Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce deformation cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-quenching high-toughness cold-working die steel and production process

InactiveCN101713052AReasonable ratioImprove compactnessMetal-working apparatusManufacturing technologyIntermediate frequency

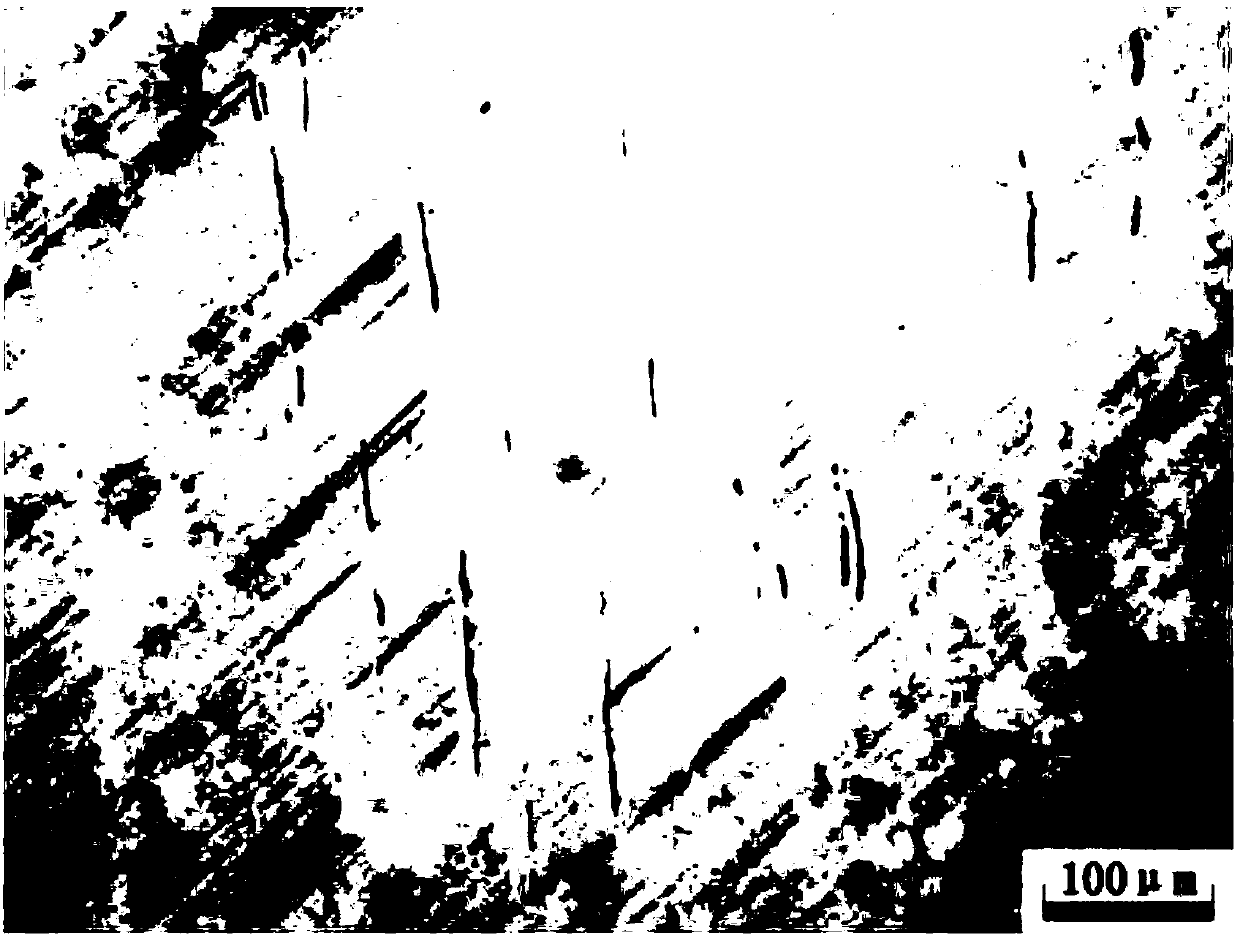

The invention relates to a non-quenching high-toughness cold-working die steel belonging to the technical field of metallurgical manufacture. The novel cold-working die steel is developed by optimizing and creating a product component formula, adding alloy elements, rolled and cold thinned texture and adopting the processes of remelting and fining electroslag in an electric furnace, forging many times in a great forging proportion and special heat treatment. The manufacture process comprises the following flows: selecting a chemical component range; drawing an ingredient scheme according to the chemical component range; melting at an intermediate frequency; remelting (refining) the electroslag; annealing; discharging; extending hydrogen; forging; normalizing; tempering; mechanically processing; and detecting. The important manufacture process comprises the steps: (1) refining; (2) forging; (3) extending hydrogen; and (4) normalizing; and tempering so as to obtain non-quenching high-toughness cold-working die steel. The invention has reasonable chemical component proportion, low manufacture cost, good alloying effect, great forging transformer ratio, favorable density of metal structure and high toughness performance index. Various performance indexes of the product reach or exceed the levels of similar international and national products.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Non-quenched and tempered steel and method for manufacturing automobile semi-axle using non-quenched and tempered steel

InactiveCN109554618AImprove mechanical propertiesReduce preparation energy consumptionQuenchingImpurity

The invention discloses non-quenched and tempered steel and a method for manufacturing an automobile semi-axle by using the non-quenched and tempered steel. The non-quenched and tempered steel is prepared from the components in percentage by mass: 0.43-0.47% of C, 0.50-0.80% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.035% of S, 0.15-0.30% of Cr, 0.10-0.15%of V, 0.01-0.05% of Al, less than or equal to 0.045% of Nb, 0.015-0.035% of Ti, 0.01-0.02% of N, less than or equal to 0.25% of Ni, less than or equal to 0.10% of Mo, less than or equal to 0.03% of Sn, less than or equal to 0.20% of Cu and the balance of Fe and impurities. According to the non-quenched and tempered steel and the method for manufacturing the automobile semi-axle by using the non-quenched and tempered steel, the high-performance micro-alloyed non-quenched and tempered steel is adopted to replace 42CrMoH quenched and tempered steel for the implementation of a semi-axle controlled-forging and controlled cooling manufacturing process, and the quenching and tempering heat treatment process is eliminated, so that energy consumption of the automobile semi-axle manufacturing can besaved by 40-50%, the cost can be reduced by 10-20%, meanwhile, deformation and cracking caused by quenching during quenching and tempering can be reduced, the straightening process is simplified, andthe technical level reaches the domestic leading position.

Owner:SHAANXI AUTOMOBILE GROUP +1

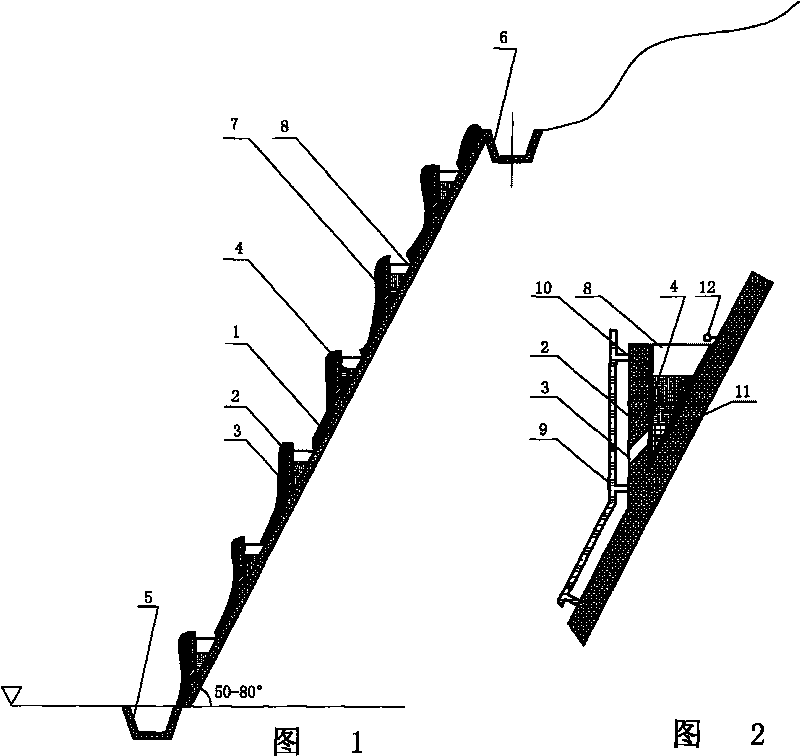

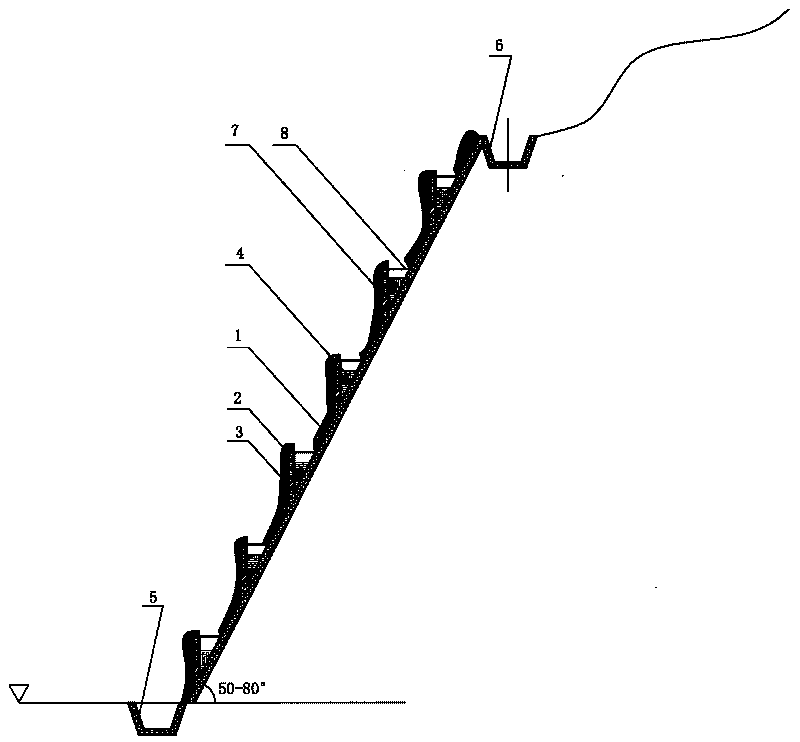

Stepped versant framed flower bed

InactiveCN101690457ASlope stabilityIncrease stiffnessExcavationsReceptacle cultivationTreatment effectEngineering

The invention discloses a stepped versant framed flower bed, which comprises a versant panel along a sloping surface of a versant, and a plurality of bed walls vertical to the ground; each bed wall is intersected with the versant panel at different heights of the versant panel; a space formed by each bed wall and the versant panel is the framed flower bed; the bed walls and the versant panel are formed by integral casting; the bed walls close to the upper parts of the intersection parts of the bed walls and the versant panel are provided with a plurality of downward inclined drain pipes in the horizontal direction; and green plants are planted or molded green plants are directly planted in the framed flower bed so as to play a role in greening the versant after artificial treatment, solve the problem that versants of northern areas and steep rock-soil versants have poor ecological greening treatment effect or are adverse to green, and also meet the requirement for quick greening. Due to the structural characteristics of the versant framed flower bed, after the bed walls and a versant anchor spray panel are formed by the integral casting, the integral rigidity of a versant reinforcing panel can be improved, and the service life of a versant reinforcing surface layer is prolonged.

