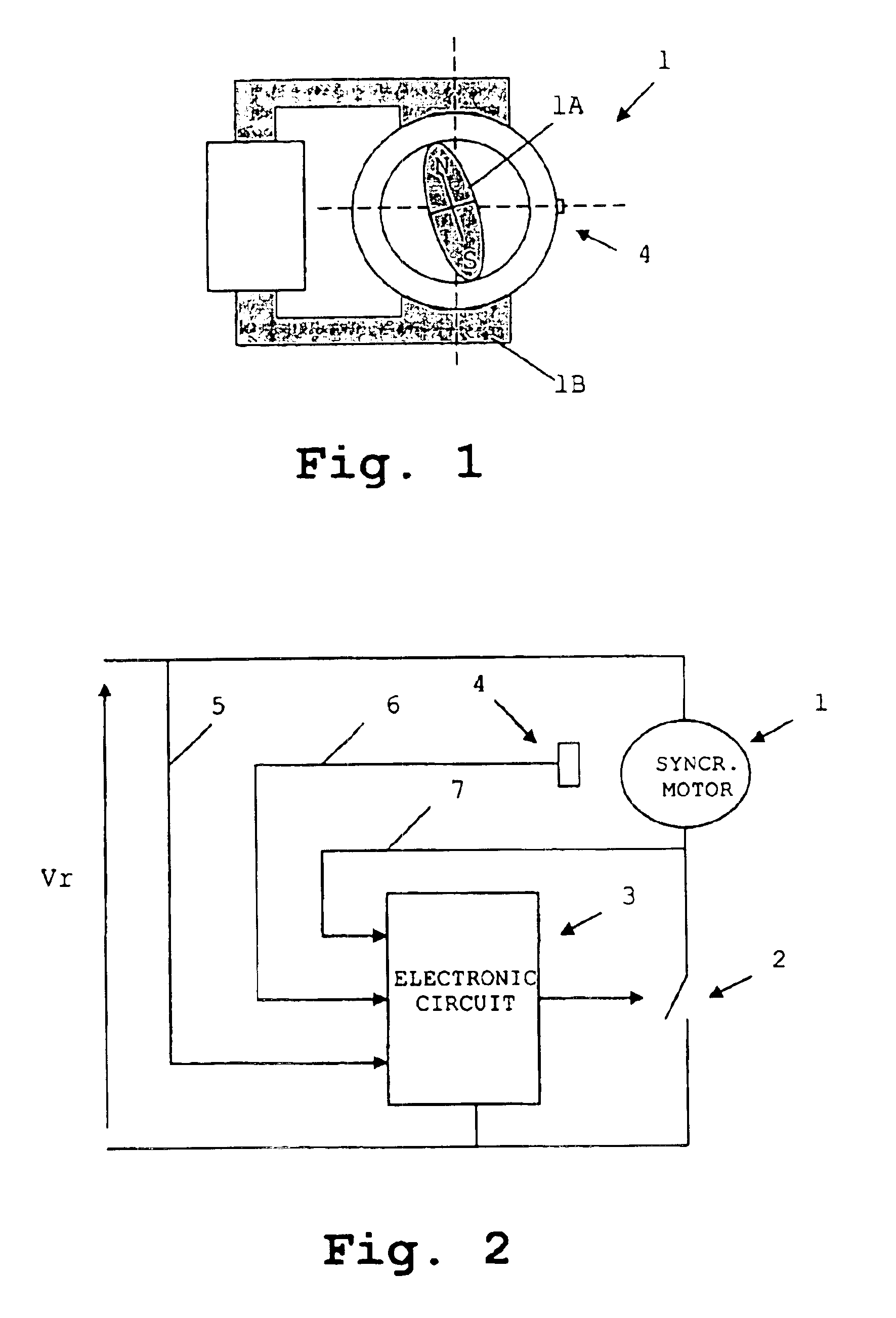

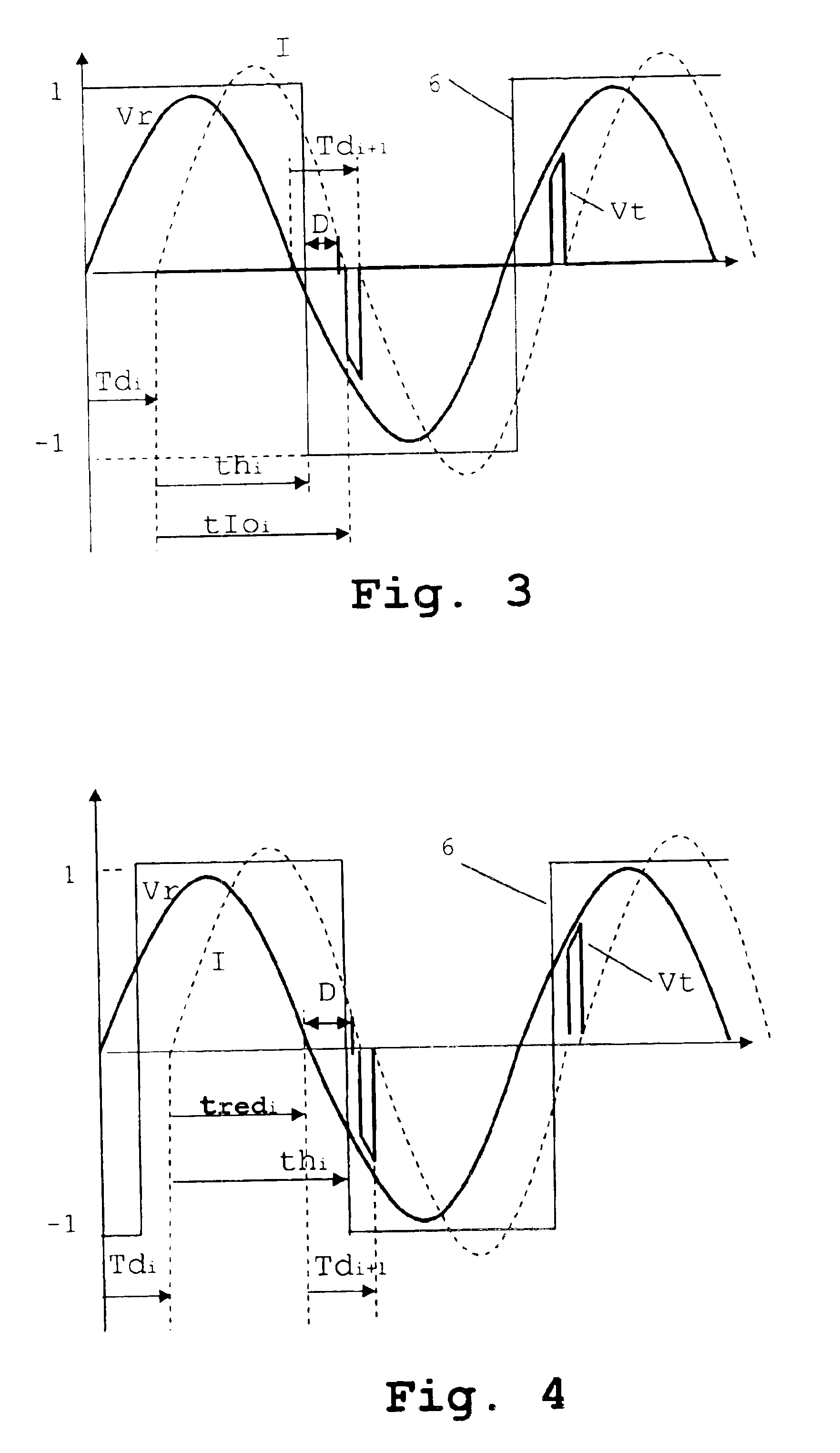

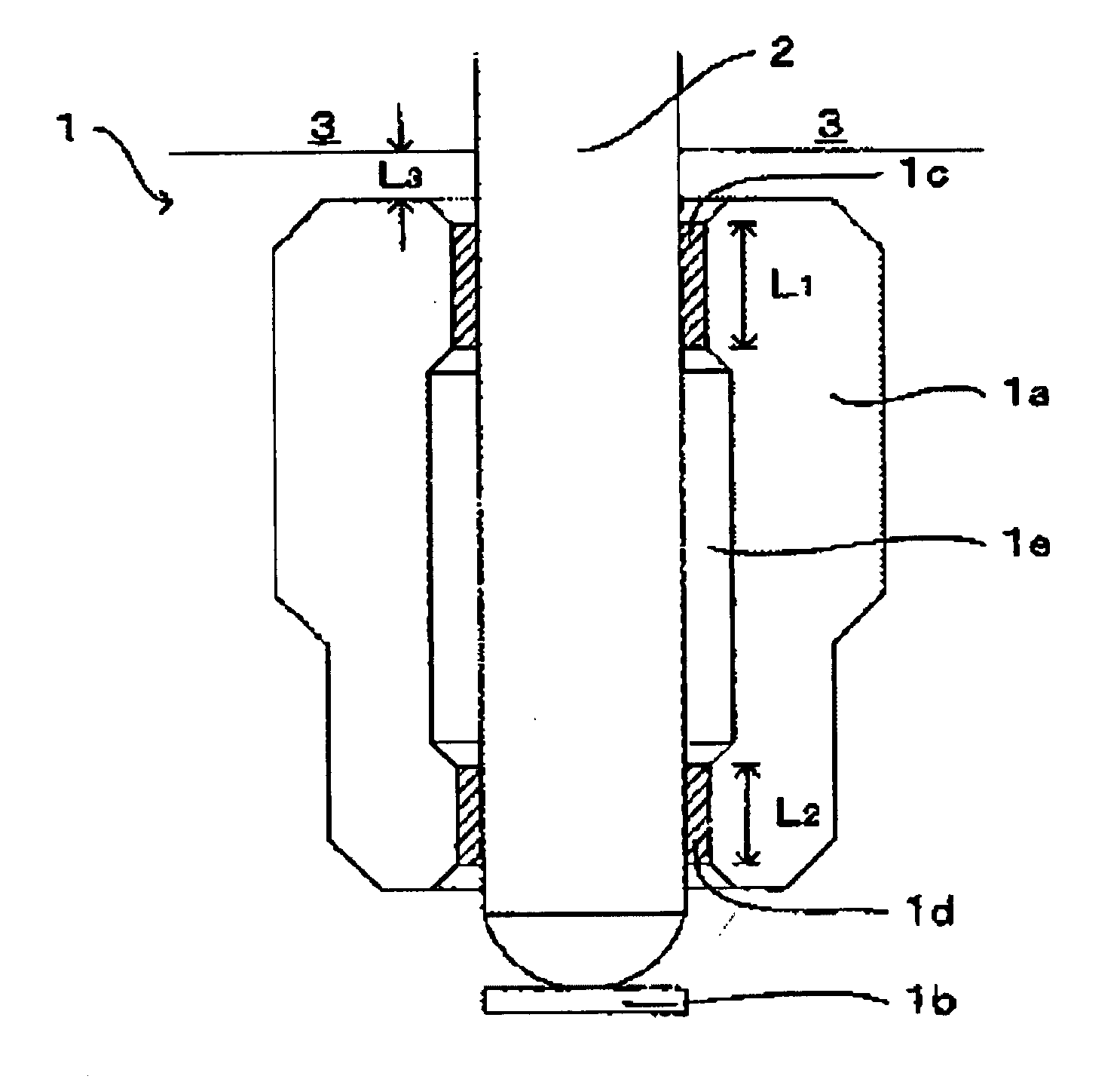

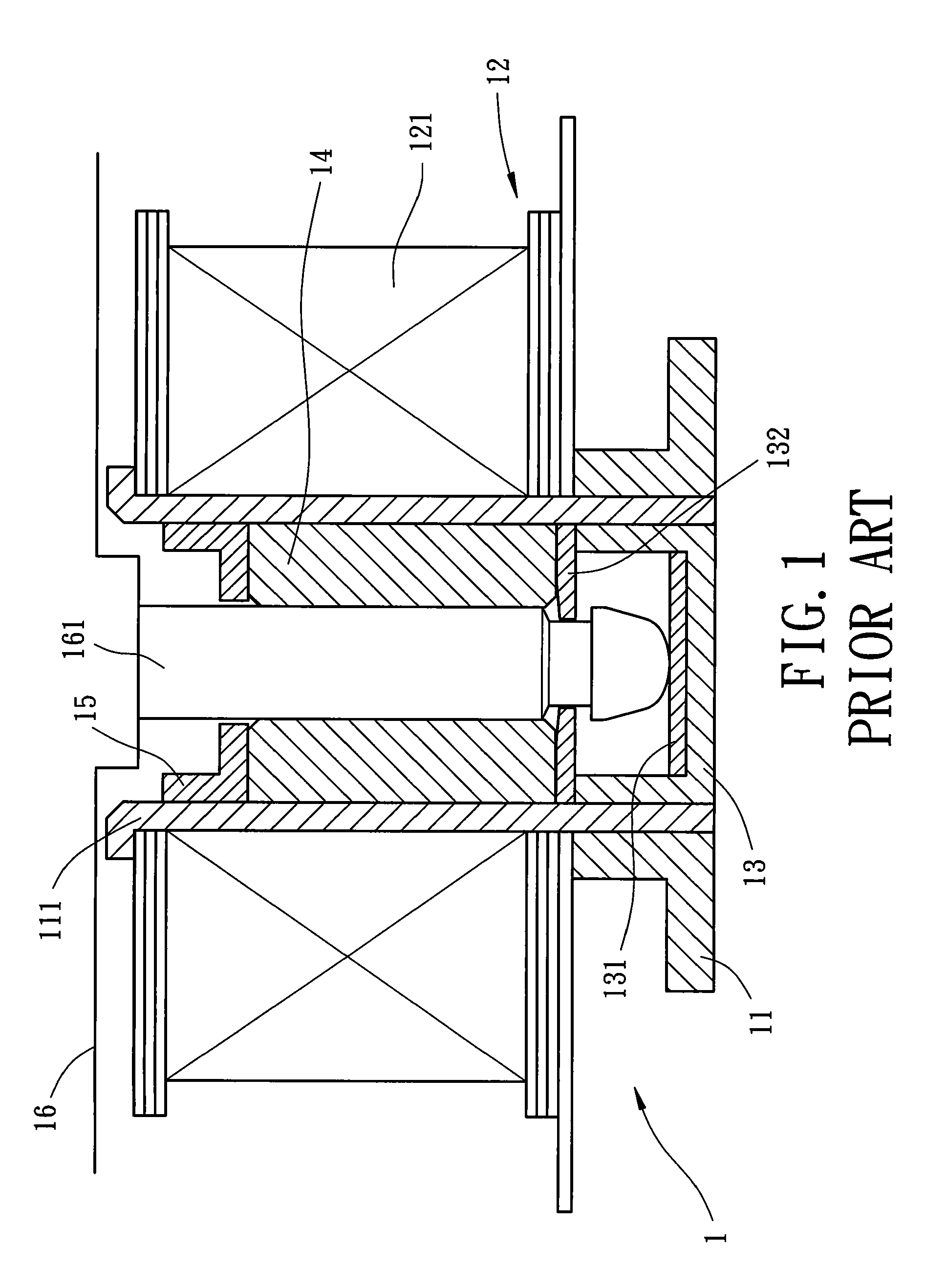

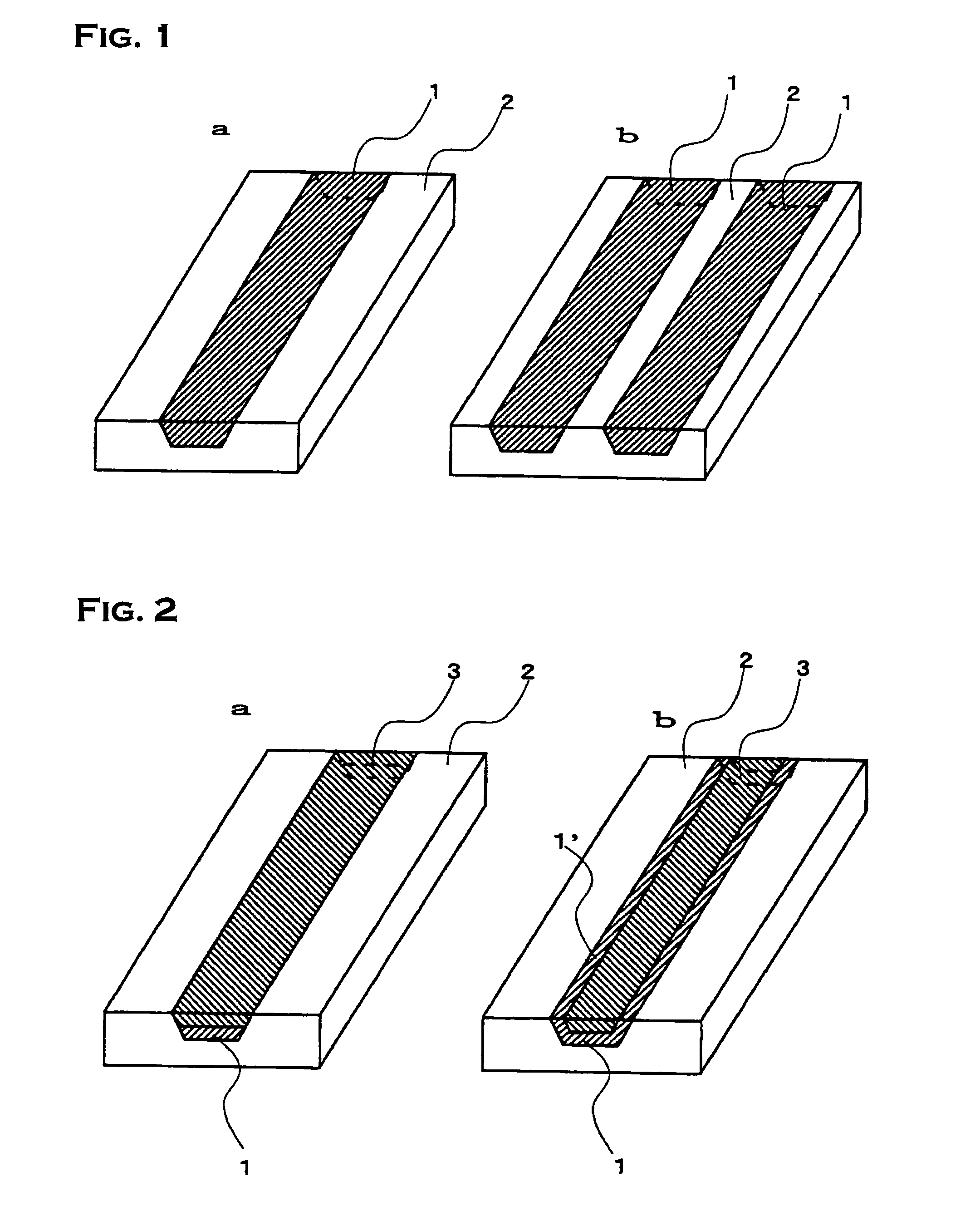

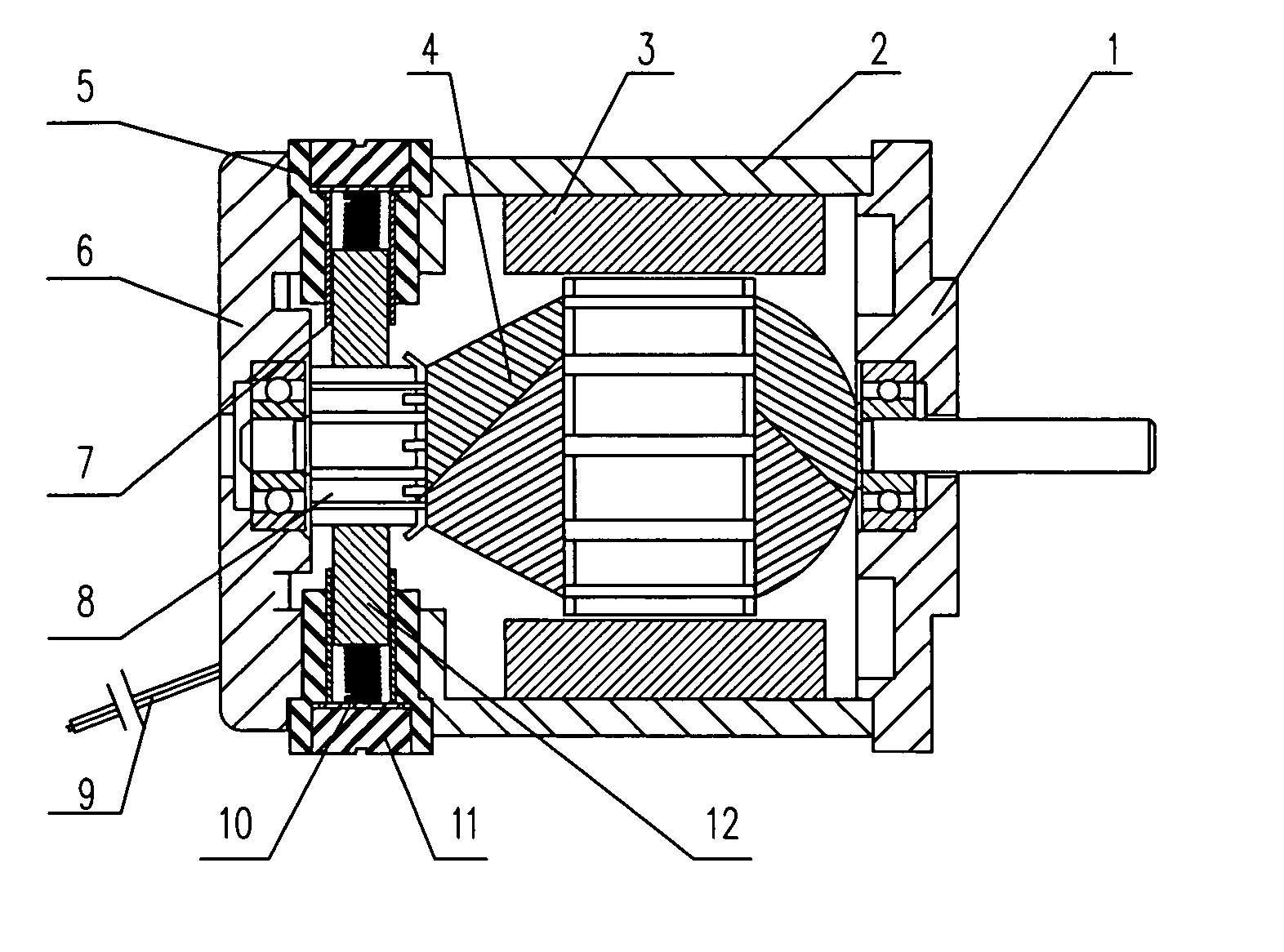

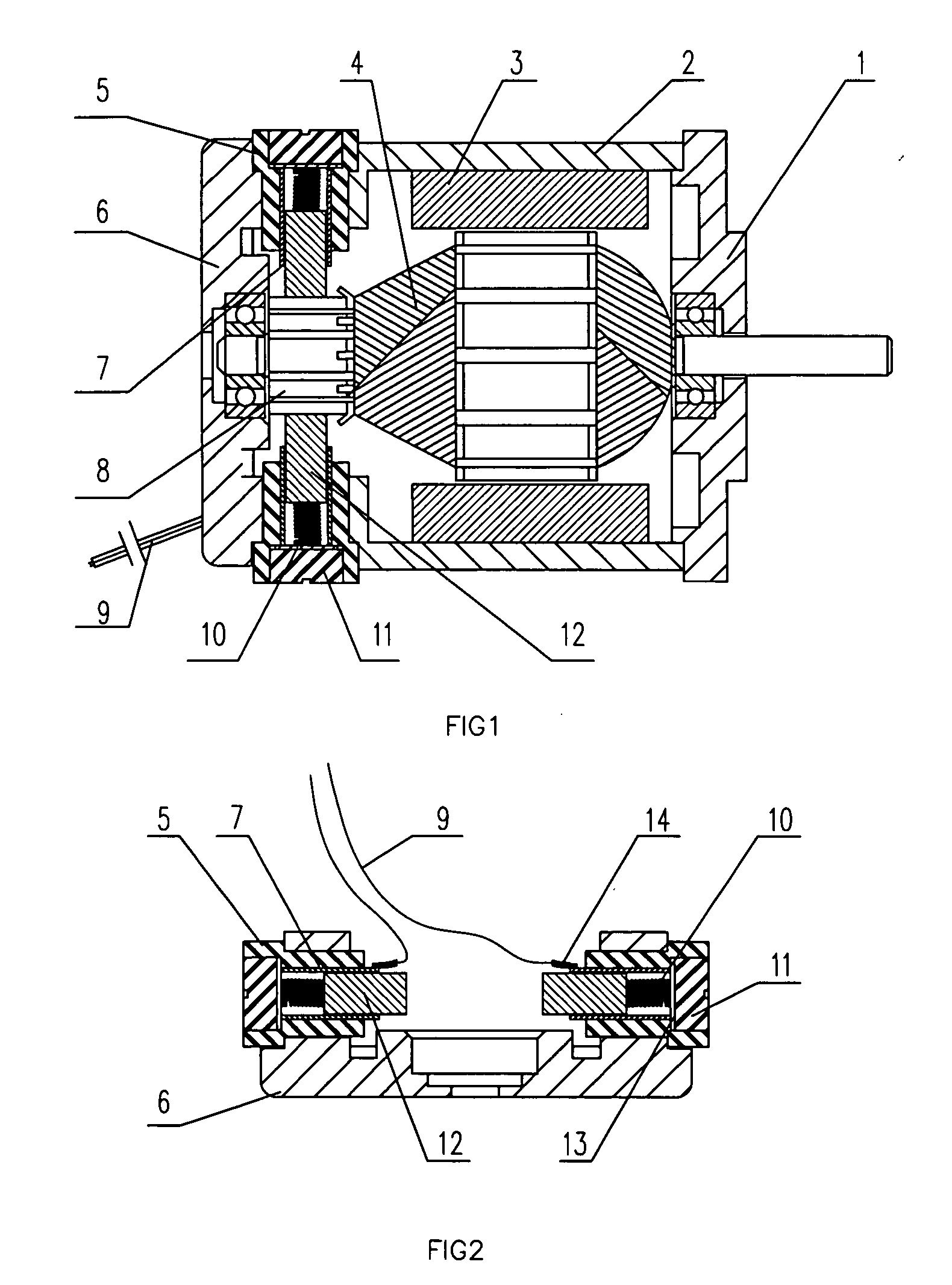

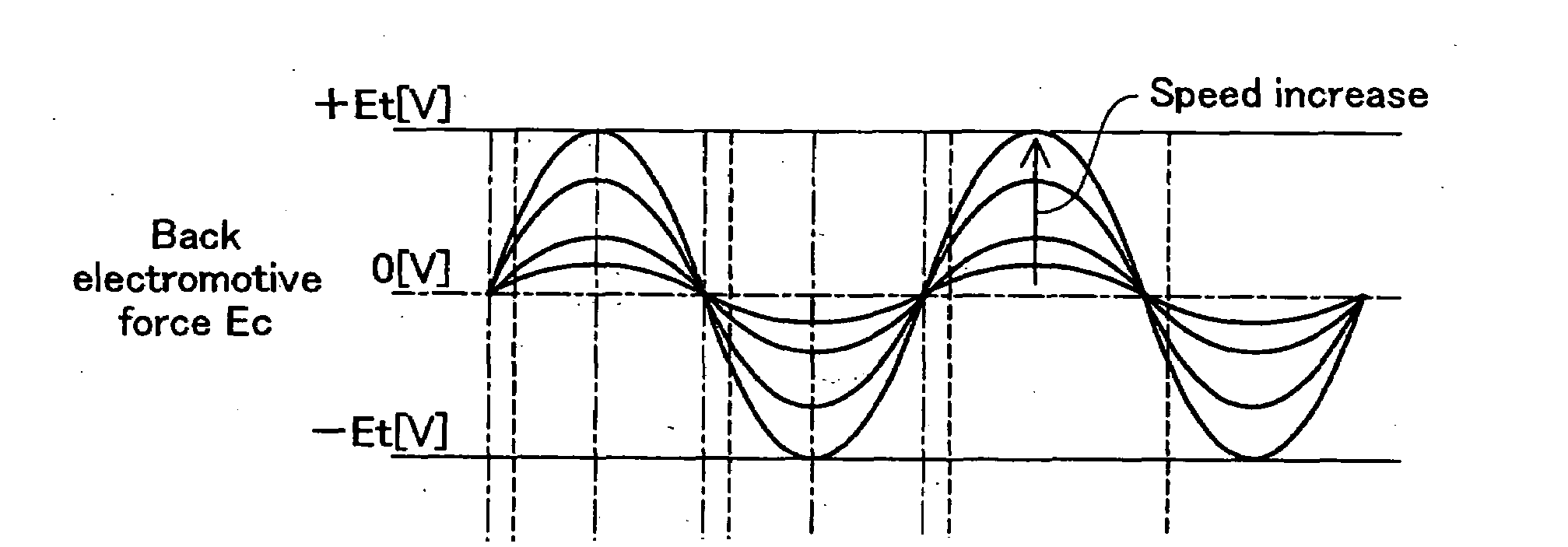

Electronic device for controlling a synchronous motor with permanent-magnet rotor

InactiveUS20030230999A1Reduce vibrationExtend motor lifeMotor/generator/converter stoppersSynchronous motors startersPermanent magnet rotorSynchronous motor

Electronic device for controlling a synchronous motor with permanent-magnet rotor, comprising an alternating voltage current source at mains frequency connected in series with said synchronous motor (1), at least one static switch (2) connected in series with said synchronous motor (1), and an electronic circuit (3) that acts on said static switch (2). Said electronic circuit (3) determines the timing for the firing of the static switch (2) taking as reference the zero-crossing of the mains voltage (Vr) and applying a firing time (Td) starting from said reference, said firing time (Td) being obtained as a function of the position of the rotor (1A) of the motor (1) in the previous half-cycles.

