Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduce intergranular corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium alloy material for radiator fin

InactiveCN102330005AImprove corrosion resistanceHigh strengthHeat exchange apparatusSolderabilityUltimate tensile strength

The invention relates to an aluminium alloy material for a radiator fin, which is characterized by comprising the following components in percentage by weight: 0.5-1.2wt% of Si, 0.5-1.8wt% of Mn, 0.25-1.8wt% of Zn, 0.30-0.55wt% of Cu and the balance of Al and inevitable impurities. The aluminium alloy material disclosed by the invention has the advantages of high strength property and solderability, excellent corrosion resistance and good machinability, and is especially suitable to serve as the radiator fin.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

Corrision-resistant zinc-base aliuminium-magnesium rare-earth alloy coating, and its preparing method

InactiveCN1850926AImprove corrosion resistanceReduce corrosionAnti-corrosive paintsEpoxy resin coatingsXylyleneFirming agent

The invention relates to a anode sacrificed type corrosion resistant zinc radical aluminum magnesium rare earth alloy coating material and the manufacture method. It mixes two constituents according to 9:1 and dilutes to 5S-20S viscosity, aging for 15-20 minutes. The first constituents include 50% E-20 epoxy resin liquid, 2.0-6.0% diluting agent, 1.0-3.0% organic modified pig bentonite, 1.5-3.0% french chalk, 60-70% Zn-15Al-5Mg-RE alloy powder. And the second constituents include 20-30% T-31 epoxy resin curing agent, 20-35% butyl alcohol, and 35-50% xylene. The invention is easy to operate, and has wide application.

Owner:WUHAN UNIV OF SCI & TECH

Technological method for improving equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets

The invention provides a technological method for improving the equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets. The technological method comprises the steps of aprimary melting furnace, AOD, VOD, LF and continuous casting. According to the technological method provided by the invention, the equiaxed crystal ratio of the bistable ferrite stainless steel continuous casting billets is improved largely, and the cold machining and molding performances of ferrite stainless steel as well as the surface quality of products are improved; and the problems of nozzle clogging and blockage caused by TiN and TiOx generated by adding excessive Ti in the continuous casting technological process are solved effectively.

Owner:UNIV OF SCI & TECH BEIJING

Zinc-base alloy

The invention discloses a zinc-base alloy. The zinc-base alloy is a Zn-Al-Cu-Mg series alloy and comprises the following elements in percentage by mass: 4%-5.5% of aluminum, 0.8%-1.2% of copper, 0.05%-0.08% of magnesium, not more than 0.02% of iron, not more than 0.001% of lead, not more than 0.002% of cadmium, not more than 0.001% of tin, and the balance of zinc and inevitable impurities, wherein the content of the zinc is no less than 94%, and the total content of the impurities is not more than 0.02%. By the manner, the zinc-base alloy is low in the content of detrimental impurities, has high corrosion resistance, high strength and high wear resistance and is suitable for the casting of metal ornaments and accessories which are high in accuracy and complicated in structure; and castings have high surface quality and are difficult to fracture.

