Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

300results about How to "Improve assembly reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

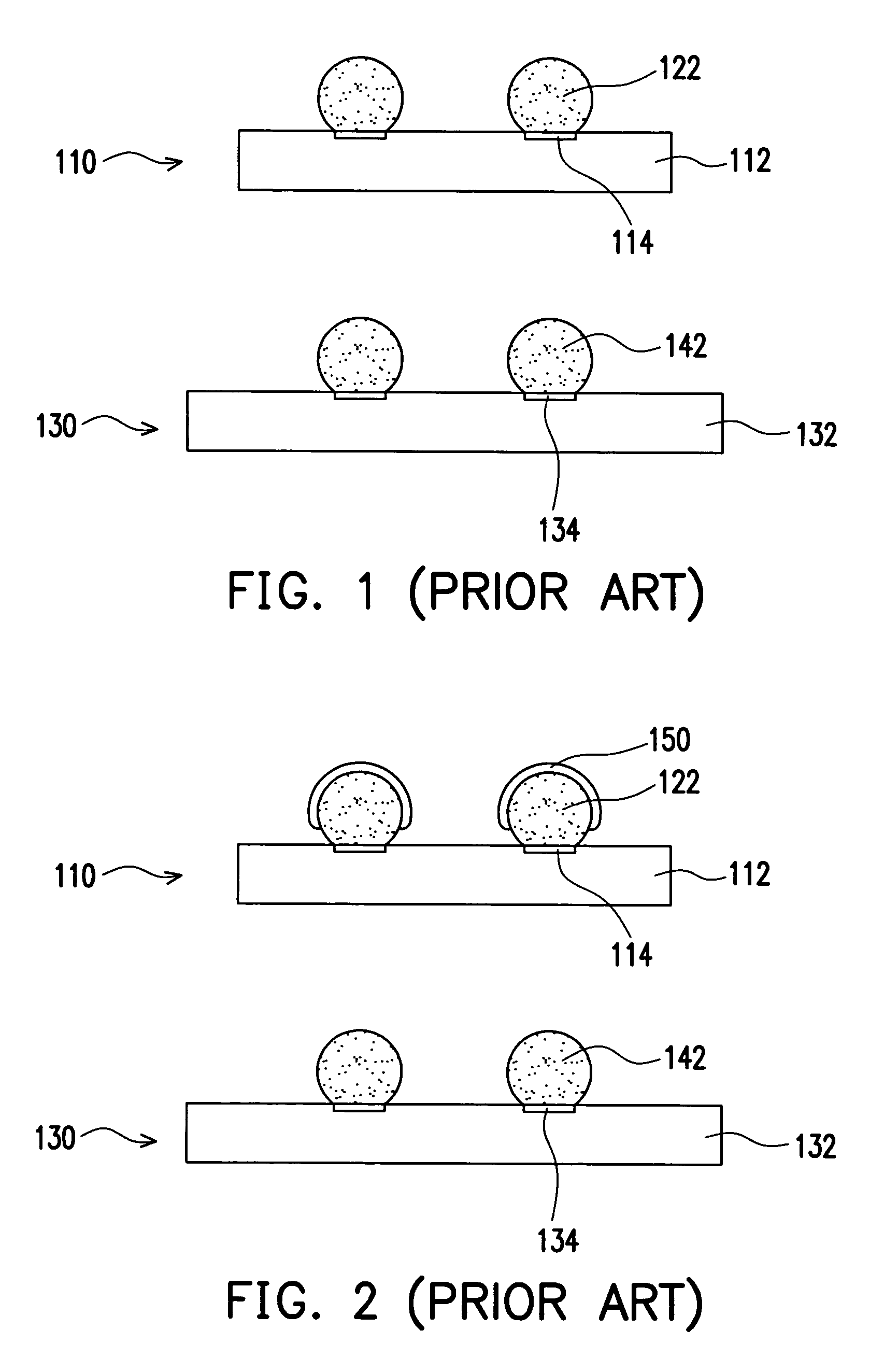

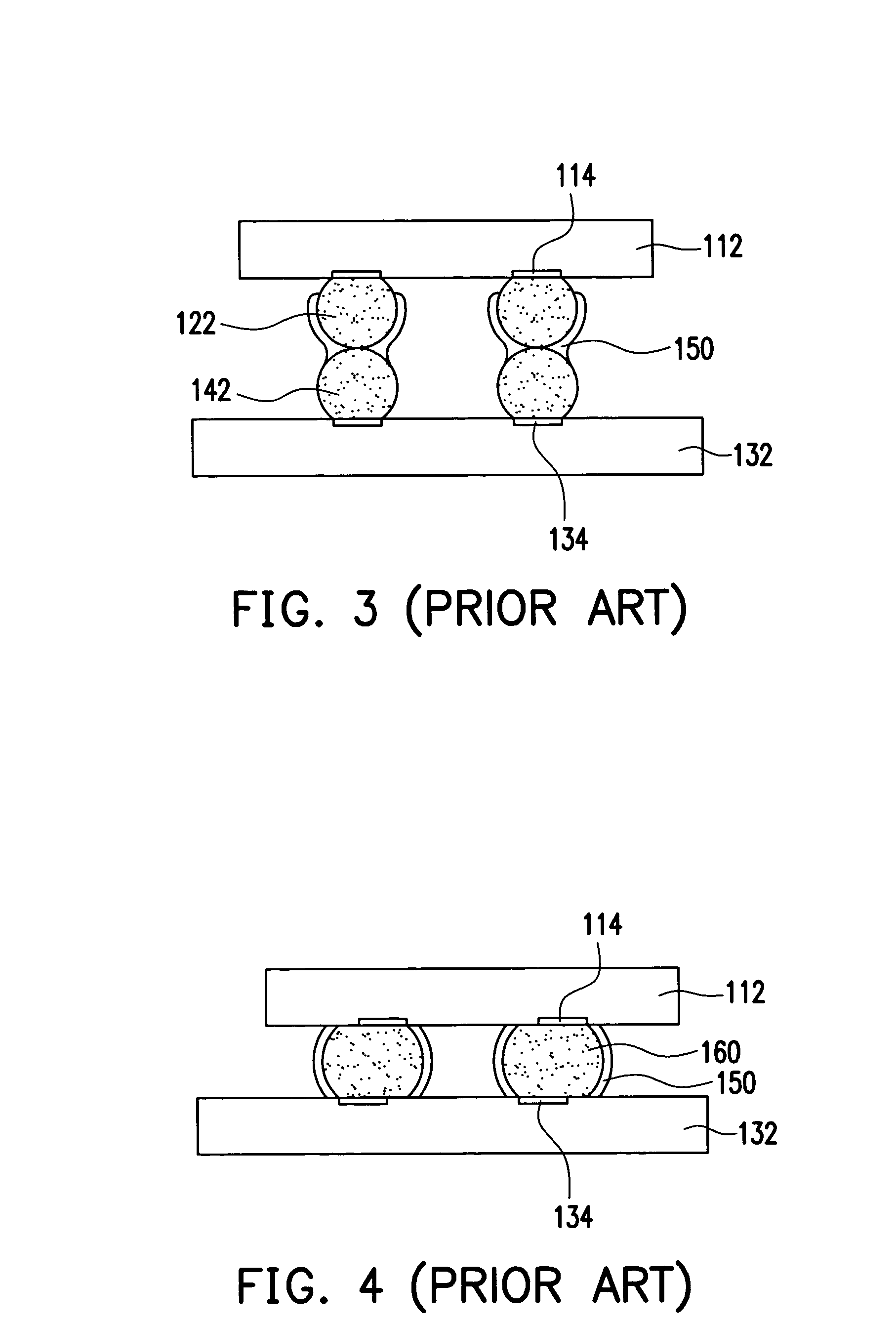

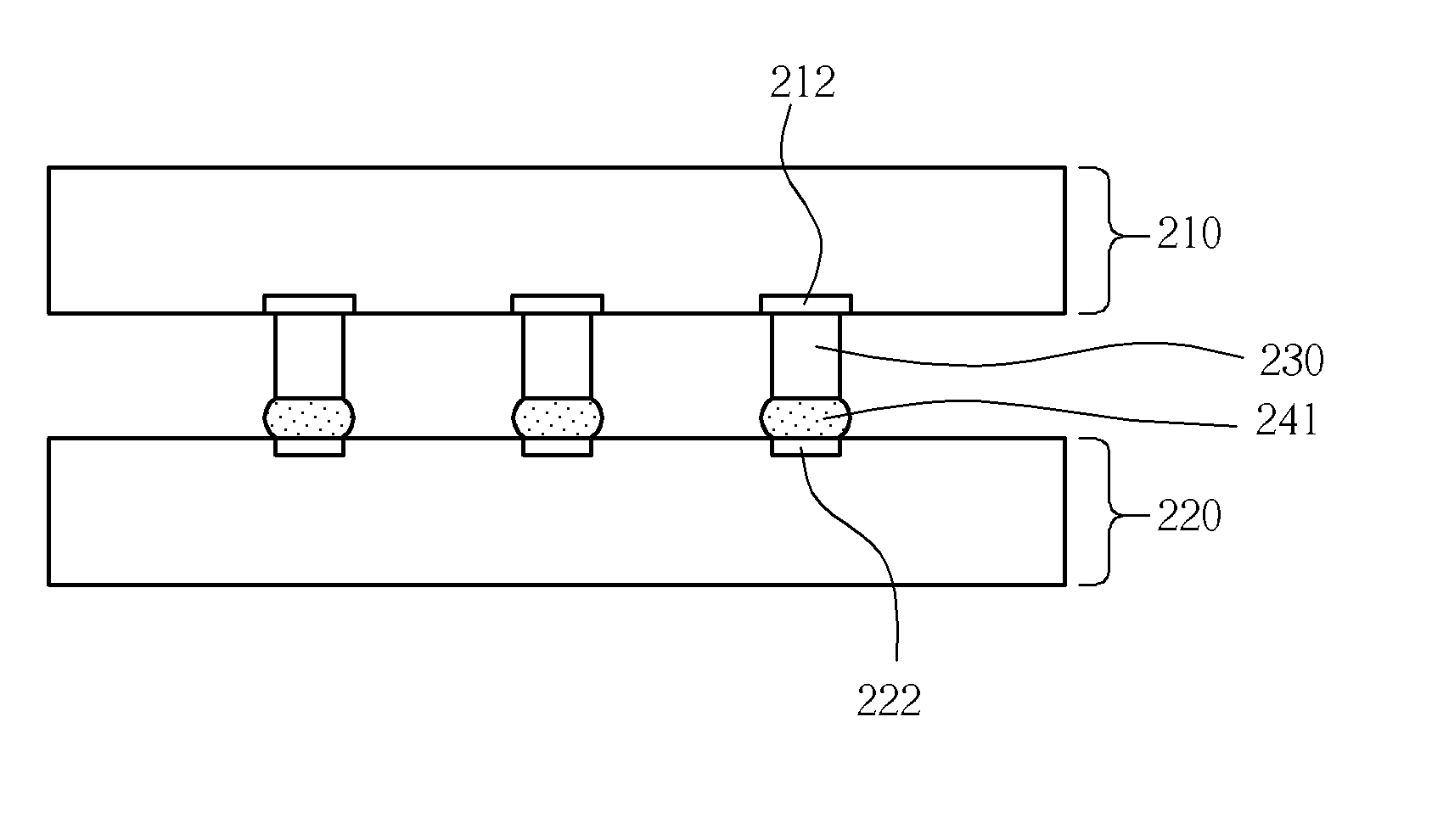

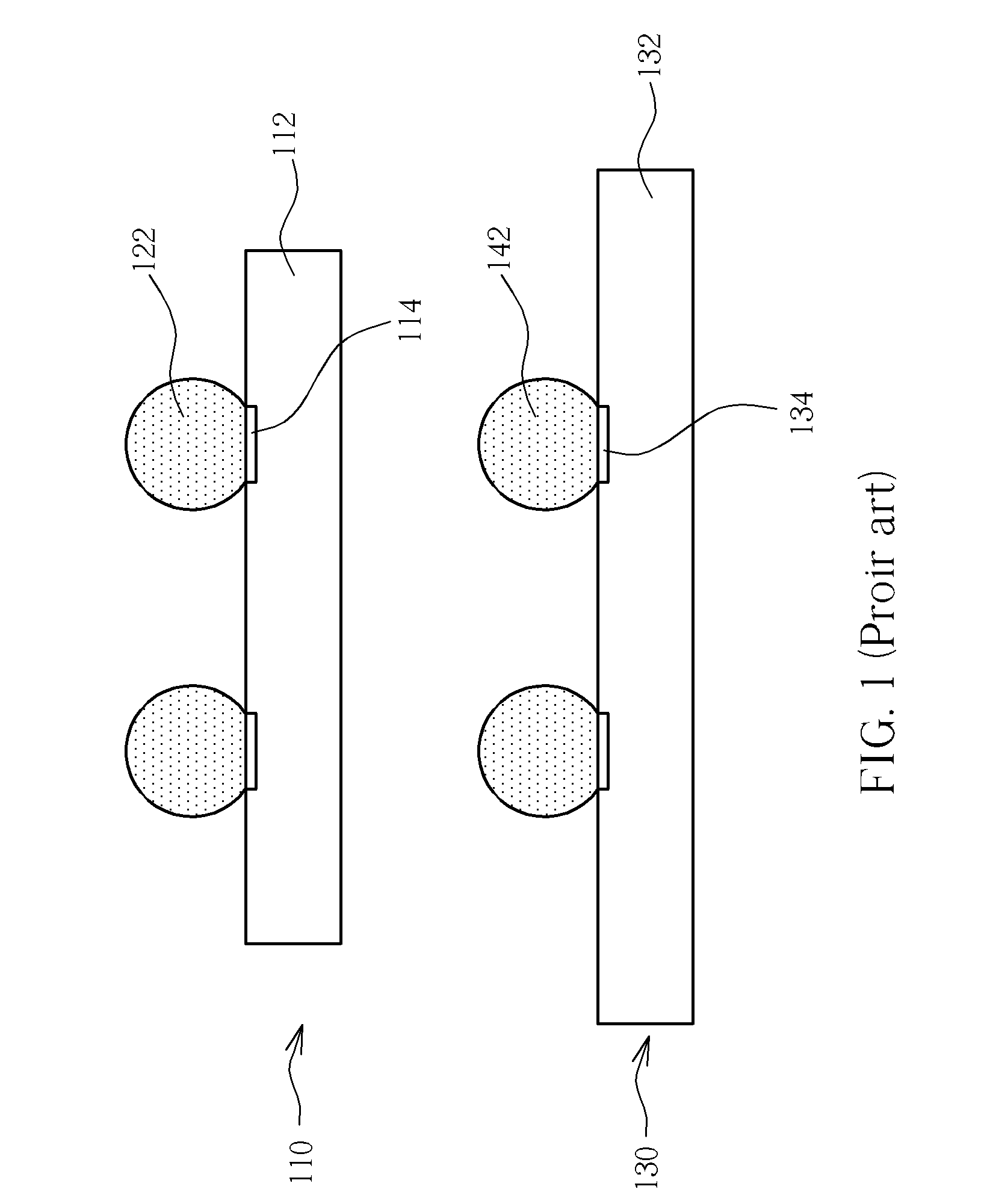

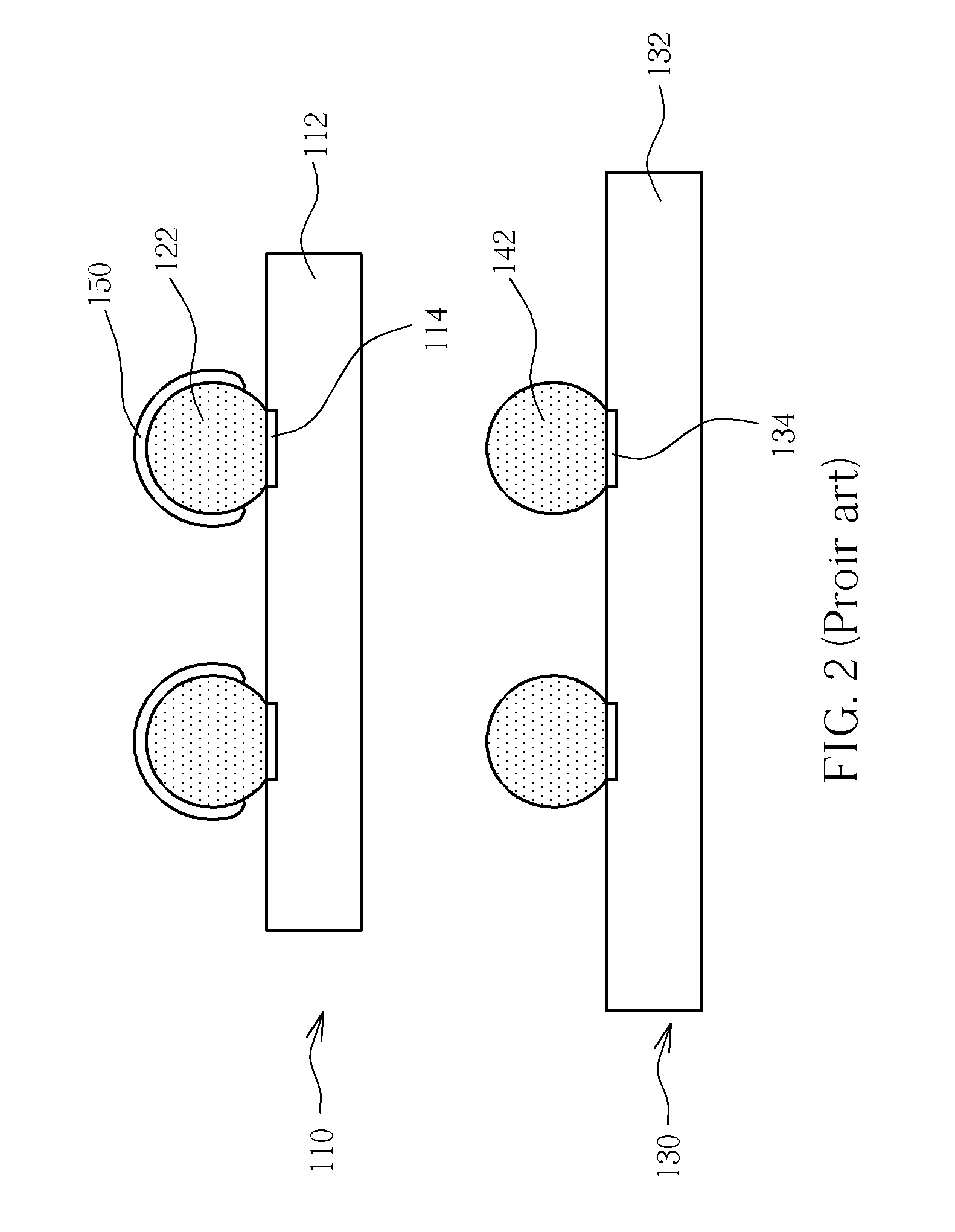

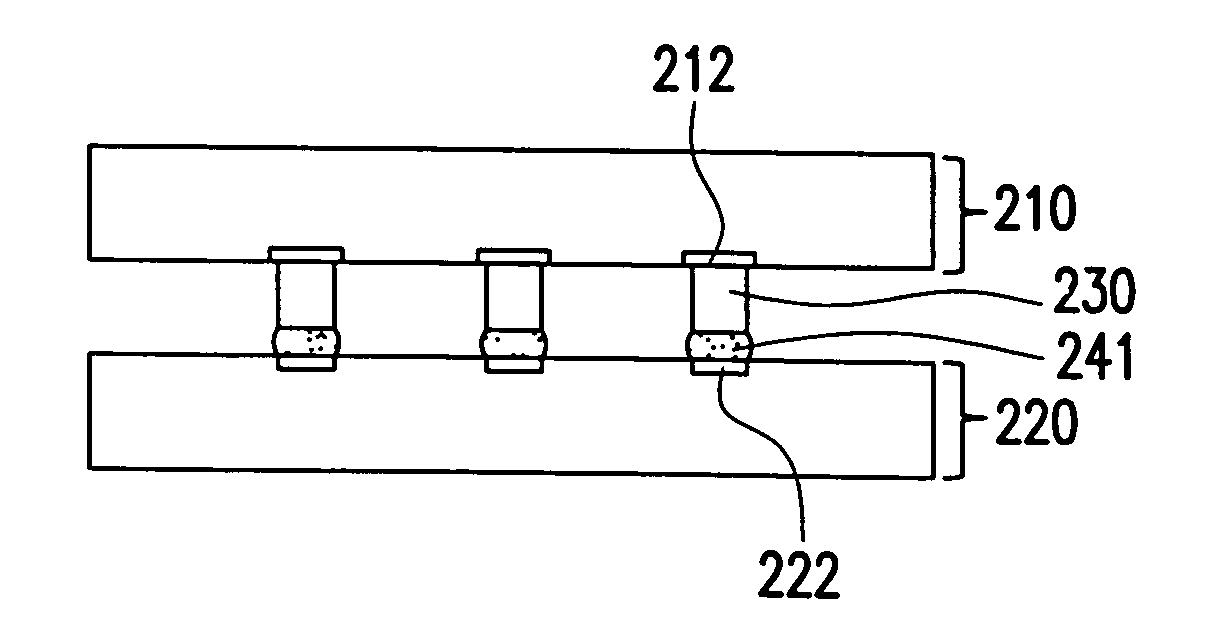

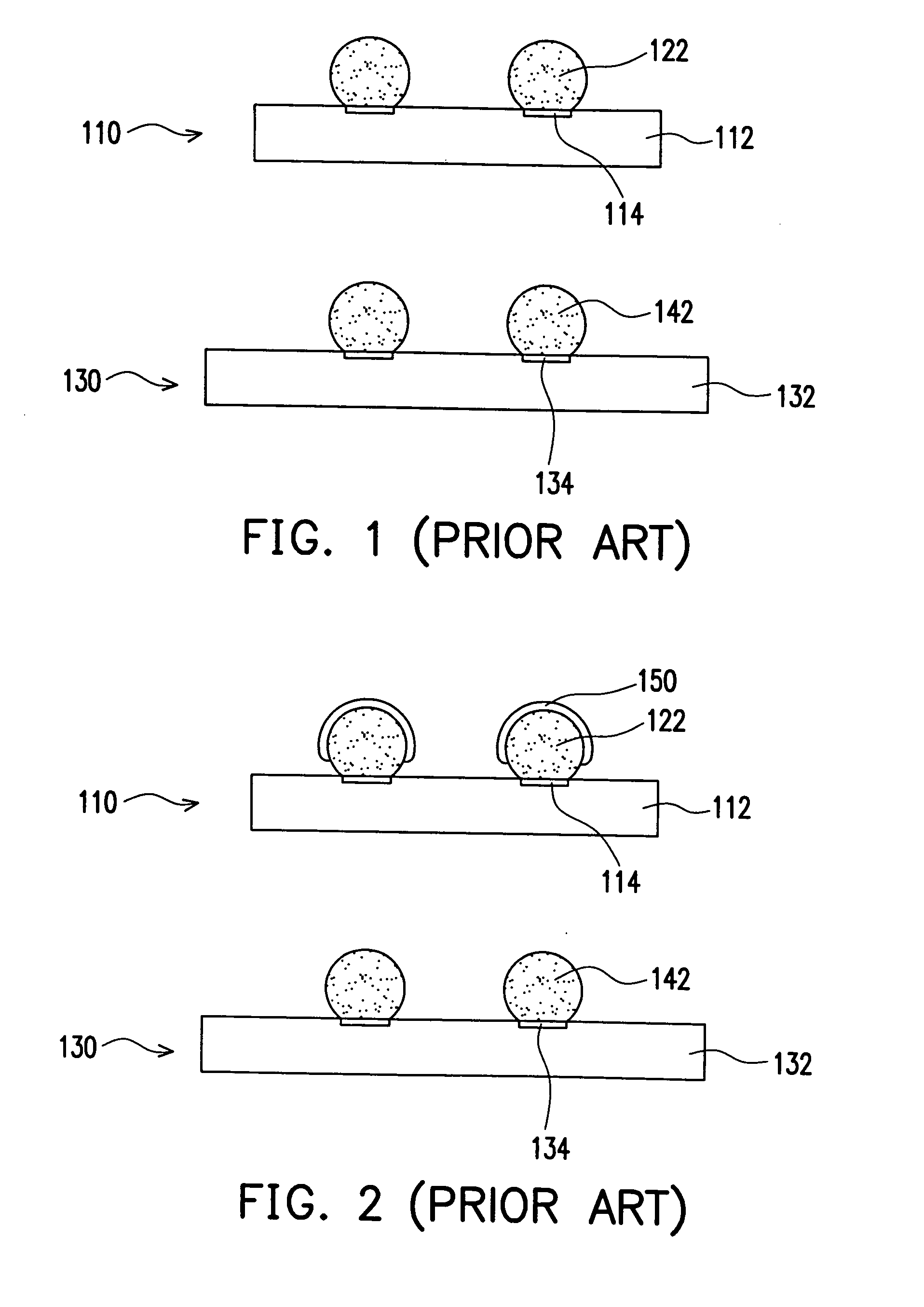

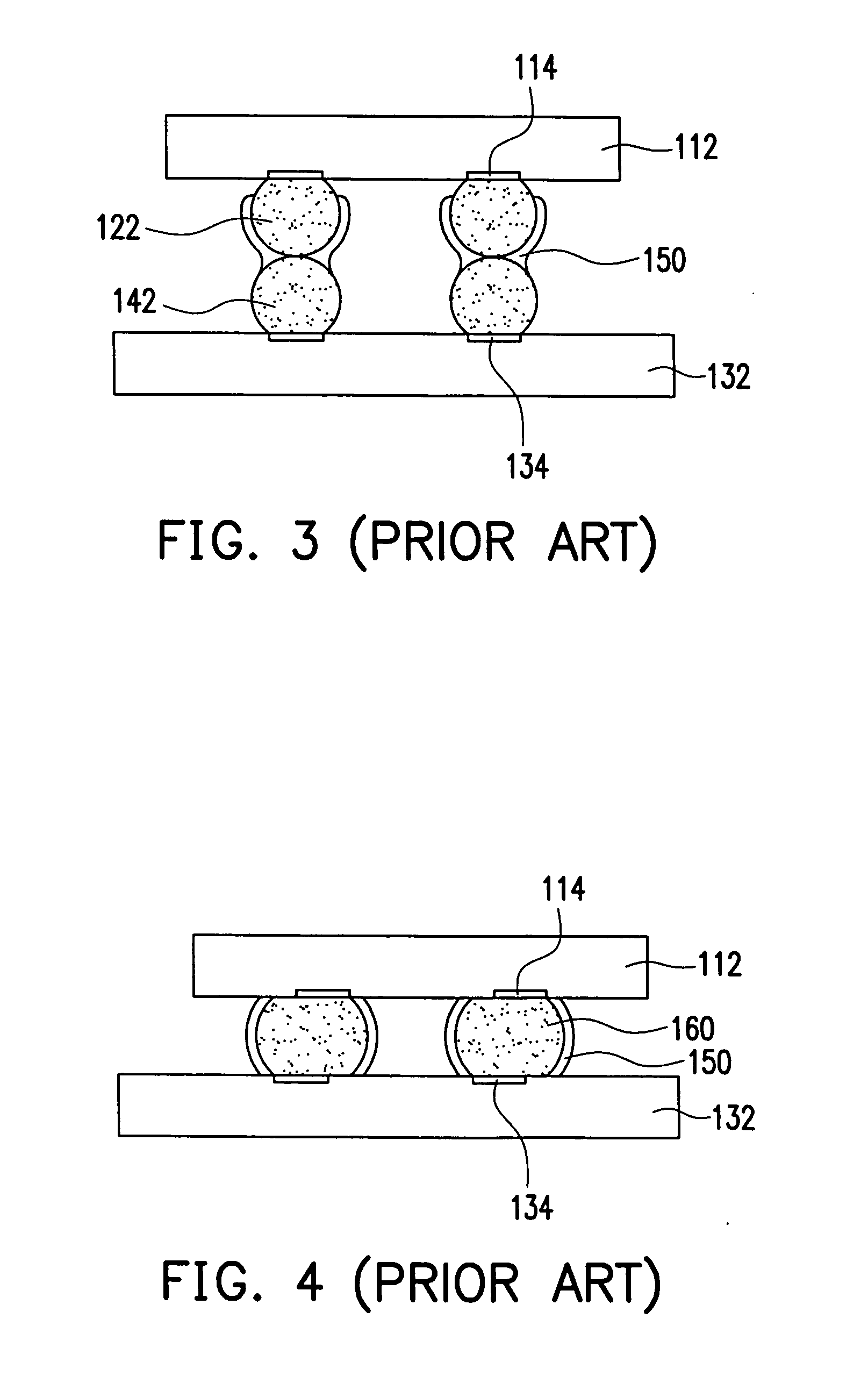

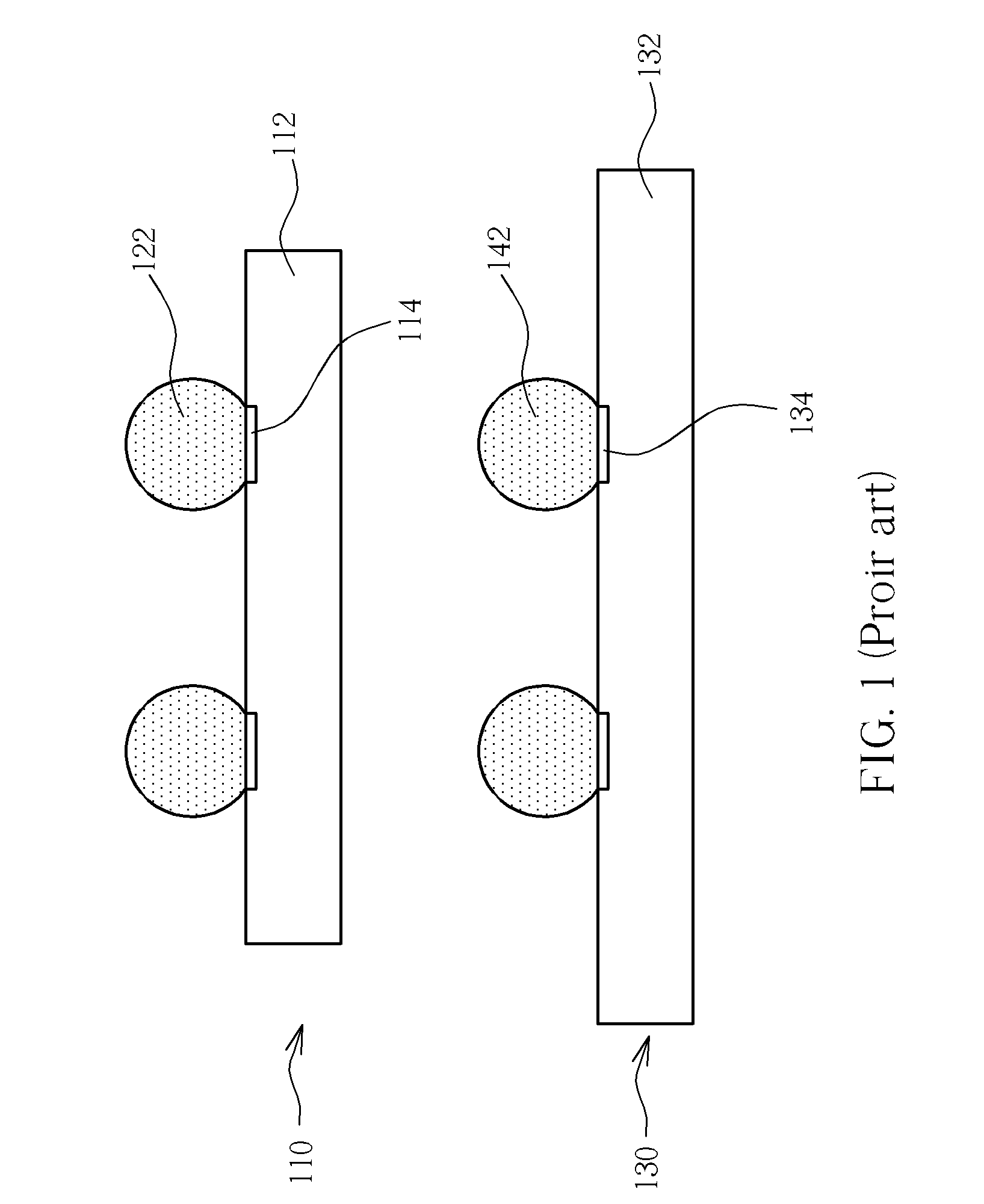

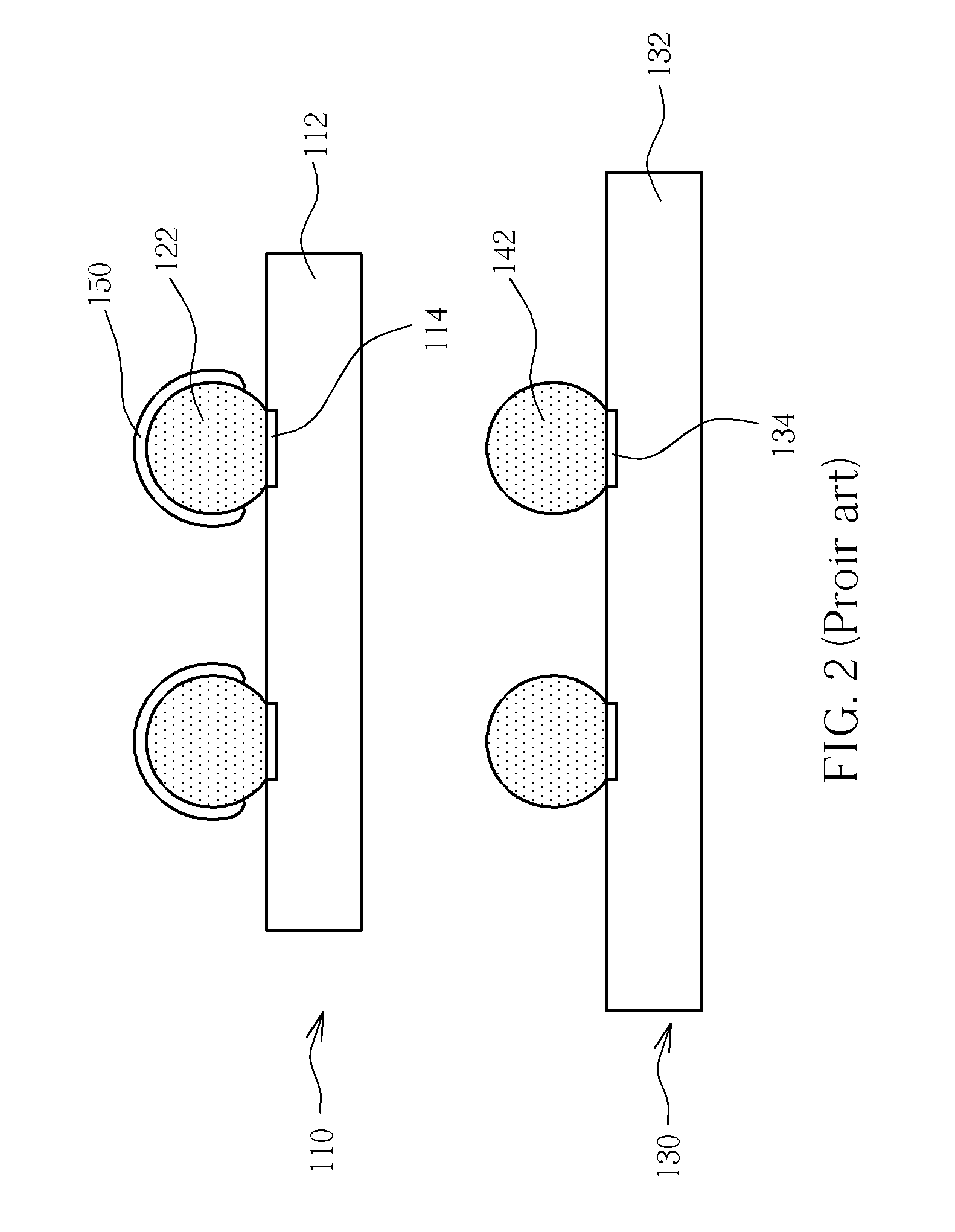

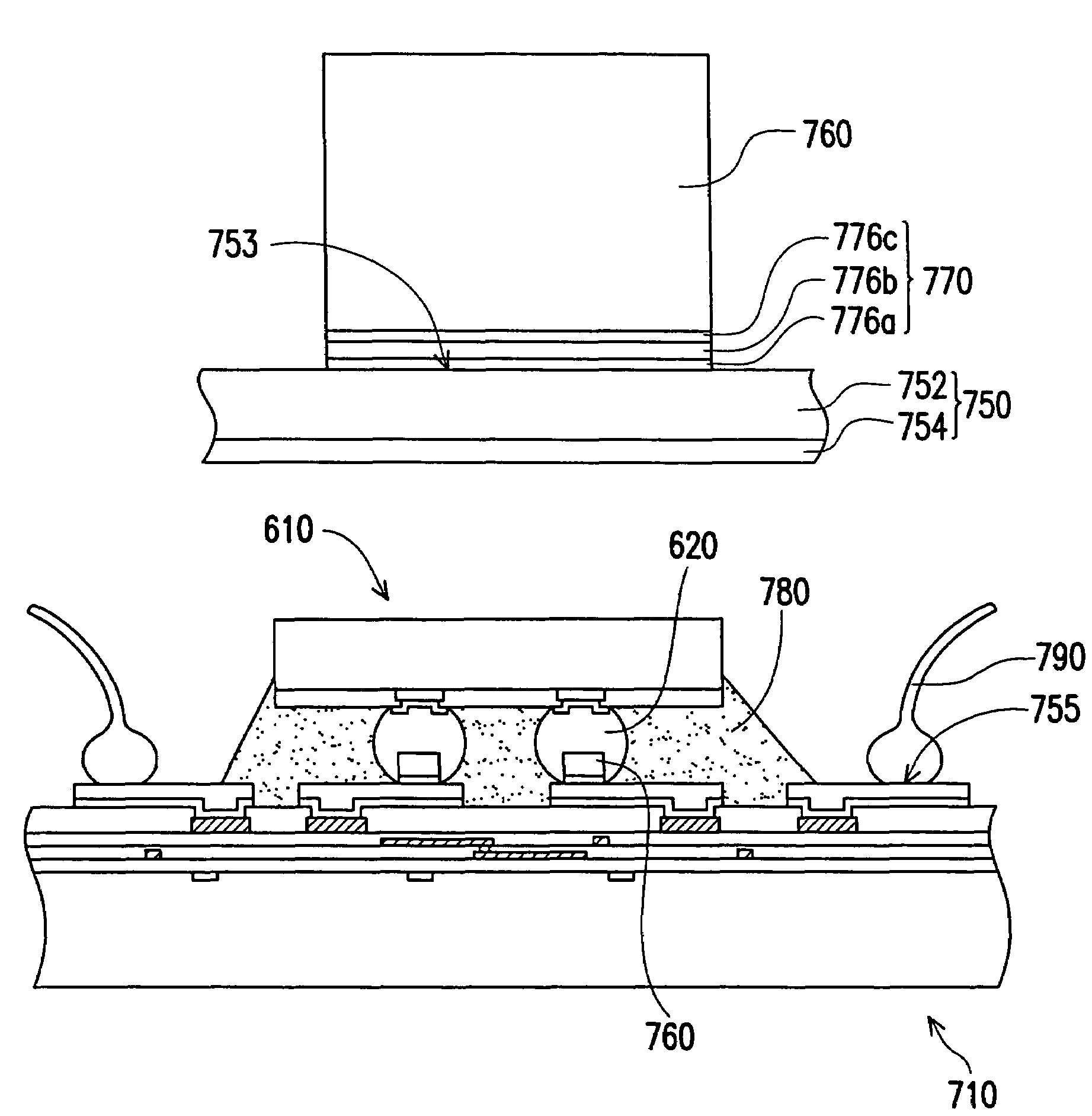

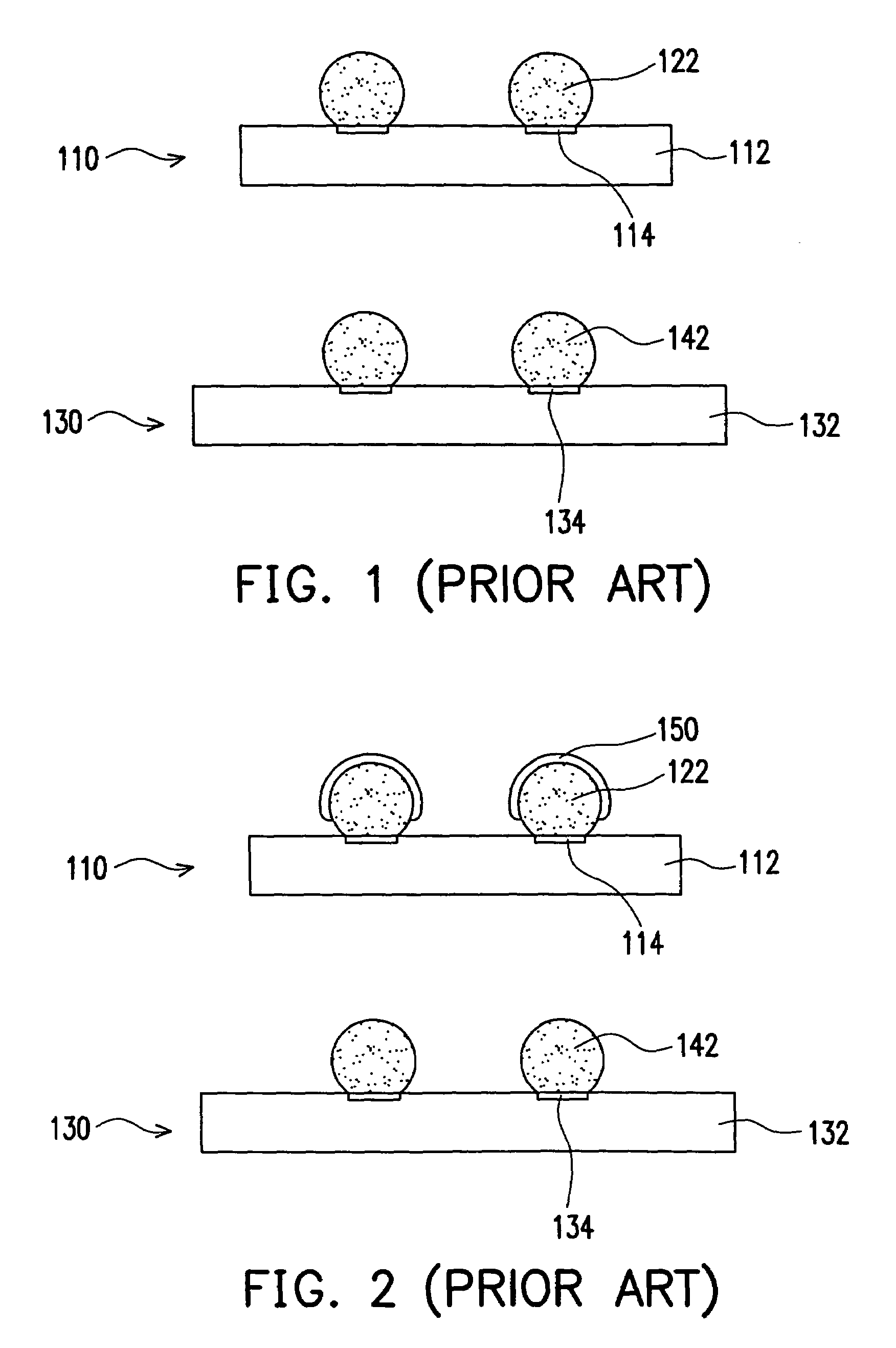

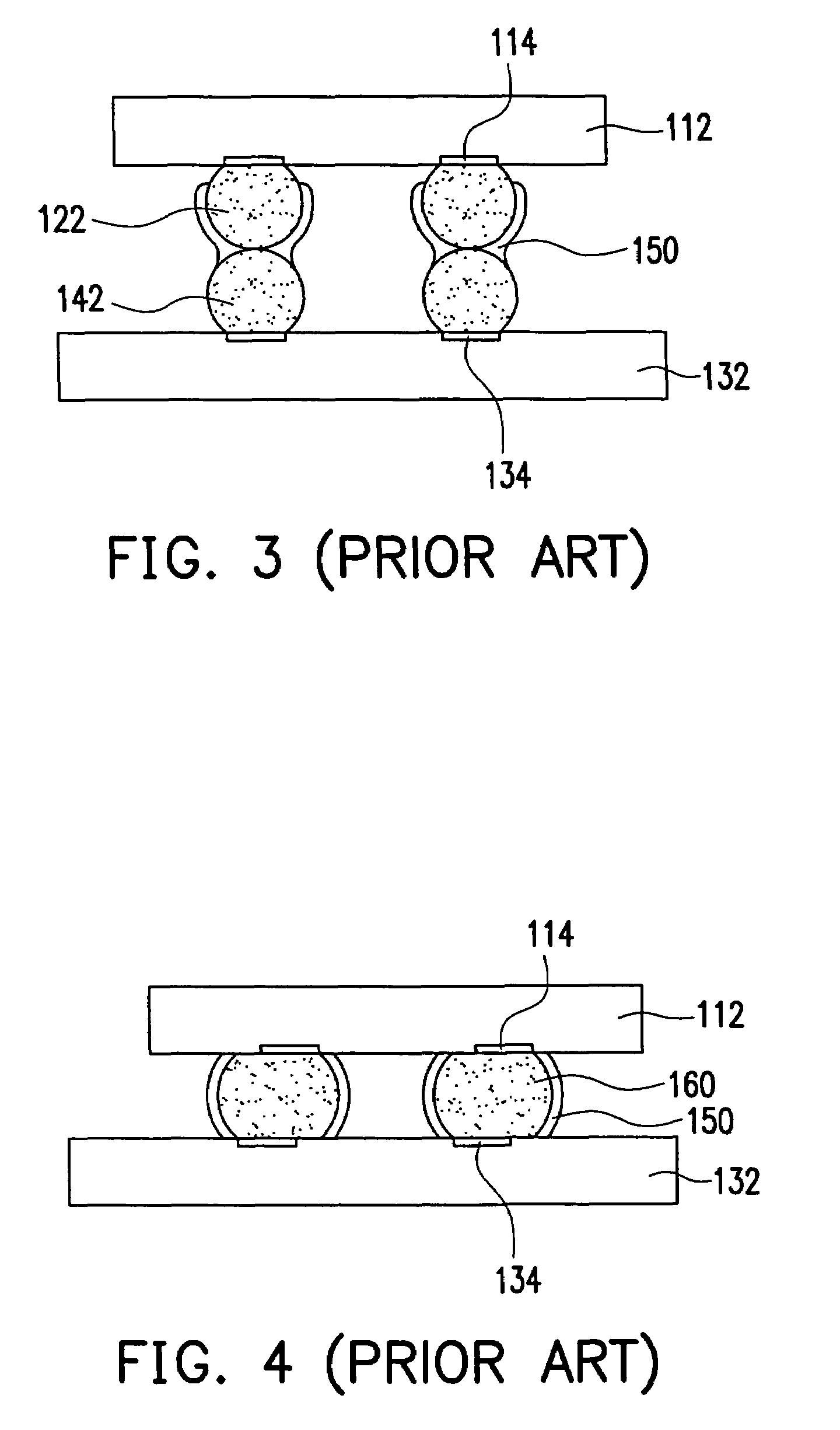

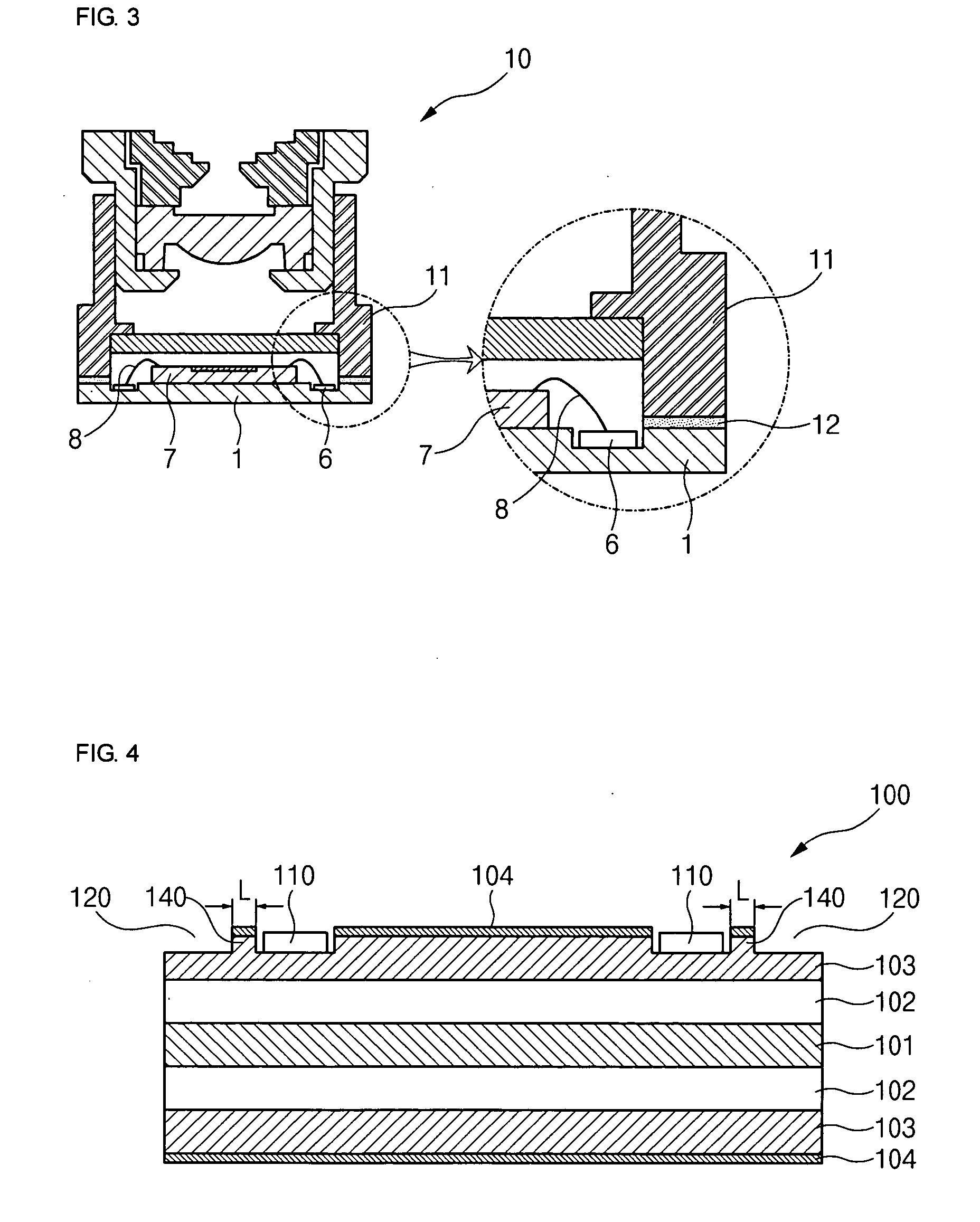

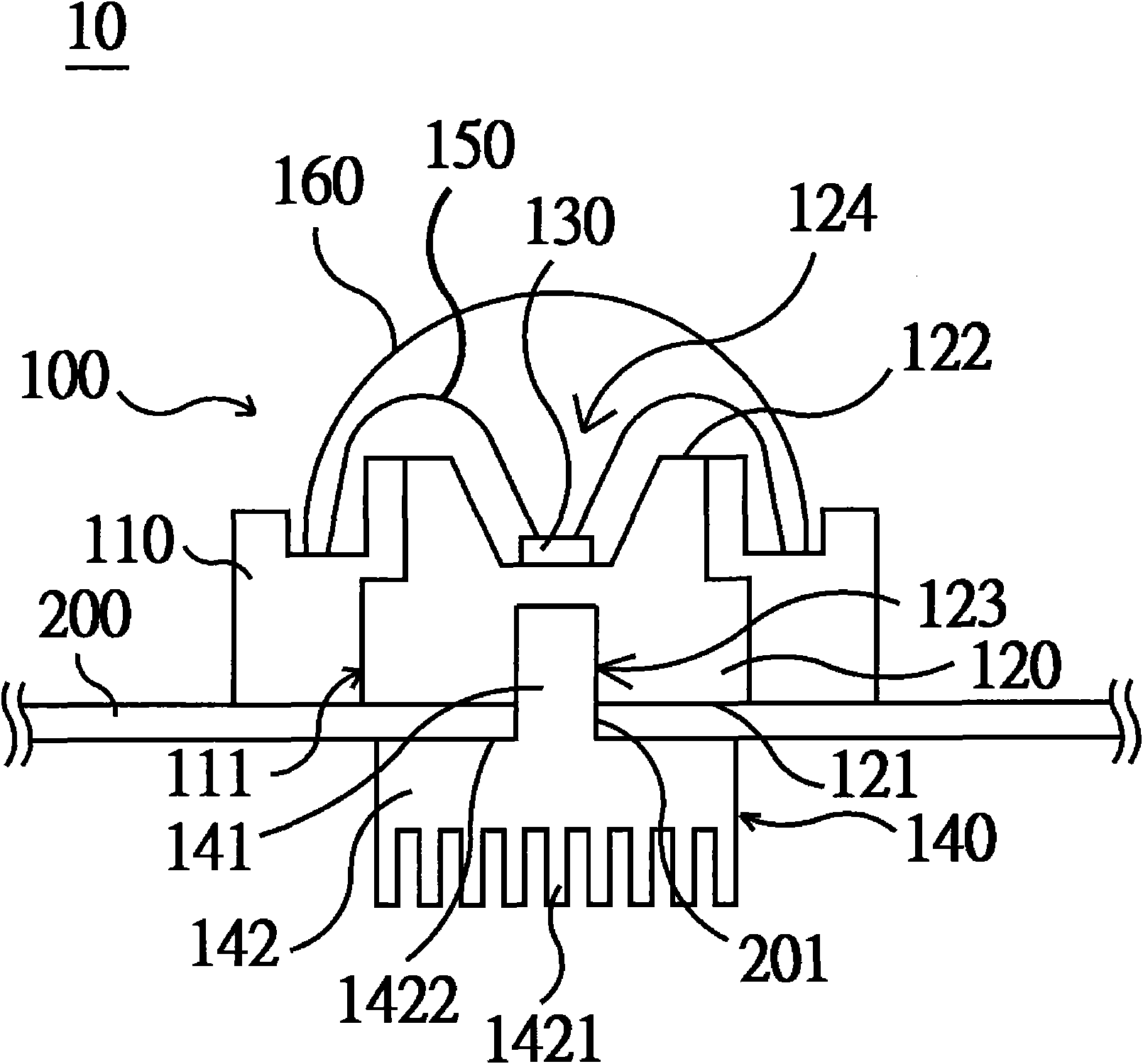

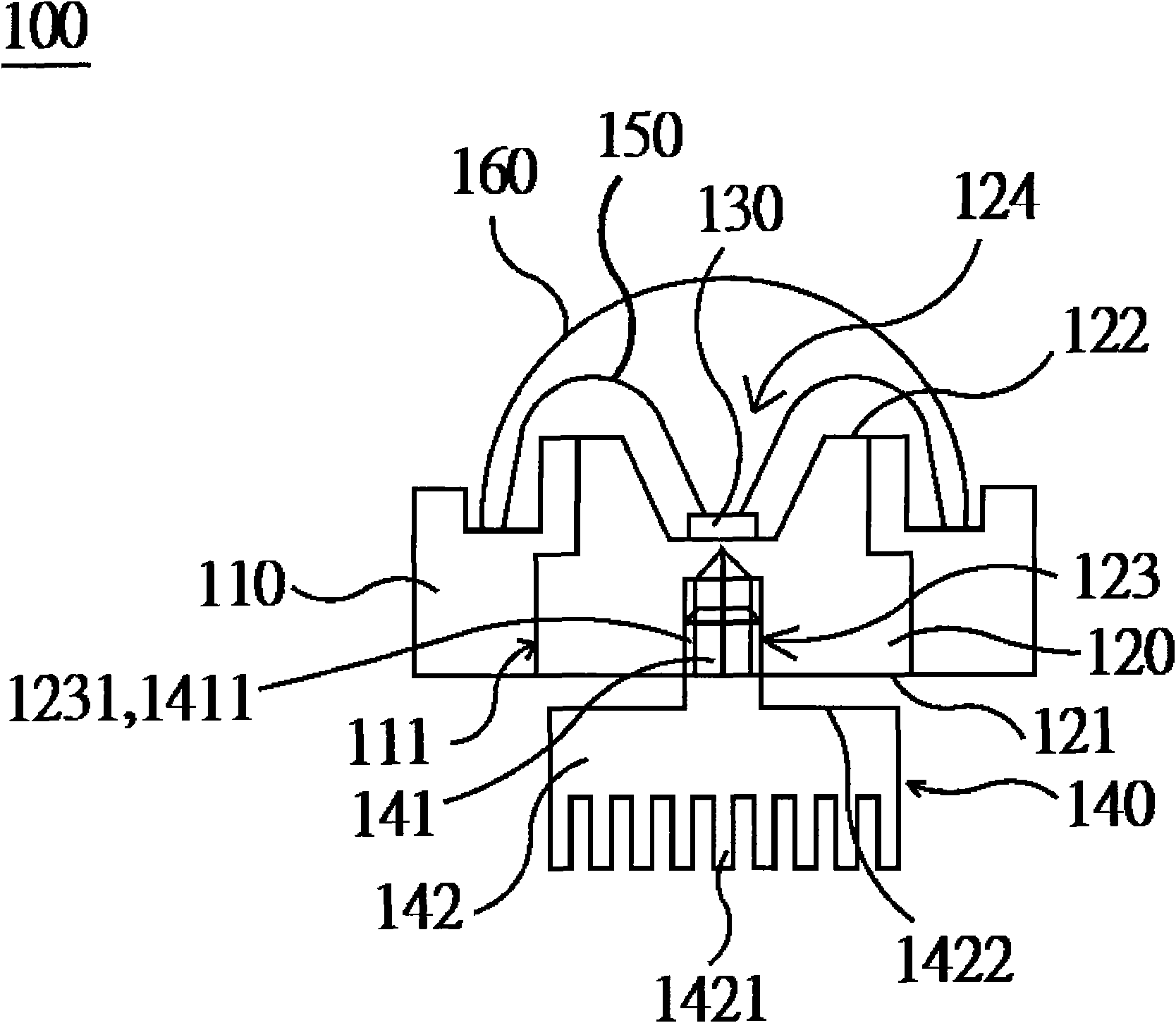

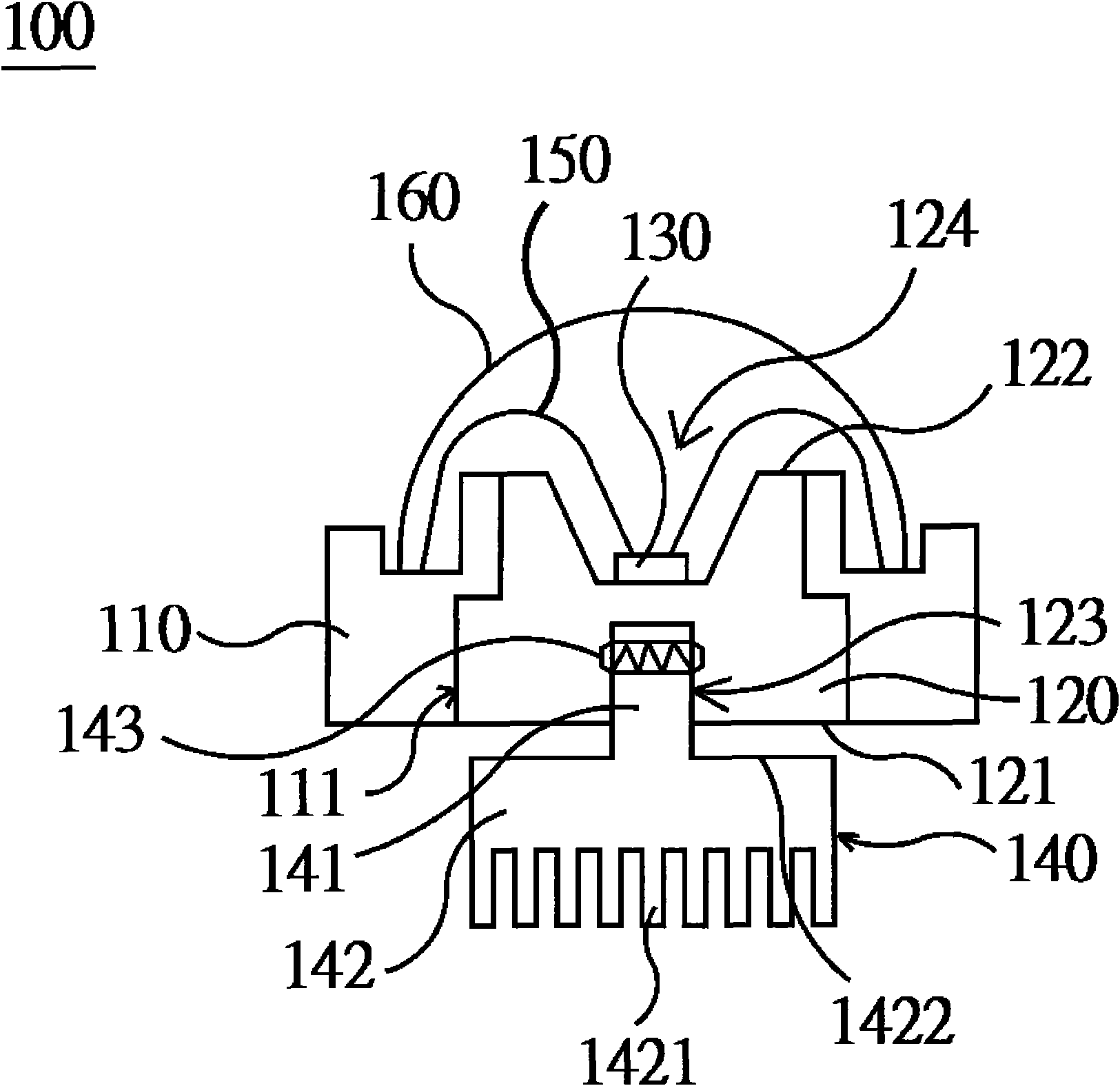

Chip package with multiple chips connected by bumps

InactiveUS7242099B2Improve assembly reliabilityPrecise alignmentPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringChip-scale package

A method of assembling chips. A first chip and a second chip are provided. At least one conductive pillar is formed on the first chip, and a conductive connecting material is formed on the conductive pillar. The second chip also comprises at least one conductive pillar. The first chip is connected to the second chip via the conductive pillars and the conductive connecting material.

Owner:QUALCOMM INC

