Full-machine-made sand plastering mortar taking limestone as aggregate and preparation method thereof

A technology of limestone machine-made sand and plastering mortar, which is applied in the field of building materials, can solve the problems of poor water retention rate of river sand, artificial sand and mixed sand, weak bonding of the wall base, rapid water loss of mortar, etc., and achieves abundant stock. , the effect of alleviating the depletion of mining and increasing the water retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0038] In Preparation Example 1-3, the magnetic chitosan microspheres were selected from Zhengzhou Yingnuo Biotechnology Co., Ltd., the carbon nanotubes were selected from the carbon nanotubes sold by Beijing Deke Daojin Technology Co., Ltd., and the aluminum powder was selected from Foshan The aluminum powder sold by City Jieke New Material Co., Ltd. is AK11, and the silicon carbide is selected from the silicon carbide sold by Qinghe County Yaoxie Metal Materials Co., Ltd. with the model YX099.

preparation example 1

[0039] Preparation Example 1: (1) According to the ratio in Table 1, mix 2kg magnetic chitosan microspheres and 4kg paraffin wax, stir for 1.5h in a constant temperature water bath at 80°C, add 2.5kg aluminum powder and 1kg silicon carbide , stirred for 1 h under negative pressure, and dried in vacuum;

[0040] (2) Mix 3.5kg cornstarch with 2kg xanthan gum, gelatinize in a water bath at 90°C, add 0.1kg N,N-methylenebisacrylamide and 0.1kg sodium persulfate after cooling, and stir for 2 hours to obtain coating fluid;

[0041] (3) After uniformly mixing the coating liquid and the product obtained in step (1), add 1.2 kg of graphite and 1 kg of carbon nanotubes, stir evenly, and dry at 40° C.

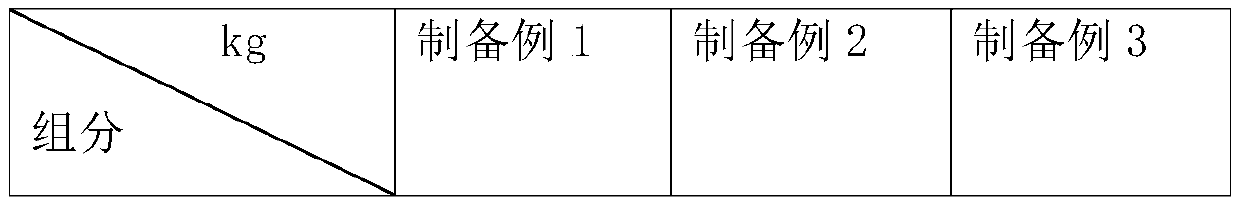

[0042] The raw material ratio of the fixed phase change material in the preparation example 1-3 of table 1

[0043]

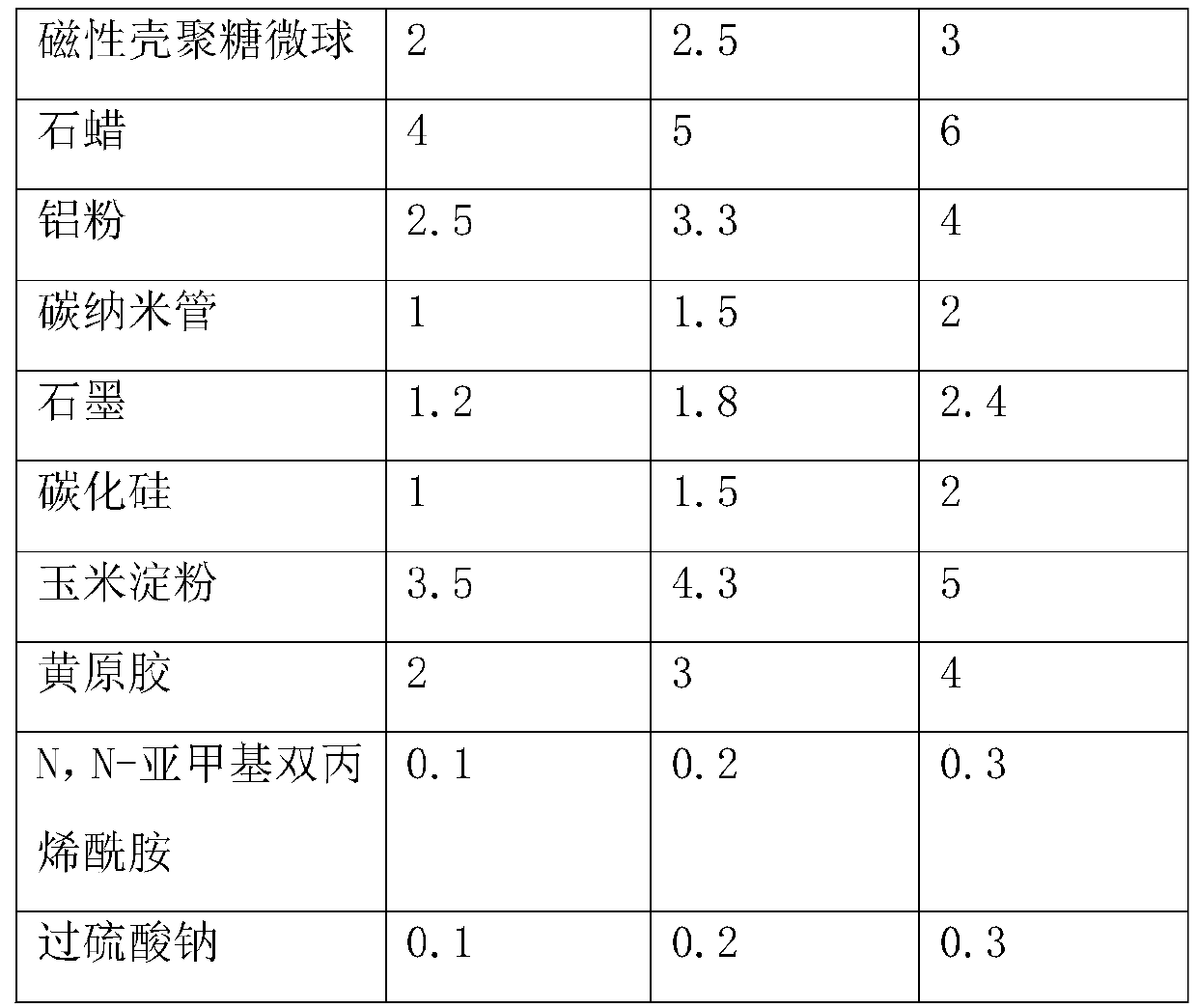

[0044]

preparation example 2

[0045] Preparation Example 2: (1) According to the proportioning in Table 1, mix 2.5kg of magnetic chitosan microspheres and 5kg of paraffin wax, stir for 1.3h in a constant temperature water bath at 85°C, add 3.3kg of aluminum powder and 1.5kg of Silicon carbide, stirred for 1.5h under negative pressure, and dried in vacuum;

[0046] (2) Mix 4.3kg cornstarch and 3kg xanthan gum, gelatinize in a water bath at 100°C, add 0.2kg N, N-methylenebisacrylamide and 0.2kg sodium persulfate after cooling, and stir for 2.5 hours to prepare get coating solution;

[0047] (3) After uniformly mixing the coating solution and the product obtained in step (1), add 1.8 kg of graphite and 1.5 kg of carbon nanotubes, stir evenly, and dry at 45° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com