Owner:CHINA JINGYE ENG +1

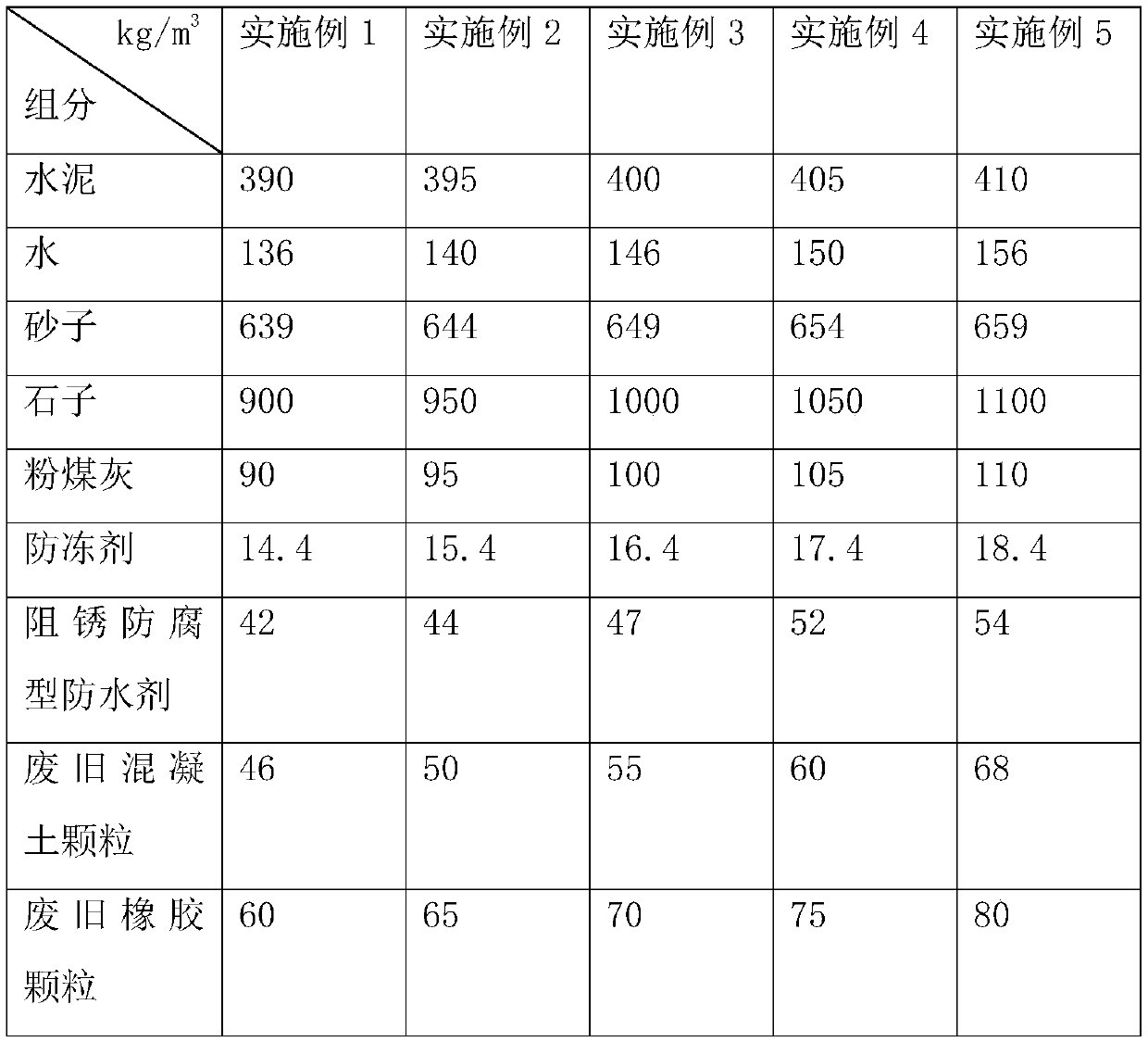

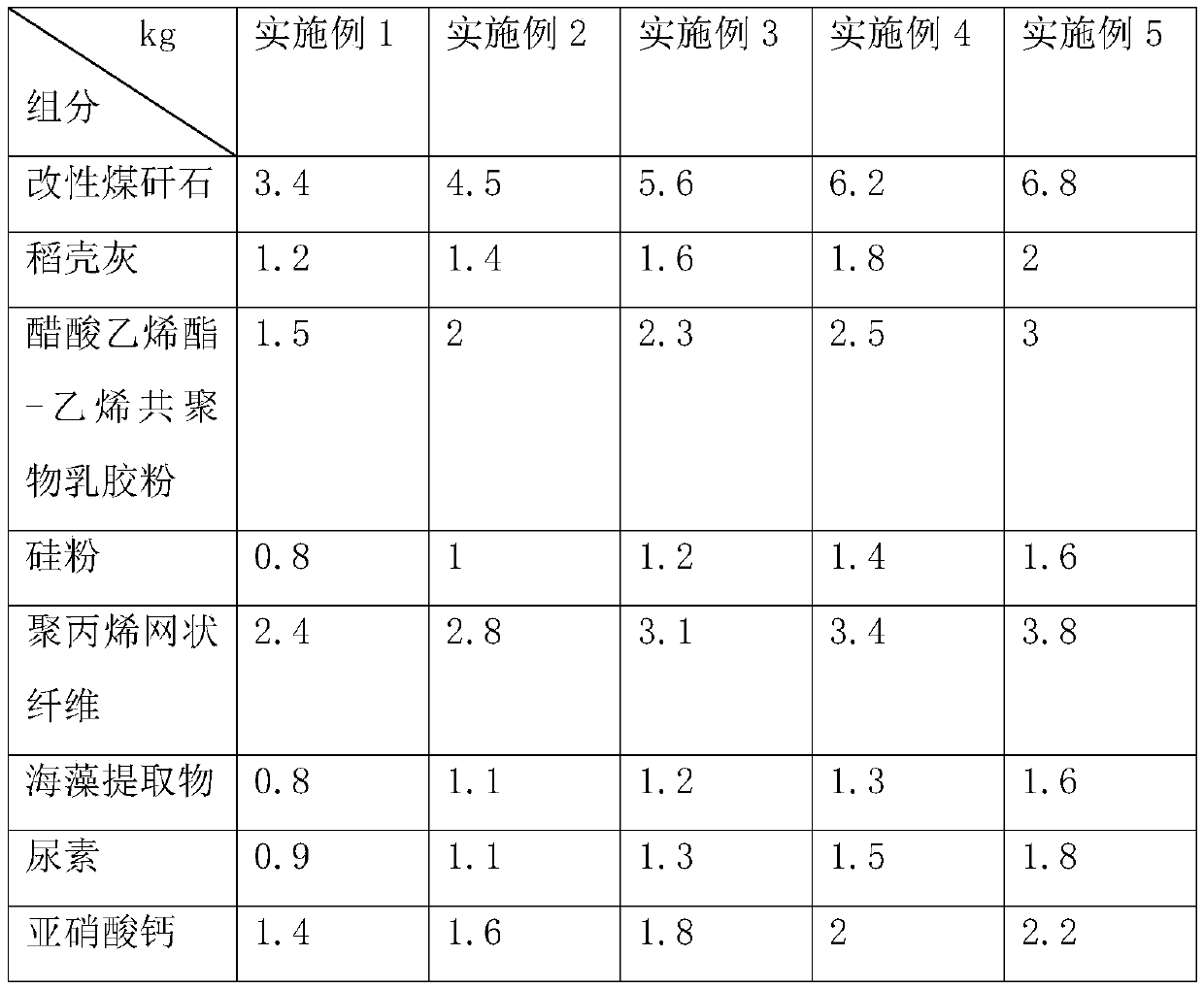

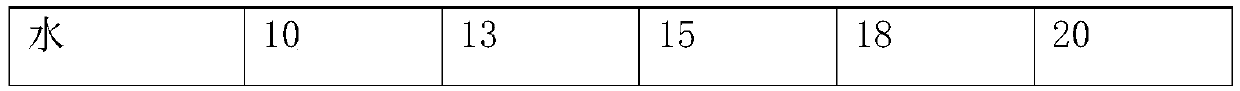

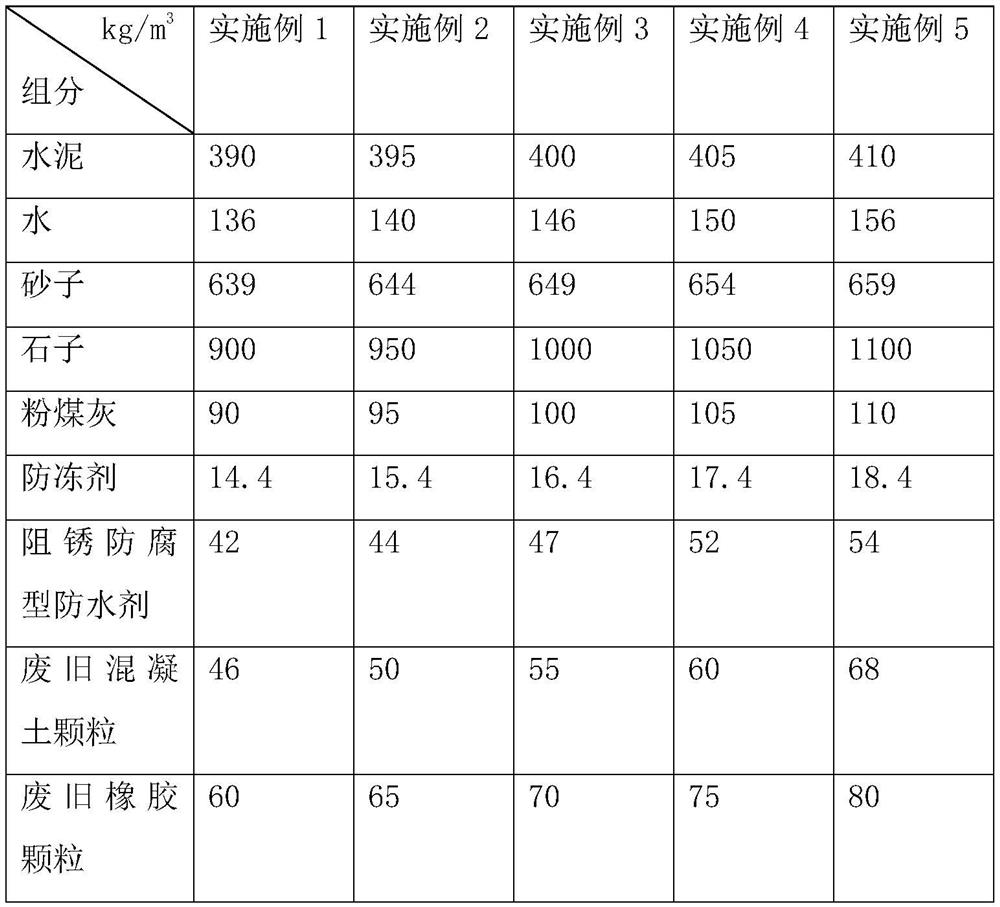

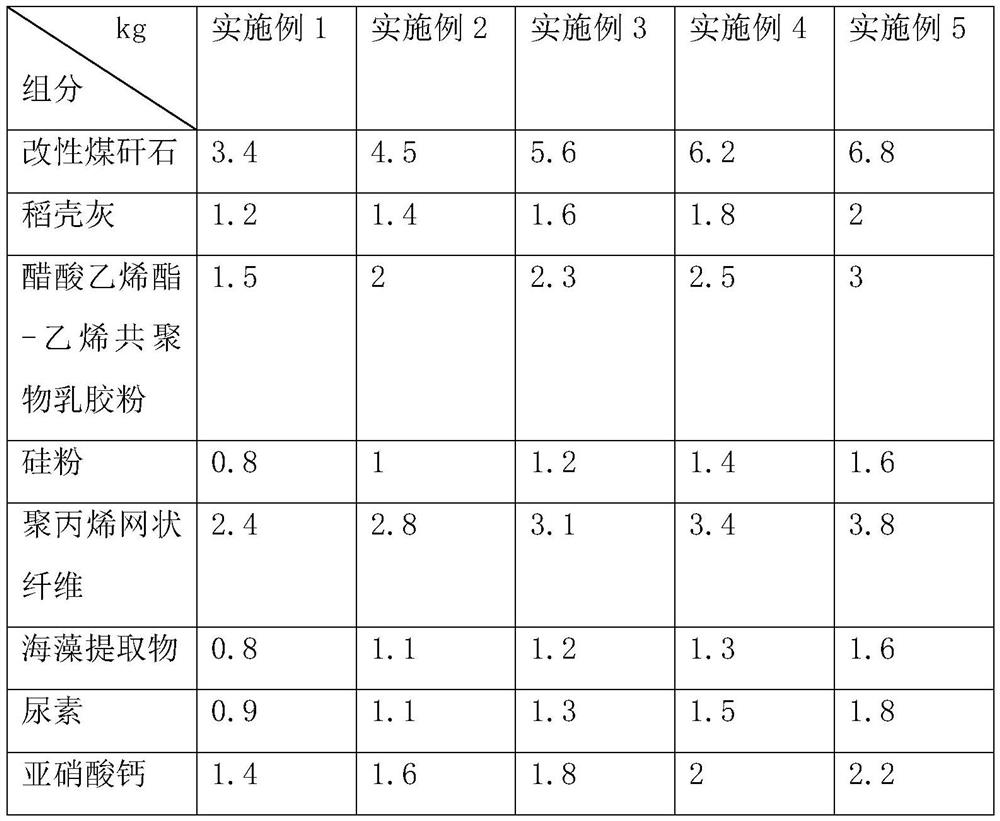

High-strength impermeable anti-freezing concrete and preparation method thereof

The invention discloses high-strength impermeable anti-freezing concrete and a preparation method thereof. The high-strength impermeable anti-freezing concrete is prepared from the following raw materials: cement, water, sand, stones, fly ash, an anti-freezing agent, a rust-inhibiting anti-corrosion waterproof agent, waste concrete particles and waste rubber particles. The anti-freezing agent is prepared from the following components in parts by weight: 3.4 to 6.8 parts of modified coal gangue; 1.2 to 2.0 parts of rice hull ash, 1.5 to 3 parts of vinyl acetate-ethylene copolymer latex powder;0.8 to 1.6 parts of silicon powder; 2.4 to 3.8 parts of polypropylene reticular fiber; 0.8 to 1.6 parts of seaweed extract; 0.9 to 1.8 parts of urea; 1.4 to 2.2 parts of calcium nitrite and 10 to 20 parts of water. The high-strength impermeable anti-freezing concrete has the advantages of effective utilization of waste materials, strong freeze-thaw resistance and mechanical properties, reduction of freeze-thaw diseases of concrete in cold regions, and purification of automobile exhaust.

Owner:青岛兴业商砼有限公司

Technology for making water-proof wood floor

A water-proof wooden floor is made up through steaming, baking, planing, slotting, painting and installation. It features that its painting step includes scraping the slotted wooden floor block except its surface with polyester putty, transparent putty or paint with sealing effect by one or two passes; after grinding, painting the said wooden floor block except its surface by 2 to 10 passes clearing off the surplus paint on the floor surface, and grinding the floor surface; and coating the floor surface with paint by 2 to 10 passes, and before each paint pass and after the previous paint being fully dried, grinding the floor surface. Its advantages are greatly reduced shrinkage, expansion, cracking and deforming, high water proof effect and long service life.

Owner:深圳市鸿飞装饰材料有限公司

Environment-friendly casting coated sand and method for preparing the coated sand

The invention discloses an environment-friendly casting coated sand, which is prepared by the following raw materials in parts by weight: 70-75 parts of quartz sand, 0.2-0.3 part of calcium stearate, 4-6 parts of corncob powder, 13-15 parts of magnesium olivine sands, 2-3 parts of water, 0.7-1 part of urotropine, 4-6 parts of a thermoplastic phenolic resin, 3-5 parts of isopropanol, 5-7 parts of Portland cement, 2.5-4 parts of boric acid, and 5-7 parts of a synergistic agent. An inorganic silicate binder is added into the environment-friendly casting coated sand, so that the use amount of the phenolic resin is reduced and the environment-friendly casting coated sand is still good in cohesiveness and strength; the boric acid is added so that the heat resisting property of the product is improved; the synergistic agent prepared by a special process is added into the environment-friendly casting coated sand, so that liquidity, breathability, heat dispersion and strength of the coated sand are enhanced, and the surface of the environment-friendly casting coated sand isn't easy to crack and deform. By adopting the prepared product, the environmental pollution can be alleviated and the production cost is reduced, the amount of generated gas is low, the casting quality is high and the casting surface is smooth.