Multi-chip structure and method of assembling chips

ActiveUS20060220259A1Improve assembly reliabilityPrecise alignmentSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A method of assembling chips. A first chip and a second chip are provided. At least one conductive pillar is formed on the first chip, and a conductive connecting material is formed on the conductive pillar. The second chip also comprises at least one conductive pillar. The first chip is connected to the second chip via the conductive pillars and the conductive connecting material.

Owner:QUALCOMM INC

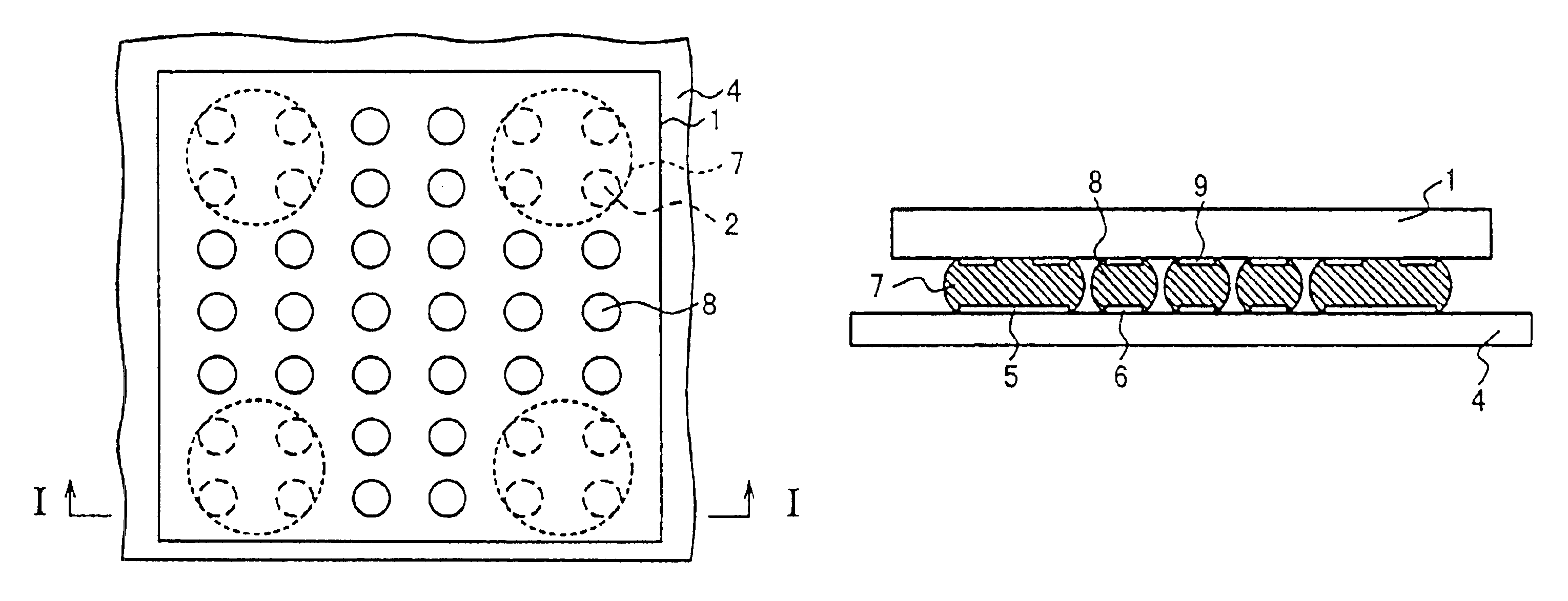

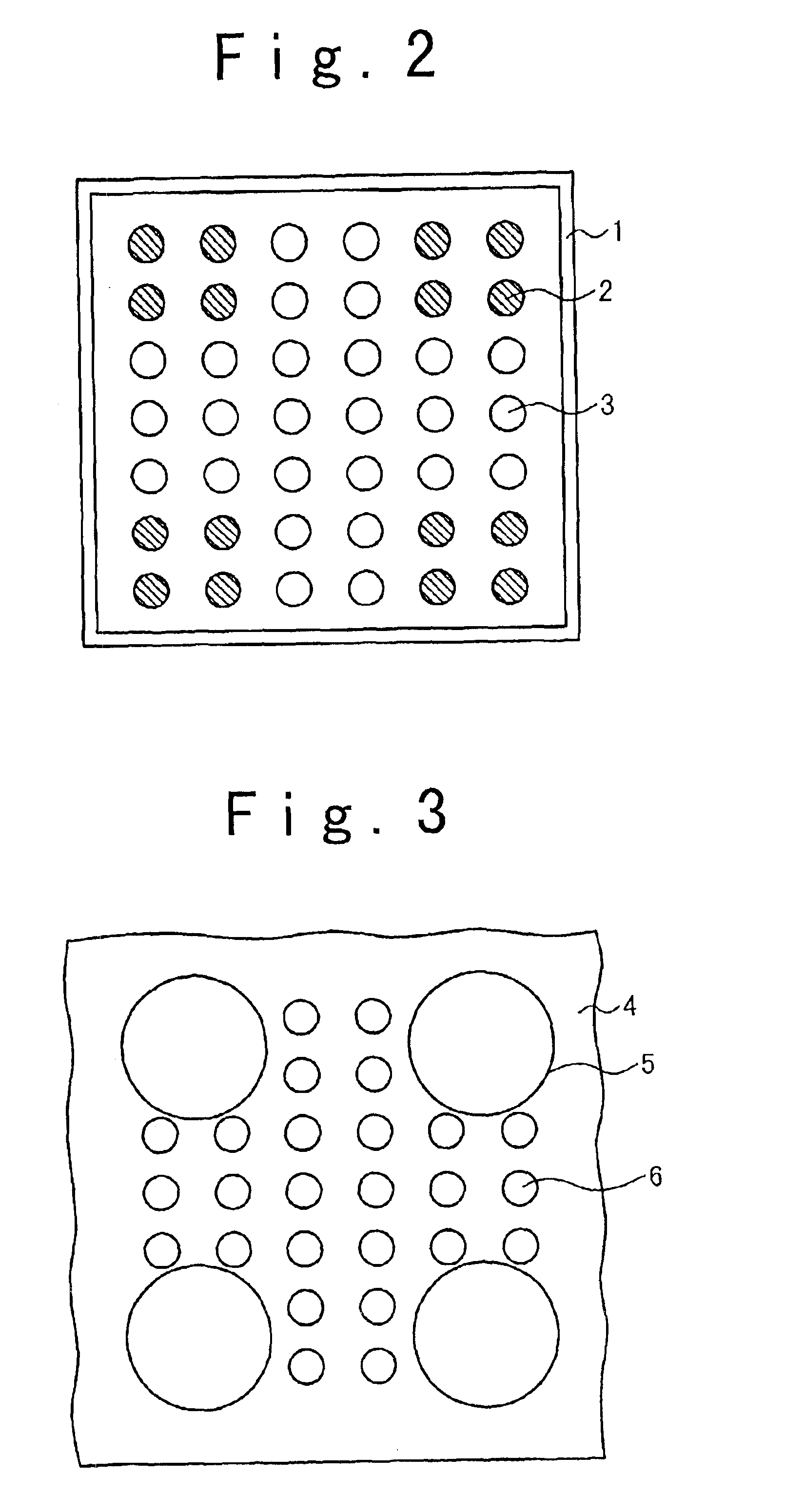

Back electrode type electronic part and electronic assembly with the same mounted on printed circuit board

InactiveUS6927491B1Improve mounting reliabilityHigh strengthPrinted circuit assemblingFinal product manufactureEngineeringElectronic assemblies

A back electrode type electronic part includes a main body including a circuit, and electrodes arranged for solder bumps on a back surface portion of the electronic part and connected to the circuit. Each of groups of the electrodes in portions of the electrode arrangement is provided for a single first solder bump which is larger than second solder bumps for the electrodes arranged other than the corner portions. Also, the group of electrodes includes electrodes having a substantially same potential level when the circuit operates.