Owner:CHANGSHU LIONY METALS

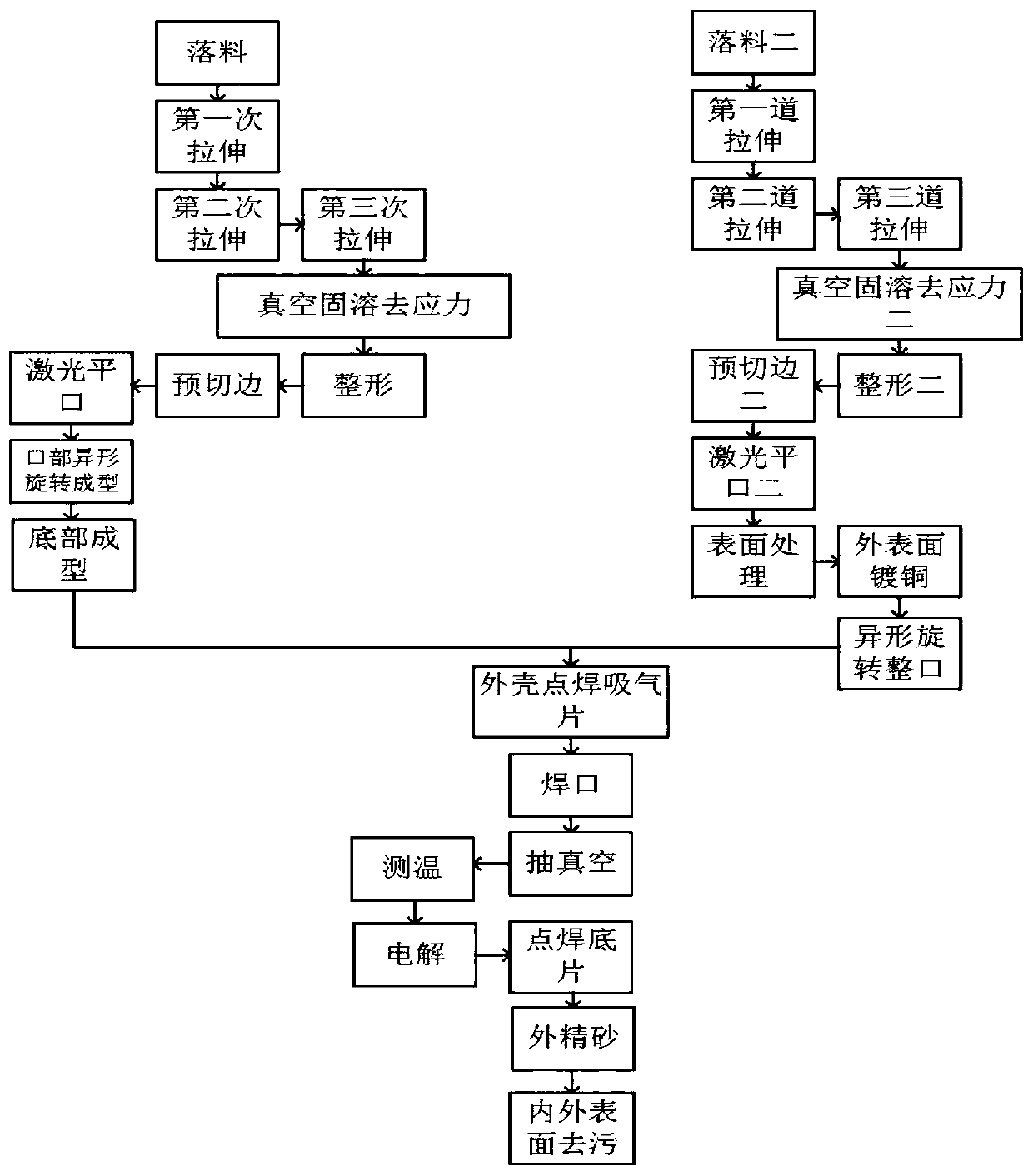

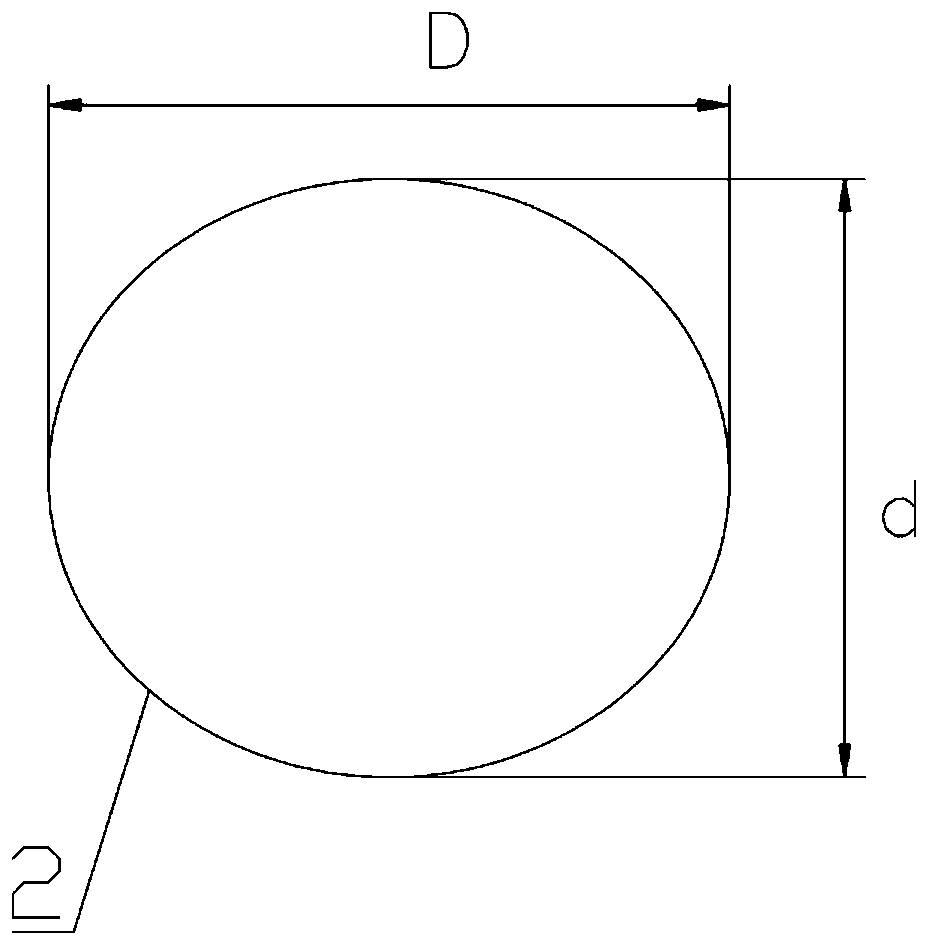

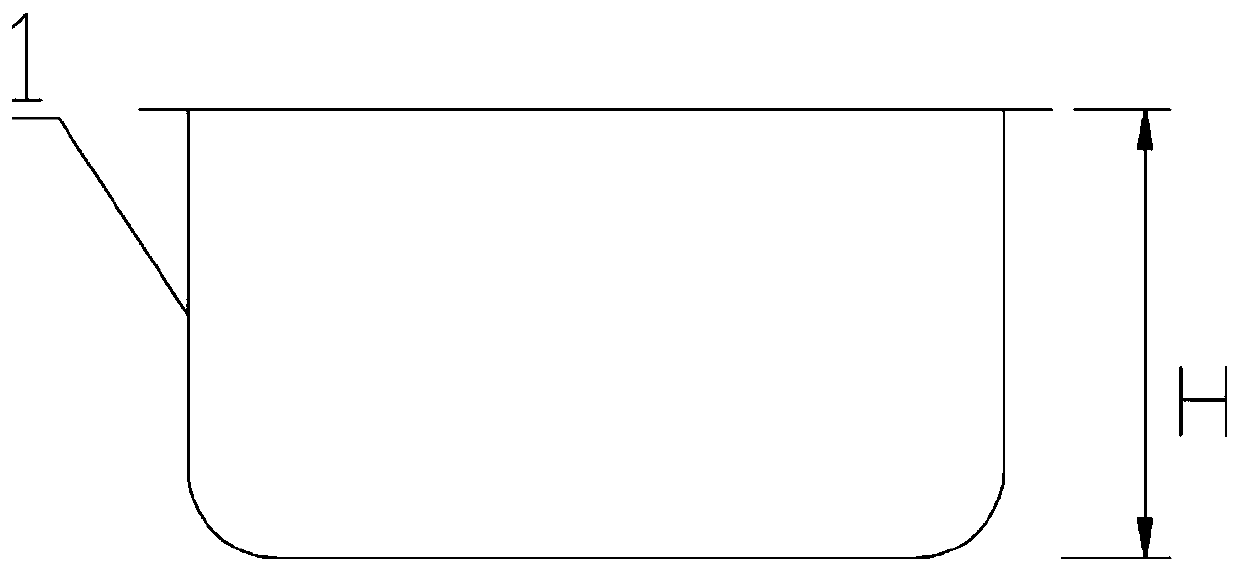

Special-shaped stretch-formed heat insulation lunch box and preparation method thereof

The invention discloses a special-shaped stretch-formed heat insulation lunch box and a preparation method thereof, and belongs to the technical field of heat insulation lunch boxes. The preparation method includes an outer shell special-shaped constant-temperature stretch-forming process, an inner container special-shaped constant-temperature stretch-forming process, an outer shell inner container special-shaped welding process, an interlayer vacuum process and a lunch box surface treatment process; the outer shell special-shaped constant-temperature stretch-forming process includes the following steps of three times of stretching, vacuum solid solution stress relief, shaping, pre-edge trimming, laser opening flatting and other steps; and the inner container special-shaped constant-temperature stretch-forming process includes the following steps of three times of stretching, secondary vacuum solid solution stress relief, secondary shaping, secondary pre-edge trimming, secondary laseropening flatting, special-shaped rotating opening flattening and other steps. The process mass production processability of products is met through multiple times of special-shaped stretch-forming, side walls are prevented from cracking, meanwhile, thick and big internal molecular lattice of a material after multiple times of forming is improved through vacuum solid solution stress relief treatment, stress relief in steps is not needed, and the outline smoothness and heat insulation effectiveness of the products are improved.

Owner:浙江安胜科技股份有限公司

Zinc-aluminum-magnesium rare earth corrosion-resistant coating

InactiveCN102534305AImprove the effect of cathodic protectionReduce porosityMolten spray coatingRare earthZinc

The invention discloses a zinc-aluminum-magnesium rare earth corrosion-resistant coating, which contains the following components in percentage by weight: 5-23 percent of Al, 0.05-0.1 percent of Mg, 0.05-1 percent of rare earth metal RE and the balance of Zn. In the zinc-aluminum-magnesium rare earth corrosion-resistant coating, the rare earth metal RE is at least one of La and Ce. The zinc-aluminum-magnesium rare earth corrosion-resistant coating in accordance with the invention has wide application range, and meets the steel and iron corrosion resistance requirements under different environments; and brine corrosion resistance performance is over 2 times that of a pure zinc layer.

Owner:STATE GRID CORP OF CHINA +1

Medical degradable zinc-based alloy intravascular stent product

The invention relates to the fields of a medical material and an apparatus thereof, and provides an in-vivo degradable implantable intravascular stent product. The product comprises 1) an in-vivo degradable implantable zinc-based metal material; 2) the intravascular stent product produced by the zinc-based alloy material in the step 1) is in a pipenet structure; 3) a magnesium metal film coating is uniformly distributed and deposed at the surface of the pipenet stent product; and 4) the magnesium film coating is coated with a degradable polymer coating, and the polymer coating can contains therapeutic drugs. The zinc based alloy has the advantages of excellent mechanical properties, strong corrosion controllability, and excellent compatibility. According to the intravascular stent product,surface special arrangement is benefit for keeping a complete initial structure, is benefit for stent endothelialization, reduces an inflammatory reaction, and reduces local inflammation, restenosisand thrombus risk in the stent after stent implantation.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