Owner:FANCHANG COUNTY JINKE CASTING

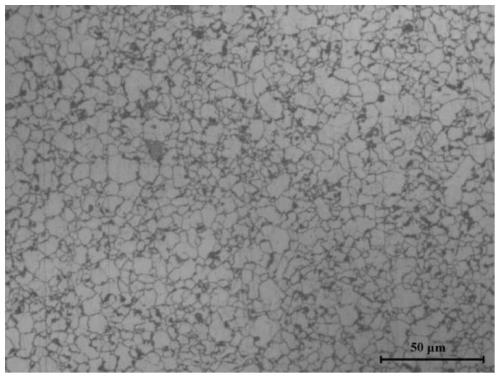

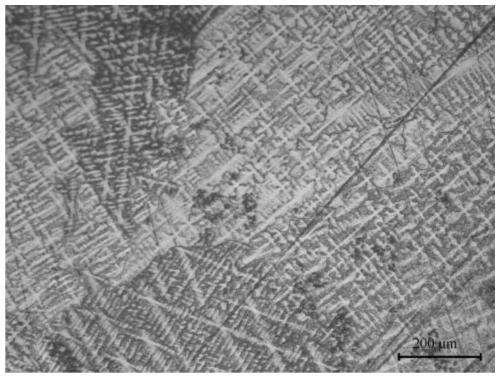

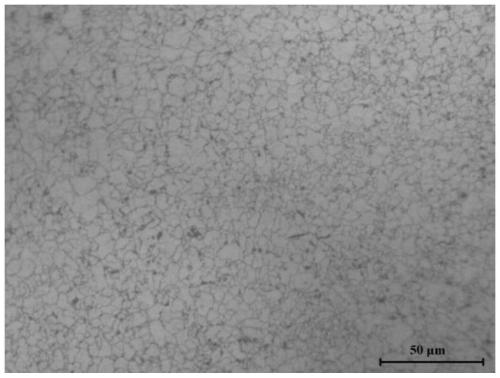

High-strength high-elasticity niobium-containing copper alloy and preparation method thereof

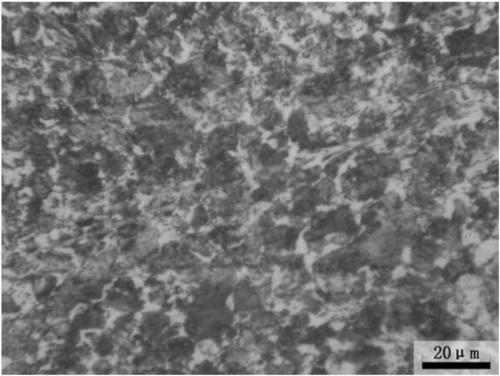

ActiveCN109763008AImprove plasticityIncrease elasticityTemperature control deviceMetal rolling arrangementsNiobiumHardness

The invention discloses a high-strength high-elasticity niobium-containing copper alloy and a preparation method thereof, and belongs to the technical field of copper alloy preparation. According to the high-strength high-elasticity niobium-containing copper alloy, the Vickers hardness is higher than or equal to 420 HV, the tensile strength is larger than or equal to 1300 MPa, the elongation is larger than or equal to 7.5%, the alloy grains are uniform and fine, the ultra-high strength, plasticity and elastic modulus are achieved, and the copper alloy and the preparation method can be widely used in the fields of high and new technologies such as automobiles, rail transits, electronic and electrical and aerospace; The preparation method of the high-strength high-elasticity niobium-containing copper alloy can effectively refine the grain size of the alloy, control the size and distribution of a precipitation second phase, strengthen the strength and elasticity of the alloy and improve the plasticity of the alloy.

Owner:CENT SOUTH UNIV

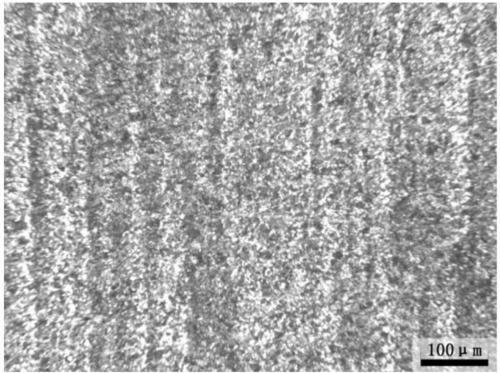

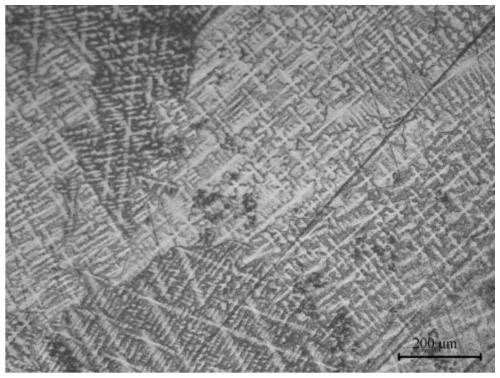

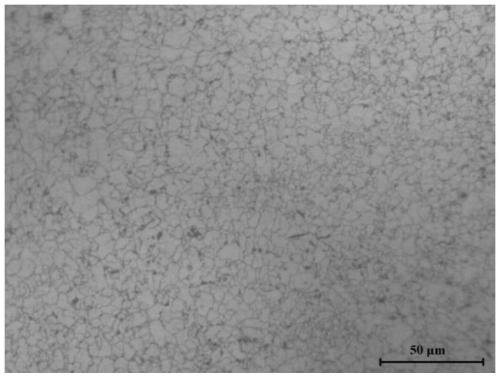

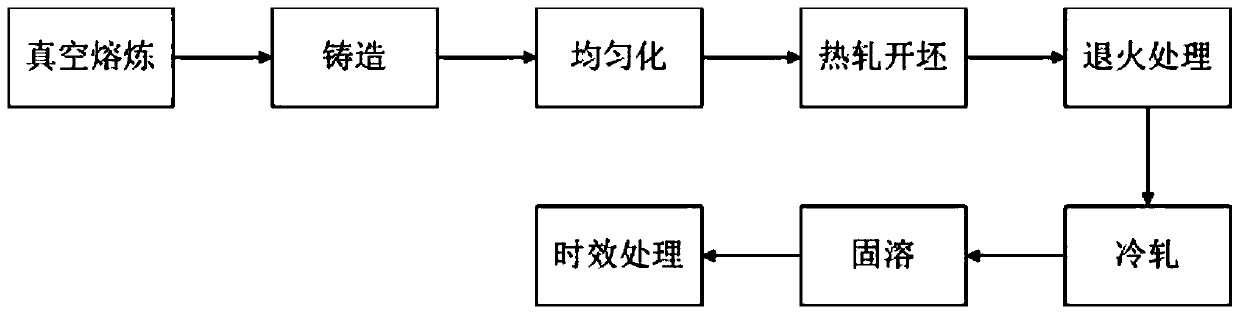

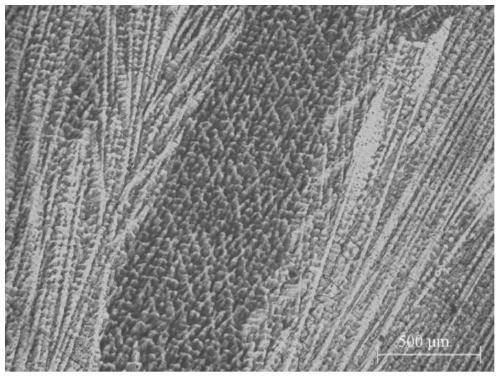

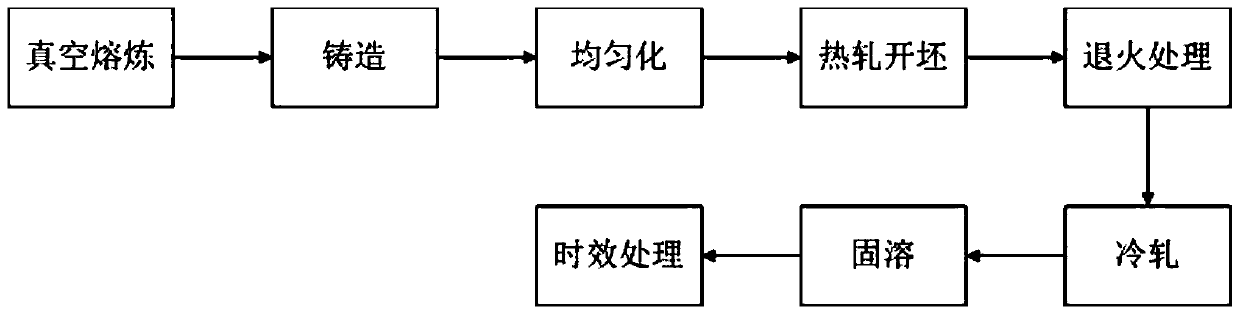

High-strength high-elasticity copper-nickel-manganese alloy and preparing method thereof

The invention discloses a high-strength high-elasticity copper-nickel-manganese alloy and a preparing method thereof, and belongs to the technical field of special material preparing. Vacuum smeltingis adopted, gas and low-smelting impurities can be sufficiently exhausted, a billet structure can be purified, an ingot microstructure is subjected to homogenization treatment and then subjected to hot rolling, deforming cracking caused by nonuniform components can be reduced, and meanwhile through hot rolling, coarse grains in the alloy can be broken; through large deforming cold rolling, grainsin the alloy can be further broken, the fiber deformed microstructure is formed, the solid-solution treatment is used for enabling the alloy structure to be subjected to perfect recrystallization, meanwhile, solute atoms are re-dissolved into a base body, a supersaturation solid solution is formed, through aging treatment, the solute atoms are separated out in a form of a second phase, temperatureand time of aging are controlled, the separated-out second phase is fine and evenly distributed in the base body, and the alloy strength can be reinforced.

Owner:CENT SOUTH UNIV

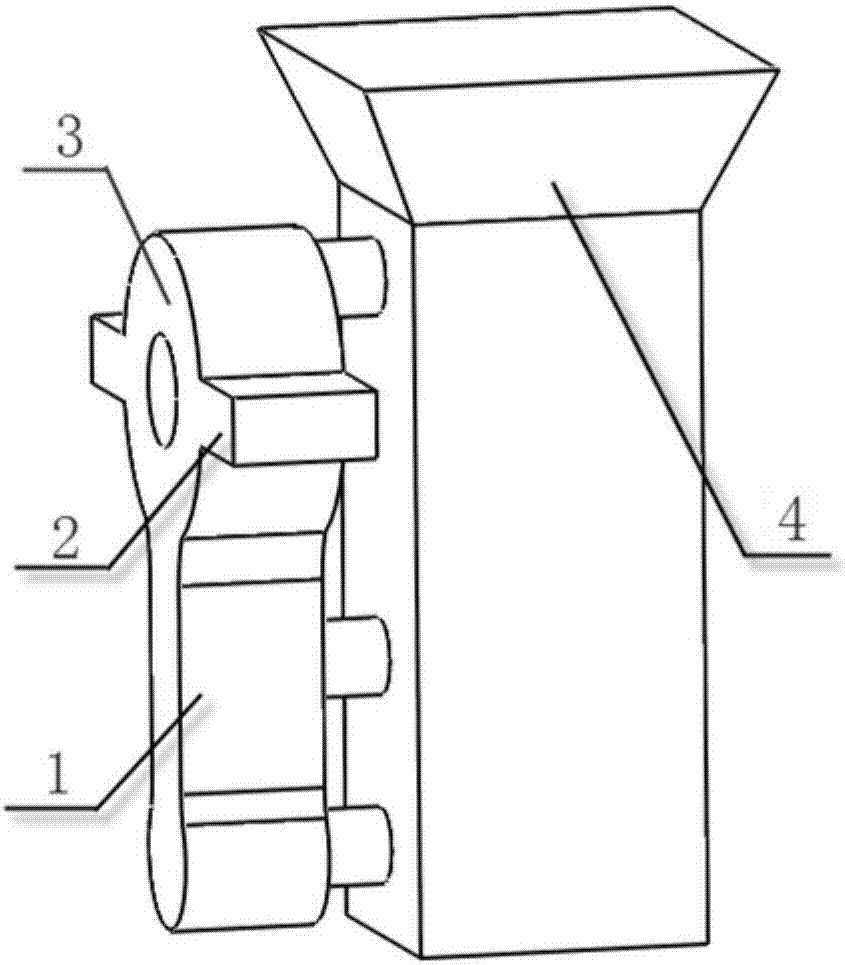

Method for forging steel bimetallic fracture splitting connecting rod

ActiveCN106994496ASolved manufacturing issues that could not be used to crack connecting rodsSolve the bonding qualityFurnace typesForging/hammering/pressing machinesCementiteBrittleness

The invention provides a method for forging a steel bimetallic fracture splitting connecting rod. The method comprises the following steps that S1, a casting blank of the steel bimetallic fracture splitting connecting rod is prepared through a casting process, and the casting blank is composed of a connecting rod body, a fracture splitting area and a connecting rod cover; S2, the casting blank is subjected to normalizing treatment and used for removing network cementite in a fracture splitting material and an interface area, and a bimetallic interface is promoted to form a continuous diffusion layer; S3, the casting blank is forged, and the flowing direction of the fracture splitting material is controlled through a forging die; S4, burrs on the surface of a forged part are cleared away, and shot blasting treatment is carried out; S5, the forged part is subjected to thermal refining, the mechanical performance of the connecting rod meets requirements, and the fracture splitting brittleness of the fracture splitting material is guaranteed; and S6, a fracture splitting groove is formed, fracture splitting and reassembly are carried out, and finally the finished steel bimetallic fracture splitting connecting rod is obtained. The limit of the fracture splitting connecting rod on the material can be broken through, and the problem that alloy steel cannot be used for producing and manufacturing the fracture splitting connecting rod is solved.

Owner:JIANGSU UNIV

Wood-bar pencil and its production method

InactiveCN1850518AIncrease profitIncrease usageNon-propelling pencilsWood veneer joiningEngineeringColor factor

The invention discloses a pole pencil which includes the pencil core and the body. The body is made by the laminated wooden veneer of 0.-2.5mm thickness and colorated by the color factor. The invention has provided the utilization ratio of the wood, the pencil is easy to cut. The pencil can appear many colors after cutting. The invention also opened the process of it.