Owner:NEC CORP

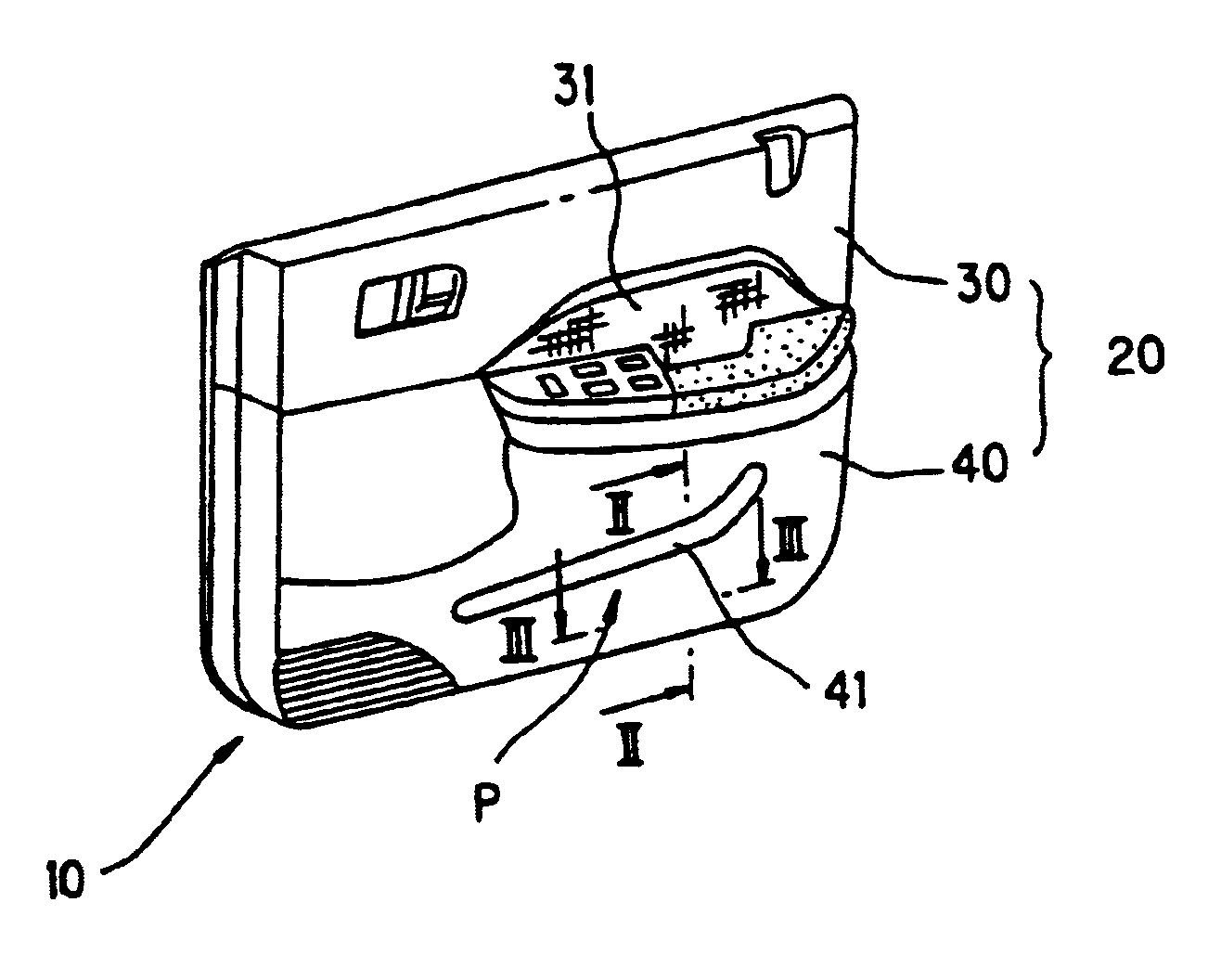

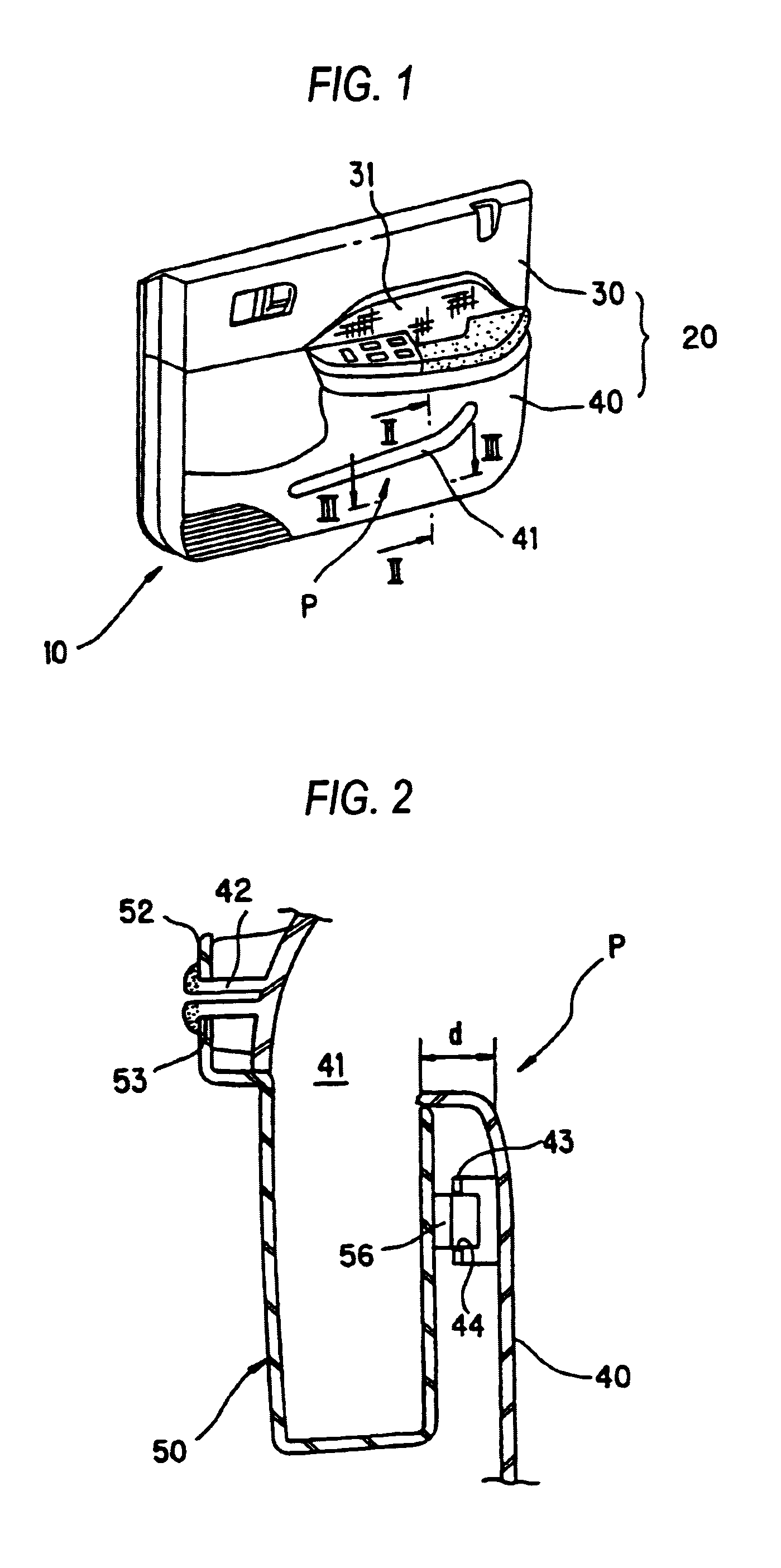

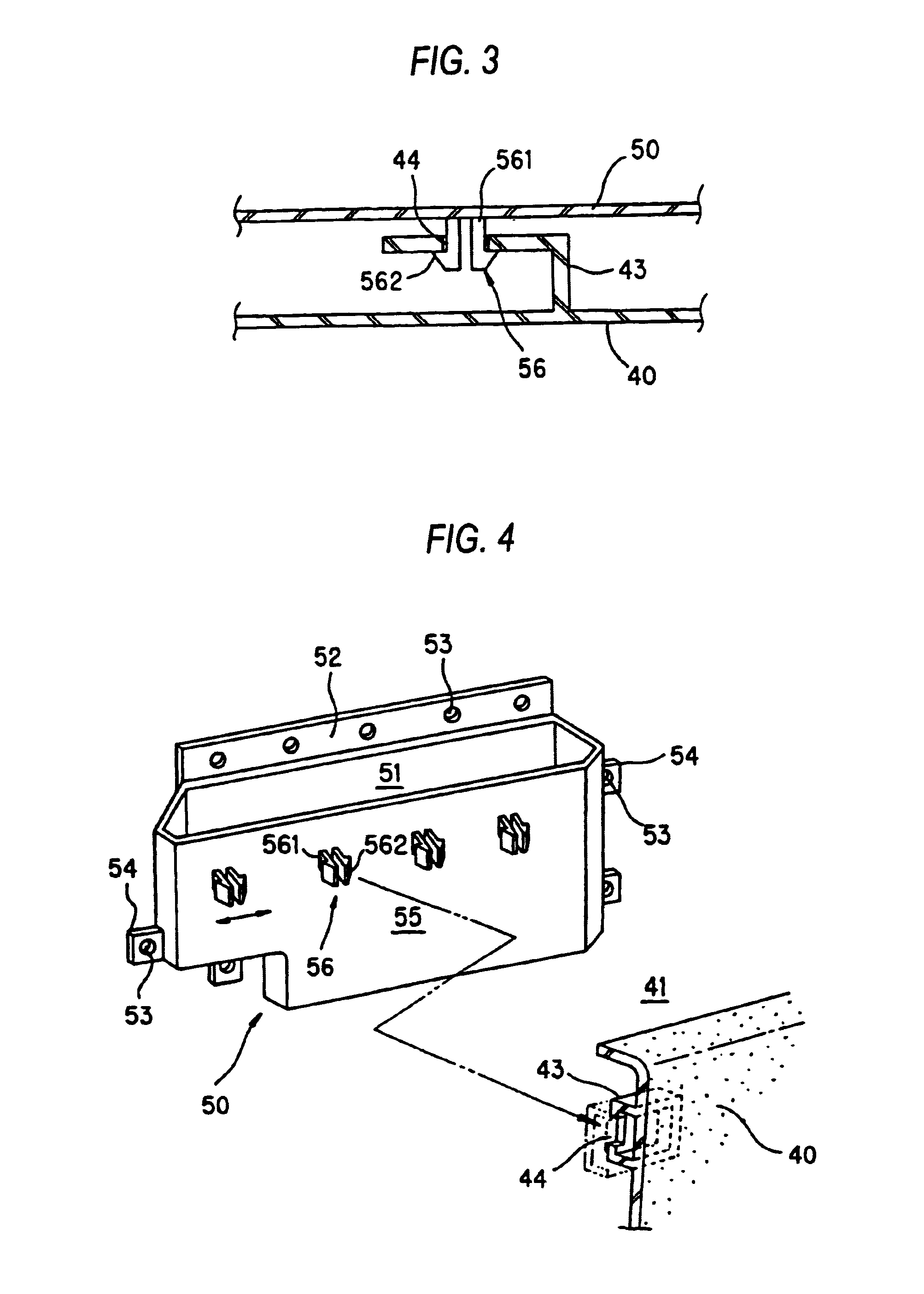

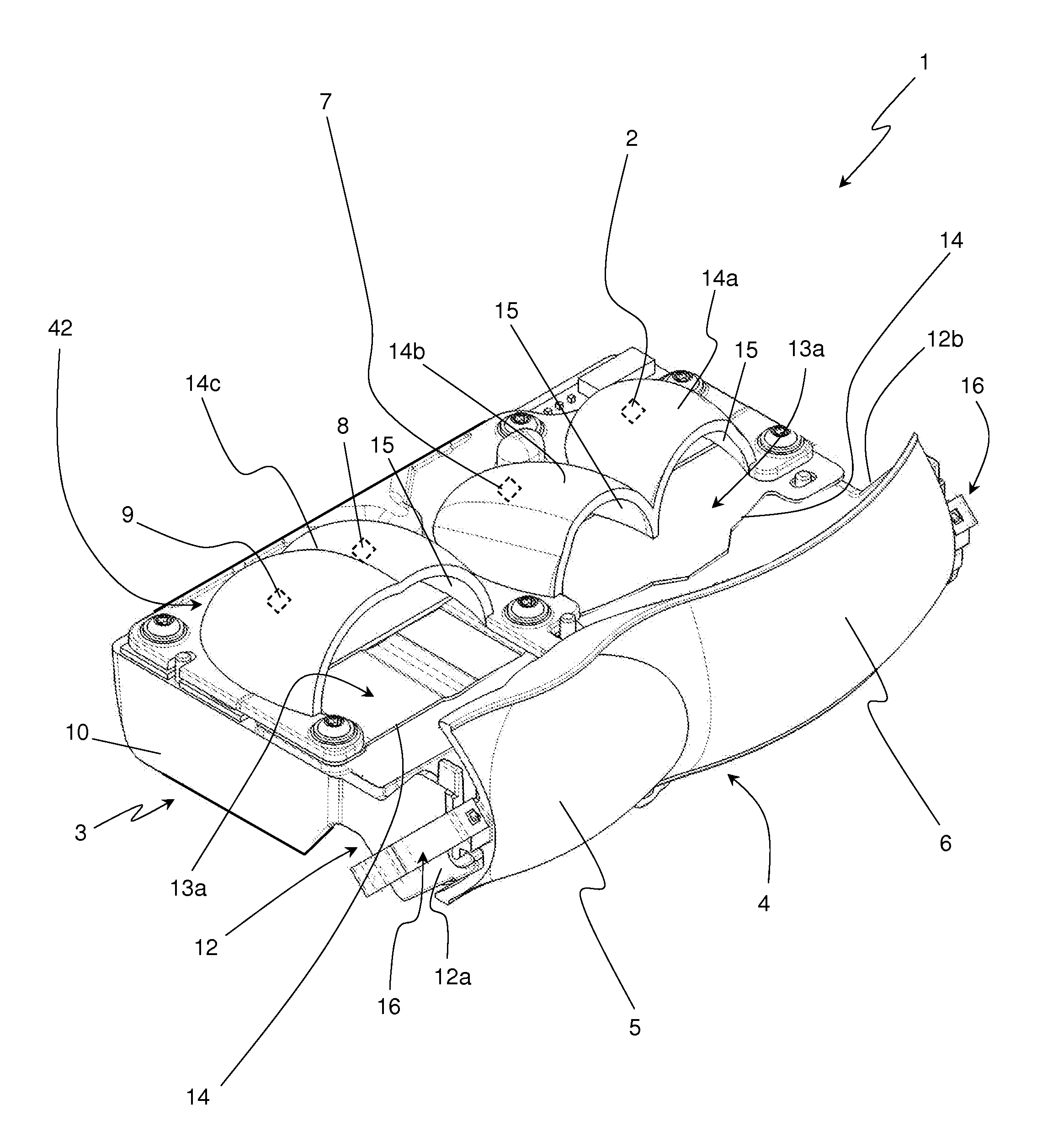

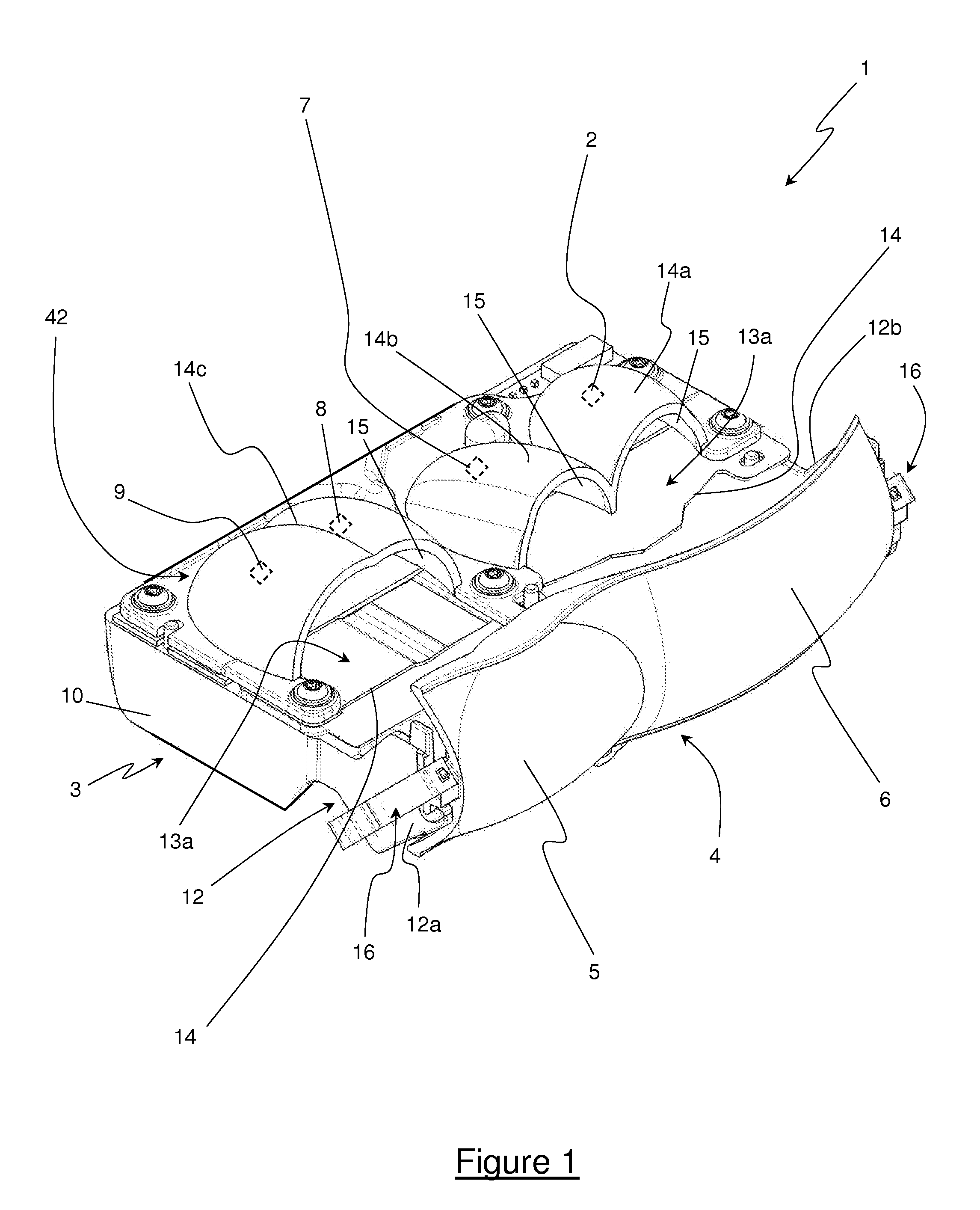

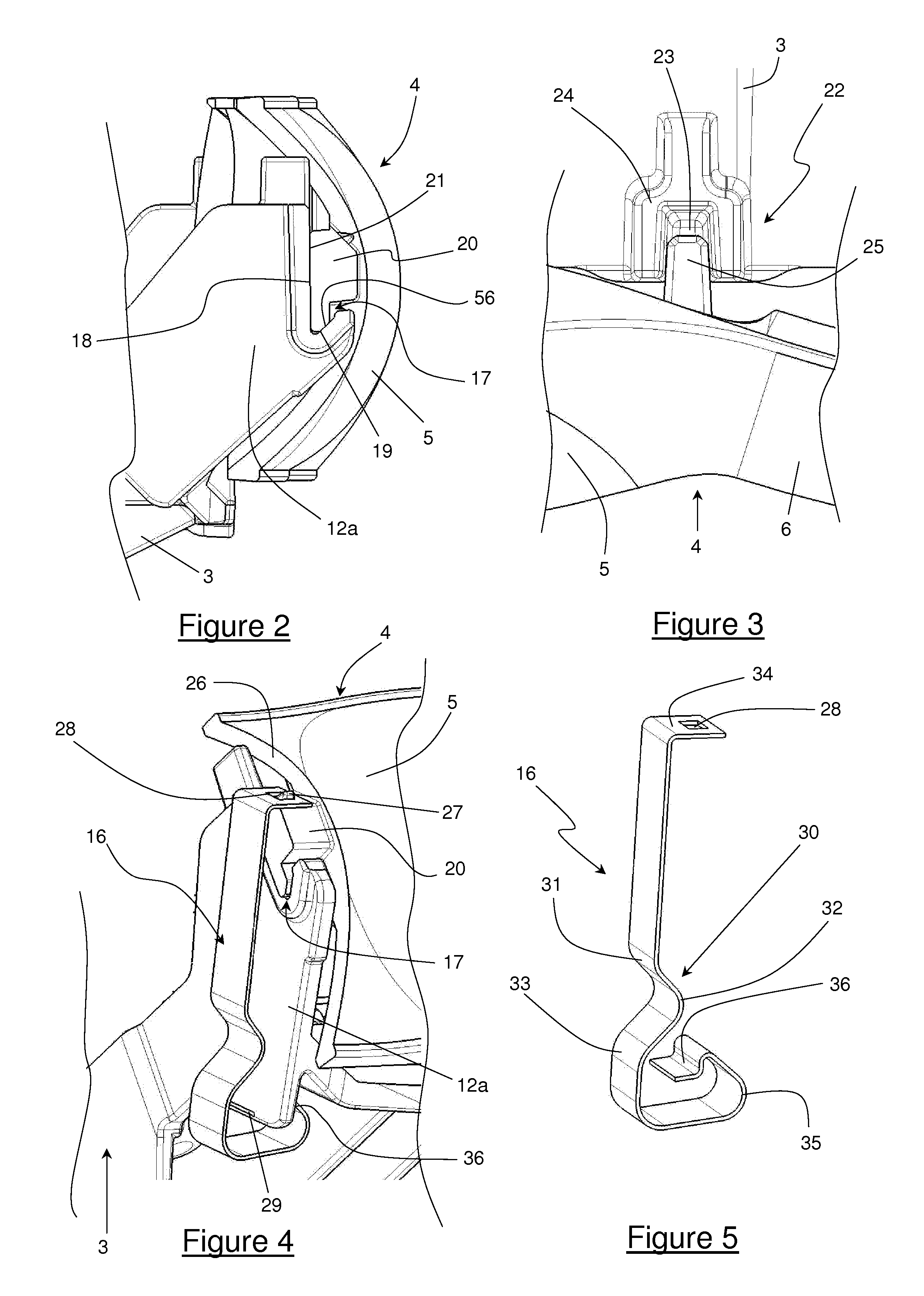

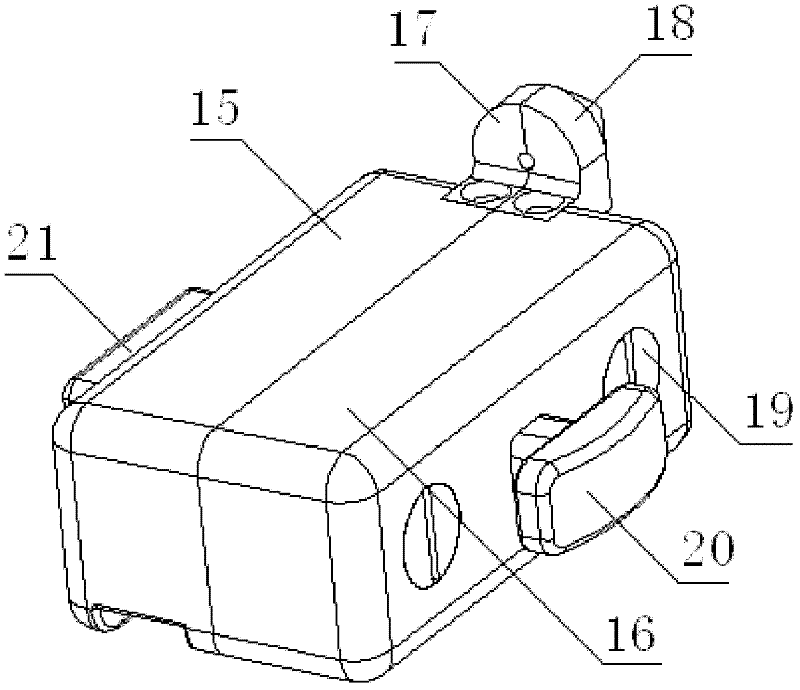

Pocket structure in interior trim

InactiveUS7008003B1Easy to recycleImprove assembly reliabilityPassenger spaceSuperstructure subunitsDouble wallEngineering

A pocket (P) structure formed by providing a pocket opening (41) in a trim main body and installing a case-shaped pocket cover (50) having an upper opening (51) on the rear side of the pocket opening (41) is provided. The front wall part of the pocket (P) is formed in a double wall structure comprising the trim main body (40) and a front wall (55) of the pocket cover (50). The trim main body (40) and the front wall (55) of the pocket cover (50) are provided with locking holes (44) and locking pieces (56), respectively, so as to eliminate iron clips in order to reduce cost and simplify a recycle operation. Patch ribs (45, 57) are installed on opposed surfaces of the rear surfaces of the trim main body and the front wall (55) of the pocket cover (50) so as to provide a good grasp at the time the pocket cover is grasped.

Owner:HONDA MOTOR CO LTD +1

Method of assembling chips

InactiveUS20050194695A1Improve assembly reliabilityPrecise alignmentSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A method of assembling chips. A first chip and a second chip are provided. At least one conductive pillar is formed on the first chip, and a conductive connecting material is formed on the conductive pillar. The second chip also comprises at least one conductive pillar. The first chip is connected to the second chip via the conductive pillars and the conductive connecting material.