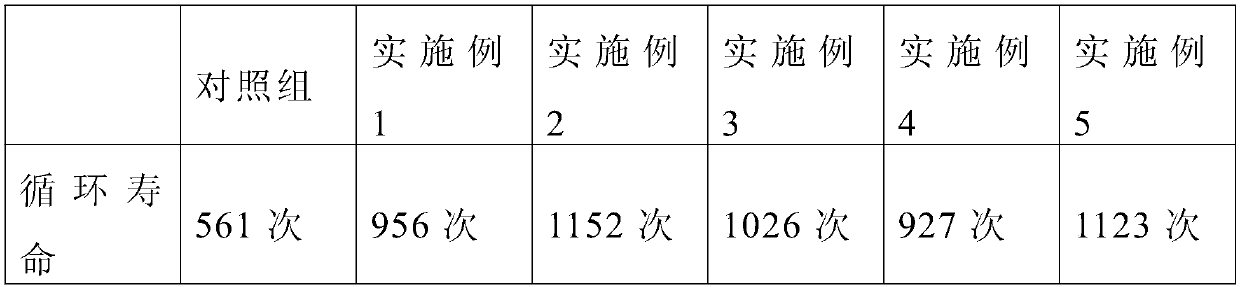

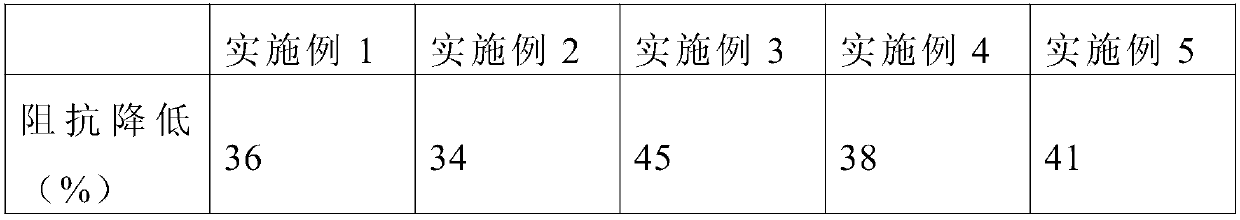

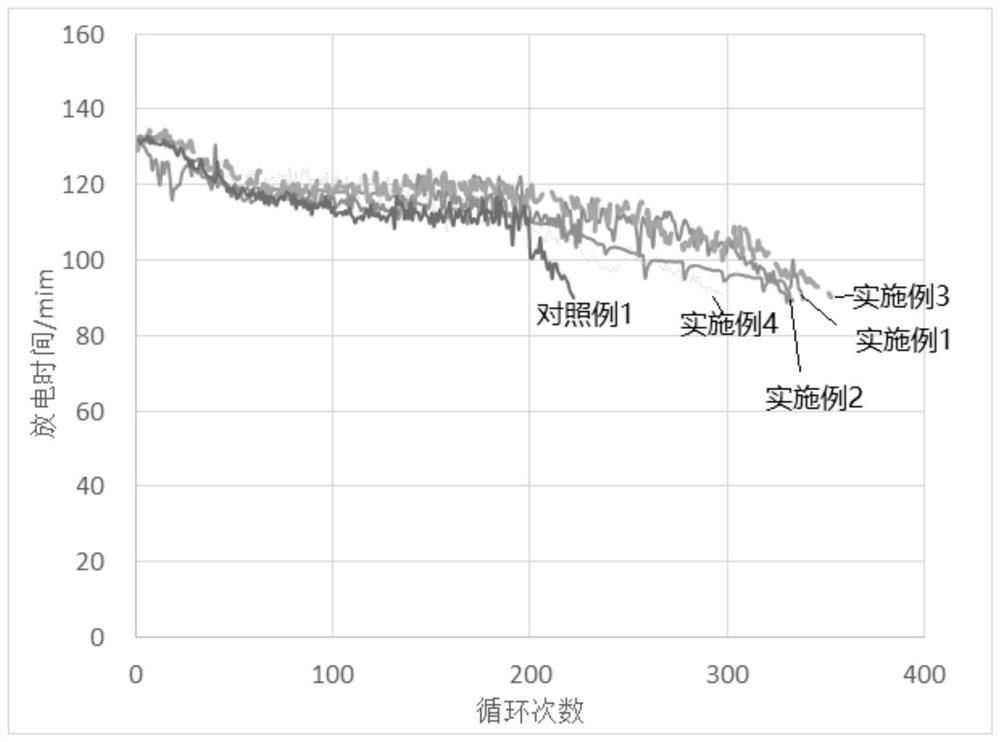

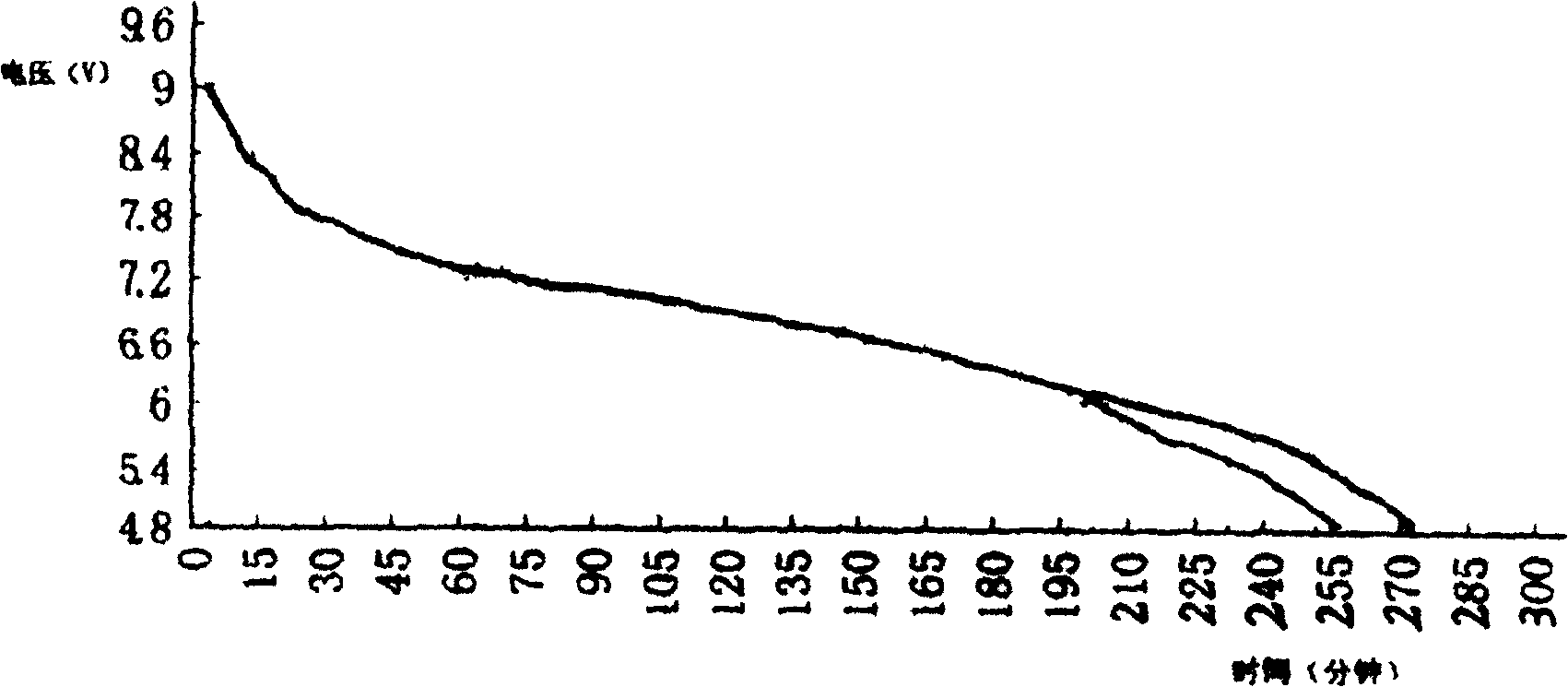

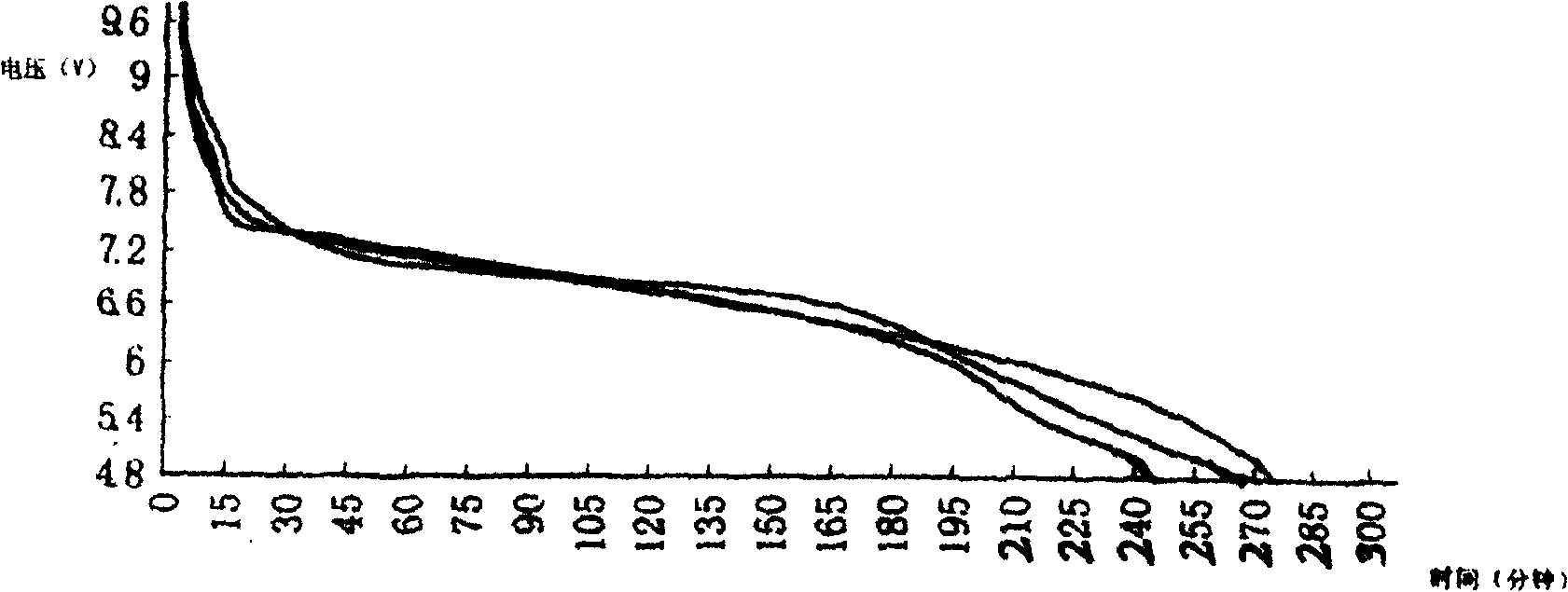

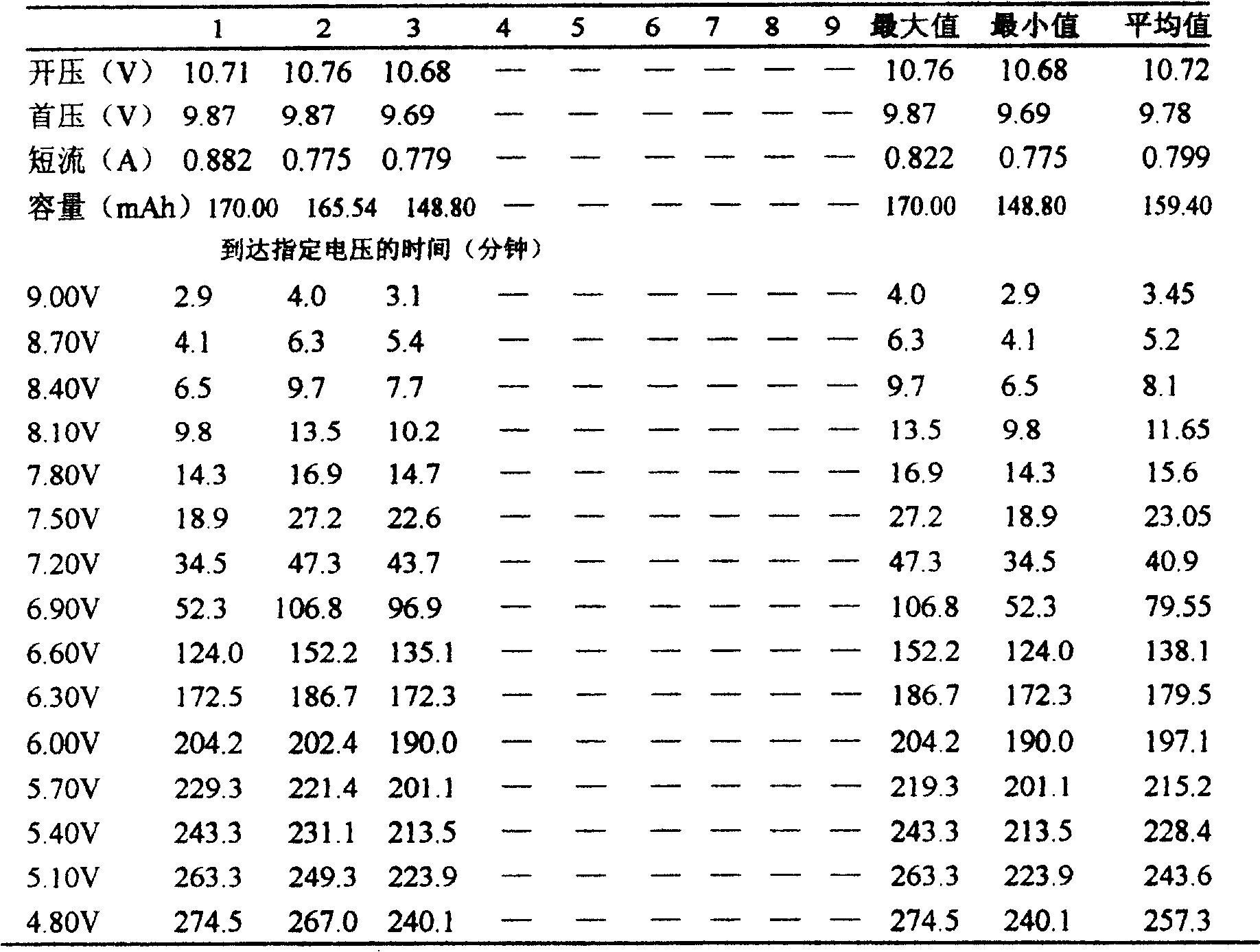

Positive grid lead-calcium alloy for lead-acid storage battery

The invention relates to a novel positive grid lead-calcium alloy for a lead-acid storage battery. The alloy is prepared from components in percentage by weight as follows: 0.05%-0.12% of calcium, 0.5%-1.5% of tin, 0.06%-0.11% of bismuth, 0.07%-0.15% of rare earth elements and the balance of lead, wherein the rare earth elements are one or more of ytterbium, gadolinium and lanthanum. The ingredients of the grid alloy are improved by adding tin, bismuth, the rare earth elements and other additives, and a novel deep-cycle and maintenance-free grid alloy material for the lead-acid storage batterywhich is corrosion-resistant, good in charging property and mechanical property and long in cycle life is obtained.

Owner:WUHAN YIWEIDENG TECH DEV

Porous zinc-tin alloy negative electrode material for zinc-air battery and preparation method of porous zinc-tin alloy negative electrode material

InactiveCN105489970AImprove corrosion resistanceStable thermodynamic propertiesFuel and primary cellsCell electrodesTechnology developmentNew energy

The invention discloses a porous zinc-tin alloy negative electrode material for a zinc-air battery and a preparation method of the porous zinc-tin alloy negative electrode material, belonging to the field of new energy technology development. The porous zinc-tin alloy negative material comprises a foamed nickel substrate and a zinc-tin alloy plating layer, wherein the zinc-tin alloy plating layer is uniformly coated on the foamed nickel substrate, tin and zinc in the zinc-tin alloy plating layer are uniformly distributed, and the mole ratio of tin to zinc is (0.01-0.20):1. In the porous zinc-tin alloy negative electrode material, foamed nickel is taken as a negative electrode, electroplating is carried out in an electroplating liquid containing a complexing agent to obtain the porous zinc-tin alloy negative electrode material, and the electroplating liquid containing the complexing agent is selected from one of a pyrophosphate system electroplating liquid, a gluconate system electroplating liquid, a citrate system electroplating liquid and a tartaric acid system electroplating liquid. The porous zinc-tin alloy negative electrode material has the advantages that the material structure is reasonable in design, the preparation process is simple, and industrial application and production at a large scale are promoted.