Owner:敦化市金海木业有限公司

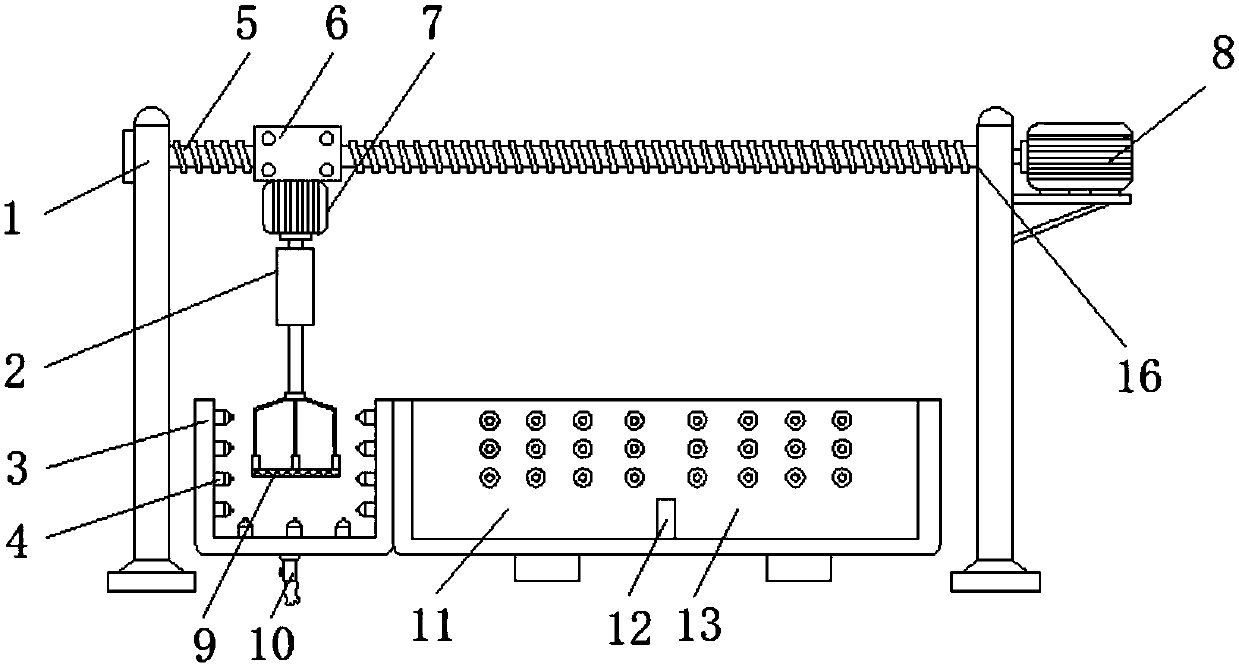

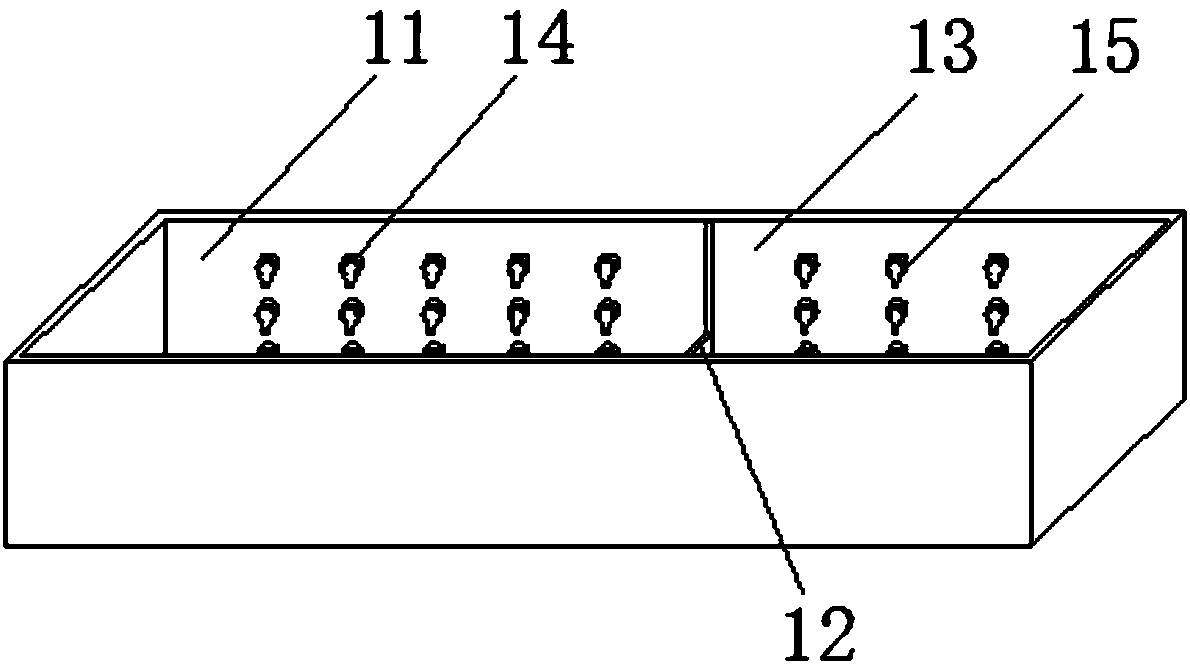

Integrated quenching equipment uniform in heating

InactiveCN107584642AEvenly heatedImprove quenching qualityCeramic shaping apparatusDrive shaftEngineering

The invention discloses integrated quenching equipment uniform in heating. The integrated quenching equipment comprises a supporting rod, a quenching bin, a water spray bin and an oil spray bin, two supporting rods are symmetrically arranged at the two sides of a quenching equipment body, a spiral shaft is rotatably connected to the top of the supporting rod, one side of the spiral shaft is in drive connection with a second motor through a transmission shaft, a first motor is welded to the bottom of a slide sleeve, the quenching bin is arranged between the portion, located between the two supporting rods, at one side of the bottom of the quenching equipment body, and water spray nozzles are uniformly arranged on the two side walls of the water spray bin. Flame spray nozzles arranged on theinner wall and the bottom of the quenching bin can provide high-temperature heat to the inside of the quenching bin by combusting fuel gas, through the transmission effect of the first motor, ceramiccan be driven to rotate in the quenching bin at a constant speed, in this way, the ceramic can be uniformly heated in the quenching process, and the quenching quality of the integrated quenching equipment is improved.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

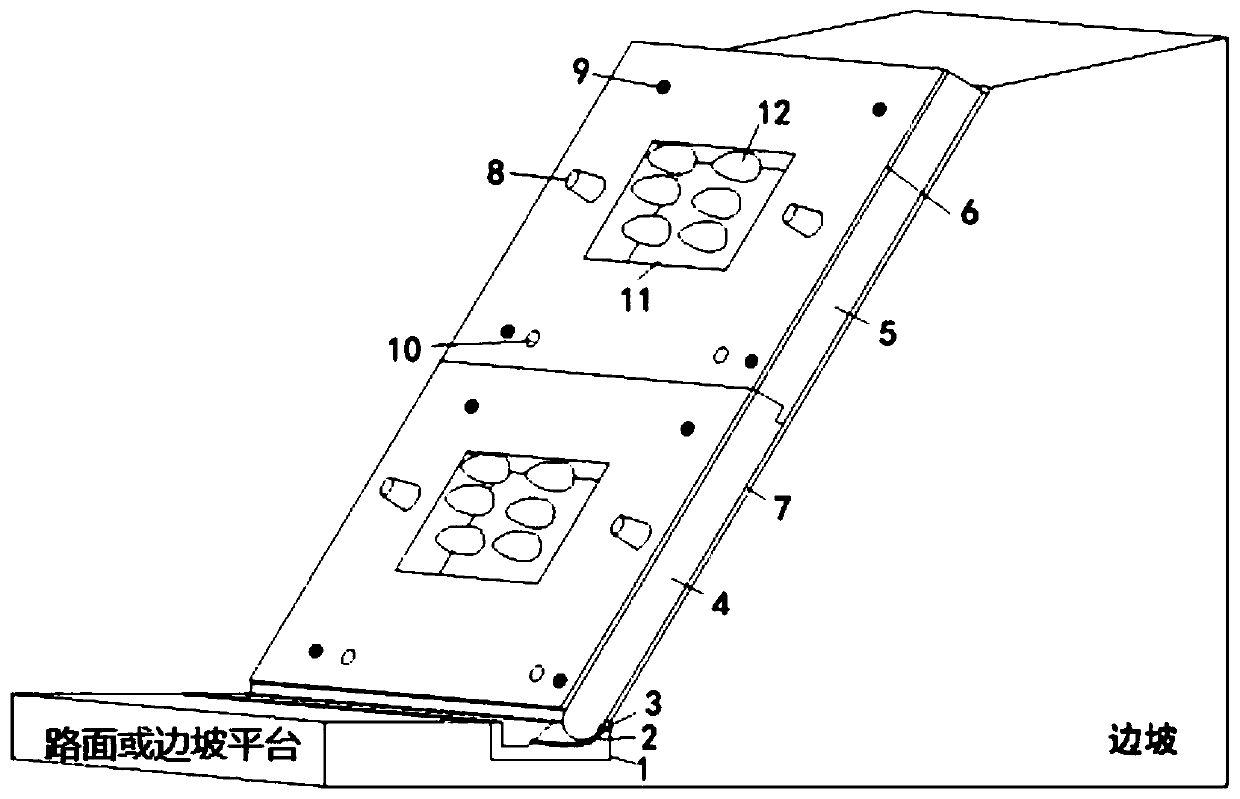

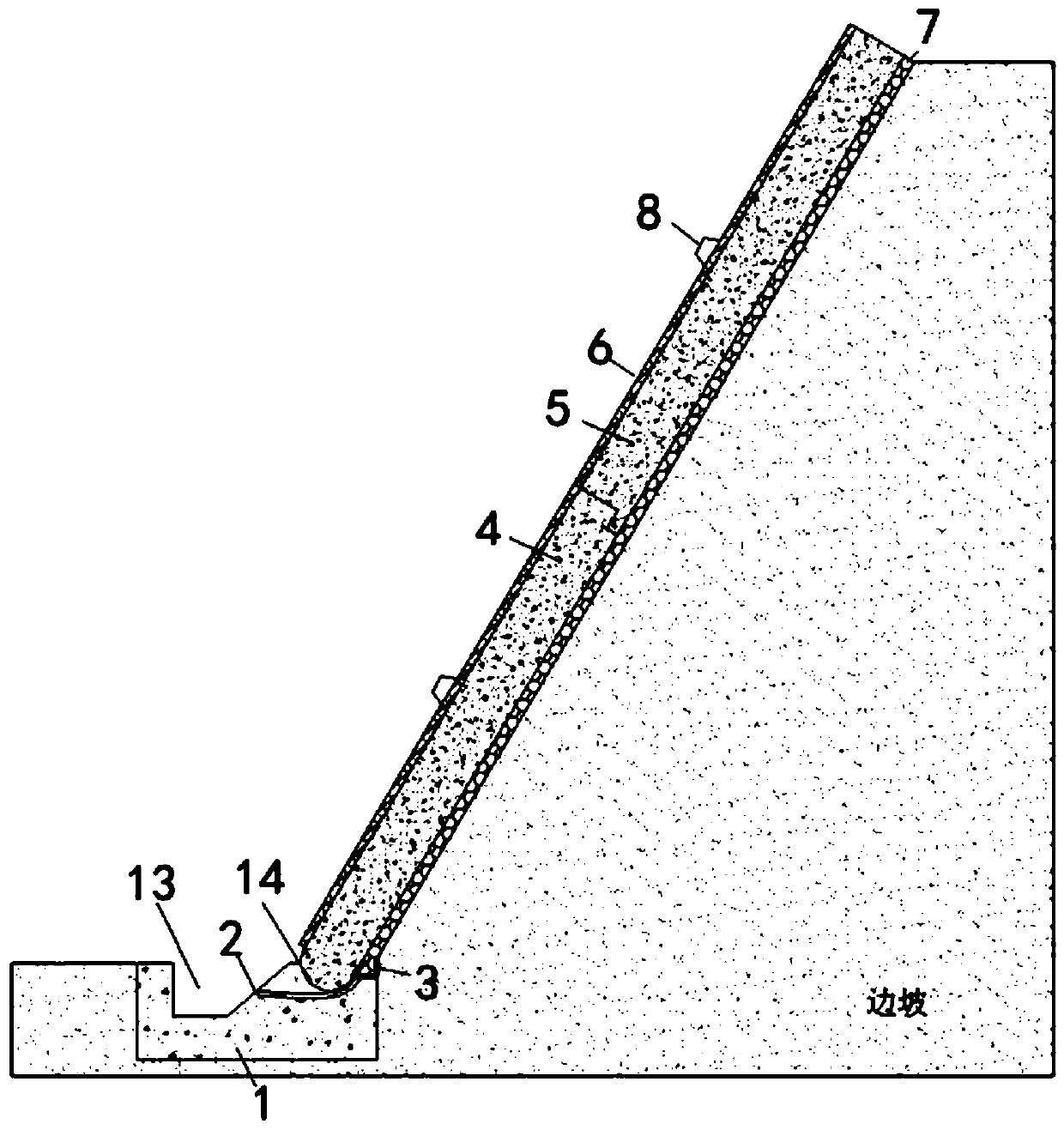

Assembling type anti-freezing ecological side slope retaining wall for bleak, wet and cold climatic region and assembling method

PendingCN110438991AImprove construction progressSimultaneous constructionArtificial islandsExcavationsGrowth plantAnti freezing

The invention discloses an assembling type anti-freezing ecological side slope retaining wall for a bleak, wet and cold climatic region and an assembling method. The side slope retaining wall comprises a foundation pit slot formed in a pavement or a part, close to a side slope, of a side slope platform; a drain integration foundation is arranged in the foundation pit slot; a drainage ditch, a mortise and a drain pipe are arranged on the drain integration foundation; a first retaining wall building block and at least one second retaining wall building block are sequentially arranged on the sideslope from bottom to top; the bottom of the first retaining wall building block is assembled in the mortise; the bottoms of the second retaining wall building blocks are arranged at the top of the first retaining wall building block in a clamping manner; a drain layer is arranged among the first retaining wall building block, the second retaining wall building blocks and the side slope; cover plates are correspondingly fixed on the surfaces of the first retaining wall building block and the second retaining wall building blocks; a window hole and drain holes are correspondingly formed in eachcover plate; plant growth articles are arranged in each window hole; and telescopic anchor rods extending into the side slope are arranged in a manner of penetrating through the cover plates and thefirst retaining wall building block and the second retaining wall building blocks below the cover plates.