Owner:FAGOR

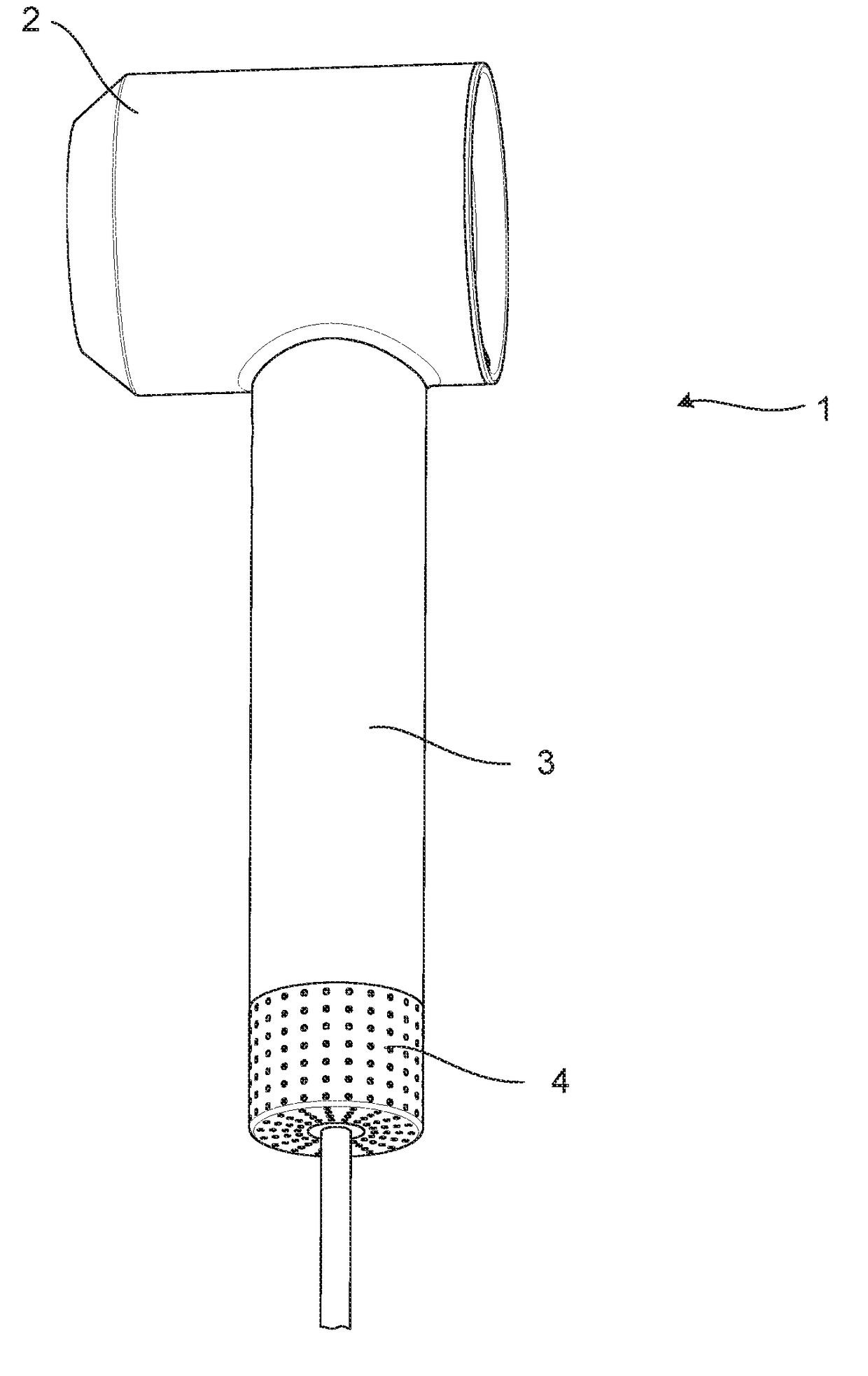

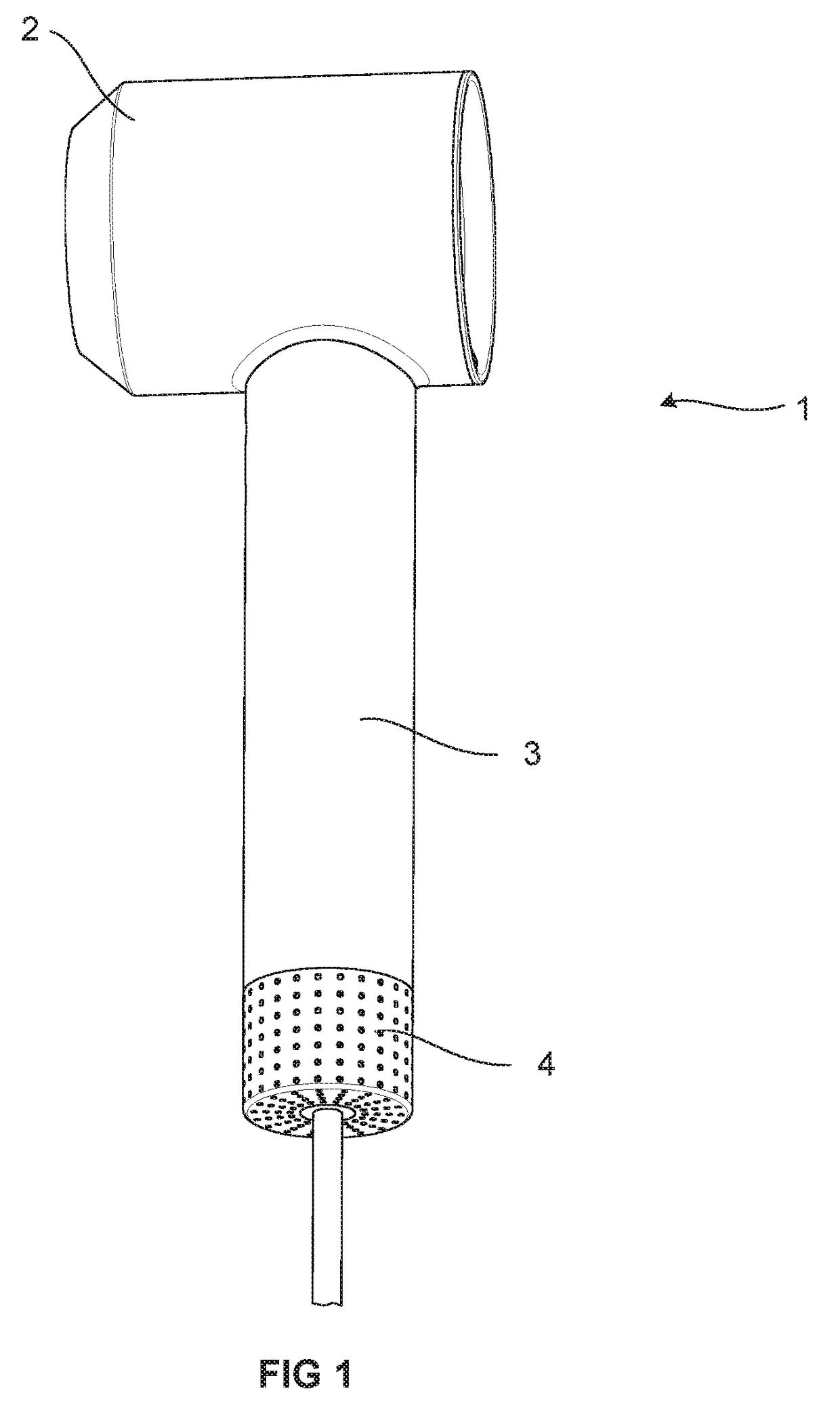

Versatile compact air precleaner, air cleaning method and disposable air filter cartridge for air precleaner

ActiveUS20130025454A1Adversely effect timeAdversely cost manufactureCombination devicesLiquid degasificationParticulate debrisAir filter

A versatile compact air precleaner for separating heaver-than-air particulate debris from debris laden air has a retroflexed flow path through a separator chamber. A motor of a motor-driven fan is located in the flow path downstream from the separator chamber. A plurality of independently rotatably adjustable housing sections of a housing are formed with respective ones of the air precleaner debris laden air inlet, particulate debris ejector ports, clean air outlet, and mounts for mounting the air precleaner to a support to provide utility with multiple clean air outlet configurations, directions of ejection of particulate debris from the ejector ports, inlet configurations, precleaner sides for mounting, and filter sizes. A separator chamber end section including the ejector ports and the filter are connected forming a removable, disposable air filter cartridge which obviates ejector port clogging with change of filters.

Owner:SY KLONE

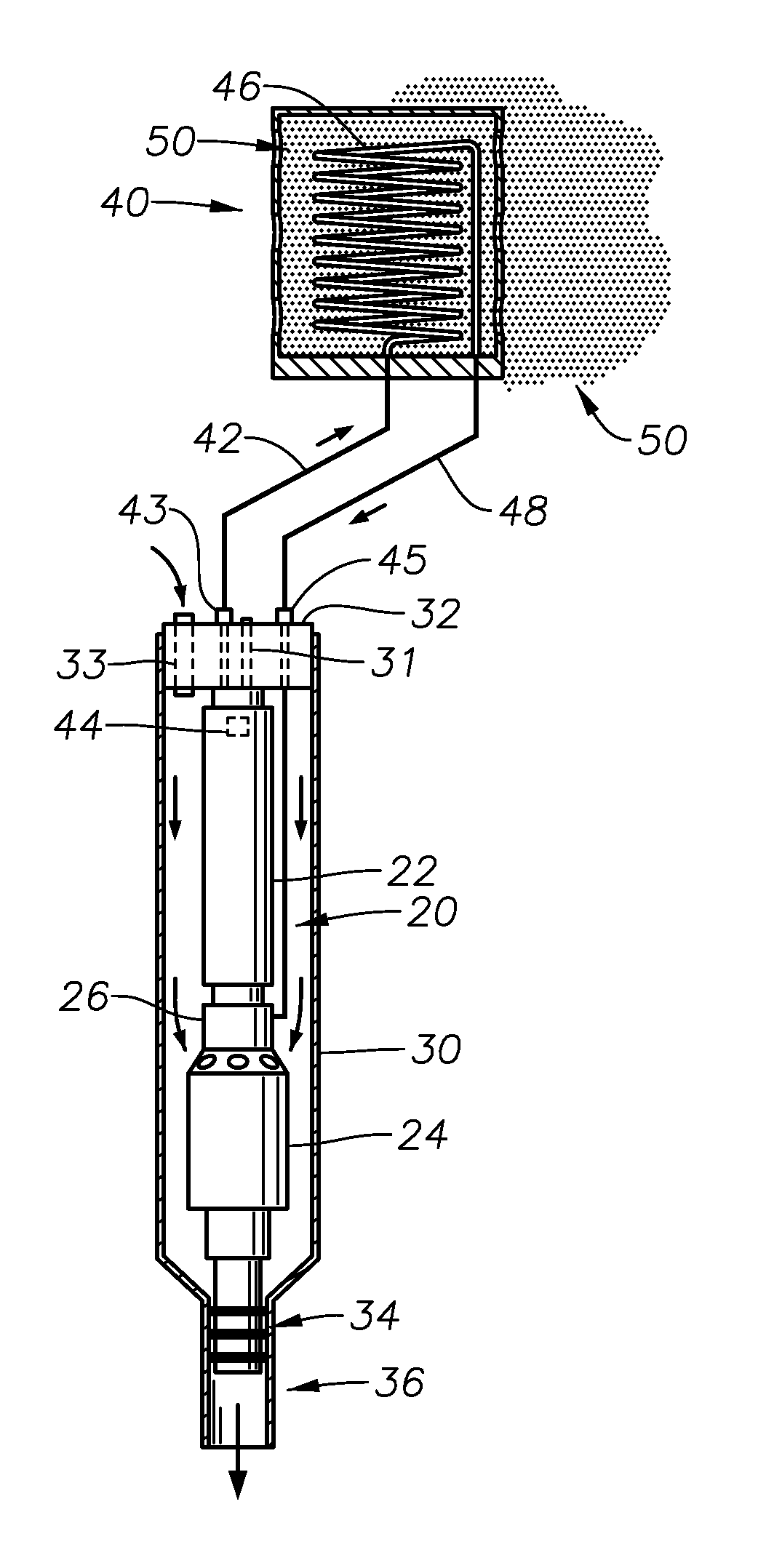

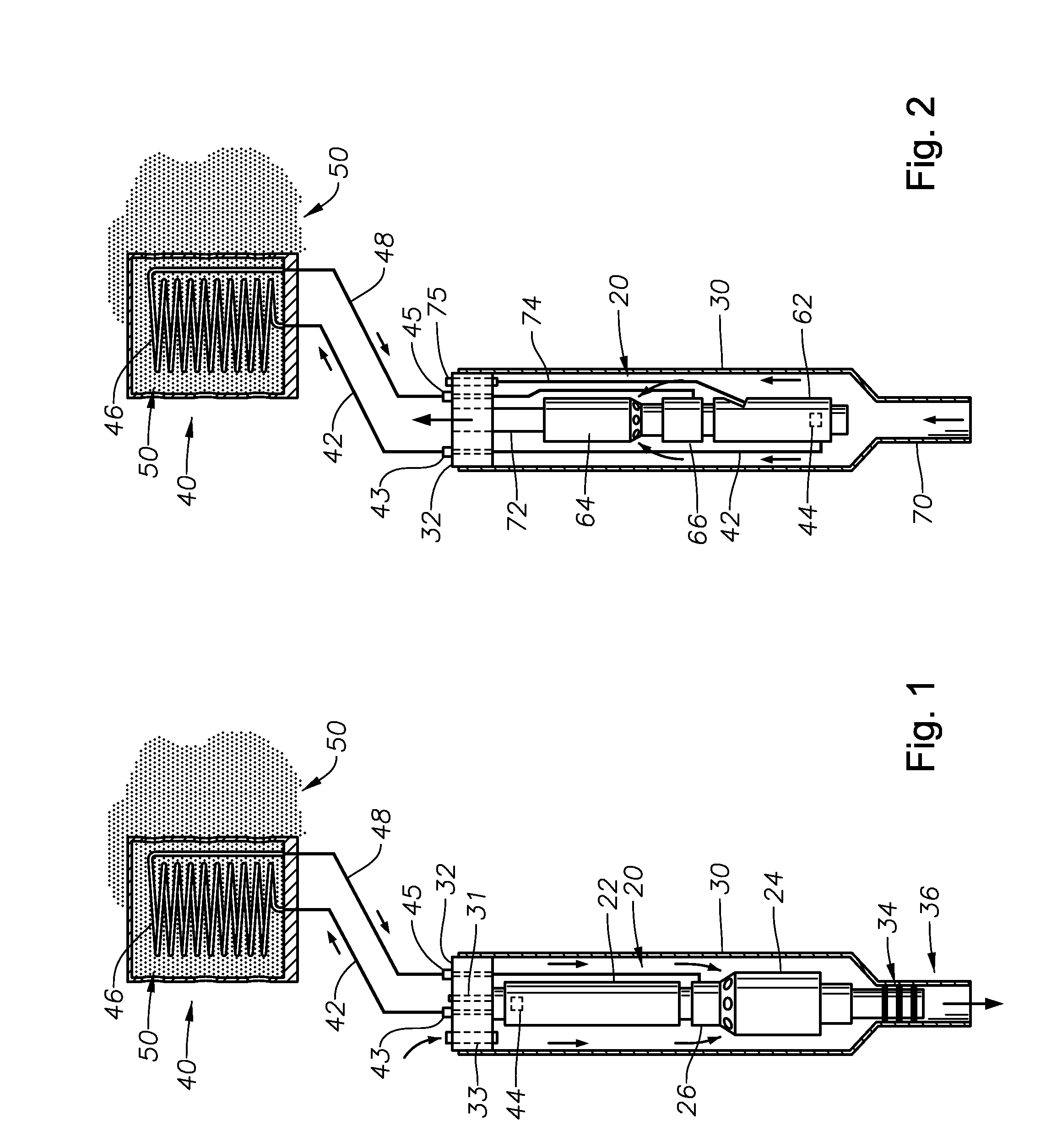

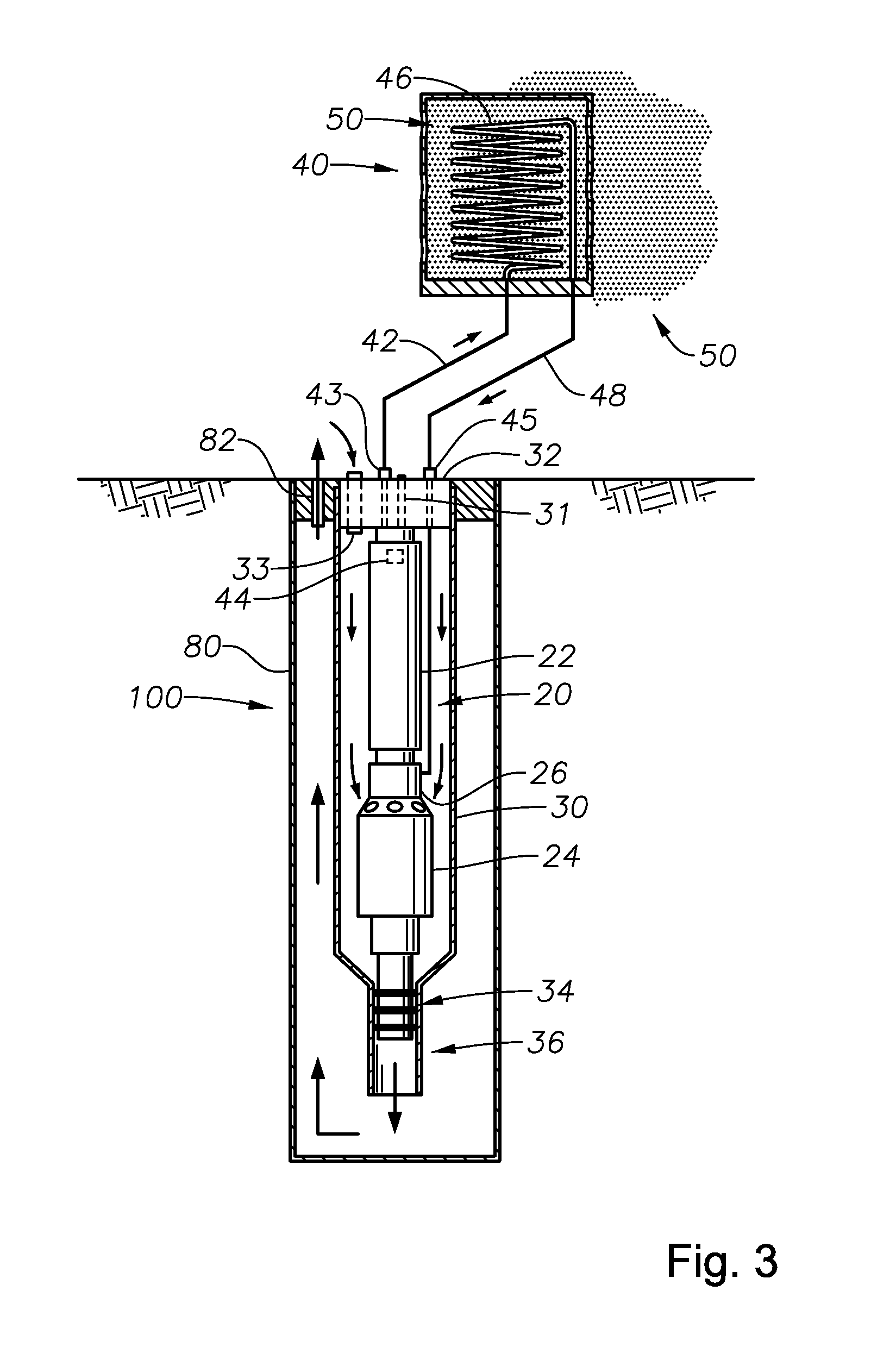

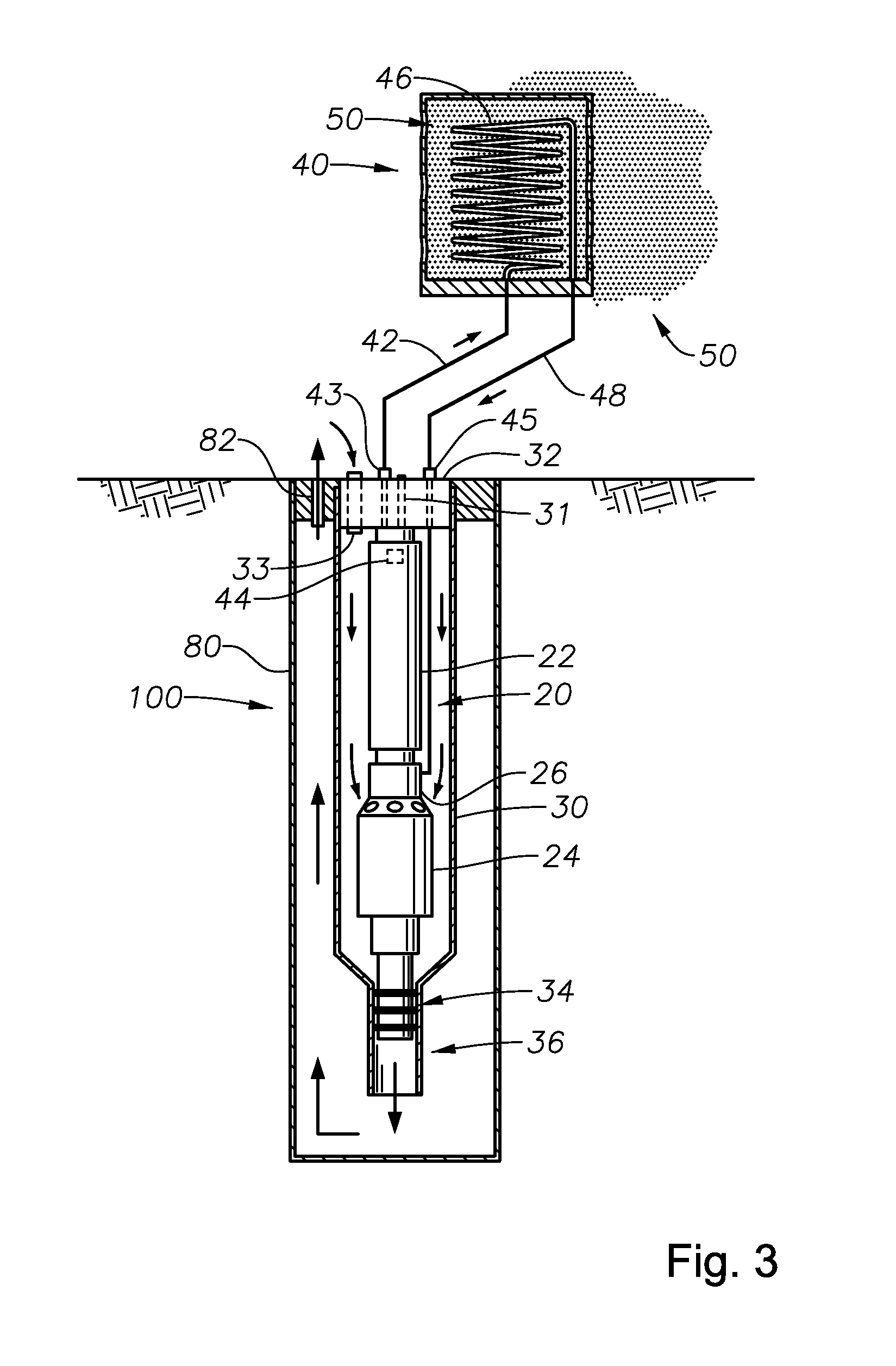

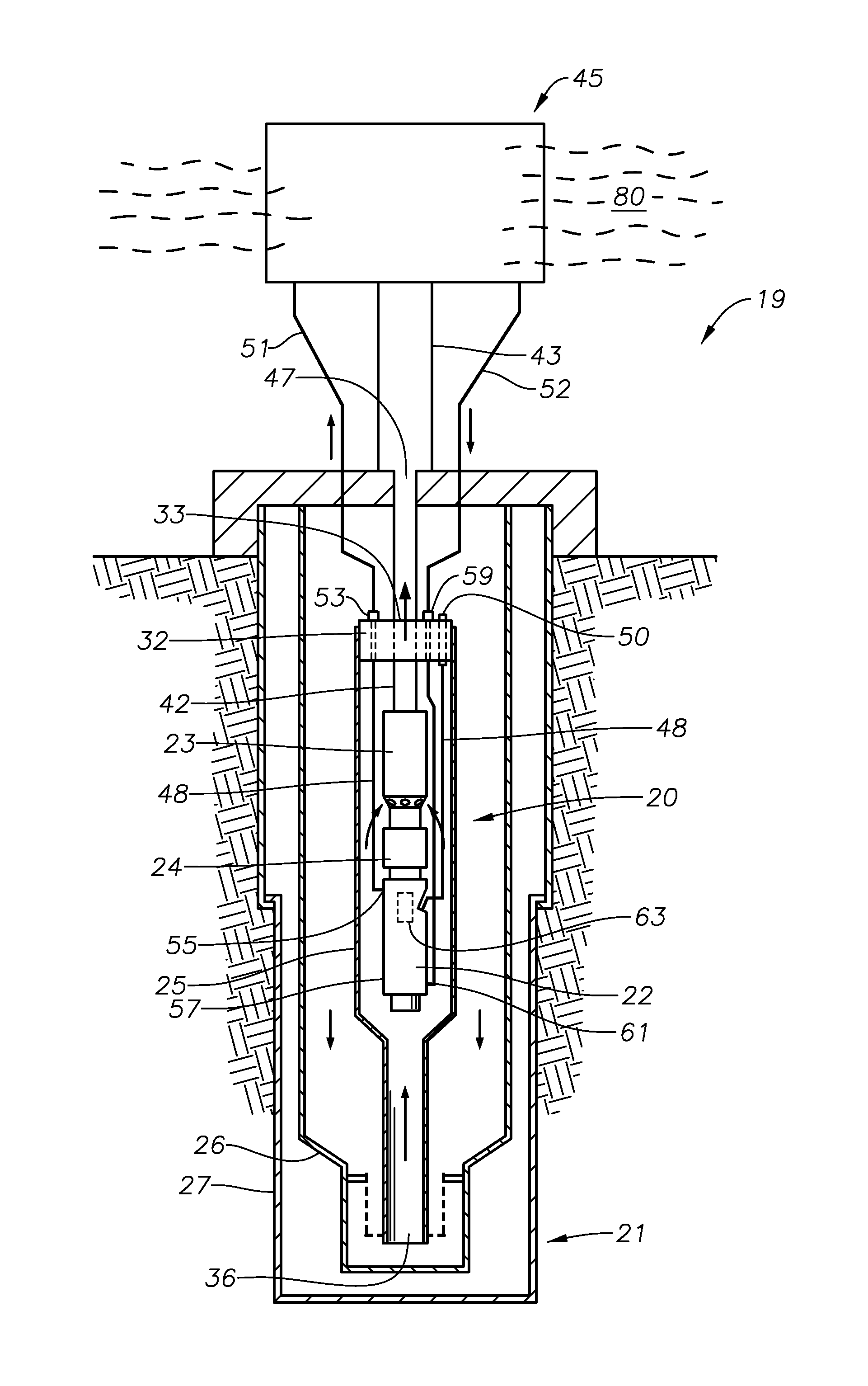

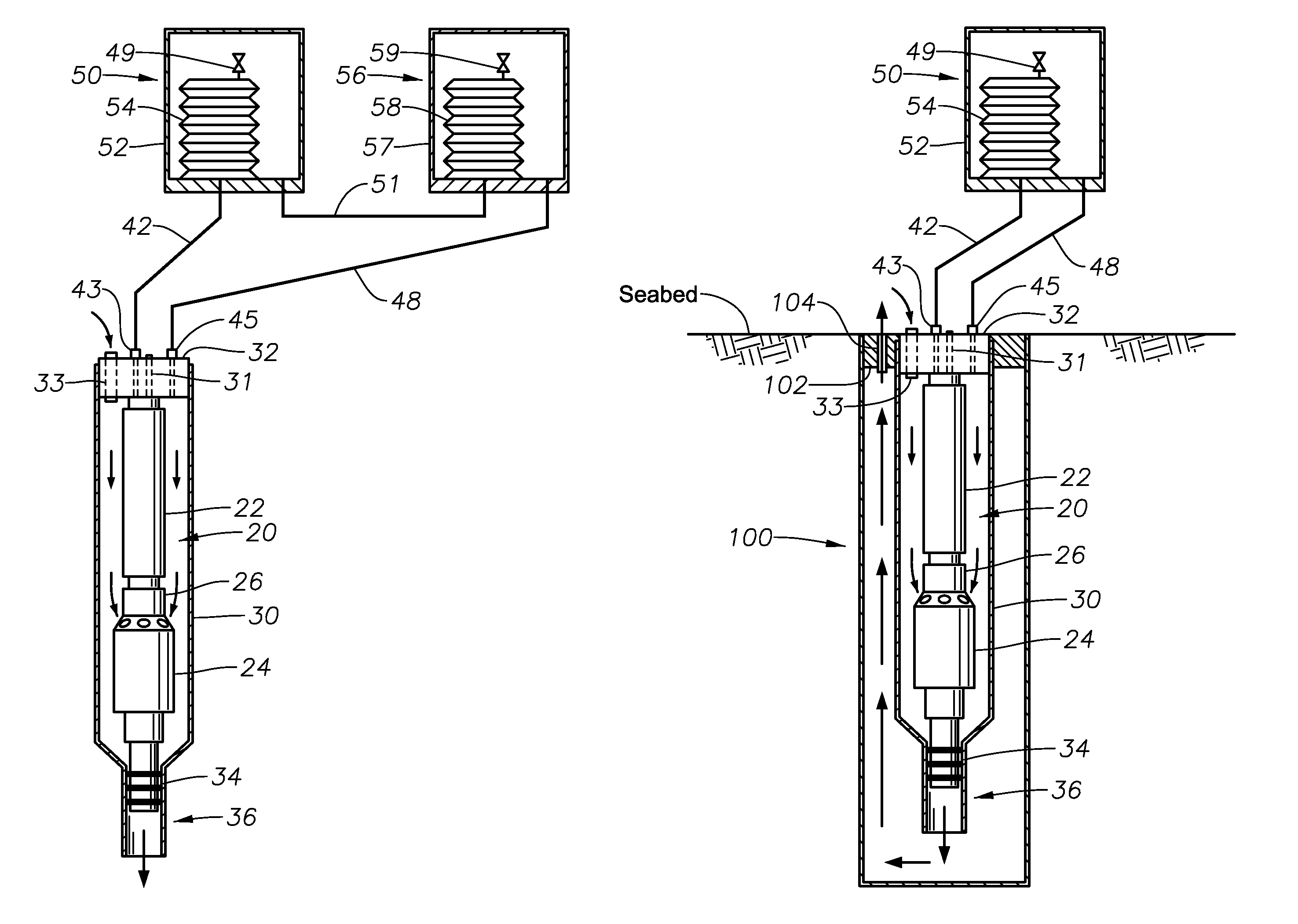

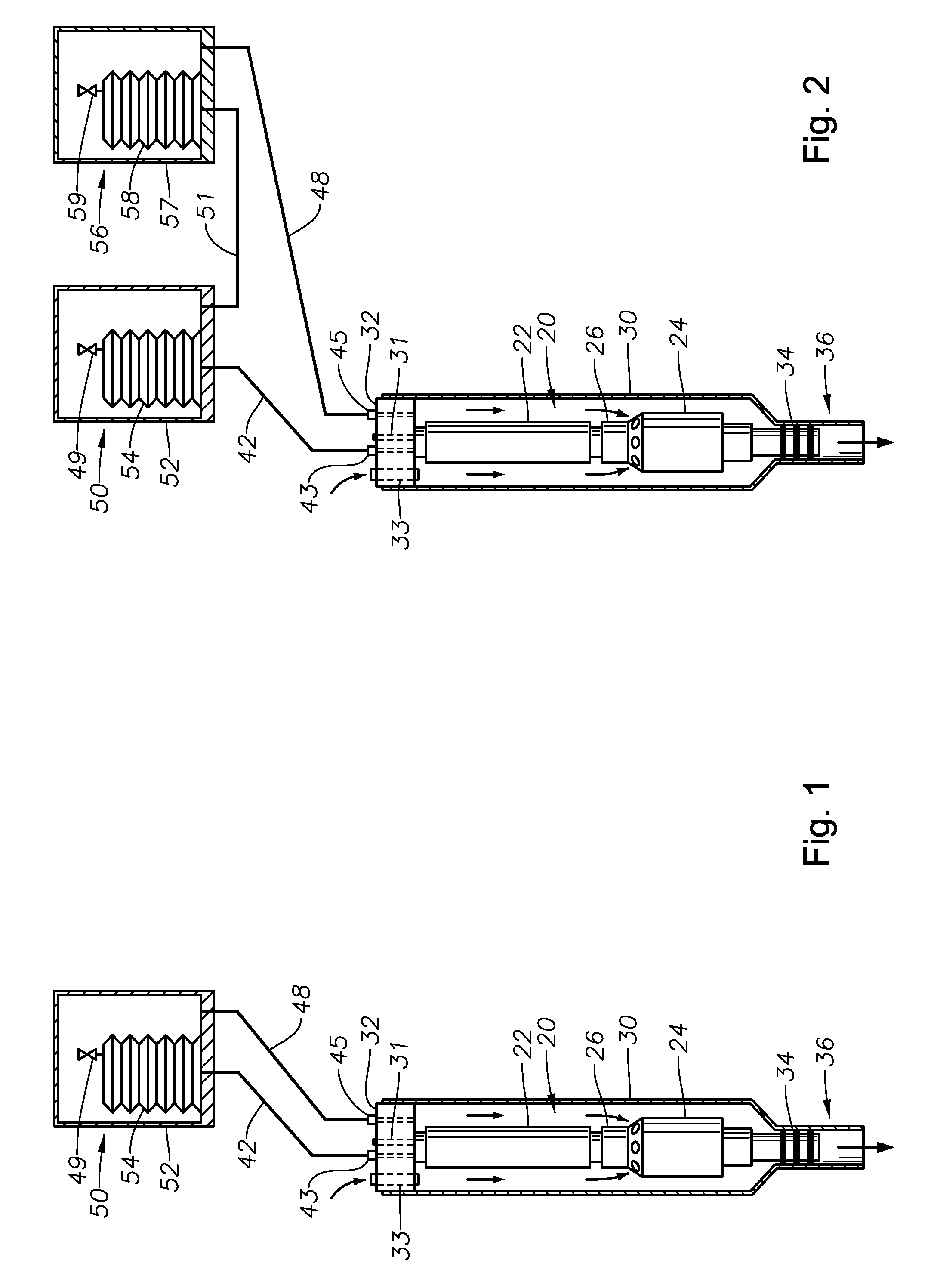

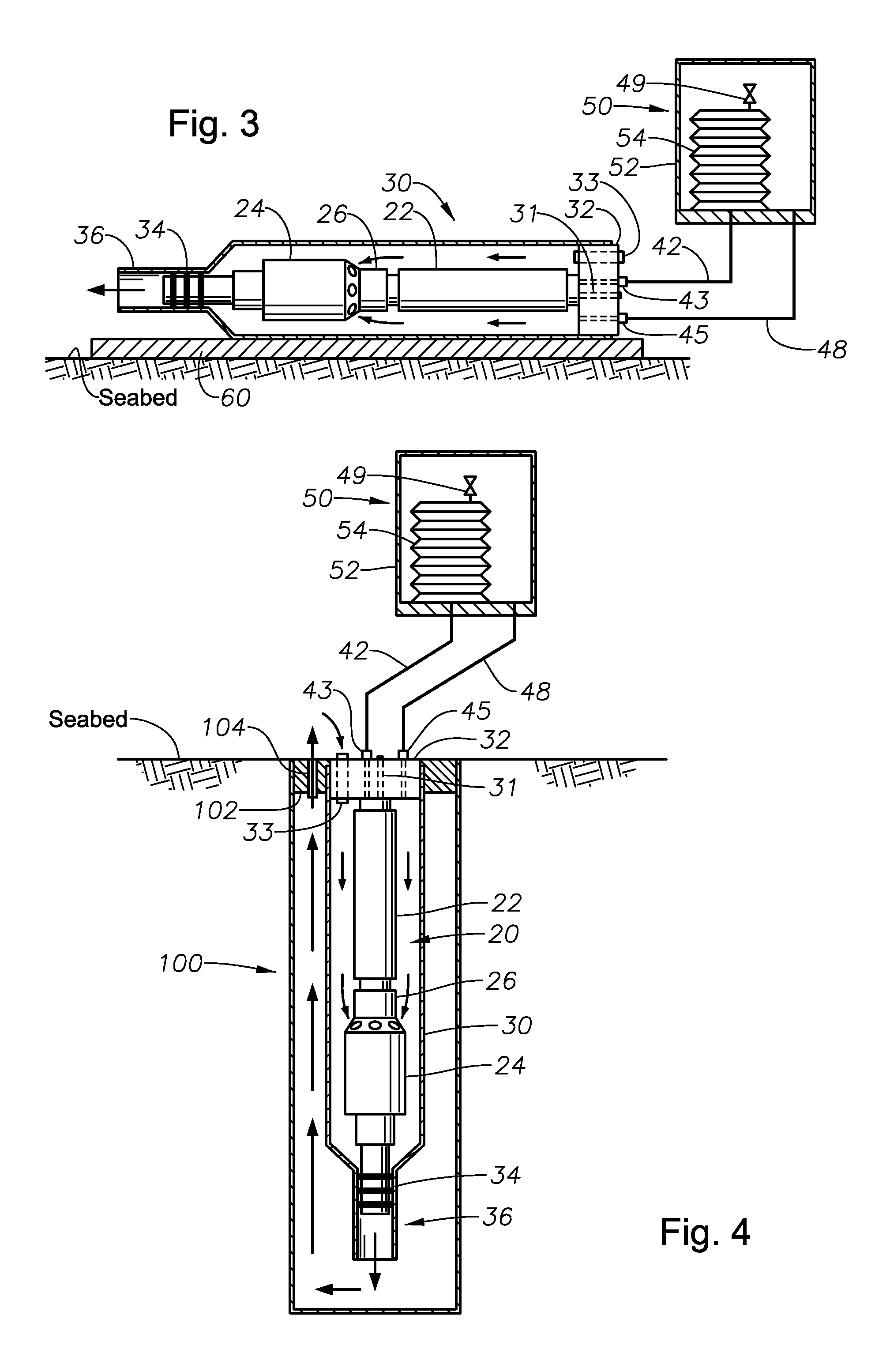

Heat exchanger for esp motor

InactiveUS20100329908A1Reduce the temperatureExtend motor lifePump componentsPiston pumpsLine tubingEngineering

A heat exchanger to serve ESP equipment installed on the seabed located in either a caisson or skid. A hot oil line connects the base of the ESP motor with the externally located heat exchanger, allowing hot motor oil to be circulated through coils externally exposed to seawater. The heat from the oil is rejected to the seawater and the cooled oil is reintroduced to the motor via a cold oil line that communicates with the seal section. The heat exchanger arrangement reduces the temperature of an ESP motor, thus allowing the motor to operate longer and more reliably.