Owner:CENT SOUTH UNIV

Non-spangle friction-resisting hot dipping K-S-B zinc aluminum alloy and machining process

InactiveCN108396198ADoes not increase crystallization pointNot easy to produceHot-dipping/immersion processesZincMachining process

The invention discloses a non-spangle friction-resisting hot dipping K-S-B zinc aluminum alloy and a machining process. The alloy comprises, by weight percent, 0.2 to 0.3% of K, 2.0to 2.5% of Mg, 1.0to 1.8% of Ca, 20.0 to 28.0% of Al, 0.2 to 0.3% of Se, 0.6 to 0.8% of In, 0.1 to 0.2% of B, 0.2 to 0.3% of S and the balance zinc. The hot dipping K-S-B zinc aluminum alloy and the process of the alloy solve the key problem in the hot-dip galvanizing aluminum alloy application research and industrialization, a final product has the excellent corrosion resistance property and the non-spangle surface state, and the material can be widely applied in the near future.

Owner:GUANGZHOU YUZHI TECH CO LTD

Anticorrosive zinc base aluminium-magnesium rare earth alloy and its preparing method

The invention belongs to the technical domain of enduring corrode metal material, especially, it relates to the zinc-base aluminium-magnesium-lanthanide alloy resisting the corroding and the producing process. The adopted technical process: the 75-85wt% zinc, the 0-1wt% lanthanide, the 12-18wt% aluminum and the 2-8wt% magnesium are placed into the heating stove, the temperature is heated up to 800-950 to melting, the temperature keeps 10-30 minutes or the material is milled 10-30 minutes. It casts under the temperature of 550-650, or, it mould to preprocessing material. The alloy produced from the invention has many merits such as the resisting causticity chronically, the good machine capability, the low melting point, the low proportion and the low cost. It is fit for the producing the engine part resisting the corrupt and sacrificing the anode material and machining to powder to produce the zinc-base aluminium-magnesium-lanthanide alloy resisting the corroding, so it is important to the project resisting the corrupt of the changing river such as the water conservabcy, the haven, the bridge and the watercraft.