Owner:CHANGAN UNIV +1

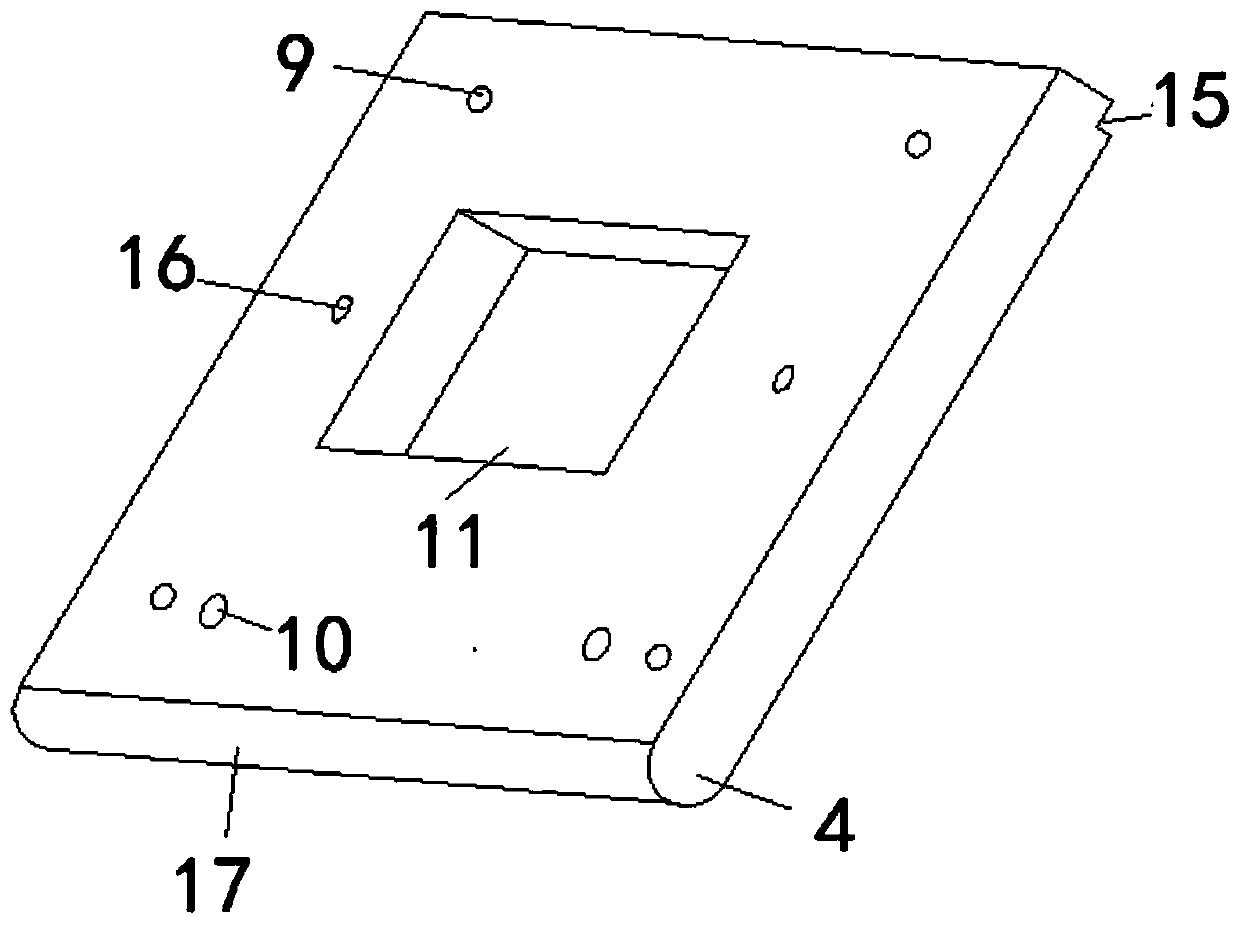

High-strength TBM center cutter box and preparation method

ActiveCN111119915AAvoid Weld CrackingAvoid large welding deformationFurnace typesTunnelsTemperingStructural engineering

The invention provides a high-strength TBM center cutter box and a preparation method. The center cutter box comprises an outer cutter box and an inner cutter box, wherein the outer cutter box is madeof a structural steel material; the inner cutter box is made of a low-carbon medium-alloy structural steel material; and the inner cutter box and the outer cutter box are combined through welding. The center cutter box provided by the invention has the beneficial effects that the inner cutter box is treated with tempering and hardening, connection is realized in a firm of welding of the inner andouter cutter boxes, the inner and outer cutter boxes are formed by a forging technology, and the inner cutter box is made of low-carbon medium-alloy structural steel, so welding stress centralization, cracking and deformation of the inner and outer cutter boxes are reduced; through surface hardening of the inner cutter box, strength and fatigue performance of bearing parts can be enhanced; and through de-stress annealing of the inner and outer cutter boxes, distribution of residual stress during forging formation and welding stress centralization points of the inner and outer cutter boxes canbe reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Batten and plank processing method

ActiveCN103433986AImprove stabilityNot easy to crack and deformWood treatment detailsWood veneer joiningMechanical engineeringWood plank

The invention discloses a batten and plank processing method which comprises the following steps that 1) moisture of timber is balanced, degreasing and draying are carried out, when the moisture content of the timber does not exceed 11%, the timber is discharged from a drying kiln, then the timber is stacked and stored for about 15 days in a gap filling mode, then the balanced timber is balanced for 3-4 days, moisture of the timber is uniform, the moisture content does not exceed 13%, and the balanced timber is stored for 15-20 days; 2) sorting is carried out, and the timber with the uniform moisture content and a compact structure is chosen; 3) slicing is carried out, transverse or longitudinal cutting is carried out, and the chosen timber is cut on the whole to be manufactured into 6cm wide battens; 4) bonding and splicing are carried out, the sliced battens are spliced and bonded into needed sizes according to original positions; 5) compaction and air drying are carried out. For an improvement, a technological contraction joint is reserved on platens after the bonding and splicing in the step 4) every a distance. Compared with the prior art, the batten and plank processing method has the advantages that the chosen batten is cut into the 6cm wide battens, wooden ribs in the battens are broken, the properties of thermal expansion and contraction of finished products are reduced, the manufactured barren and platen finished products are stable in quality, and deformation and cracking do not easily occur.

Owner:ZHEJIANG XIYINGMEN WOOD

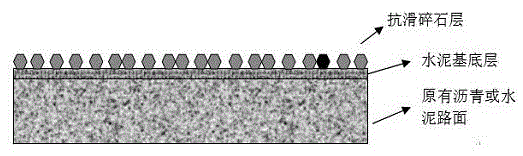

Cement-base colored microsurface and construction method thereof

The invention discloses a cement-base colored microsurface, belonging to the technical field of road engineering. The microsurface pavement comprises a cement-base layer, wherein the cement-base layer comprises the following components in parts by mass: 100 parts of cement, 150-170 parts of colored quartz sand, 50 parts of water, 7 parts of waterproofing agent and 10 parts of pigment; and the cement-base layer also comprises 0.1 vol% of polyvinyl alcohol fiber and a right amount of modifier. The modifier is composed of a water-based epoxy resin (the mass ratio of the water-based epoxy resin to the cement is (8-12):100) and a curing agent (the mass ratio of the curing agent to the water-based epoxy resin is 1.3:1), or hydroxy cellulose (the mass ratio of the hydroxy cellulose to the water is 3:100), or a water-based organic silicon resin (the mass ratio of the water-based organic silicon resin to the cement is 2.5:100). The color of the colored quartz sand has the same color system as the color of the pigment. The invention also discloses a construction method of the cement-base colored microsurface. The cement-base colored microsurface has the advantages of higher water resistance, higher crack resistance, higher wear resistance, higher color distinction degree and high color durability, and is easy for construction.

Owner:SOUTHEAST UNIV

3D overprinting and casing pressure decorative film production process, application and intermediate product

ActiveCN109532178AImprove surface strengthImproves scratch and oil resistanceCeilingsCovering/liningsFiberSurface layer

The invention discloses a 3D overprinting and casing pressure decorative film and a production process and application thereof. The decorative film successively comprises a staple fiber non-woven paper layer, a twin-block composite rubber layer, a PET transparent film layer, a release agent layer, a composite rubber layer and a PVC calendaring film layer. The process comprises the following steps:preparing a bottom PET composite layer: compounding the softened PVC calendaring film and the bottom PET composite layer to obtain an intermediate product; printing, pre-softening the intermediate product, embossing, cooling and rolling; wherein the pre-softening process is gradient heating softening. According to the product, the PVC calendaring film layer is arranged to replace the compoundingprocess of surface layer PVC and PVC base film. Since the PVC calendaring film layer is high-density PVC, surface strength of the 3D overprinting and casing pressure decorative film is greatly increased, and scratch resistance and oil fouling resistance are improved. Furthermore, the separation and delamination rate of the surface layer PVC coating and the bottom PVC calendaring film composite layer in the traditional process is reduced.

Owner:浙江锦盛装饰材料股份有限公司

Non-quenching high-toughness cold-working die steel and production process

InactiveCN101713052BReasonable ratioImprove compactnessMetal-working apparatusManufacturing technologyTransformer

The invention relates to a non-quenching high-toughness cold-working die steel belonging to the technical field of metallurgical manufacture. The novel cold-working die steel is developed by optimizing and creating a product component formula, adding alloy elements, rolled and cold thinned texture and adopting the processes of remelting and fining electroslag in an electric furnace, forging many times in a great forging proportion and special heat treatment. The manufacture process comprises the following flows: selecting a chemical component range; drawing an ingredient scheme according to the chemical component range; melting at an intermediate frequency; remelting (refining) the electroslag; annealing; discharging; extending hydrogen; forging; normalizing; tempering; mechanically processing; and detecting. The important manufacture process comprises the steps: (1) refining; (2) forging; (3) extending hydrogen; and (4) normalizing; and tempering so as to obtain non-quenching high-toughness cold-working die steel. The invention has reasonable chemical component proportion, low manufacture cost, good alloying effect, great forging transformer ratio, favorable density of metal structure and high toughness performance index. Various performance indexes of the product reach or exceed the levels of similar international and national products.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

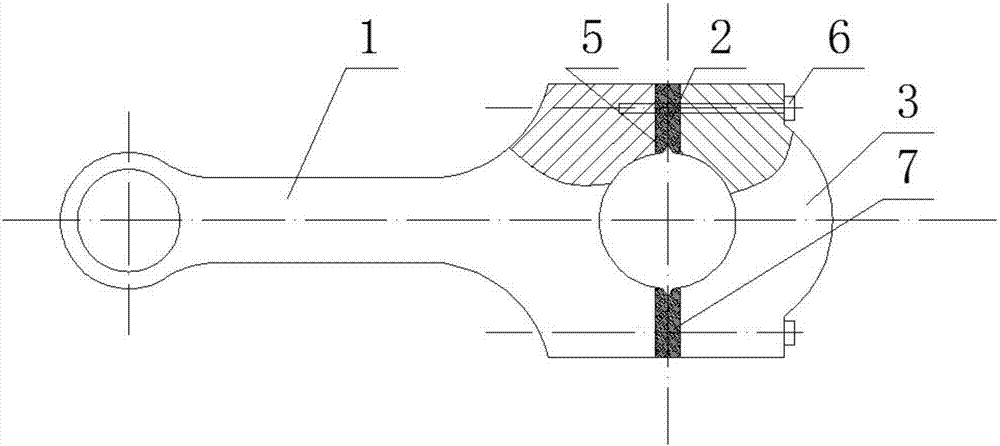

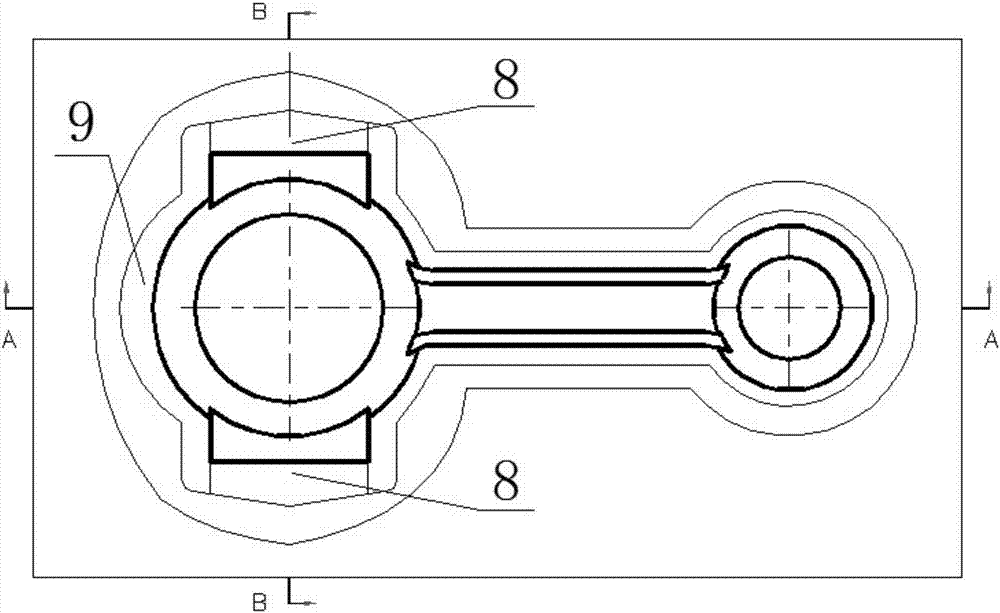

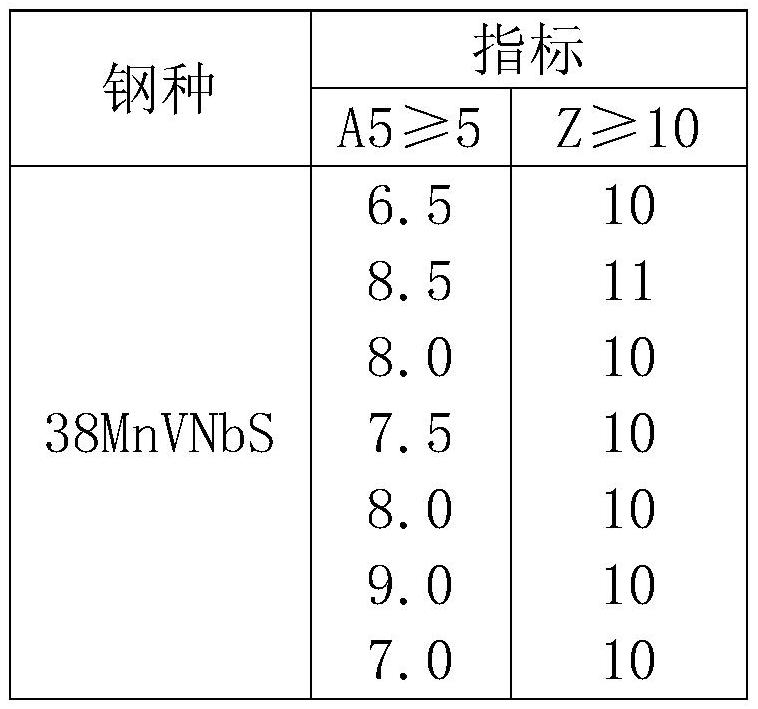

High-strength non-quenched and tempered steel connecting rod for heavy-duty car and manufacturing method thereof