Owner:QUALCOMM INC

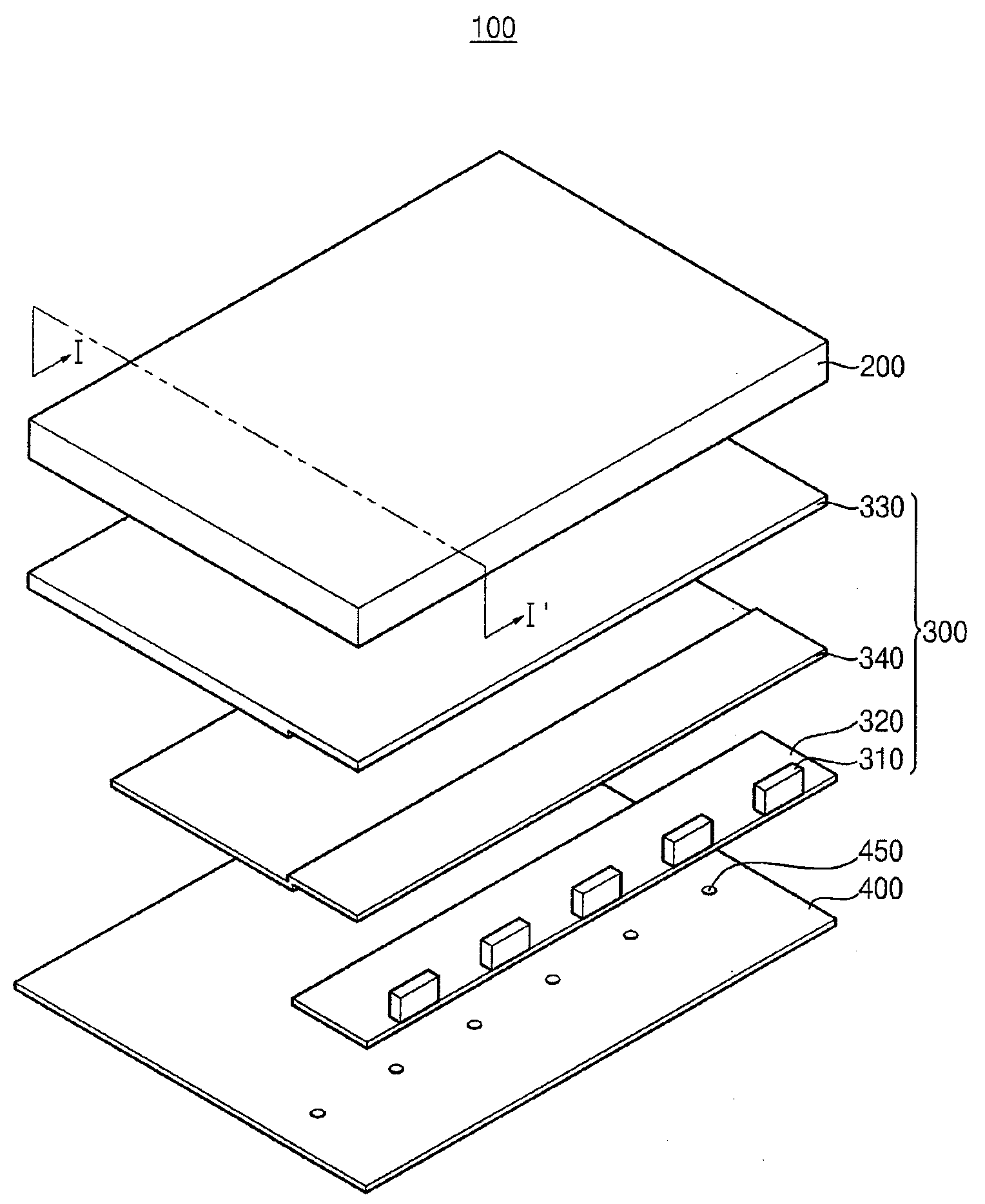

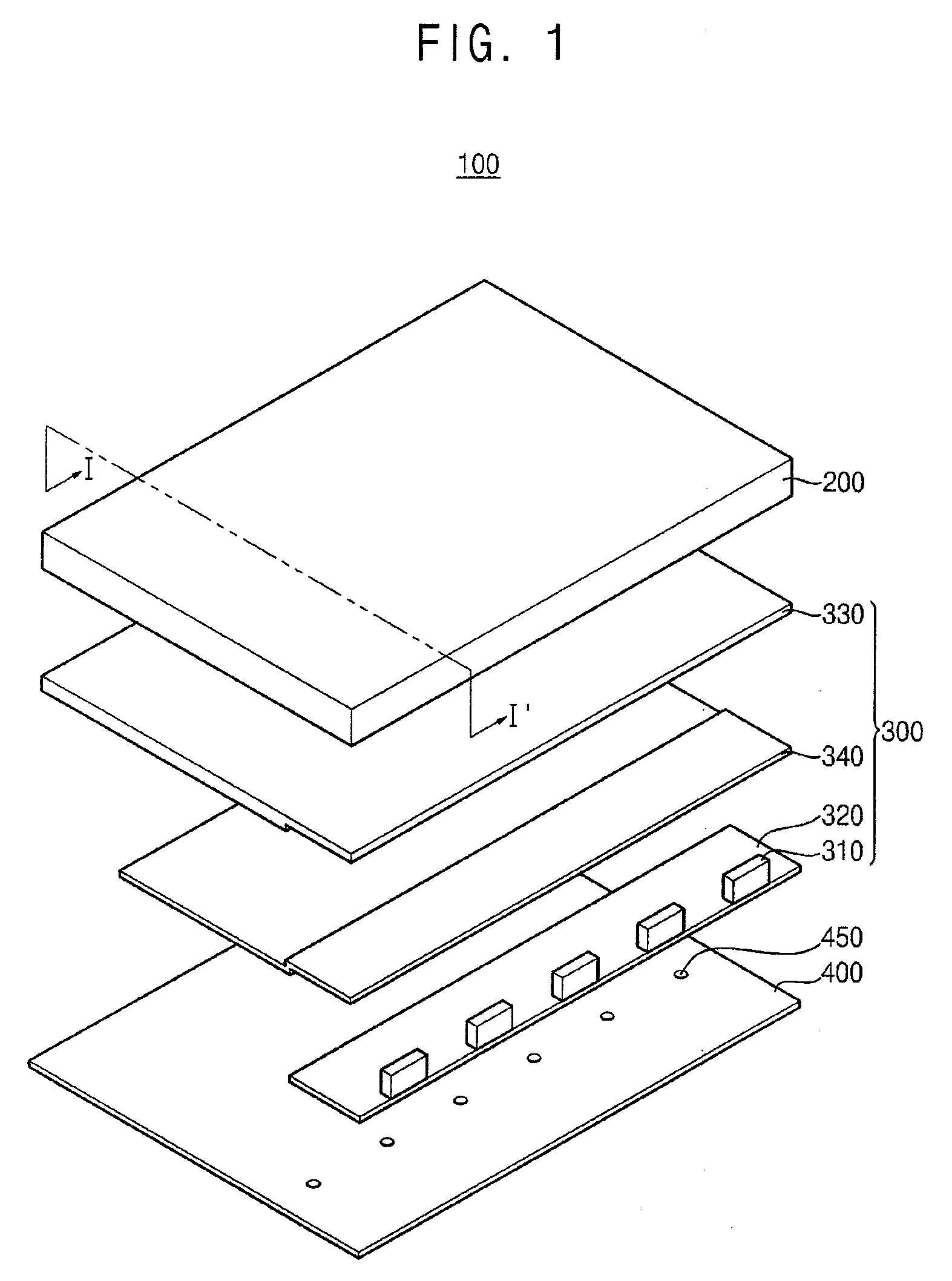

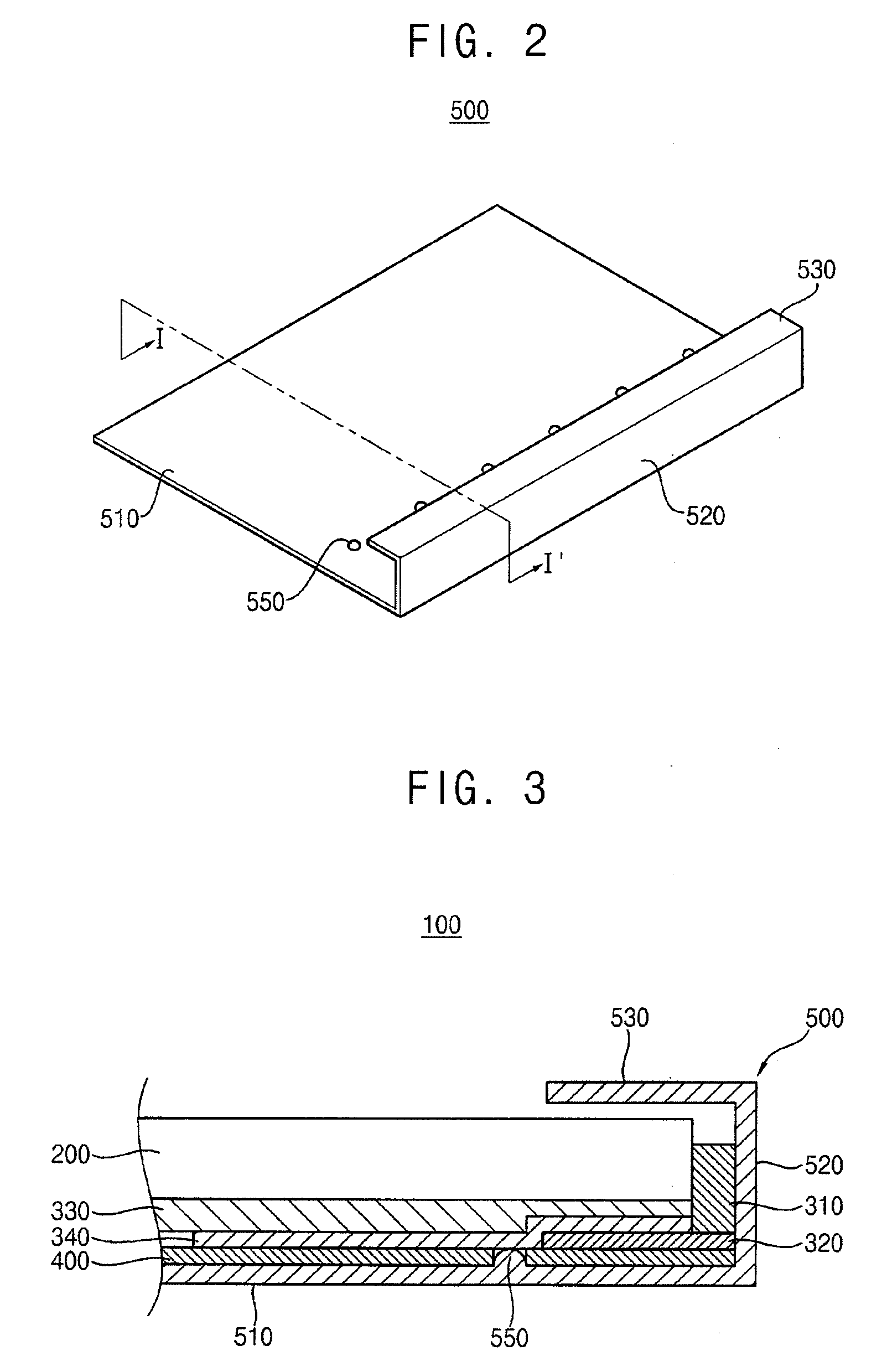

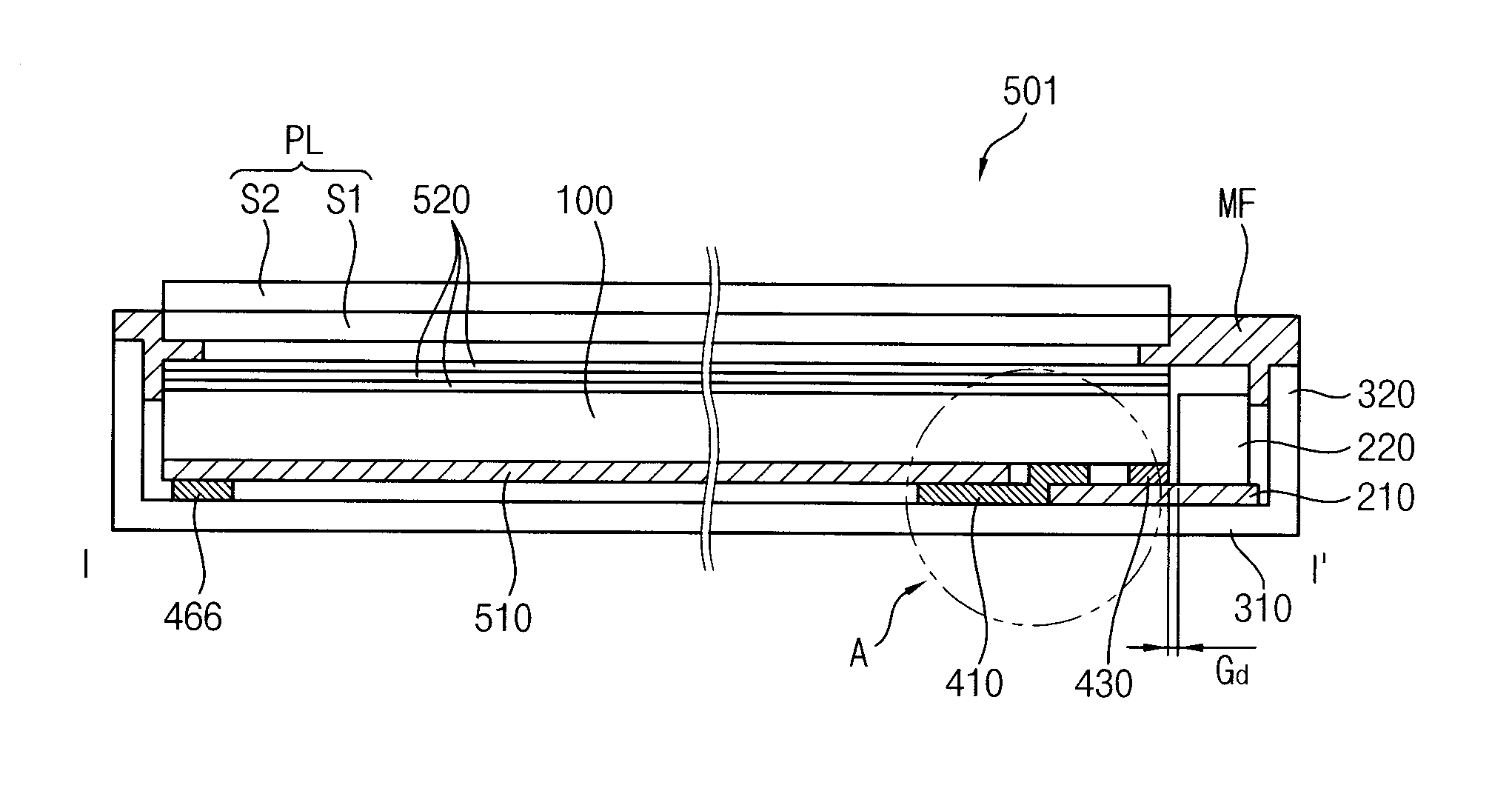

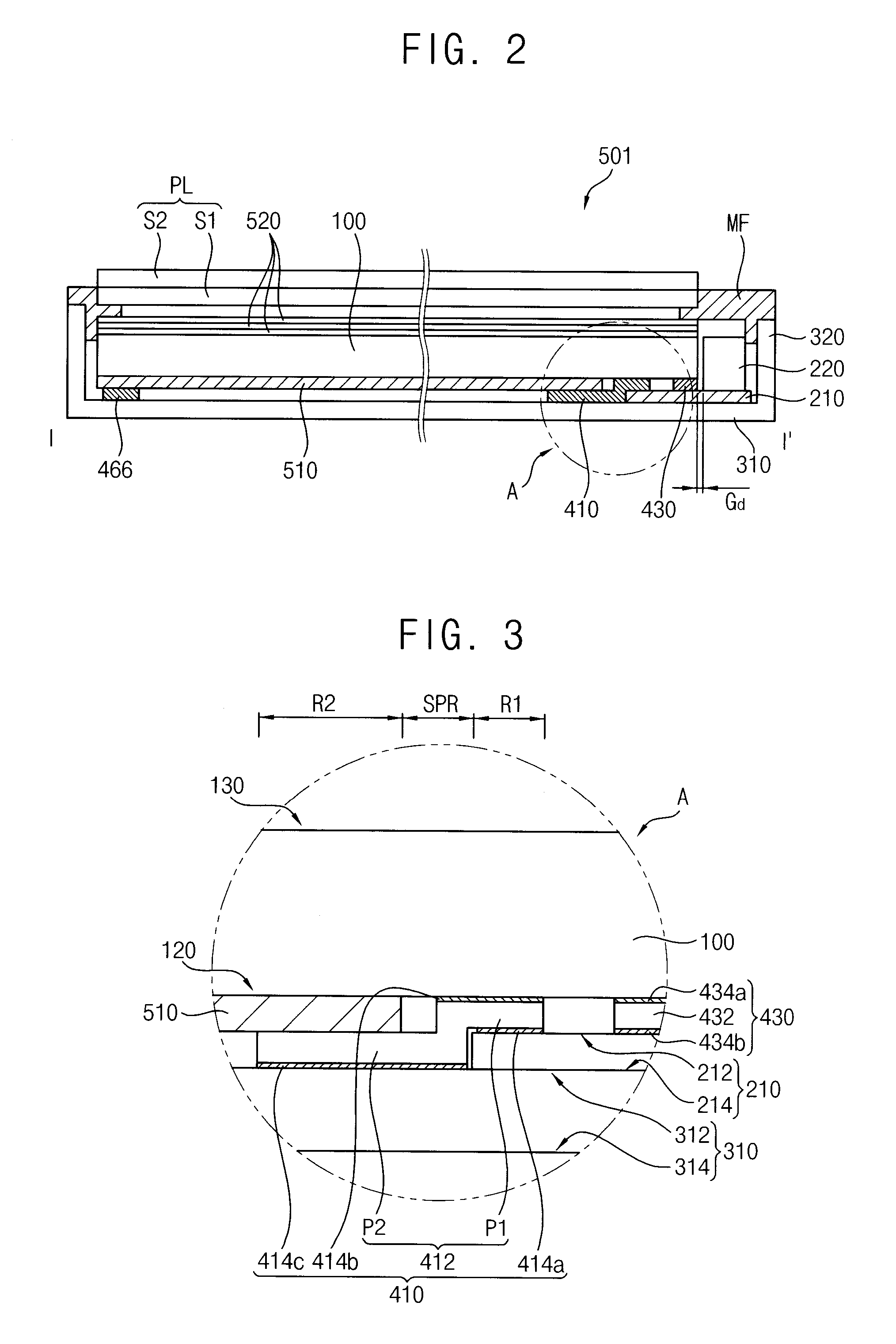

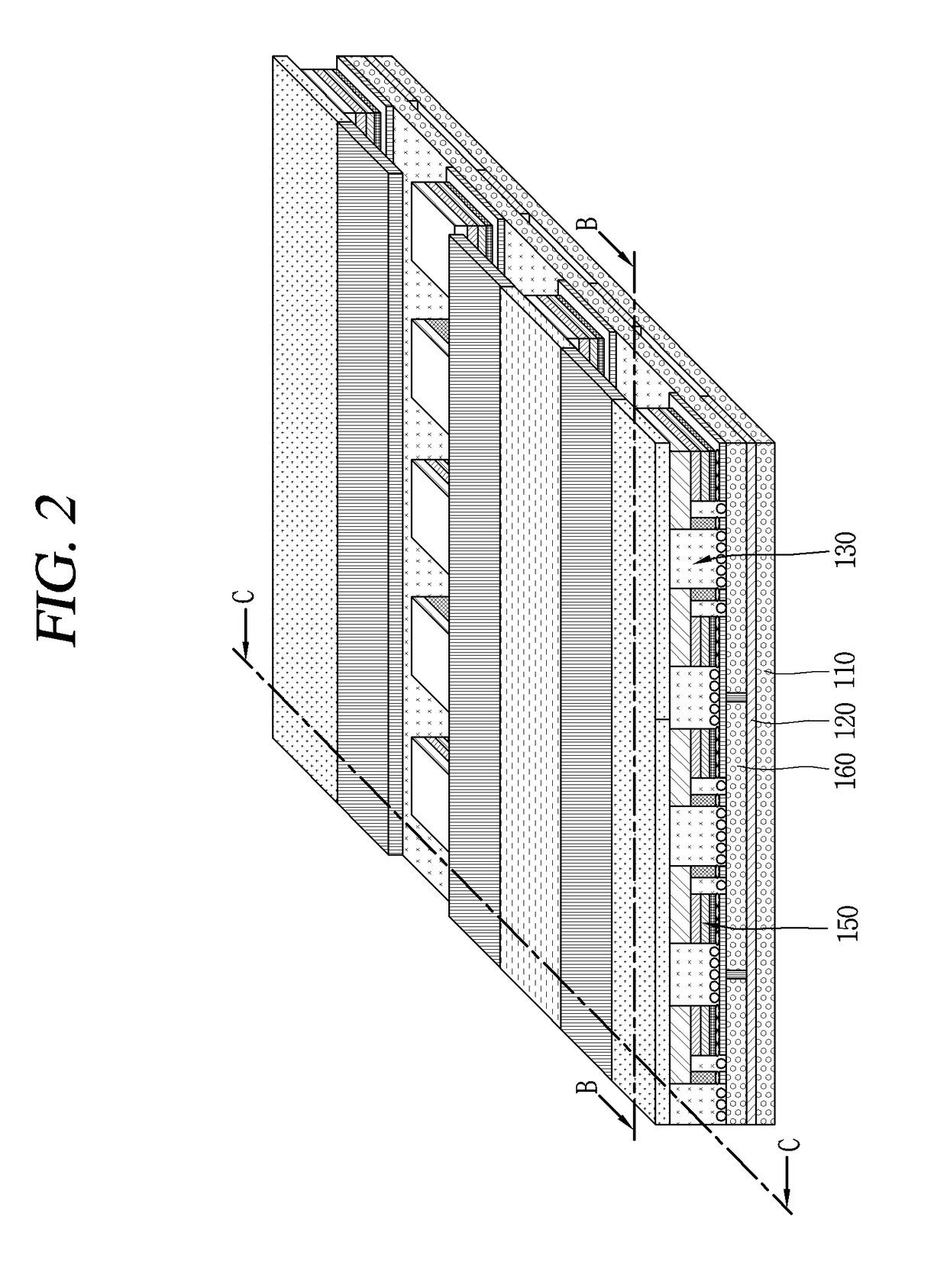

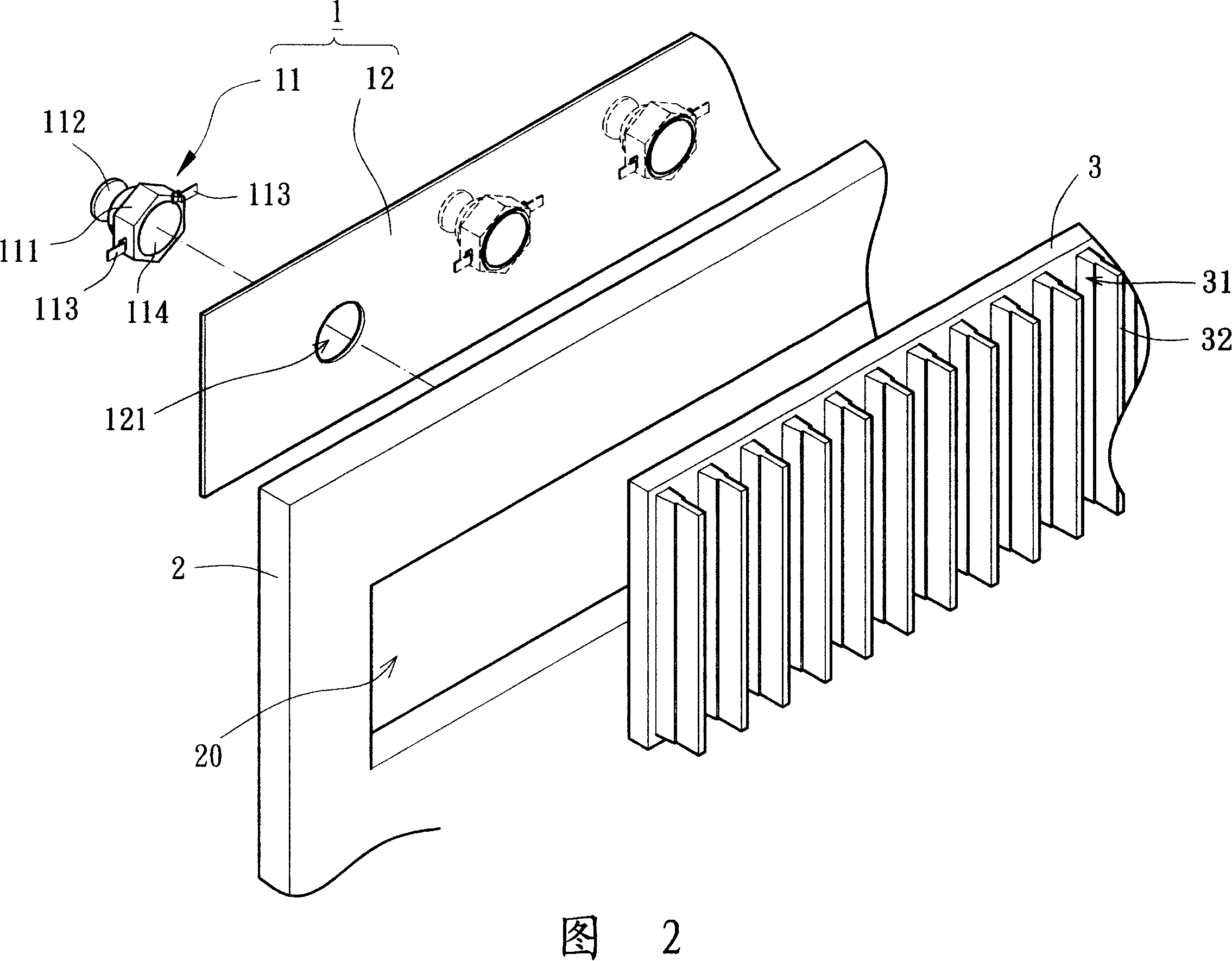

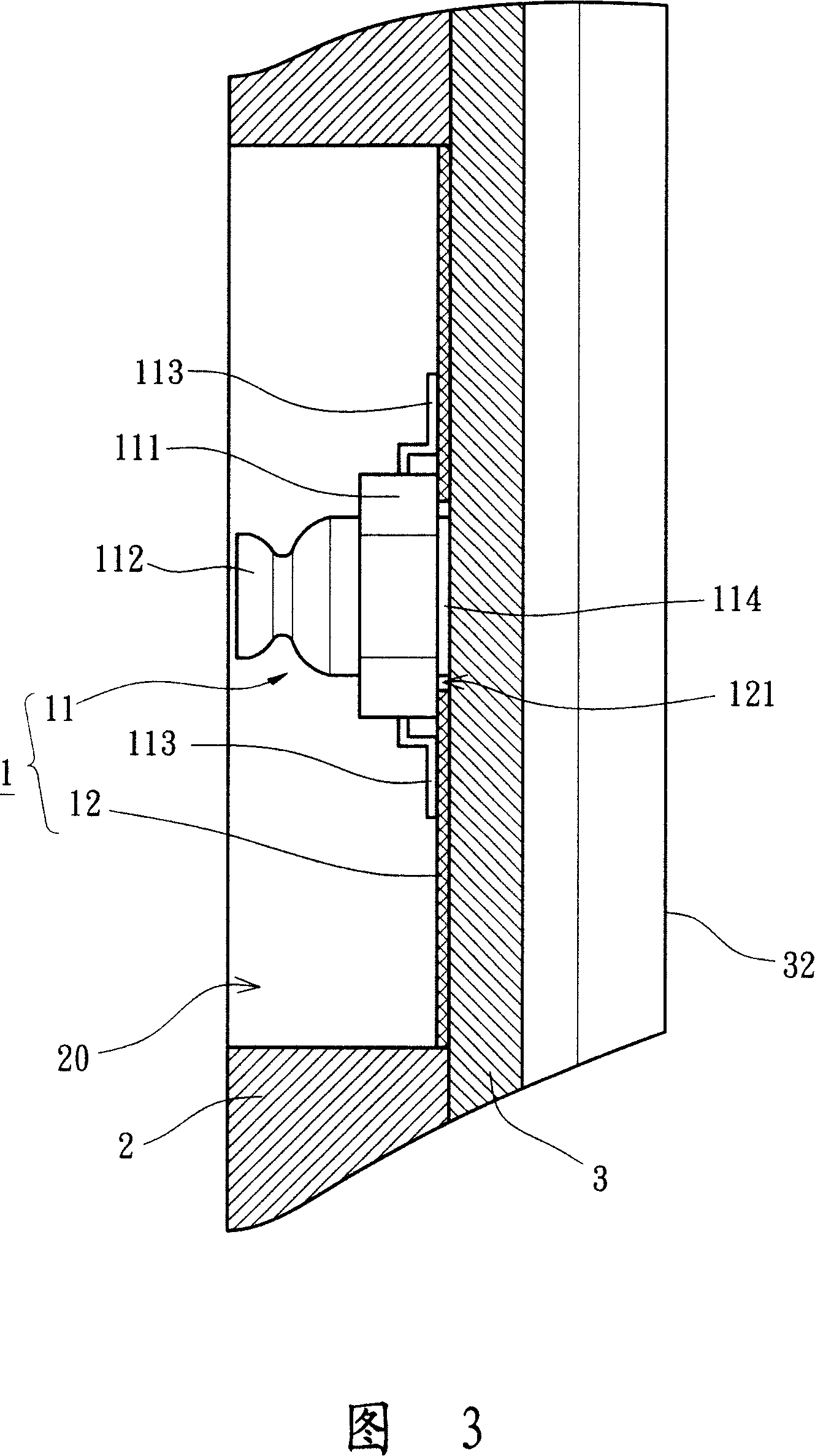

Backlight assembly, display apparatus having the same and method for manufacturing the same

InactiveUS20080239754A1Improve assembly reliabilityImprove cooling effectVessels or leading-in conductors manufacturePlanar/plate-like light guidesManufacturing cost reductionLight guide

A backlight assembly, a display apparatus and a method for manufacturing the backlight assembly. The backlight assembly includes a light-guide plate, a point light source unit, a fixing plate and a cover. The point light source unit includes at least one point light source disposed at a side of the light-guide plate, and a flexible printed circuit board (FPC) disposed under the light-guide plate and having the point light source. The fixing plate is disposed under the FPC and has at least one first combining member. The cover is disposed under the fixing plate and has a first surface on which at least one second combining member is formed. The first and second combining members are combined with each other. Thus, assembling time may be decreased, heat may be efficiently dissipated, and manufacturing costs may be decreased.

Owner:SAMSUNG ELECTRONICS CO LTD

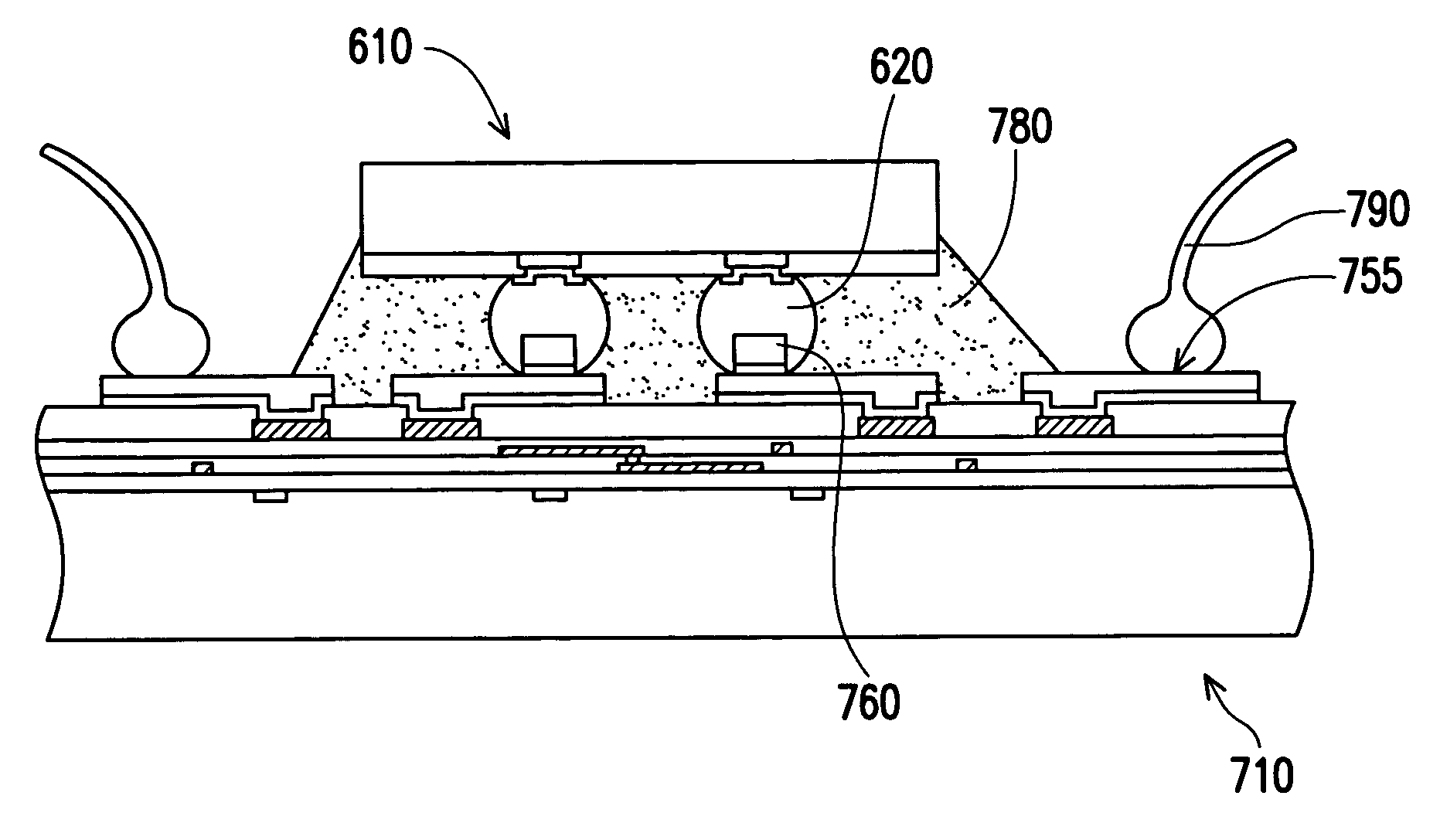

Chip package with dam bar restricting flow of underfill

ActiveUS8294279B2Improve assembly reliabilityPrecise alignmentSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A method of assembling chips. A first chip and a second chip are provided. At least one conductive pillar is formed on the first chip, and a conductive connecting material is formed on the conductive pillar. The second chip also comprises at least one conductive pillar. The first chip is connected to the second chip via the conductive pillars and the conductive connecting material.

Owner:QUALCOMM INC

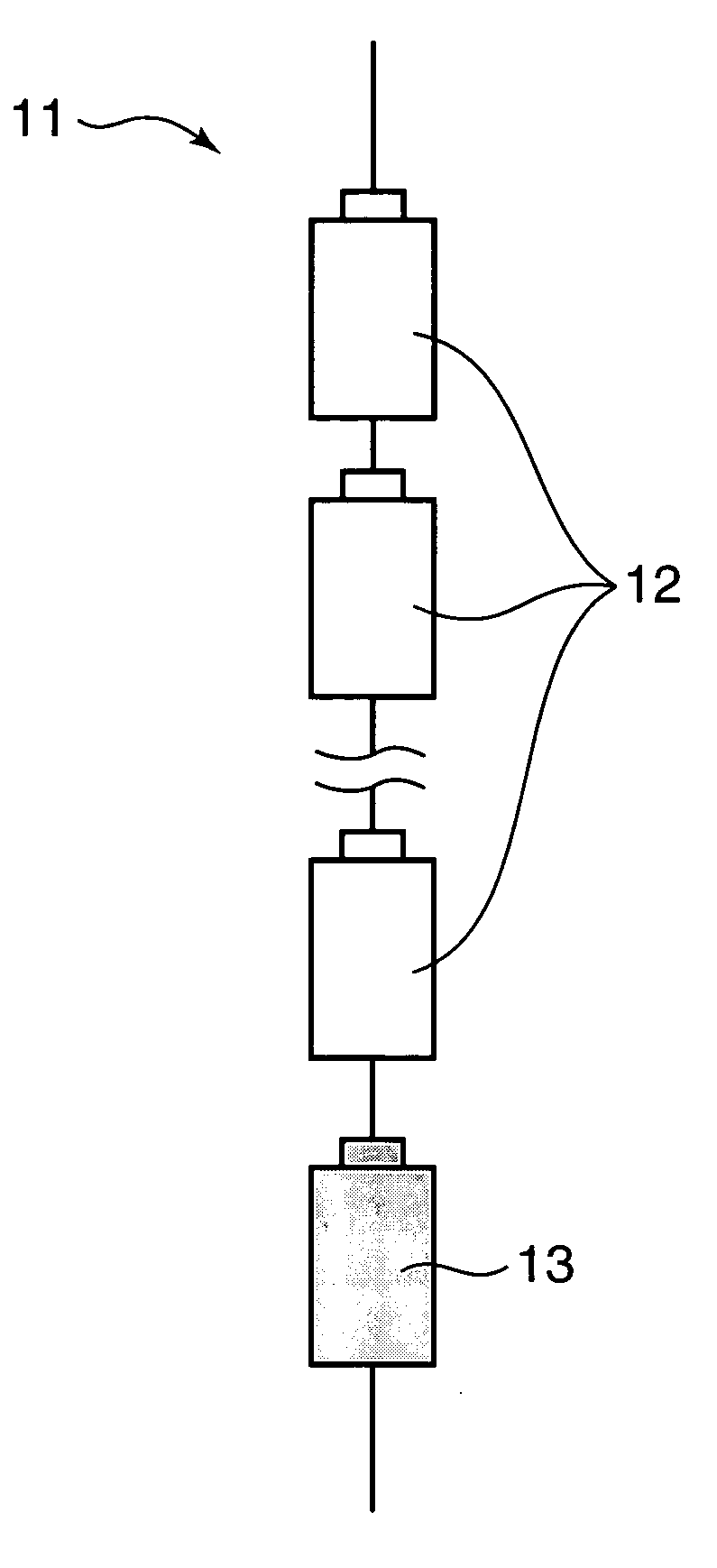

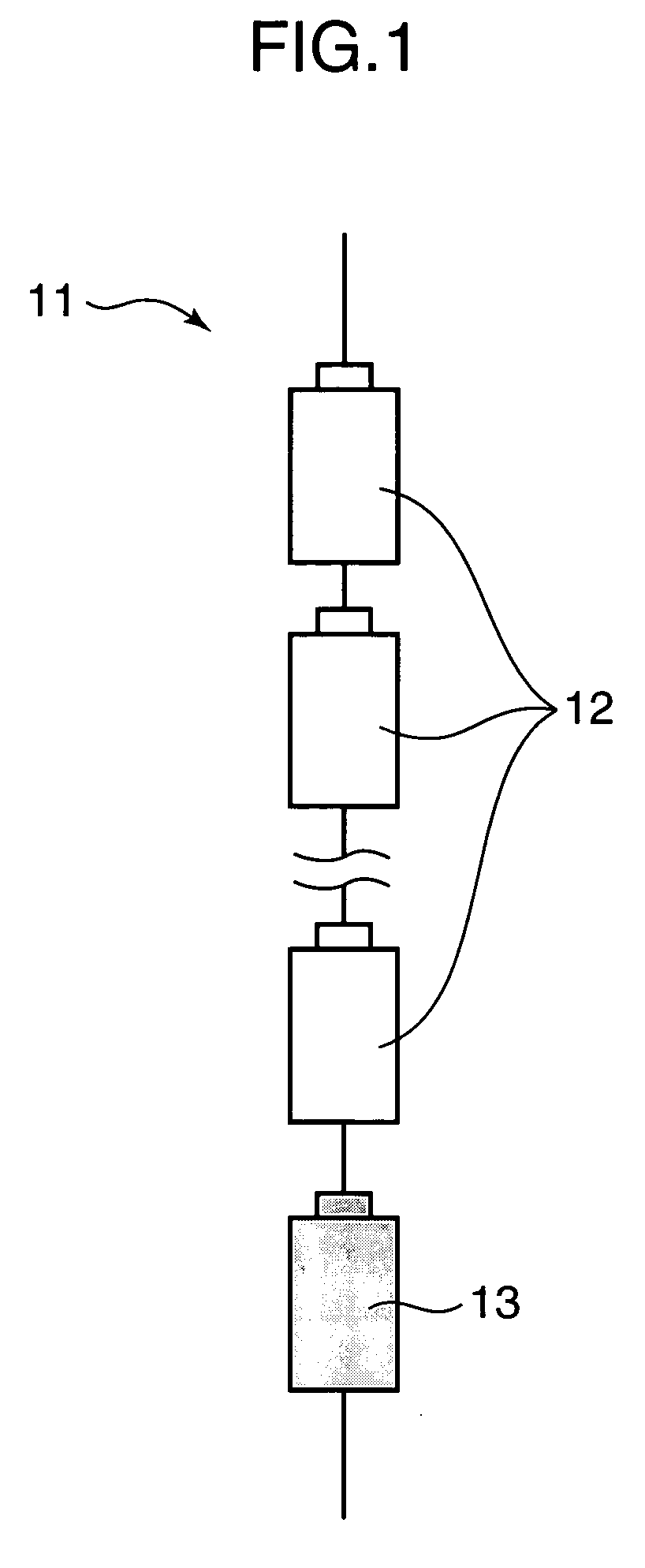

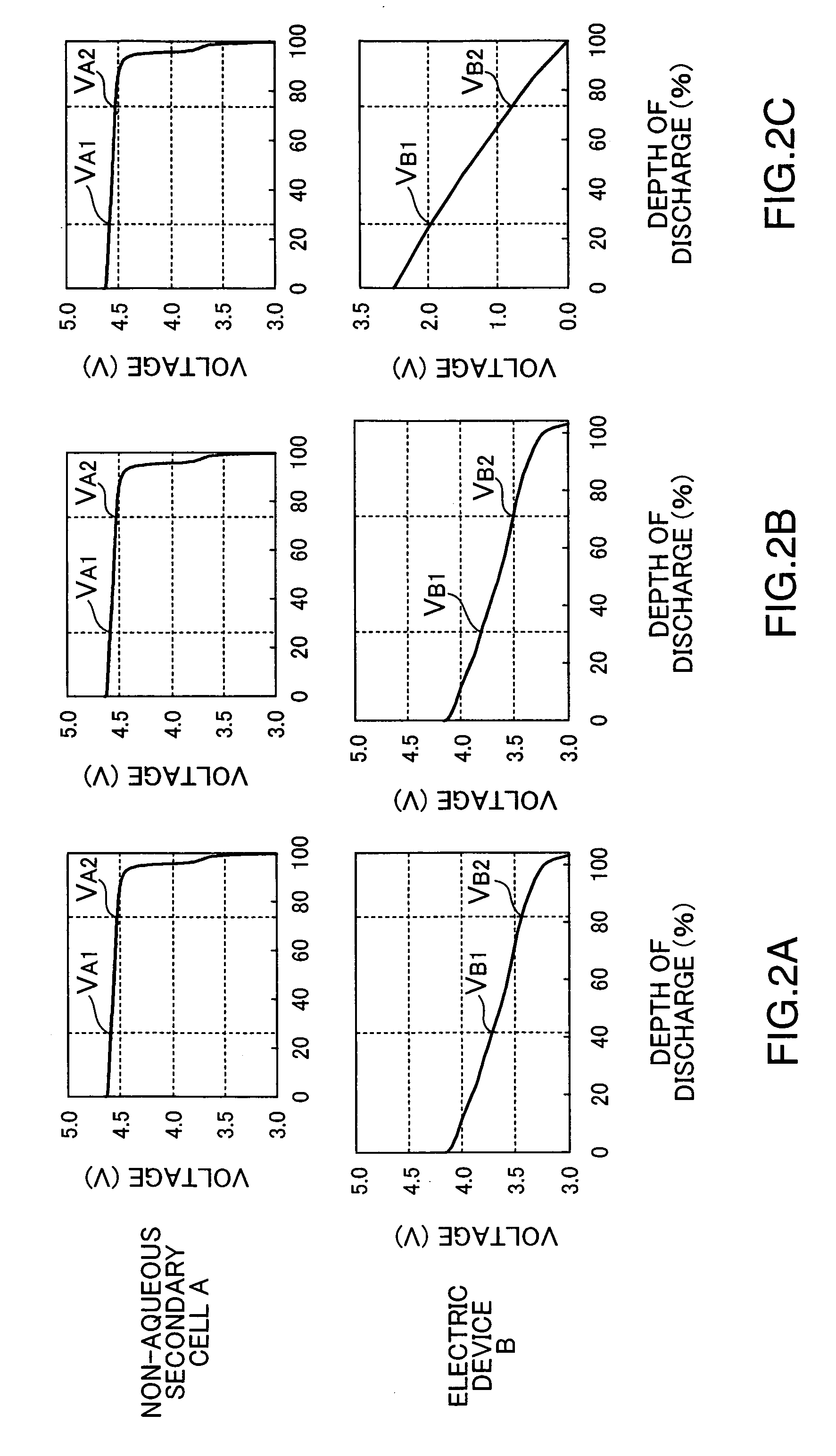

Assembled battery, power-supply system and production method of assembled battery

InactiveUS20070166607A1Increase powerPrevent overcharge and overdischarge effectivelyPrimary cell to battery groupingElectrode carriers/collectorsEngineeringDepth of discharge

An assembled battery comprises mainly multiple non-aqueous secondary cells A and at least one electric device B for voltage detection containing a non-aqueous electrolyte connected to the multiple non-aqueous secondary cells A in series. When a difference in the non-aqueous secondary cell A between a voltage per cell (VA1) at a depth of discharge of 25% and a voltage per cell (VA2) at a depth of discharge of 75% is designated as ΔVA, and a difference in the electric device B between a voltage per cell (VB1) at a depth of discharge equivalent to the depth of discharge of 25% of the non-aqueous secondary cell A and a voltage per cell (VB2) at a depth of discharge equivalent to the depth of discharge of 75% of the non-aqueous secondary cell A is designated as ΔVB, the ΔVB of electric device B is greater than the ΔVA of non-aqueous secondary cell A.

Owner:PANASONIC CORP

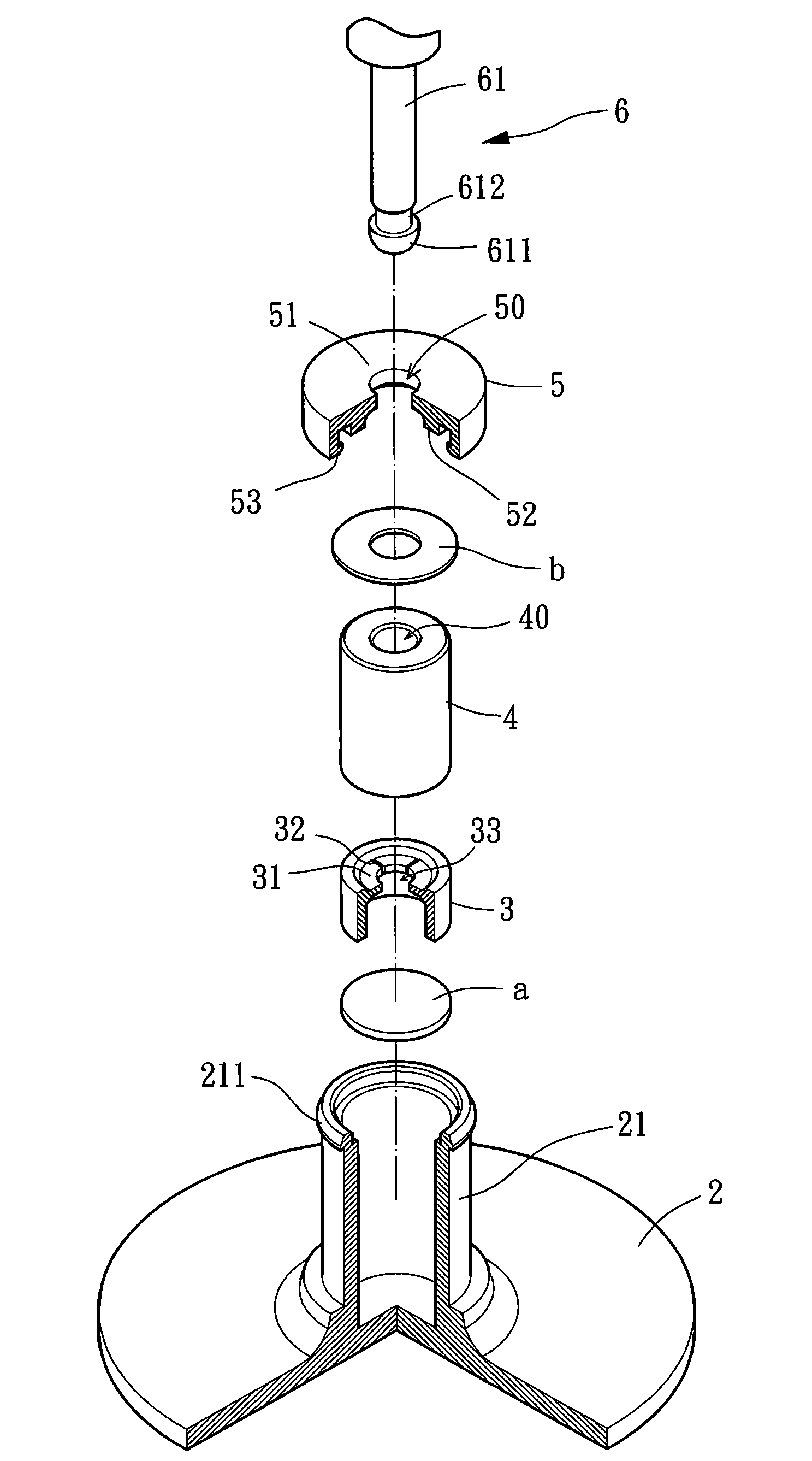

Optical module with common part reference for motor vehicle lighting and/or signalling

ActiveUS20140226355A1Reduce lighting costsLow costVehicle headlampsLighting support devicesMobile vehicleOptical Module

An optical module DE for a lighting and / or signaling device of a vehicle, comprising at least one light source capable of generating a light beam, a cooling device capable of dissipating heat and a device for focusing the light beam, characterized in that the focusing device is borne directly by the cooling device.Application to motor vehicles.