Owner:WUHAN UNIV OF SCI & TECH

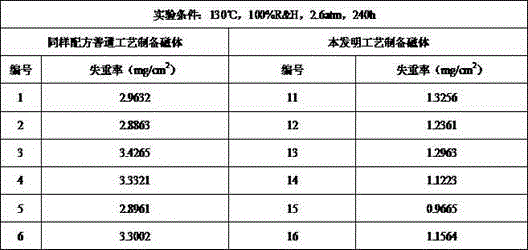

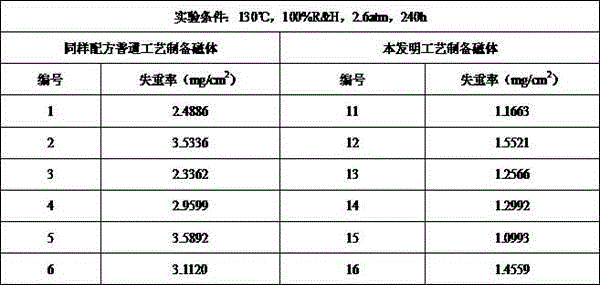

Preparation for low-weightlessness rare earth-iron-boron magnetic body

ActiveCN104966606AReduce weightlessnessImprove corrosion resistanceInductances/transformers/magnets manufactureMagnetic materialsWeightlessnessRare earth

The invention relates to preparation for a low-weightlessness rare earth-iron-boron magnetic body, and belongs to the field of magnetic materials. The preparation comprises the following steps of smelting, hydrogenating, powdering making, powder mixing, orienting and forming, sintering and aging treatment. According to the technical scheme, in the powder mixing process of preparation of a rare earth-iron-boron magnetic body, RE-MM-N nano-alloy is added to rare earth-iron-boron magnetic powder, after sintering and aging heating treatment are carried out, RE-MM-N nanometers are distributed on a grain boundary phase in a scattering mode, the grain boundary of the rare earth-iron-boron magnetic body is strengthened, the difference between the grain boundary abundant RE corrosion potential and the main corrosion potential is lowered, the intergranular corrosion is lowered, the corrosion resistance of the grain boundary phase in the environment of high temperature and high humidity is improved, and the weightlessness of the rare earth-iron-boron magnetic body is lowered. Compared with the general technology of preparing the rare earth-iron-boron magnetic body, the weightlessness is achieved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

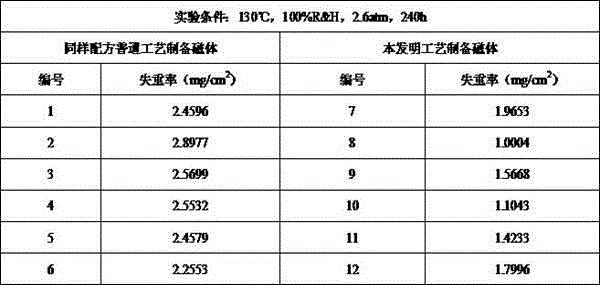

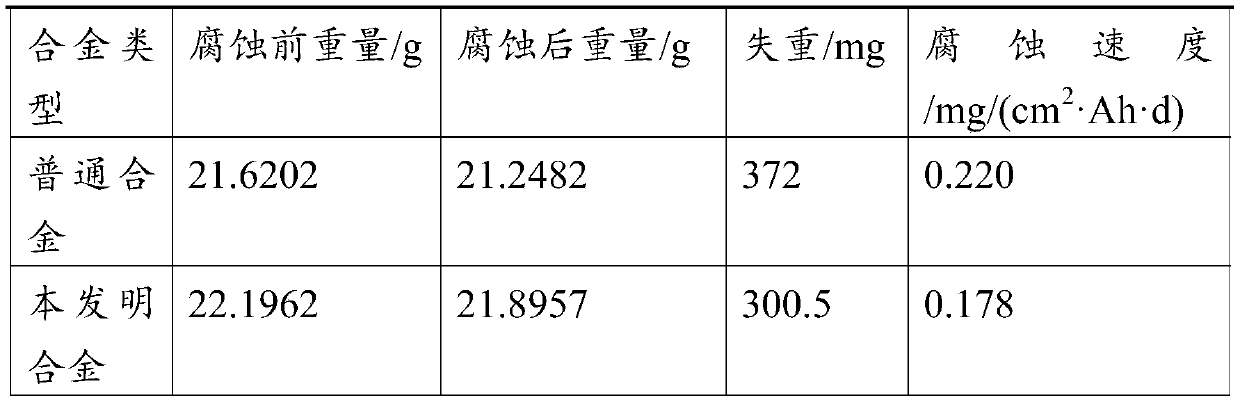

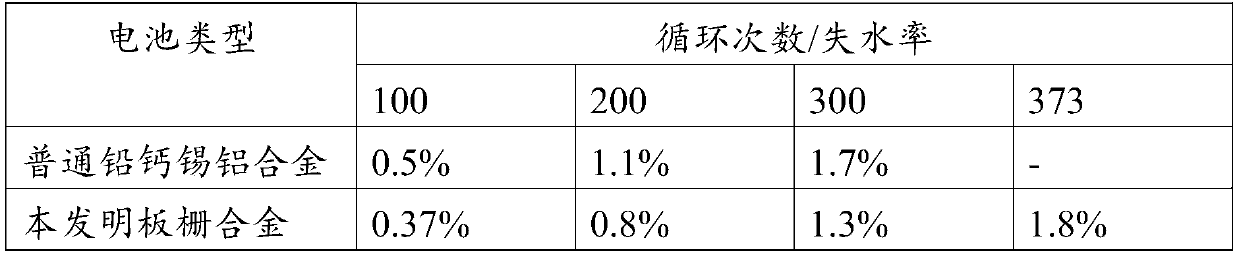

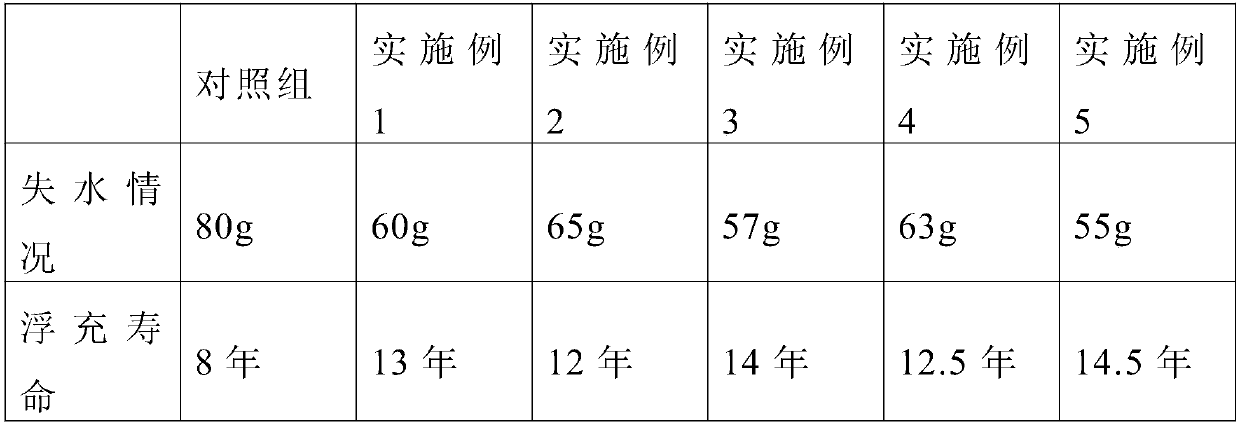

Novel grid alloy, positive plate grid containing novel grid alloy and lead-acid storage battery

The invention relates to a grid alloy. The grid alloy is prepared from the components in percentage by weight: 0.08-0.09% of calcium, 0.4-0.8% of tin, 0.015-0.025% of aluminum, 0.02-0.03% of cerium, 0.025-0.035% of copper, 0.015-0.025% of sodium and the balance of lead. The invention further relates to a positive plate grid comprising the grid alloy, a preparation method of the grid alloy, a preparation method of the positive plate grid and a lead-acid storage battery provided with the positive plate grid. Through constant current corrosion tests and water loss rate tests, it is found that thecorrosion resistance of the lead-acid storage battery provided with the positive plate grid made of the novel grid alloy is greatly improved, and the water loss rate is further greatly reduced.

Owner:ANHUI LEOCH BATTERY TECH

Zinc alloy

The invention provides a zinc alloy which comprises the following components in percentage by mass: 3.5-6.0% of aluminum, 0.5-1.8% of copper, 0.02-0.05% of magnesium and the balance of zinc and other impurities, wherein the iron content is not greater than 0.1%, the lead content is not greater than 0.03%, the cadmium content is not greater than 0.01%, and the tin content is not greater than 0.01%. When preparing the zinc alloy, the solution temperature is controlled at 390-410 DEG C, and detrimental impurities are controlled within the specified range to obtain the zinc alloy satisfying the RoHS standard, thereby lowering the damage to the human body and environment.