InactiveCN111876682ARaise the brittle transition temperatureGrain refinementEngine componentsUltimate tensile strengthMaterials science

The invention discloses a high-strength non-quenched and tempered steel connecting rod for a heavy-duty car and a manufacturing method thereof, and mainly relates to the field of manufacturing of non-quenched and tempered steel connecting rods. The steel comprises the following components in percentage by weight: 0.30-0.50% of C, 0.40-0.70% of Si, 1.10-1.50% of Mn, less than or equal to 0.035% ofP, 0.030-0.050% of S, 0.10-0.30% of Cr, 0.05-0.15% of V and 0.015-0.040% of Nb, and the plasticity indexes are as follows: the transverse sample A5 is more than or equal to 5%, Z is more than or equalto 10%, the C segregation content is less than or equal to 15%, and the S segregation content is less than or equal to 25%. The manufacturing method has the beneficial effects that the manufacturingprocess of the connecting rod can be greatly simplified, the strength of the produced connecting rod is higher, and correction is more convenient.

Owner:SINO TRUK JINAN POWER

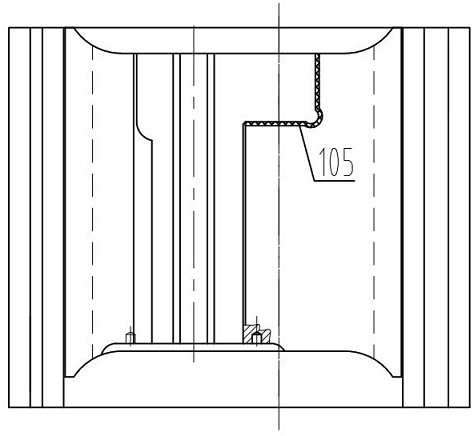

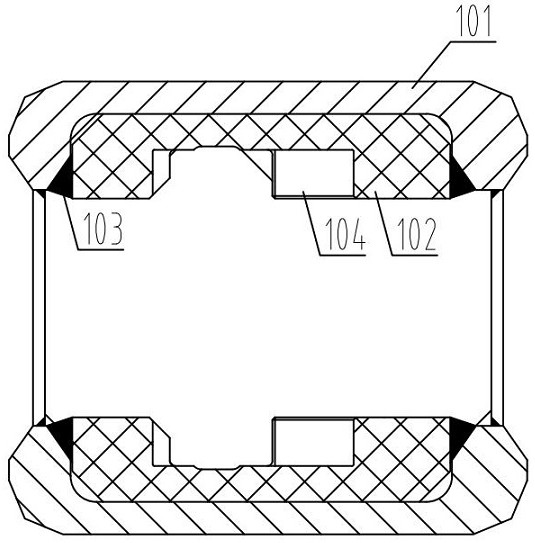

A kind of high-strength TBM center tool box and preparation method

ActiveCN111119915BReduce stressReduce deformation crackingFurnace typesTunnelsStress concentrationTempering

The invention provides a high-strength TBM center knife box and a preparation method thereof, comprising an outer knife box and an inner knife box, the outer knife box is made of structural steel material, the inner knife box is made of low-carbon medium alloy structural steel material, and the inner and outer knife boxes are welded combined in a way. The inner knife box of the present invention adopts quenching and tempering and hardening treatment, and at the same time adopts the form of welding the inner and outer knife boxes to connect, the inner and outer knife boxes are formed by forging process, and the inner knife box is made of low-carbon medium alloy structural steel to reduce the welding stress concentration of the inner and outer knife boxes. Cracking and deformation; the surface hardening treatment of the inner knife box can improve the strength and fatigue performance of the bearing part, and the stress relief annealing treatment of the inner and outer knife boxes can effectively reduce the distribution of residual stress in the forging process and the welding stress concentration point of the inner and outer knife boxes.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