Owner:BAKER HUGHES INC

Electronic device for controlling a synchronous motor with permanent-magnet rotor

InactiveUS6885161B2Reduce usageReduce consumptionMotor/generator/converter stoppersAC motor controlPermanent magnet rotorSynchronous motor

Electronic device for controlling a synchronous motor with permanent-magnet rotor, comprising an alternating voltage current source at mains frequency connected in series with said synchronous motor (1), at least one static switch (2) connected in series with said synchronous motor (1), and an electronic circuit (3) that acts on said static switch (2). Said electronic circuit (3) determines the timing for the firing of the static switch (2) taking as reference the zero-crossing of the mains voltage (Vr) and applying a firing time (Td) starting from said reference, said firing time (Td) being obtained as a function of the position of the rotor (1A) of the motor (1) in the previous half-cycles.

Owner:FAGOR SCOOP LTDA

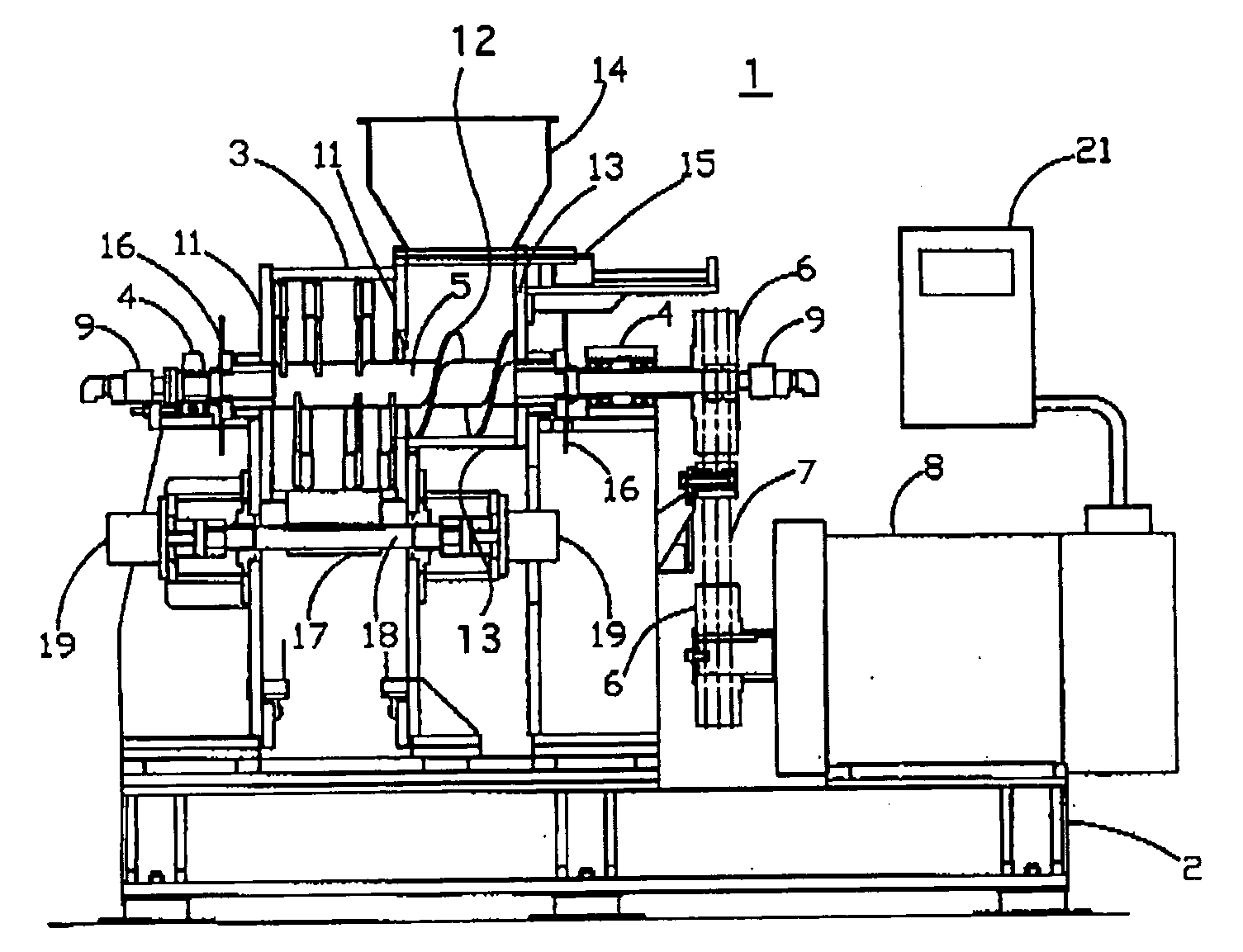

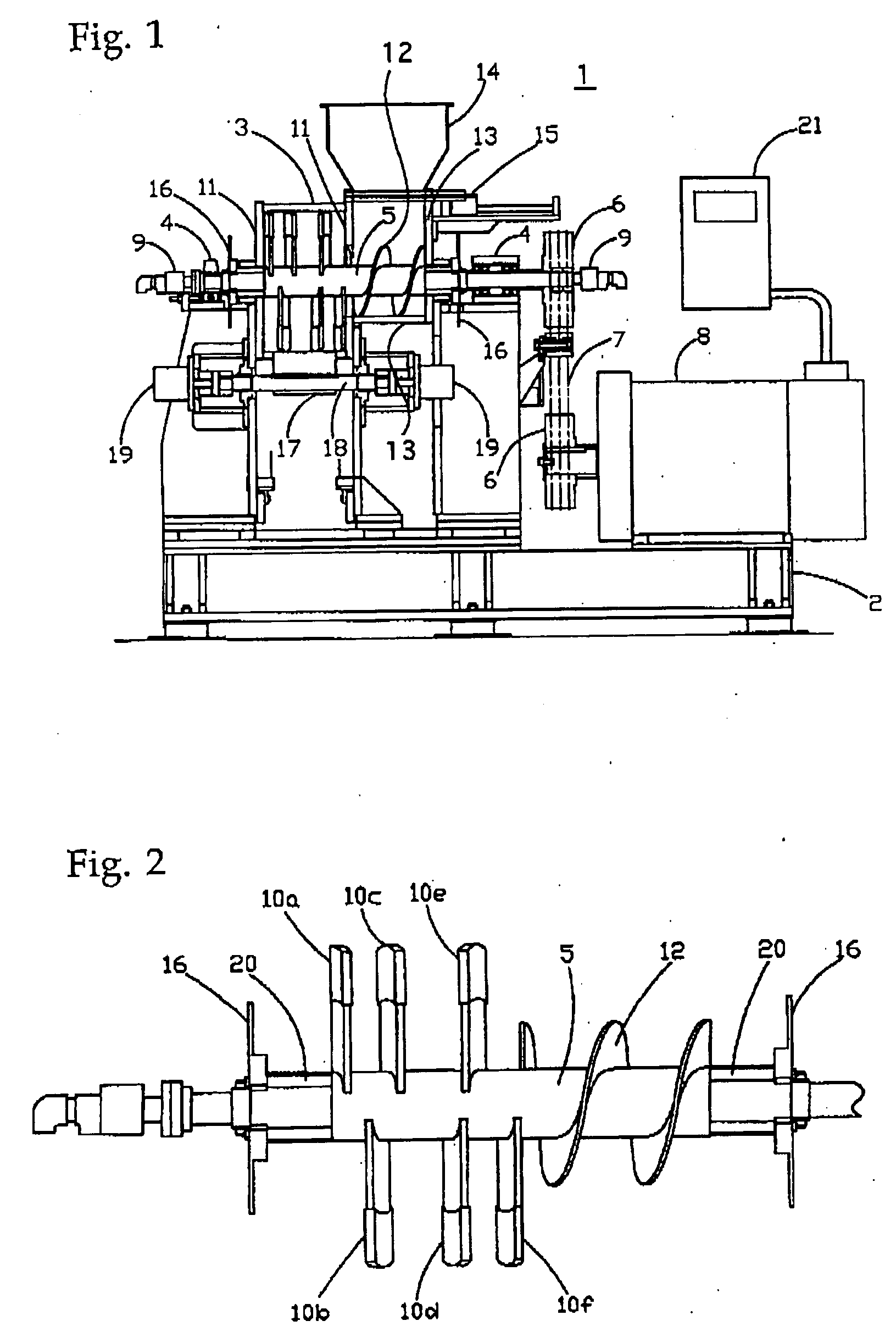

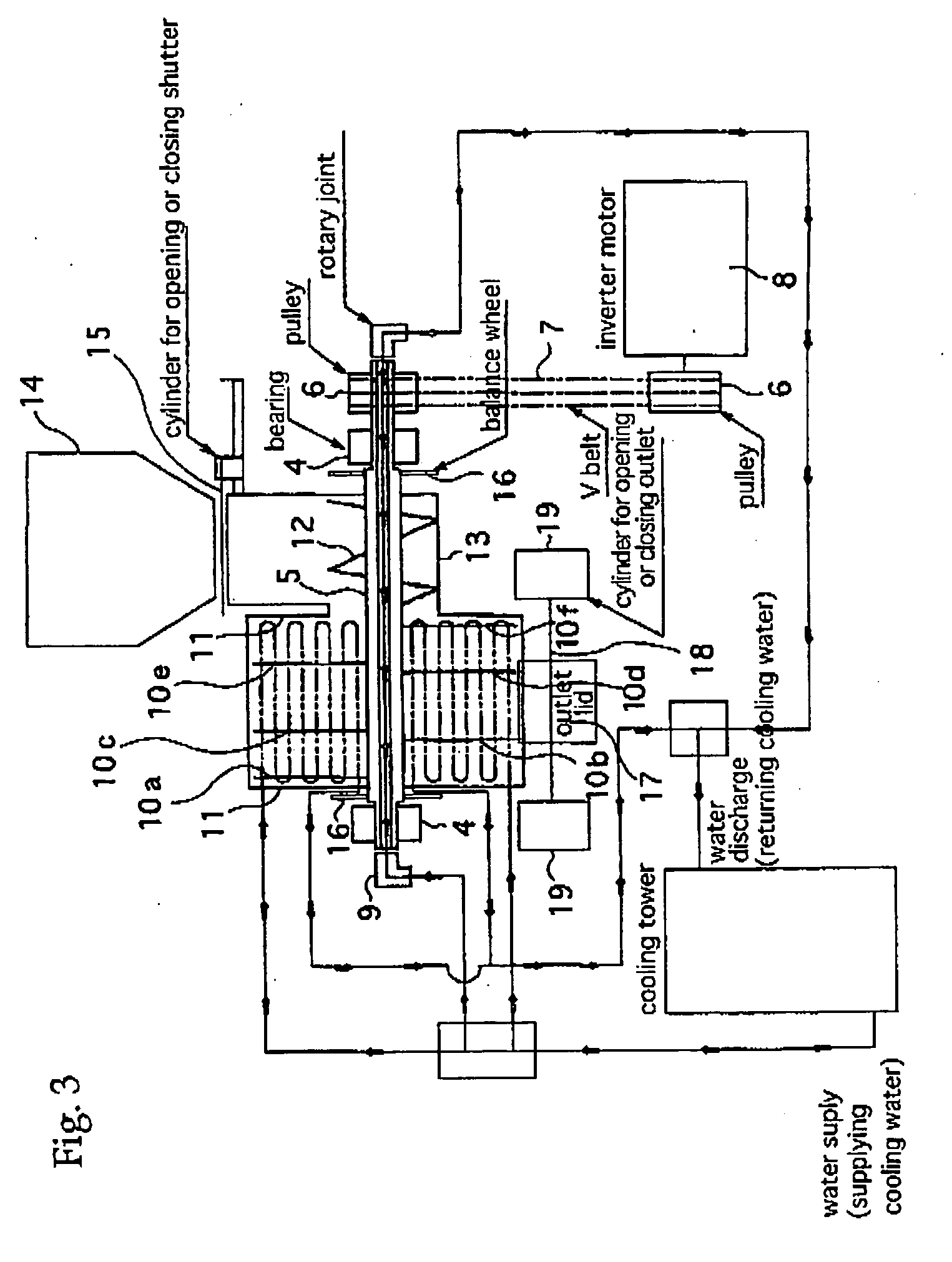

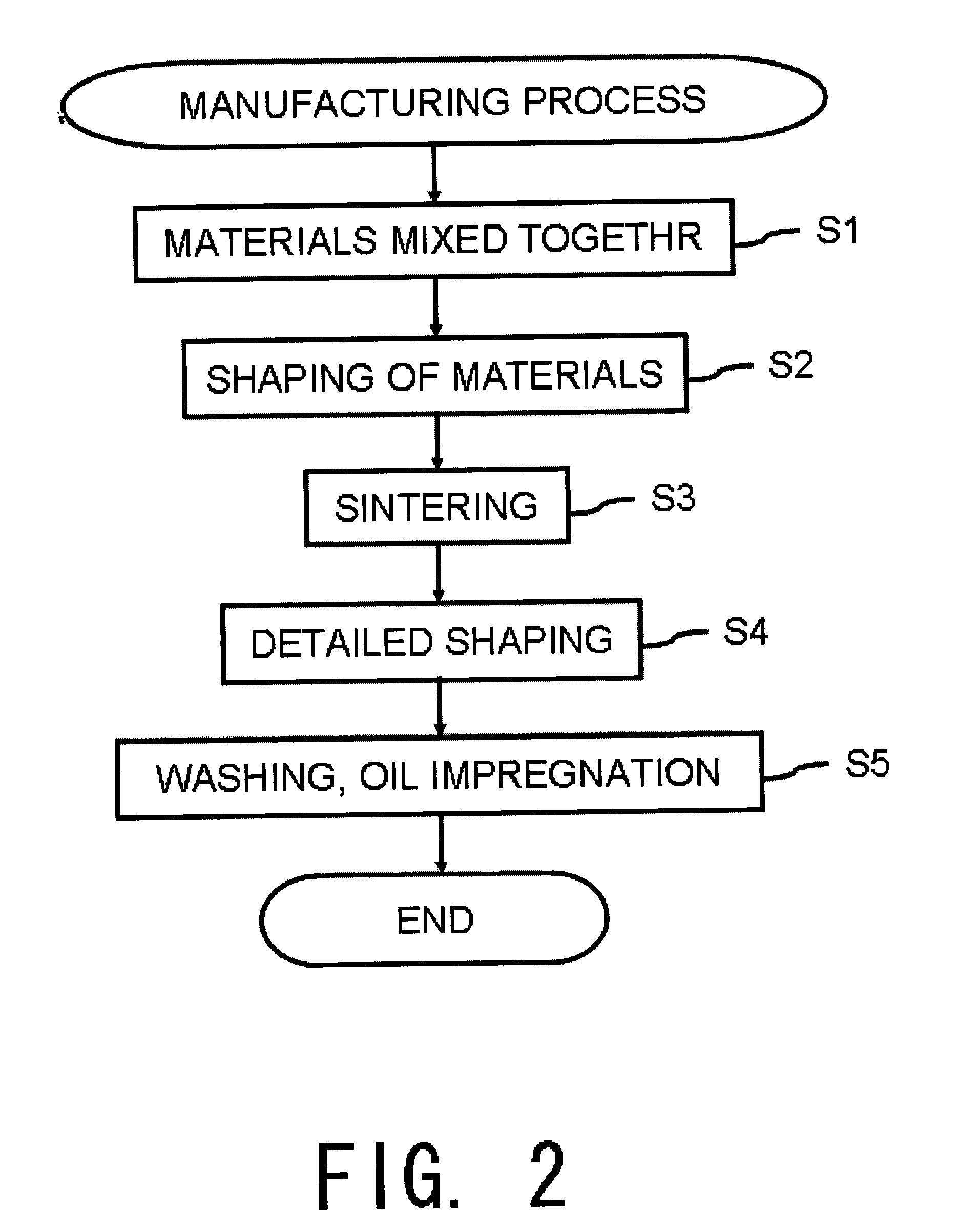

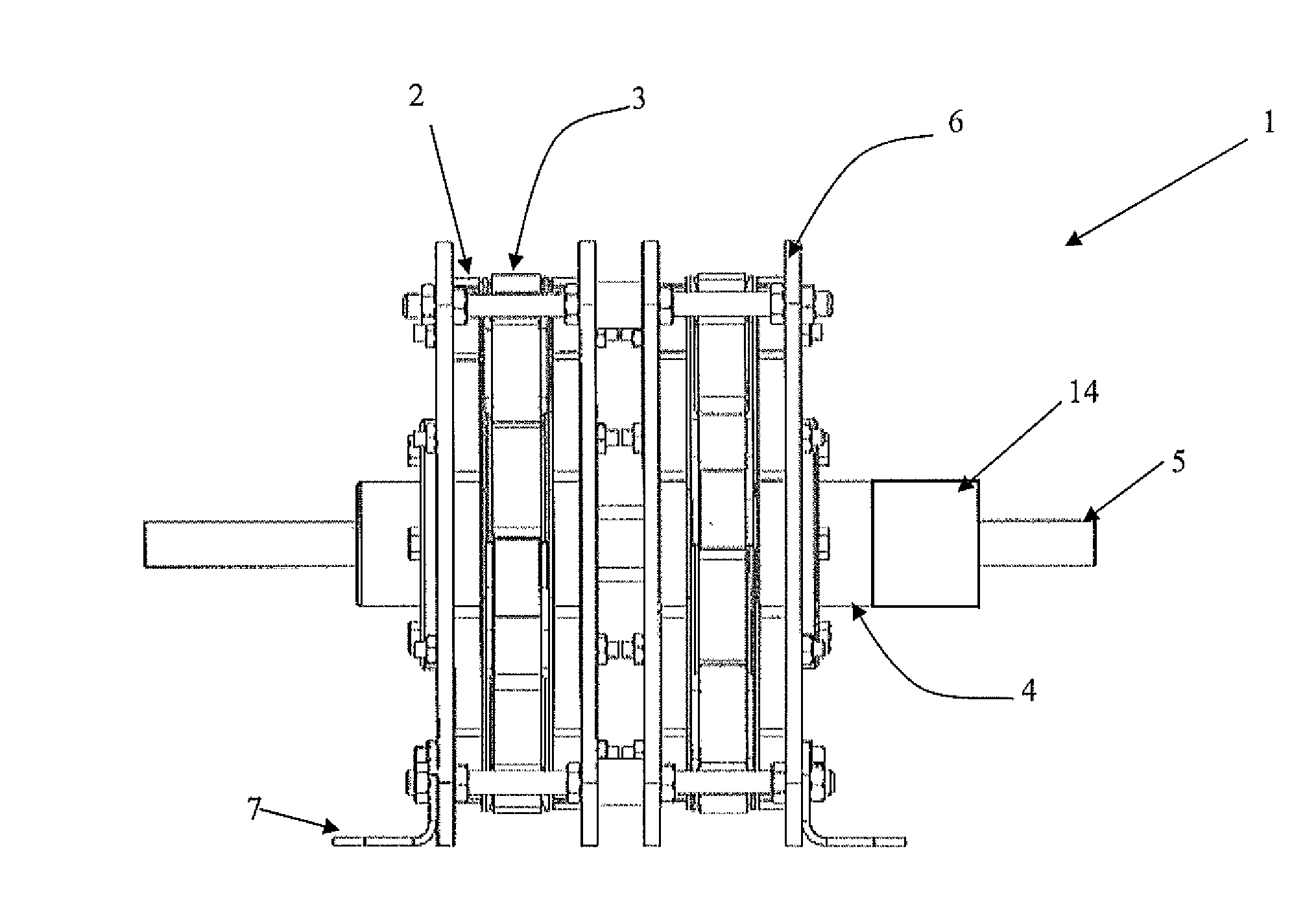

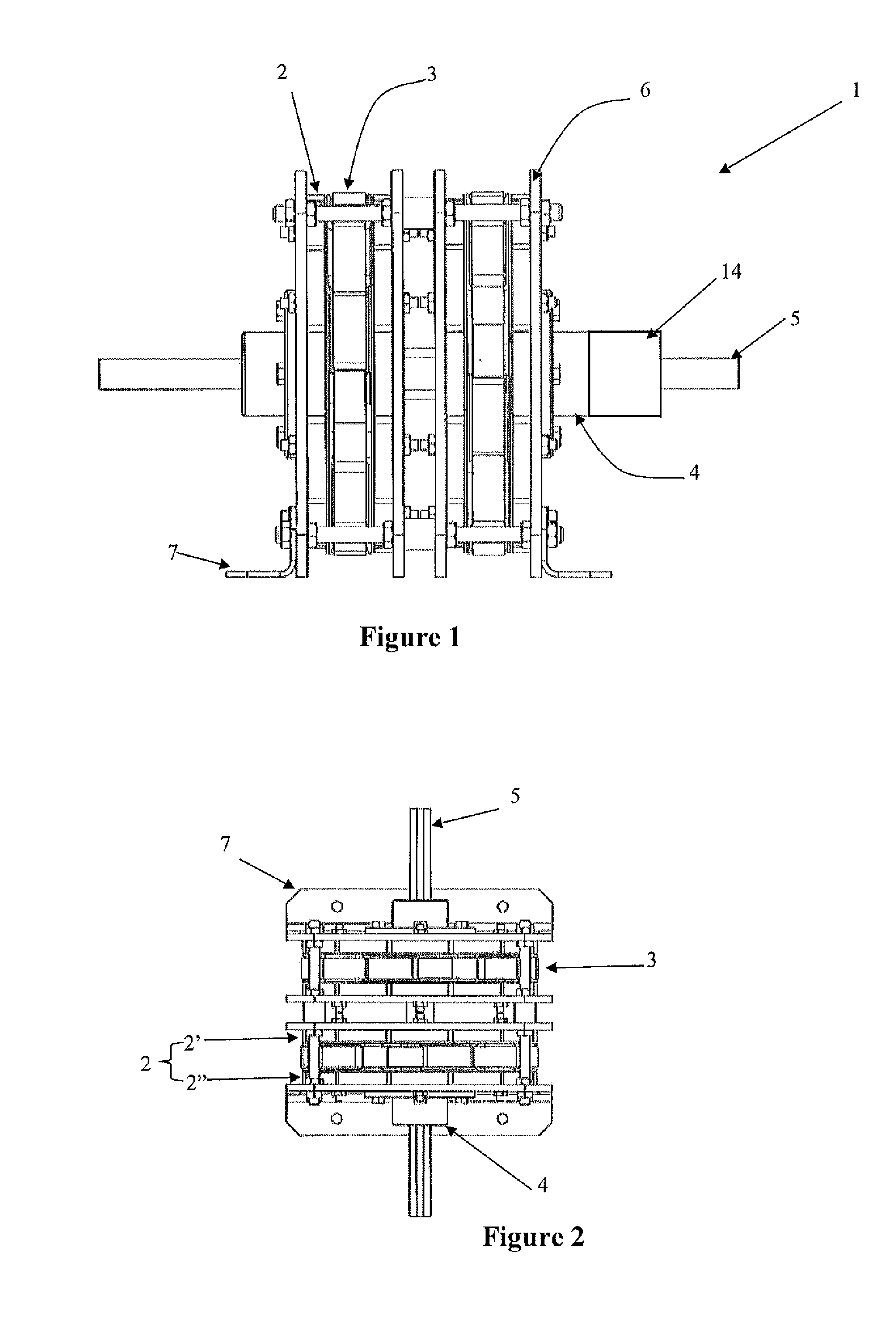

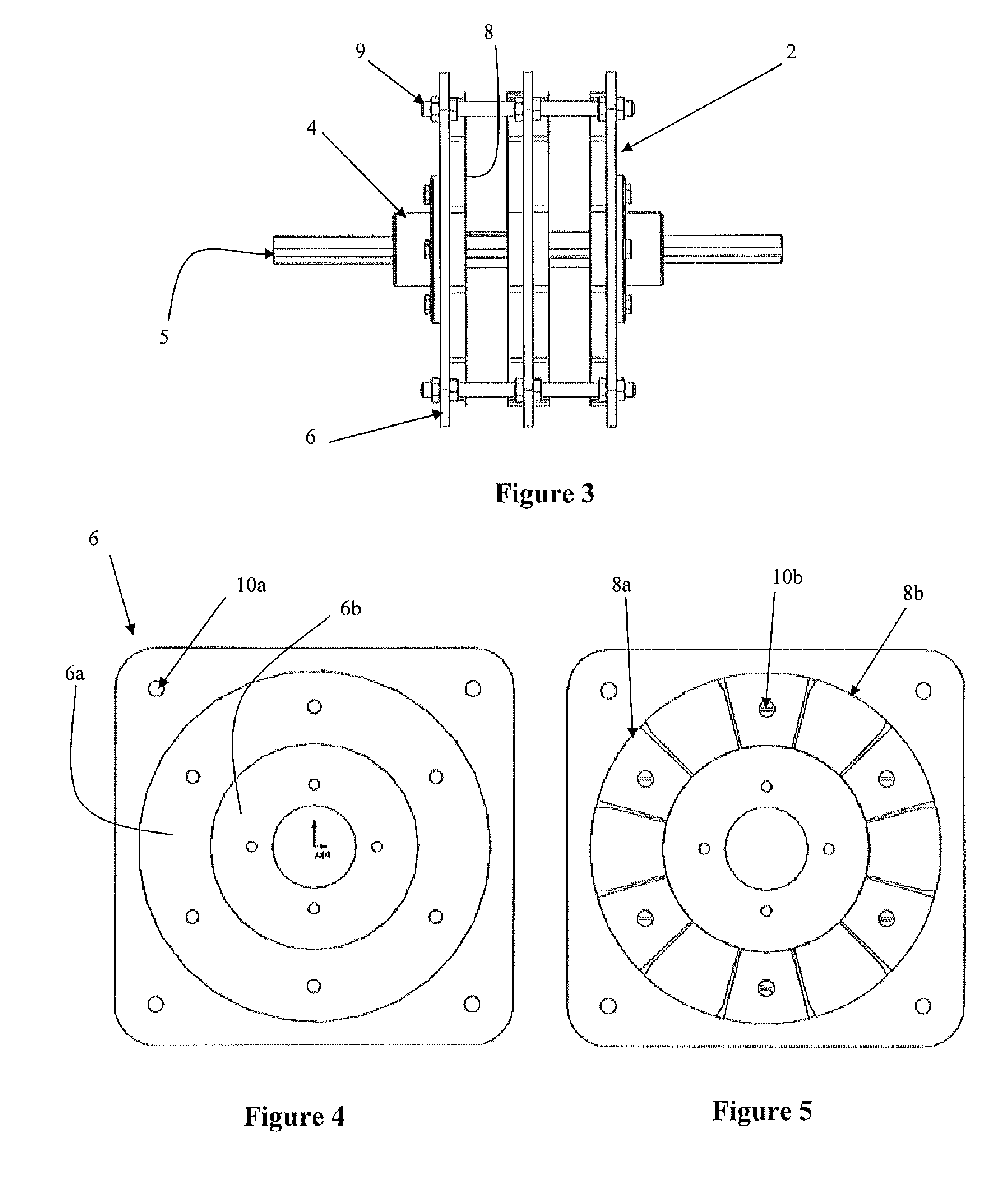

Mixing and pulverizing device, melting method for mixing, and method of molding cellulose material impregnated with binder

InactiveUS20070003654A1Extend motor lifeSmall loadRotary stirring mixersTransportation and packagingProduction rateCellulose

A crushing and mixing device and a mixing and melting method attained by the crushing and mixing device having a mixing vessel 3 in which a plurality of blades 10a to 10f are installed on a rotary shaft 5 which is rotated by a motor 8 as a driving source and freely rotatably supported, to mix and crush materials; wherein a spiral vane 12 is equipped to supply the materials which are introduced to a rotary shaft 5 corresponding to an inlet for materials, to the mixing vessel 3; at least two blades of the plurality of blades 10a to 10f are installed on the rotary shaft at an inclined angle which reduces each other's opposing space in the rotating direction; an outlet 17 is disposed at a side of a wall of the mixing vessel to take out the materials when the mixed and crushed material reaches a predetermined state; the materials are mixed and crushed in the mixing vessel 3, and an entrained moisture therein is dewaterd by the heat generated by actions of shearing, friction and compression; and a molten binder is impregnated in the dehydrated materials. This device and method provide methods for utilizing or reusing materials which are problematic for conventional methods in terms of cost and productivity, the materials such as chipped woody waste materials or woody waste materials like pruned branches and leaves of trees, and plant materials and plant-waste materials like stems and leaves of wheat, and are suitable for applications to enhance utilization of wasted materials by improving the filling ratio thereof and to promote reuse of the wasted materials.