Owner:SIHUI FENGYIXIN METAL CASTING

Antibiotic corrosion resistant aluminum alloy heat exchange plate

InactiveCN102329996AImprove corrosion resistanceImprove antibacterial propertiesHeat exchange apparatusColiform bacilliStaphylococcus

The invention relates to an antibiotic corrosion resistant aluminum alloy heat exchange plate, which is characterized by being prepared from the following materials: 0.5 to 1.2 weight percent of Si, 0.5 to 1.8 weight percent of Mn, 0.25 to 1.8 weight percent of Zn, 0.20 to 0.55 weight percent of Cu, 0.01 to 0.02 weight percent of Ag and the balance Al and inevitable impurities. Security compass web application auditing tool (SWAAT) experiments are adopted for testing the corrosion behavior of the alloy material and show that the corrosion resistance of the aluminum alloy is obviously improved, and in addition, the aluminum alloy heat exchange plate has good antibacterial property and has more than 99 percent antibacterial rate on colon bacilli and staphylococcus aureus.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

Aluminium alloy material of radiator heat pipe

The invention relates to an aluminium alloy material of a radiator heat pipe, which is characterized by comprising the following components in percentage by weight: 0.5-1.2wt% of Si, 0.5-1.8wt% of Mn, 8.5-23.5wt% of Zn, 0.20-0.60wt% of Fe and the balance of Al and inevitable impurities. The aluminium alloy material disclosed by the invention has the advantages of high strength property and solderability, excellent corrosion resistance and good machinability, and is especially suitable to serve as the radiator heat pipe.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

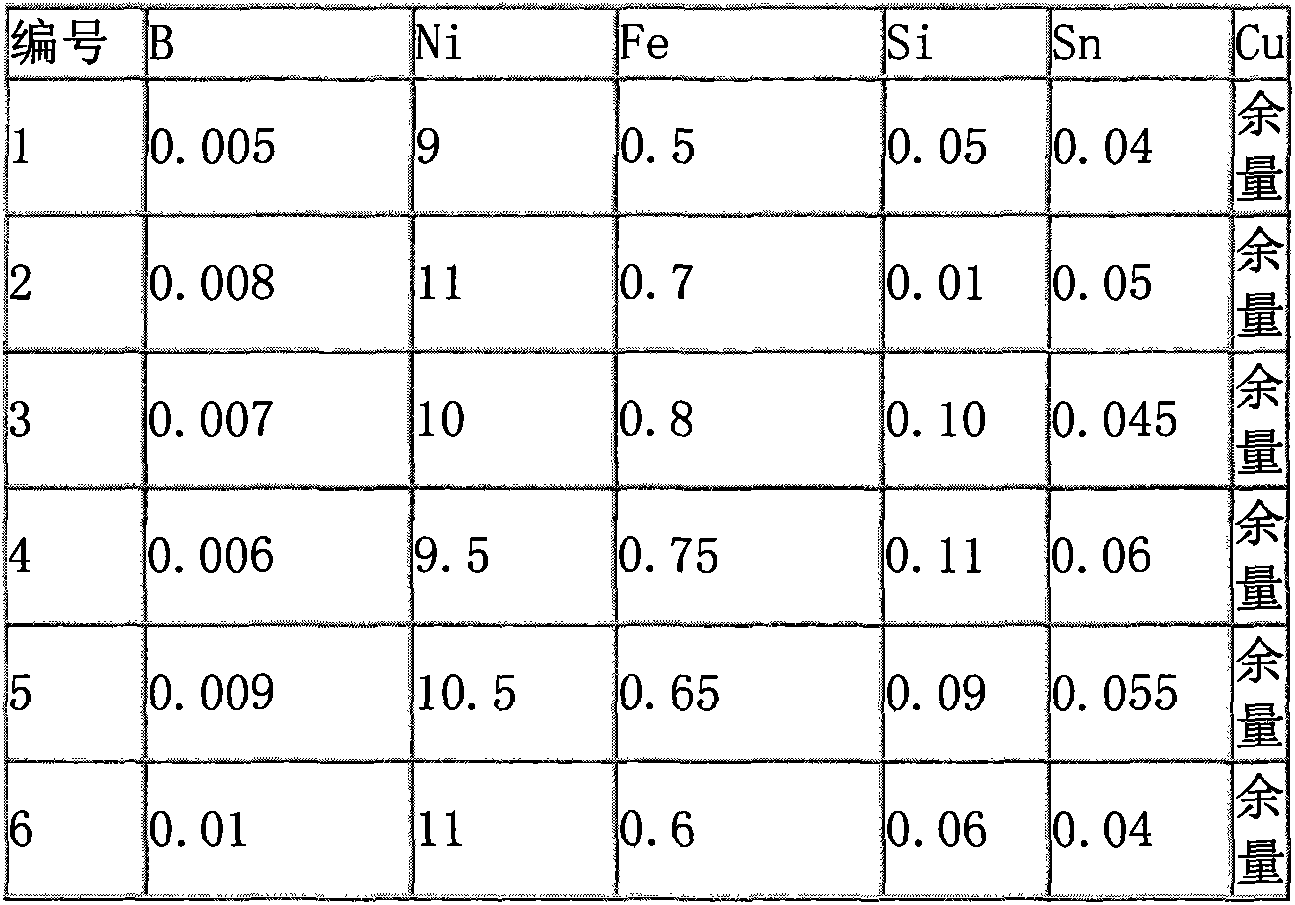

Copper-nickel alloy

The present invention relates to a copper-nickel alloy, which comprises (wt%), 9-11% of Ni, 0.5-0.8% of Fe, 0.005-0.01% of boron, less than or equal to 0.13% of Si, 0.04-0.06% of Sn, and the balance of copper. The heat exchange plate manufactured from the copper-nickel alloy has advantages of low cost, high strength characteristic, high solderability, excellent corrosion resistance, and good workability.

Owner:贵州合润铝业新材料科技股份有限公司

Zinc alloy

The invention provides a zinc alloy, comprising 3.5-4.3% of aluminum, 0.5-0.9% of copper, 0.08-0.15% of magnesium, and the balance of zinc and other impurities, wherein the content of Fe is not more than 0.1%, the content of lead is not more than 0.015%, the content of cadmium is not more than 0.01%, the content of tin is not more than 0.005%, and the above content refers to weight percentage. The temperature of the solution in the preparation of the above environment-friendly zinc alloy is controlled within the range from 390 DEG C to 410 DEG C, each harmful impurity in the zinc alloy is controlled within the range specified by RoHS (restriction of the use of certain hazardous substances), so that the property of the zinc alloy is enhanced, and the damages to environment and human bodies are reduced.