Owner:VALEO VISION SA

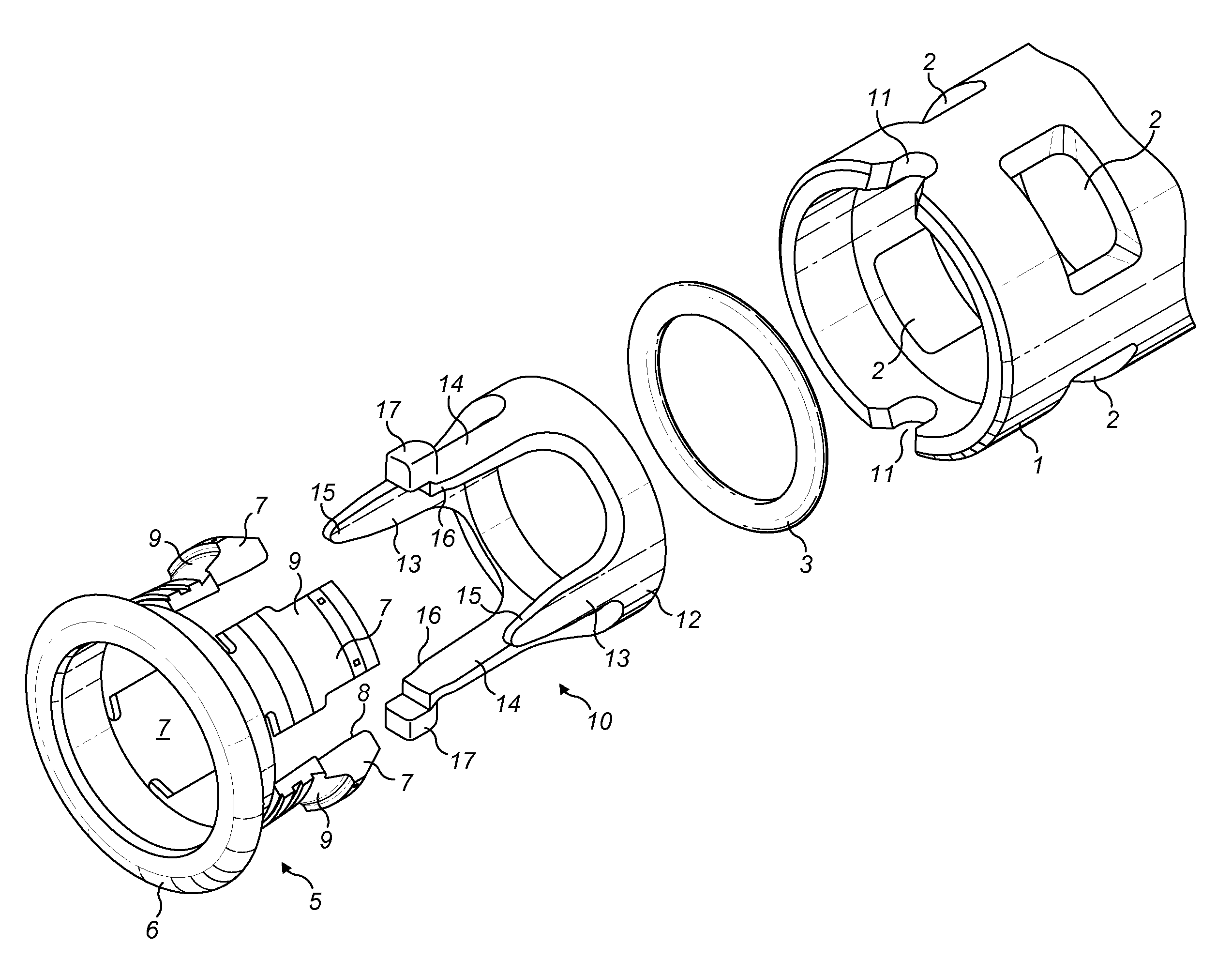

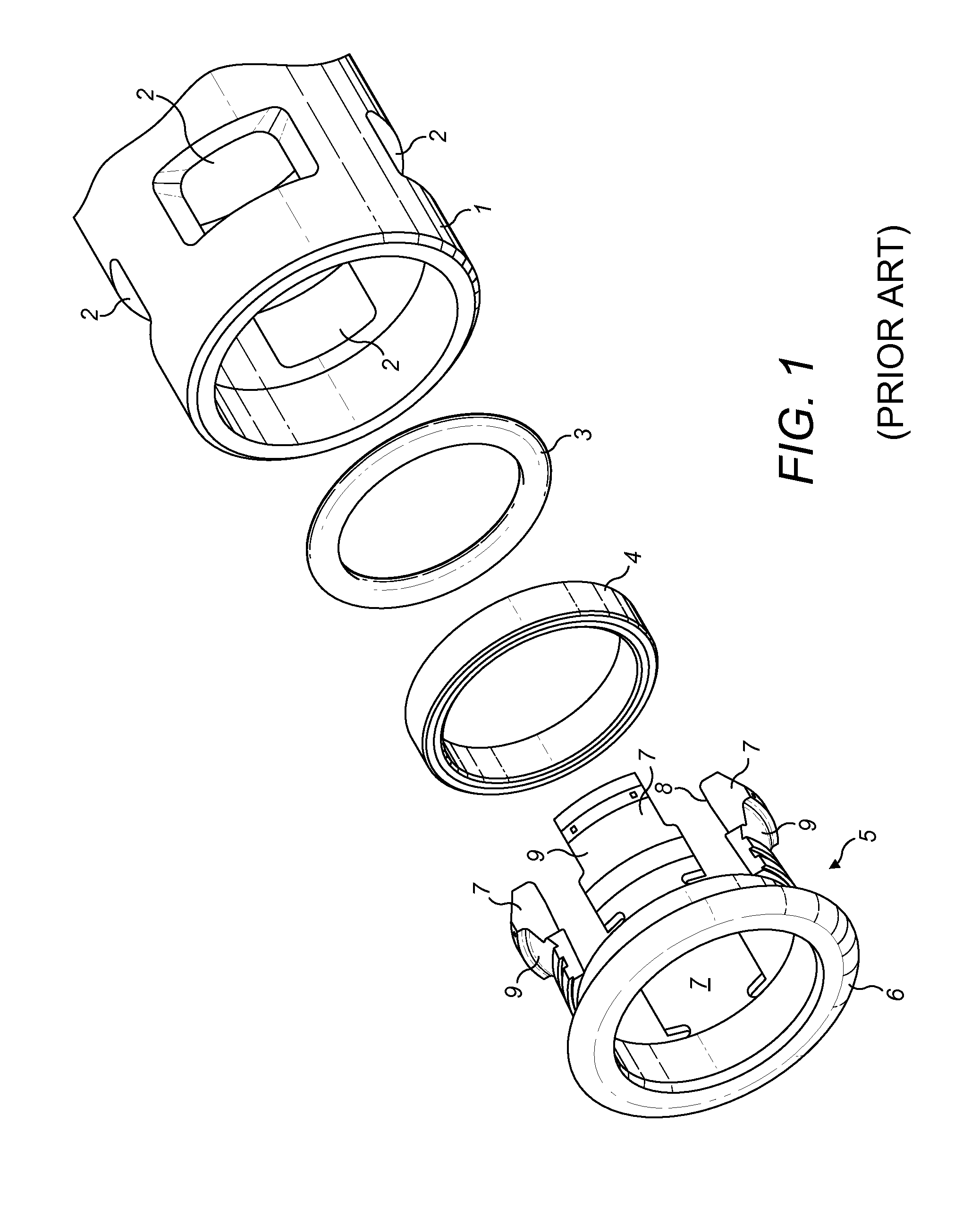

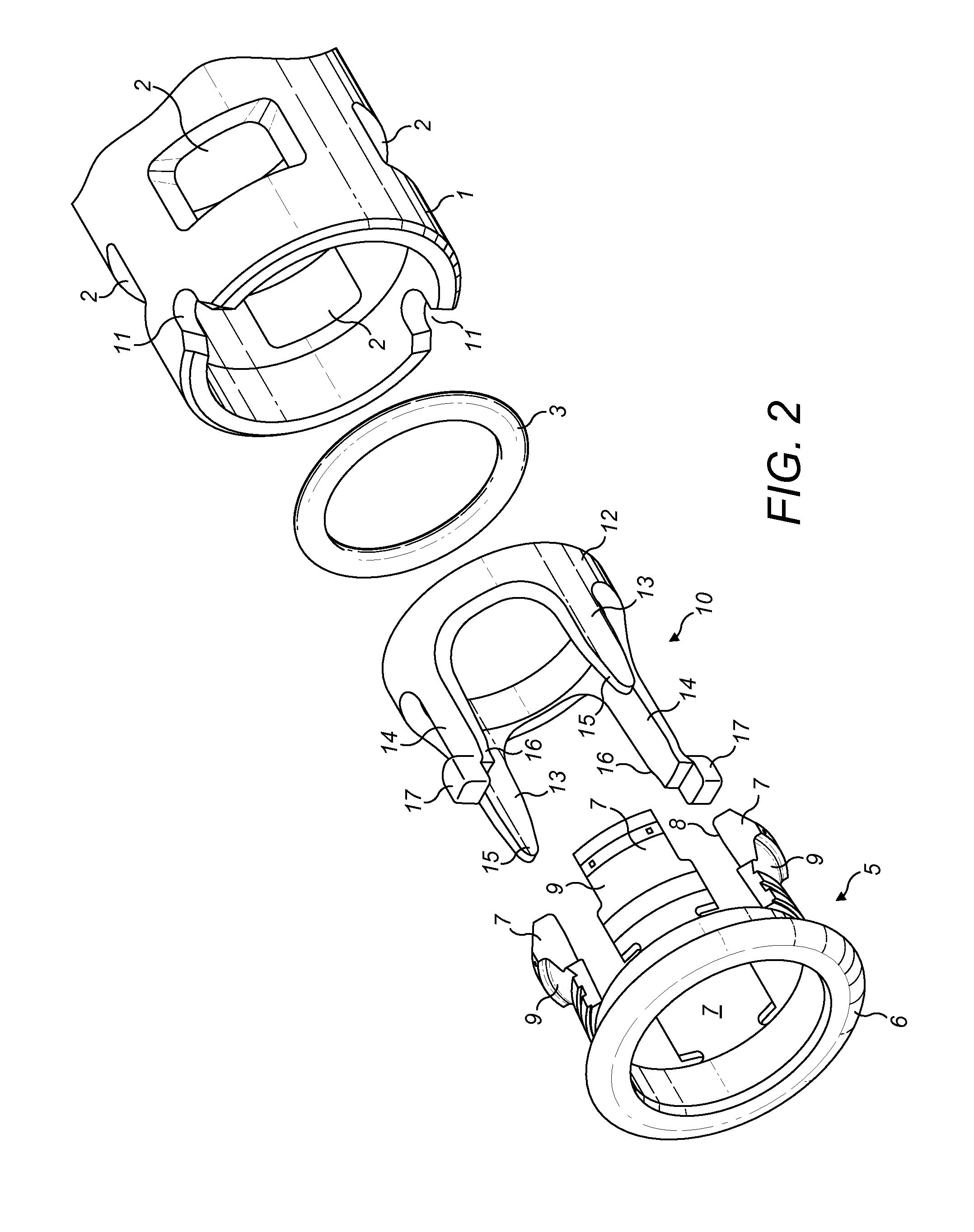

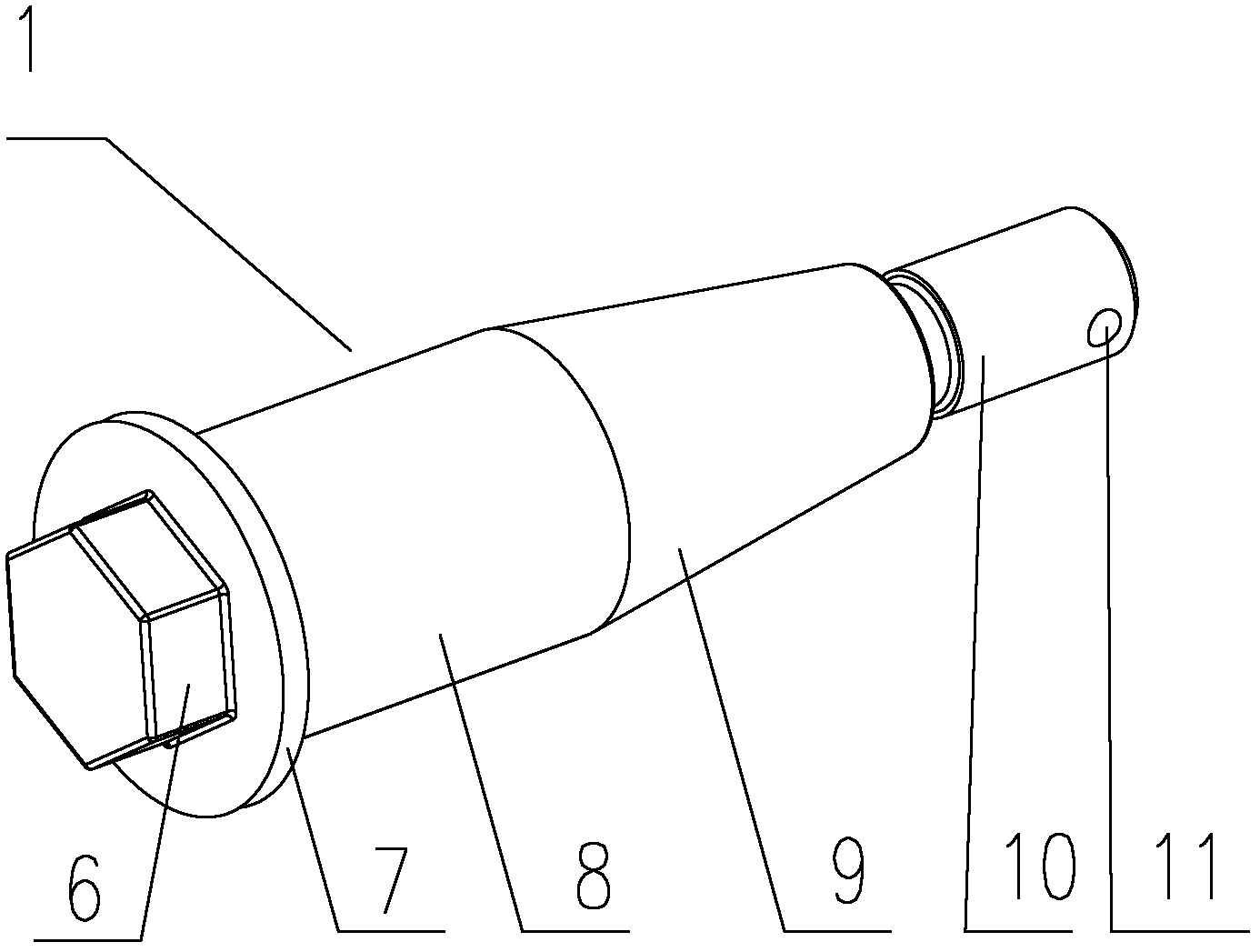

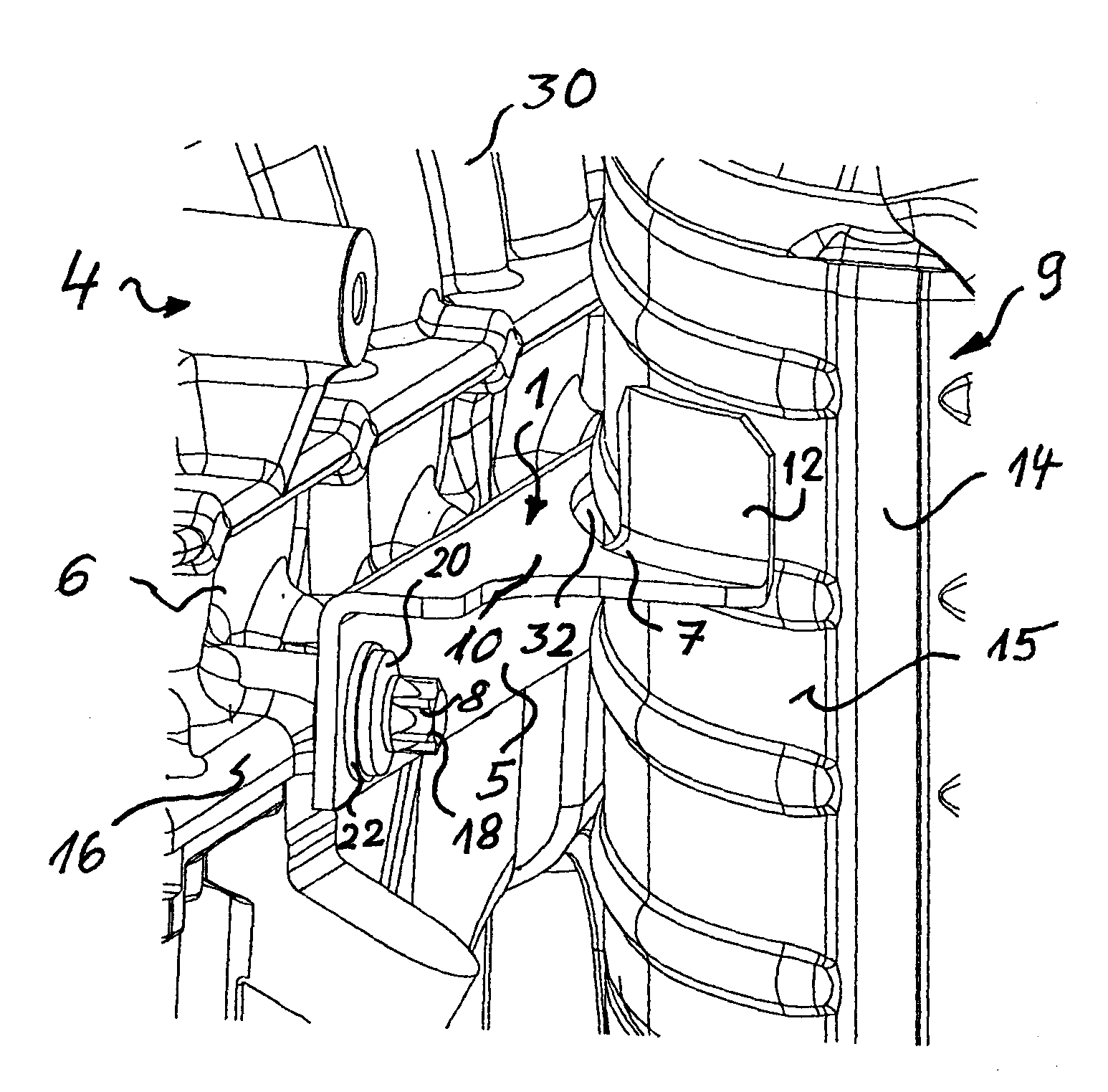

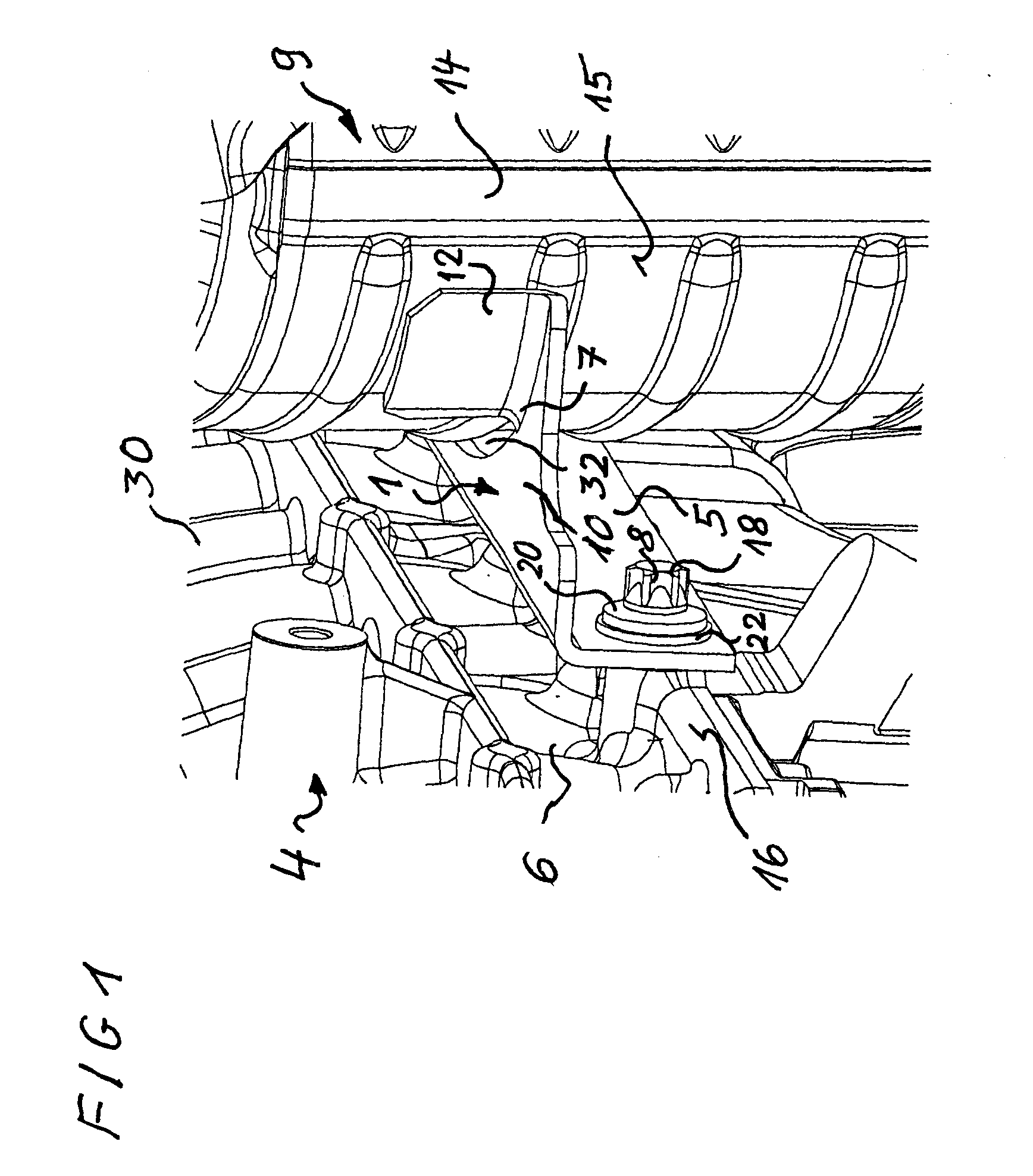

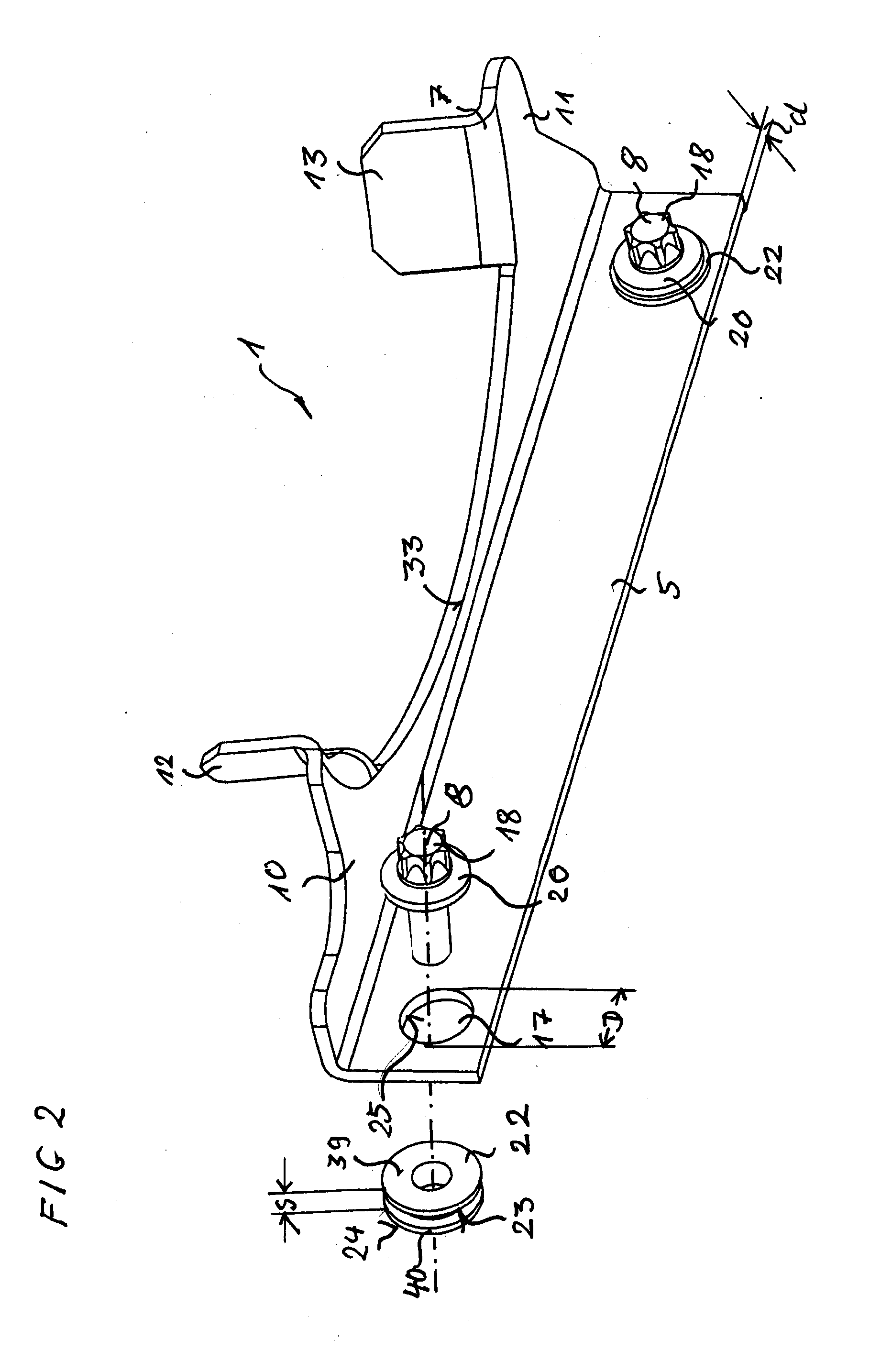

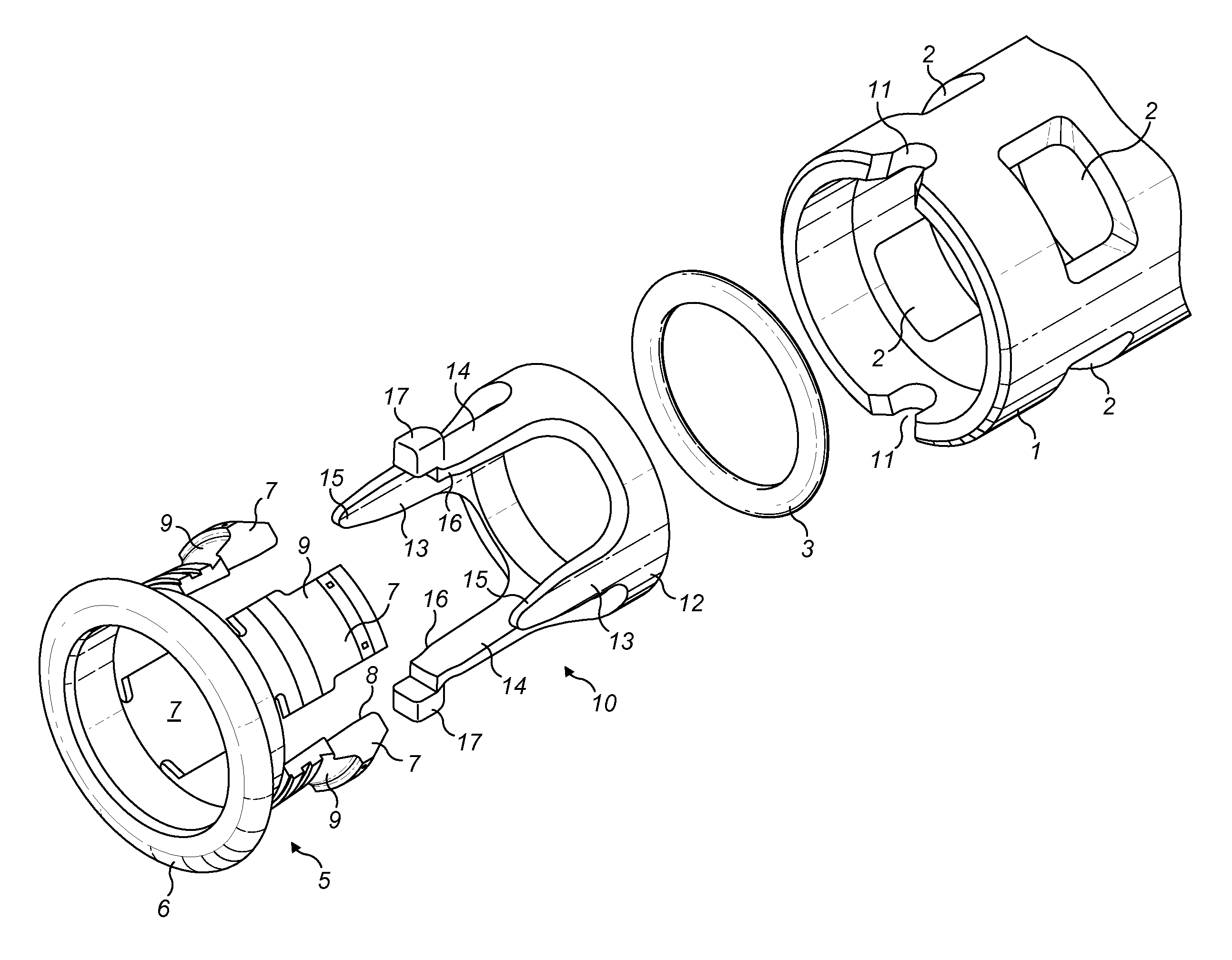

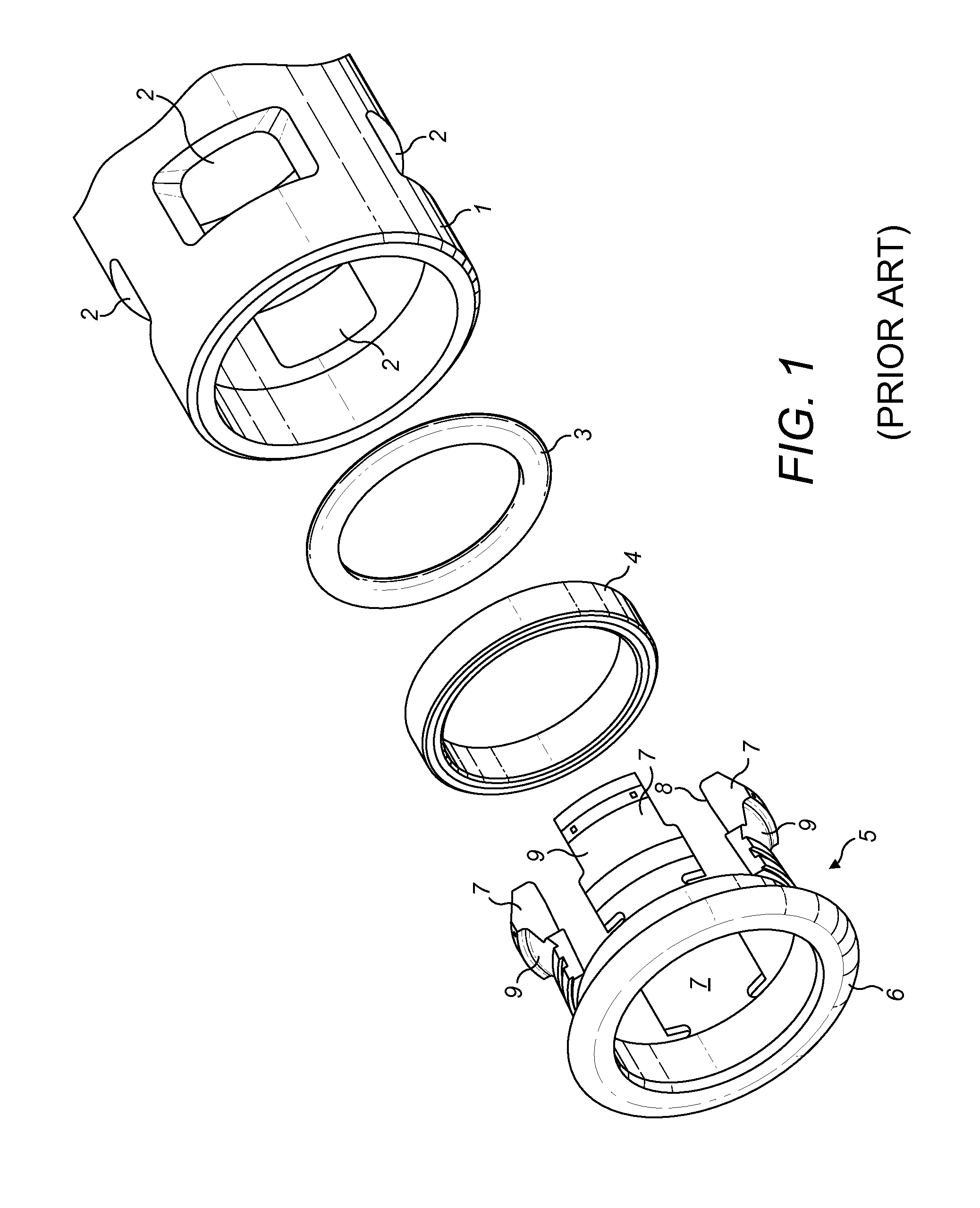

Tube coupling

ActiveUS20110309614A1Interference fit tightEasy alignmentSleeve/socket jointsCouplingsLateral recessCoupling

A tube coupling includes a body (1) to receive a tube (22). The body has lateral recesses (12) extending outwardly from an internal wall. An O-ring (3) is retained by the body distally of the recesses. A collet (5) includes a ring (6) and collet legs (7) to be received in the lateral recesses and having a tooth (8) facing the passageway. Proximal movement of the collet with respect to the body causes the fingers to deflect inwardly. A tube support (10) includes a ring (12) and has a key to align with the body. Castellations (13, 14) extend proximately from the tube support ring and are complementary to the collet legs to align the collet with respect to the body as the collet is inserted into the body.

Owner:JOHN GUEST INT LTD

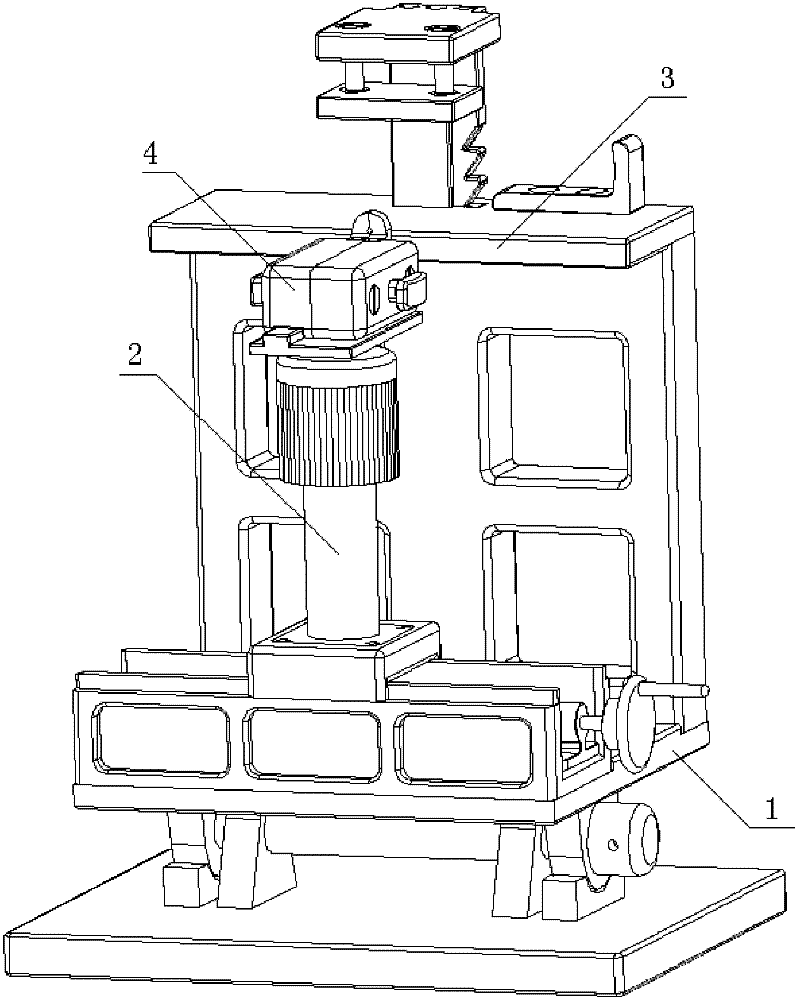

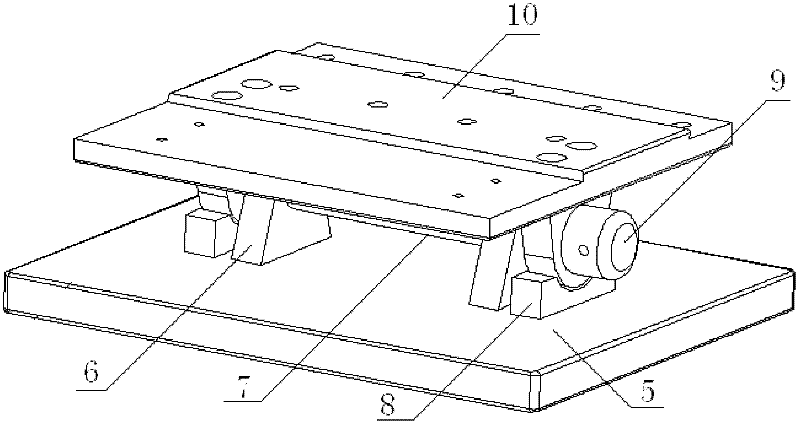

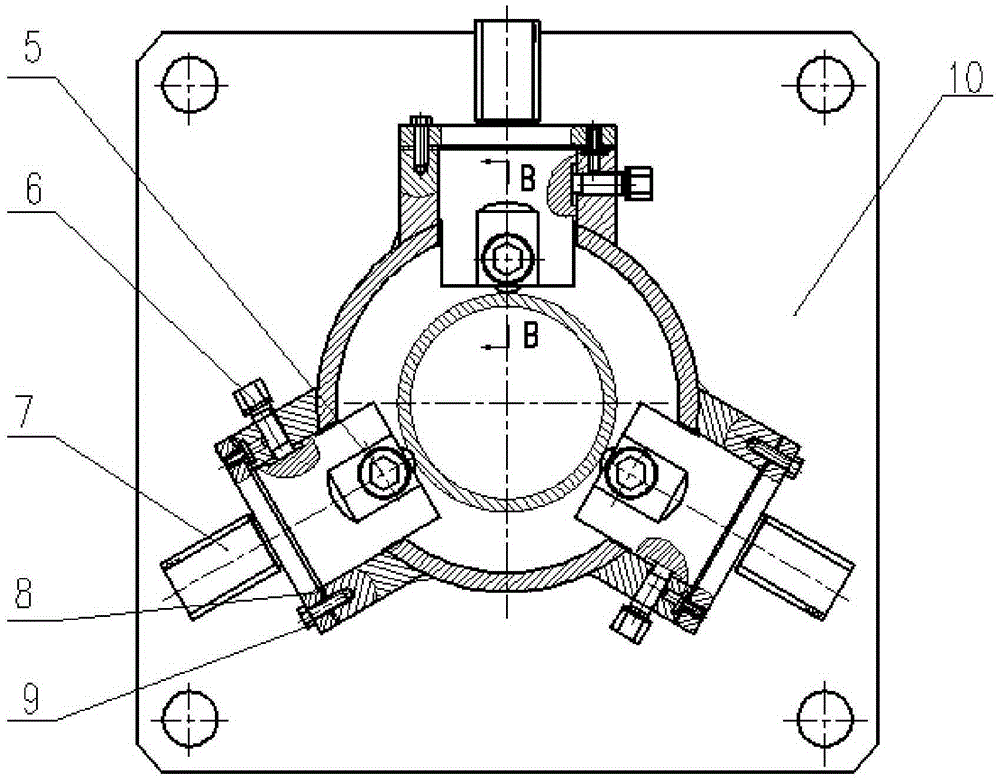

Tool clamping apparatus for operations of tin-plating and welding leads of wire-welded type components and parts

ActiveCN102357699AAchieve fixationAchieve deflectionMetal working apparatusSoldering auxillary devicesTin platingEngineering

The invention relates to a tool clamping apparatus for the operations of tin-plating and welding the leads of wire-welded type components and parts, belonging to the technical field of welding. The clamping apparatus comprises a turntable, a transverse / longitudinal adjustment mechanism, a component fixing mechanism and a tin-leakage preventing clamp; the bottom face of the tin-leakage preventing clamp is matched with a slide rail of a transverse / longitudinal adjustment mechanism supporting plate; the transverse / longitudinal adjustment mechanism is fixedly mounted on a seat board of the turntable as a whole through a slide rail bottom plate; and the component fixing mechanism is fixedly mounted on the seat board of the turntable through a fixing mechanism body and is opposite to the transverse / longitudinal adjustment mechanism. According to the invention, core wires of the leads are clamped through the tin-leakage preventing clamp so as to exert effects of clamping and tin-leakage preventing, a fixing surface can deflect within 30 DEG towards two sides from the vertical direction through the adjustment of the turntable, and the alignment between the leads and a welding pin (groove)can be realized through adjusting the transverse / longitudinal adjustment mechanism and adjusting the sliding of the tin-leakage preventing clamp on the transverse / longitudinal adjustment mechanism. The tool clamping apparatus can effectively standardize various operations in processes of assembling and connecting and reduces the influence on welding quality caused by human factors.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

Backlight assembly and method of assembling a backlight assembly

ActiveUS20120287672A1High light efficiencyImprove brightness uniformityLaminationLamination apparatusLight guideEngineering

A backlight assembly includes a first light-emitting module, a light guide plate, a receiving container and a main adhesion member. The first light-emitting module includes a first circuit board including a first mounting surface, and a first light source on the first mounting surface. The light guide plate is on the first mounting surface and guides light from the first light source. The receiving container includes a bottom portion and receives the first light-emitting module and the light guide plate. The main adhesion member is between the first mounting surface and the light guide plate and is attached to the first circuit board and the light guide plate, and is between the light guide plate and the bottom portion and movable with respect to the light guide plate.

Owner:SAMSUNG DISPLAY CO LTD

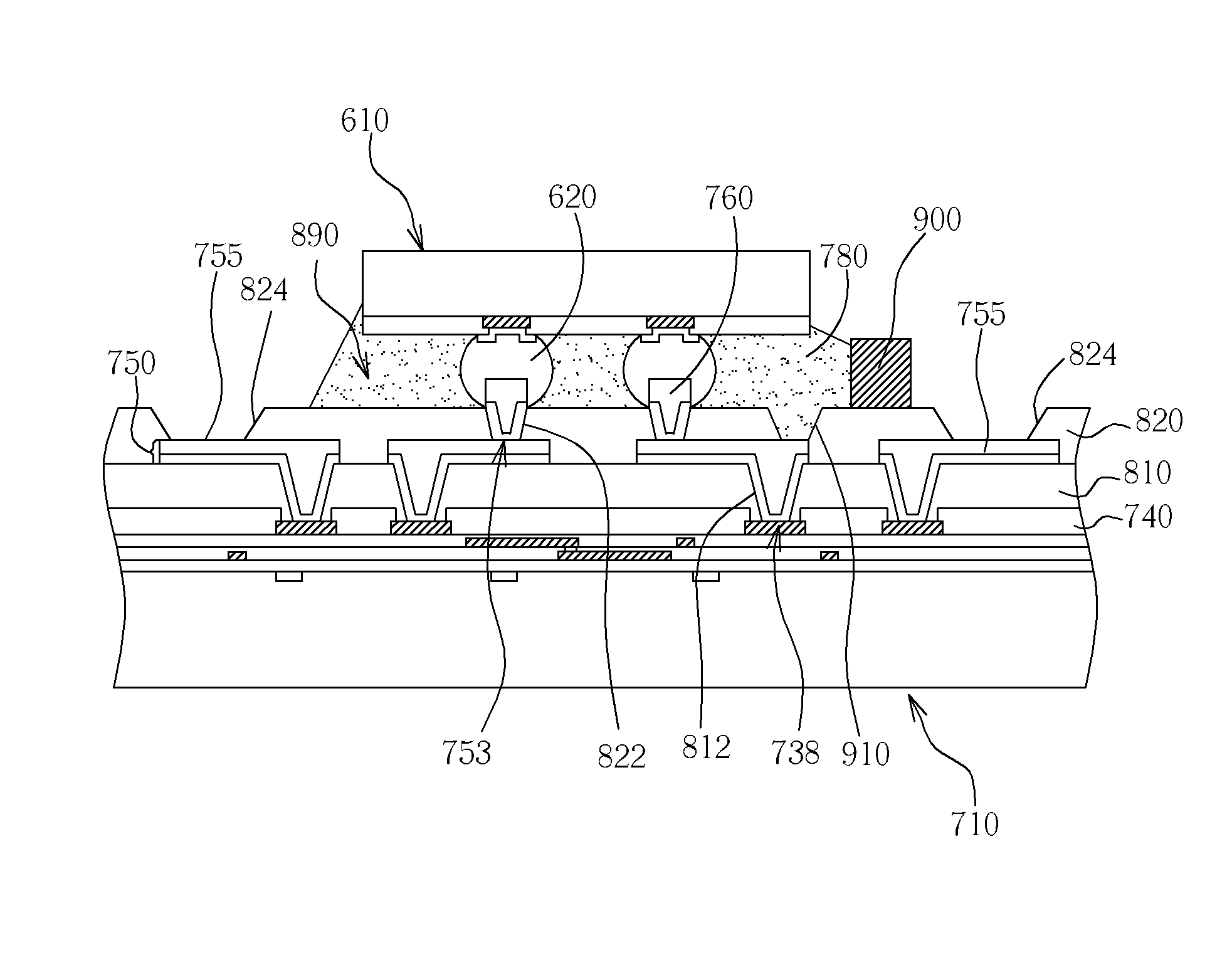

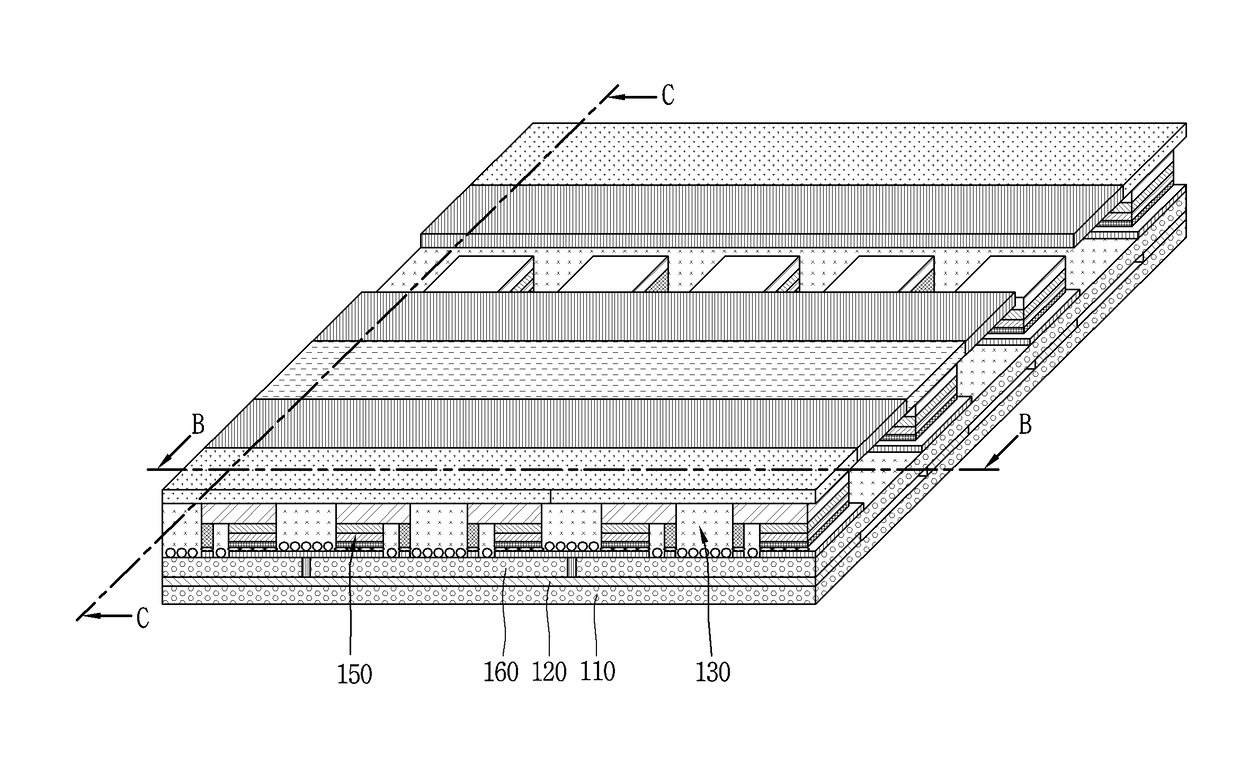

Display device using semiconductor light emitting diode

ActiveUS20180240937A1Improve assembly reliabilityElectroluminescent light sourcesPrinted circuit aspectsElectricityDisplay device

The present invention relates to a display device and, in particular, to a display device using a semiconductor light emitting diode. A display device according to the present invention comprises a substrate having a plurality of metal pads; and a plurality of semiconductor light emitting diodes electrically connected to the metal pads through self-assembly. The present invention is characterized in that: the semiconductor light emitting diodes respectively include a conductive semiconductor layer, a conductive electrode formed on one surface of the conductive semiconductor layer, and a passivation layer enclosing the semiconductor light emitting diode and provided with a through hole for exposing the conductive electrode; one end portion of the semiconductor light emitting diodes is divided into a first portion in which the conductive electrode is exposed, and a second portion in which the passivation layer is exposed; and the maximum width of the metal pad is set to a range of the width to twice the width of the second portion.