Owner:M & F TECH

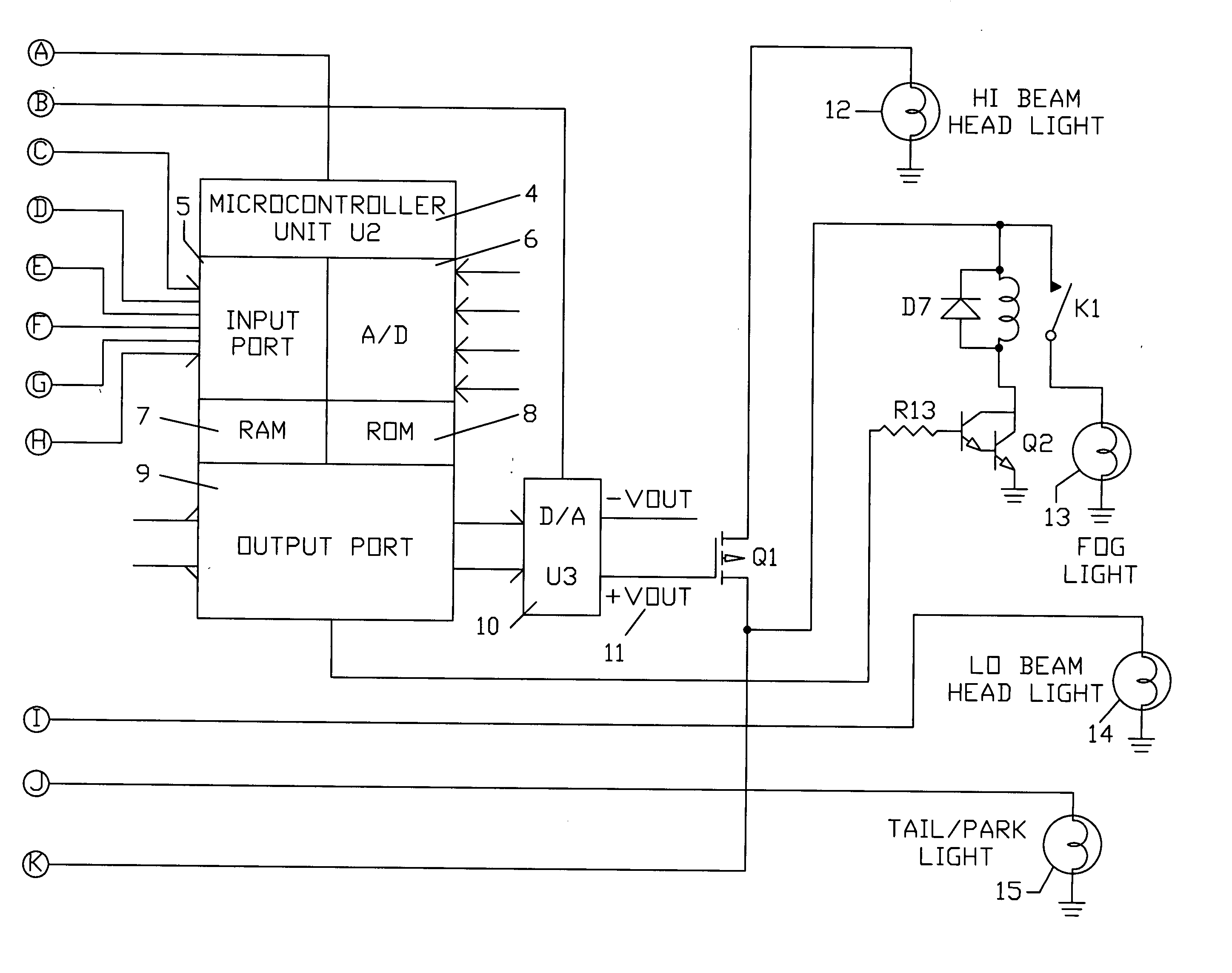

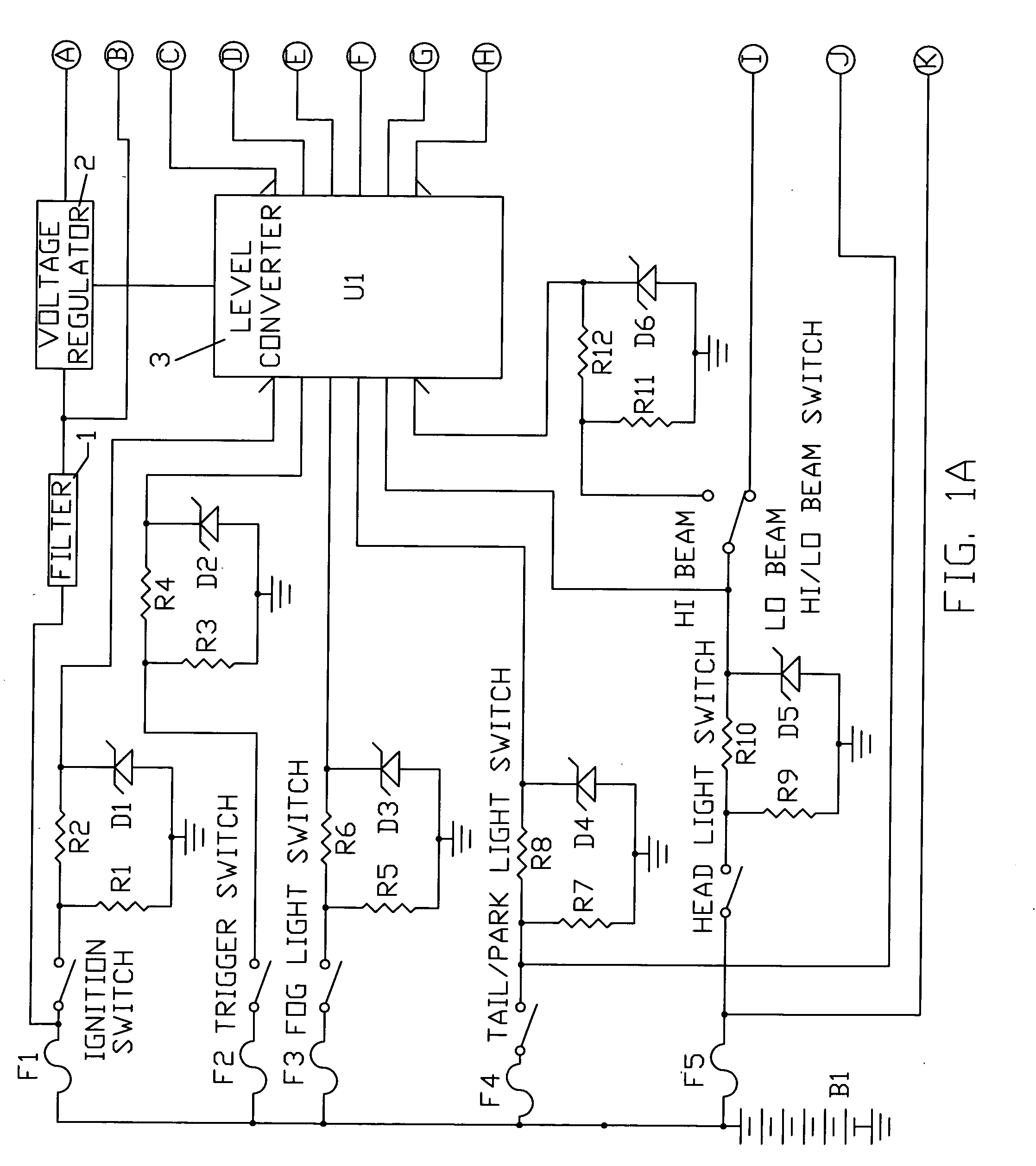

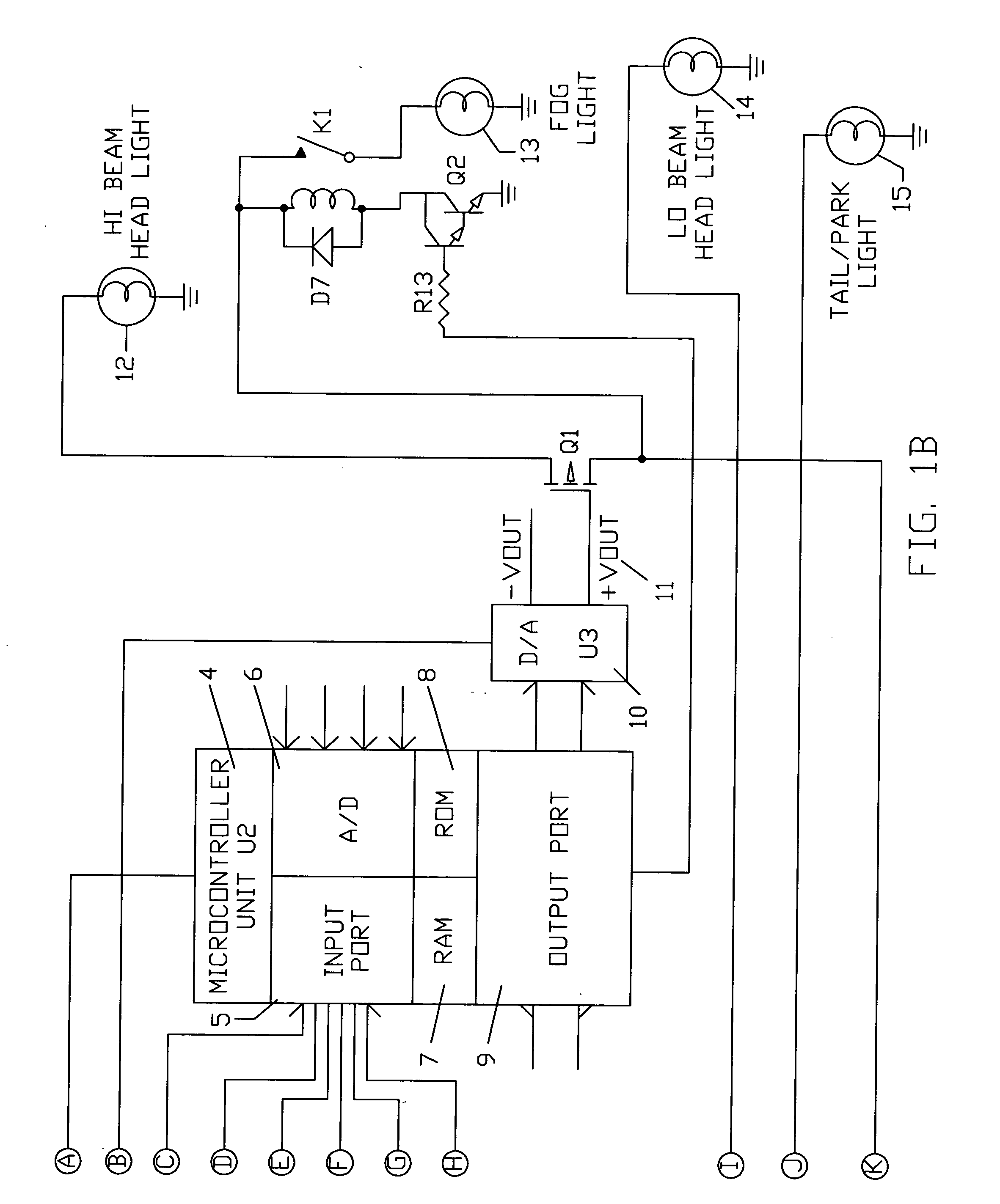

System to control the luminosity and extend the life of motor vehicle lights

InactiveUS20050057162A1Prolong lifeReduced stateVehicle headlampsElectric light circuit arrangementVisibilityMobile vehicle

The present invention relates to a system to control the luminosity and extend the life of the motor vehicle lghts. The present invention can further be extended to where the motor vehicle lights are progressively increased as the current ambient light conditions or the current visibility conditions decrease and progressively decreased as the current ambient light conditions or the current visibility conditions.

Owner:KOVER JOSEPH JR +1

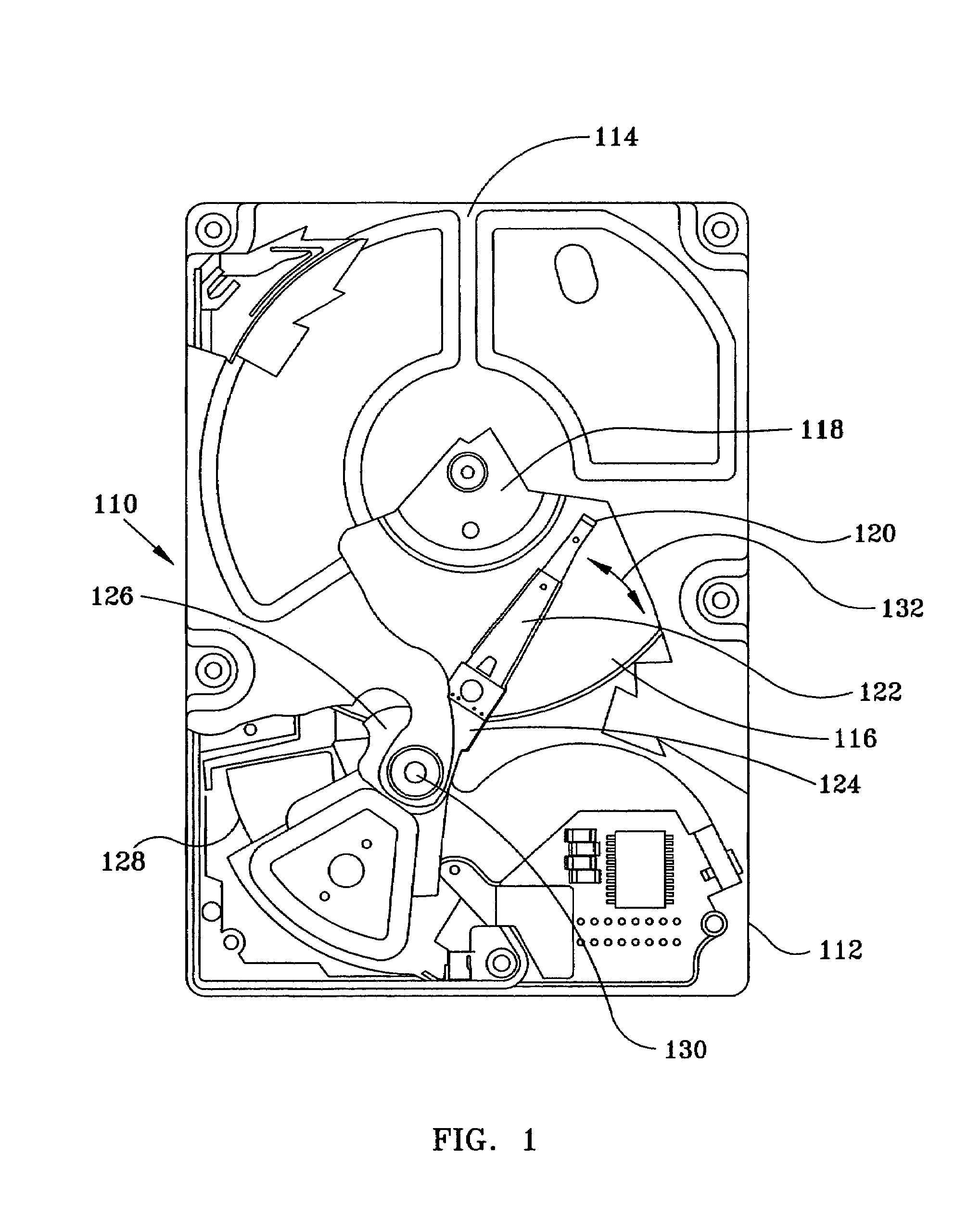

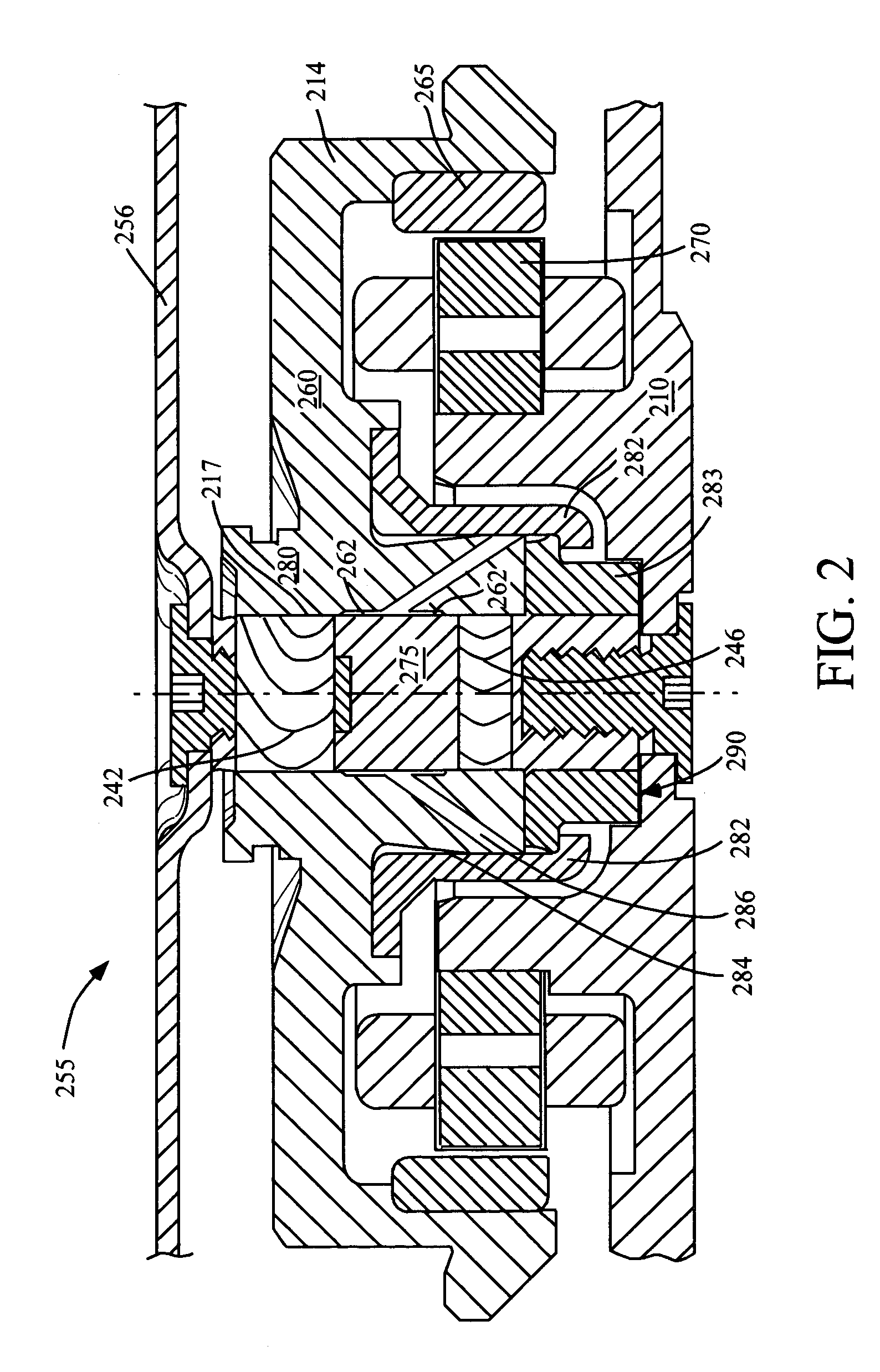

Through hub oil fill and vent for a fluid dynamic bearing motor

A through hub fill hole and air vent having an enlarged fluid diffusion path is provided for spindle motors. Oil leakage and evaporation from a motor is reduced. In an aspect, oil is retained under conditions of at least a 1000 G shock event. In an aspect, the hub fill hole has a varying diameter and geometry, and is angled, further reducing oil leakage. In an aspect, an additional cavity is employed within the hub, for maintaining rotor rotational balance. The process of filling oil into a spindle motor is made easier from a motor set up and tooling perspective. Removal of the hub and other motor components is not necessary for filling a motor. Large diameter oil fill dispenser heads, subambient and ambient fill processes, and micro dispenser fill processes may be utilized. A measured and controlled amount of oil can be dispensed, reducing variability in the motor filling process.

