Preparation method of cracking-resistance and maintenance-free plastering mortar, product and construction method thereof

A plastering mortar and anti-cracking technology, applied in the field of plastering mortar, can solve the problems of large plastering thickness, inadequate maintenance, and the mortar is prone to crispness, etc., achieves good tensile bond strength, reduces maintenance costs, and formula design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

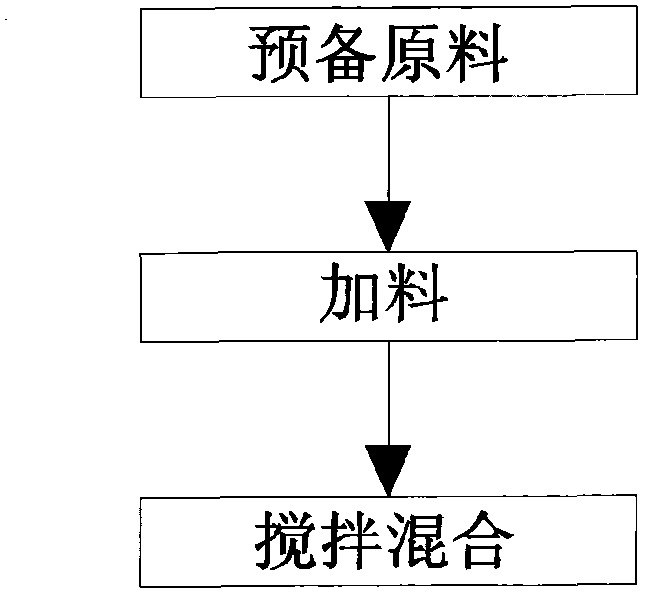

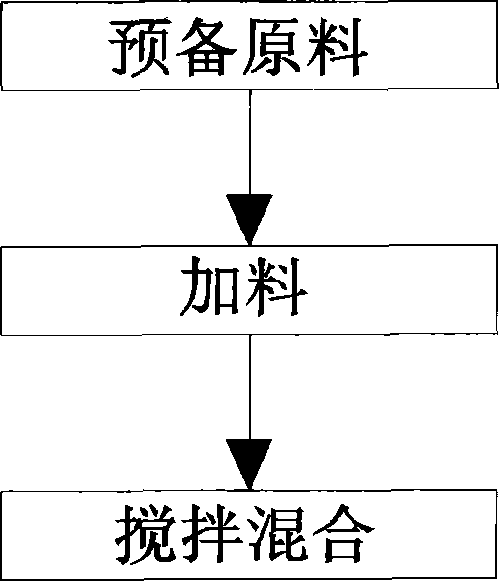

[0056] Embodiment 1: see figure 1 , a method for preparing anti-cracking and maintenance-free plastering mortar provided in this embodiment, comprising the following steps:

[0057] (1) Prepare raw materials: the components and weight ratios of the raw materials are as follows:

[0058] Cement 200Kg,

[0059] Secondary fly ash 30Kg,

[0060] Slaked lime 20Kg,

[0061] The dried medium sand is 746Kg,

[0064] Air-entraining agent 0.3Kg,

[0065] Polypropylene staple fiber 2Kg;

[0066] Water reducer 0.7Kg;

[0067] (2) Feeding: First add half of the cement and medium sand into the mixing equipment, and then add secondary fly ash, slaked lime, cellulose ether, starch ether, air-entraining agent, polypropylene short fiber and water reducer to mix equipment, and then add the remaining cement and medium sand to the mixing equipment;

[0068] (3) Stirring and mixing: start the mixing equipment and stir for 4 to 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com