Owner:LG ELECTRONICS INC

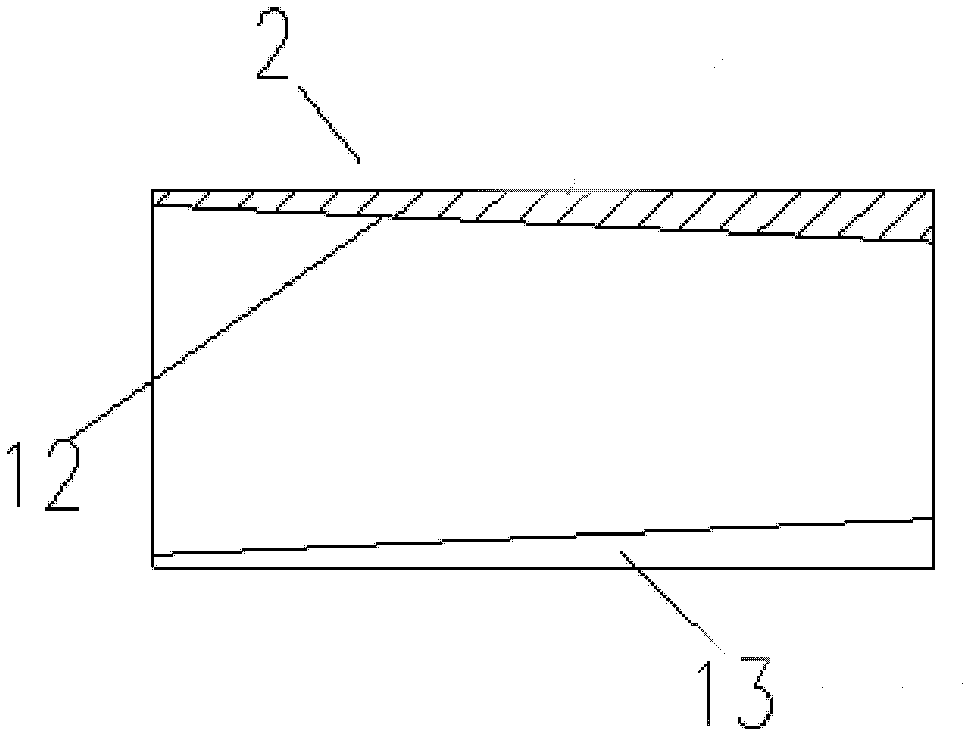

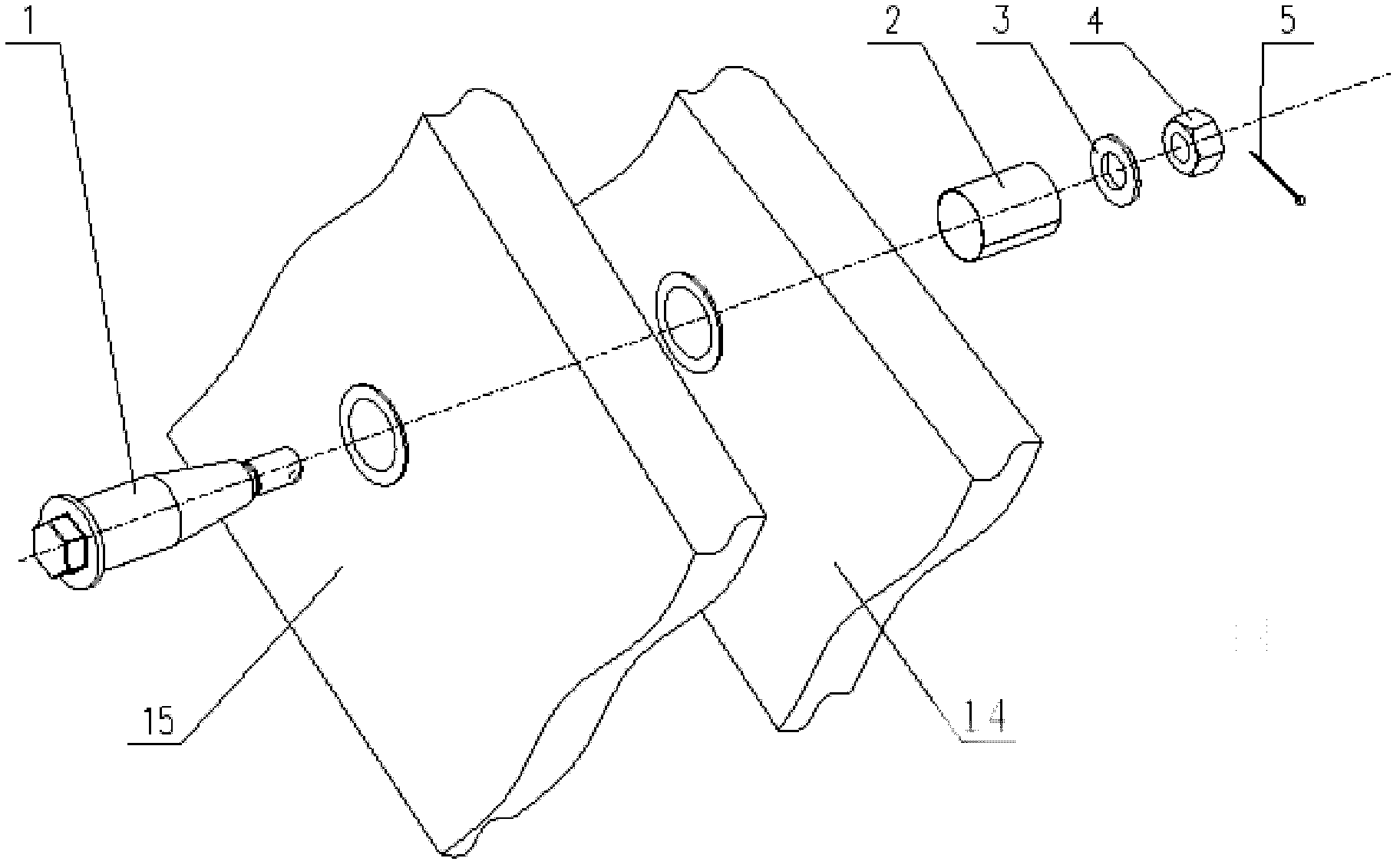

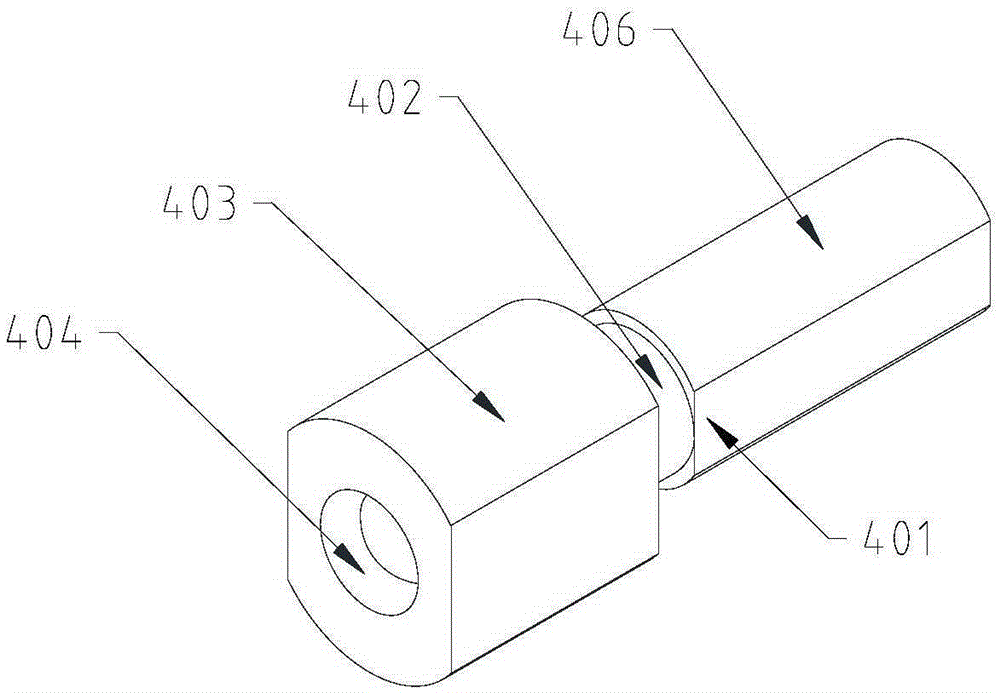

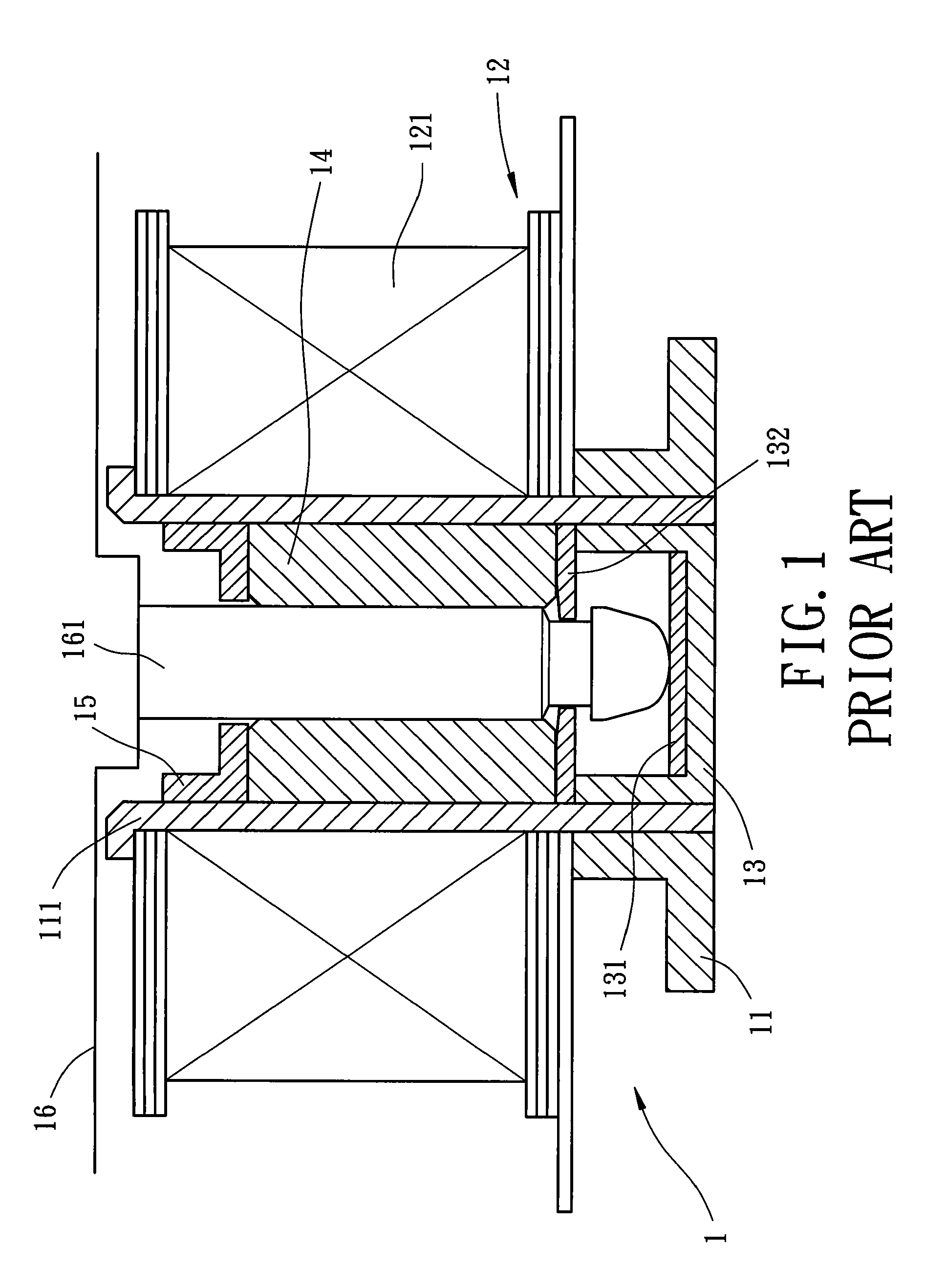

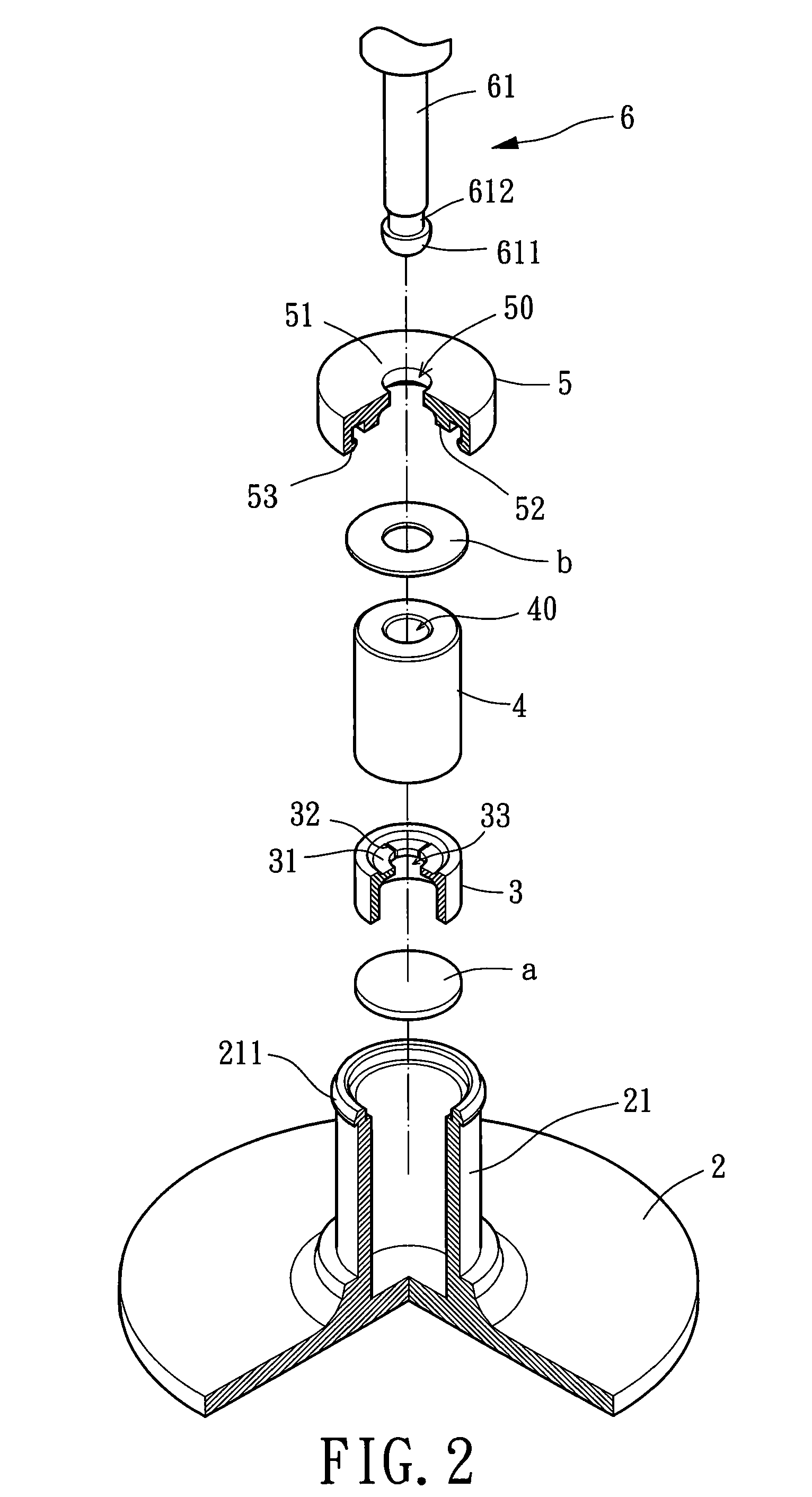

Positioning connection pin

InactiveCN102537006ALower manufacturing requirementsFirmly connectedNutsBoltsConical formsEngineering

A positioning connection pin includes a main pin shaft (1), a gasket (3) and a nut (4). The main pin shaft (1) includes a flange (7), a cylindrical shaft section (8), a conical shaft section (9) and a threaded section (10) sequentially, and further includes a cylindrical pin bush (2) provided with a conical inner hole (12) and a radial open slot (13), wherein the cylindrical pin bush (2) is matched with the conical shaft section (9) of the main shaft pin (1) in a sleeving manner, and the gasket (3) and the nut (4) are mounted on the threaded section (10). The positioning connection pin is different from the common cylindrical pin and conical pin connection structure, and the conical shaft section (9) of the main shaft pin (1) is matched with the conical inner hole (12) of the main pin shaft (1) for use, thereby greatly facilitating connection, lowering the manufacturing requirements of connected pieces, and improving the assembly efficiency and the reliability.

Owner:HUNAN SUNWARD SCI & TECH +1

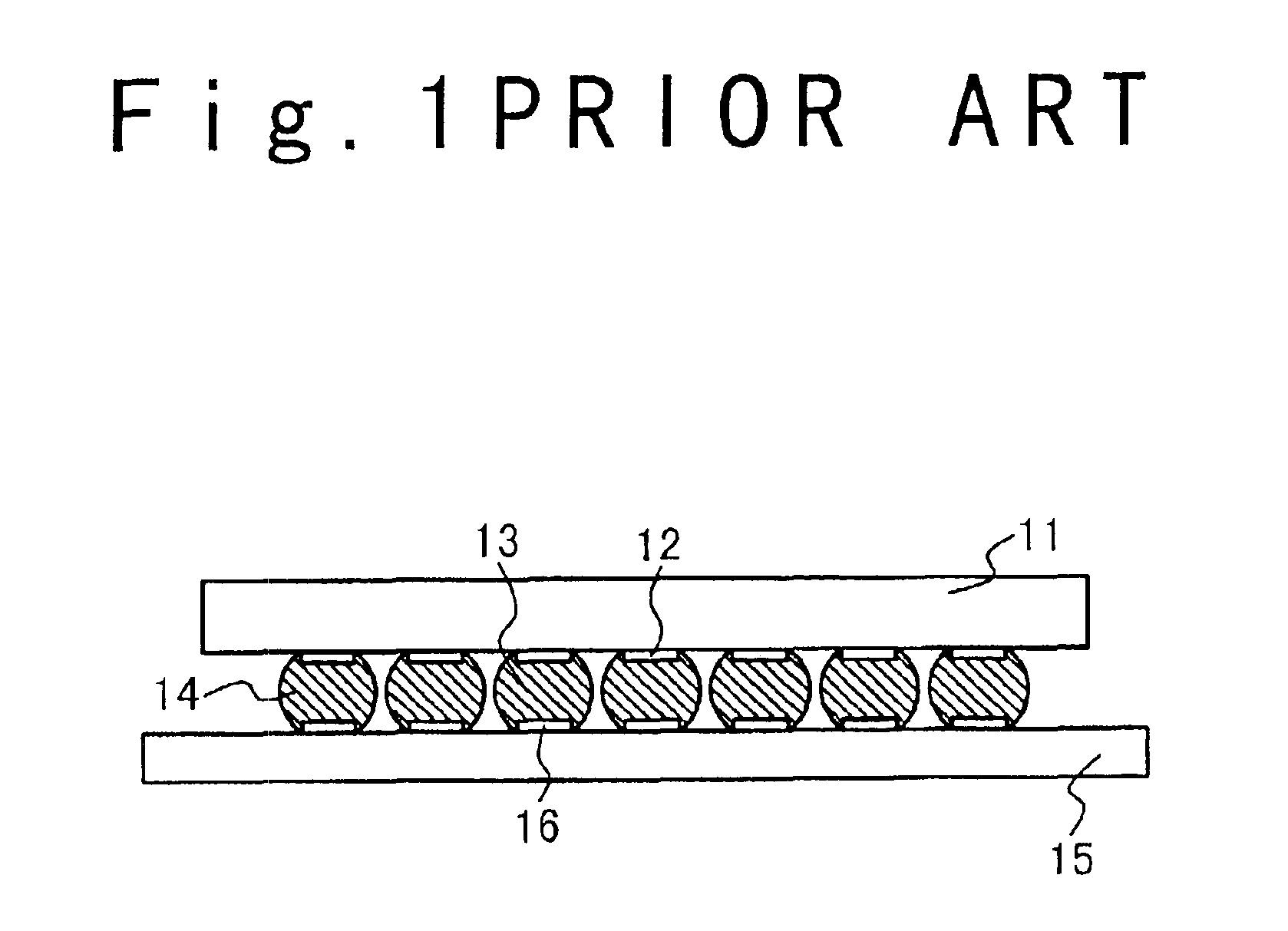

Circuit component with bump formed over chip

InactiveUS7382005B2Improve assembly reliabilityPrecise alignmentSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

Owner:QUALCOMM INC

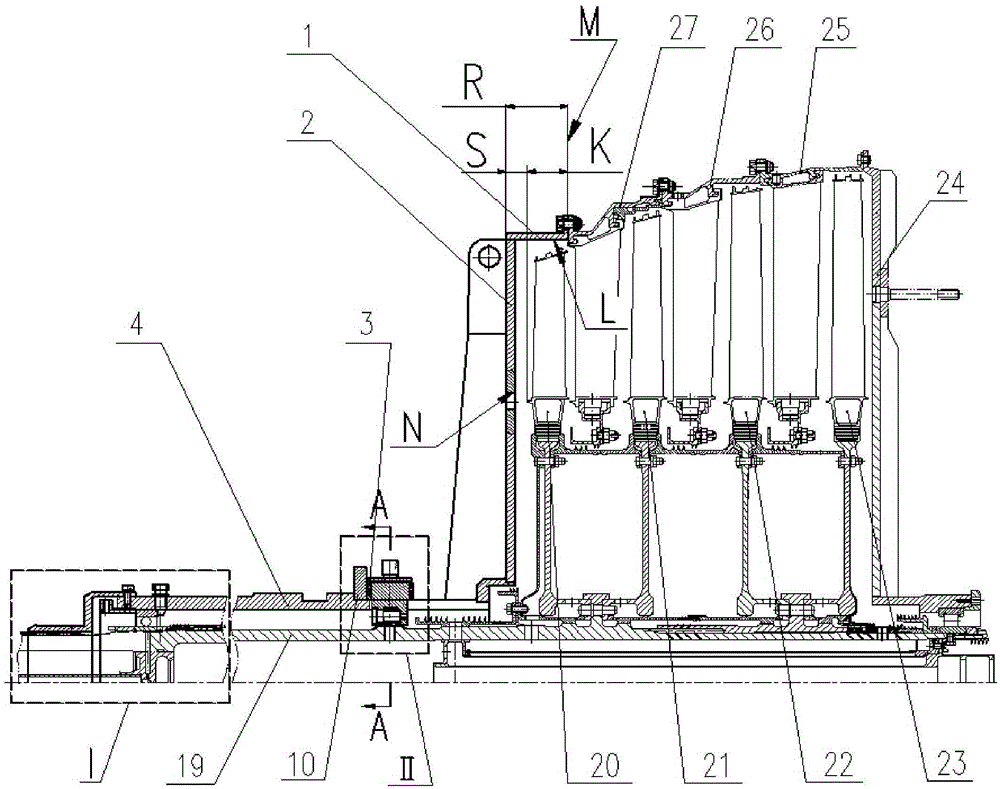

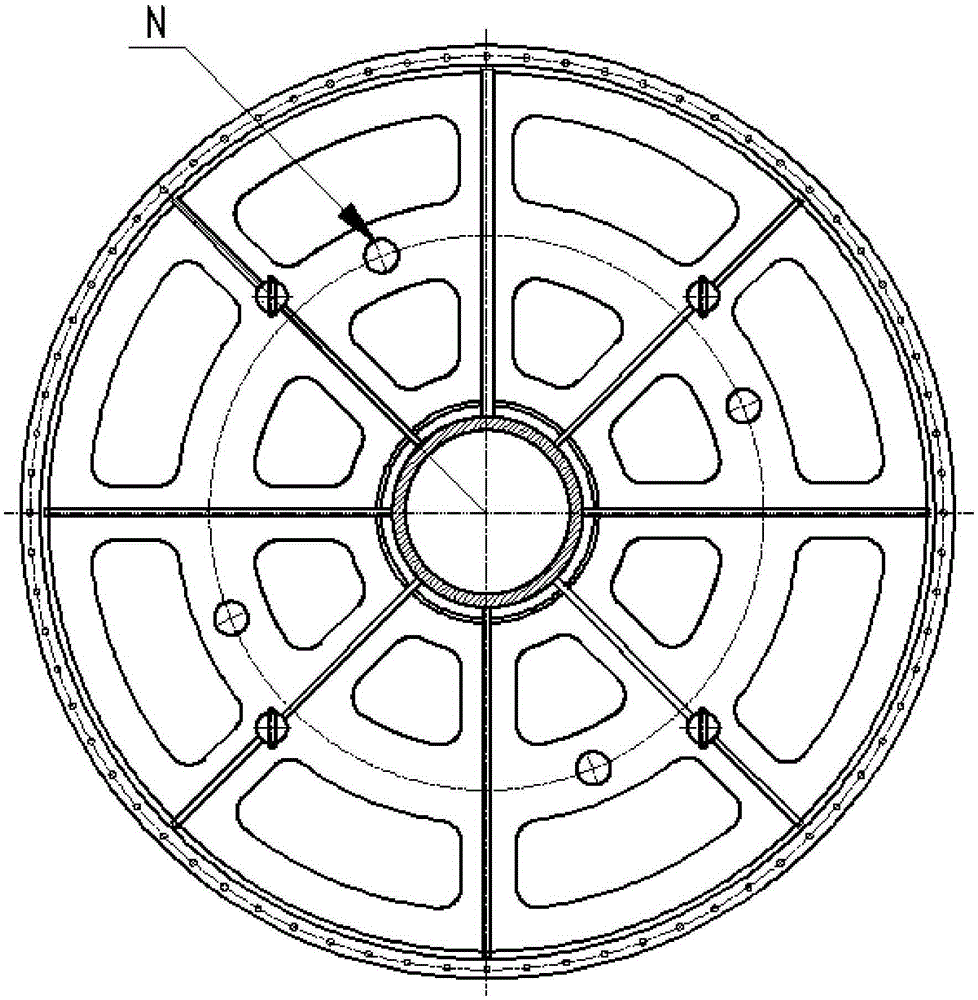

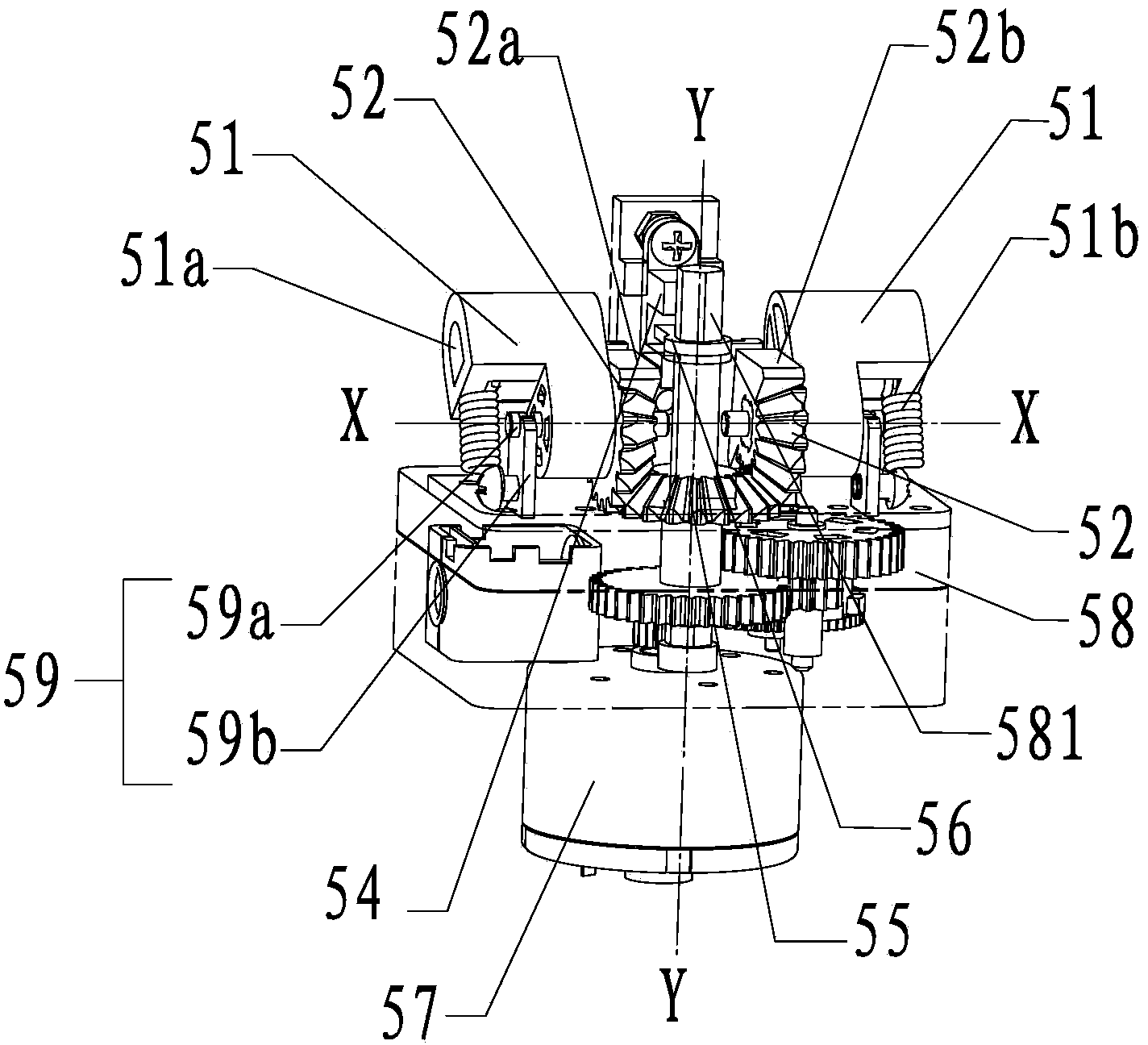

Assembly device for engine turbine

ActiveCN105397465AImprove assembly accuracyImprove assembly reliabilityMetal working apparatusRadial positionEngineering

The invention provides an assembly device for an engine turbine. The assembly device comprises a cylinder body, a bracket disk, a positioning ring and an annular plate, wherein the cylinder body is mounted on a turbine rotor shaft through two bearing devices and can rotate relative to the rotor shaft; the bracket disk is perpendicular to the cylinder body and is fixedly arranged on the cylinder body which is close to one end of the turbine rotor; the positioning ring and the cylinder body are coaxially and fixedly arranged on the bracket disk, and the inner diameter of the positioning ring is used as a mounting radial location reference of a guider; the annular plate is positioned at the outer end of the positioning ring, and the end surface, which is butted to a case of the guider, of the annular plate is used as a mounting axial positioning base of the guider. The cylinder body is mounted on the rotor shaft through the two bearing devices, wherein one bearing device which is close to one end of the turbine rotor is provided with a radial fine tuning structure, and the other bearing device is provided with an axial fine tuning structure; the bracket disk is provided with measuring holes for measuring the distances between front edges of blades. Through the adoption of the assembly device, the precise adjustment of the axial position relation and the radial position relation of a turbine rotor and the guider can be realized, and the assembly of the turbine belt guider and the level by level dynamic equilibrium of the turbine belt guider are realized, so that the assembly precision and the assembly reliability of the turbine belt guider are improved.

Owner:AECC AERO SCI & TECH CO LTD

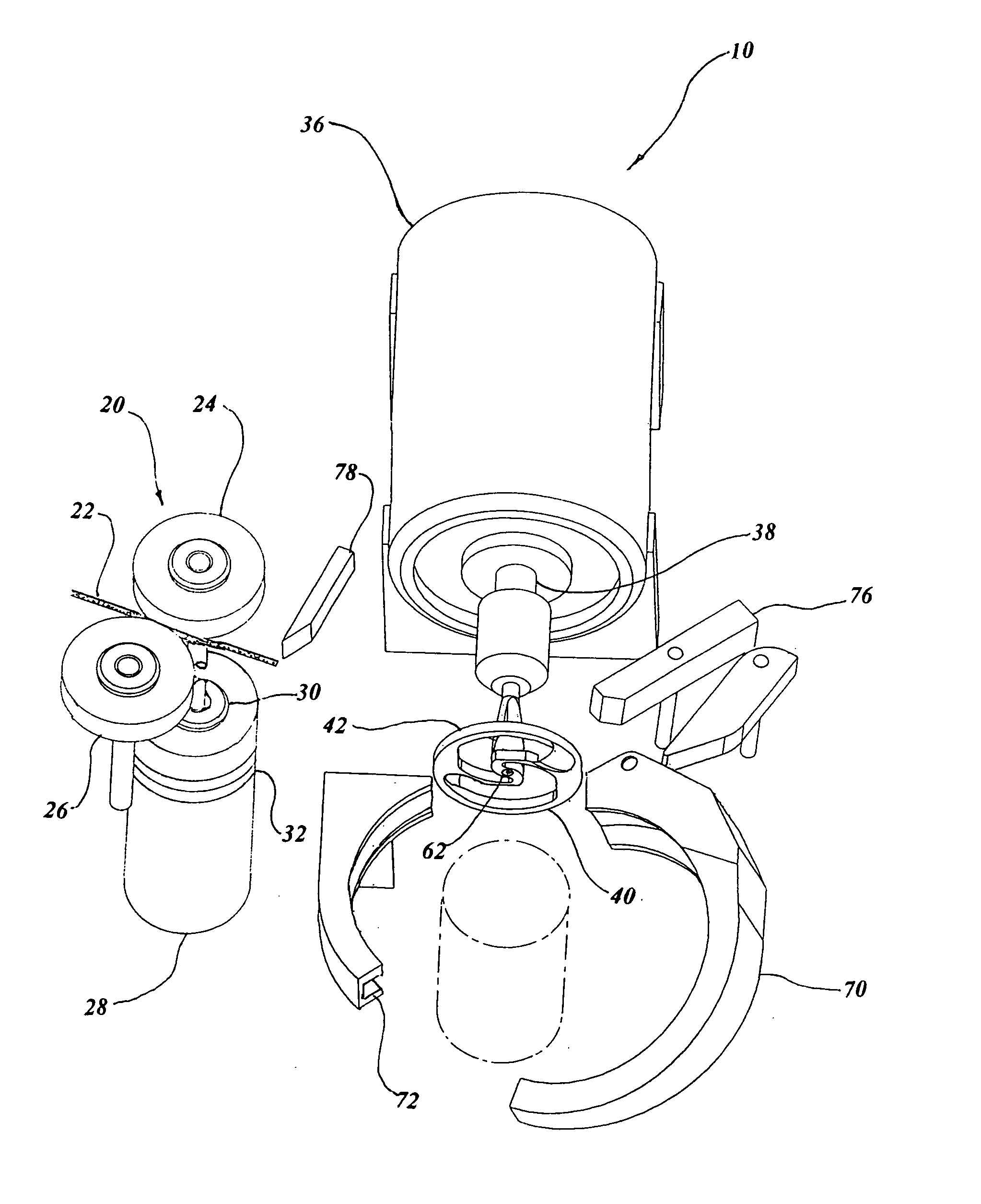

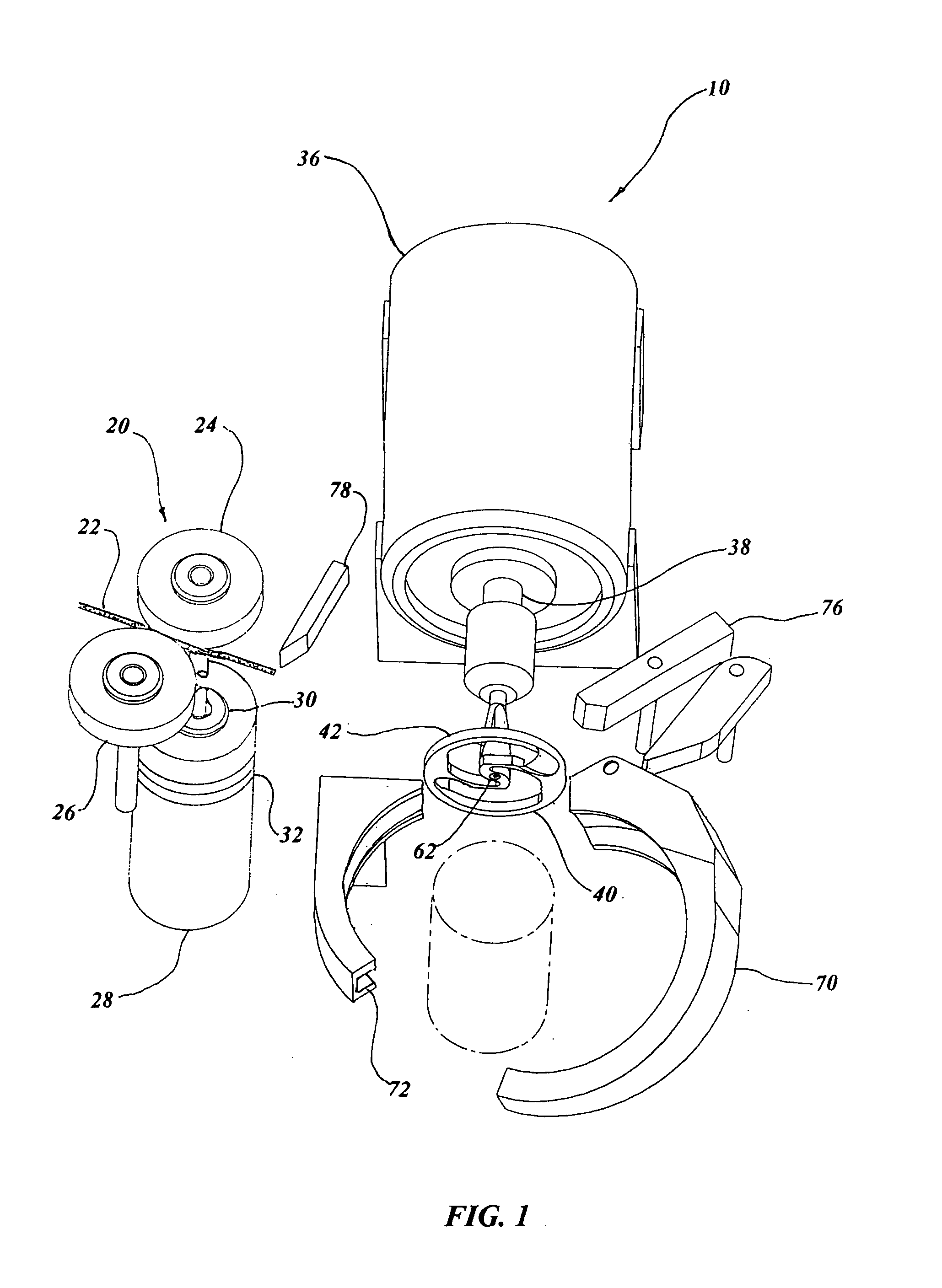

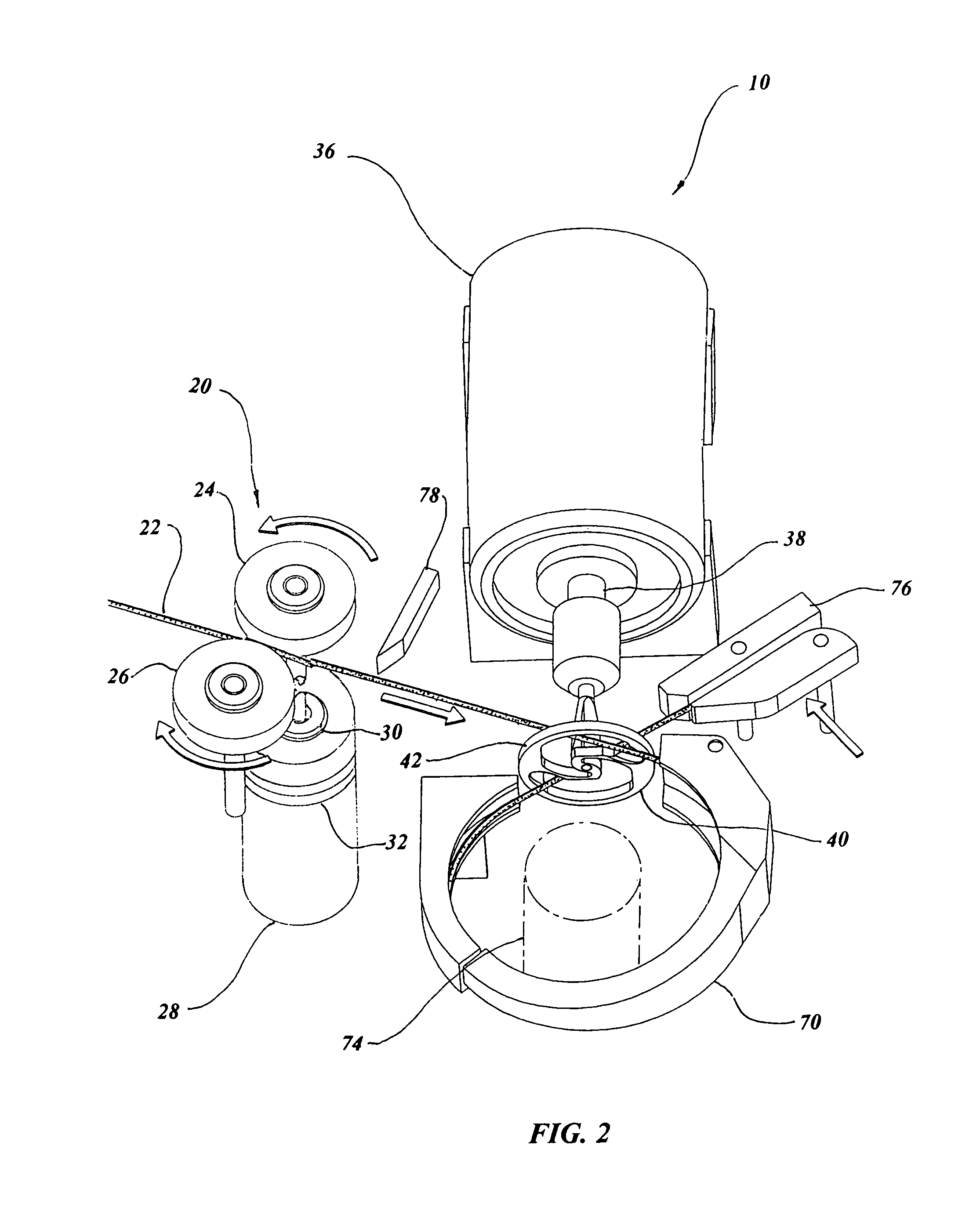

Twist-tie catch twister apparatus

ActiveUS8281712B1Easy programmingPrecise repeatable operationWire articlesBundling machine detailsSplit ringEngineering

A twist-tie catch twister apparatus is taught that consists of dual feed rollers that feed twist-tie material through a back opening in a catch twister into the groove of a peripheral ring, which continues around the ring penetrating the front side of the catch twister through a second opening. The twist-tie material is then retained by a twist-tie clamp and the rollers reverse rotation drawing the twist-tie material onto a workpiece. The catch twist motor rotates the catch twister one half turn twisting to hold tension on the workpiece. A twist-tie cutter, positioned between the feed rollers and split ring, severs the twist-tie material and the twist-tie tape clamp opens with the motor rotating the catch twister a predetermined number of turns and then reverses at least one half turn to release the twisted material and the split ring opens for removal of the twist-tie secured workpiece.

