Rare earth alloy hot-dip coating steel plate and production method thereof

A technology of rare earth alloy and production method, which is applied in hot-dip plating process, metal material coating process, coating, etc., which can solve the problems of poor overall performance such as appearance and strength, low bonding strength between coating and substrate, general corrosion resistance, etc. problems, to achieve the effect of flat and smooth coating surface, meet the requirements of heavy anti-corrosion, and high tensile bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

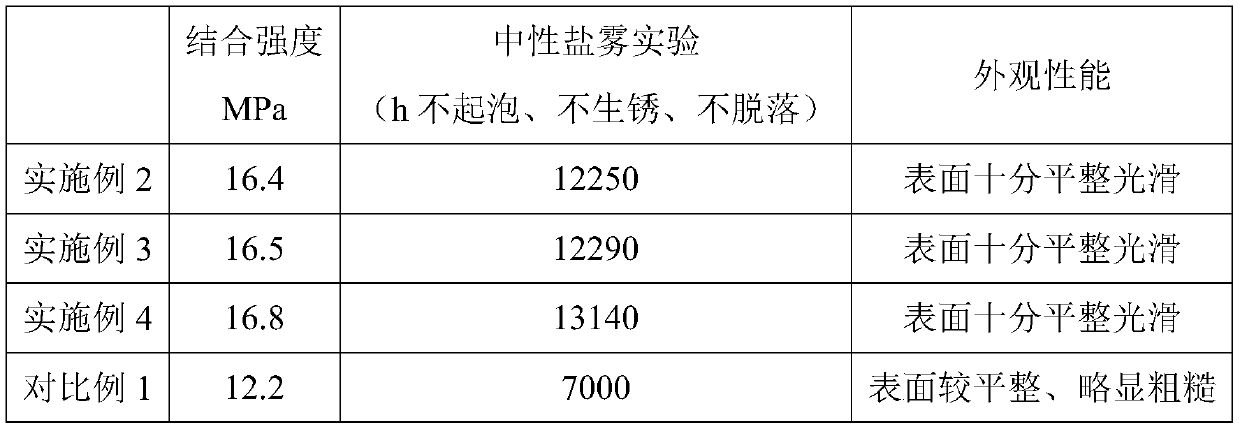

Examples

Embodiment 1

[0048] A rare earth alloy hot-dip coating steel plate, comprising a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the composition of the rare earth alloy hot-dip coating contains :

[0049] 0.1-0.8% magnesium, 0.05-0.15% aluminum, 0.002-0.090% lanthanum and vanadium, 0.03-0.09% nickel, 0.01-0.25% bismuth, 0.05-0.13% lead, and the remainder includes zinc and unavoidable impurities; among them, The mass ratio of lanthanum and vanadium is 1: (0.42-0.48).

[0050] Preferably, the composition of the rare earth alloy hot-dip coating contains in mass %:

[0051] 0.25-0.65% magnesium, 0.08-0.13% aluminum, 0.038-0.082% lanthanum and vanadium, 0.04-0.08% nickel, 0.11-0.21% bismuth, 0.07-0.12% lead, and the remainder includes zinc and unavoidable impurities; among them, The mass ratio of lanthanum and vanadium is 1:(0.44~0.47).

[0052] Preferably, the composition of the rare earth alloy hot-di...

Embodiment 2

[0067] A rare earth alloy hot-dip coating steel plate, comprising a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the composition of the rare earth alloy hot-dip coating contains :

[0068] Magnesium 0.25%, aluminum 0.08%, lanthanum and vanadium 0.038%, nickel 0.04%, bismuth 0.11%, lead 0.07%, the rest includes zinc and unavoidable impurities; among them, the mass ratio of lanthanum and vanadium is 1:0.44.

[0069] In this embodiment, the base steel plate is 45 carbon steel plate.

[0070] In this embodiment, the composition of the rare earth alloy hot-dip coating is in mass%, and further contains:

[0071] Ce 0.085%.

[0072] In this embodiment, the composition of the rare earth alloy hot-dip coating is in mass%, and further contains:

[0073] Titanium 0.092%.

[0074] In this embodiment, the production method of the rare earth alloy hot-dip coated steel sheet includes the followin...

Embodiment 3

[0082] A rare earth alloy hot-dip coating steel plate, comprising a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the composition of the rare earth alloy hot-dip coating contains :

[0083] Magnesium 0.65%, aluminum 0.13%, lanthanum and vanadium 0.082%, nickel 0.08%, bismuth 0.21%, lead 0.12%, the rest includes zinc and unavoidable impurities; among them, the mass ratio of lanthanum and vanadium is 1:0.47.

[0084] In this embodiment, the base steel plate is 45 carbon steel plate.

[0085] In this embodiment, the composition of the rare earth alloy hot-dip coating is in mass%, and further contains:

[0086] Ce 0.093%.

[0087] In this embodiment, the composition of the rare earth alloy hot-dip coating is in mass%, and further contains:

[0088] Titanium 0.110%.

[0089] In this embodiment, the production method of the rare earth alloy hot-dip coated steel sheet includes the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com