Owner:SIHUI FENGYIXIN METAL CASTING

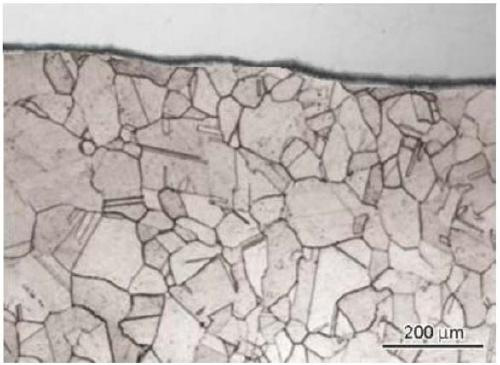

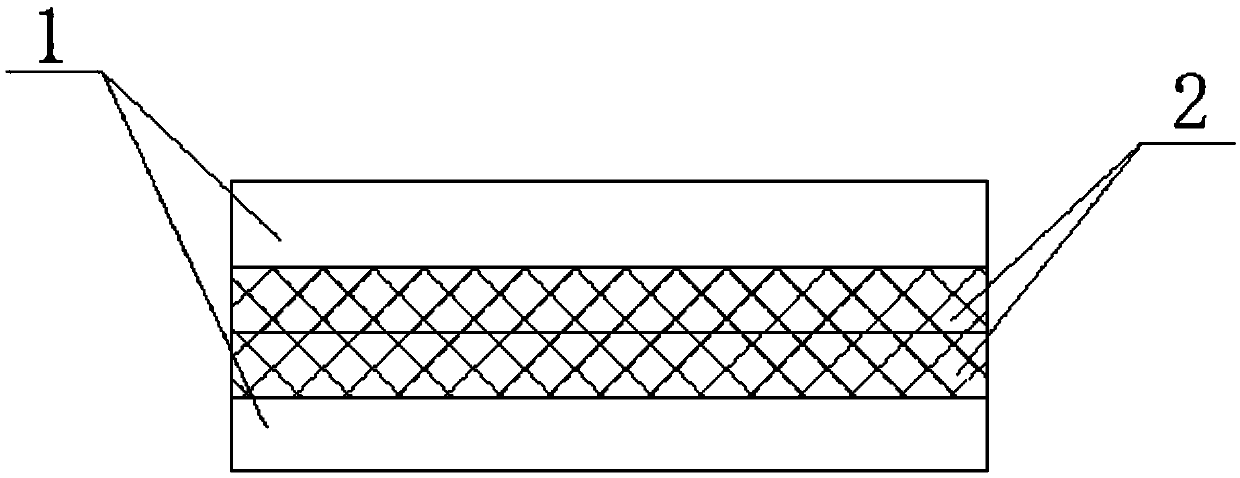

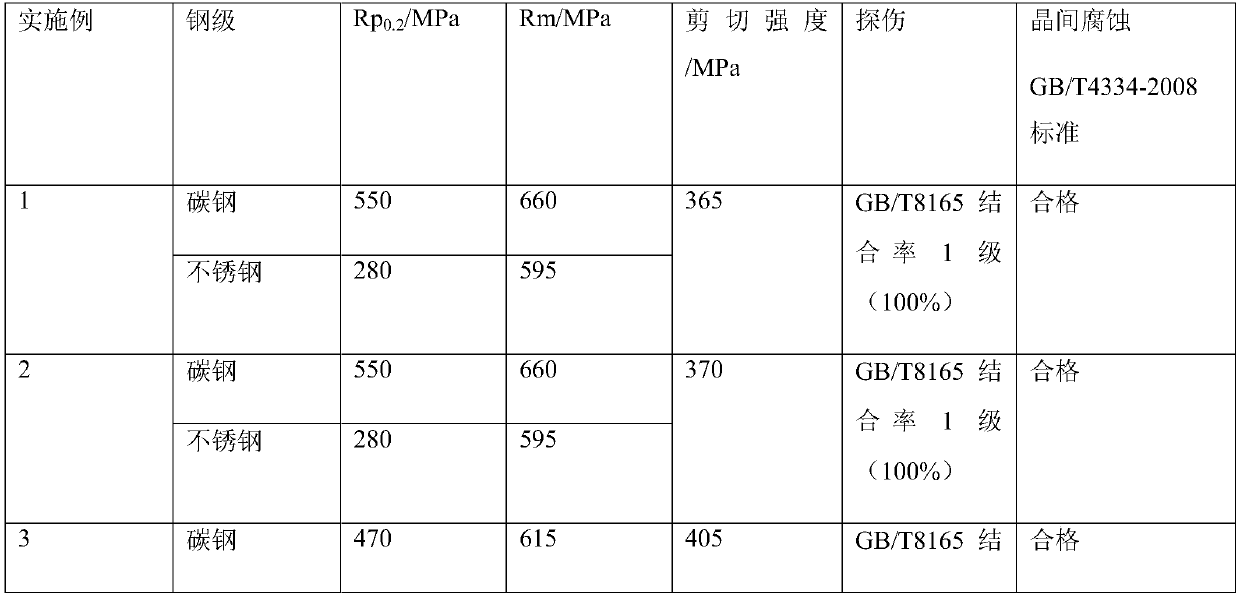

Stainless-steel and carbon-steel composite plate and preparation method thereof

ActiveCN109591396AReduce intergranular corrosionReduce Cr-poorMetal layered productsSteel platesCarbon steel

The invention discloses a stainless-steel and carbon-steel composite plate and a preparation method thereof. The stainless-steel and carbon-steel composite board is manufactured by stacking and compositing of a carbon-steel plate, a stainless-steel plate, a stainless-steel plate and a carbon-steel plate in sequence, wherein the carbon-steel plate comprises the following metal components in percentby weight: 0.15-0.20% of C, 0.19-0.35% of Si, 0.5-1.0% of Mn, 0.02-0.025% of S, 0.023-0.025% of P, 0.04-0.06% of Cr, 0.02-0.05% of Nb, 0.04-0.06% of Al, 0.40-0.60% of Ni and the balance of Fe; the stainless-steel plate comprises the following metal components in percent by weight: 0.07-0.075% of C, 0.65-0.75% of Si, 1.4-1.8% of Mn, 0.003-0.01% of S, 0.035-0.04% of P, 18-20% of Cr, 8.5-13% of Ni,0.02-0.05% of Nb, 0.10-0.15% of Al, 0.30-0.45% of Cu, 0.18-0.20% of Ti and the balance of Fe. The stainless-steel and carbon-steel composite plate and the preparation method disclosed by the inventionhave the beneficial effects that the corrosion resistance is good and the phenomenon of intercrystalline corrosion can be effectively reduced.

Owner:宁波市博祥新材料科技有限公司

Lead-acid battery positive-grid low antimony alloy

InactiveCN107681162AAdd lessReduce self-discharge phenomenonElectrode carriers/collectorsLead-acid accumulator electrodesRare-earth elementOver potential

The present invention relates to a lead-acid battery positive-grid low antimony alloy. The alloy comprises, by weight, 0.07-1.5% of manganese, 0.005-0.008% of silver, 0.05-0.12% of tin, 1.2-2.5% of antimony, 0.07-0.15% of rare earth element(s), and the balance lead. The rare earth element(s) is one kind or several kinds of ytterbium, samarium and lanthanum. According to the alloy, by adding the manganese, the silver and the rare earth element(s) into the low antimony alloy, the problems of low hydrogen evolution over-potential and easiness for losing water of the low antimony alloy are solved,the electrical conductivity, the strength, the hardness and the creep resistance of the alloy are improved, the capability of deep discharging cycle of a battery is improved, and the life of the battery is greatly improved.

Owner:WUHAN YIWEIDENG TECH DEV

Zinc alloy

InactiveCN102766784AReduce intergranular corrosionImprove mechanical propertiesHazardous substanceZinc alloys

The invention provides zinc alloy. The zinc alloy comprises, by weight percent, 3.5%-4.3% of aluminum, 0.1%-0.25% of copper, 0.05%-0.1% of magnesium, the balance of zinc and other impurities, not larger than 0.1% of iron, not larger than 0.005% of lead, not larger than 0.004% of cadmium, and not larger than 0.003% of tin. Melt temperature is controlled at 390-410 DEG C during production of the zinc alloy. Detrimental impurities in the zinc alloy are controlled within the range specified by the RoHs (restriction of hazardous substances) regulation. The performance of the zinc alloy is improved, and harm to environment and human health is reduced.

Owner:SIHUI FENGYIXIN METAL CASTING

Zinc alloy

InactiveCN102766783AReduce intergranular corrosionImprove mechanical propertiesHazardous substanceZinc alloys

The invention provides zinc alloy. The zinc alloy comprises, by weight percent, 3.9%-4.3% of aluminum, 0.03%-0.06% of magnesium, the balance of zinc and other impurities, not larger than 0.03% of copper, not larger than 0.1% of iron, not larger than 0.005% of lead, not larger than 0.003% of cadmium, not larger than 0.002% of tin. Melt temperature is controlled at 390-410 DEG C during production of the zinc alloy, and the produced zinc alloy meets the RoHs (restriction of hazardous substances) standard of European Union. Overall performance of the zinc alloy is improved, resources are saved, and pollution is lowered.

Owner:SIHUI FENGYIXIN METAL CASTING

Aluminium alloy material for radiator cooling fin

The invention relates to an aluminium alloy material for a radiator cooling fin, which is characterized by comprising the following components in percentage by weight: 0.3-0.85wt% of B, 0.5-1.8wt% of Mn, 10.5-27.5wt% of Zn, 0.05-0.30wt% of Ni and the balance of Al and inevitable impurities. The aluminium alloy material for a radiator cooling fin has the advantages of high strength property and solderability, excellent corrosion resistance and good machinability, and is especially suitable to serve as the radiator cooling fin.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

Antibiotic corrosion resistant heat exchanger aluminum pipe

InactiveCN102330000AImprove corrosion resistanceGood antibacterial propertiesHeat exchange apparatusBacilliCorrosion resistant

The invention relates to an antibiotic corrosion resistant heat exchanger aluminum pipe, which is characterized by being prepared from the following materials: 0.3 to 0.85 weight percent of B, 0.5 to 1.8 weight percent of Mn, 10.5 to 27.5 weight percent of Zn, 0.05 to 0.30 weight percent of Ni, 0.01 to 0.02 weight percent of Ag and the balance Al and inevitable impurities. Security compass web application auditing tool (SWAAT) experiments are adopted for testing the corrosion behavior of the alloy material and show that the corrosion resistance of the aluminum alloy is obviously improved, and in addition, the heat exchanger aluminum pipe has good antibacterial property and has more than 99 percent antibacterial rate on colon bacilli and staphylococcus aureus.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

Novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y

InactiveCN108588503AAvoid corrosionReduced service lifeHot-dipping/immersion processesAlloyDip-coating

The invention discloses a novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y. The alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Na,1.5-1.8% of Ti, 0.4-0.8% of Ca, 15.0-22.0 % of Sn, 0.2-0.4% of Y, 0.3-0.5% of Yb, 0.1-0.2% of P and the balance aluminum. By means of the hot dip coating aluminum tin alloy, the key problems that thetechnology in the present hot dip coating alloy field lags behind, product quality is poor, the product cost is high, energy consumption is large, and the like are solved, and in the near future, thealloy will be applied to more fields more widely.