Owner:JOHNSON INT CORP

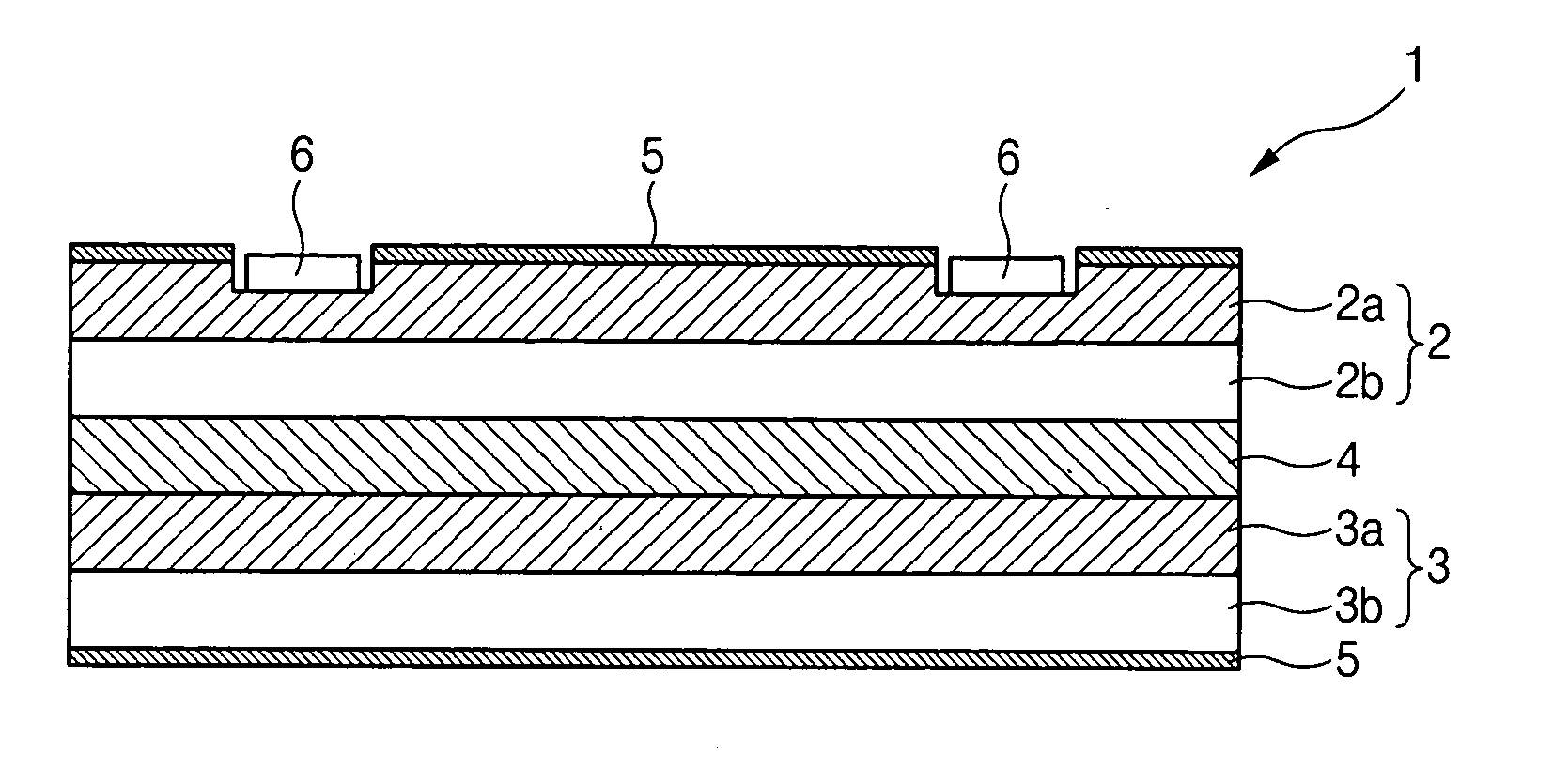

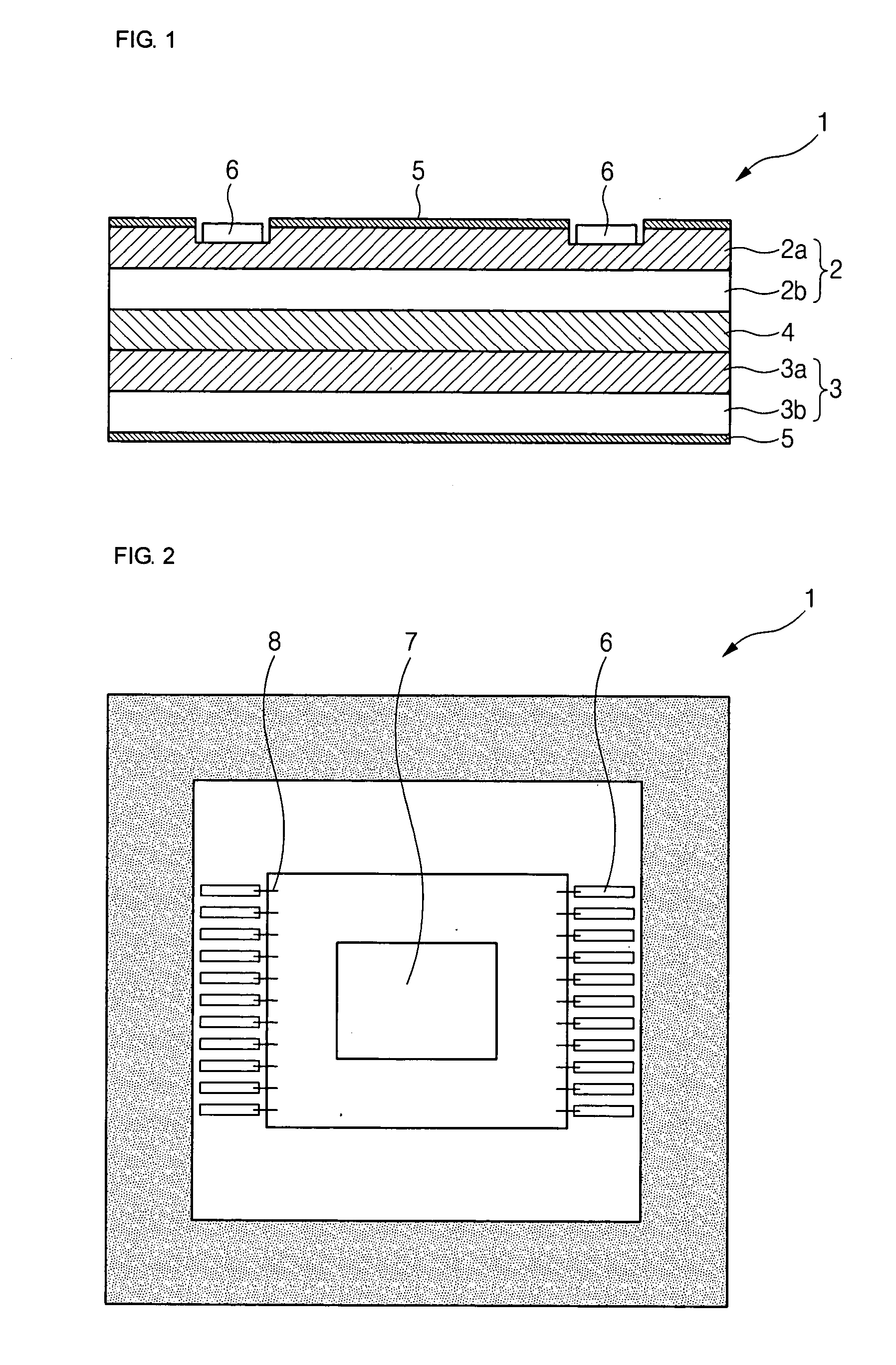

Camera module using printed circuit board with step portion

InactiveUS20070117423A1Improve image qualityImprove assembly reliabilityTelevision system detailsPrinted circuit detailsImage sensorPrinted circuit board

Provided is a camera module using a PCB with a step portion. The camera module includes a PCB, a housing, and a lens barrel. The PCB includes a substrate main body, a plurality of pads, and a step portion. The substrate main body is formed of a stacked structure with the shape of a rectangular plate. The pads is formed on both sides of the top of the substrate main body and is electrically connected through wires to an image sensor mounted on a central portion of the top of the substrate main body. The step portion is formed at the peripheral edges of the pads. The housing has a bottom peripheral portion that is closely attached to the step portion of the PCB. The lens barrel is installed vertically in an upper region of the housing. Accordingly, it is possible to enhance the quality of image taken by the image sensor. In addition, the contact area between the housing and the PCB is increased to make it possible to enhance the assembly reliability of the camera module.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

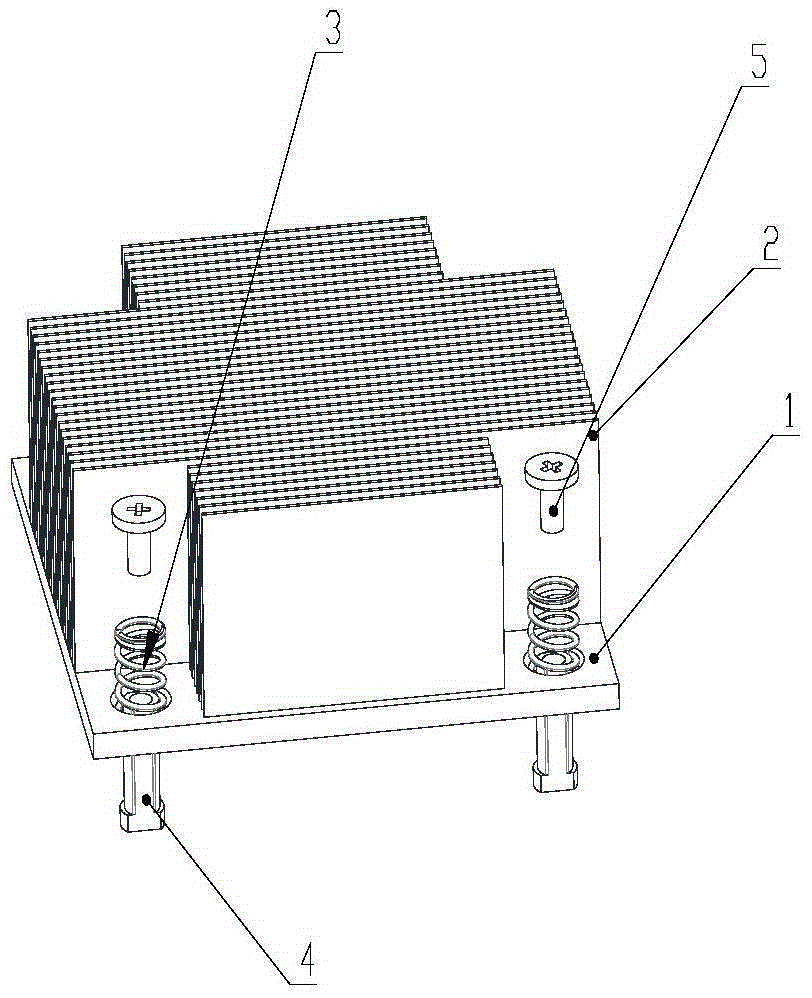

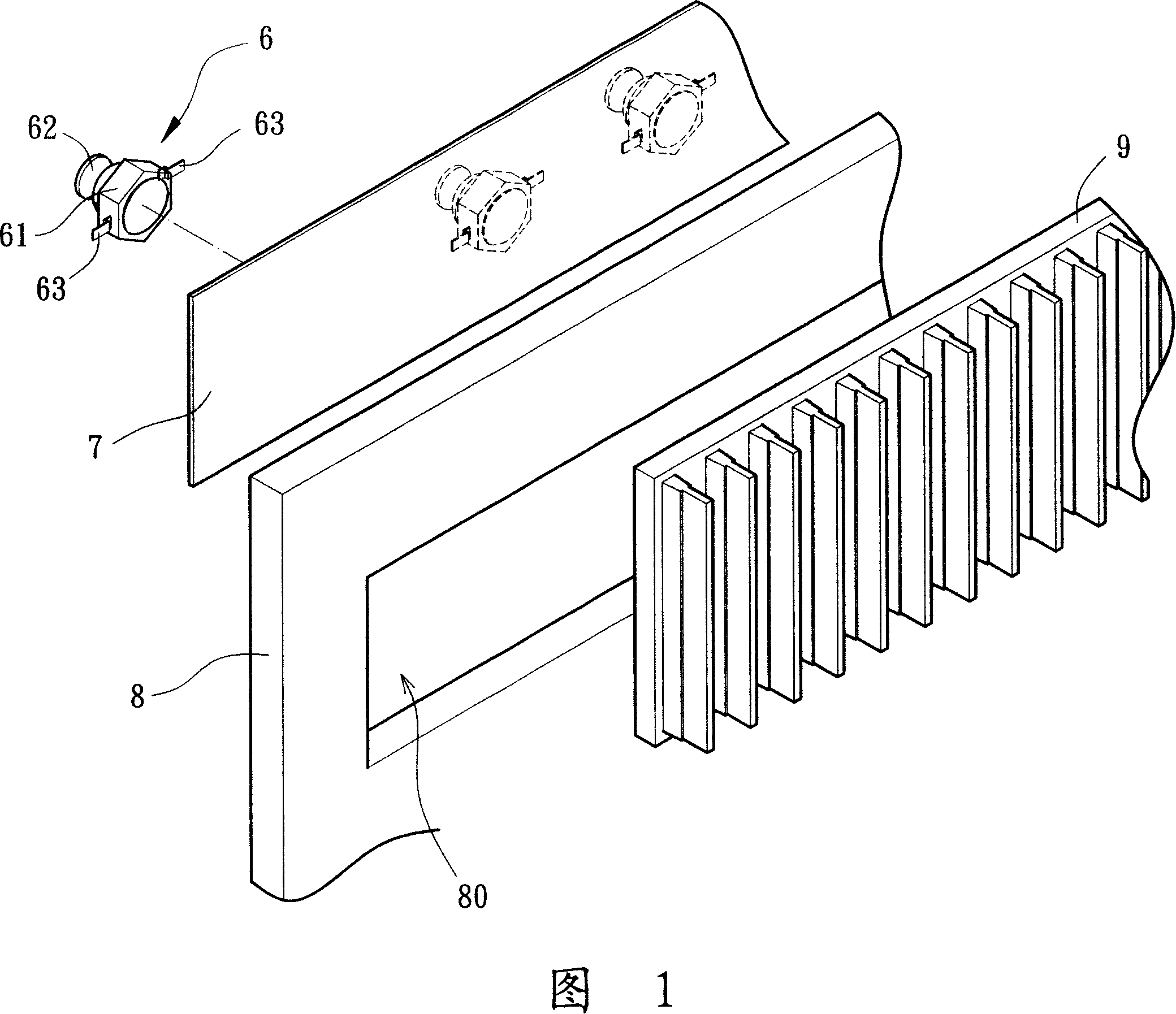

Chip heat radiation assembly and chip circuit board thereof

InactiveCN105280589AImprove reliabilityImprove assembly efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringRadiation effect

The invention discloses a chip heat radiation assembly and a chip circuit board thereof. The heat radiation assembly comprises a base (1), heat radiation fins (2), springs (3), adjusting rod assemblies (4) and locking screws (5). The upper surface (104) of the base (1) is provided with circular holes (102) and special-shaped through holes (101), wherein the depths of the circular holes (102) are smaller than the thickness of the base (1). The lower surface (105) of the base is provided with a base boss (103) for installing a chip. Each adjusting rod assembly (4) comprises a support bar (401) and an adjusting nut (403), the support bar (401) is composed of a polished rod (406) and a threaded rod (402), the adjusting nut (403) is internally provided with a threaded through hole (405), and the threaded rod (402) is provided with external threads screwed with an inner threaded hole (404). The height of each adjusting nut (403) is smaller than the sum of heights of the chip and the base boss (103), and the locking screws (5) are screwed into the threaded through holes (405). The invention can improve the heat radiation effect and the assembly reliability.

Owner:GUANGXUN SCI & TECH WUHAN

Catalytic converter fastening for a combustion engine

InactiveUS20110215220A1Easy to assembleReducing heat connectionPortable framesExhaust apparatusCombustionEngineering

A catalytic converter fastening is provided for a combustion engine. The catalytic converter fastening includes, but is not limited to an engine block bracket that is releasably connected to an engine block. The engine block bracket fixes the catalytic converter at a distance to the engine block. A catalytic converter support is materially connected to the catalytic converter, and connecting elements releasably connect the engine block bracket to the engine block. The catalytic converter support comprises at least one arm angled-off towards the engine block bracket, while on the arm at least one angled-off strap is arranged. The strap is materially connected to a catalytic converter housing. Here, the catalytic converter fastening of engine block bracket and catalytic converter support is of the unitary type.

Owner:GM GLOBAL TECH OPERATIONS LLC

Back light source of planar display heat radiating device

InactiveCN101140057AImprove cooling efficiencyExtended service lifeElectric circuit arrangementsLighting heating/cooling arrangementsHeat conductingDisplay device

The invention relates to a back light source radiating device for a flat plane display, which comprises at least a back light unit, a circuit board and a radiating base plate. The back light unit and the circuit board commonly form a back light source module. The back light unit is provided with a luminous element and a heat conducting part, and the heat conducting part is arranged on one end of the luminous element in order to absorb the heat energy produced by the luminous element. The circuit board is arranged on the back of the radiating base plate, and the heat conducting part of the back light unit is directly stuck on the back of the radiating base plate through at least an assembly hole of the circuit board in order that the radiating base plate directly absorbs and dissipates the heat energy produced by the back light source module.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

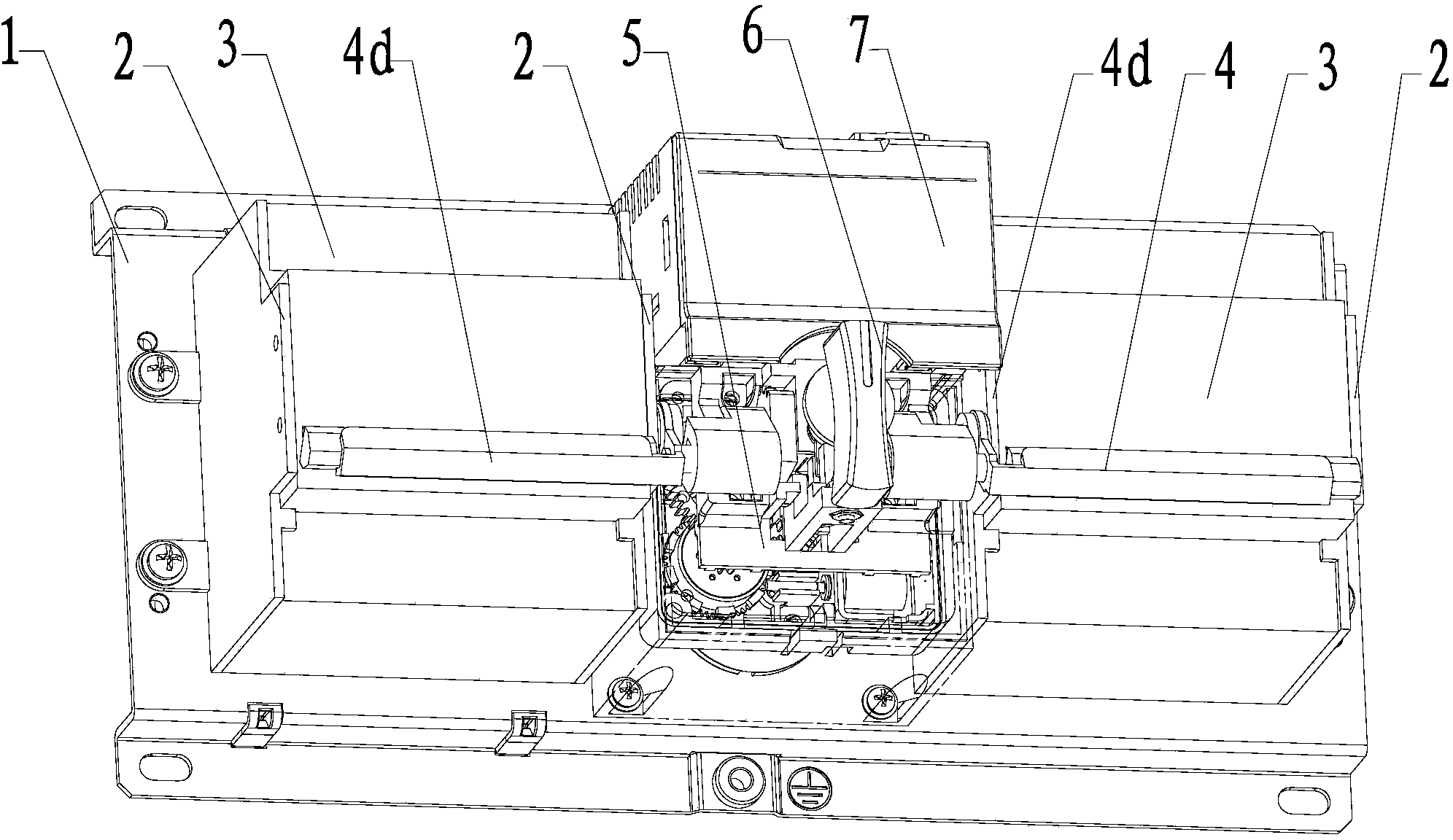

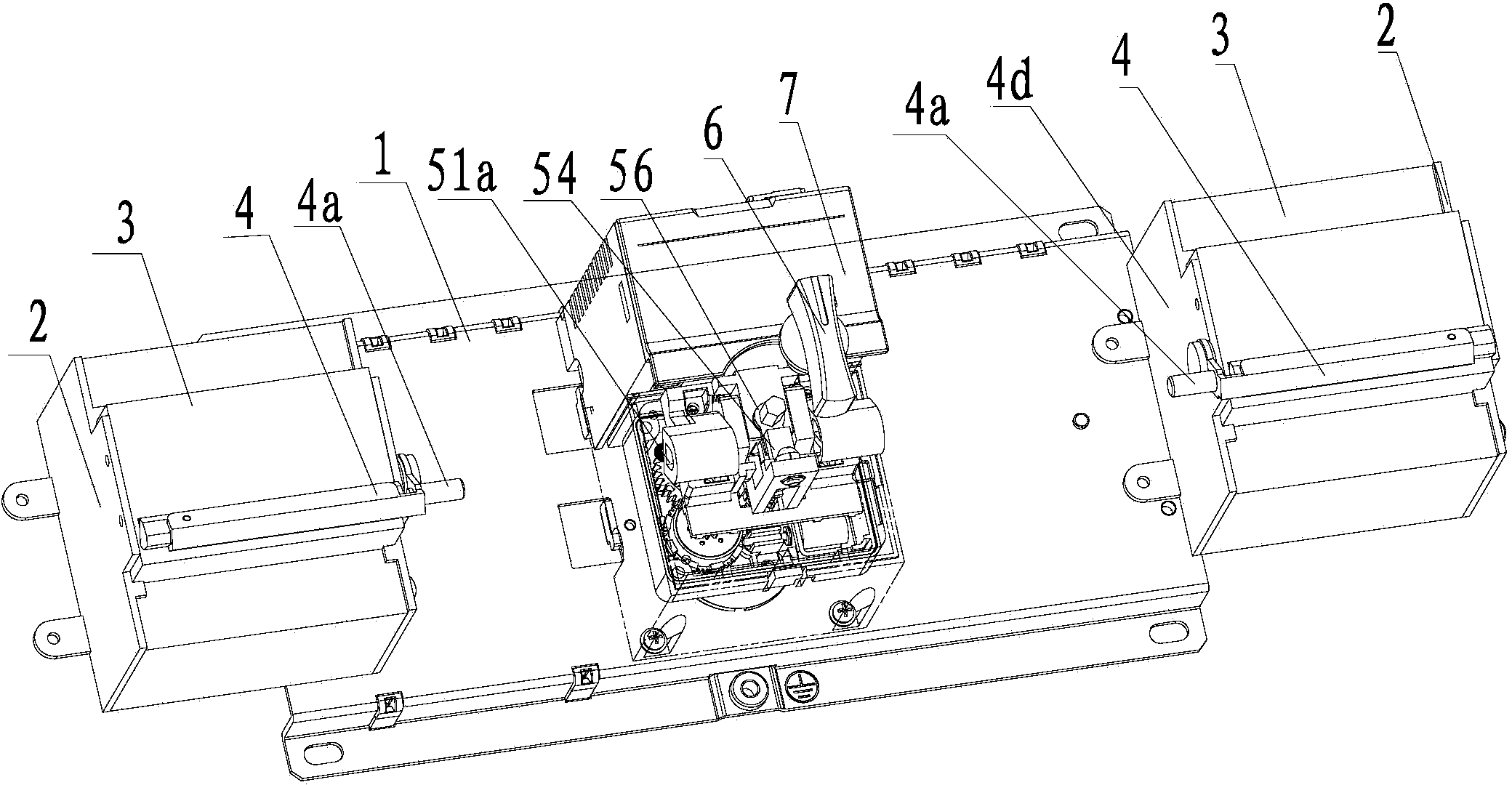

Automatic change-over switch with disengaging and engaging functions

ActiveCN104240984ASimple structural designEasy to processContact mechanismsHorizontal axisEngineering

The invention provides an automatic change-over switch with disengaging and engaging functions. The automatic change-over switch with the disengaging and engaging functions comprises two actuation switches fixed to a bottom plate, two push rods, a transmission mechanism, a controller and an engaging and disengaging mechanism. The transmission mechanism comprises a motor, a reduction box, a horizontal bevel gear fixedly installed on an output shaft, two vertical bevel gears and two rocker arms, wherein the two vertical bevel gears are respectively in transmission with the horizontal bevel gear and are installed on the same horizontal axis through the corresponding horizontal shaft supporting mechanisms, and the two rocker arms are connected with the push rods through a link mechanism and are in linkage with the push rods. The reduction box comprises a planet gear set and a plurality of gear pairs. The engaging and disengaging mechanism is provided with a planet gear ring selective locking structure used for the planet gear set of the reduction box. The planet gear ring selective locking structure comprises an electromagnetic driving device, an ejector rod capable of moving in straight lines, and a boss arranged on the outer circle of each planet gear ring. The ejector rod interferes with the boss only when being electrically driven and enables the planet gear rings to be locked, the planet gear rings can rotate freely under manual operation, and disengaging and engaging of the transmission mechanism and the motor under the manual operation are achieved. The structure is simplified, and assembling efficiency and reliability are high.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

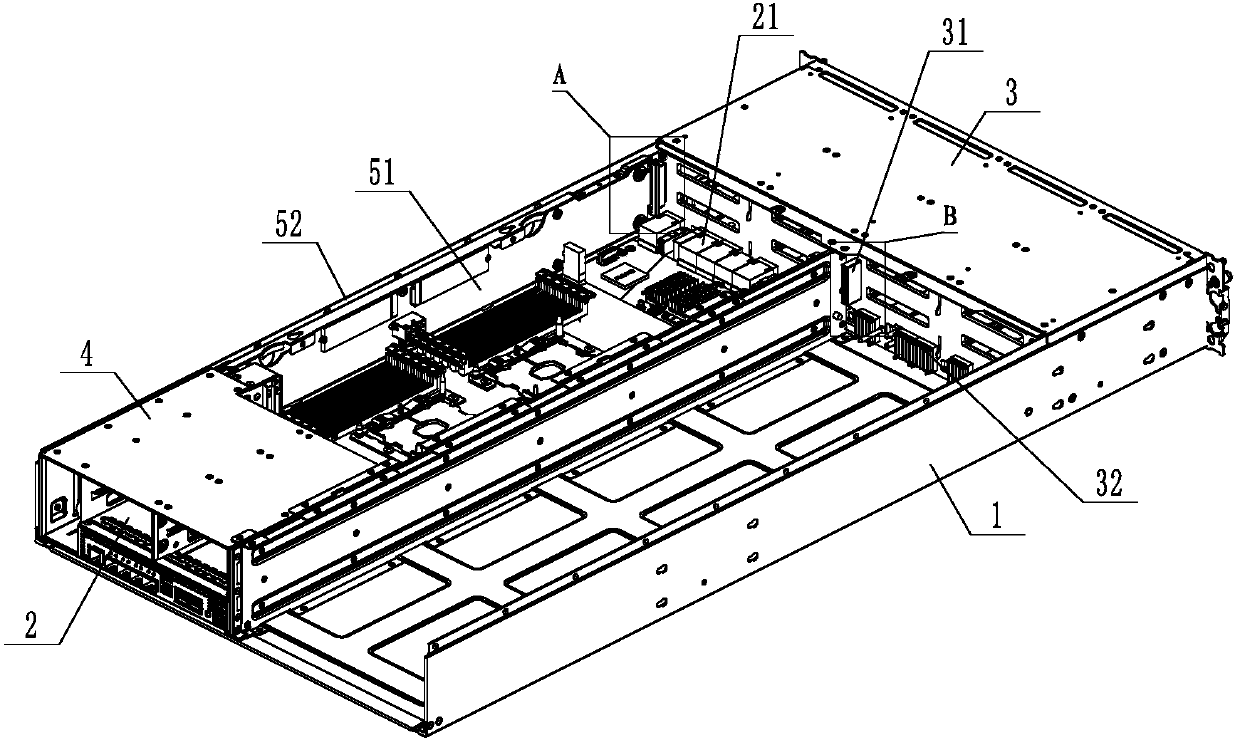

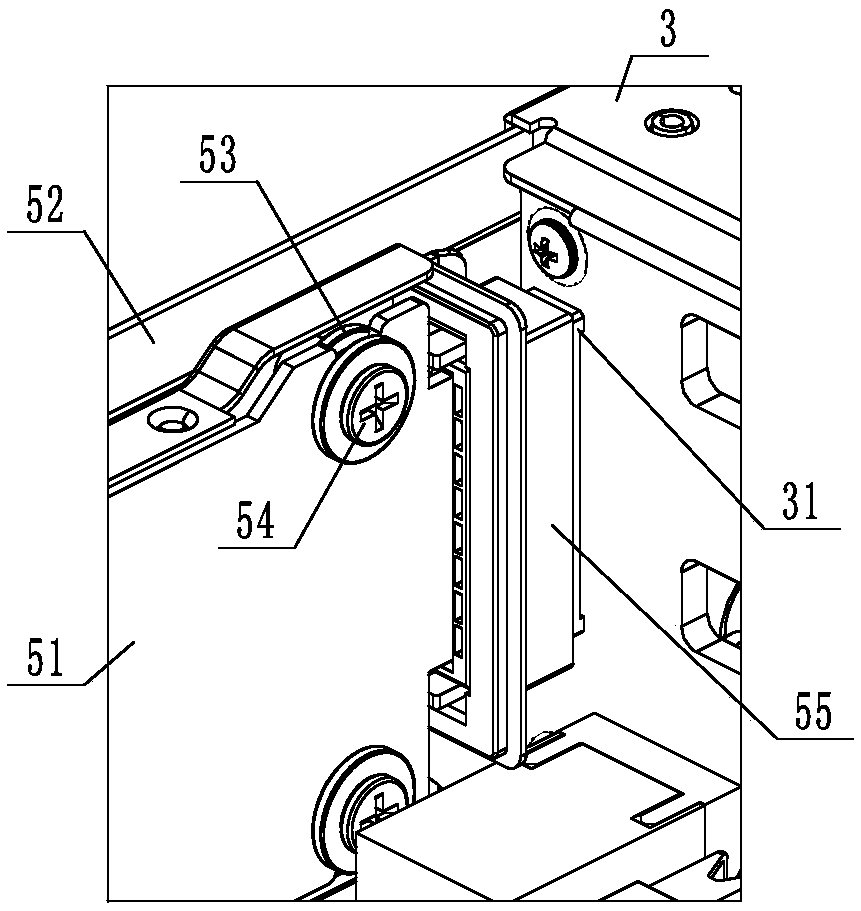

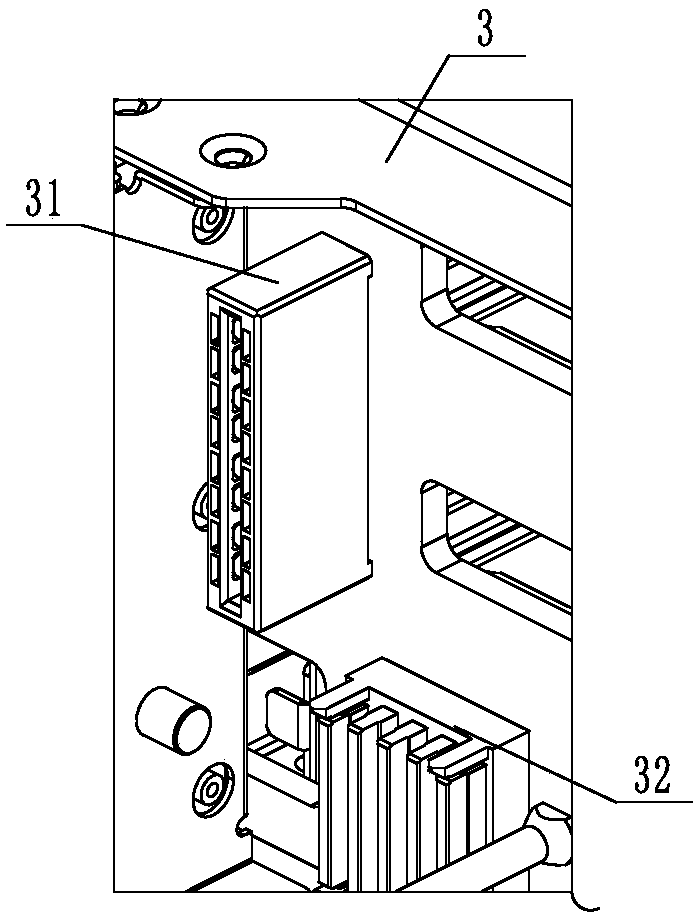

Adapter plate device capable of being mounted in floating way through automatic positioning

ActiveCN107589796ASolve assembly problemsImprove assembly reliabilityDigital processing power distributionPrinted circuit boardMotherboard

The invention discloses an adapter plate device capable of being mounted in a floating way through automatic positioning, and relates to the technical field of servers. The adapter plate device comprises a memory chassis, wherein a back end of the memory chassis is provided with a controller; a front end of the memory chassis is provided with a hard disk backplate; the hard disk backplate is provided with a power connector and a high-speed connector; and a controller chassis is provided with an adapter assembly which is connected with a controller motherboard and the hard disk backplate. An adapter plate is designed with a certain floating amount to absorb an accumulation tolerance. Meanwhile, an auxiliary guide structure is adopted, the adapter plate is guided to a correct assembly positioned before the adapter plate is inserted into a backplate connector, and the backplate connector is inserted correctly through floatation of a PCB (Printed Circuit Board), so that an assembly problemcaused by the accumulation tolerance is solved; the assembly reliability of a product is enhanced; and the overall competitiveness is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

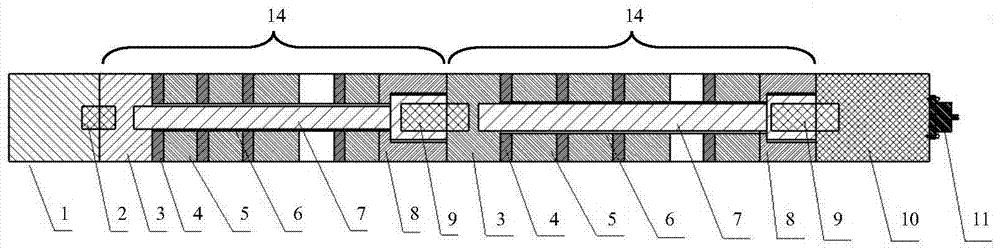

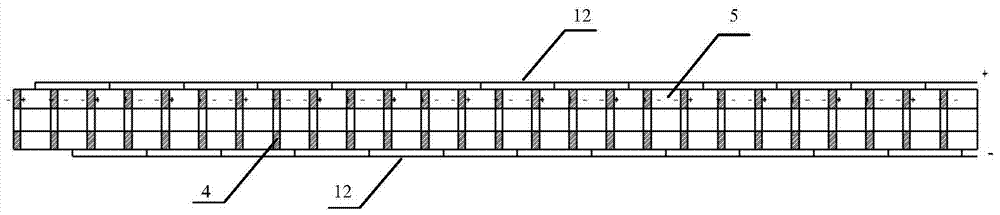

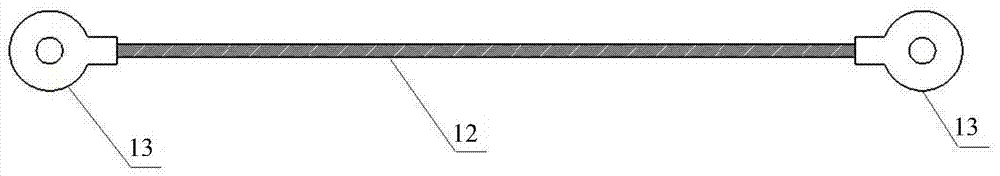

Low-frequency longitudinal vibration transducer used for oil well sound wave communication and manufacturing method thereof

The invention provides a low-frequency longitudinal vibration transducer used for oil well sound wave communication and a manufacturing method thereof. The low-frequency longitudinal vibration transducer comprises a radiation head (1) and at least two crystal stack modules (14). Each crystal stack module is formed by piling piezoelectric crystal plates and metals alternately. Every two adjacent crystal stack modules (14) are connected end to end and generate longitudinal vibration low-frequency sound waves after being connected with the positive pole and the negative pole of a power source. The radiation head (1) is fixed to the front end of the longitudinal vibration transducer and used for outputting the low-frequency sound waves generated through the crystal stack modules (14). According to the low-frequency longitudinal vibration transducer, the piezoelectric crystal plates and the metals are piled alternately, and thus radiating can be conducted effectively; and meanwhile, through the modular design, the operation simplicity and convenience and assembling reliability are greatly improved, and the problems of difficult machining and assembling and liable fracture during application caused by simplex long and thin prestressed screws are effectively solved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Tube coupling having an improved collet alignment

ActiveUS9261214B2Prevent insertionAccurate locationSleeve/socket jointsCouplingsLateral recessCoupling

A tube coupling includes a body (1) to receive a tube (22). The body has lateral recesses (12) extending outwardly from an internal wall. An O-ring (3) is retained by the body distally of the recesses. A collet (5) includes a ring (6) and collet legs (7) to be received in the lateral recesses and having a tooth (8) facing the passageway. Proximal movement of the collet with respect to the body causes the fingers to deflect inwardly. A tube support (10) includes a ring (12) and has a key to align with the body. Castellations (13, 14) extend proximately from the tube support ring and are complementary to the collet legs to align the collet with respect to the body as the collet is inserted into the body.

