Chip heat radiation assembly and chip circuit board thereof

A chip heat dissipation and circuit board technology, applied in the field of communications, can solve the problems of radiator falling off, production efficiency reduction, falling off, etc., to avoid chip being crushed, improve assembly efficiency, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be introduced below in conjunction with the accompanying drawings.

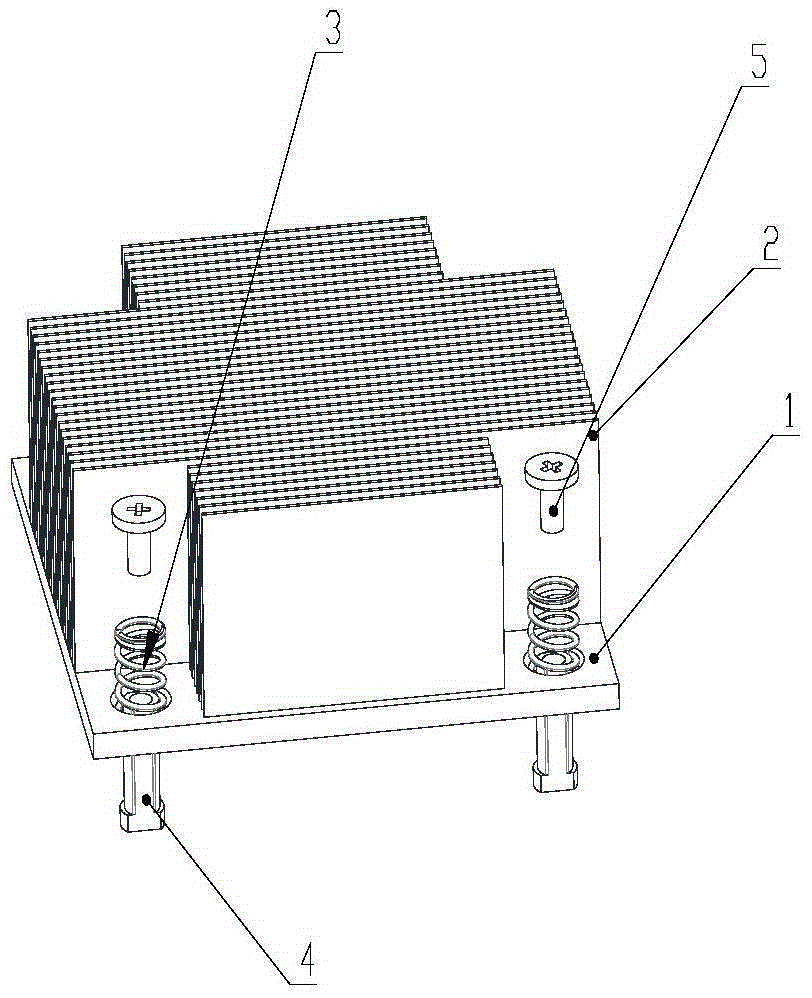

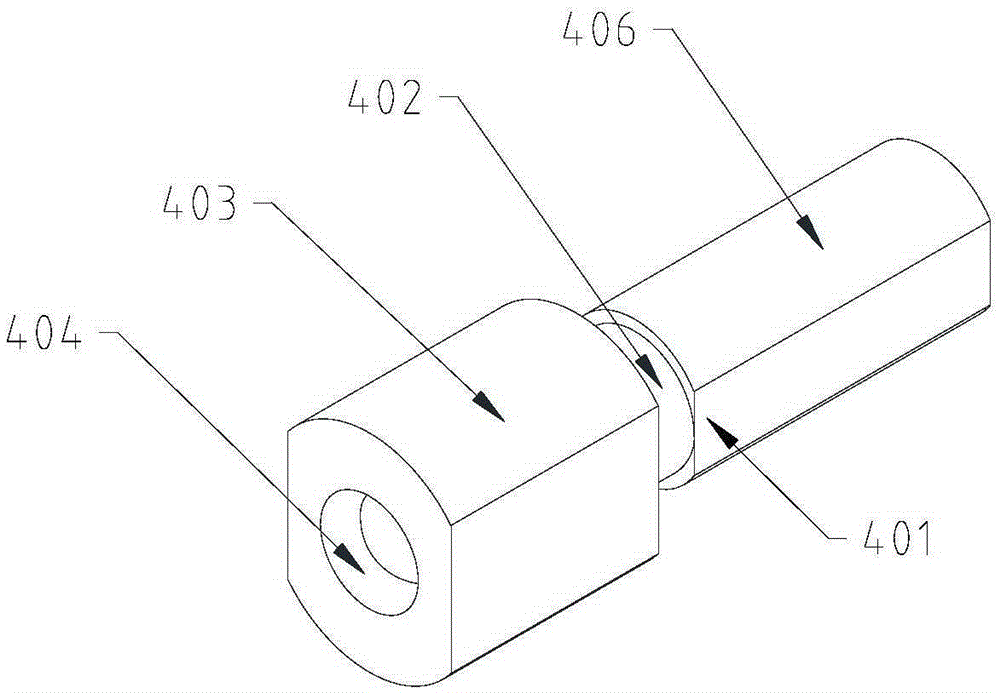

[0047] The invention provides a chip cooling assembly, such as figure 1 , Figure 4 , Figure 3a , Figure 3b As shown, it is applied to dissipate heat from a chip 7 located on a circuit board. The chip heat dissipation assembly includes: a base 1, a plurality of heat dissipation fins 2, a plurality of springs 3, a plurality of adjustment rod assemblies 4, a plurality of locking screws 5, a plurality of fastening Screw 8 ( figure 1 and Figure 4 The case where the number of springs, adjusting rod assemblies, locking screws and fastening screws is 4 is shown); the base 1 includes an upper surface 104 and a lower surface 105, and the heat dissipation fins 2 are installed on the upper surface 104 On, described lower surface 105 is provided with base boss 103, and the height of described base boss 103 is H2, and described base upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com