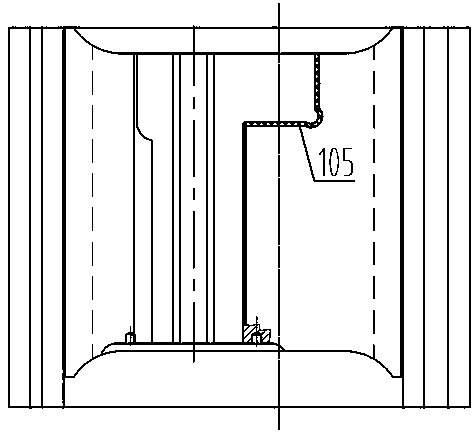

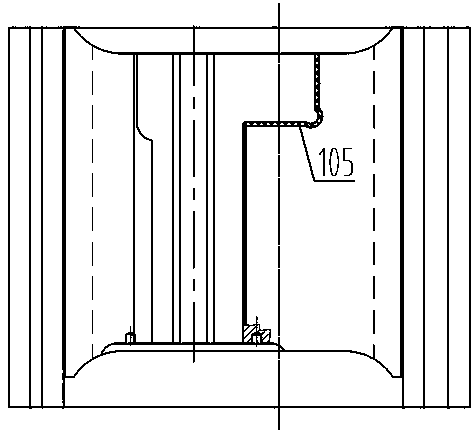

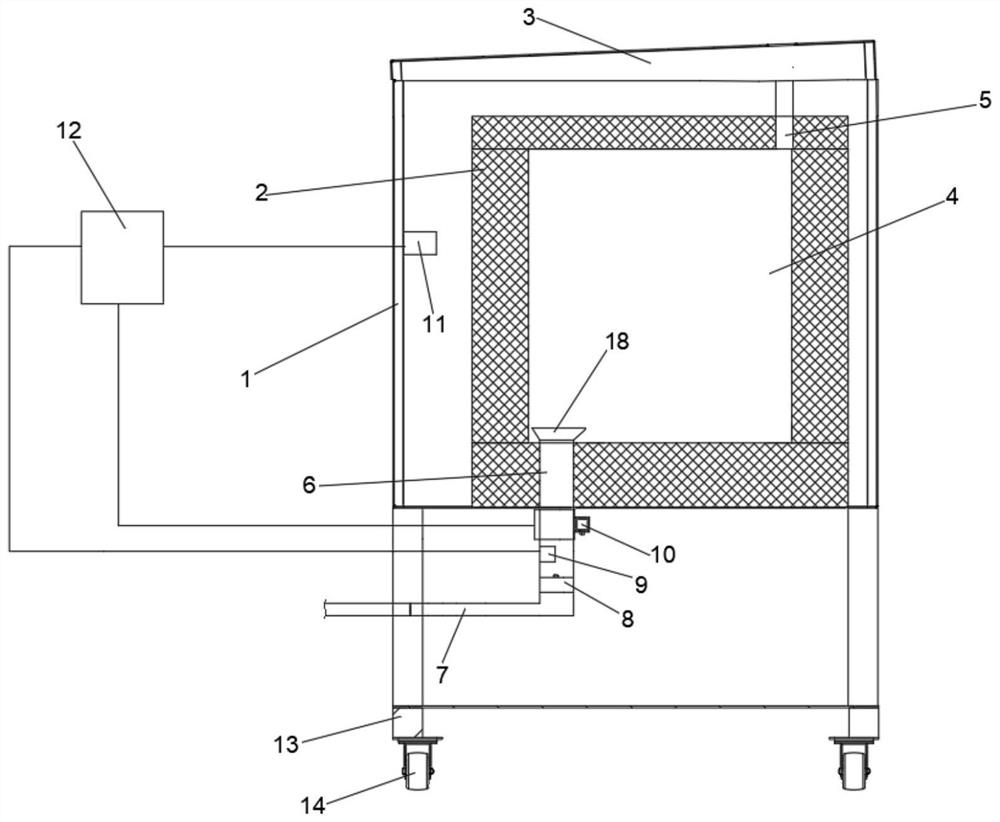

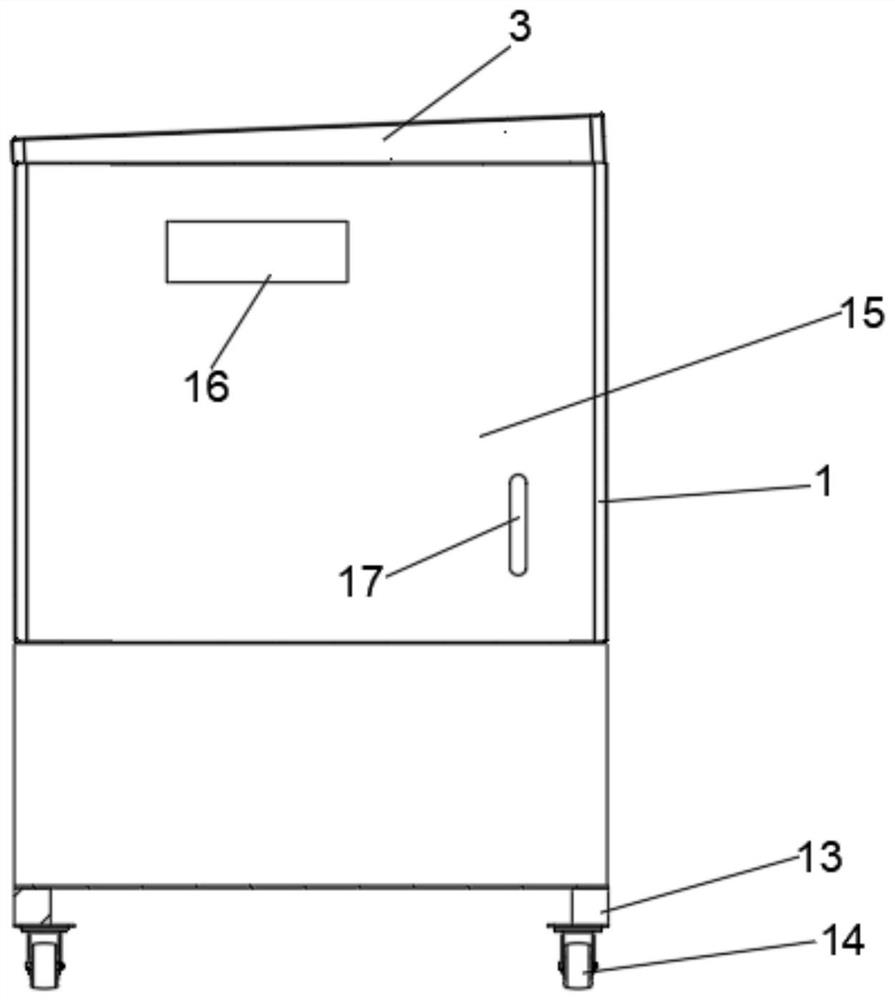

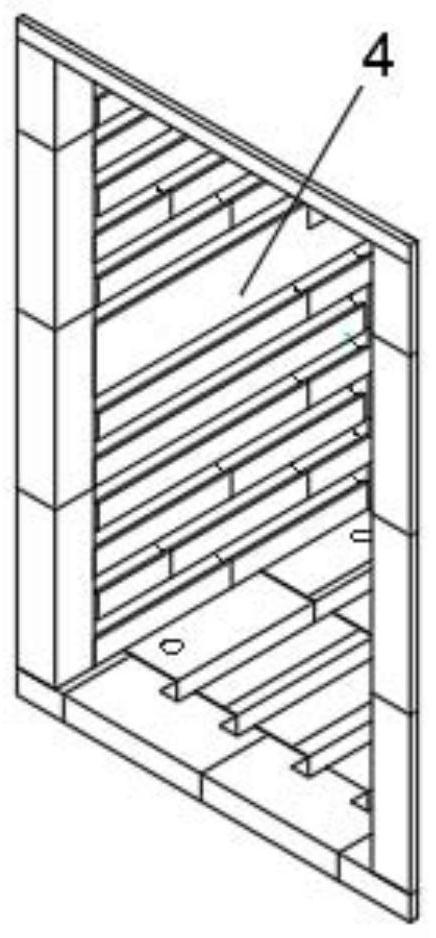

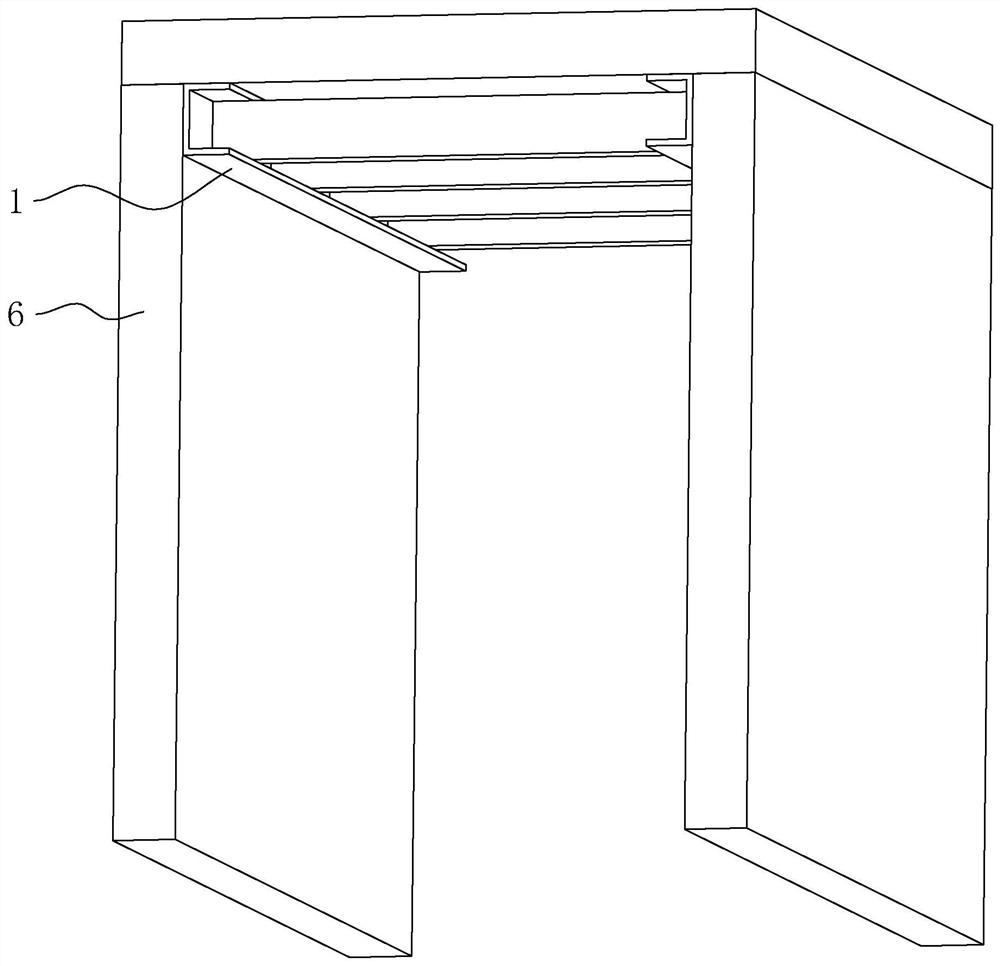

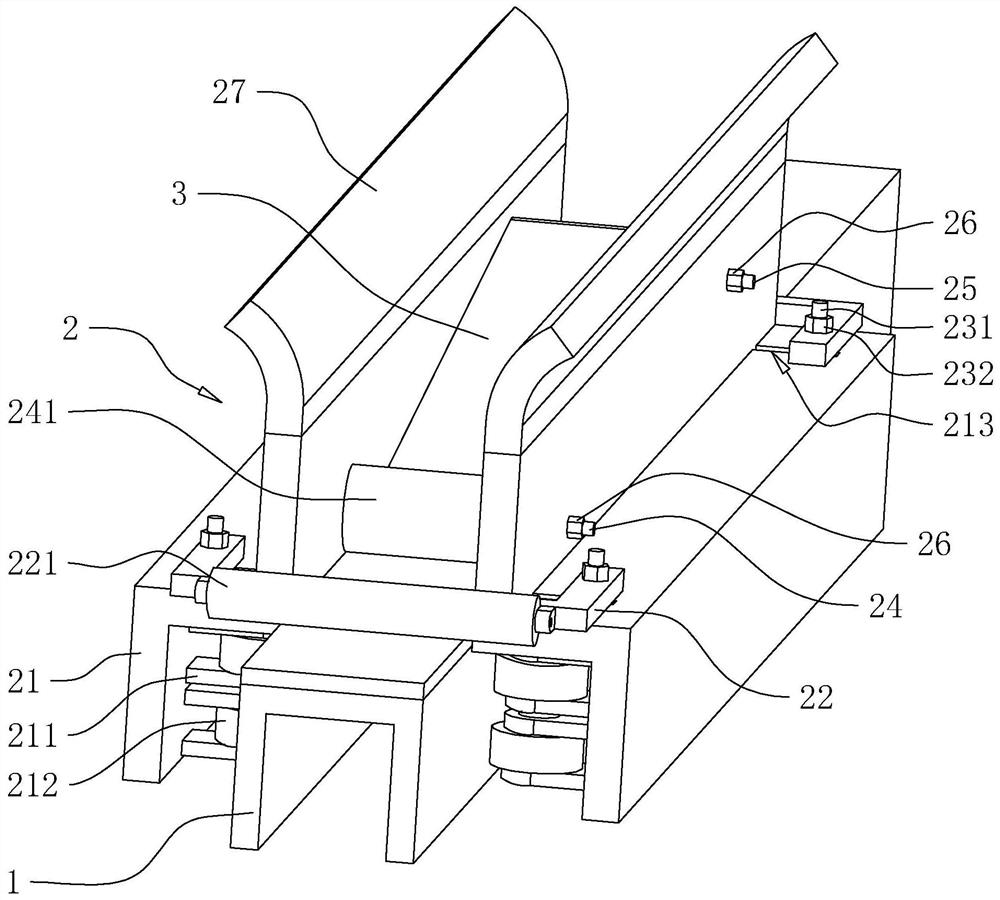

Anti-detonation ceramic kiln

InactiveCN111811272AQuick installationReduce deformation crackingFurnace safety devicesFurnace typesCombustion systemBrick

The invention discloses an anti-detonation ceramic kiln. The anti-detonation ceramic kiln comprises a kiln frame and kiln bricks arranged inside the kiln frame, wherein the adjacent kiln bricks are spliced through mortise and tenon joint structures, a heat dissipation exhaust hole is formed in one end above the kiln bricks, a combustion system is arranged on one side of the lower end of the kiln bricks and communicates with an external fuel gas conveying pipeline, a burner and a flameout protection device are arranged in the combustion system, the flameout protection device comprises an igniter used for igniting fuel gas to form open fire, a thermocouple used for sensing the temperature of the combustion gas and a safety protection valve used for controlling the fuel gas inside the burnerto be introduced into a sealing cavity, and a fuel gas leakage alarm is arranged between the kiln frame and the kiln bricks. According to the anti-detonation ceramic kiln, the extremely safe ceramic kiln is manufactured, and it is guaranteed that potential safety hazards such as explosion cannot be generated even if abnormal flameout occurs in the using process of a user.

Owner:景德镇百陶会陶艺装备有限公司

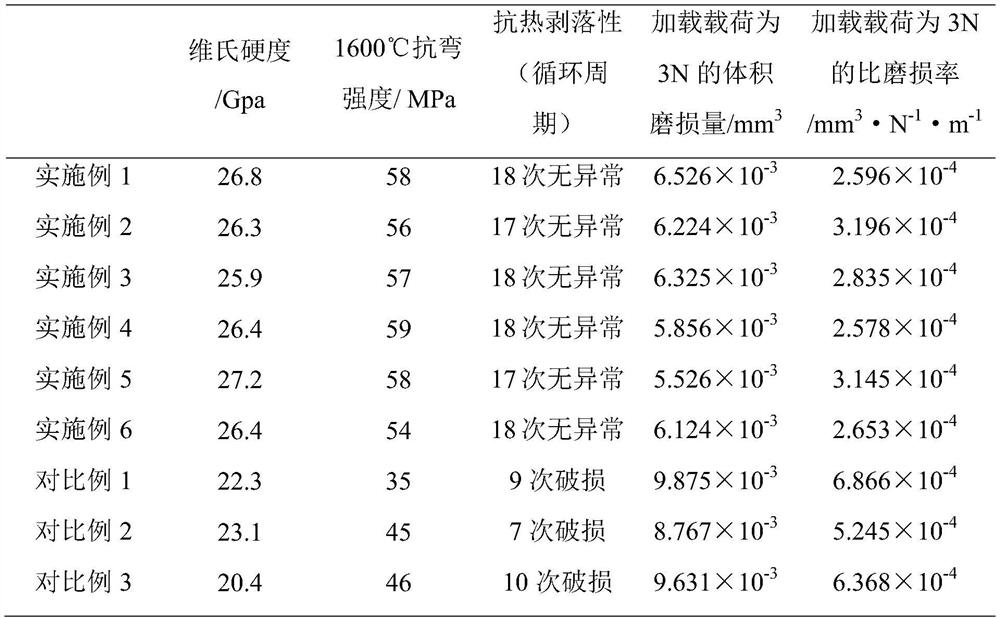

A wear-resistant high-performance ceramic roller rod and its preparation method

ActiveCN113004027BImprove wear resistanceImprove high temperature resistanceCeramic materials productionMulliteUltimate tensile strength

Owner:福建安溪马斯特陶瓷有限公司

A kind of high-strength anti-seepage and anti-freeze concrete and preparation method thereof

The invention discloses a high-strength anti-seepage and anti-freeze concrete and a preparation method thereof. The high-strength anti-seepage and anti-freeze concrete includes the following raw materials: cement, water, sand, gravel, fly ash, antifreeze, anti-rust and anti-corrosion waterproofing agent, waste concrete particles, waste rubber particles; the antifreeze includes the following components in parts by weight: 3.4-6.8 parts of modified coal gangue, 1.2-2.0 parts of rice husk ash, 1.5-3 parts of vinyl acetate-ethylene copolymer latex powder, 0.8-1.6 parts of silica fume, 2.4-3.8 parts of polypropylene mesh fiber, 0.8-3 parts 1.6 parts seaweed extract, 0.9‑1.8 parts urea, 1.4‑2.2 parts calcium nitrite, 10‑20 parts water. The high-strength anti-seepage and anti-freeze concrete of the invention has the advantages of effectively utilizing waste materials, having strong anti-freezing and thawing properties and mechanical properties, being able to reduce freezing and thawing diseases of concrete in cold regions, and being able to purify automobile tail gas.

Owner:青岛兴业商砼有限公司

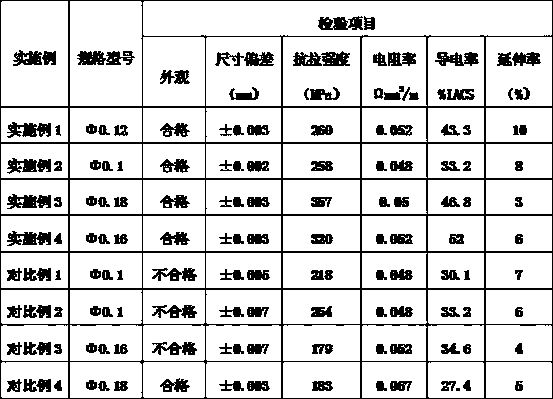

Preparation method of superconducting and ultra-fine aluminum-magnesium alloy wires

The invention discloses a preparation method of superconducting and ultra-fine aluminum-magnesium alloy wires. Aluminum ingots and magnesium ingots are added to intermediate alloys and taken as raw materials, and the superconducting and ultra-fine effects are finally realized through smelting, refining, casting rods, multi-annealing drawing and high-speed micro-drawing.The preparation method of the superconducting and ultra-fine aluminum-magnesium alloy wires not only effectively realizes recycling of the intermediate alloys such as waste rods, inferior products and the like in the productionprocess, but also can effectively reduce deformation and cracking of the alloy wires, and the overall conductivity of the alloy wires is obviously improved.

Owner:GUANGXI PINGGUO BODAO MG CABLE

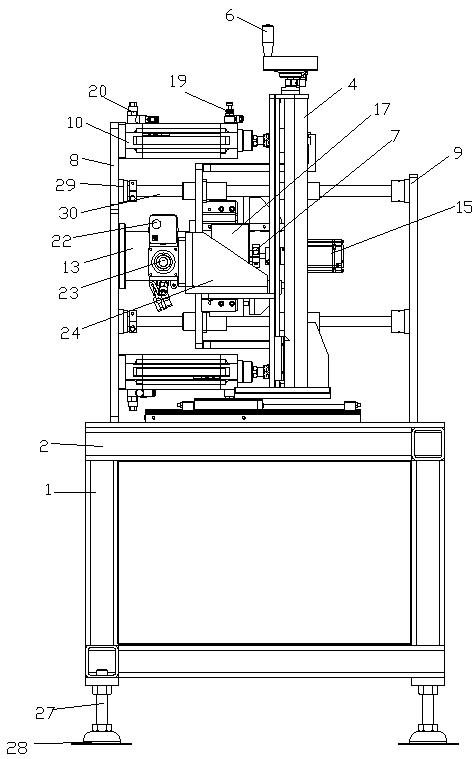

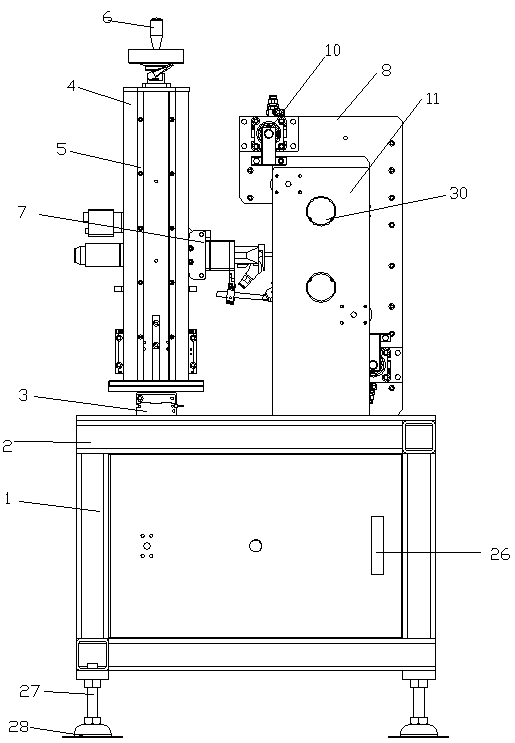

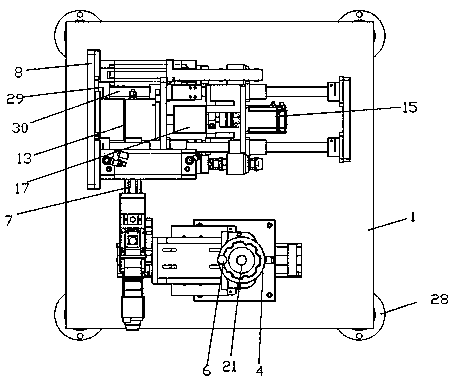

Vacuum laser welding device

PendingCN111482704AEasy to useAchieve interference-free laser weldingLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses a vacuum laser welding device. The vacuum laser welding device comprises an equipment base frame, wherein a Z-axis lifting machine is arranged on the equipment base frame, a laser welding gun is arranged on the Z-axis lifting machine, a first fixation plate and a second fixation plate are arranged on the base frame, a pressure maintaining air cylinder is arranged at the topend of the first fixation plate, a first stopping plate and a second stopping plate are arranged between the first fixation plate and the second fixation plate, guide shafts are arranged on the firstfixation plate and the second fixation plate, a vacuum box is fixed to the first fixation plate, a servo motor is arranged on the second baffle, the output end of the servo motor runs through the second baffle and is connected with a coupler, and the pressure maintaining air cylinder is arranged at one end of the coupler. The vacuum laser welding device is simple in structure and convenient to weld, contact with air is reduced, oxidation of the product is lowered, welding is more uniform, and the product is prevented from being deformed or cracked.