Owner:SEAGATE TECH LLC

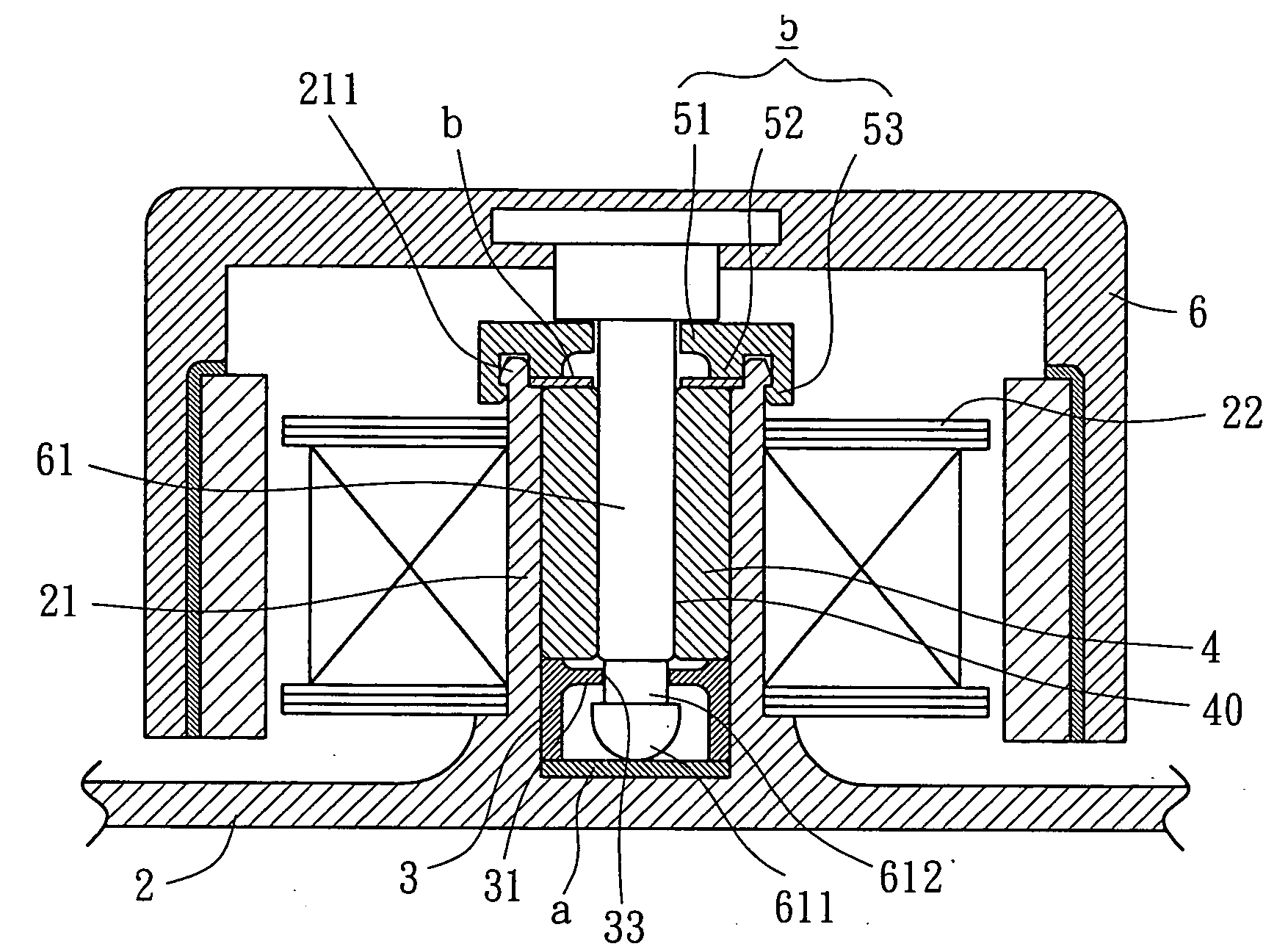

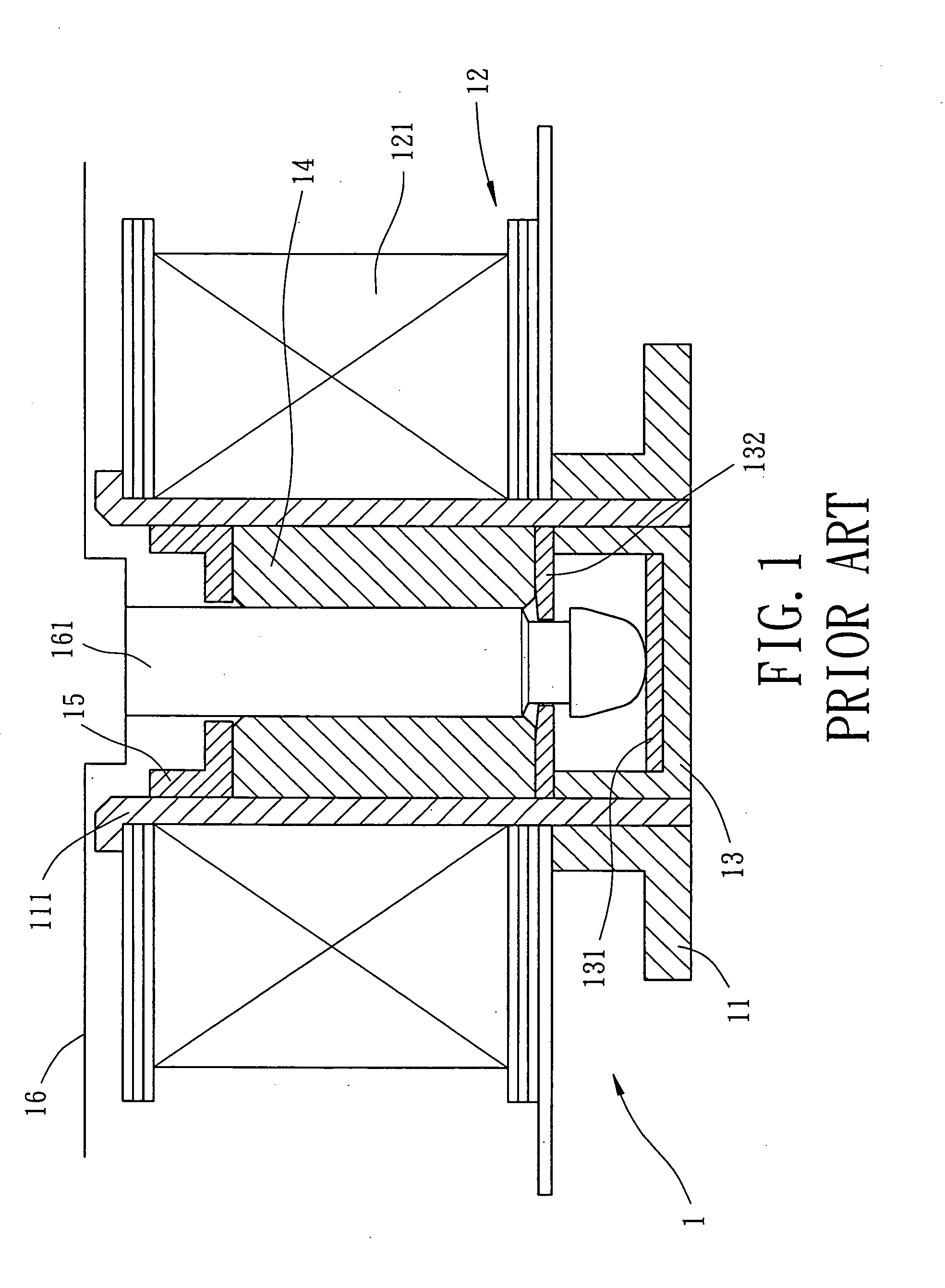

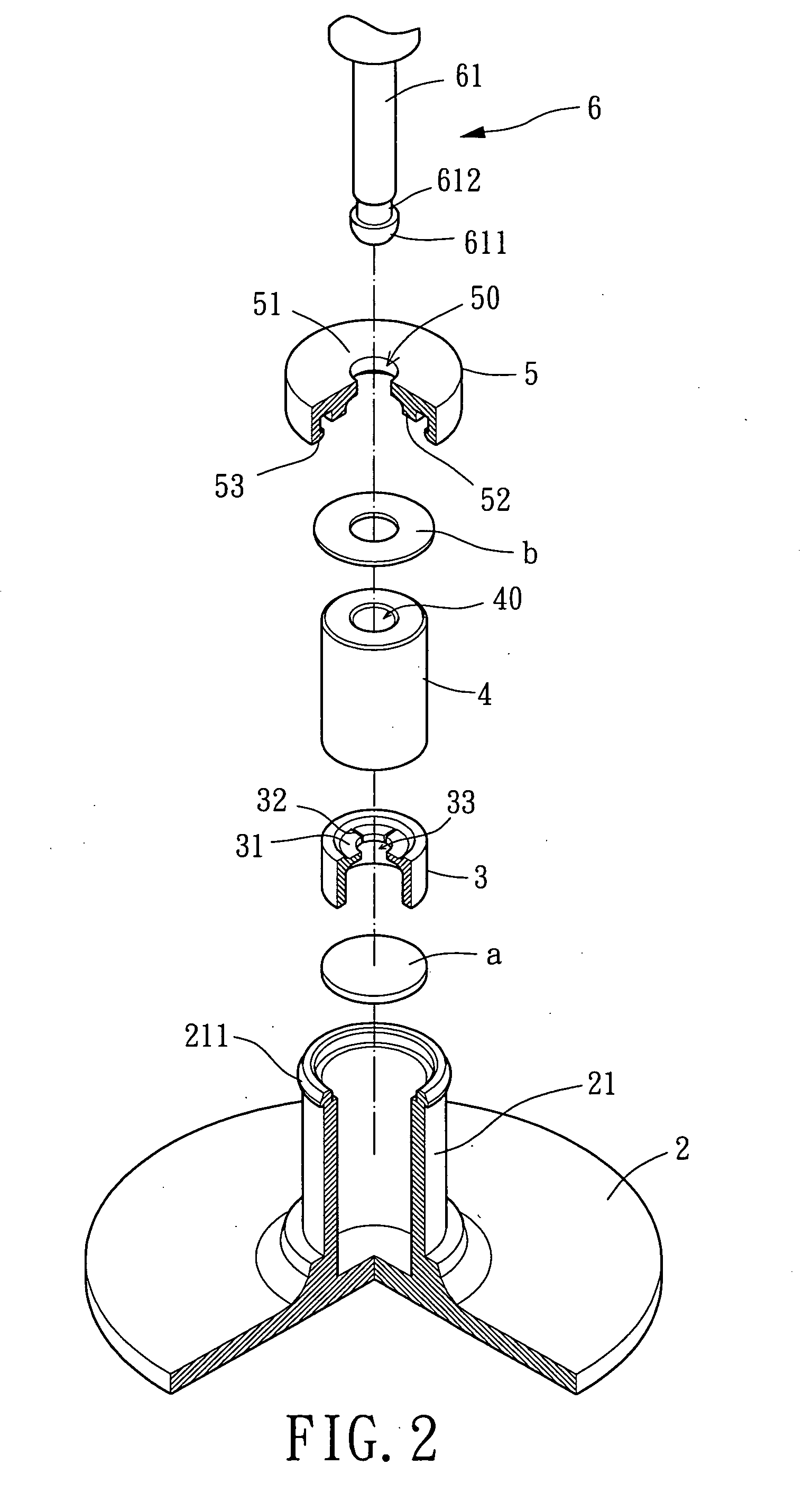

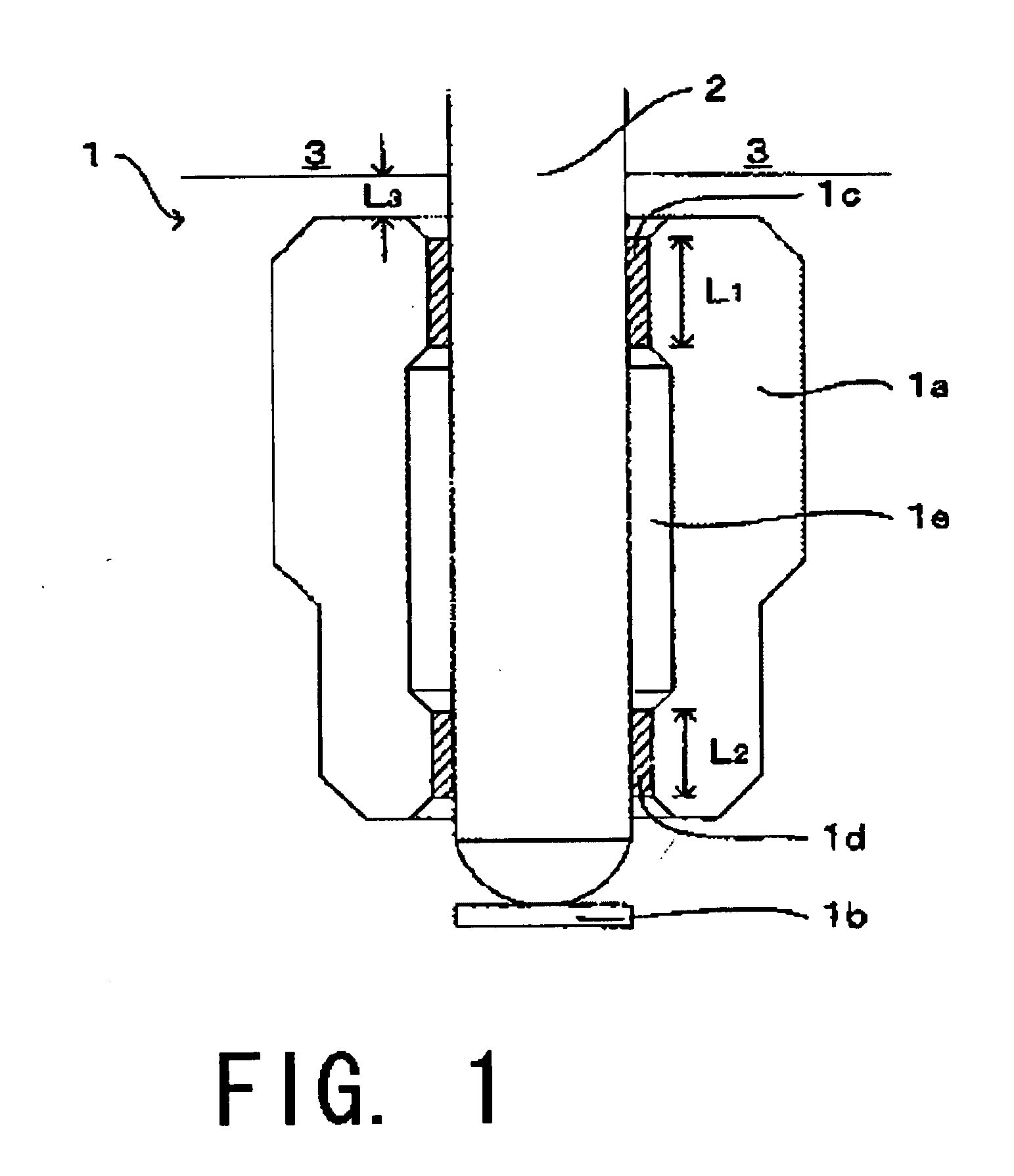

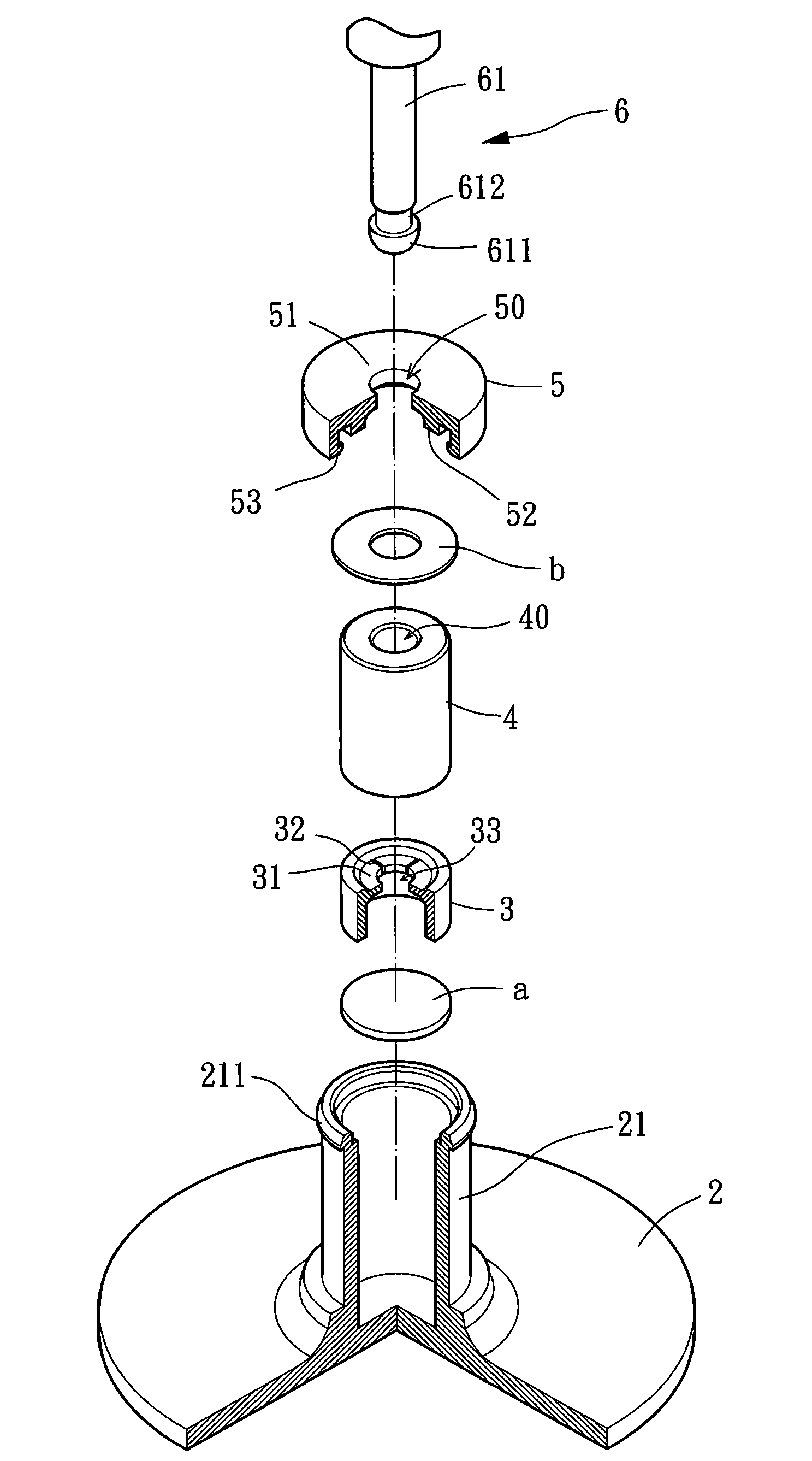

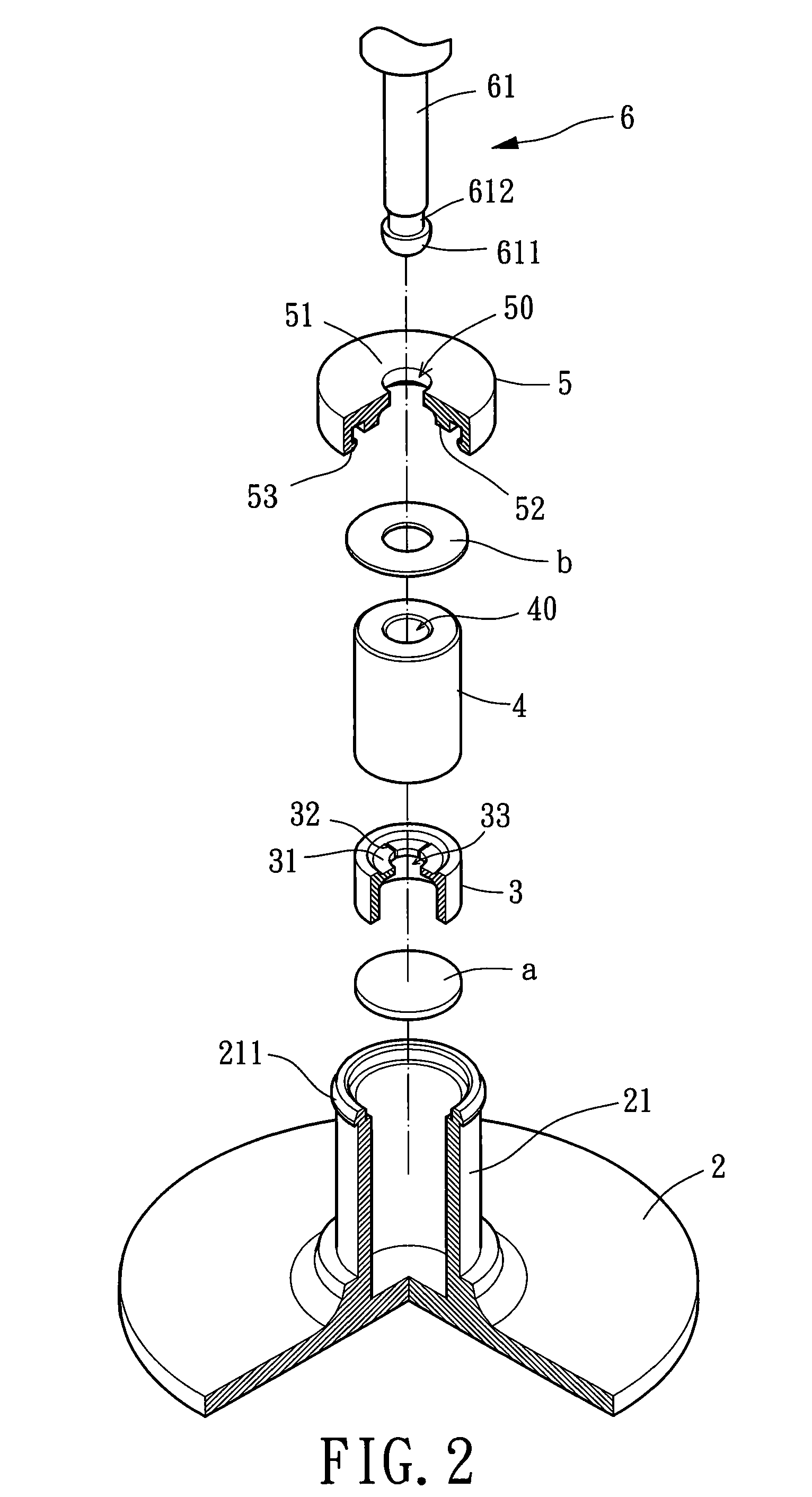

Bearing positioning structure for motor

InactiveUS20080056627A1Improve assembly reliabilityExtend motor lifeShaftsRecord information storageCouplingElectric motor

A bearing positioning structure for a motor includes an axial tube and a positioning member. The positioning member includes a pressing portion and a coupling portion. The coupling portion of the positioning member is engaged with a coupling section of the axial tube for securely mounting the positioning member to the axial tube, with the pressing portion of the positioning member pressing against a bearing to position the bearing in the axial tube. In another example, the coupling portion of the positioning member engages with a coupling section on a stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

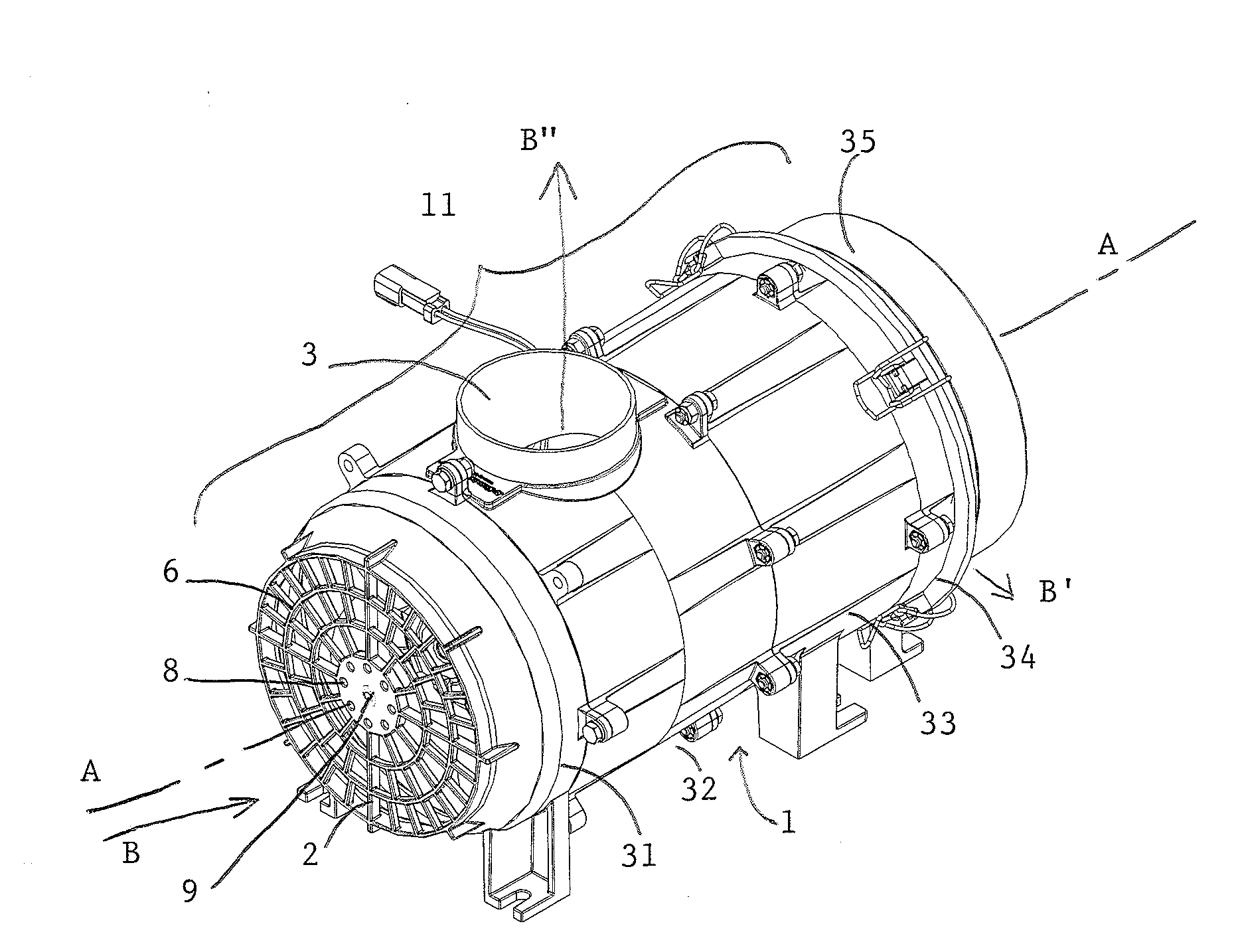

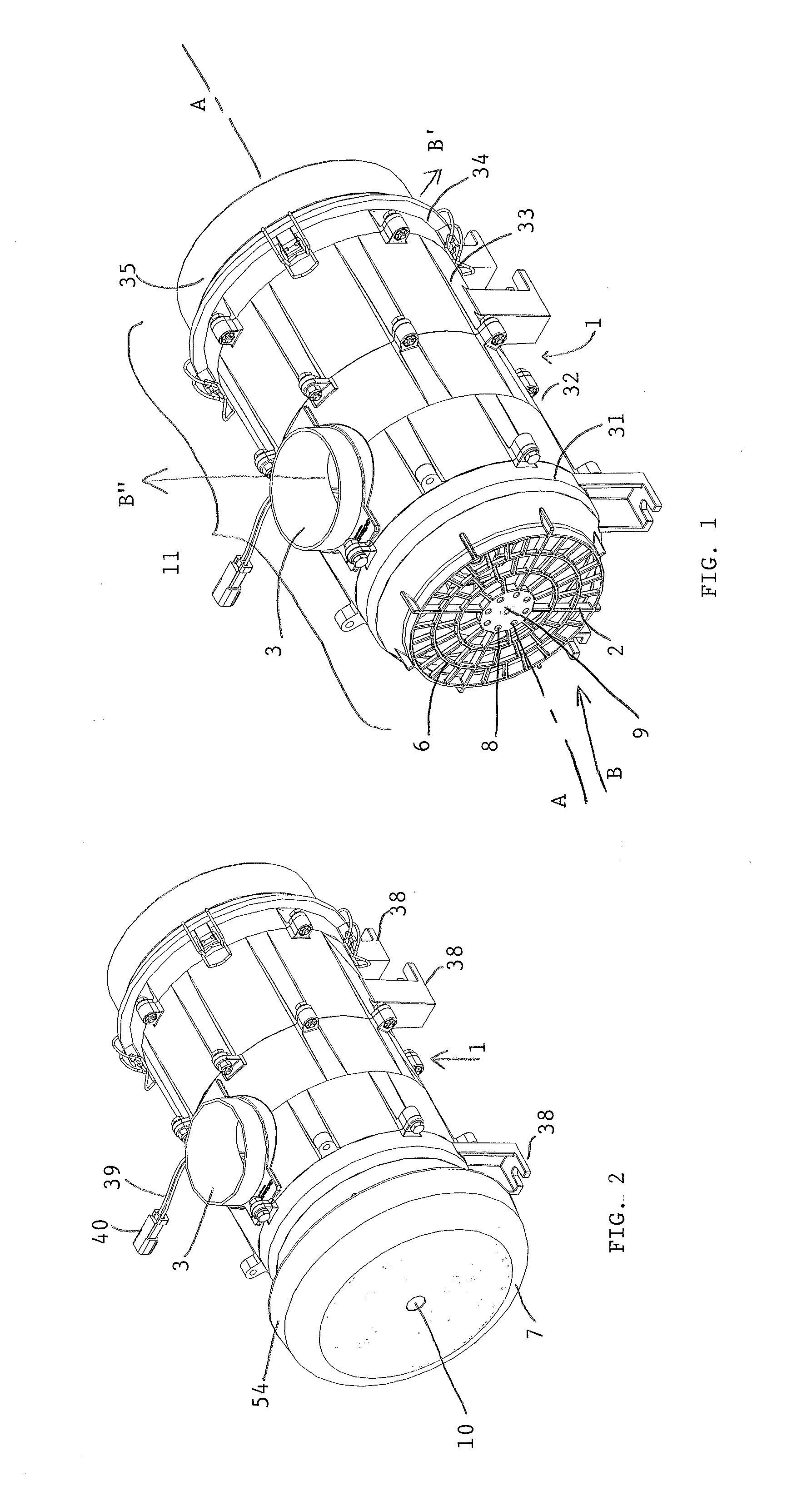

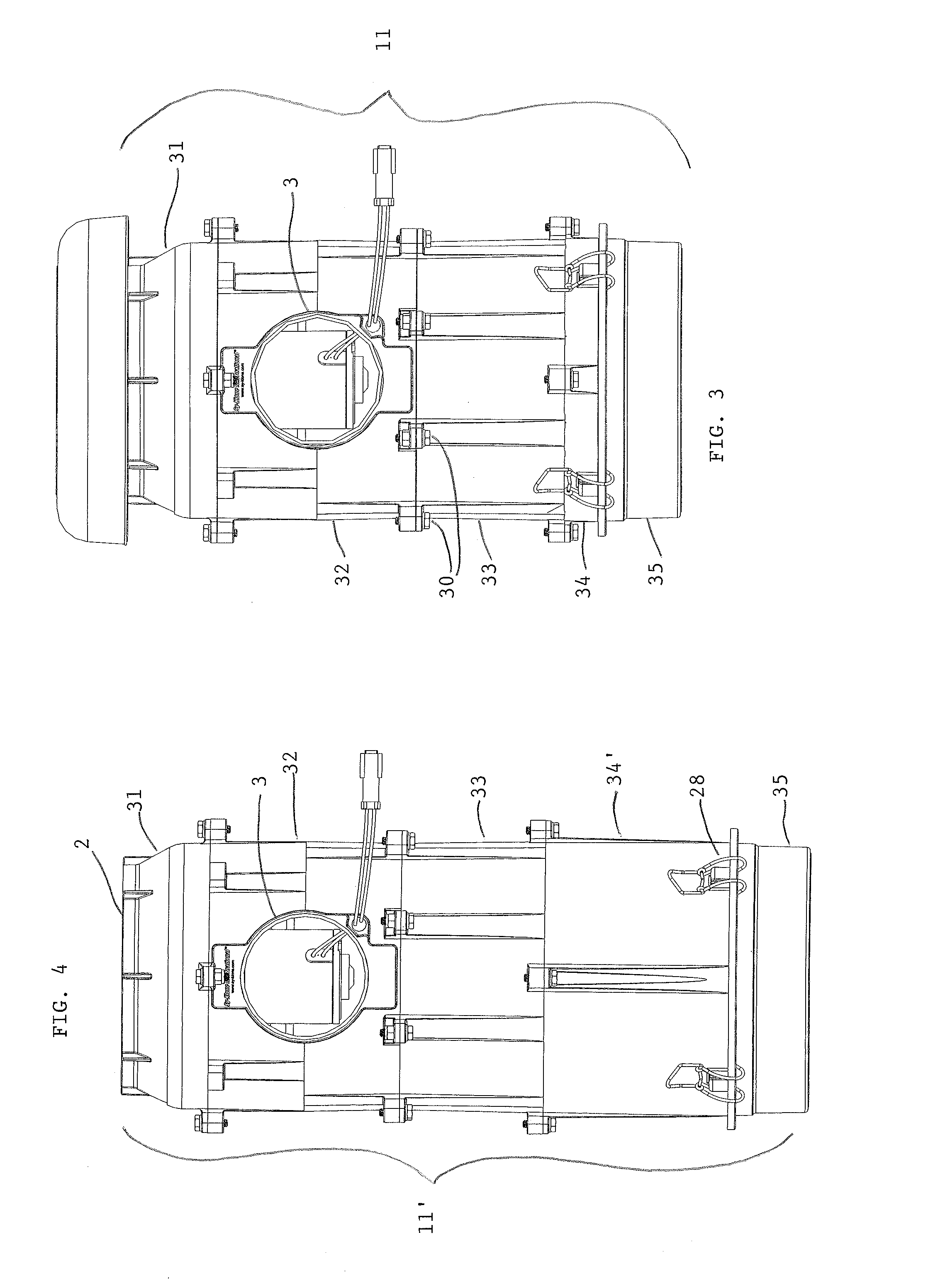

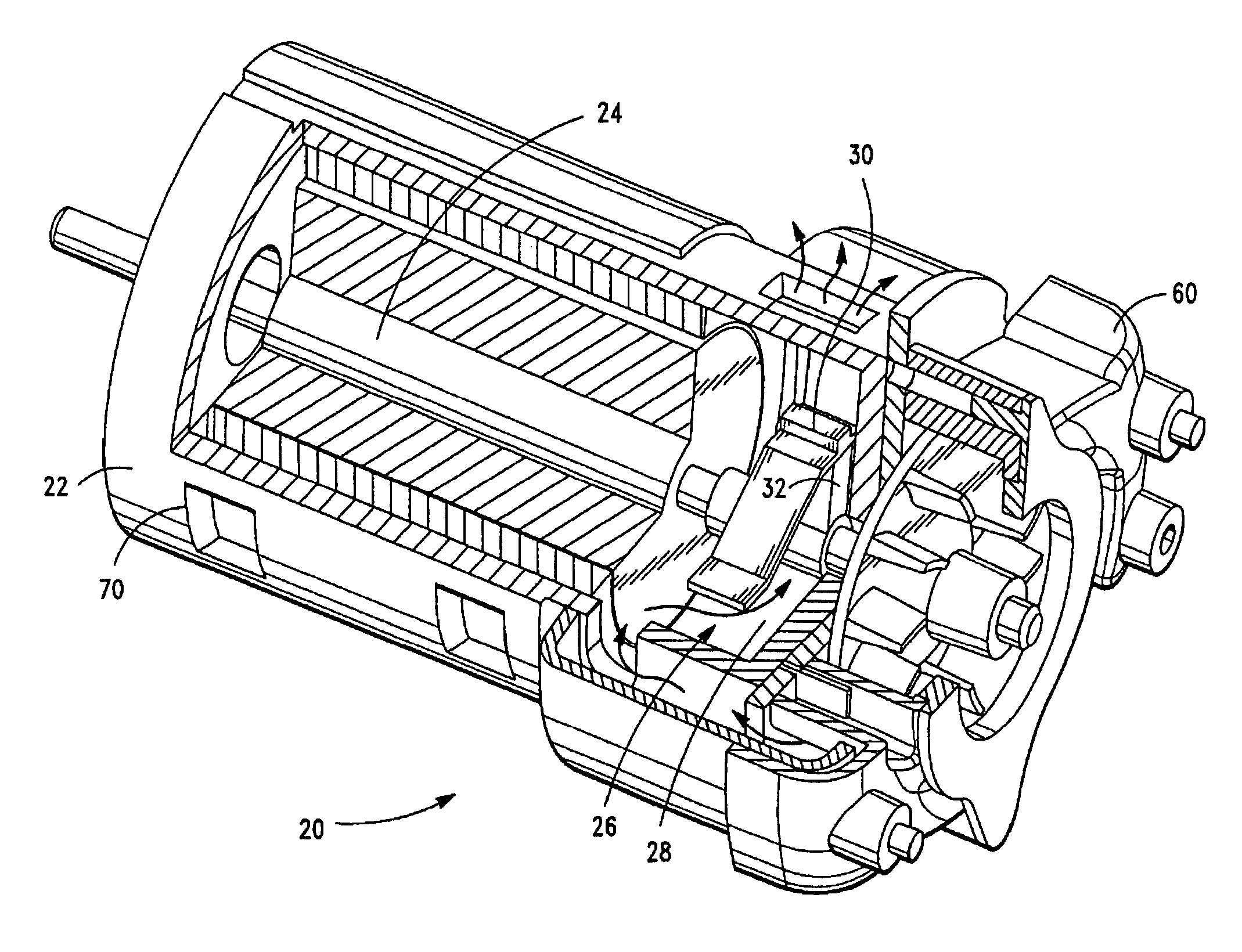

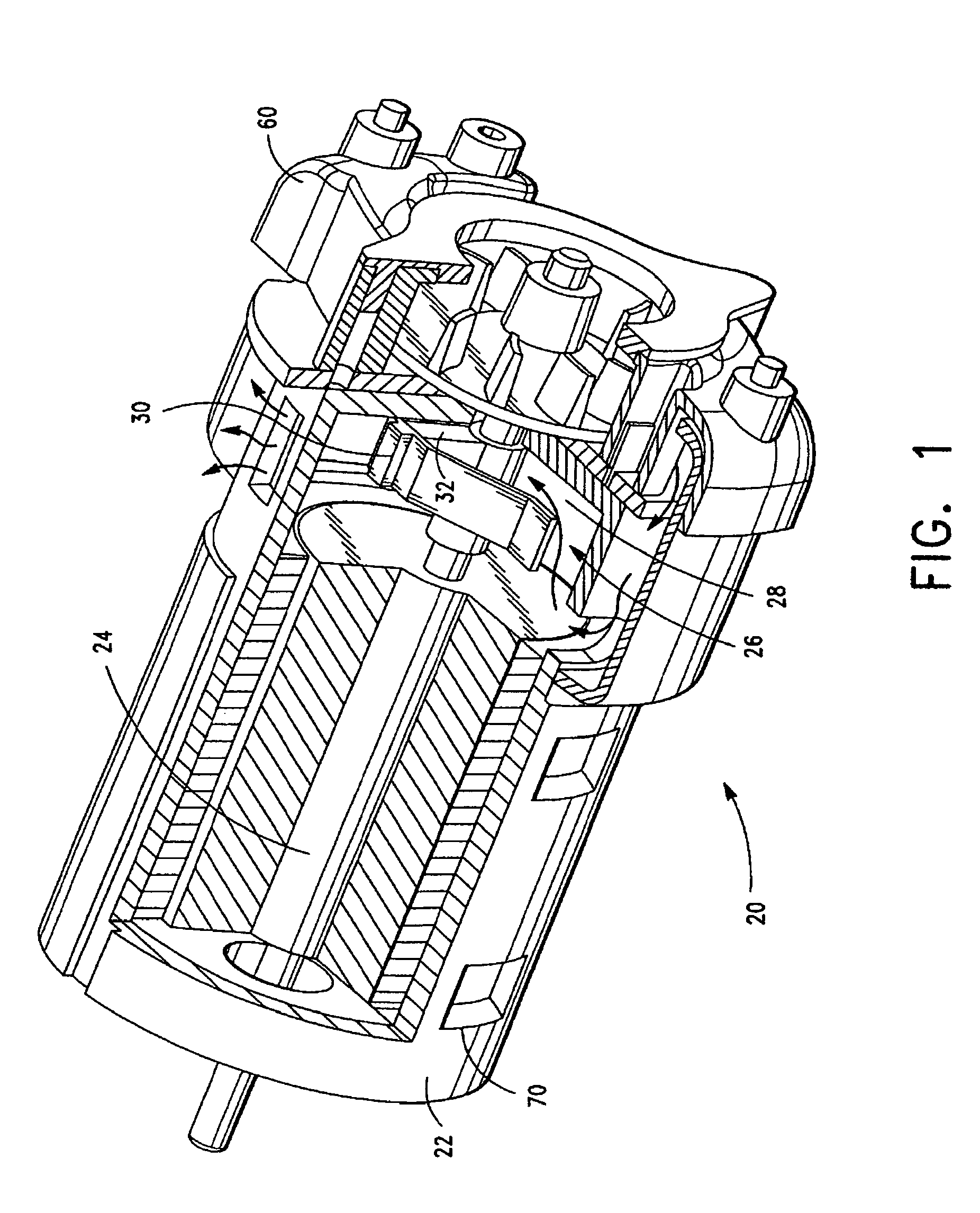

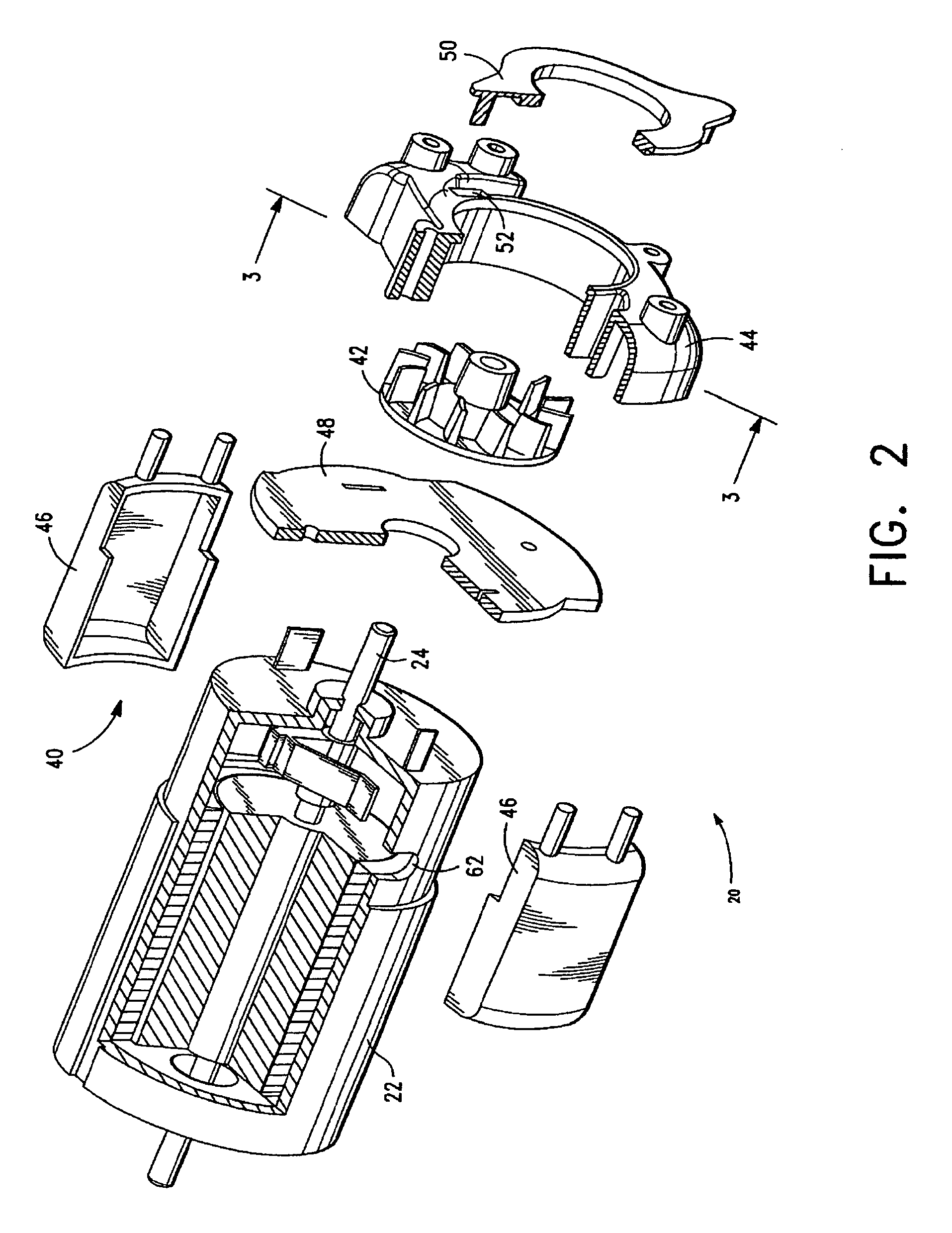

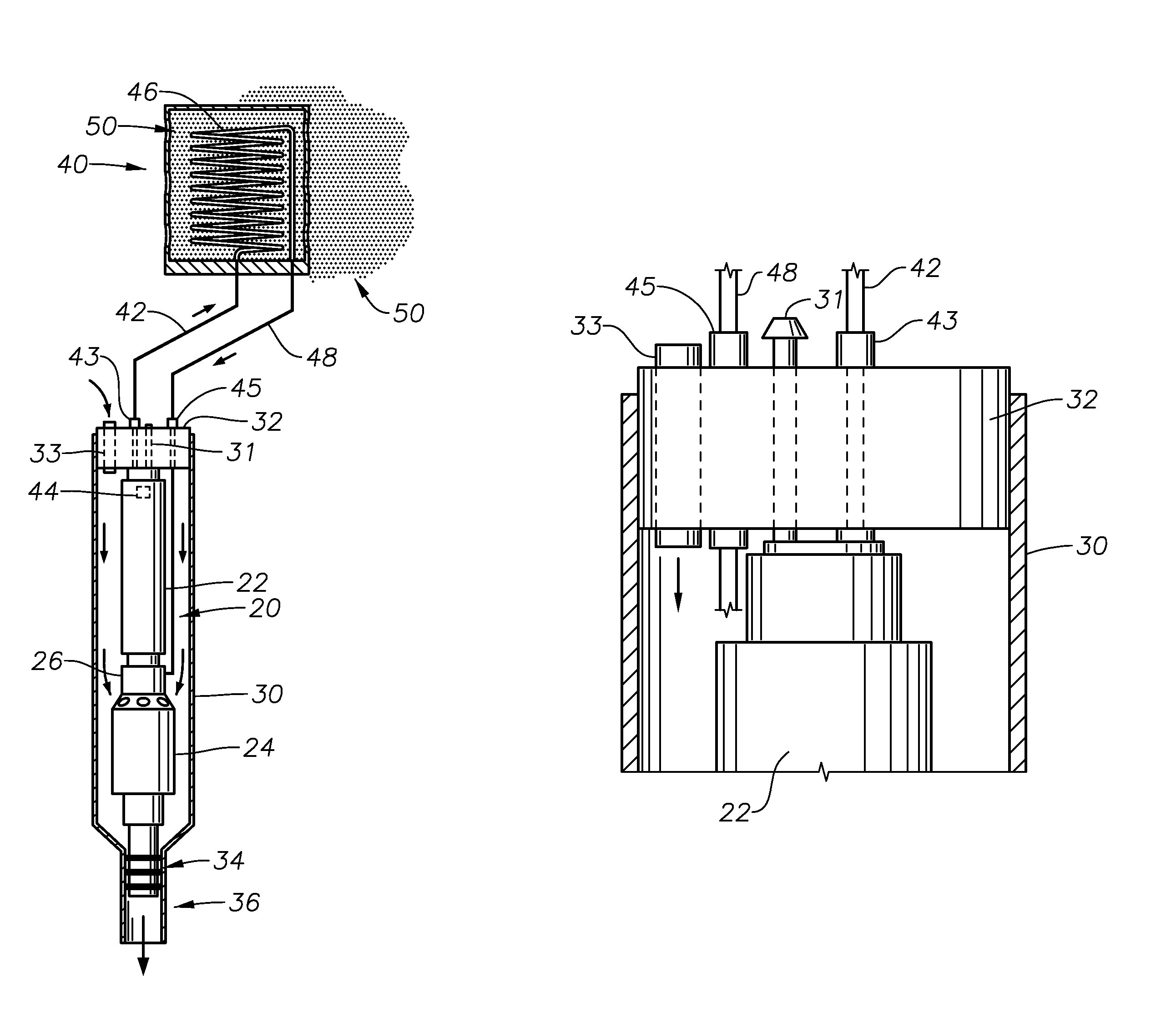

Method and structure for cooling an electric motor

InactiveUS7804208B2Prolong lifeExtend motor lifeCooling/ventillation arrangementForced-airEngineering

A high speed electric motor for use in a variety of applications. The electric motor an electric motor including a motor housing or stator, a rotor having a commutator and brushes for contacting the commutator at a predefined area known as the contact area. Additionally, the motor includes a forced air cooling assembly. The forced air cooling assembly includes a centrifugal fan for creating air flow, a manifold for accelerating the air flow. The manifold having exit ports and the exit ports being positioned directly over the contact area for directing the accelerated air flow at the contact area and the motor housing having at least one opening aligned with the contact area and at least a second opening defining an exit vent. Additionally, a method of cooling the motor in accordance with the invention is also disclosed.

