Storage battery grid alloy and preparation method thereof

A battery plate and alloy technology, applied in the field of battery grid alloy and its preparation, can solve the problems of easily oxidized lead slag, environmental pollution, etc., and achieve the reduction of intergranular corrosion, simple element composition, corrosion resistance and creep resistance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

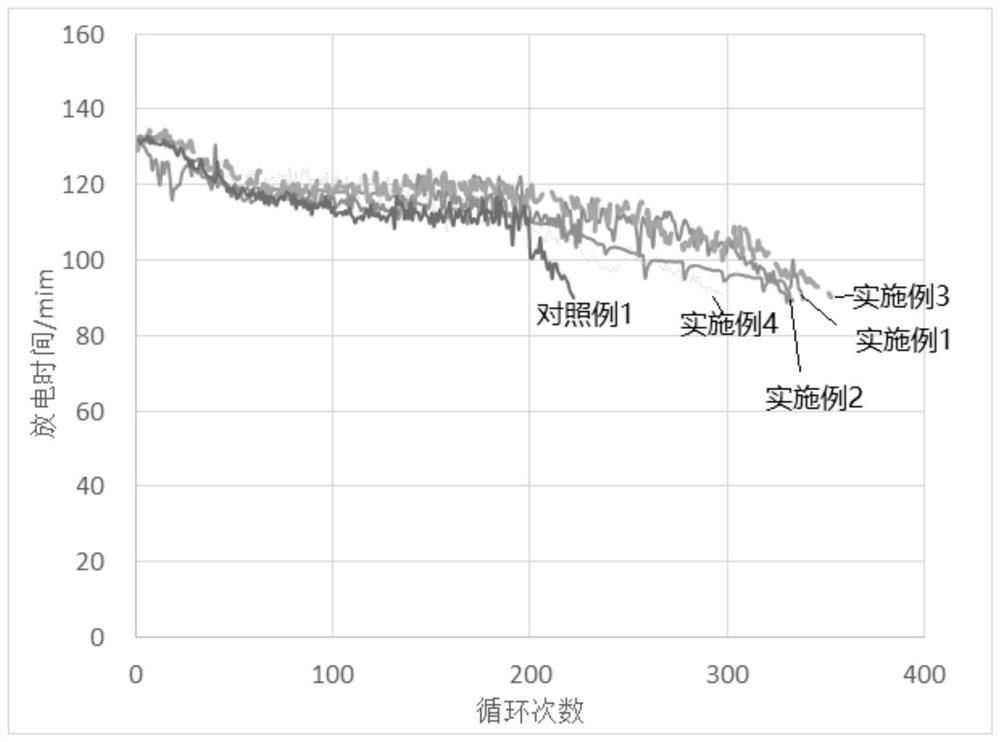

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing battery grid alloy, comprising the following steps:

[0042] Step 1, preparing MAX phase ceramic materials by high-temperature microwave solid-phase synthesis;

[0043] When using high-temperature microwave solid-phase method to synthesize MAX-phase ceramic materials, firstly, M element metal elemental powder, tin powder and graphite powder are added to the high-energy ball mill according to the molar ratio. Among them, the pressure of the powder compactor is 30-100 MPa, and the compaction time is 3-5 minutes; the bulk sample is put into a microwave sintering furnace for vacuum sintering to obtain the synthesized MAX material.

[0044] In the above step 1, the particle size of M element metal elemental powder, tin powder and graphite powder is 10-50 μm; the particle size of M element metal elemental powder, tin powder and graphite powder is strictly controlled because: too large particle size is not conducive to...

Embodiment 1

[0052] This embodiment 1 provides a preparation method of battery grid alloy, comprising the following steps:

[0053] Step 1, prepare Ti 2 SnC material;

[0054] Add Ti powder, Sn powder and graphite powder into the high-energy ball mill according to the molar ratio of 2:1:1. The average particle size of the powder is 50 μm. The speed of the ball mill is set at 1500 rpm, and the ball milling time is 2 hours. The sample mixed with the ball mill was pressed with a pressure of 30 MPa for 3 minutes, and vacuum sintered at 700 ° C for 8 hours in a microwave sintering furnace to obtain Ti 2 SnC material.

[0055] Step 2, prepare Ti 2 SnC master alloy ingot;

[0056] Dissolve 60 parts of electrolytic lead in the smelting furnace, keep the temperature at 550 ° C, and use lead skin to dissolve 10 parts of Ti 2 The SnC material is pressed into the melting furnace, fully stirred for 0.5h, then 30 parts of electrolytic lead is added, stirred for 0.5h, and finally cast into ingots to...

Embodiment 2

[0065] This embodiment 2 provides a preparation method of battery grid alloy, comprising the following steps:

[0066] Step 1, prepare Ti 3 SnC 2 Material;

[0067] Add Ti powder, Sn powder and graphite powder into the high-energy ball mill according to the molar ratio of 3:1:2. The average particle size of the powder is 15 μm. The speed of the ball mill is set at 1000 rpm, and the ball milling time is 1 h. The sample mixed with the ball mill was pressed with a pressure of 50 MPa for 3 minutes, and vacuum sintered at 800 ° C for 9 hours in a microwave sintering furnace to obtain Ti 2 SnC powder.

[0068] Step 2, prepare Ti 2 SnC master alloy ingot;

[0069] Dissolve 60 parts of electrolytic lead in the smelting furnace, keep the temperature at 560 ° C, and use lead skin to dissolve 10 parts of Ti 2 The SnC material is pressed into the melting furnace, fully stirred for 0.5h, then 30 parts of electrolytic lead is added, stirred for 0.5h, and finally cast into ingots to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com