A physical crushing and dissociation re-washing process for medium coal

A dissociation and washing technology, applied in grain processing, solid separation, etc., can solve the problems of reduced selectivity, poor economy, waste of resources, etc., to improve selectivity, improve resource recovery, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for physical crushing, dissociation and re-washing of medium coal, comprising the following steps:

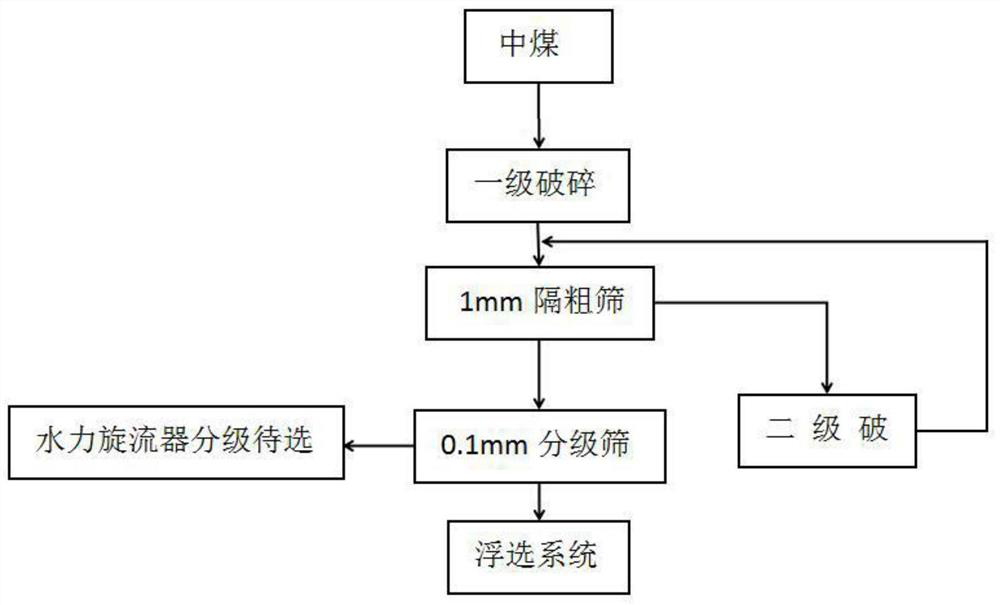

[0027] Step 1. The incoming medium coal is subjected to primary crushing and dissociation. After the crushing and dissociation, the medium coal is sieved through a 1.0mm coarse sieve, and the sieve with a particle size greater than 1.0mm enters the secondary crushing. After the secondary crushing, the medium coal Add water until the concentration is 200g / l, and then put it into a 1.0mm coarse sieve for coarse separation; add water to the undersize material with a particle size of less than 1.0mm to form a middling suspension, the concentration of the middling suspension does not exceed 400g / l, and then put the middling The coal suspension is put into the 0.1mm sieve grading sieve;

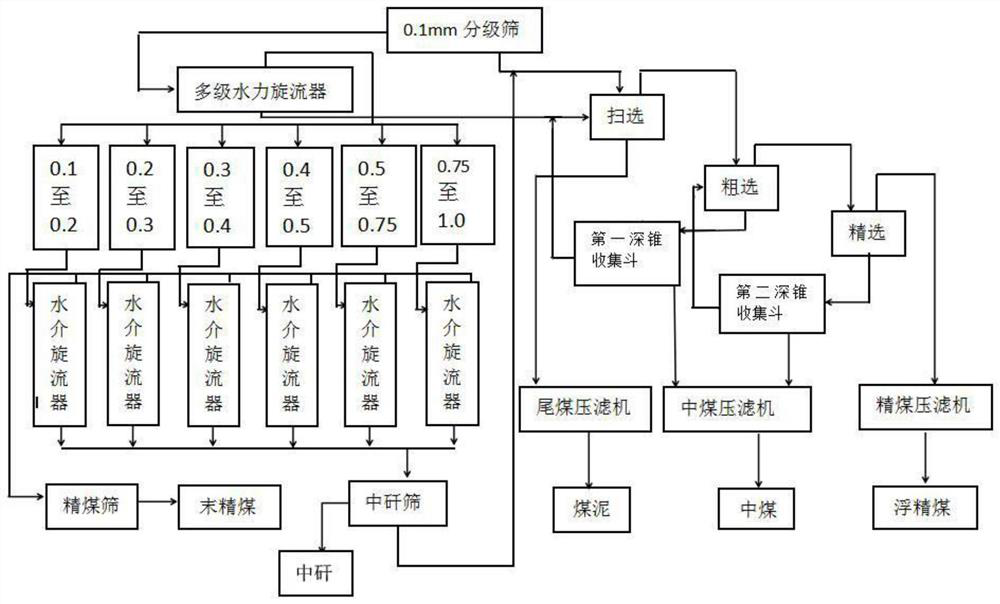

[0028] Step 2. After the 1.0-0.1mm oversize material classified by the 0.1mm mesh sieve is distributed with water, it enters the multi-stage hydrocyclone for secondary classificatio...

Embodiment 2

[0038] 1. Analyze the medium coal in different regions and different coal washing plants, and find out the particle size class with more clean coal (taking the No. 8 Coal Washing Plant of Pingdingshan Coal Co., Ltd. as an example, the particle size class with more clean coal is between 0.5mm and 1mm , other coal washing plants can be found out through experiments). Select the crushing and dissociation equipment (the combined mode of hammer crushing and ball milling can be selected to grind medium coal to 1mm to 200 mesh).

[0039] 2. Set the grinding dissociation particle size.

[0040] 3. According to figure 1 , figure 2 The process schematic diagram determines the process plan. It is also possible to design, construct or renovate existing washing systems.

[0041] 4. Implement crushing and dissociation for unsuitable coal preparation, so that coal and pollutants are separated, and enter the corresponding washing system.

[0042] Table 1: Screening data of middle coal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com