Owner:SMARTPOOL

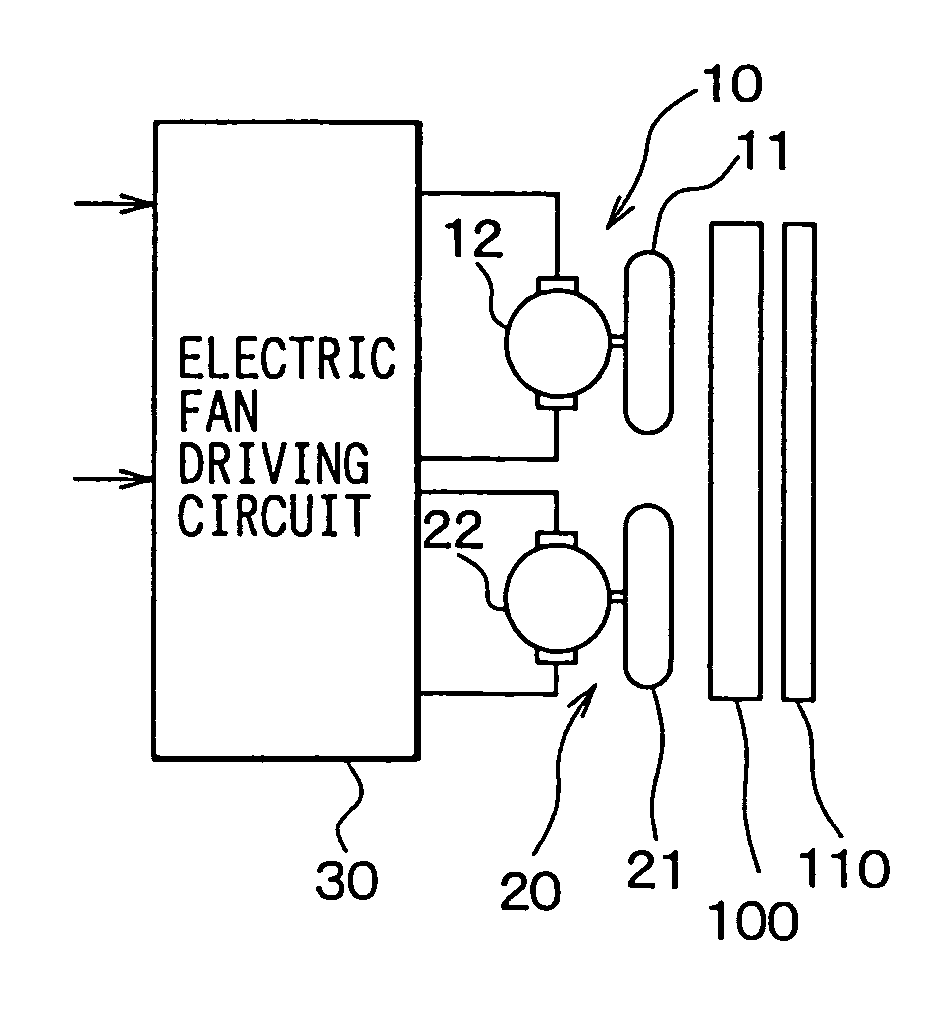

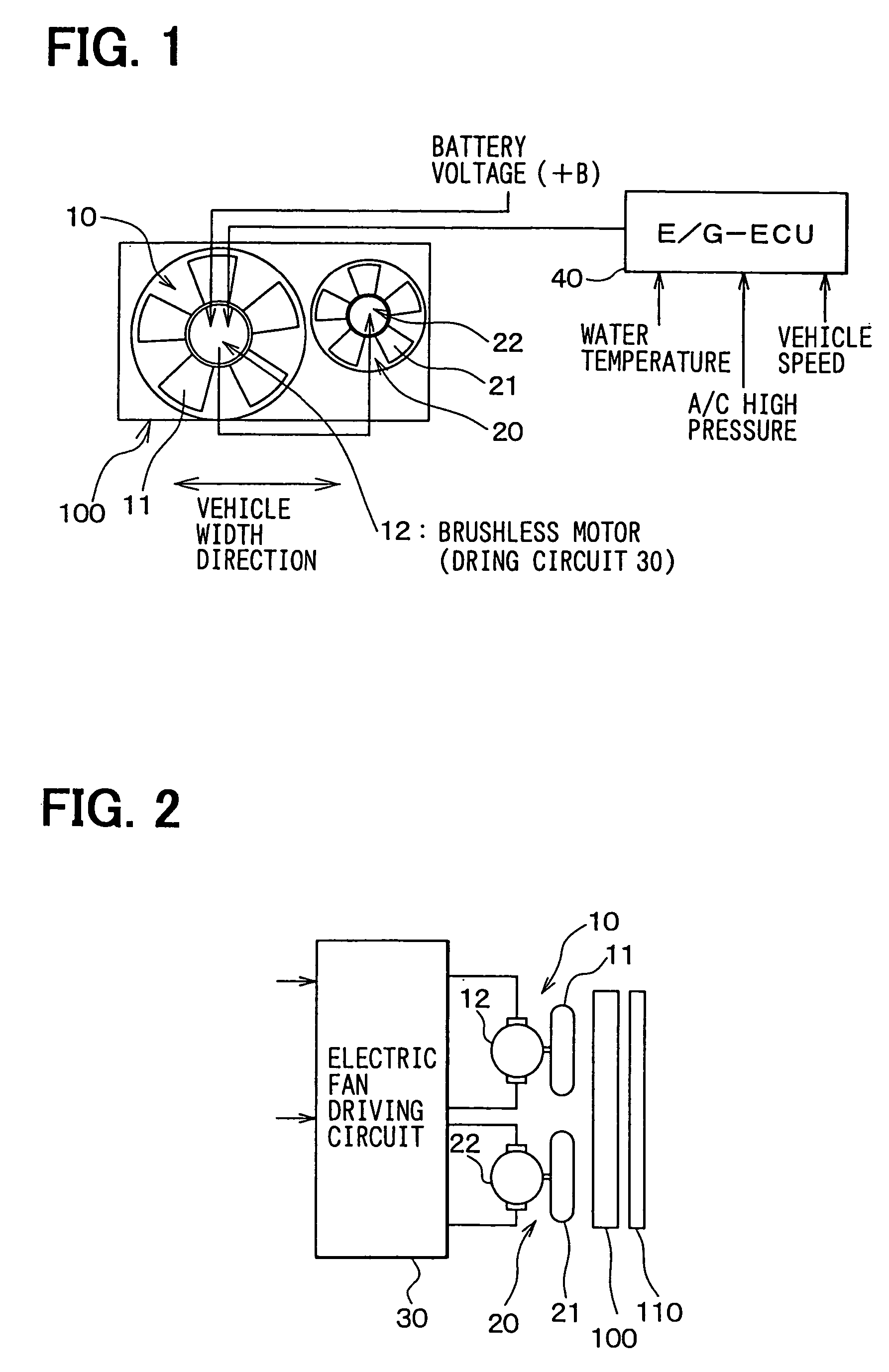

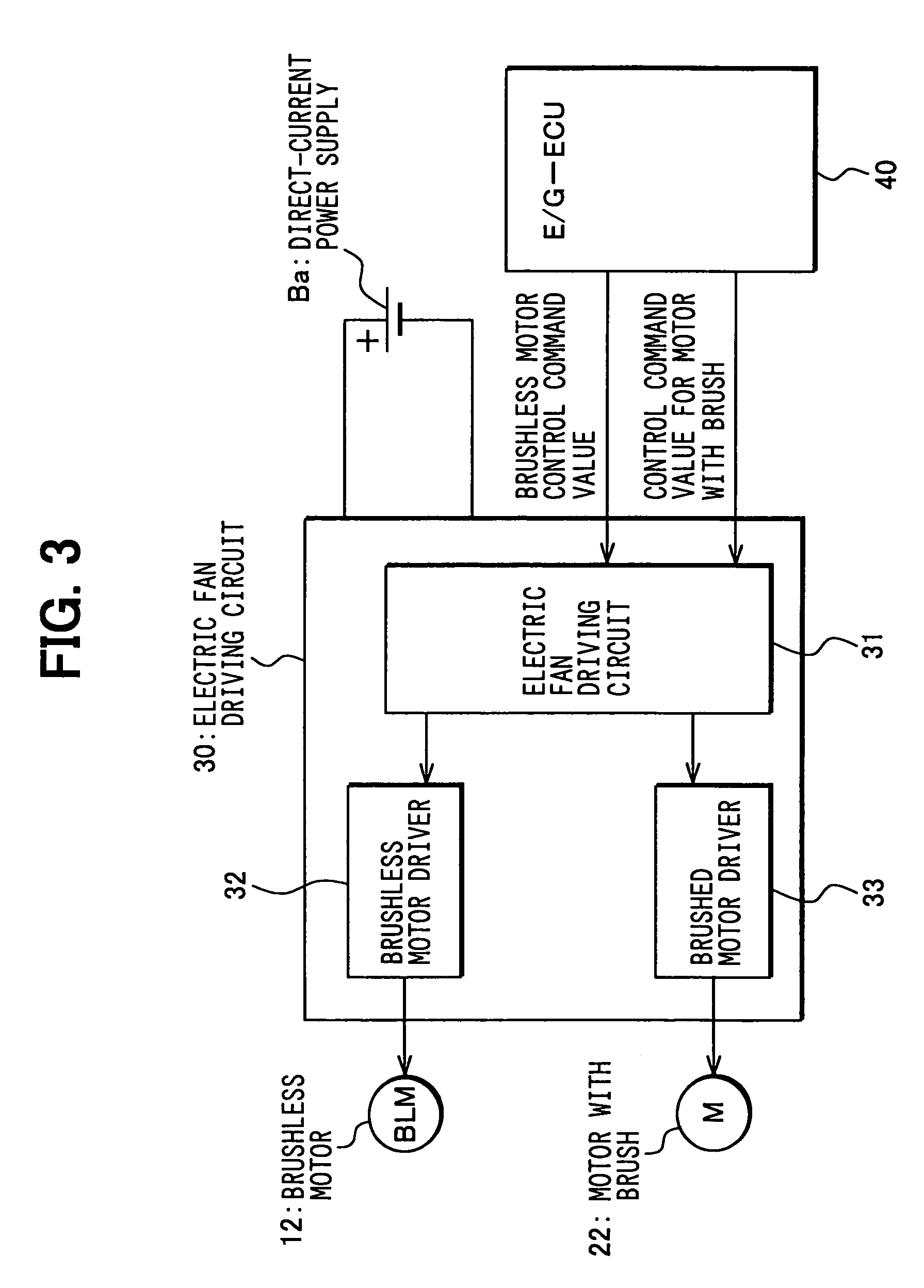

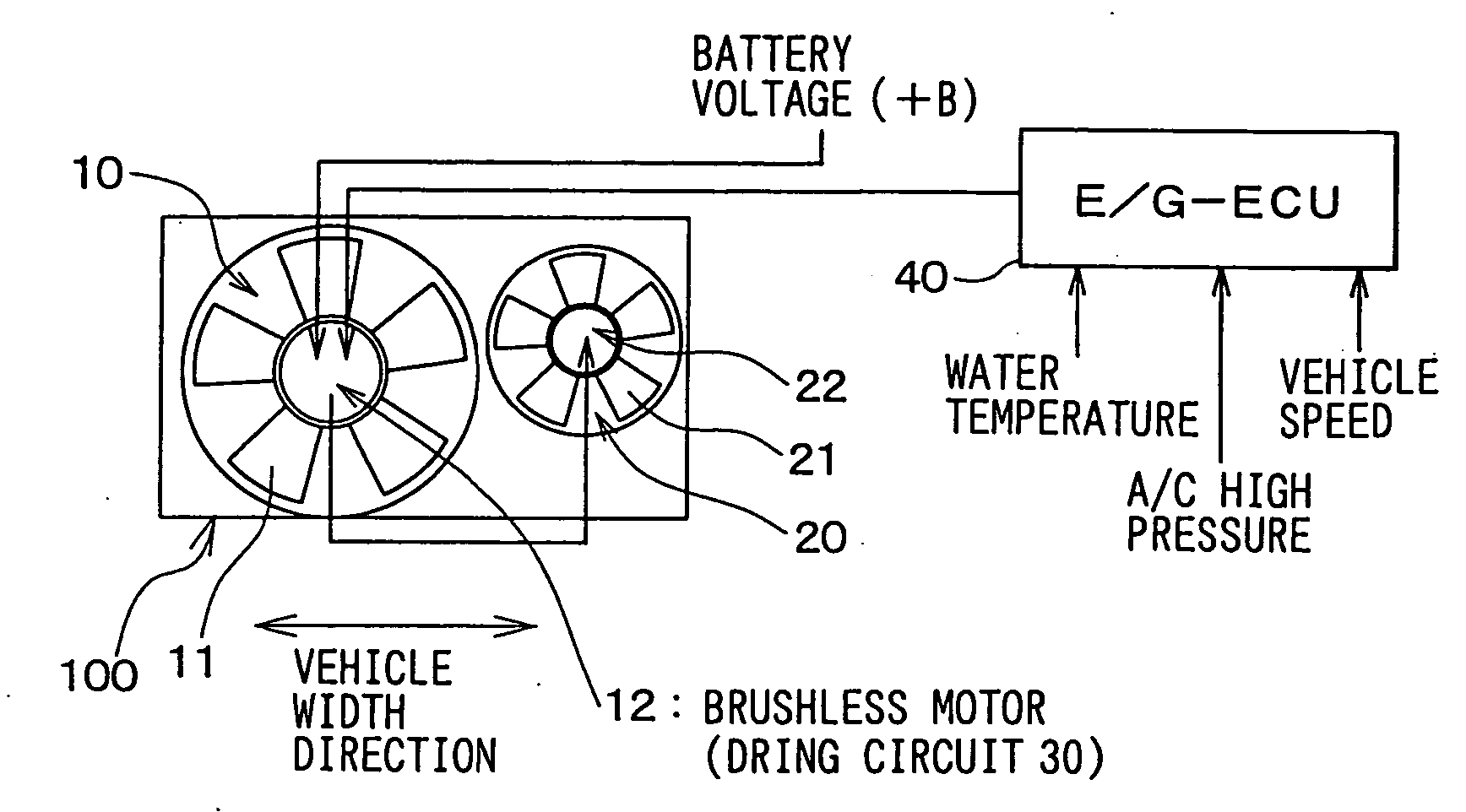

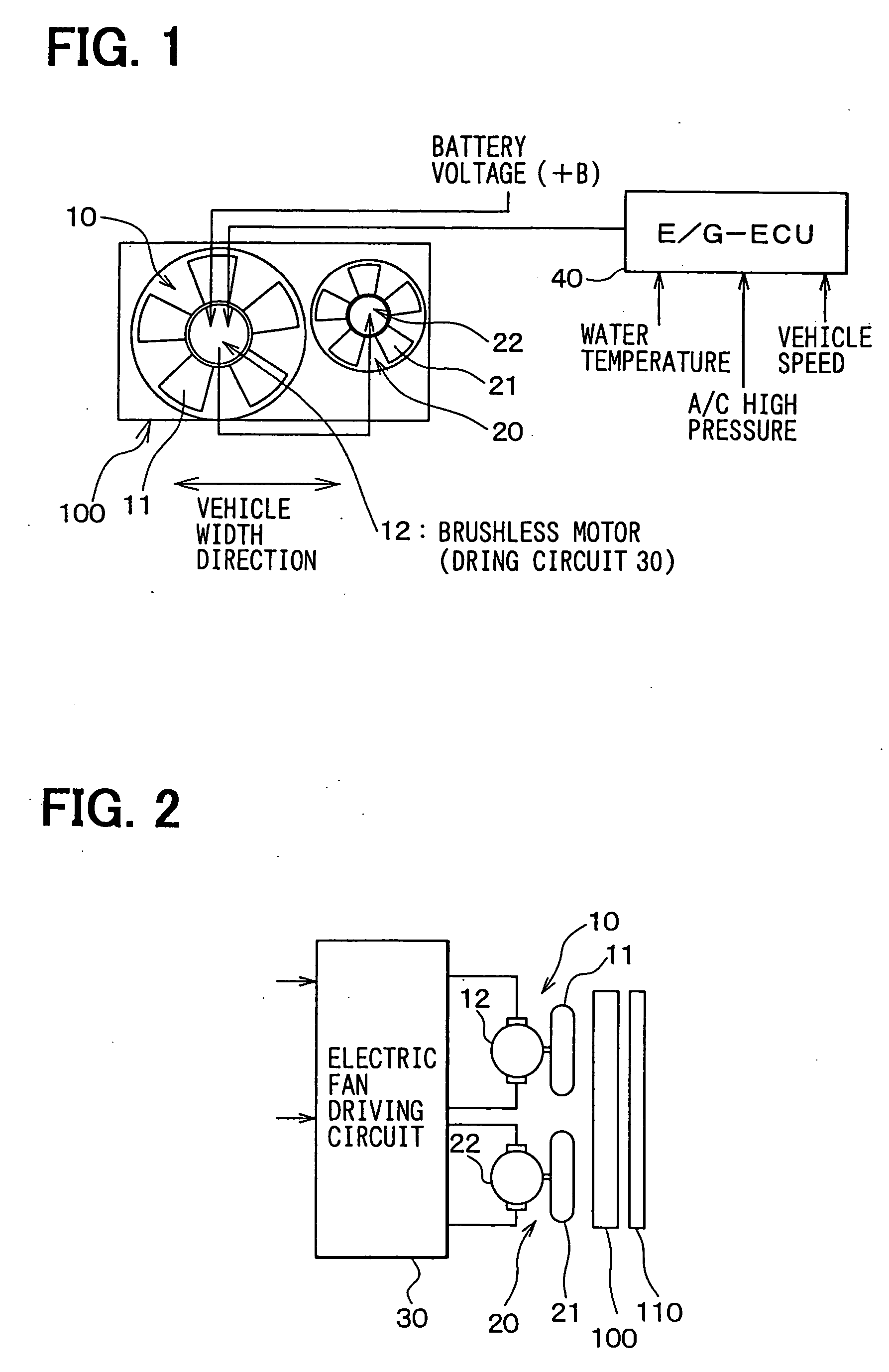

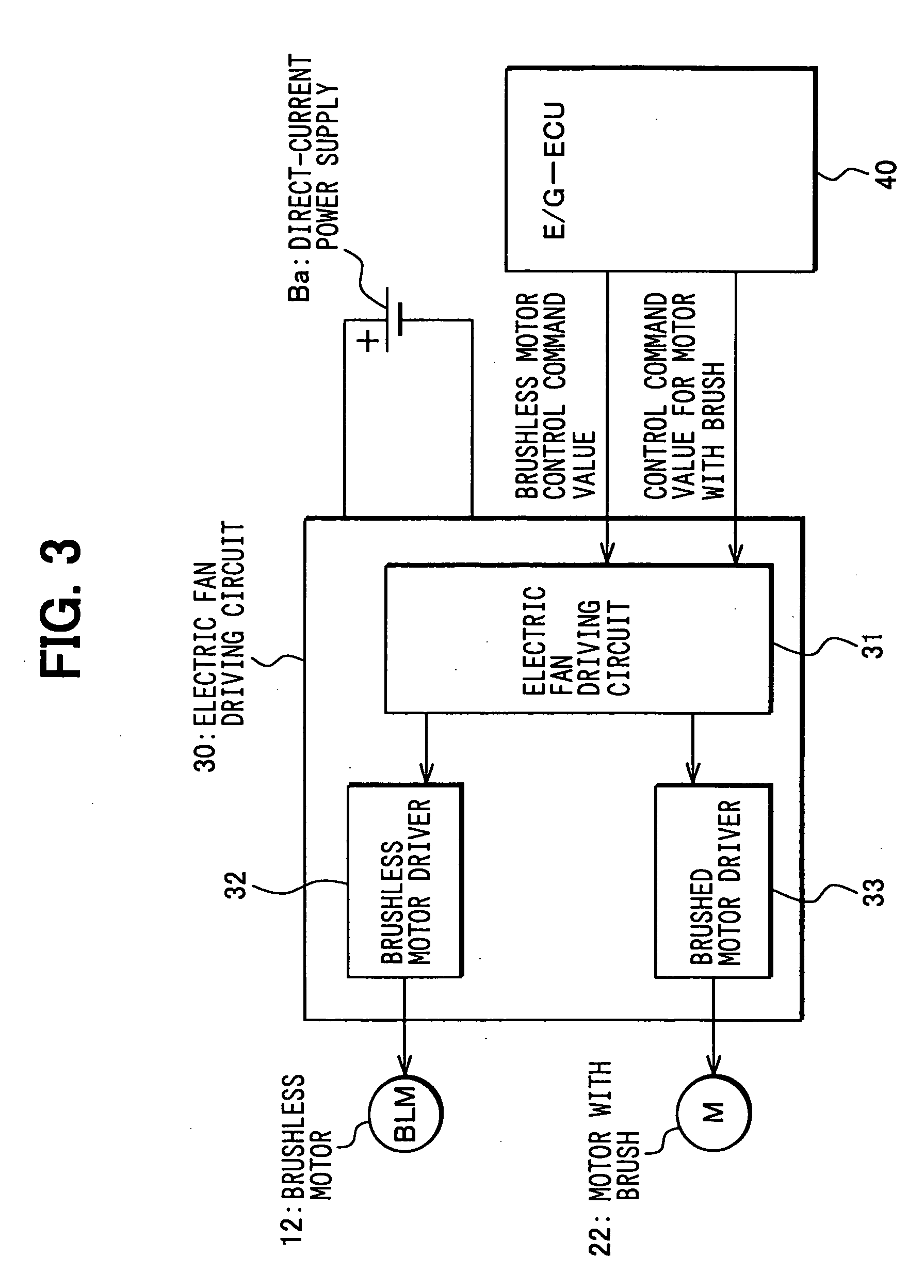

Electrical fan system for vehicle

InactiveUS6986260B2Reduce stepsReduce wearAir-treating devicesCoolant flow controlBrushless motorsElectron

An electric fan system has a first electric blower 10, which utilizes a brushless motor, and a second electric blower, which utilizes a brushed motor, for distributing the cooling air to the radiator and the condenser. The system has an electronic engine control unit which activates only the first electric blower when it determines that the cooling water temperature is less than T2, and activates both the first and second electric blowers when it determines that the cooling water temperature is T2 or higher. The water temperature is based on a detection output from a cooling water temperature sensor. Thus, since the electric blower is not activated unless the cooling water temperature becomes T2 or higher, use of the brushed motor is limited and its life is increased.

Owner:DENSO CORP +1

Bearing mechanism and spindle motor having the same

InactiveUS20070242911A1Increase rotation speedReduce the valueBearing componentsElectric machineryBearing surface

A bearing mechanism having a sleeve including at an inner circumferential surface thereof a first bearing surface and a relief portion including a diameter greater than that of the first bearing surface is used in a spindle motor. An axial length of the first bearing surface is between approximately 1.2 mm and 1.8 mm. By virtue of such configuration, characteristics of the spindle motor are improved and an operating life of the spindle motor is extended.

Owner:NIDEC CORP

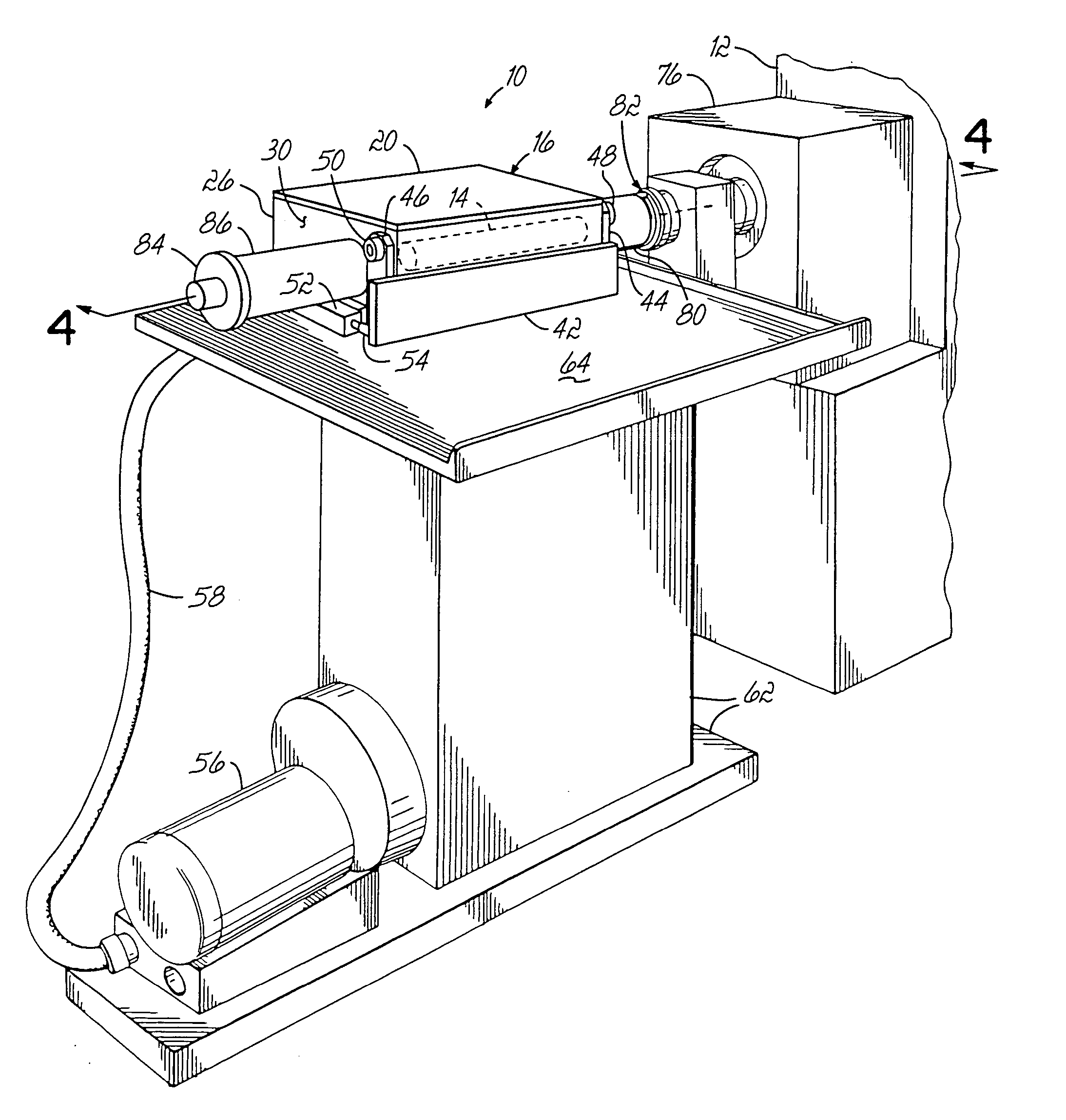

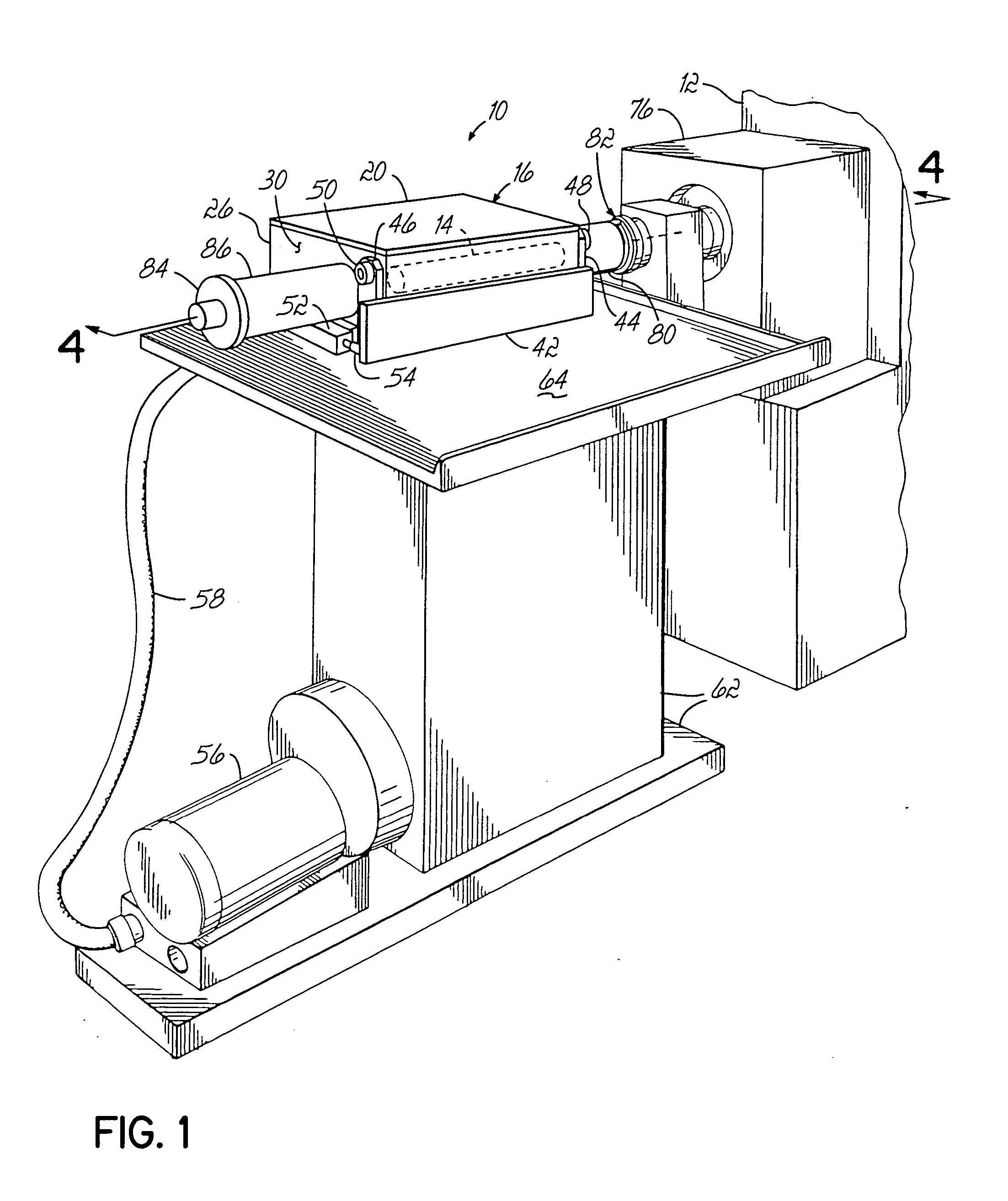

Air operated unloading device

ActiveUS20050111957A1Easy dischargeSimplifies and eliminatesLathesAutomatic conveying/guiding stockCouplingEngineering

A device for effecting an unloading operation of a workpiece with respect to a machine tool. The device includes a non-rotating dump tube having one end adapted for communication with a machine tool and a sidewall defining an opening for discharging a workpiece, a vacuum chamber enclosing the opening in the sidewall and including a workpiece outlet, the chamber configured to receive a workpiece from the dump tube, a door selectively sealingly engaged with the workpiece outlet, and configured to allow the unloading of a workpiece, and a source of vacuum coupled to the vacuum chamber and configured to draw a workpiece through the dump tube and into the vacuum chamber for unloading. A coupling may be disposed between an unloading device and a machine tool to allow the machine tool to operate at increased rates during an unloading operation.