Owner:JOHN GUEST INT LTD

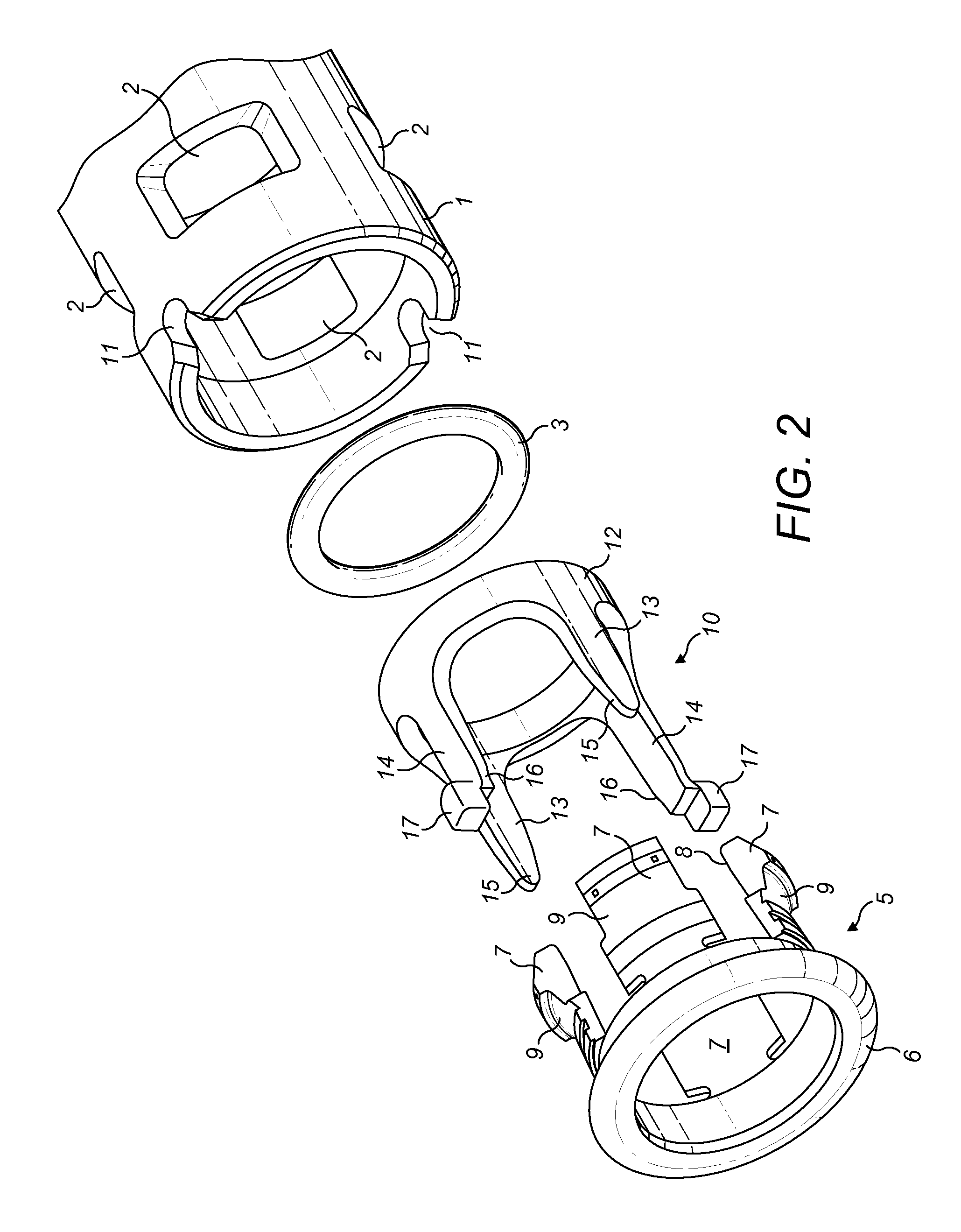

Bearing positioning structure for motor

ActiveUS20090261672A1Improve assembly reliabilityExtend motor lifeShaftsRecord information storageCouplingEngineering

A bearing positioning structure for a motor includes an axial tube and a positioning member. The positioning member includes a pressing portion and a coupling portion. The coupling portion of the positioning member is engaged with a coupling section of the axial tube for securely mounting the positioning member to the axial tube, with the pressing portion of the positioning member pressing against a bearing to position the bearing in the axial tube. In another example, the coupling portion of the positioning member engages with a coupling section on a stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

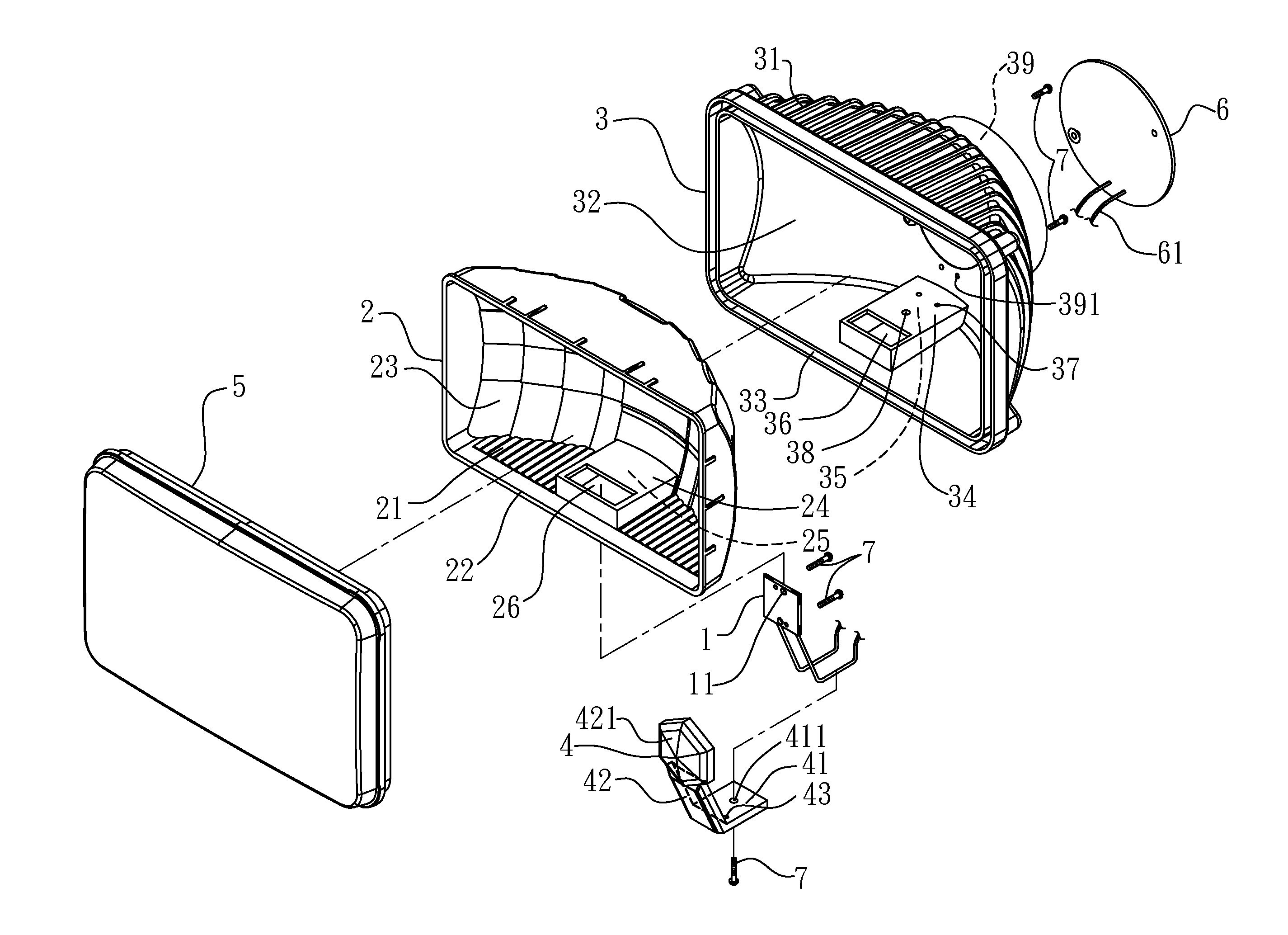

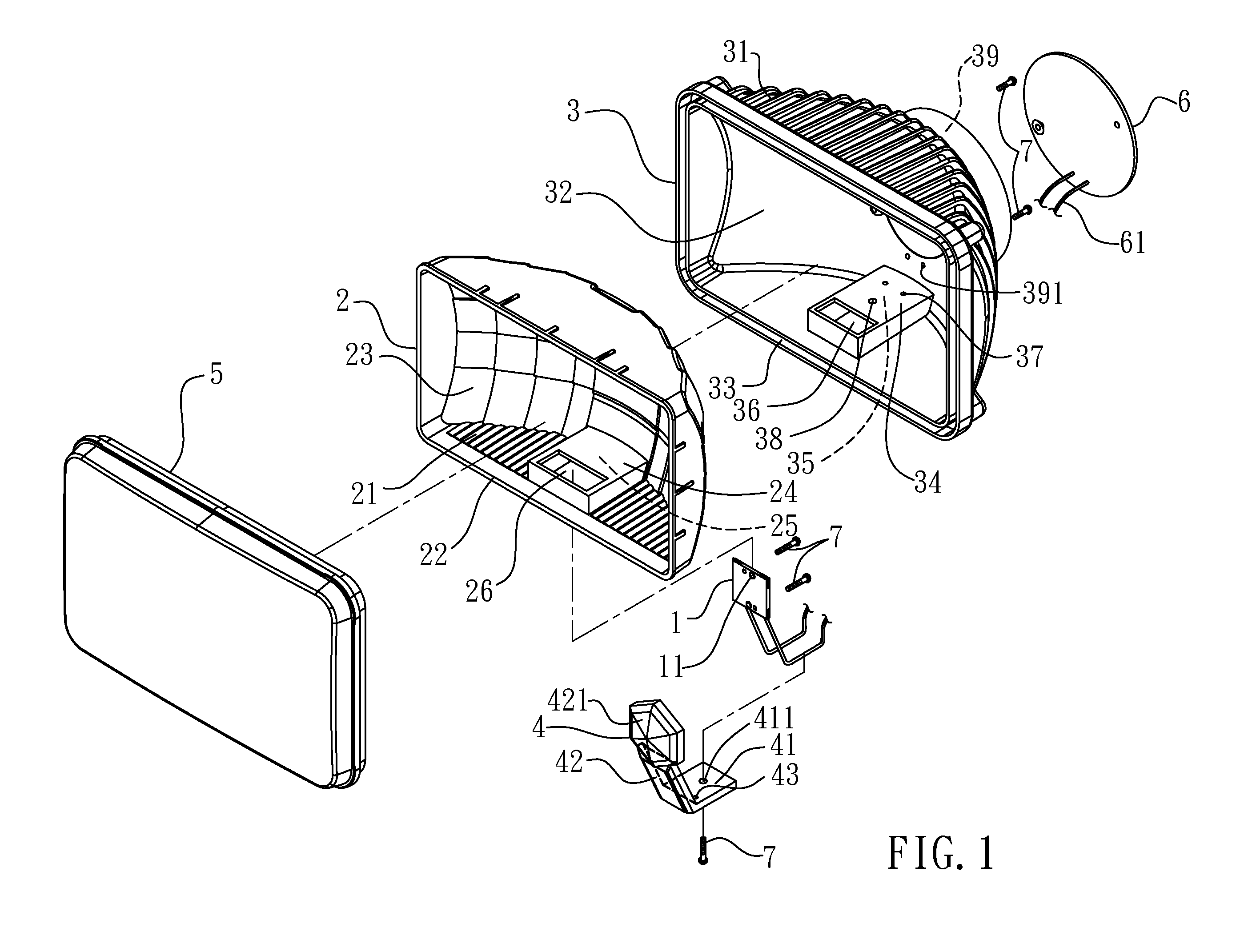

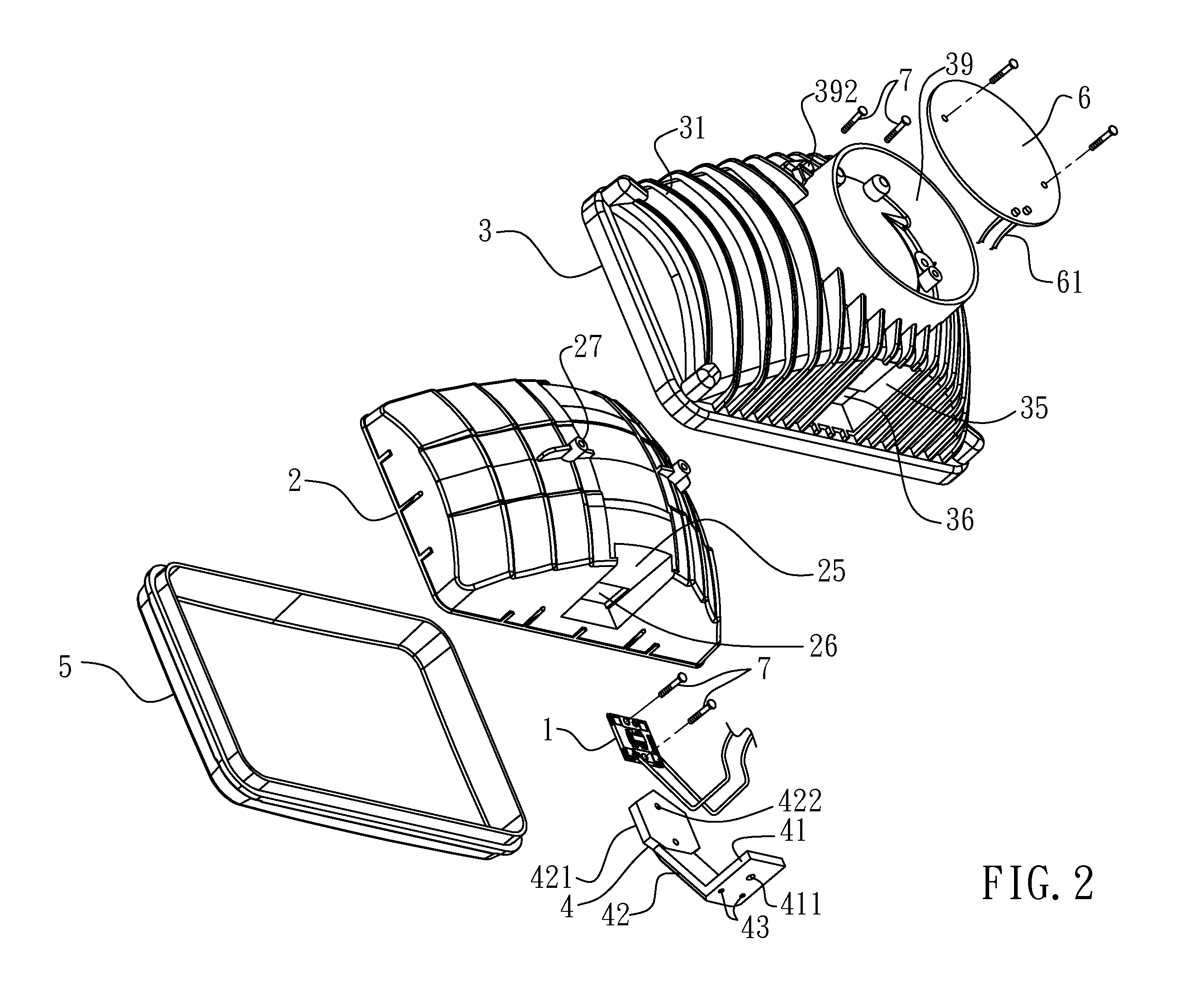

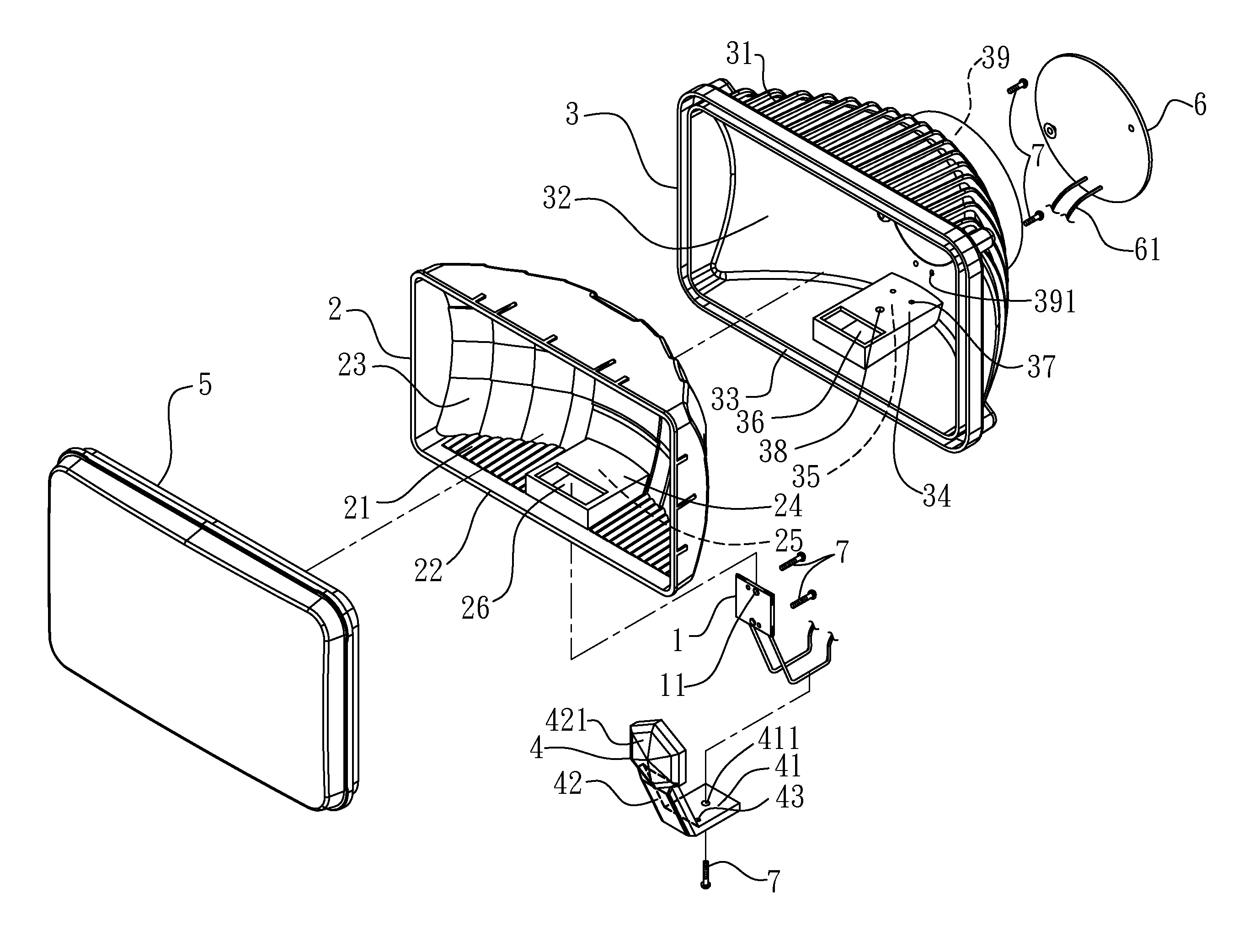

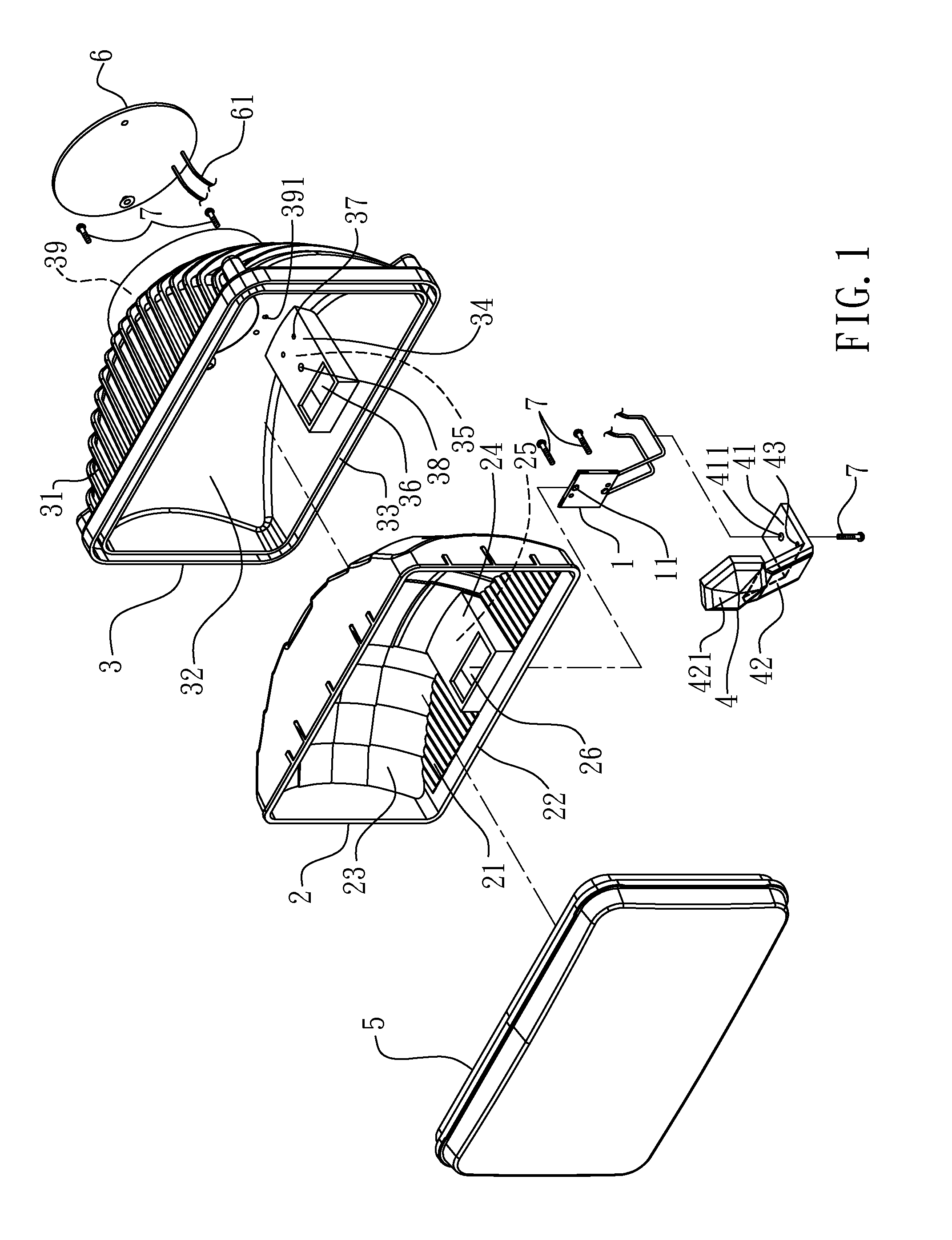

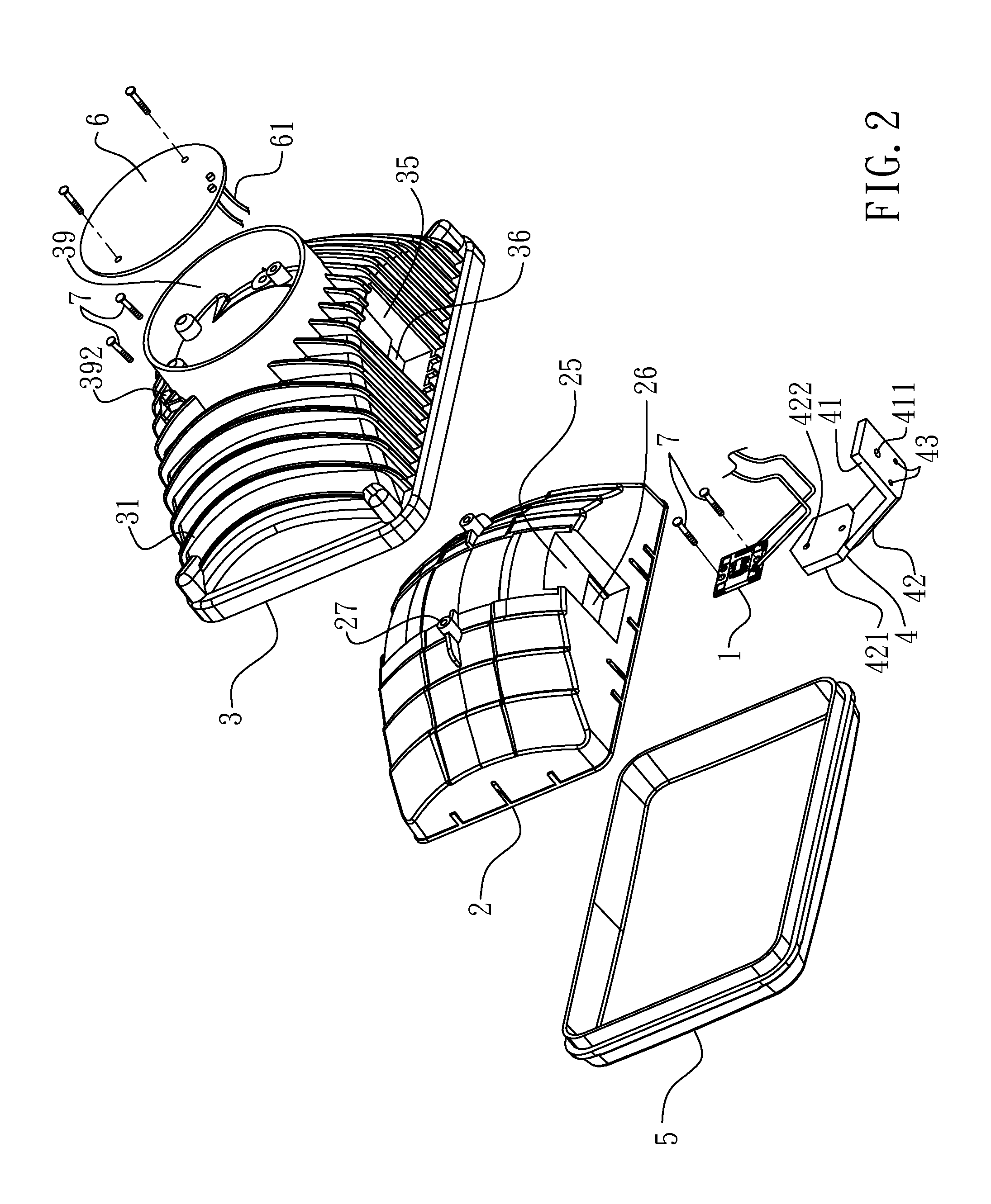

Vehicular Lamp

ActiveUS20120182750A1Improve cooling efficiencyEasy to assembleNon-electric lightingVehicle headlampsEngineeringLED lamp

Owner:MIN HSIANG CORP

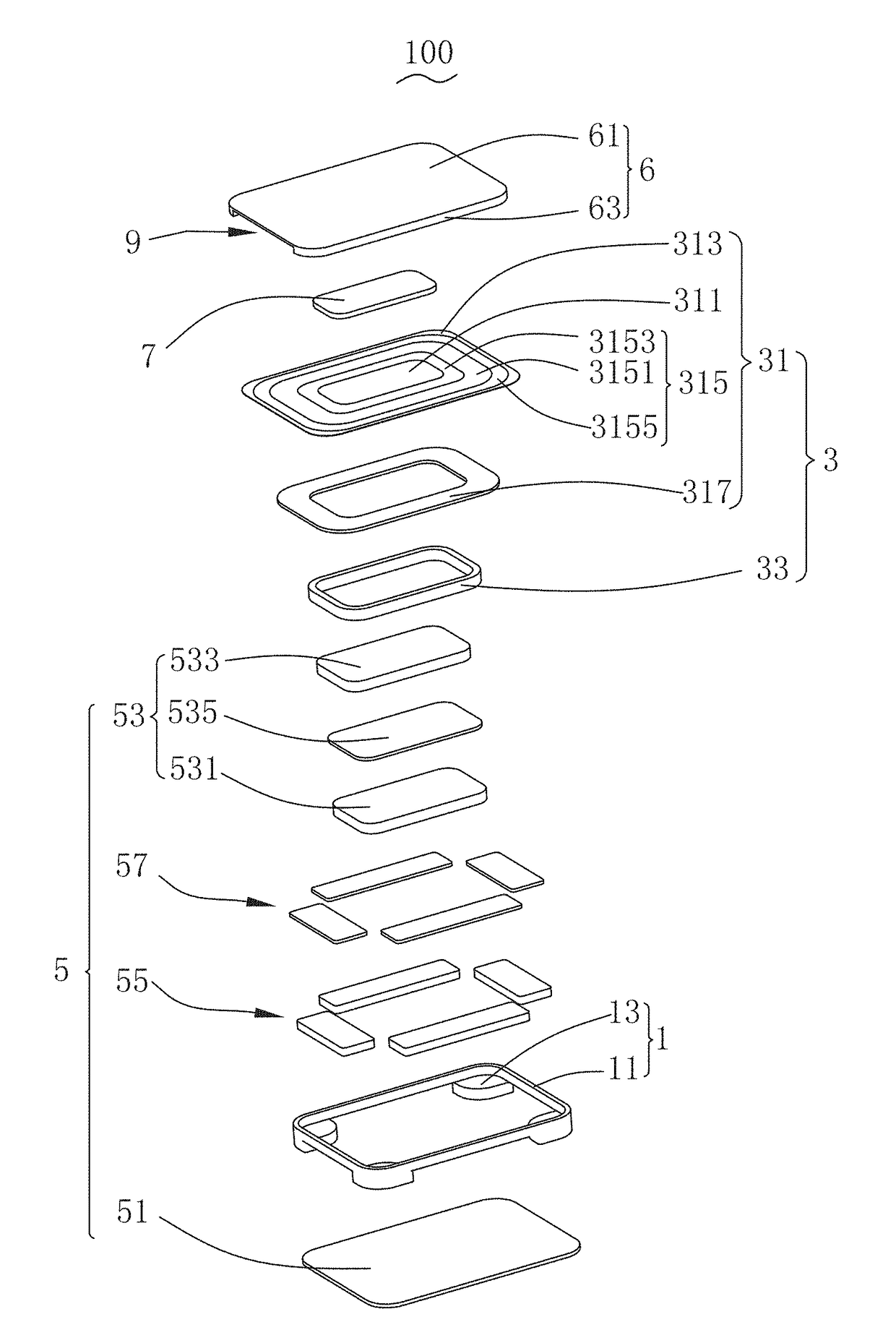

Backlight module and luminous source encapsulation structure thereof

ActiveCN101943356AEasy to assembleDecrease productivityPoint-like light sourceLighting heating/cooling arrangementsComputer moduleTight binding

The invention discloses a backlight module and a luminous source encapsulation structure thereof. The luminous source encapsulation structure comprises a heat radiating seat, at least one chip and a heat radiating and fixing piece, wherein the heat radiating seat is provided with a combining hole, the dimension of the heat radiating and fixing piece is less than that of the heat radiating seat, and the heat radiating and fixing piece comprises a combining post and a heat radiating fin with a butt surface; the combining post passes through a through hole of a fixing plate and is combined with the combining hole, the butt surface of the heat radiating fin is supported on the fixing plate, therefore, the heat radiating seat and the heat radiating and fixing piece can be stably combined on both sides of the fixing plate in order to ensure the tight binding relation with the fixing plate and increase assembling reliability, meanwhile, the heat radiating fin can be used for increasing the heat radiating effect of the heat radiating seat in extra, and therefore, the heat radiating fin can assuredly help the chip to reduce temperature in order to avoid the work efficiency reduction of the chip and is beneficial to ensuring that the chip stably operates and prolonging the service life.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

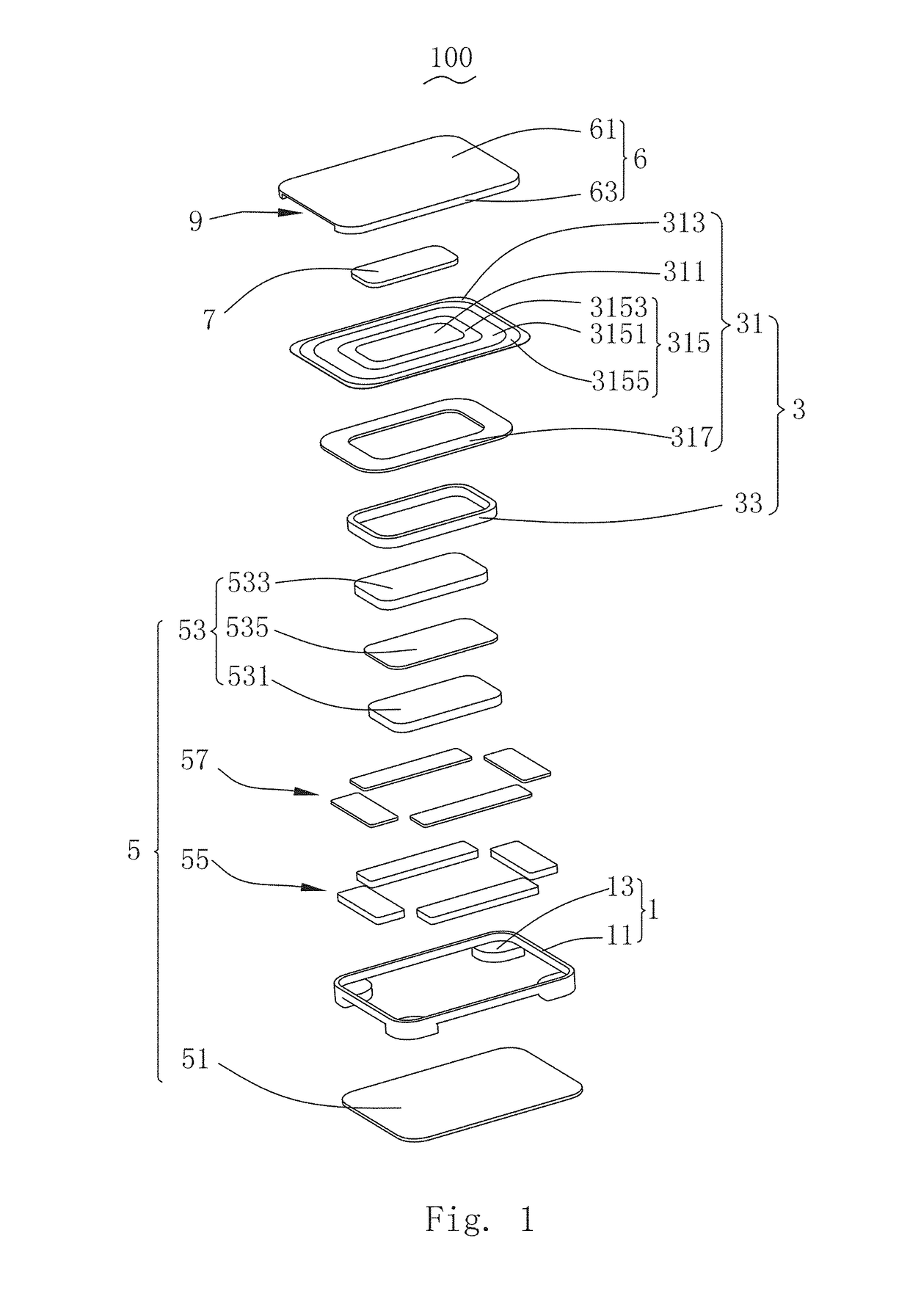

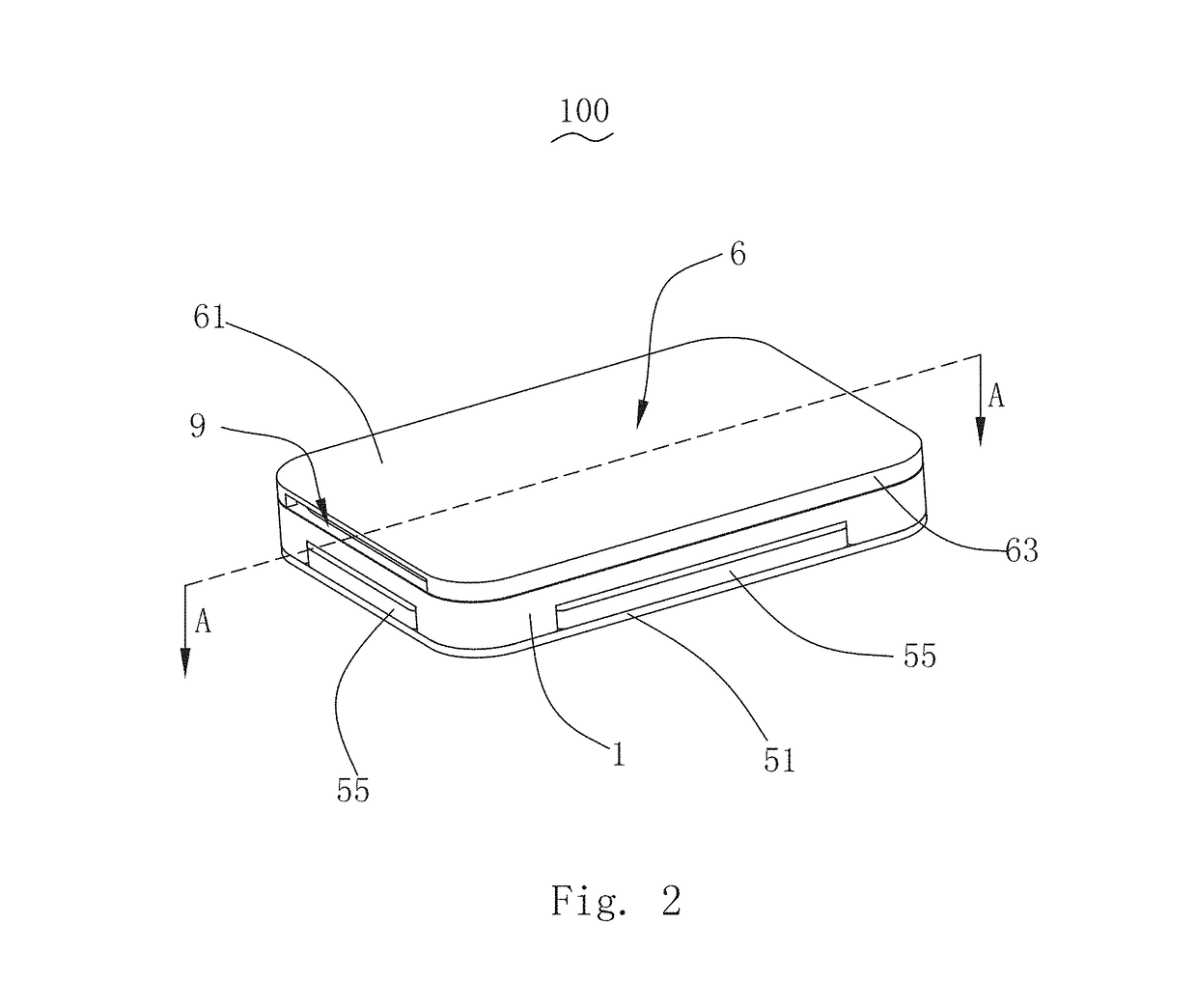

Miniature speaker

ActiveUS20180027333A1Improve assembly reliabilityImprove magnetismLoudspeakersNon-planar diaphragms/conesEngineeringLoudspeaker

A miniature speaker includes a frame; a vibration system including a diaphragm and a voice coil driving the diaphragm. The diaphragm includes a first fixation part located on a middle position of the diaphragm, a second fixation part located on an edge of the diaphragm and connected fixedly on the frame, and a vibration part connected between the first fixation part and the second fixation part. A magnetic circuit system includes a lower plate and a magnet part on the lower plate. A cover plate includes a bottom wall, and a side wall connected with the second fixation part. A gasket is located between and abuts against the bottom wall and the first fixation part. The gasket, the first fixation part and the magnet part are sandwiched firmly between the bottom wall and the lower plate.

Owner:AAC TECH PTE LTD

Vehicular lamp

ActiveUS8408764B2Improve cooling efficiencyEasy to assembleNon-electric lightingVehicle headlampsEngineeringLED lamp

Owner:MIN HSIANG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com