Owner:上海百善实业发展有限公司

Batten and plank processing method

ActiveCN103433986BImprove stabilityNot easy to crack and deformWood treatment detailsWood veneer joiningPulp and paper industryBatten

The invention discloses a method for processing wood strips and boards, which comprises the following steps: 1) balancing the moisture content of the wood, degreasing and drying, and leaving the kiln from the drying kiln when the moisture content of the wood is not more than 11%, and then stacking The wood is filled and stored for about 15 days, and then balanced in a balancing kiln for 3-4 days to make the moisture of the wood uniform, and the moisture content does not exceed 13%, and then the balanced wood is stored for 15-20 days; 2) Material selection: choose moisture Uniform and tightly structured wood; 3) Slicing: Carry out horizontal or vertical cutting, and cut the selected wood as a whole to make 6cm wide wooden strips; 4) Bonding and splicing: the planed wooden strips are still Splicing and bonding into the required size according to the original position; 5) compacting and air-drying. As an improvement, step 4) reserves a process contraction joint at intervals for the planks after bonding and splicing. Compared with the prior art, the present invention cuts the selected wooden strips into wooden strips with a width of about 6 cm, and breaks the wooden bars therein, so that the thermal expansion and contraction of the finished product is reduced, and the quality of the finished wooden strips and boards is improved. Stable and not prone to deformation and cracking.

Owner:ZHEJIANG XIYINGMEN WOOD

A kind of high-strength and high-elastic niobium-containing copper alloy and its preparation method

ActiveCN109763008BReduced strengthImprove plasticityTemperature control deviceMetal rolling arrangementsNiobiumUltimate tensile strength

The invention discloses a high-strength high-elasticity niobium-containing copper alloy and a preparation method thereof, and belongs to the technical field of copper alloy preparation. According to the high-strength high-elasticity niobium-containing copper alloy, the Vickers hardness is higher than or equal to 420 HV, the tensile strength is larger than or equal to 1300 MPa, the elongation is larger than or equal to 7.5%, the alloy grains are uniform and fine, the ultra-high strength, plasticity and elastic modulus are achieved, and the copper alloy and the preparation method can be widely used in the fields of high and new technologies such as automobiles, rail transits, electronic and electrical and aerospace; The preparation method of the high-strength high-elasticity niobium-containing copper alloy can effectively refine the grain size of the alloy, control the size and distribution of a precipitation second phase, strengthen the strength and elasticity of the alloy and improve the plasticity of the alloy.

Owner:CENT SOUTH UNIV

A side keel connection process

This application relates to a side keel connection process, which includes the following steps: S1: a guide device is installed on the side keel, and a first sealing tape is pasted on the side keel through the guide device; S2: the pasting material on the other side of the first sealing tape is The connection plate of polyethylene foam cotton; S3: the side keel is fixedly connected with the wall through the connection plate; S4: install gypsum board under the side keel. This application has the effect of reducing the adverse effects of the vibration frequency of different materials or the normal settlement of the house on the house, and reducing the possible effect of cracking and deformation of the gypsum board.

Owner:YENOVA NOVARTIS HOME DECORATION GRP CO LTD

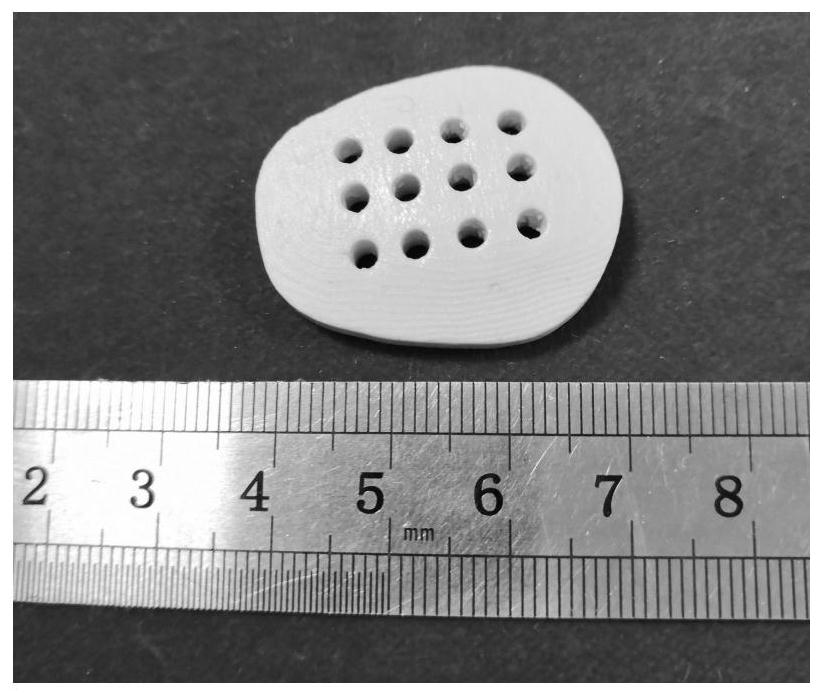

A kind of light-cured calcium silicate/β-tricalcium phosphate ceramic paste and preparation method of porous scaffold

ActiveCN113636836BGood compatibilityHigh solid contentAdditive manufacturing apparatusTissue regenerationCalcium silicatePhysical chemistry

A kind of optical curing of calcium silicate / β‑ phosphate three calcium ceramic cream and porous stent preparation methods. Ceramic cream is based on quality ratio, including ceramic powder 78‑83 %, premixed 14‑16 %, dispersant 1.0‑2.0%, 0.5 光1.0 % of the light -induced agent, 1.0‑2.0 % compatible agent and 0.5‑1.0 % flowing agent; the preparation method is optimized by optimizing the ingredients of calcium calcium silicate / β‑ phosphate cream, and rationally selected optical curing to curing curingFormed printing parameters, optimizing the design of porous bracket structure, and reasonable design subsequent sintering process, which improves the printing accuracy of photocalized calcium silicate / β‑ phosphate, reducing the cracking and deformation of the sintering process, and obtaining high accuracy, obtaining high accuracy, and obtaining high accuracy, and obtaining high accuracy and accuracy.Cracking and deformed calcium silicate / β -phosphate trigly -porous bracket.

Owner:XI AN JIAOTONG UNIV

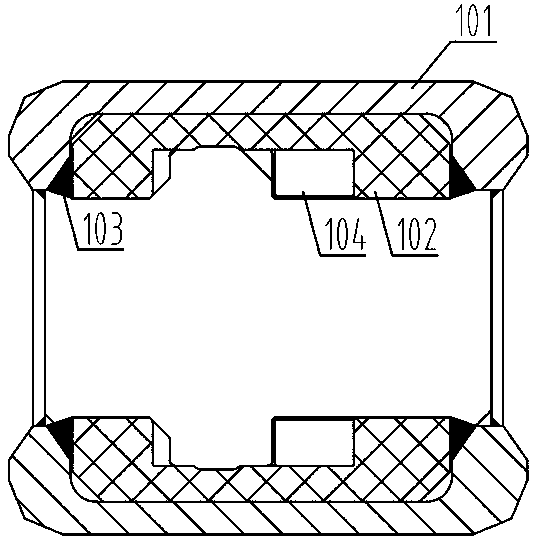

Method for sintering radially-oriented sintering samarium cobalt integrated magnetic ring

ActiveCN102615283BReduce internal stressShorten temperature uniformity timeInorganic material magnetismElectrical resistance and conductanceMicrowave

The invention discloses a method for sintering a radially-oriented sintering samarium cobalt integrated magnetic ring and aims to solve the problems that in the conventional sintering method, the radially-oriented sintering samarium cobalt integrated magnetic ring is susceptible to cracking and has low finished product rate and the production cost is greatly increased. According to the method, the pressed radially-oriented sintering samarium cobalt integrated magnetic ring is placed into a novel vacuum sintering furnace, and heating and heat preservation are performed by the heating method of combining the traditional resistance heating with the microwave heating, so that the temperature of the magnetic ring is increased uniformly, thermal stress generated by that the magnetic ring is heated non-uniformly due to heating of a traditional resistance is reduced, the integrity of the magnetic ring is maintained, the finished product rate is increased, and the cost is reduced.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

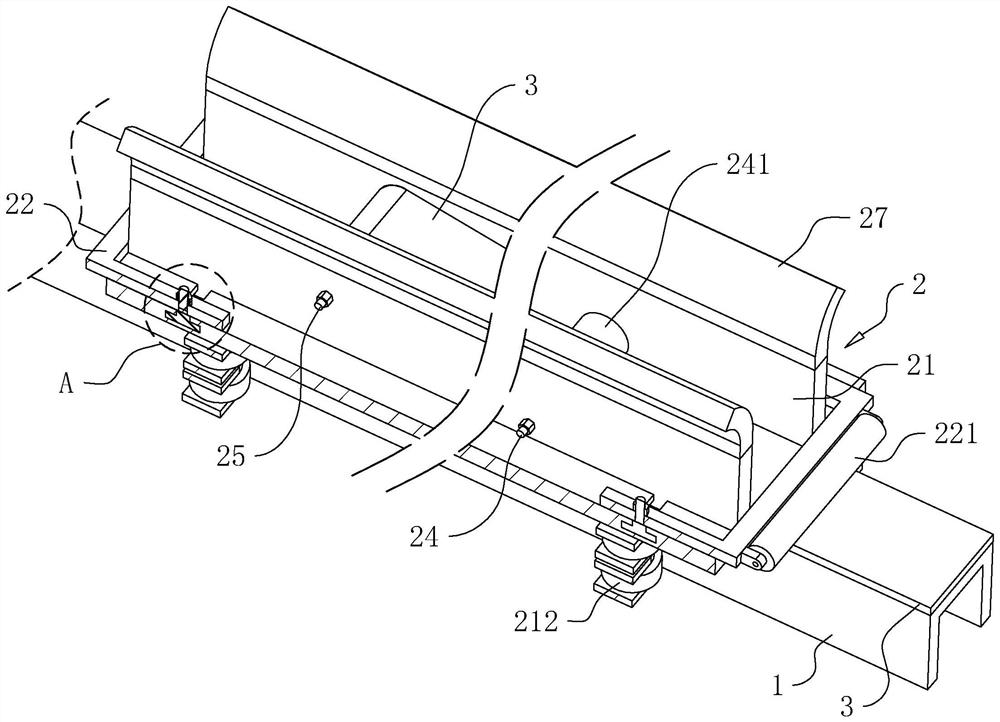

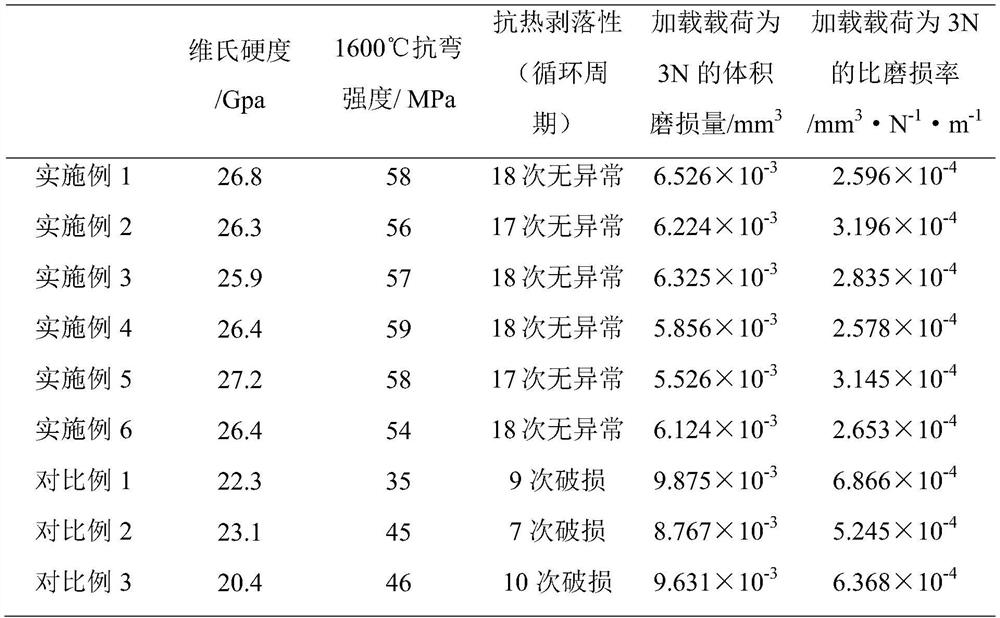

Wear-resistant high-performance ceramic roller and preparation method thereof

ActiveCN113004027AImprove wear resistanceImprove high temperature resistanceCeramic materials productionMulliteWear resistance

The invention relates to a wear-resistant high-performance ceramic roller and a preparation method thereof, by adjusting the weight parts of the raw materials and replacing common mullite and aluminum oxide with electric smelting mullite and electric smelting aluminum oxide, the finally prepared ceramic roller has excellent wear resistance and high temperature resistance, the addition amount of inorganic filler is adjusted and controlled, the strength of the ceramic roller is improved, but also the thermal stripping resistance of the ceramic roller is further enhanced. The invention further discloses a preparation method of the wear-resistant high-performance ceramic roller, a spiral extrusion molding process is adopted, continuous extrusion molding is achieved, the production efficiency is high, the compactness and mechanical strength of the ceramic roller are high, deformation and cracking of the ceramic roller are reduced from the aspect of process preparation, and various properties of the ceramic roller are improved.

Owner:福建安溪马斯特陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com