Owner:J F BERNS

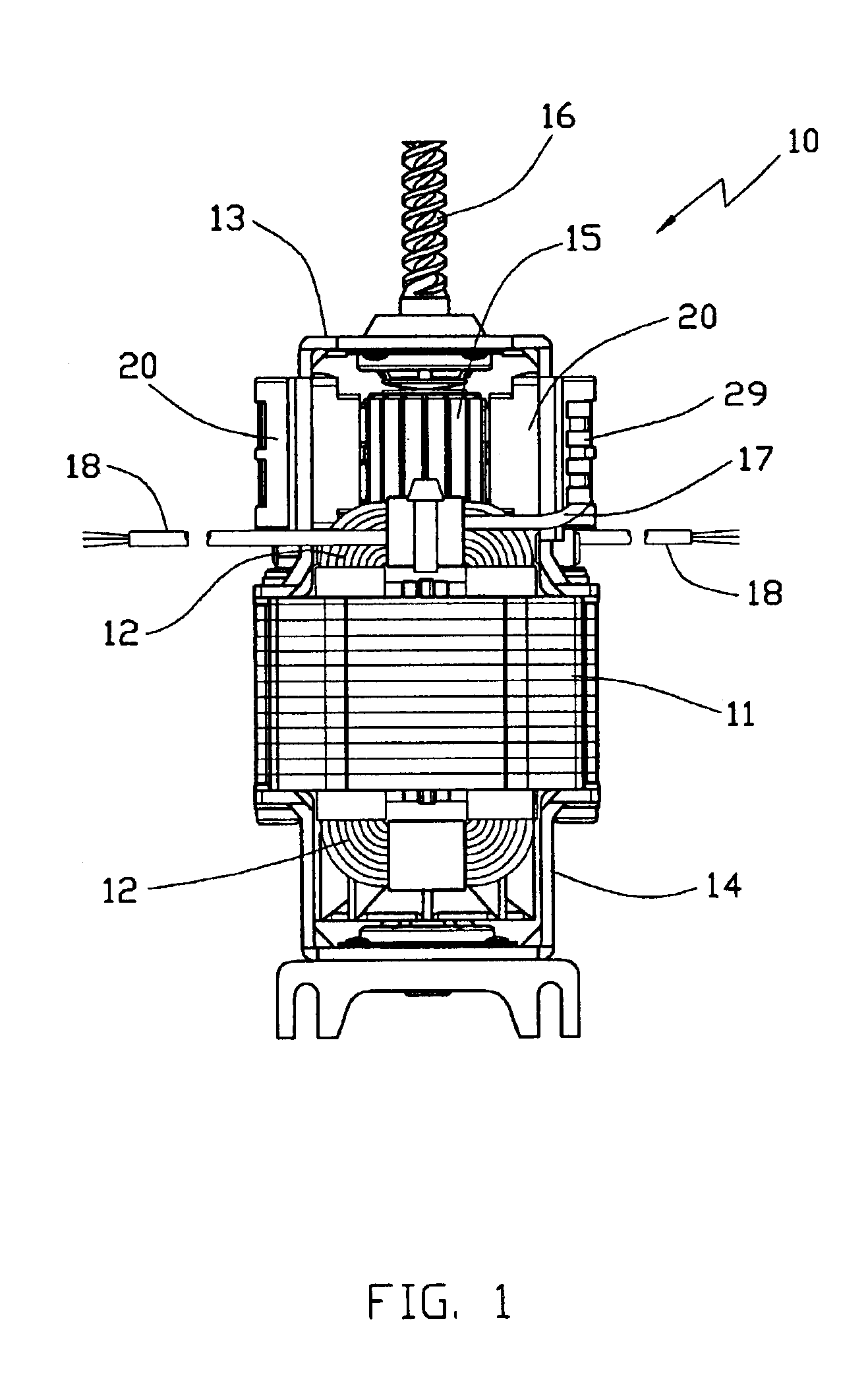

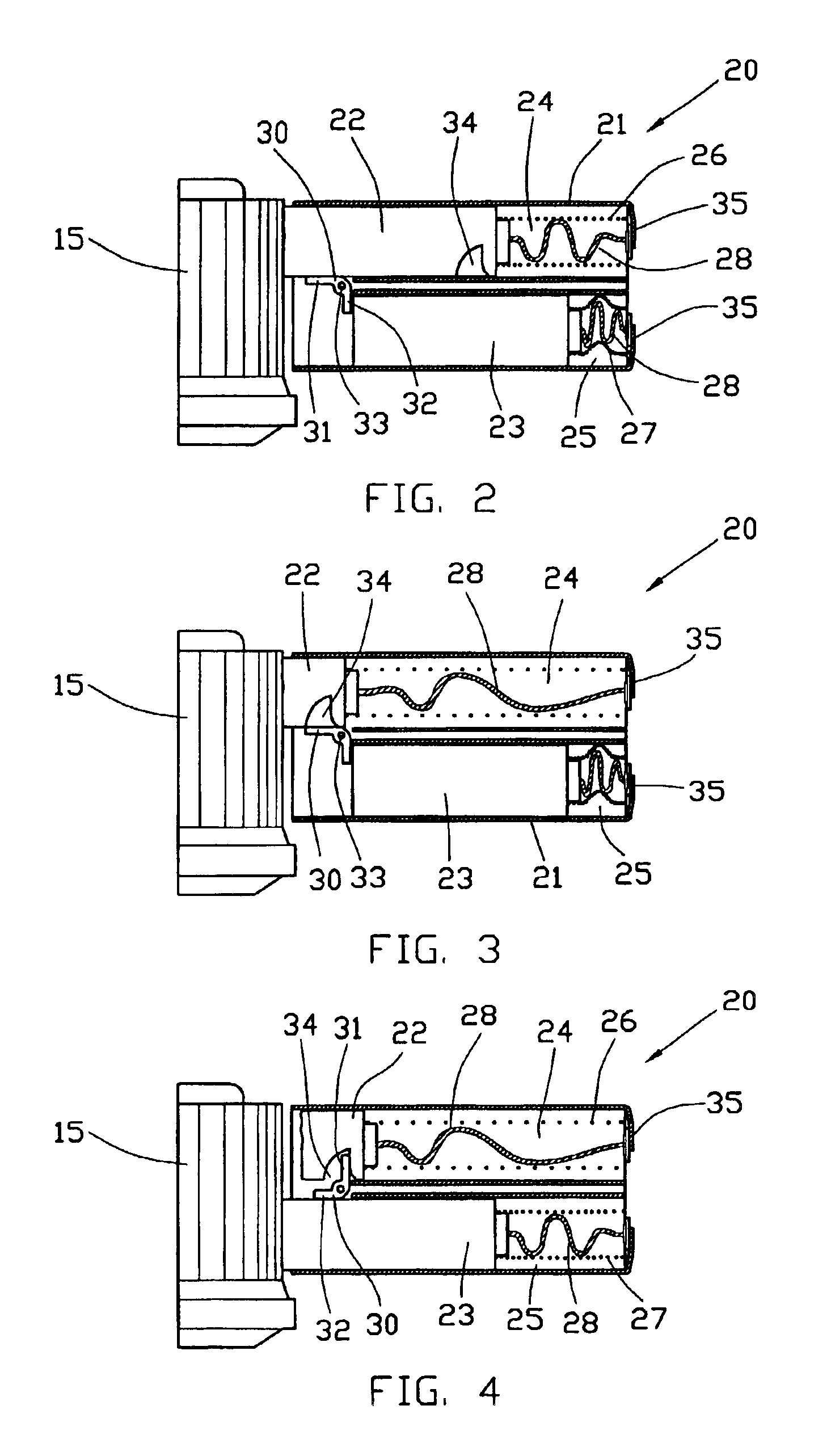

Double brush assembly

InactiveUS6873083B2Extend motor lifeProlong lifeRotary current collectorSupports/enclosures/casingsEngineeringElectric motor

A multi-brush cage assembly for a subfractional horsepower electric motor has two brushes 22, 23 received in separate chambers 24, 25 of the cage and urged by springs 26, 27 towards a commutator 15 of the motor. An L-shaped changeover lever 30 is located on a pivot 33 between the chambers and keeps one brush 23 retracted until the other brush 22 has worn out.

Owner:JOHNSON ELECTRIC INTERNATIONAL AG

Orbital hybrid magnetic electronic engine and generator

InactiveUS20090200882A1Reduce energy consumptionReduce heatSynchronous generatorsMagnetic circuit rotating partsLife timeDynamo

A motor configuration between the rotor and the commutation system, comprising rotor coils energized by mechanical or electrical ways wherein a positive charge, negative charge and a no-charge section is applied in order to reduce the heat and energy consumption and therefore increasing the motor life.

Owner:BERDUT TERUEL ELBERTO

Heat exchanger for ESP motor

InactiveUS8740586B2Reduce the temperatureCool the motor more effectivelyFlexible member pumpsTunnel/mines ventillationLine tubingEngineering

Owner:BAKER HUGHES INC

Electrical fan system for vehicle

InactiveUS20050005620A1Reduce wearReduce tearingAir-treating devicesCoolant flow controlBrushless motorsElectric machine

An electric fan system has a first electric blower 10, which utilizes a brushless motor, and a second electric blower, which utilizes a brushed motor, for distributing the cooling air to the radiator and the condenser. The system has an electronic engine control unit which activates only the first electric blower when it determines that the cooling water temperature is less than T2, and activates both the first and second electric blowers when it determines that the cooling water temperature is T2 or higher. The water temperature is based on a detection output from a cooling water temperature sensor. Thus, since the electric blower is not activated unless the cooling water temperature becomes T2 or higher, use of the brushed motor is limited and its life is increased.

Owner:DENSO CORP +1

Systems and methods of using subsea frames as a heat exchanger in subsea boosting systems

InactiveUS20110247788A1Reduce the temperatureComponents is relatively effectivePump componentsIndirect heat exchangersOcean bottomPlate heat exchanger

Systems and methods of cooling a motor of an electrical submersible pump (ESP) assembly employed in an electrical submersible subsea booster pumping system, are provided. A supporting frame structure such as an ESP mounting skid or top end assembly of a caisson having structural members exposed to environmental seawater, is modified or designed to include fluid conduits within the structural members to establish lubricant pathways for lubricant to flow. A heated / hot lubricant line connects between a supporting structure lubricant inlet port and an ESP motor lubricant outlet port. A cooled lubricant line connects between a supporting structure lubricant outlet port and an ESP motor lubricant inlet port. A pump or other fluid moving device circulates lubricant from the ESP motor to the lubricant pathways within the supporting frame structure, whereby the seawater cools the lubricant contained therein, which is then circulated back into the motor to assisting cooling the motor.

Owner:BAKER HUGHES INC

Bearing positioning structure for motor

ActiveUS20090261672A1Improve assembly reliabilityExtend motor lifeShaftsRecord information storageCouplingEngineering

A bearing positioning structure for a motor includes an axial tube and a positioning member. The positioning member includes a pressing portion and a coupling portion. The coupling portion of the positioning member is engaged with a coupling section of the axial tube for securely mounting the positioning member to the axial tube, with the pressing portion of the positioning member pressing against a bearing to position the bearing in the axial tube. In another example, the coupling portion of the positioning member engages with a coupling section on a stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

External oil expansion chamber for seabed boosting ESP equipment

ActiveUS8485797B2EffectiveLoss of motor oil decreasesConstructionsPump componentsEngineeringFormation fluid

An expansion chamber to serve ESP equipment installed on the seabed located in either a caisson or a conduit on a skid. The expansion chamber provides an external reservoir for expansion and contraction of motor oil in the ESP equipment. During operation of an ESP, the heat generated in the motor raises the temperature of the motor oil, causing it to expand. The expansion chamber is connected to the ESP equipment via oil lines that allow oil to expand into the expansion chamber when the temperature of the motor oil increases. The expansion chamber has a movable barrier therein that defines primary and secondary chamber. Oil communicates with the primary chamber. Formation fluid within the conduit surrounding the motor communicates with the secondary chamber.

Owner:BAKER HUGHES INC

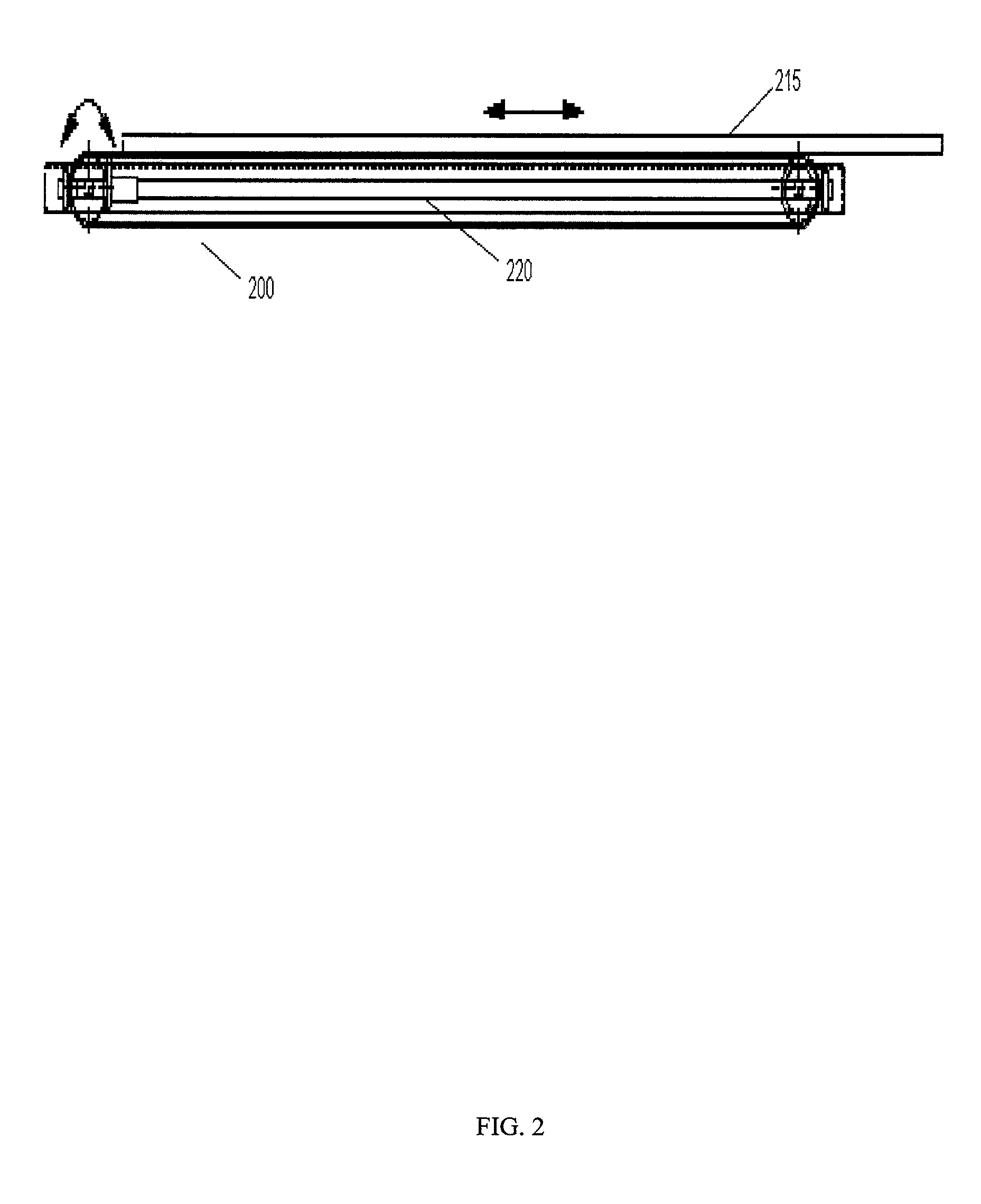

Drive system for imaging device

ActiveUS20070226906A1Simple and compact and reliable and accurateSimple methodPatient positioning for diagnosticsNursing bedsEngineeringImaging equipment

A drive system for an imaging device is provided. The drive system comprises a table assembly for engaging and supporting a patient and a driving system for moving the table assembly. The driving system can be directly coupled to the table assembly. The table assembly comprises a carrier that engages and supports a patient and at least two elongated rails placed beneath the carrier and extending between the opposing sides of the table assembly. The driving system for moving the table assembly comprises at least one double end shaft motor, at least one belt coupled to the double end shaft motor via a coupling device and at least one pair of timer pulleys coupled to the belt. Further, each timer pulley is directly coupled to a feedback device at a first end and a brake device at a second end.

Owner:GENERAL ELECTRIC CO

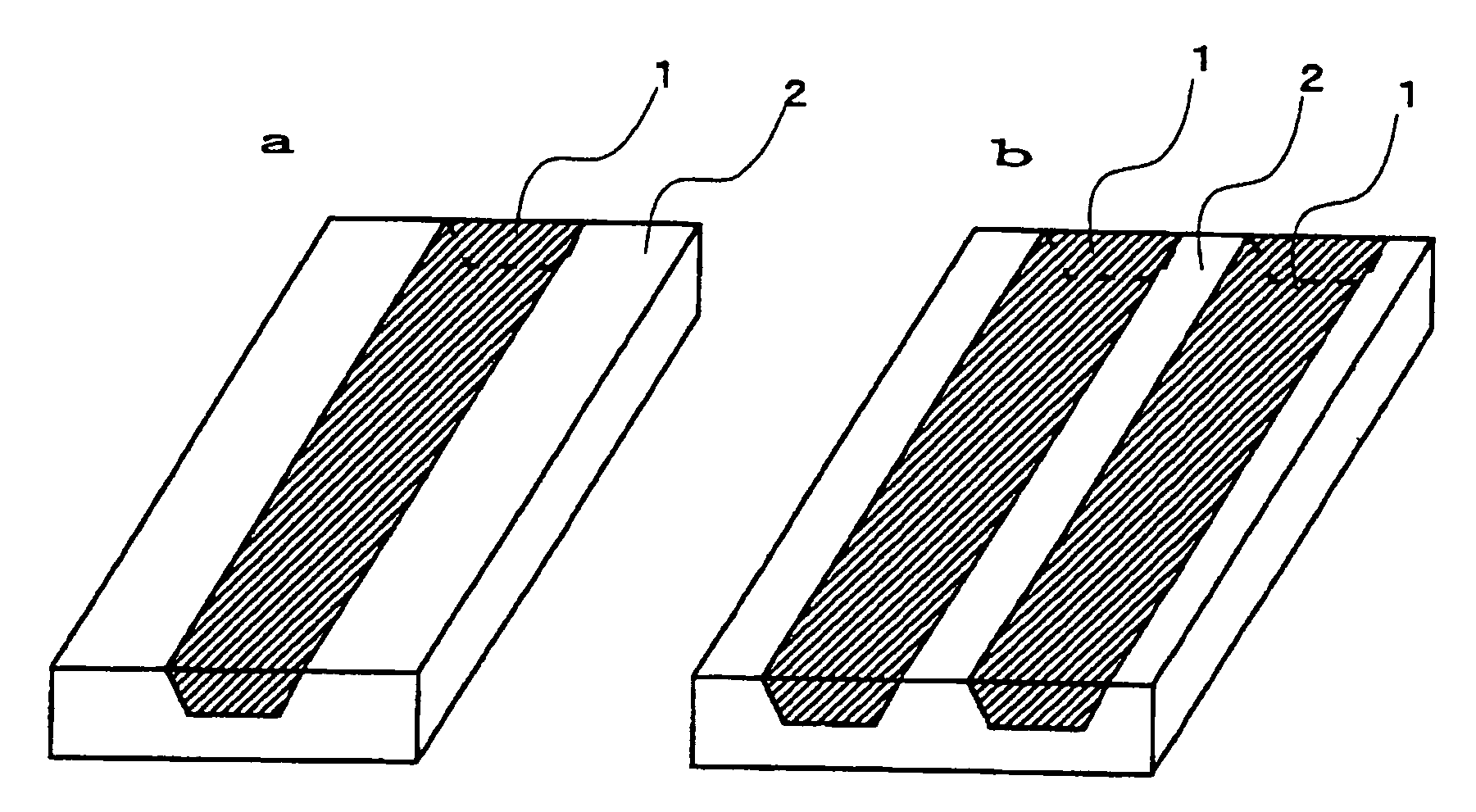

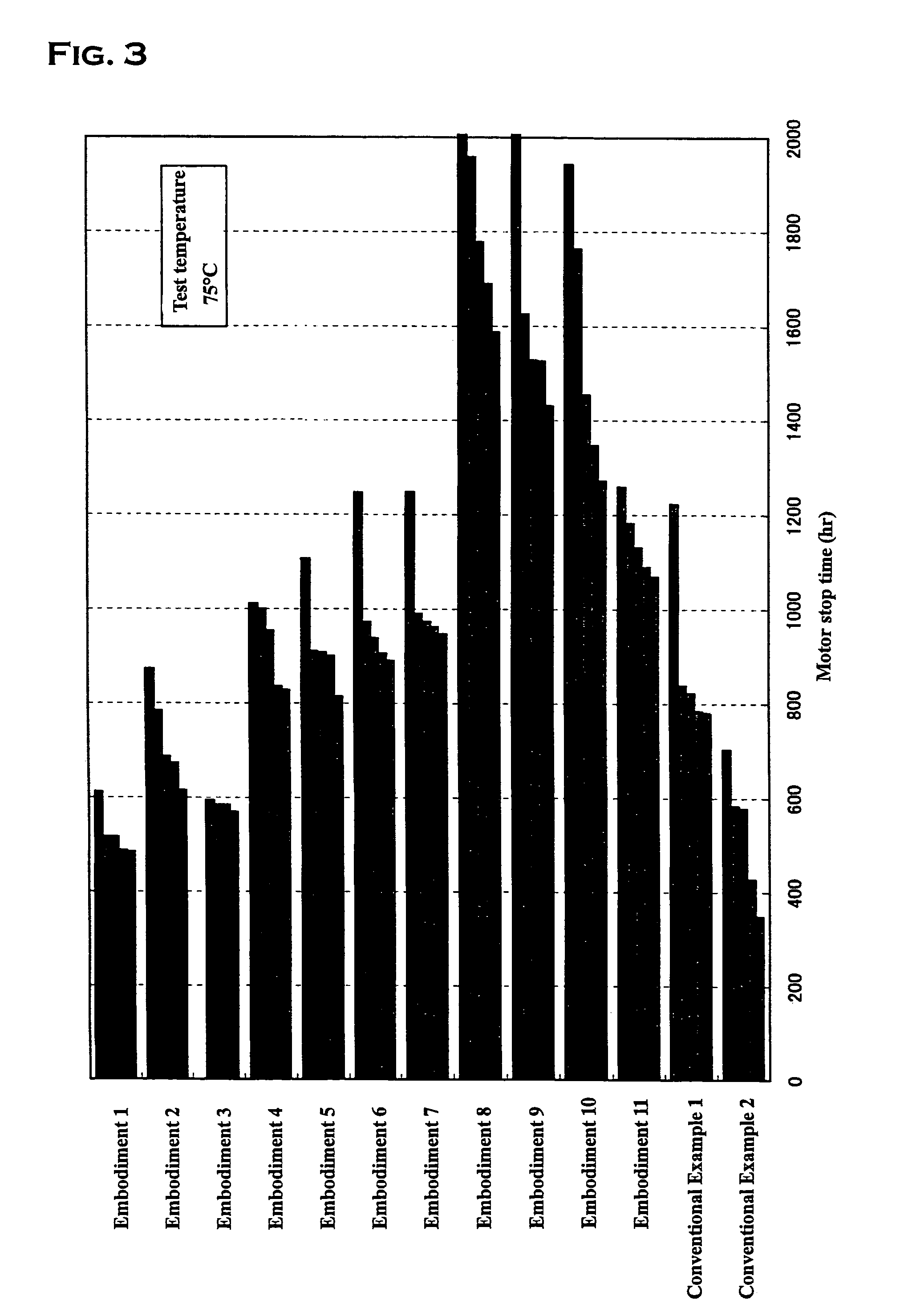

Material for sliding contacts, clad composite material and small-sized DC motor using the same

ActiveUS7160632B2Increase contact resistanceImprove electrical performanceContact materialsRotary current collectorCD playerMetal particle

The invention provides a material for sliding contacts that is suitable for a small-sized DC motor used in recent downsized CD players and is excellent in durability. A material for sliding contacts used in a commutator of a small-sized DC motor that consists essentially of 0.01 to 3.0% Ni by weight, 0.01 to 6.0% ZnO by weight and / or 0.01 to 3.0% MgO by weight, furthermore, in some cases, 0.01 to 5.0% Cu by weight, and the balance Ag, in which Ni metal particles, ZnO particles or MgO particles are dispersed in the matrix of Ag.

Owner:MABUCHI MOTOR +1

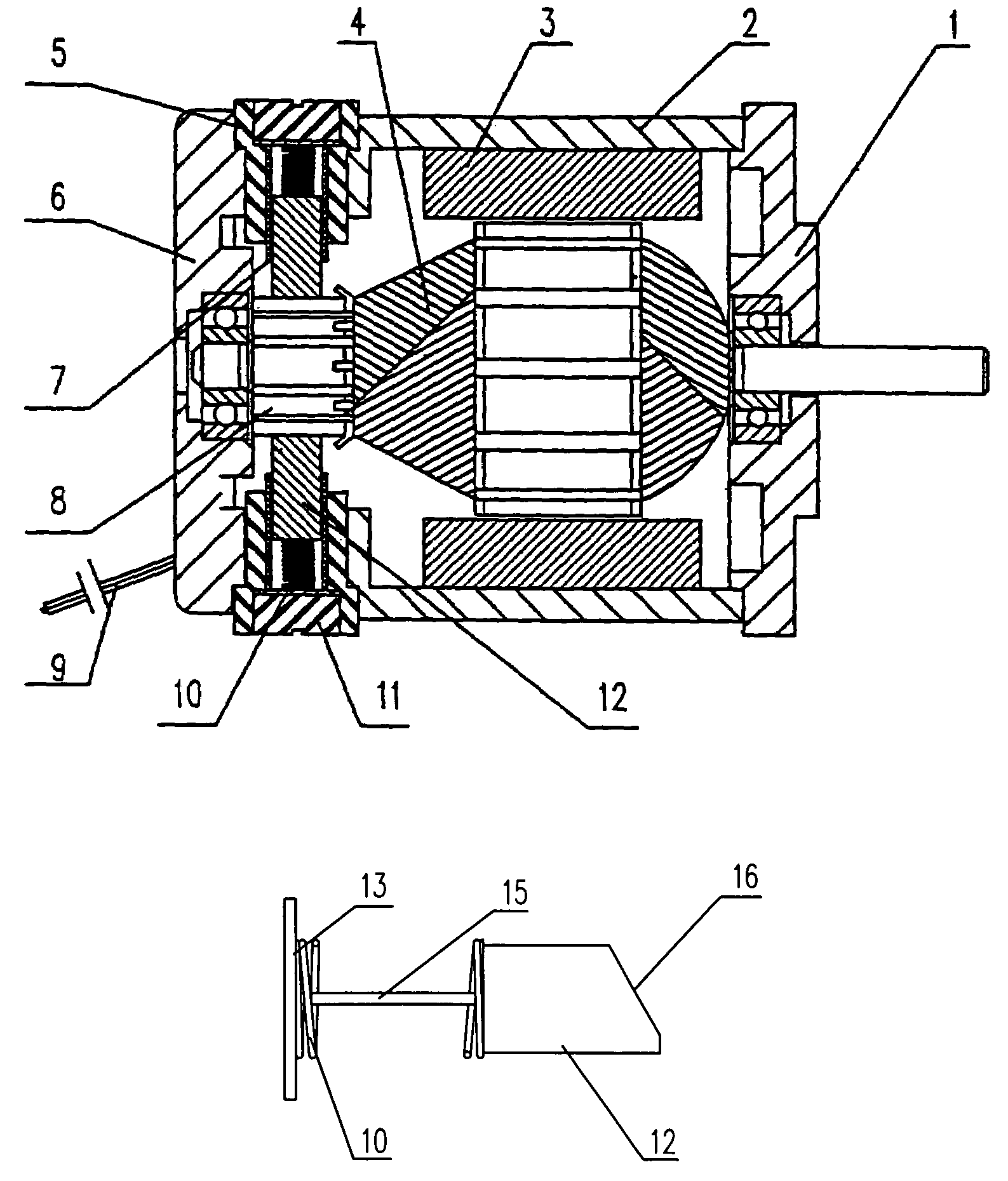

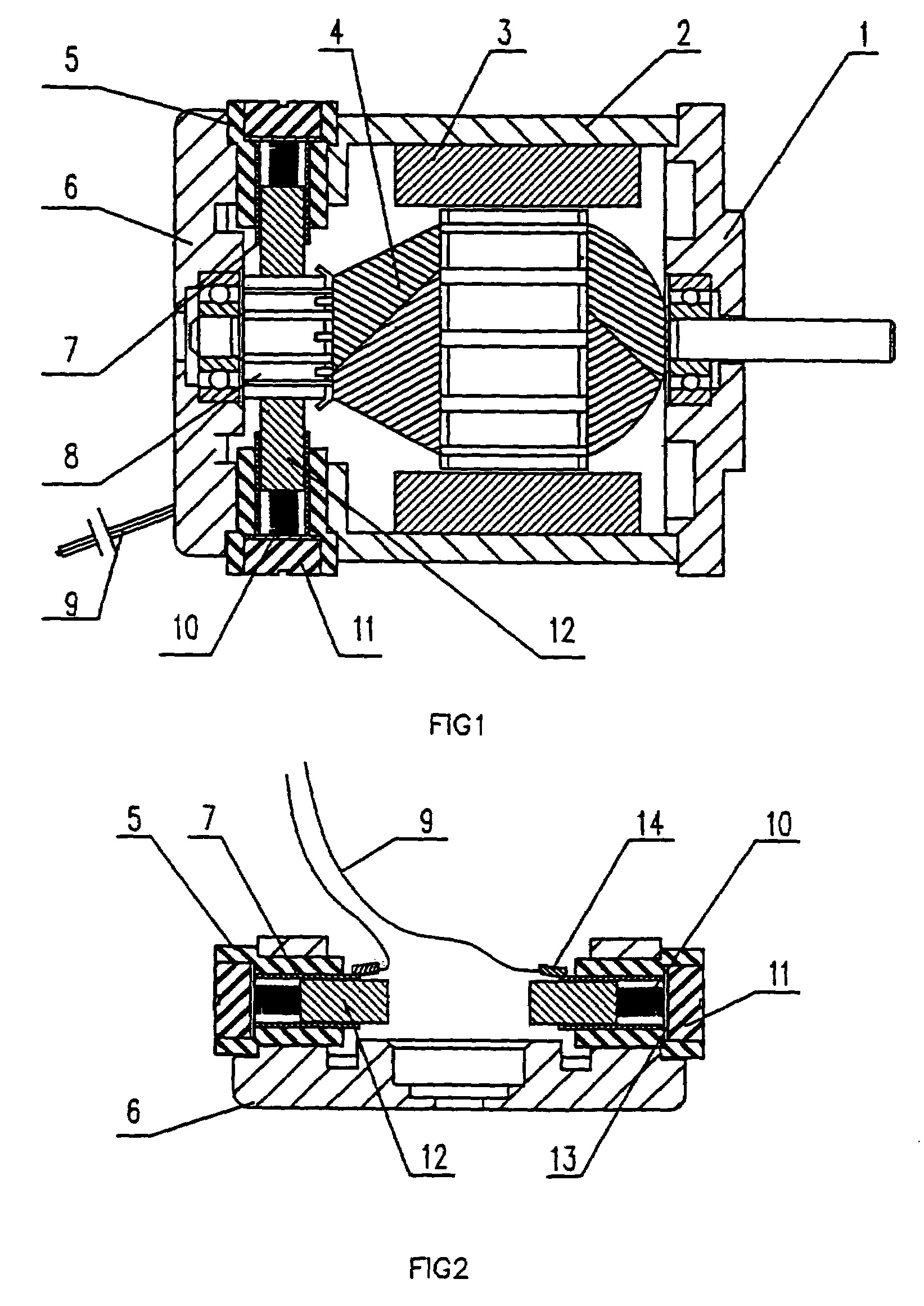

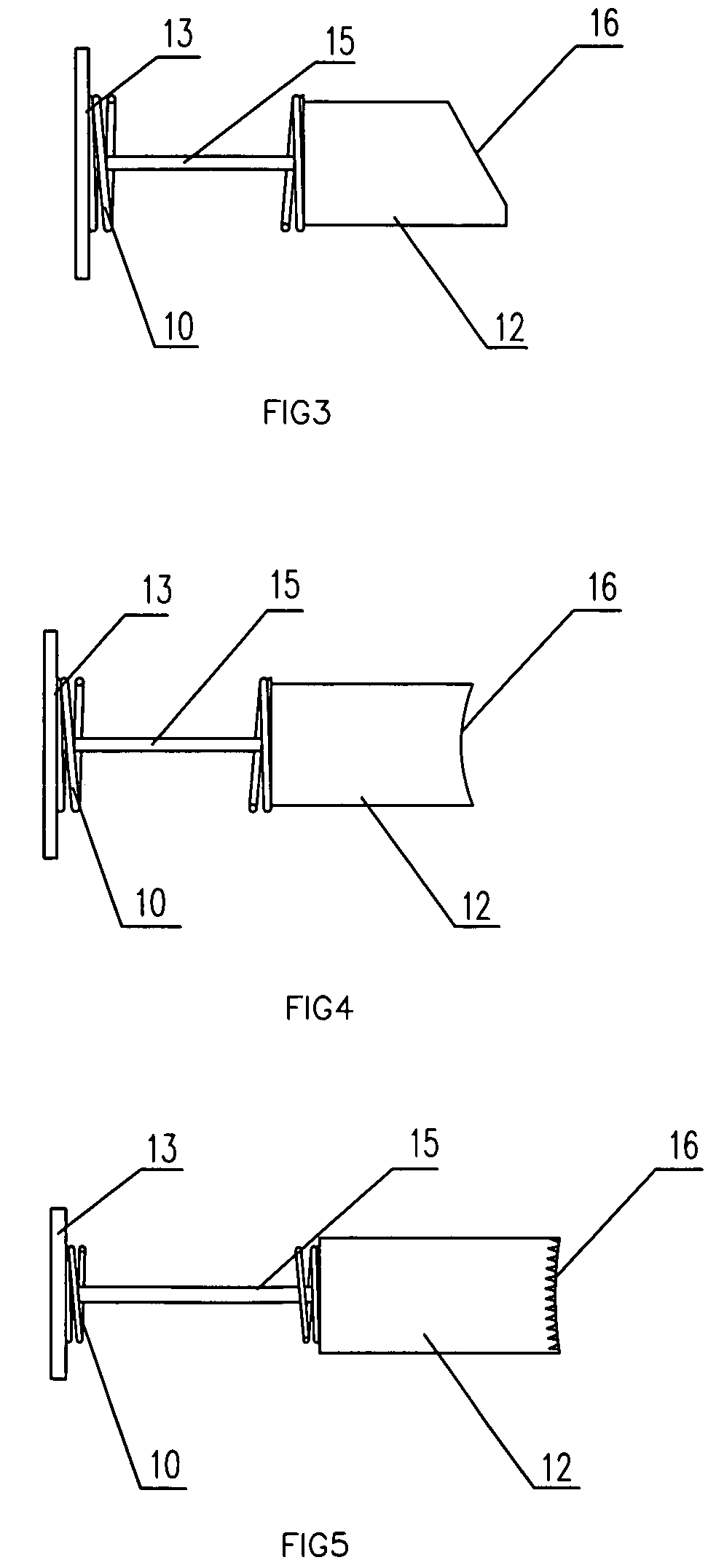

DC motor with externally mounted carbon brush

InactiveUS7180219B2Simple structureEasy to operateRotary current collectorSupports/enclosures/casingsElectrical connectionEngineering

This invention discloses a DC motor with externally mounted carbon brushes, comprising a front end cover, a housing, magnet, a rotor, a commutator and a back end cover, characterized in that the outer wall of the back end cover is provided with two mounting holes for brush brackets which are mounted with annular brush brackets having identical structures, a radial sliding tube used to mount the carbon brush is located in said brackets, said carbon brush in the sliding tube for carbon brush contacts the commutator by a spring biasing against a brush cap, the outward end thereof being connected to a copper sheet through a brush shunt, said copper sheet is held against the back end of the sliding tube, a lead wire for a power source is lead out from an outlet of another copper sheet at an outer wall of the sliding tube. The electrical connection of the carbon brush is lead out from the sliding tube through the brush shunt and the copper sheet, therefore the electrical connection is reliable. The present invention is simply constructed and easily mounted, the volume thereof is small, the operation thereof is reliable, it is easy to maintain and replace the carbon brushes and it extends significantly the life of the motor.

