Flange plate rapid-connecting device and operation method thereof

A quick connection and flange technology, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of limited transformer models, difficult fixing, troublesome operation, etc., and achieve simple and easy fastening operation , reduce the amount of oil leakage, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

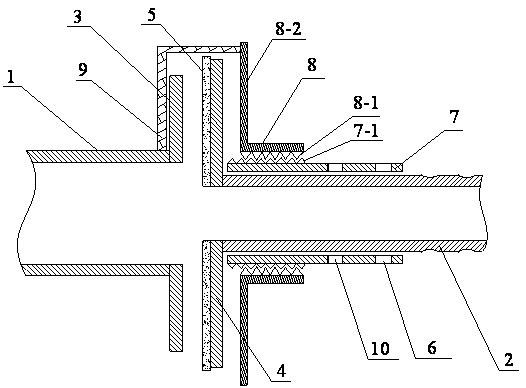

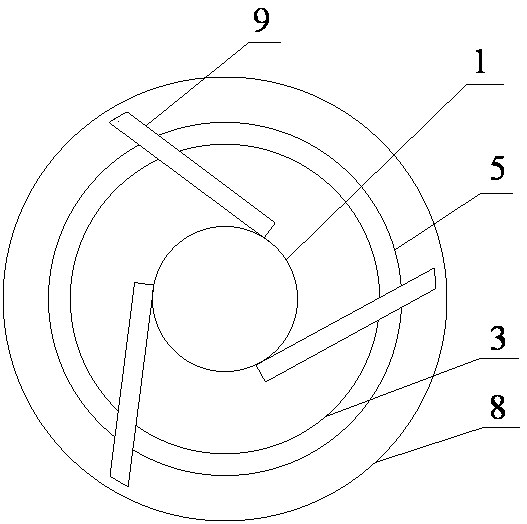

[0029] refer to figure 1 and figure 2 , the present invention provides a flange quick connection device, comprising a transformer filling and discharging oil pipe 1, oil pipe self-sealing joint 2, transformer oil filling and discharging valve flange 3, oil pipe joint flange 4, sealing gasket 5, adjusting steel pipe 7, clamping Disc 8 and buckle 9, transformer oil filling and discharging valve flange 3 is connected with transformer oil filling and discharging pipe 1, oil pipe joint flange 4 is connected with oil pipe self-sealing joint 2, oil pipe joint flange 4 is connected with transformer oil filling and discharging valve flange 3 A sealing gasket 5 is arranged between them, and an adjustment steel pipe 7 is coaxially arranged on the outside of the oil pipe self-sealing joint 2. The end of the adjustment steel pipe 7 away from the oil pipe joint flange 4 is provided with a number of connecting holes 6 and a number of threaded holes 10, and the adjustment steel pipe 7 is clo...

Embodiment 2

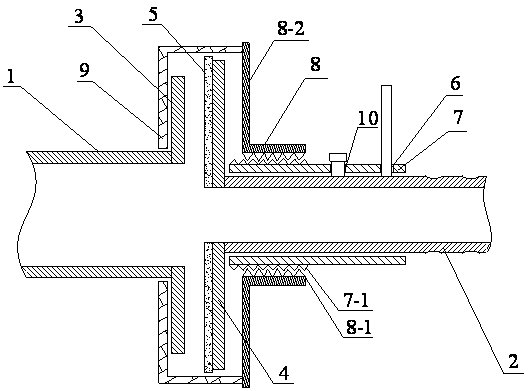

[0040] refer to image 3 and Figure 4 , the present invention provides a flange quick connection device, comprising a transformer filling and discharging oil pipe 1, oil pipe self-sealing joint 2, transformer oil filling and discharging valve flange 3, oil pipe joint flange 4, sealing gasket 5, adjusting steel pipe 7, clamping Disc 8 and buckle 9, transformer oil filling and discharging valve flange 3 is connected with transformer oil filling and discharging pipe 1, oil pipe joint flange 4 is connected with oil pipe self-sealing joint 2, oil pipe joint flange 4 is connected with transformer oil filling and discharging valve flange 3 A sealing gasket 5 is arranged between them, and an adjustment steel pipe 7 is coaxially arranged on the outside of the oil pipe self-sealing joint 2. The end of the adjustment steel pipe 7 away from the oil pipe joint flange 4 is provided with a number of connecting holes 6 and a number of threaded holes 10, and the adjustment steel pipe 7 is clo...

Embodiment 3

[0046] refer to Figure 5 , the present invention provides a flange quick connection device, comprising a transformer filling and discharging oil pipe 1, oil pipe self-sealing joint 2, transformer oil filling and discharging valve flange 3, oil pipe joint flange 4, sealing gasket 5, adjusting steel pipe 7, clamping Disc 8 and buckle 9, transformer oil filling and discharging valve flange 3 is connected with transformer oil filling and discharging pipe 1, oil pipe joint flange 4 is connected with oil pipe self-sealing joint 2, oil pipe joint flange 4 is connected with transformer oil filling and discharging valve flange 3 A sealing gasket 5 is arranged between them, and an adjustment steel pipe 7 is coaxially arranged on the outside of the oil pipe self-sealing joint 2. The end of the adjustment steel pipe 7 away from the oil pipe joint flange 4 is provided with a number of connecting holes 6 and a number of threaded holes 10, and the adjustment steel pipe 7 is close to the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com