Owner:GUANGZHOU YUZHI TECH CO LTD

Rare earth alloy hot-dip coating steel plate and production method thereof

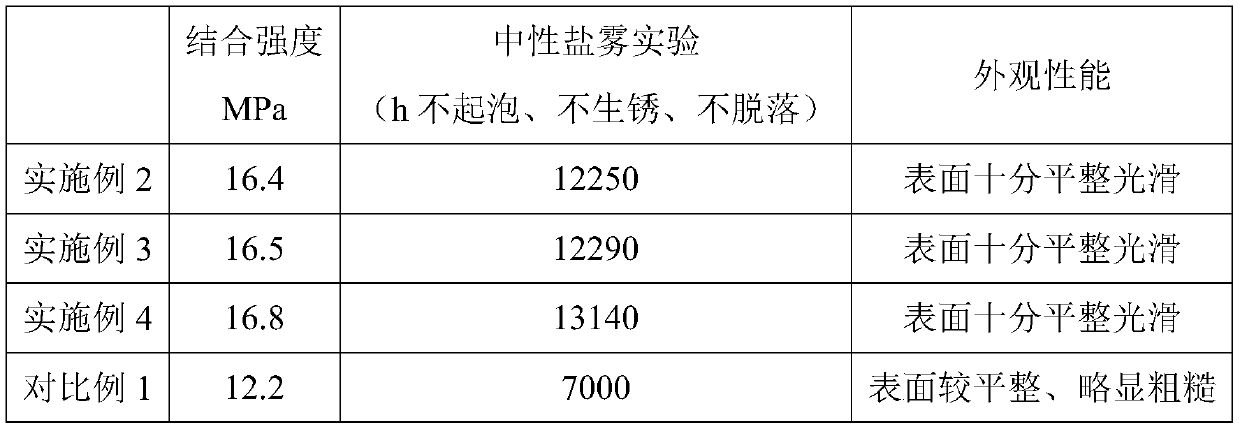

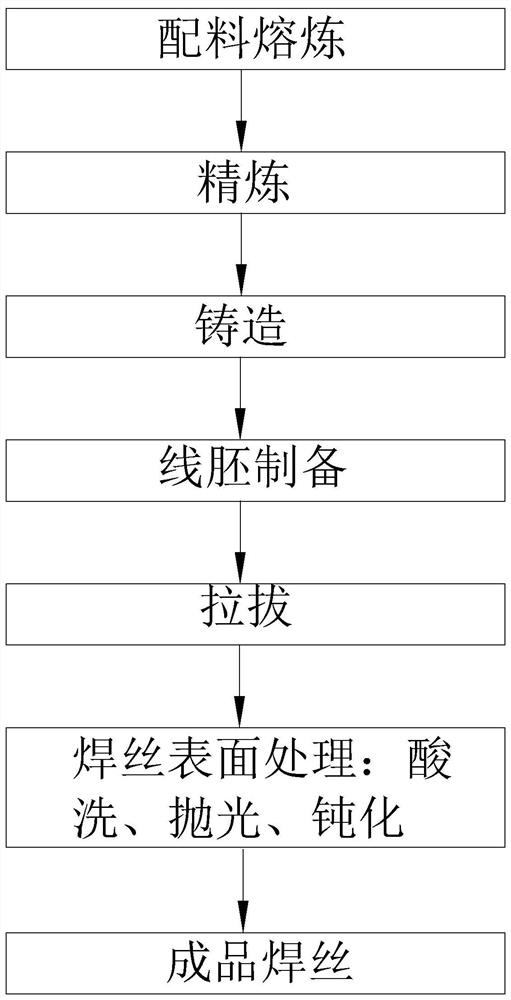

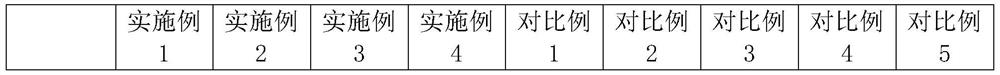

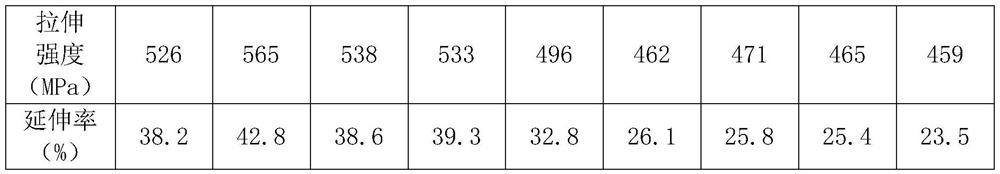

ActiveCN110777316AHigh tensile bond strengthImprove corrosion resistanceHot-dipping/immersion processesAlloyDip-coating

The invention discloses a rare earth alloy hot-dip coating steel plate and a production method thereof. The rare earth alloy hot-dip coating steel plate comprises a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the rare earth alloy hot-dip coating comprises, by mass, 0.1-0.8% of magnesium, 0.05- 0.15% of aluminum, 0.002-0.090% of lanthanum and vanadium, 0.03-0.09% of nickel, 0.01-0.25% of bismuth, 0.05-0.13% of lead and the balance zinc and inevitable impurities; and the ratio of the mass of the lanthanum and the vanadium is 1: (0.42-0.48). According to the rare earth alloy hot-dip coating steel plate, the tensile bonding strength of the rare earth alloy hot-dip coating and the base steel plate is high; in the case of the same thickness of the coating, compared with a traditional pure zinc coating, the corrosion resistance of the rare earth alloy hot-dip coating steel plate is greatly improved to 175% or above; and the obtained coating surface is quite smooth.

Owner:JINJIANG ANNENG BUILDING MATERIALS MFG

Copper alloy material of radiating fin of radiator

InactiveCN102363847AImprove corrosion resistanceHigh strengthHeat exchange apparatusHeat resistanceUltimate tensile strength

The invention relates to a copper alloy material of a radiating fin of a radiator. The copper alloy material comprises 0.5-1.2 wt% of Sn, 0.05-0.10 wt% of P, 2.2-8.5 wt% of Zn, 1.2-5.0 wt% of Ni, 0.5-1.2 wt% of Co, 0.3-1.2 wt% of Ti, and the balance Cu and avoidless impurities. The copper alloy material of the present invention, which has a good heat resistance, allows the excellent strength performance of the preparative copper alloy radiating fin of the radiator to be still maintained when the copper alloy radiating fin of the radiator is heated to a high temperature of 750DEG C; and the copper alloy material has an excellent processing performance, especially a cold working performance.

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

A kind of ultra-low carbon high temperature resistant welding wire and preparation method thereof

ActiveCN110551951BReduce formationReduce intergranular corrosionWelding/cutting media/materialsSoldering mediaImpurityMaterials science

The invention relates to an ultralow-carbon high-temperature-resistant welding wire and a preparation method thereof. The ultralow-carbon high-temperature-resistant welding wire comprises the following chemical components, in percentage by mass, of 0.01%-0.04% of C, 22.0%-24.0% of Cr, 1.5%-3.5% of Si, 12.0%-14.0% of Ni, 0.5%-1.2% of Ti, 0.1%-0.4% of Mn, 0.2%-0.5% of Zr, 0.3%-0.6% of Sc, 0.1%-0.3%of Mo, 0.3%-0.5% of Nb, 3.0%-5.0% of Mg, 0.6%-1.2% of Al, 0.03%-0.07% of P, 0.02%-0.05% of S, 0.2%-0.4% of V, 1.3%-1.6% of B, and the balance Fe and other inevitable impurity elements. According to the method, the mechanical property of the welding wire can be improved while the low carbon of the welding wire is ensured.

Owner:常州长海焊材有限公司

Storage battery grid alloy and preparation method thereof

ActiveCN111647769AHigh electrical and thermal conductivity and corrosion resistanceReduce intergranular corrosionGrid alloySmelting process

The invention relates to a storage battery grid alloy and a preparation method thereof, which belong to the technical field of lead acid storage battery production, and solves the problem that environmental pollution is caused as existing grid alloy contains metal calcium, and lead slag is easily oxidized and generated in a smelting process. The storage battery grid alloy provided by the inventioncomprises 0.5-5% of a MAX-phase ceramic material, and the balance of pure lead; in the MAX-phase ceramic material, M is a transition metal element, A is a Sn element, and X is a carbon element. The preparation method for the storage battery grid alloy comprises the following steps: step 1, adopting a high-temperature microwave solid-phase synthesis method to prepare the MAX-phase ceramic material; step 2, preparing a mother alloy ingot; and step 3, forming the grid alloy. The MAX-phase material is adopted, so that inter-crystalline corrosion of the grid alloy is obviously reduced, the structure of an alloy crystalline grain interface is improved, strength, corrosion resistance, creep resistance, and the like of the alloy are remarkably improved.

Owner:CHAOWEI POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com