Owner:XU XIAOHUA

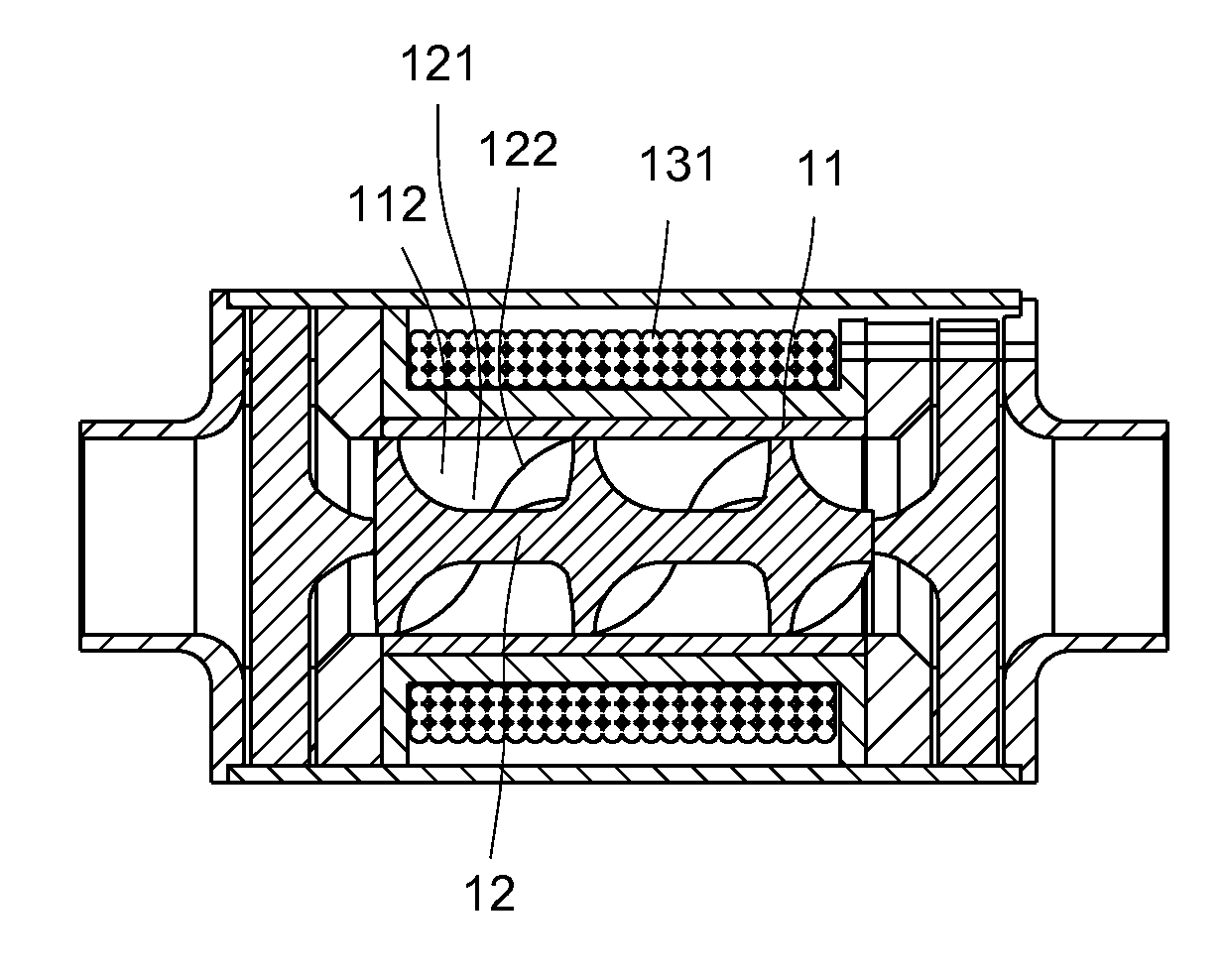

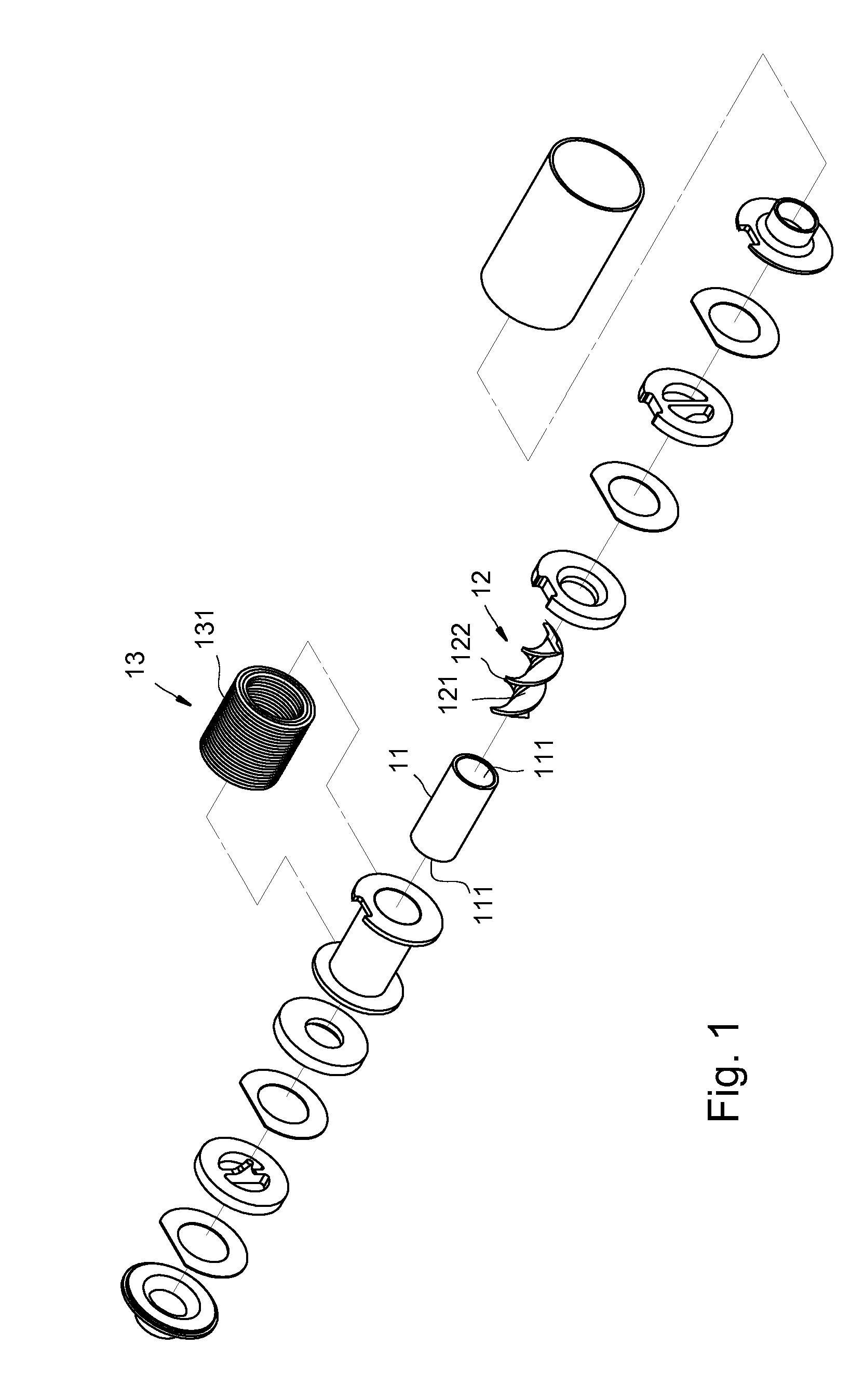

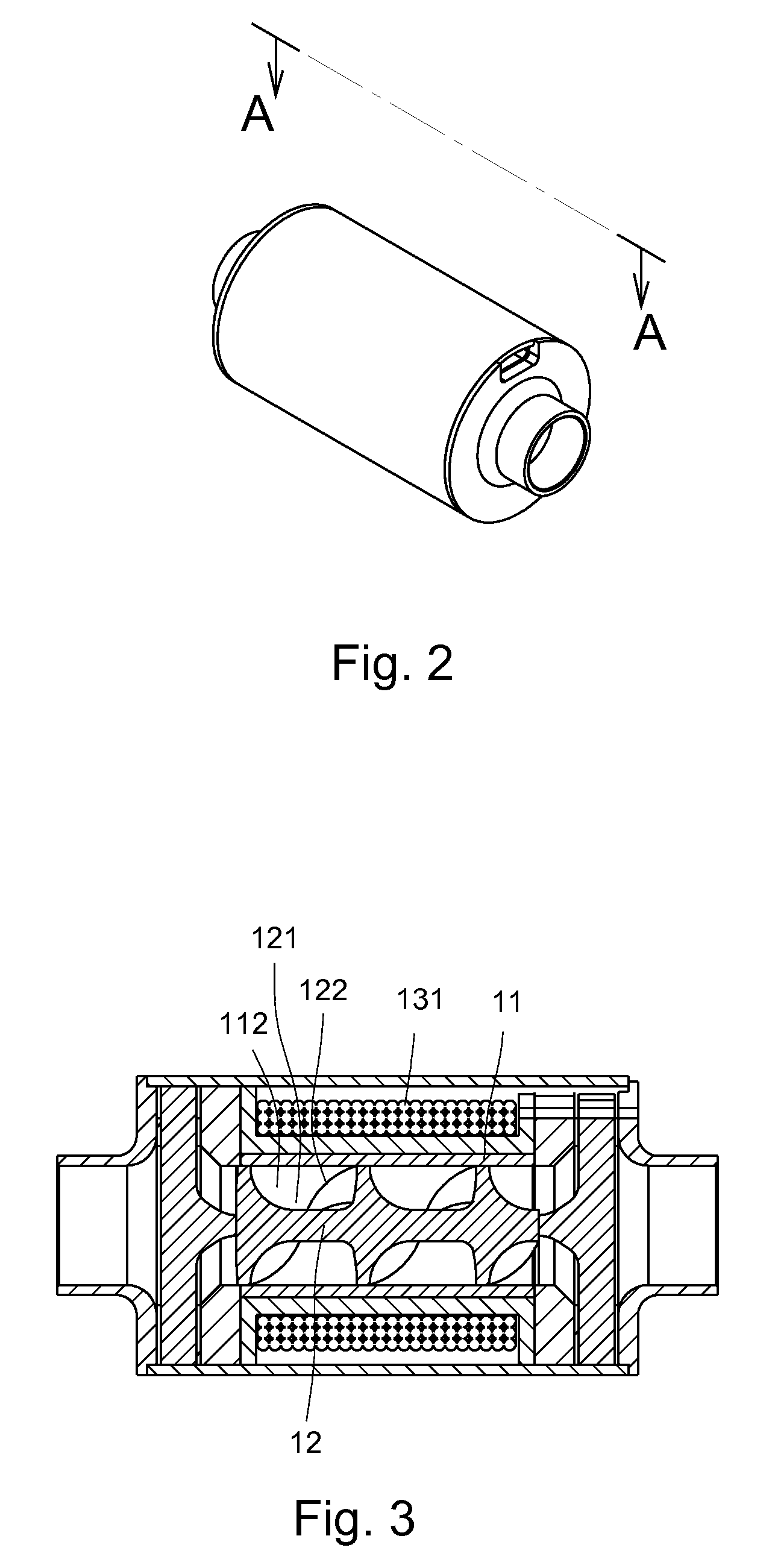

Motor and a handheld device having a motor

ActiveUS20170164711A1Reduce weightReduce noise levelMagnetic circuit rotating partsPump componentsImpellerMagnet

A handheld device comprising a motor for generating an airflow through the device, the motor including: a frame for supporting a rotor assembly and a stator assembly, the frame including an inner wall and an outer wall and a plurality of diffuser vanes extending between the inner wall and outer wall; a rotor assembly including a shaft, a magnet, a bearing assembly and an impeller; and a stator assembly including a bobbin, a stator core and a winding wound around the bobbin; the frame being formed of zinc and the impeller being formed of aluminium.

Owner:DYSON TECH LTD

DC motor with externally mounted carbon brush

InactiveUS20060028091A1Simply constructedEasy and reliable operationRotary current collectorSupports/enclosures/casingsMagnetElectrical connection

This invention discloses a DC motor with externally mounted carbon brushes, comprising a front end cover, a housing, magnet, a rotor, a commutator and a back end cover, characterized in that the outer wall of the back end cover is provided with two mounting holes for brush brackets which are mounted with annular brush brackets having identical structures, a radial sliding tube used to mount the carbon brush is located in said brackets, said carbon brush in the sliding tube for carbon brush contacts the commutator by a spring biasing against a brush cap, the outward end thereof being connected to a copper sheet through a brush shunt, said copper sheet is held against the back end of the sliding tube, a lead wire for a power source is lead out from an outlet of another copper sheet at an outer wall of the sliding tube. The electrical connection of the carbon brush is lead out from the sliding tube through the brush shunt and the copper sheet, therefore the electrical connection is reliable. The present invention is simply constructed and easily mounted, the volume thereof is small, the operation thereof is reliable, it is easy to maintain and replace the carbon brushes and it extends significantly the life of the motor.

Owner:XU XIAOHUA

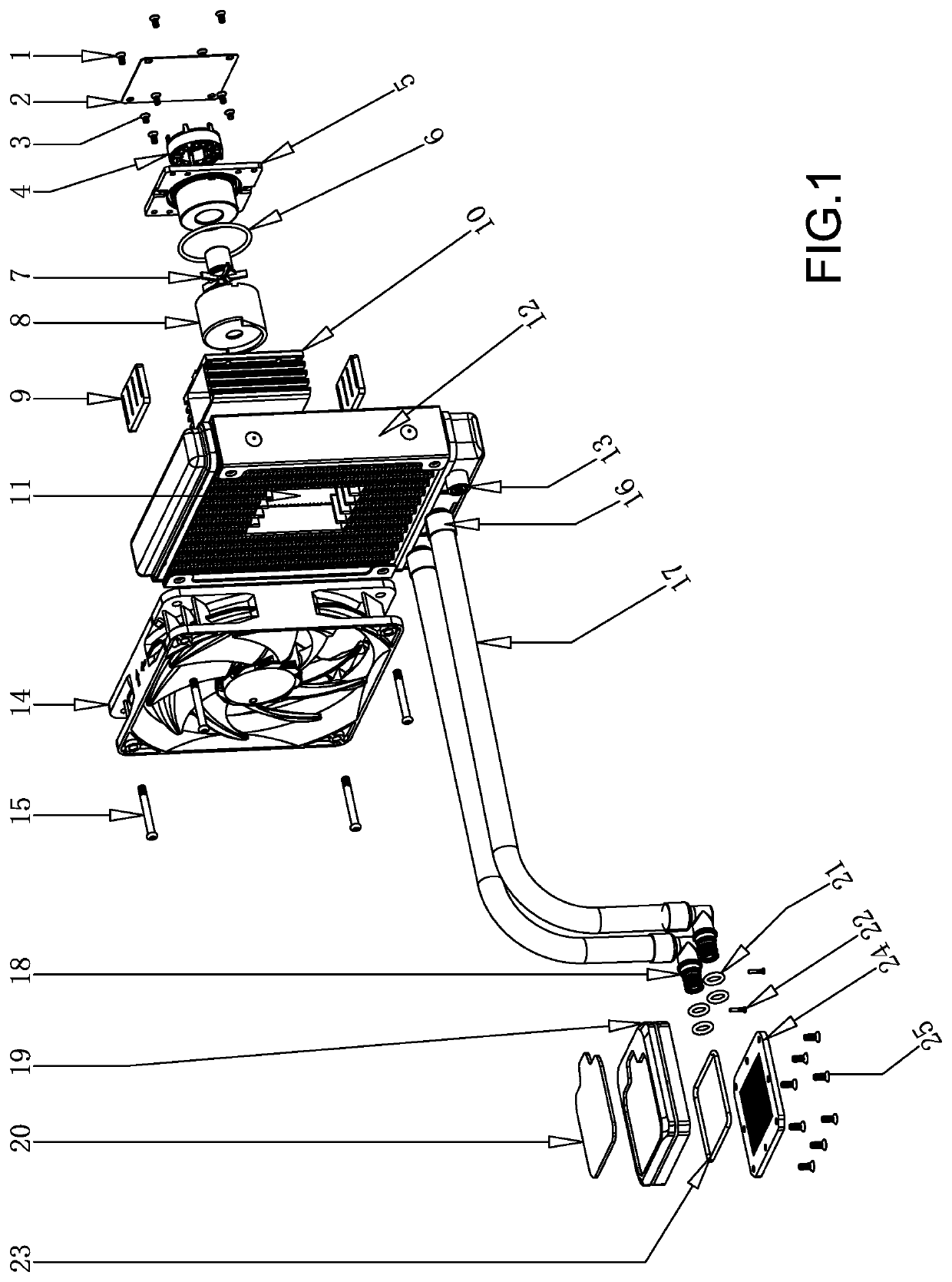

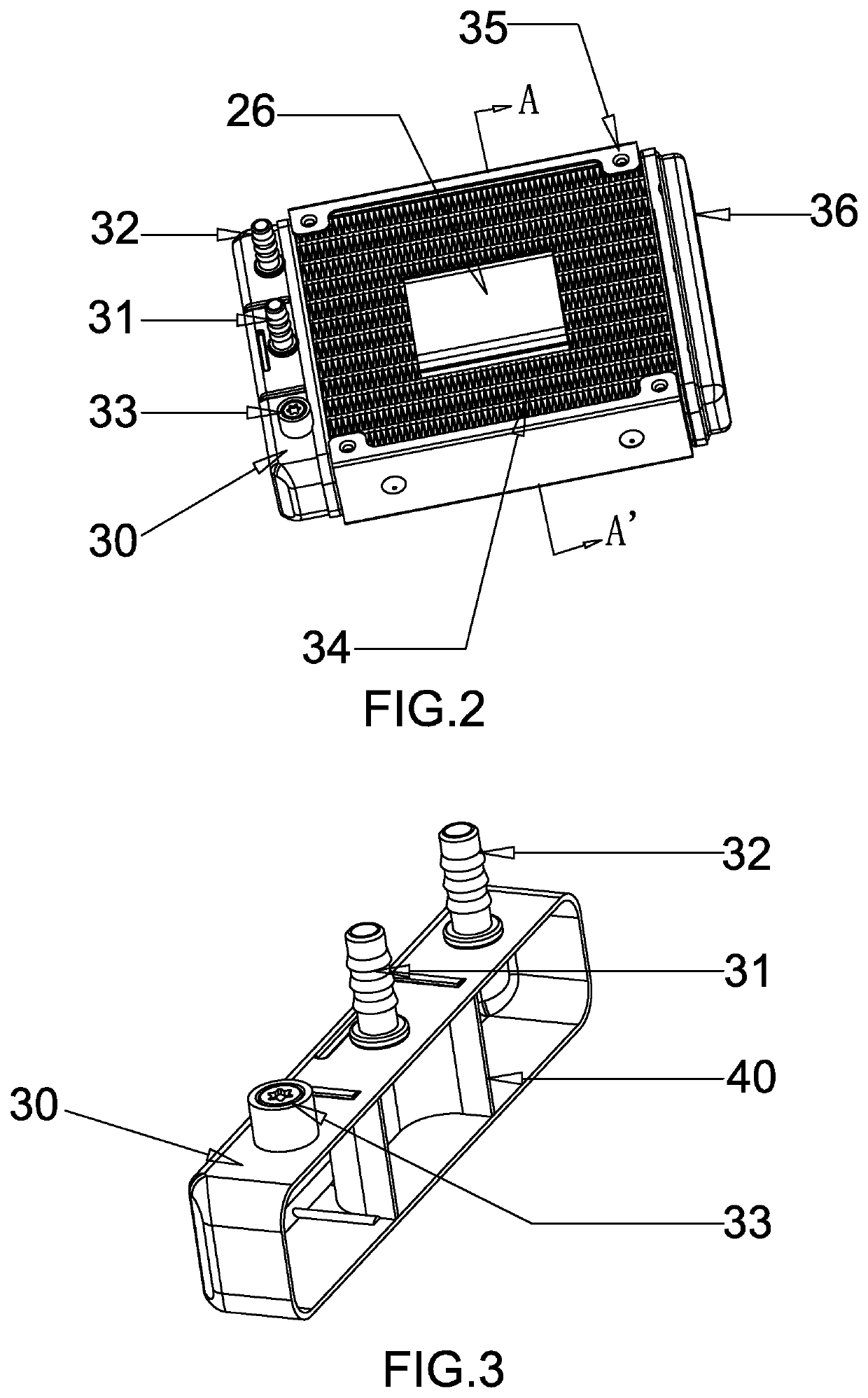

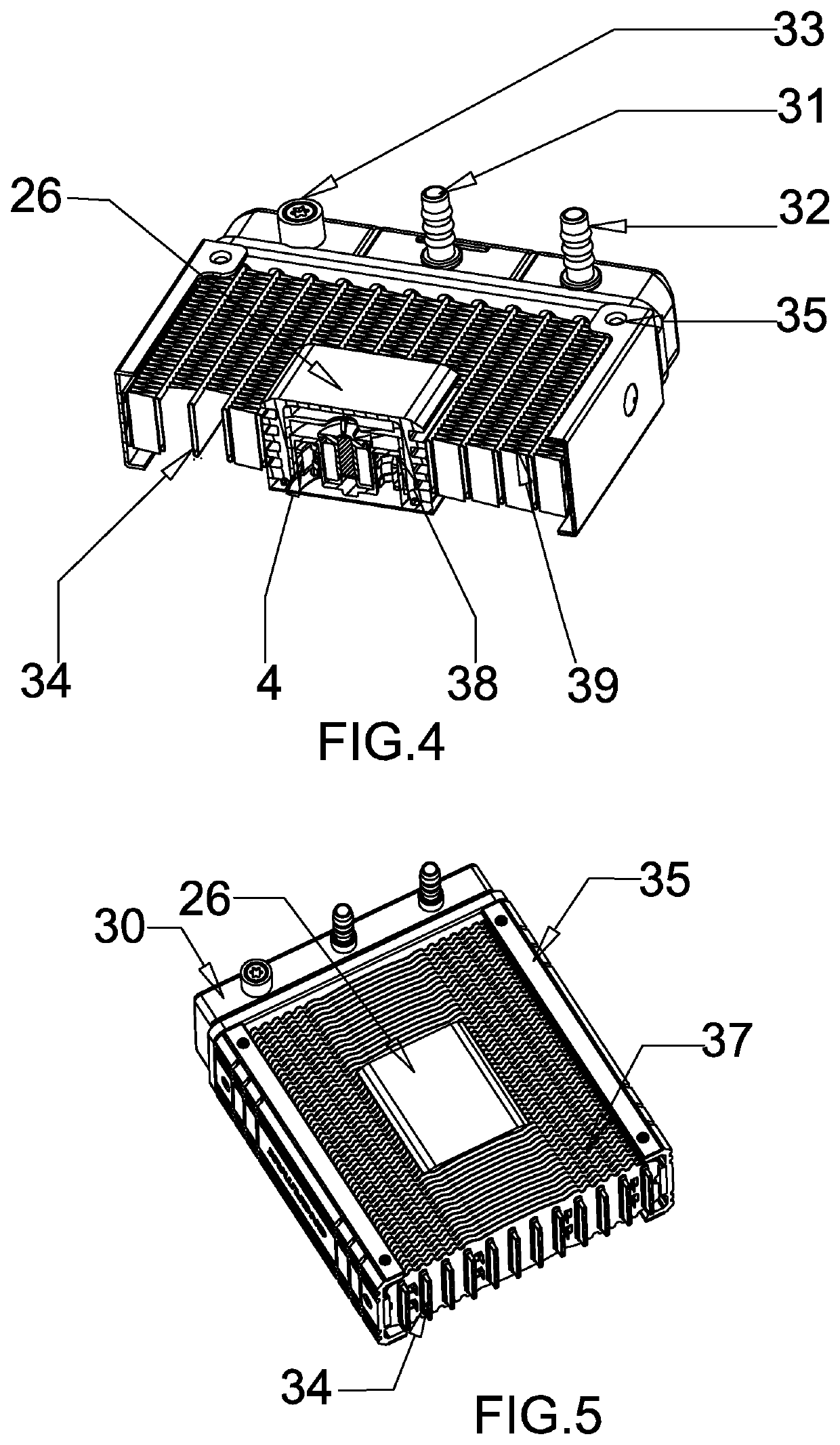

Liquid cooling radiation system and liquid radiator thereof

ActiveUS10609841B2Low heating temperatureImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsElectric machineCooling pipe

Disclosed is a liquid cooling radiation system. The technical solution used by the present invention to solve the technical problem is: the liquid cooling radiation system comprises: a radiation device, comprising cooling pipes and a radiation structure device arranged on the cooling pipes; a pumping device, integrally arranged between the cooling pipes and generating power so that a coolant circulates within the cooling pipes; a heat absorption device, attached to a heating device and having a heat conduction effect with the heating device; a pipeline, used for connecting the radiation device and the heat absorption device. On the basis of existing products, the present invention utilises a solution wherein a liquid pump main body and a radiator are integrally arranged together. Thus, the radiation of a fan is used to take away heat on the radiator and heat generated by a pump power main body (i.e. a motor) itself is also taken away, thereby extending the service life of the motor. In addition, the occupied space is significantly reduced, the heat transfer effect is significantly improved, and the production and assembly costs are reduced, so that product assembly is convenient and efficiency is high.

Owner:APALTEK CO LTD

Motor device utilizing magnetic force to drive a rotor

InactiveUS20070145855A1Extend motor lifeImprove motor efficiencyMagnetic circuit rotating partsAsynchronous induction motorsMagnetic tension forceEngineering

The present invention relates to a motor device utilizing magnetic force to drive a rotor. The motor device includes a main body, a rotor and a controlling unit. The main body has two openings and an internal chamber. The rotor is magnetic and swingably disposed in the chamber between the two openings. The controlling unit is disposed on outer side of the main body to apply a magnetic force to the rotor for driving the rotor to at least rotate. The rotor is a column body with a certain length. The rotor has a profile corresponding to a configuration of a peripheral wall of the chamber. The outer face of the rotor is formed with at least one spiral groove to define at least one spiral stripe. The rotor is magnetically driven to drive a fluid to flow from one opening to the other opening.

Owner:LIU MING HWA +2

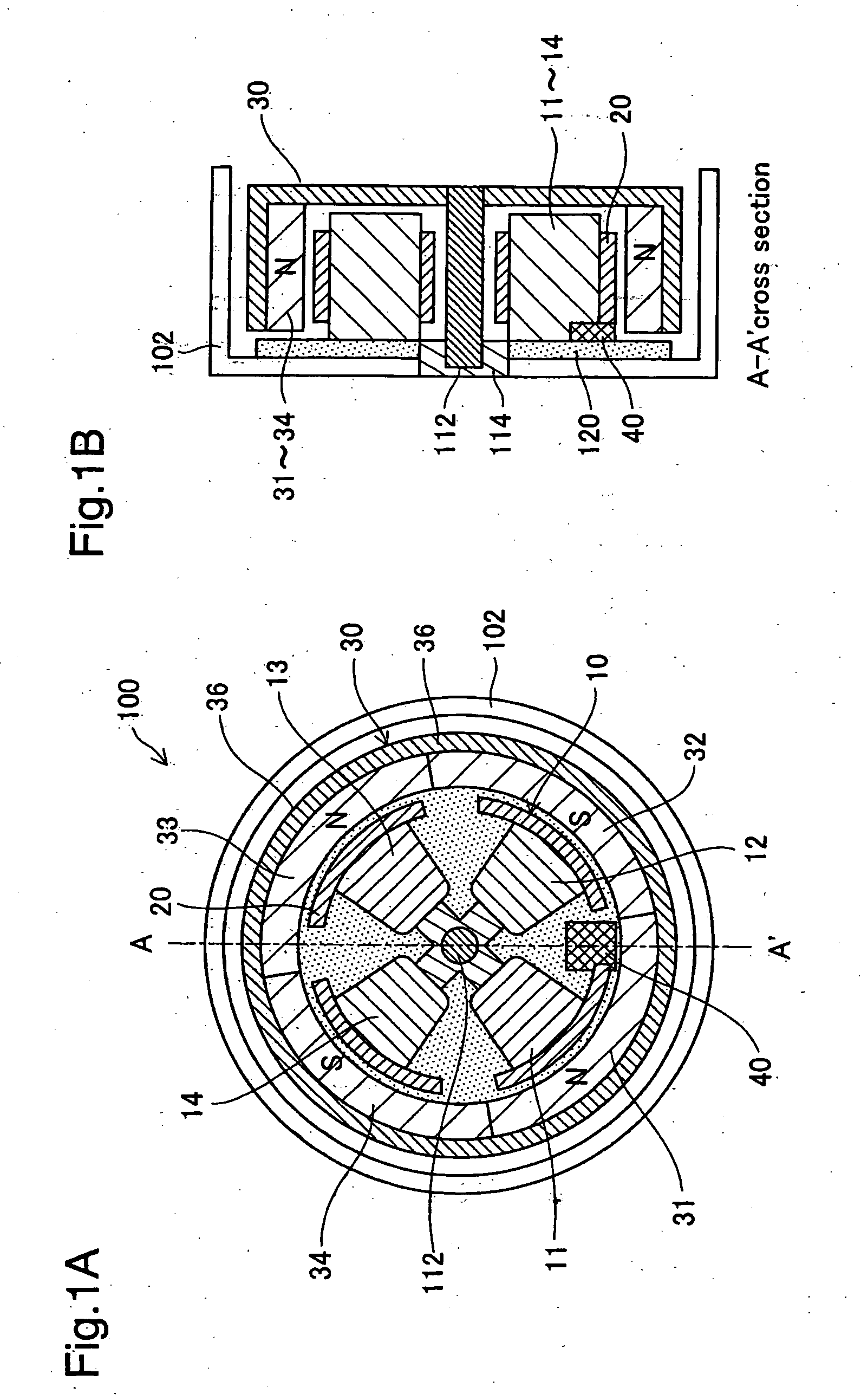

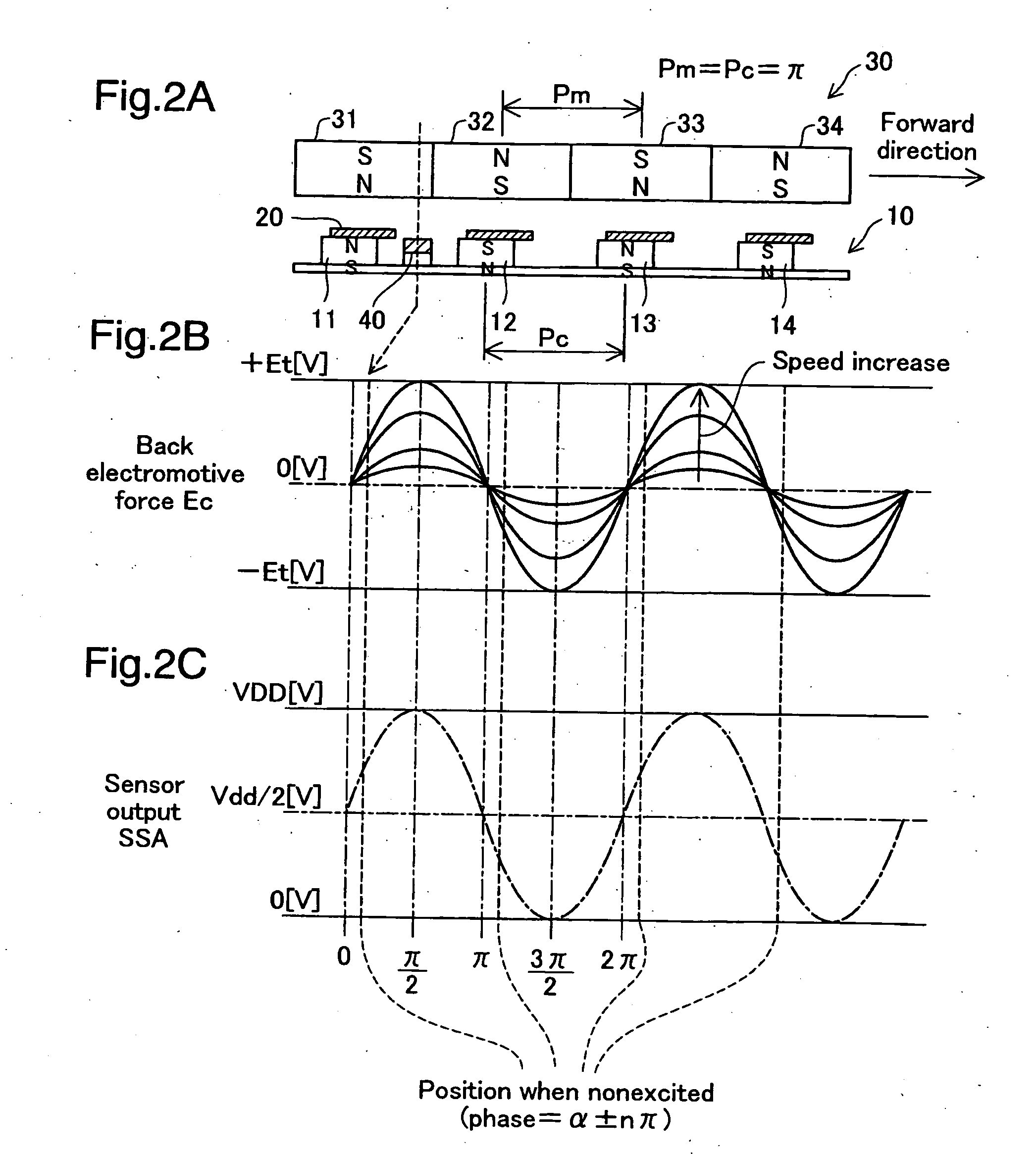

Single-Phase Brushless Motor

InactiveUS20090179514A1Increased power consumptionIncrease heightSynchronous motors startersVector control systemsBrushless motorsCoil array

The single-phase brushless motor according to one aspect of the present invention includes a coil array having a plurality of magnetic coils 11-14; a magnet array having a plurality of permanent magnets 31-34; a magnetic sensor 40 for detecting relative position of the magnet array and the coil array; and a drive control circuit that, utilizing the output signal SSA of the magnetic sensor, generates application voltage for driving the coil array with a single-phase drive signal. The coil array includes a magnetic member 20. This magnetic member 20 is constituted such that, with the single-phase brushless motor at a stop, the centers of the permanent magnets 31-34 come to a stop at locations offsetted from the centers of the magnetic coils 11-14, due to attraction of the magnetic member 20 by the magnet array.

Owner:GK BRIDGE 1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com